Review on Research Progress of Pulsating Heat Pipes

Abstract

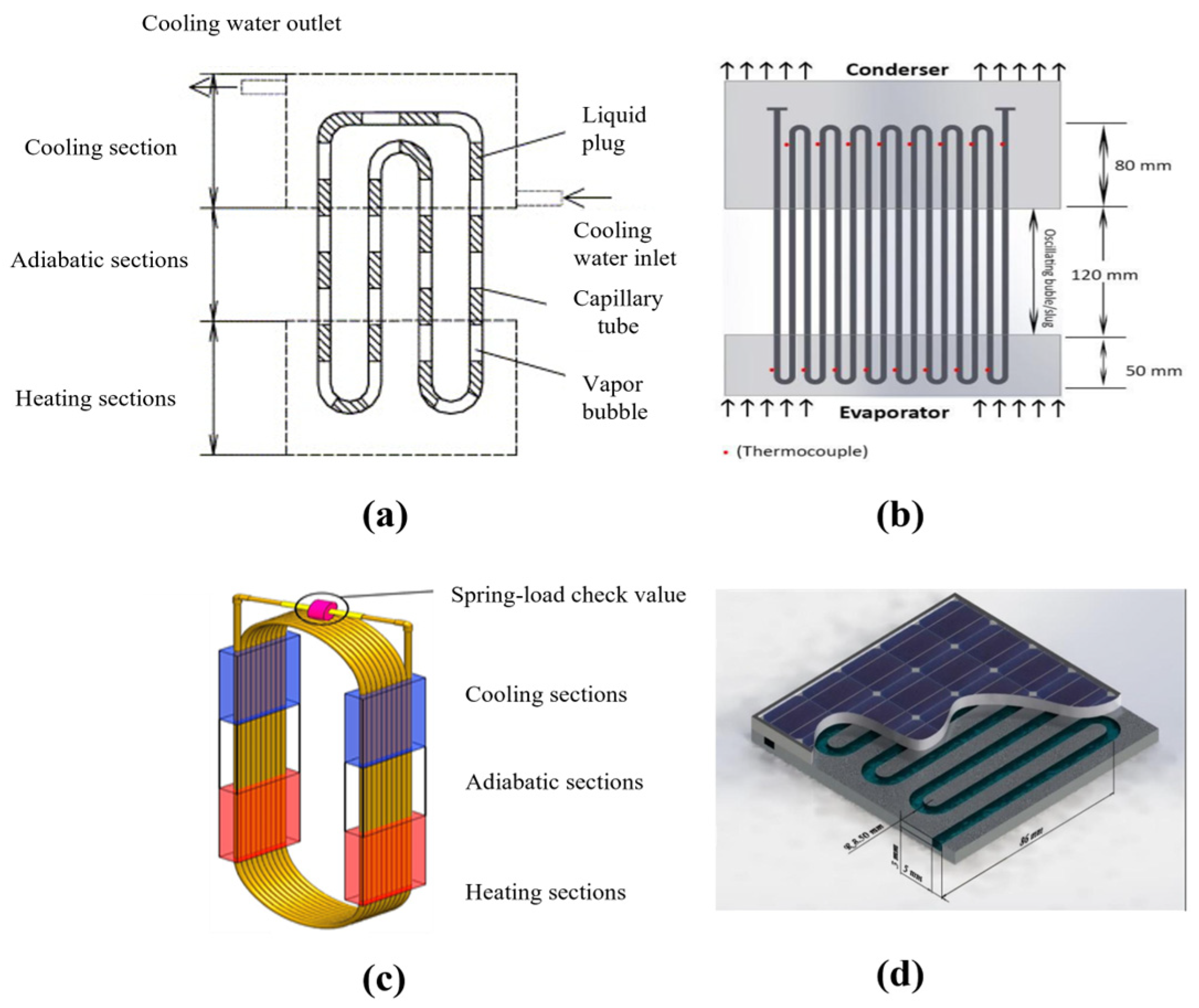

1. Introduction

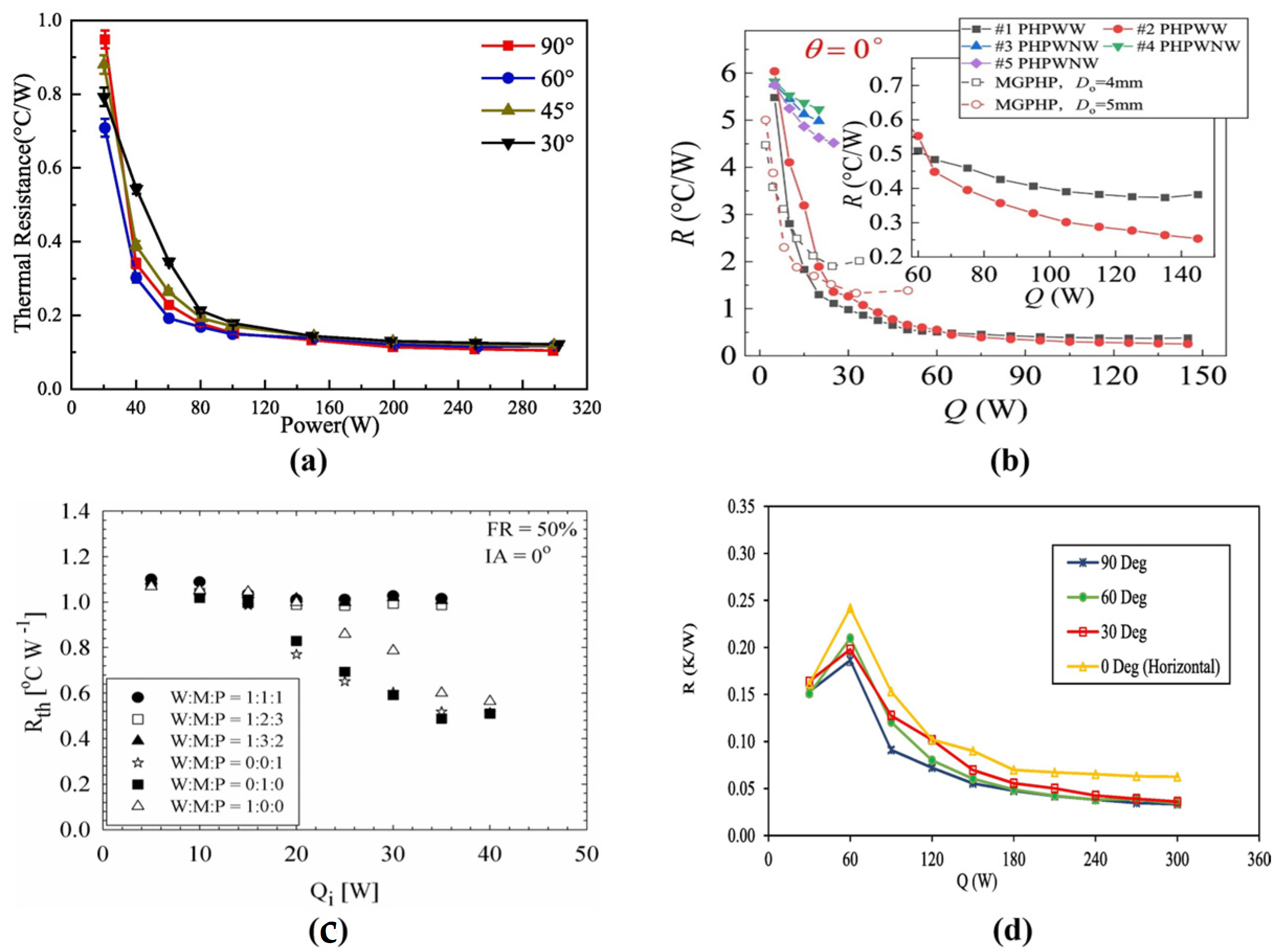

2. Heat Transfer Performance of PHPs

2.1. Working Fluid

2.1.1. Single Working Fluids

2.1.2. Composite Working Fluids

| Composite Working Fluids | Effects | Refs. |

|---|---|---|

| Mono-nanofluids | High thermal conductivity; nucleation enhancement | [55,56,57,58,59,60] |

| Hybrid nanofluids | Rheological characteristic enhancement | [70,71,72,73] |

| Surfactant fluids | Surface tension reduction | [35,75,76,77,78,79,80,81] |

2.1.3. Mixed Working Fluids

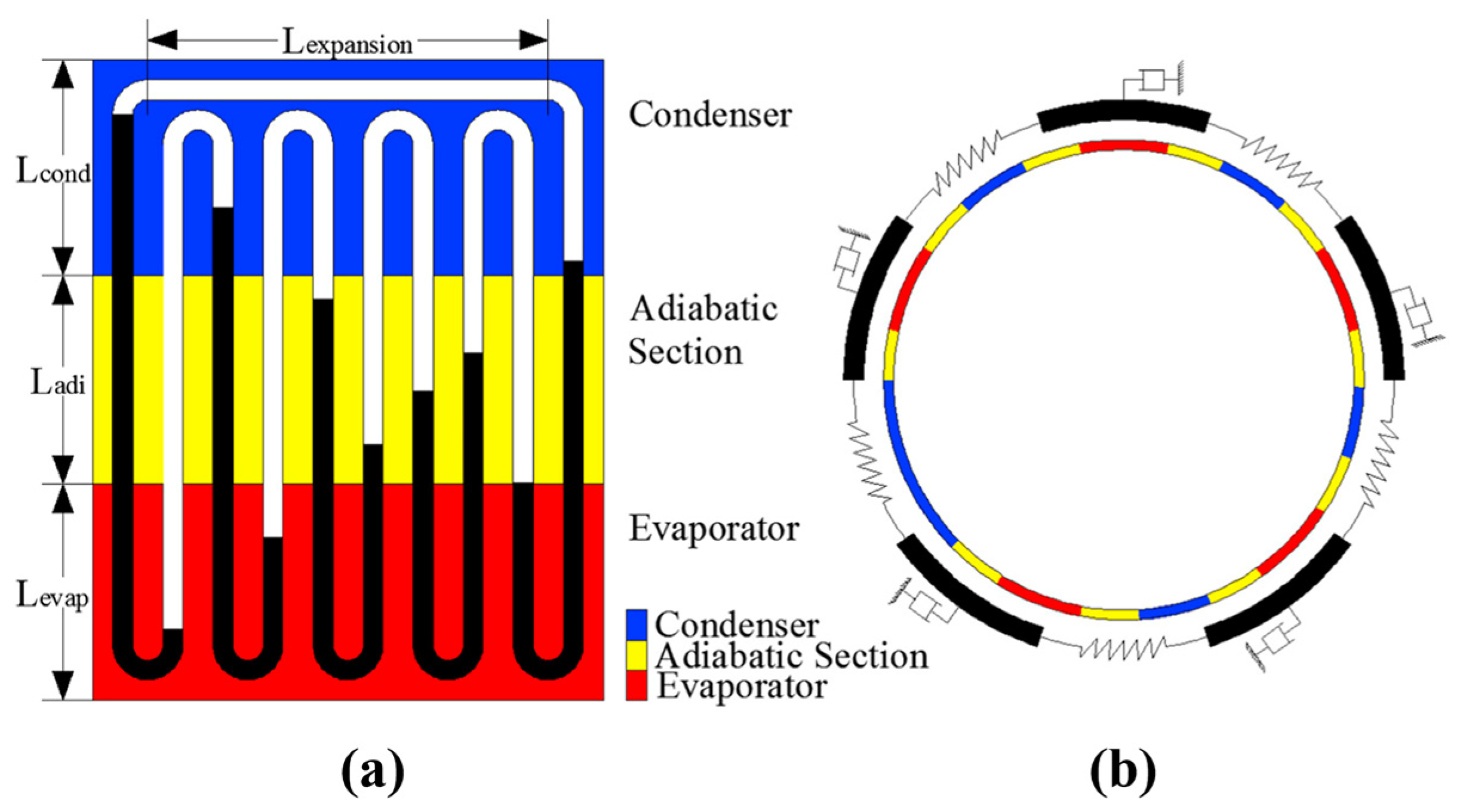

2.2. Structure Parameters

2.2.1. Channel Size

2.2.2. Length of Each Section

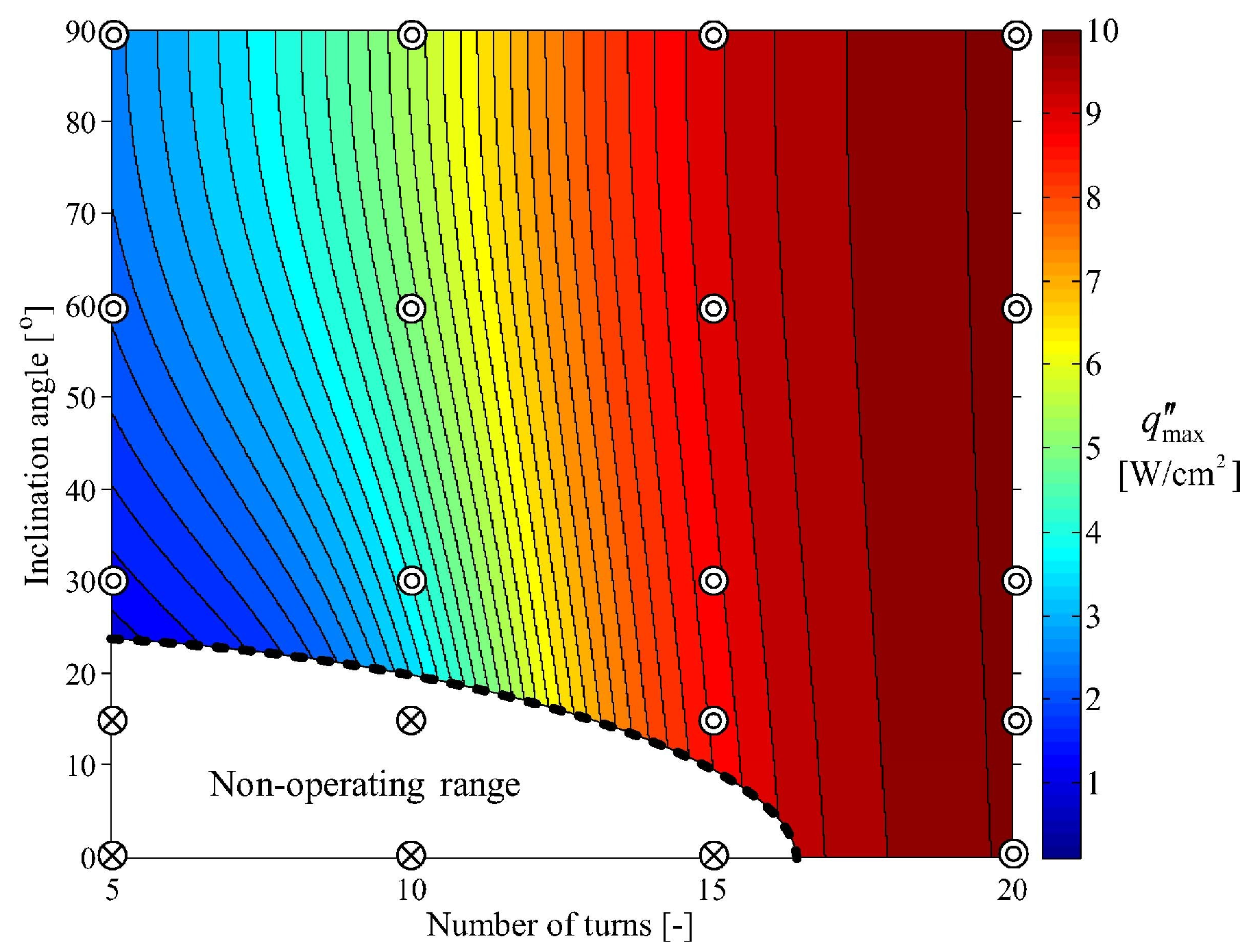

2.2.3. Number of Turns

2.2.4. Surface Modification

2.3. Operation Conditions

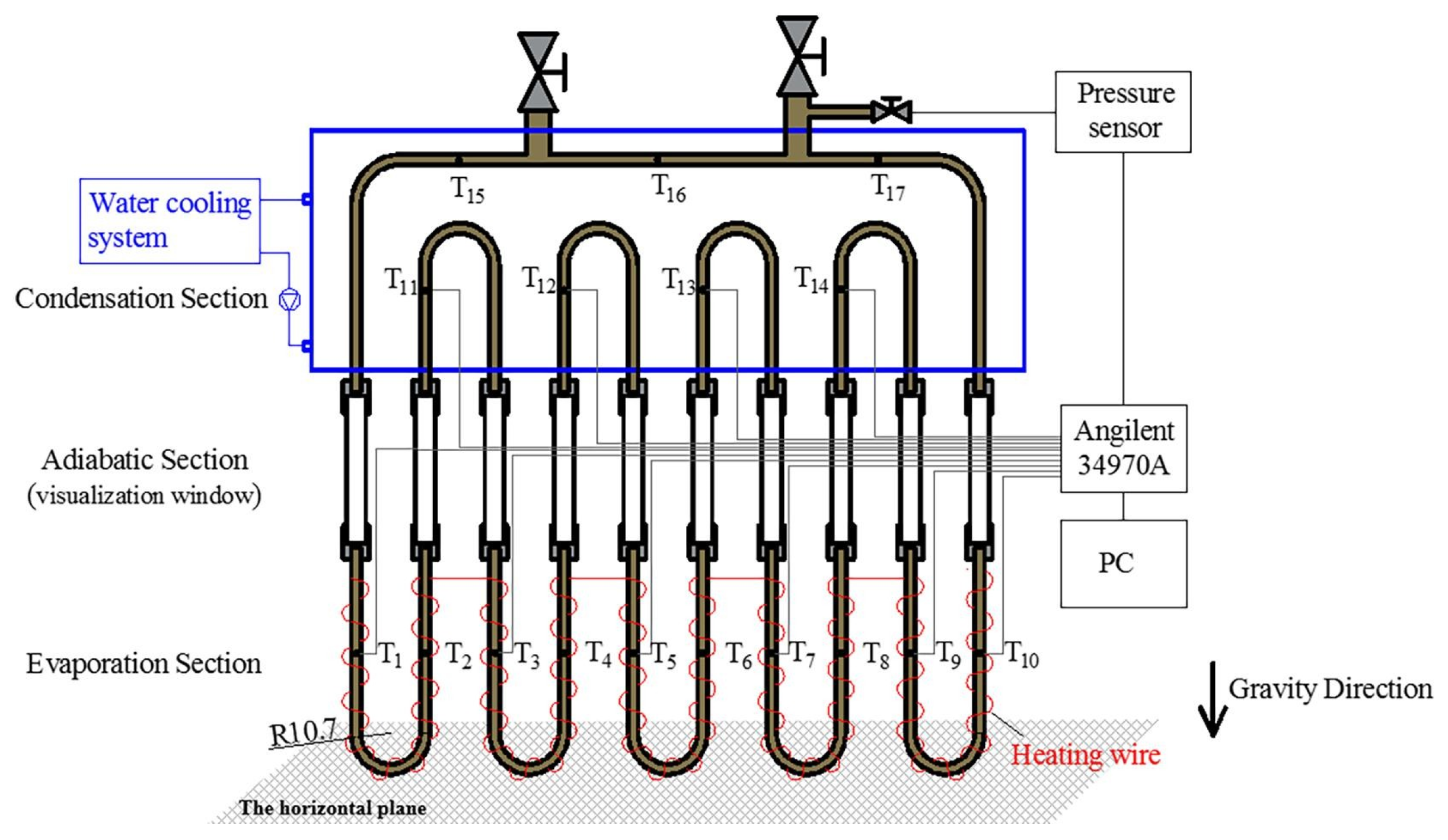

2.3.1. Status without Motion

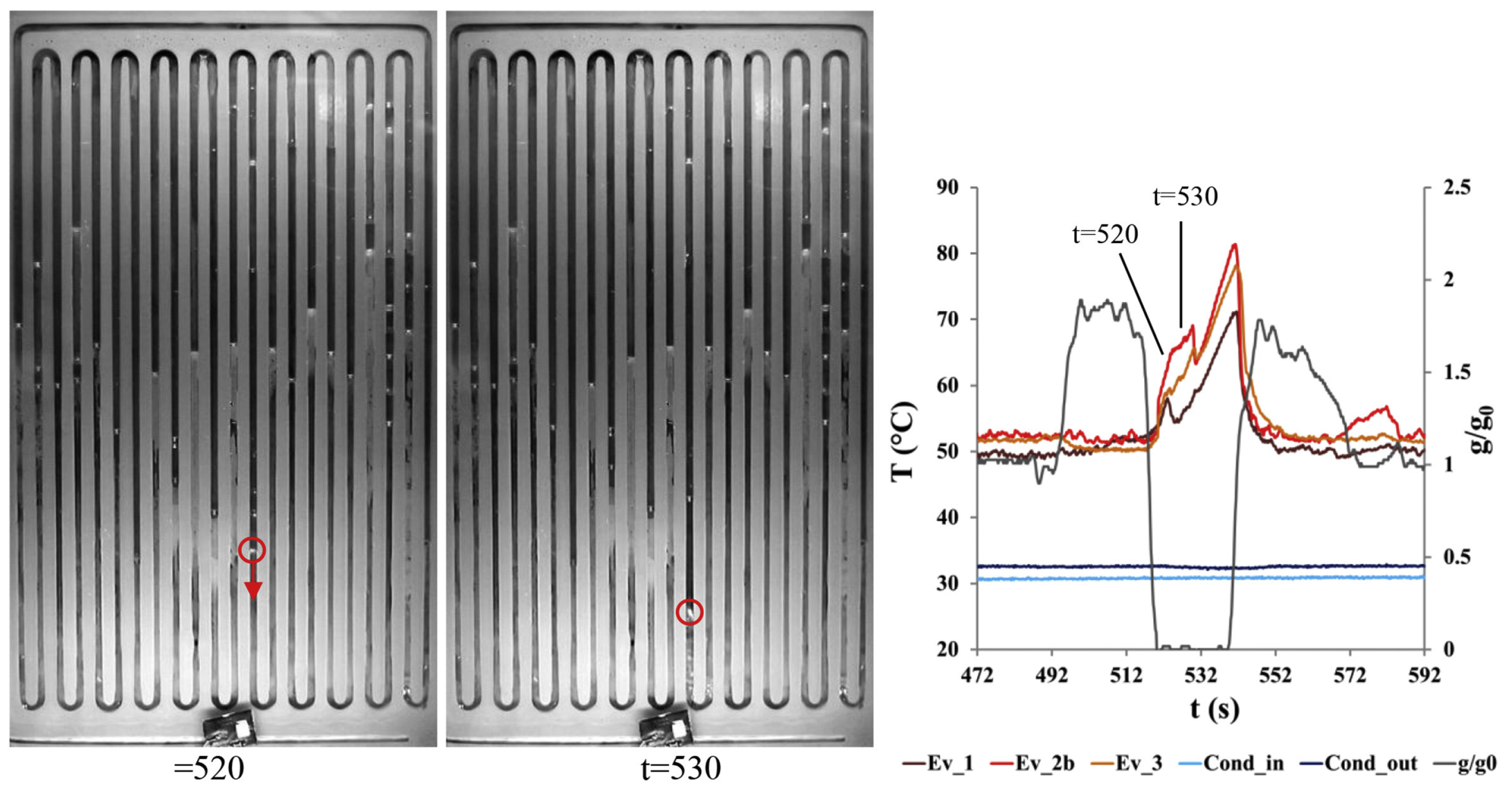

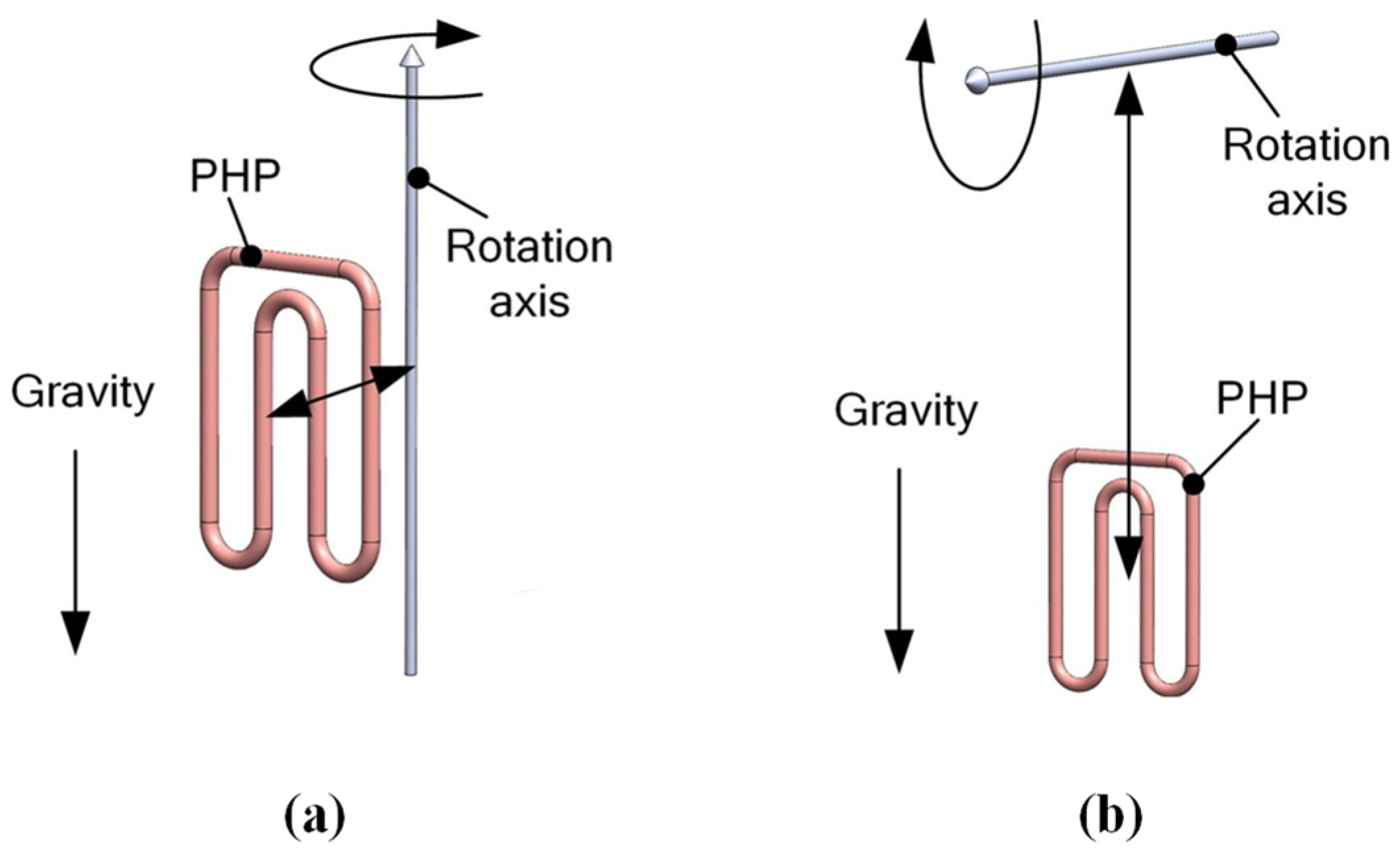

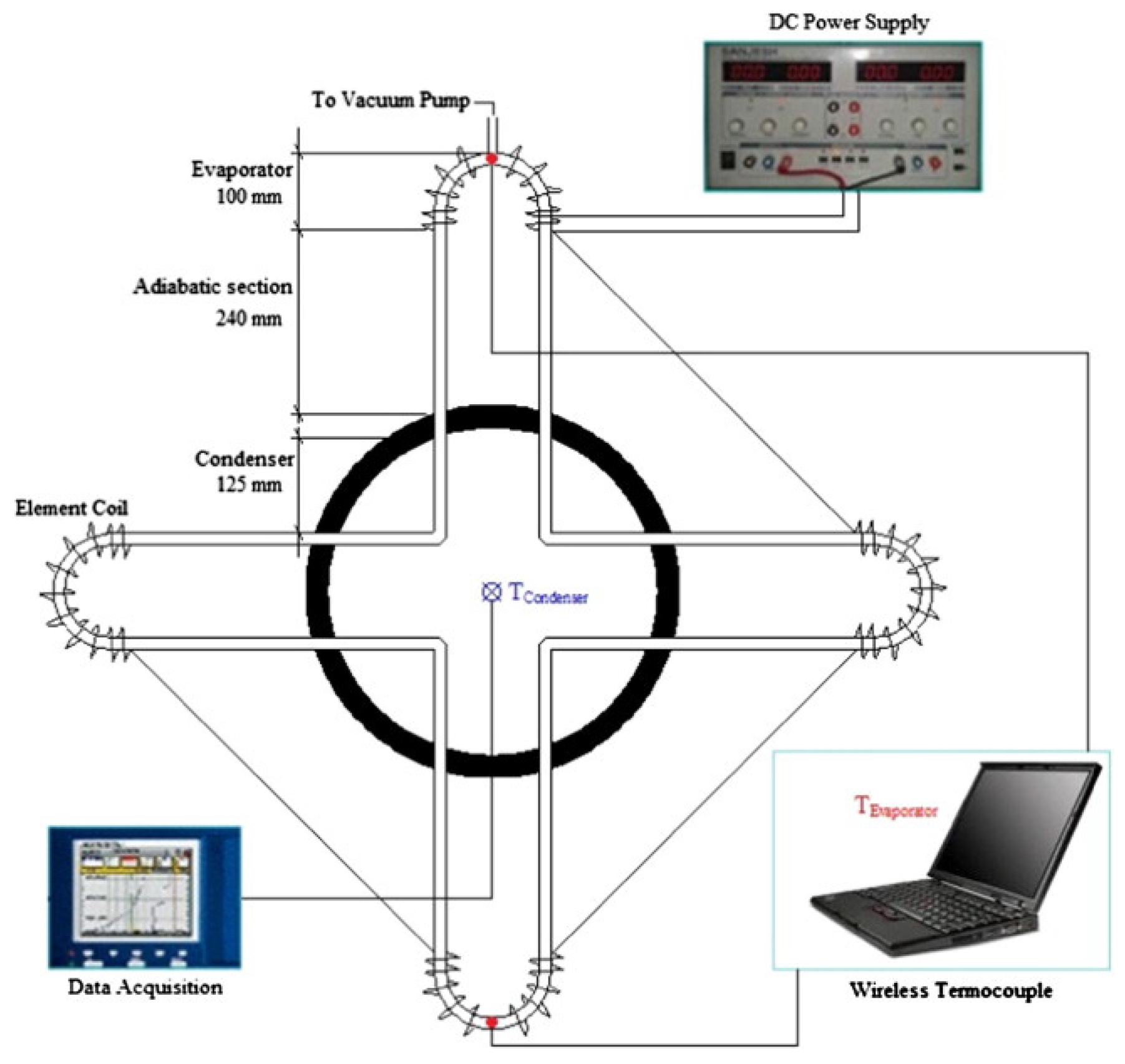

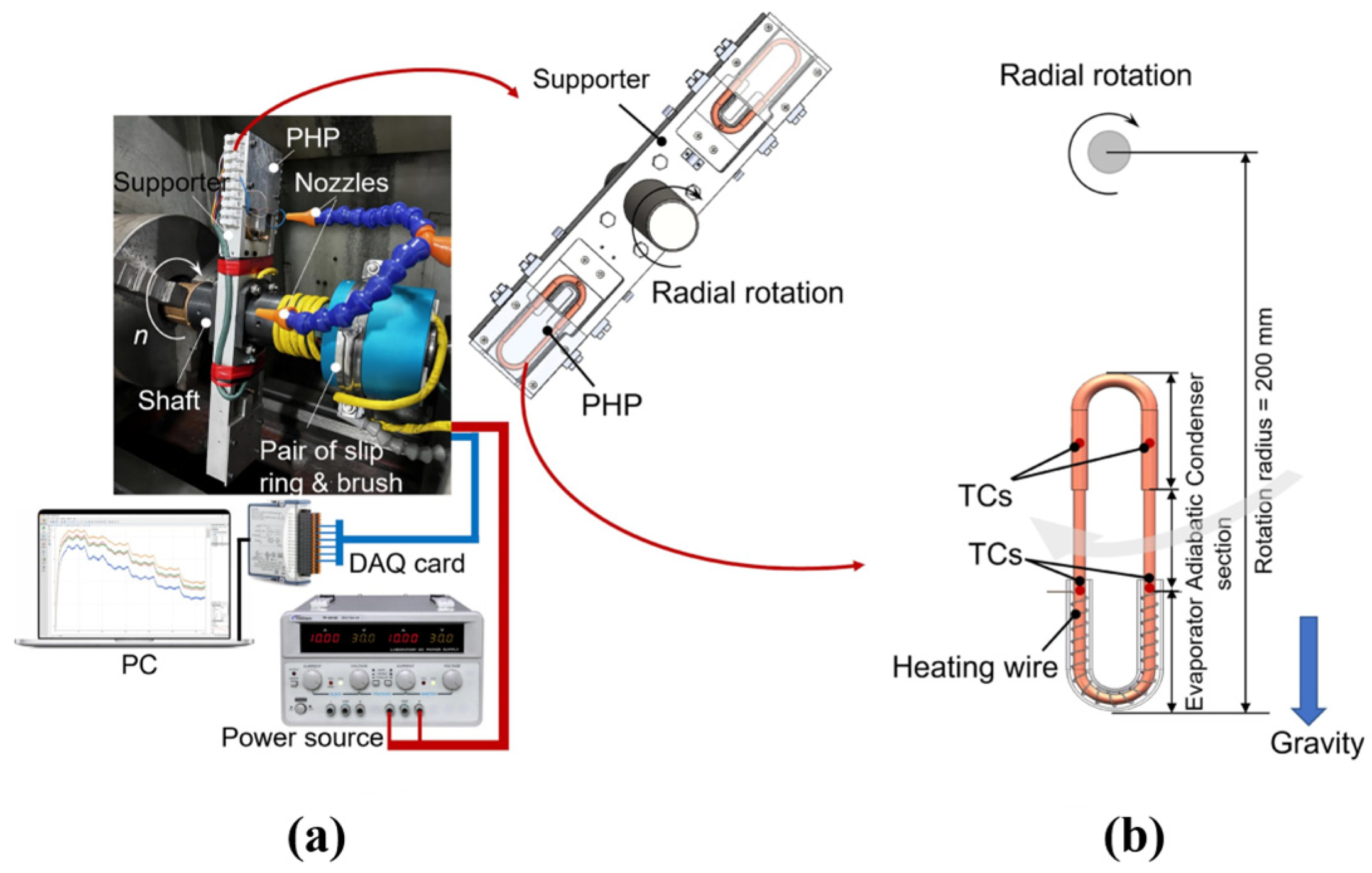

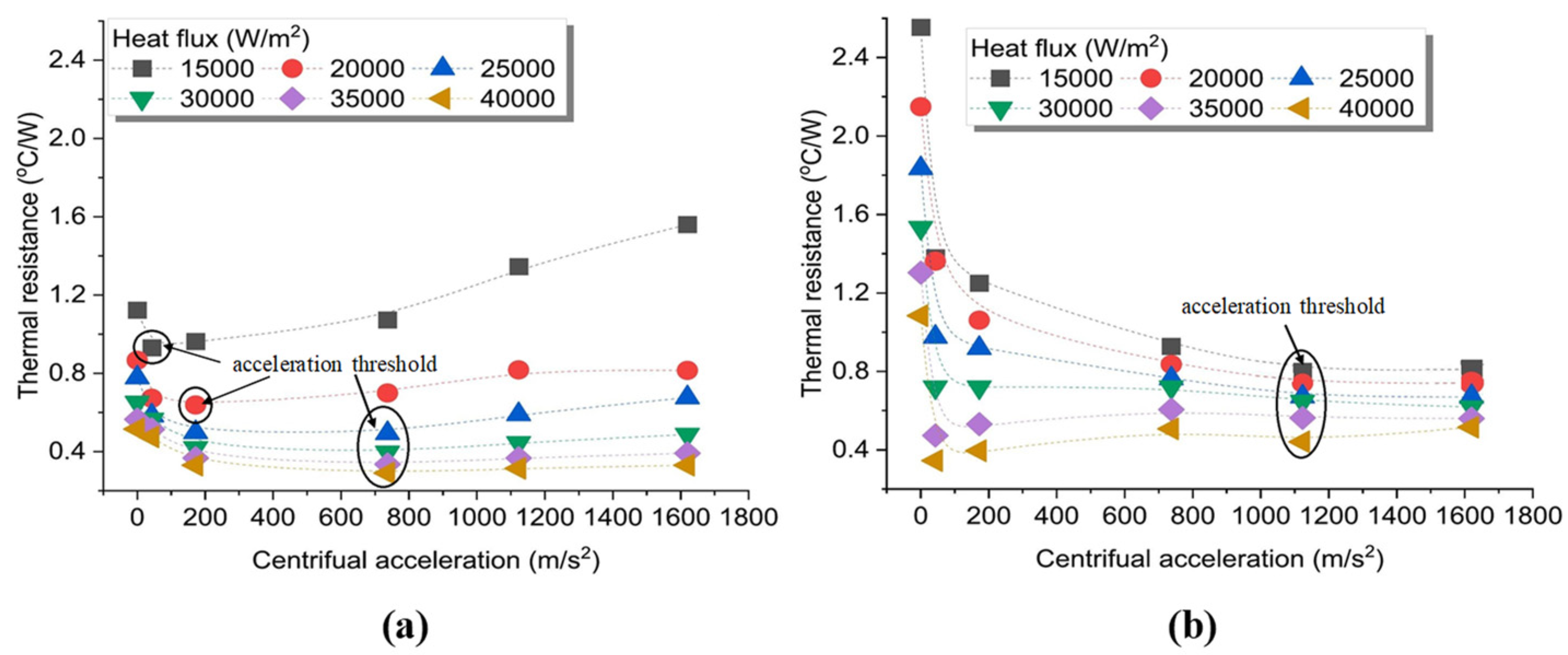

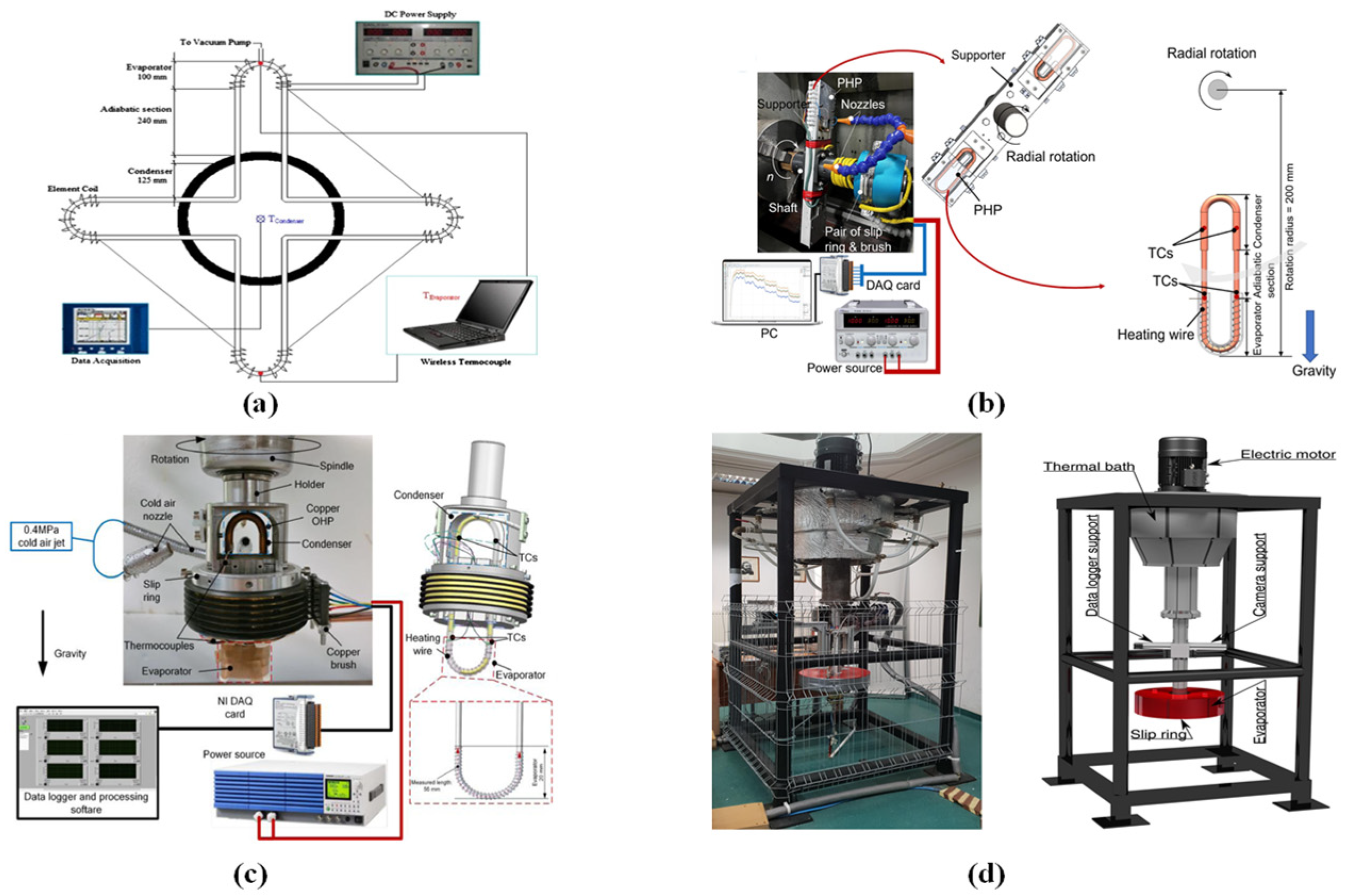

2.3.2. Status with Motion

| Condition | Phenomenon | Refs. |

|---|---|---|

| Microgravity and Hypergravity | Evaporation temperature rises rapidly. Stop-over phenomena occur. Dry-out results in deterioration of heat transfer performance. Reactivation phenomenon leads to enhancement of heat transfer performance. Large inner diameter, self-replenishing wetting, and large temperature difference are essential for stable operation. | [9,22,123,124,125] |

| Centrifugal force | Heat transfer is enhanced with acceleration in rotation less than the threshold value. However, heat transfer performance is deteriorated once the threshold is exceeded. | [5,126,128] |

2.3.3. Heat Input Mode

3. Mechanism of Pulsating Heat Pipes

3.1. Theoretical Model of PHPs

3.1.1. Spring–Mass–Damper Model

3.1.2. Mass–Momentum–Energy Equation Model

3.1.3. Semi-Empirical Model

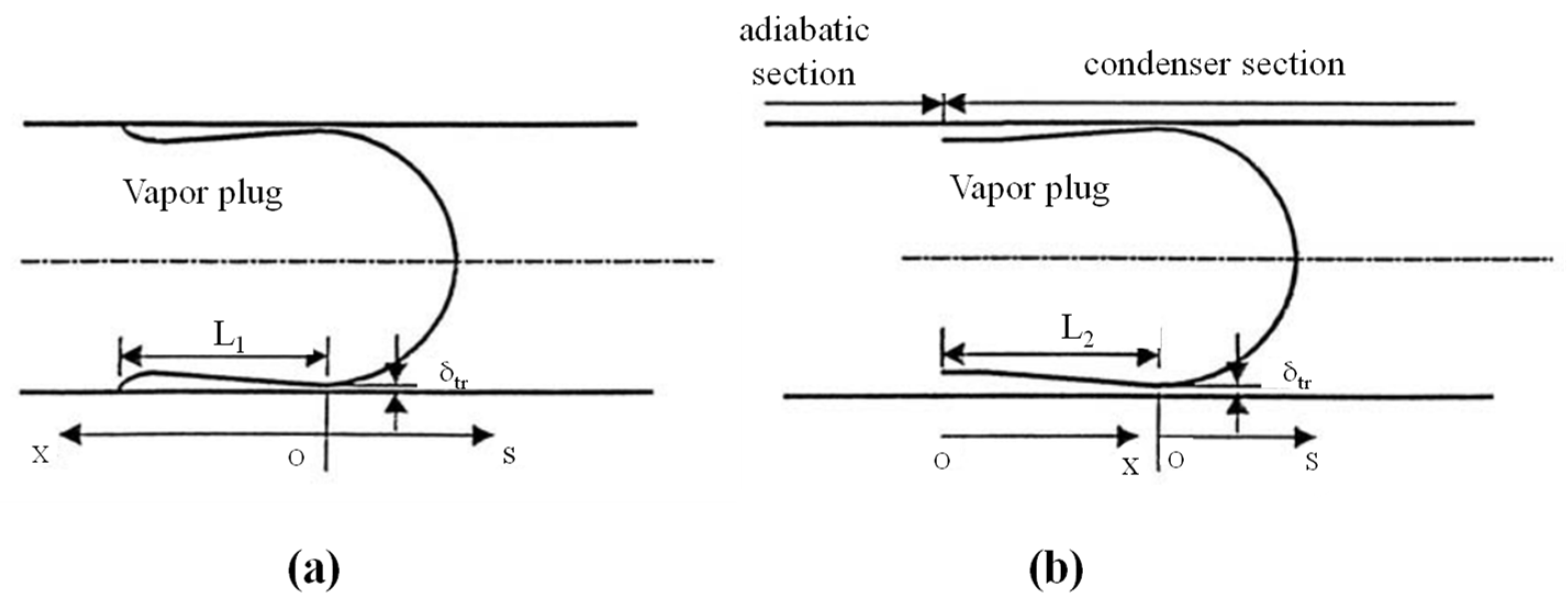

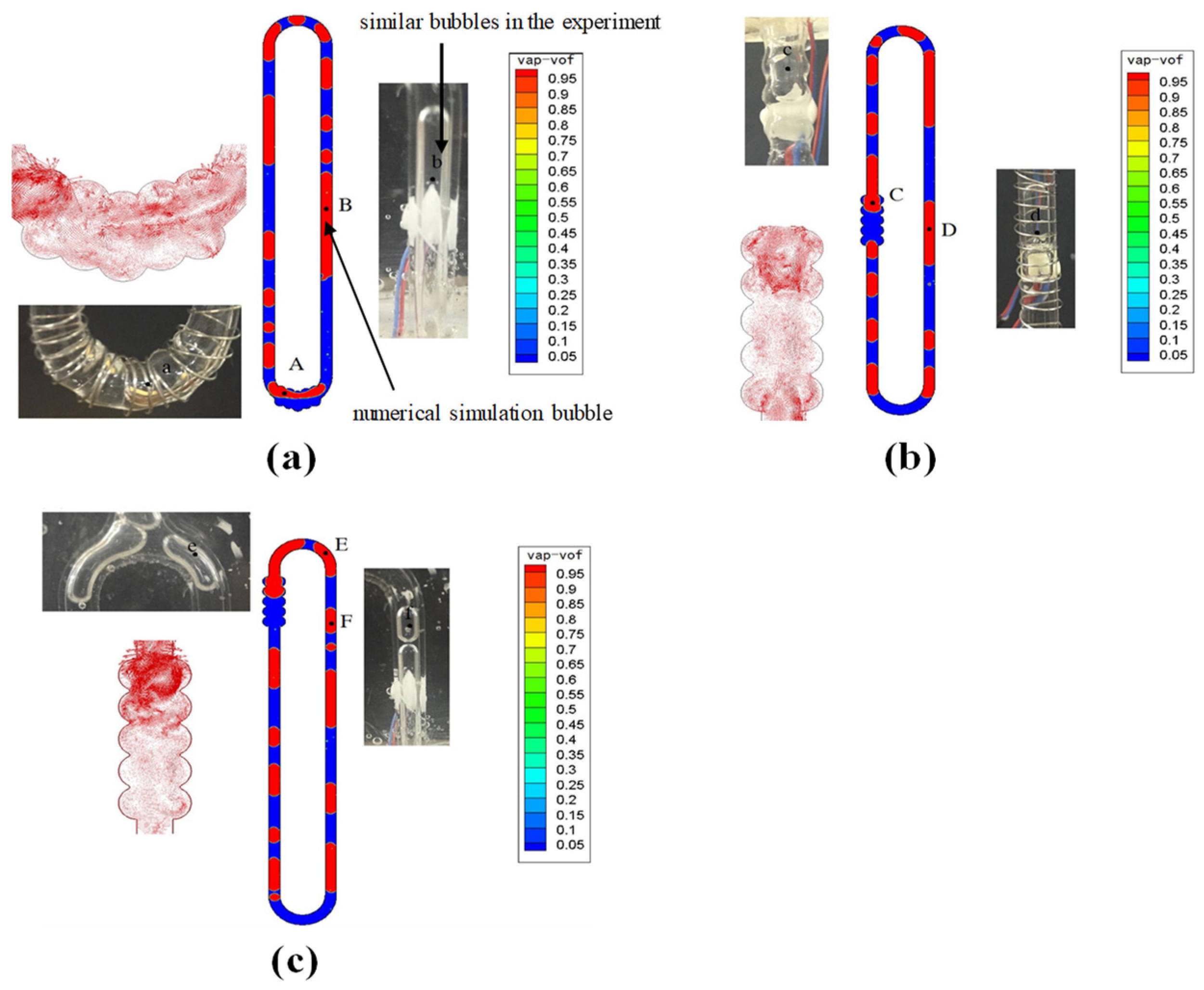

3.2. Numerical Simulation of PHPs

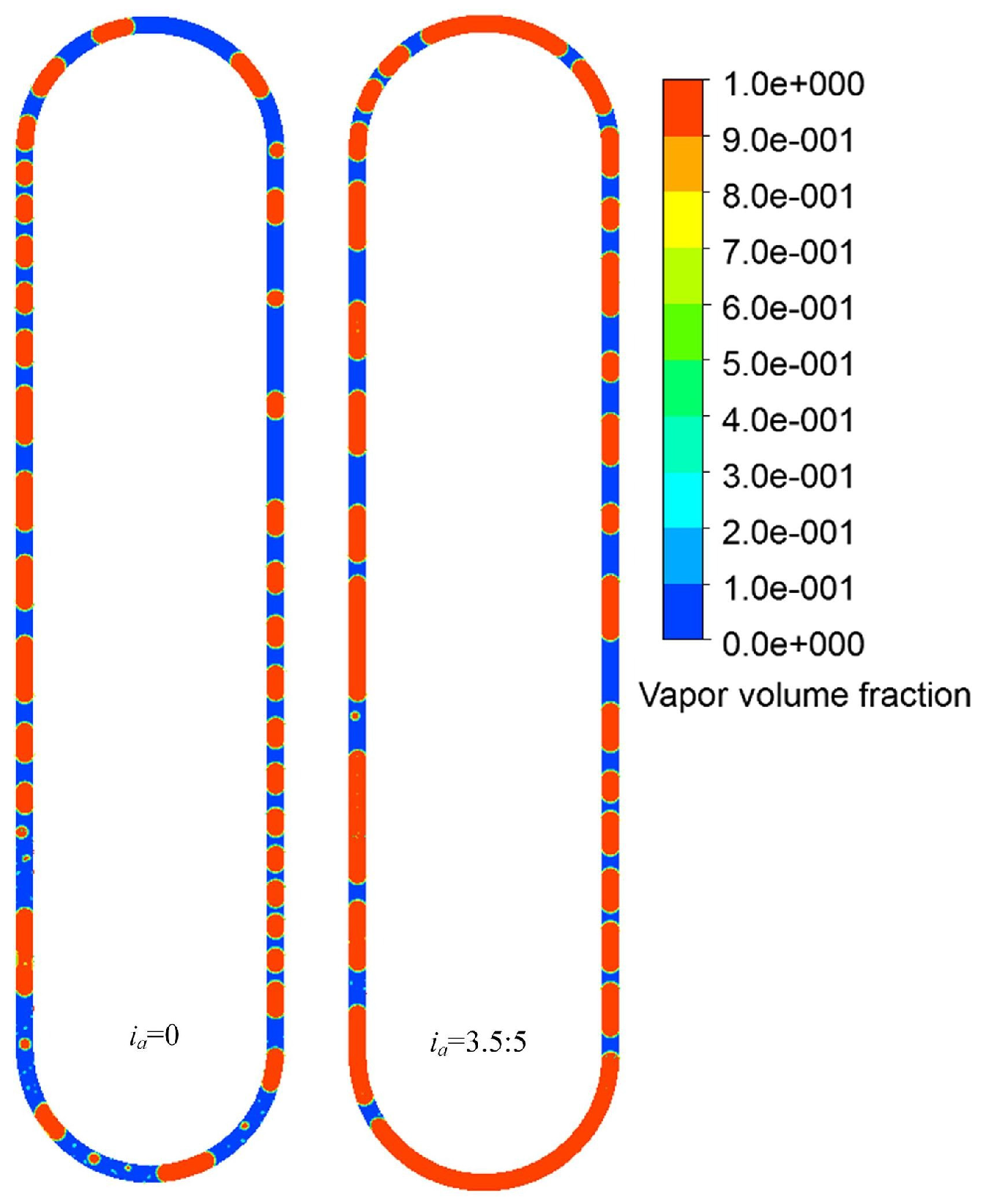

3.2.1. Numerical Simulation of Geometric Structures

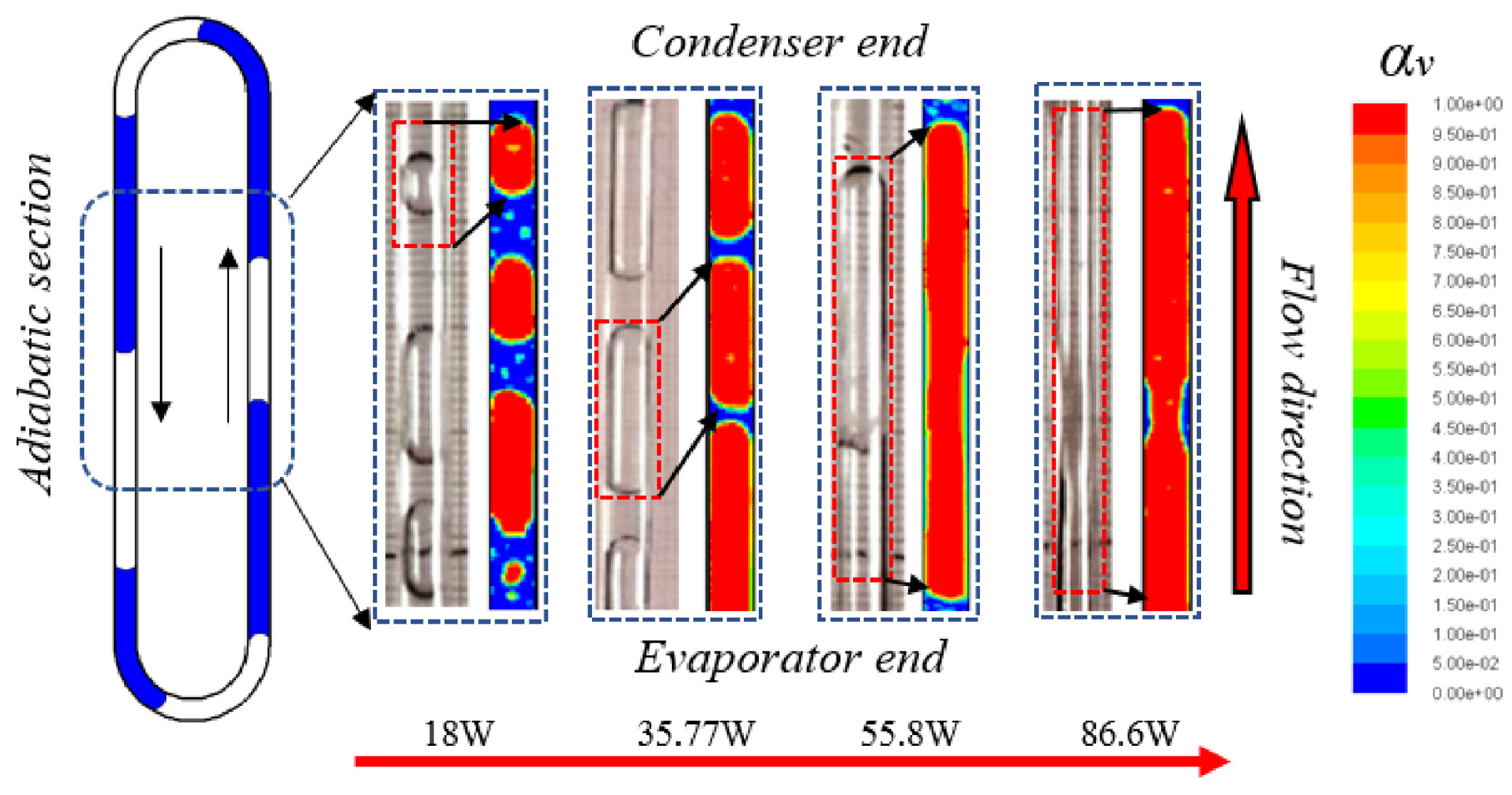

3.2.2. Numerical Simulation of Heat Input

3.2.3. Numerical Simulation of Liquid Film

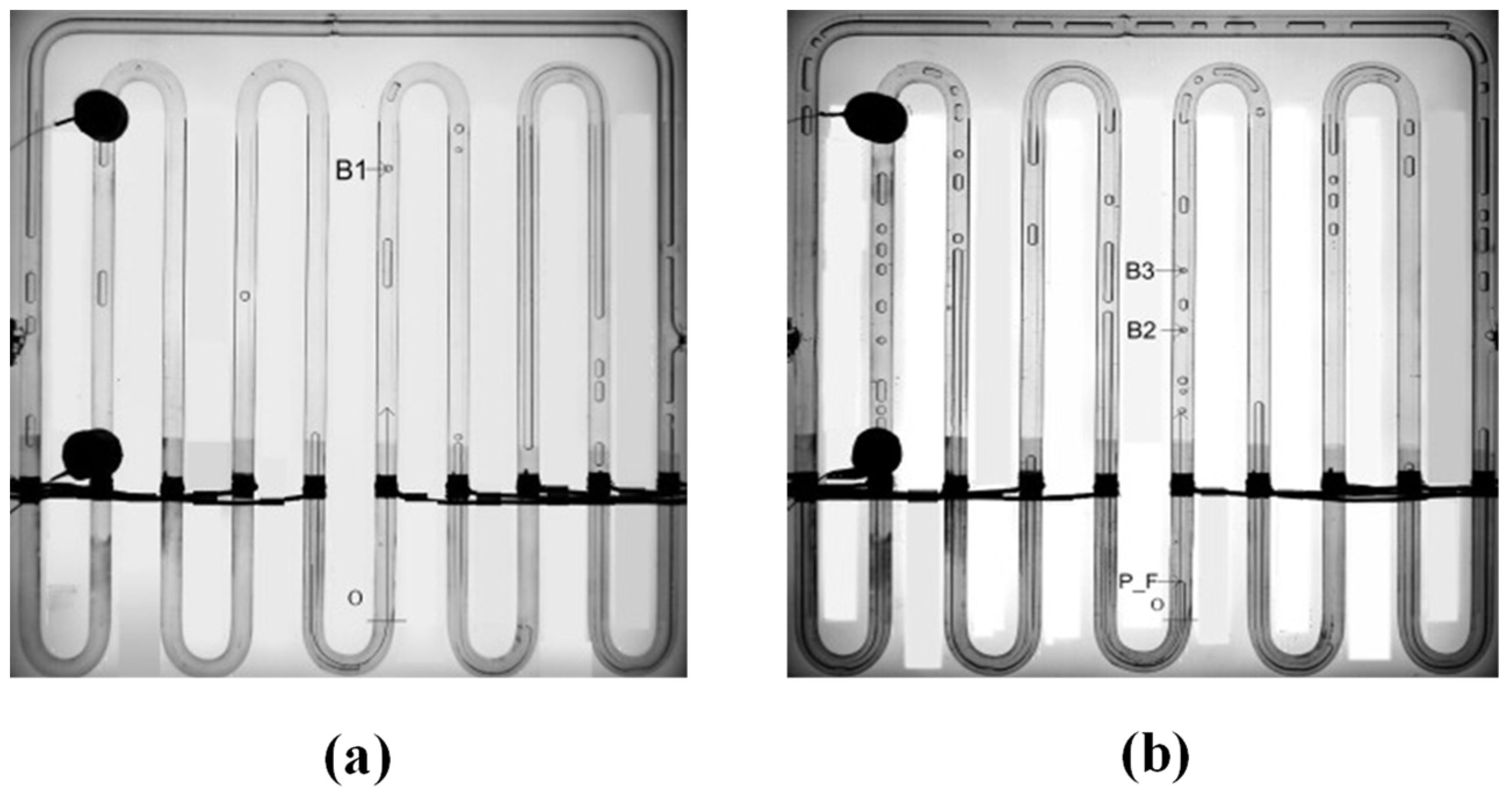

3.3. Visulation Experiments of PHPs

3.3.1. Conventional Visualization Technology

3.3.2. Novel Visualization Technology

4. Application of PHPs

4.1. Rotating Mechanical Cooling

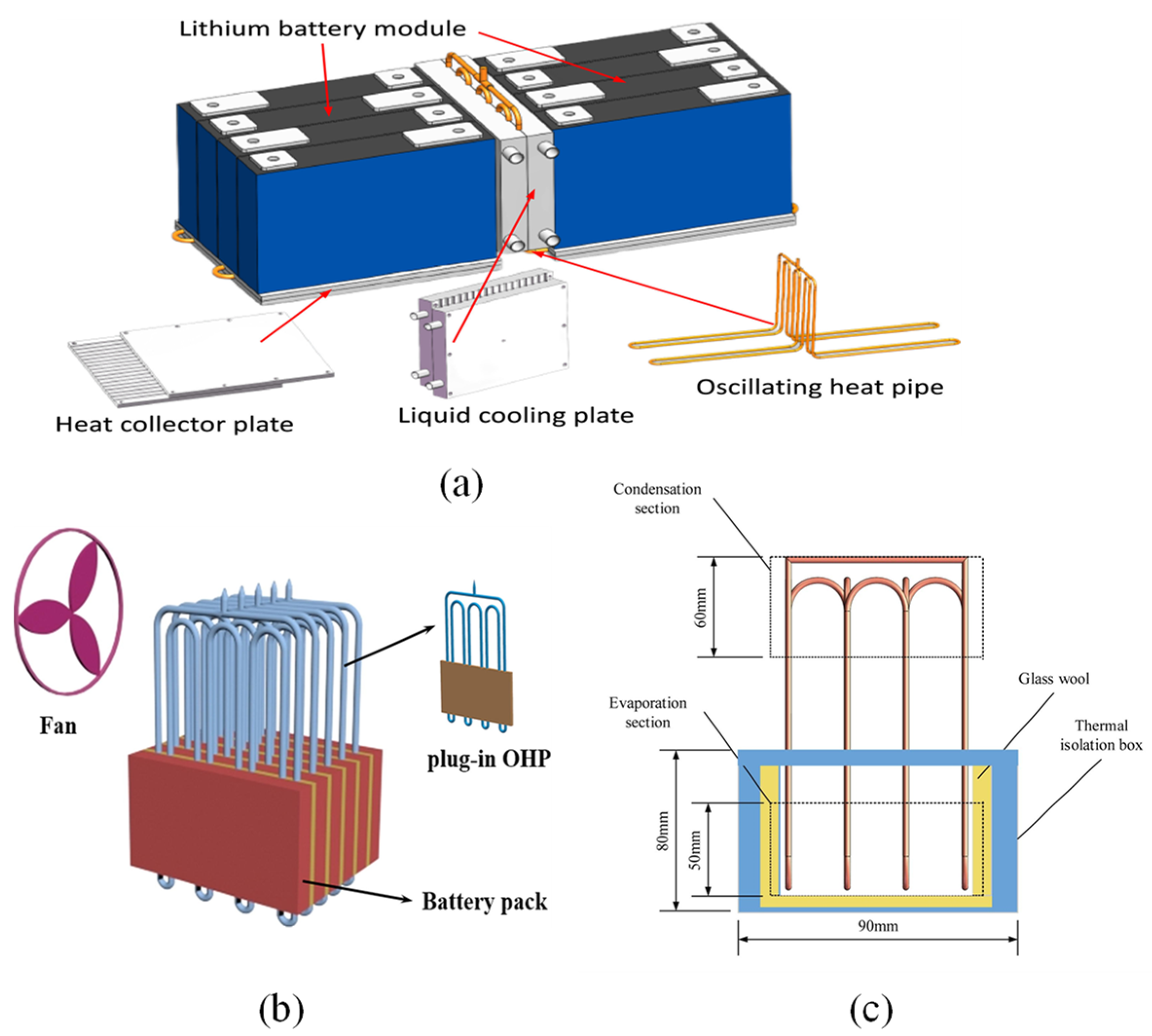

4.2. Battery Thermal Management Systems (BTMSs)

- It is difficult to provide precise temperature control and they require other temperature control devices to accurately regulate temperature.

- The structure of PHPs is difficult to fabricate to fit the shape of batteries in order to increase the cooling area.

- High start-up power may cause battery damage. Although some research has identified methods to start PHPs at low power [88,134,192], whether these methods can be applied to PHPs under other operating conditions remains unverified. Therefore, further research into the operating mechanism of PHPs is needed.

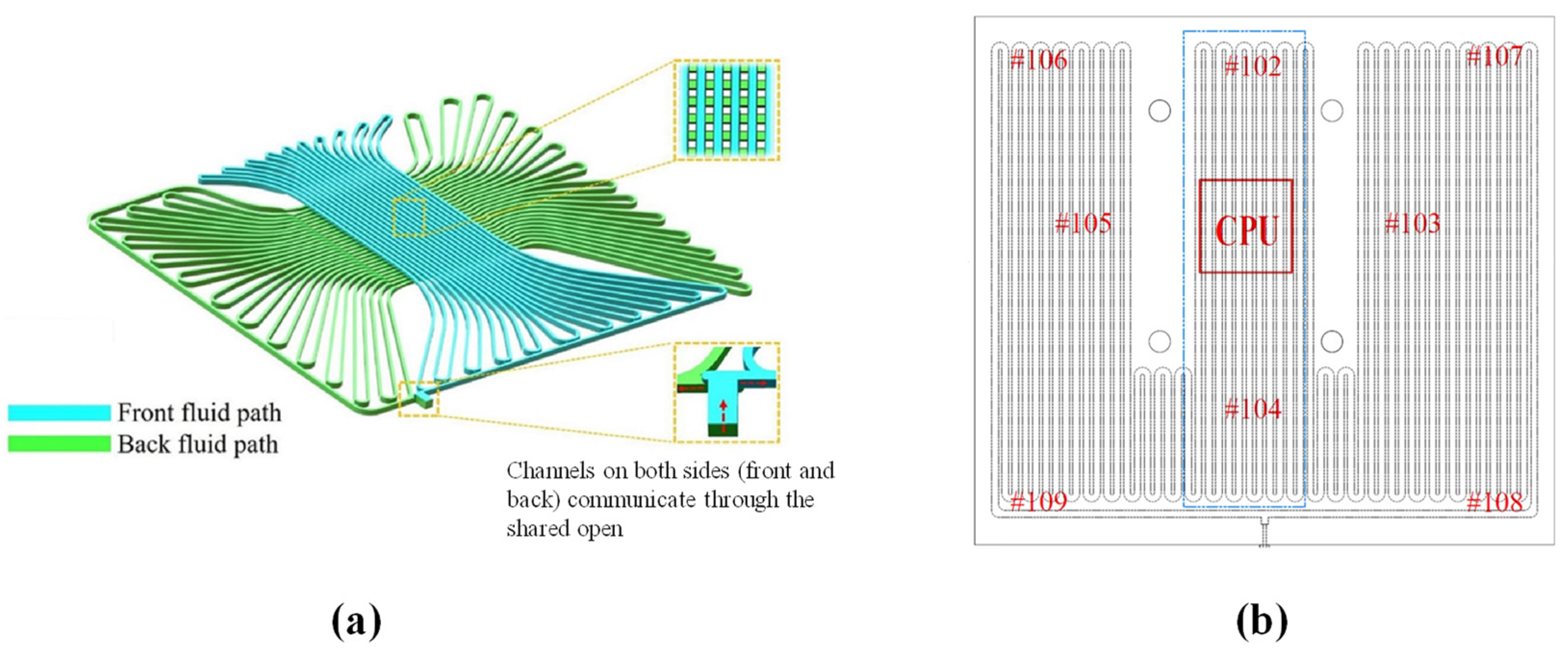

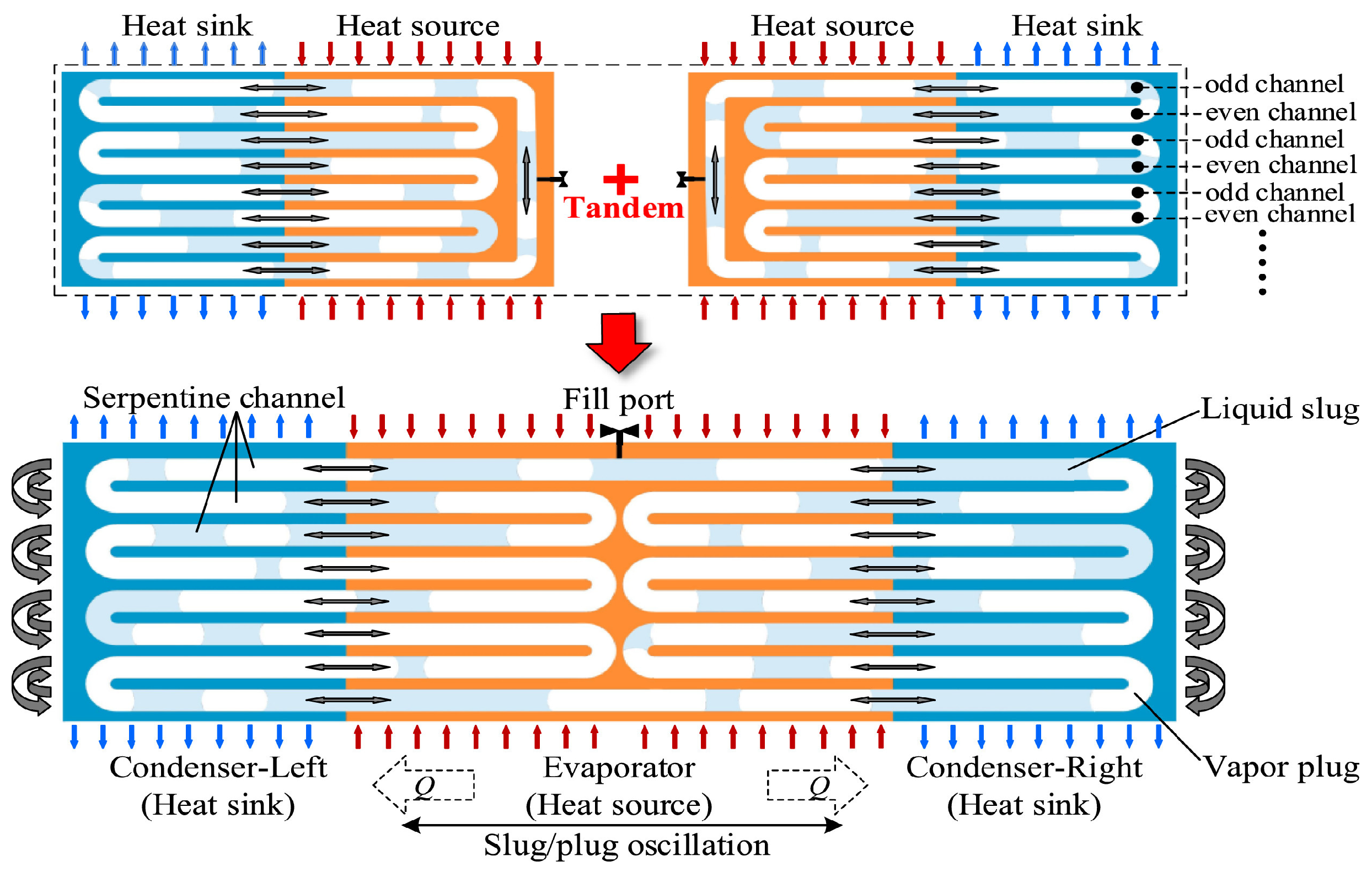

4.3. Electronic Cooling

- Manufacturing miniaturized PHPs requires a high level of industrial manufacturing capability.

- Operating for extended periods at high temperatures may lead to decreased cooling efficiency and lifespan of PHPs.

- The smaller size will increase flow resistance, leading to reduced cooling efficiency.

- Variations in the inclination angle of PHPs can affect cooling efficiency, highlighting the need for further research into the operational mechanisms of PHPs.

4.4. Aerospace Cooling

- Design with larger diameters and multiple turns will occupy a larger space, thereby increasing energy consumption.

- Operating PHPs for extended periods in high- or low-temperature environments may reduce their cooling efficiency and lifespan.

- Due to the high cost associated with studying PHP operations in aerospace, there is relatively little research in this domain.

5. Conclusions

- The thermophysical properties of working fluids are essential for the development of PHPs. Most of the research is focused on the application of composite or mixed working fluids, for the improvement of the performance of PHPs, due to the effects on rheologic properties, thermal conductivity, surface tension, phase change processes, etc. A proper concentration of composite or mixed working fluids can improve the start-up performance and heat transfer performance of pulsed heat pipes, but excessive composite or mixed working fluids will increase the dynamic viscosity of the working fluid, resulting in particle clustering, which will worsen the heat transfer performance of PHPs.

- The bond number is the criterion for the channel size of PHPs. The number of turns can enhance the heat transfer capacity of pulsating heat pipes, but the stability of heat pipes is affected by excessive turns. The design of the relevant length of each part of the pulsating heat pipes needs to be rationally configured according to the specific conditions.

- The incline angle shows a significant influence on the start-up and performance of PHPs. With surface modification and the adoption of centrifugal force for microgravity or hypergravity conditions, the performance of PHPs may be improved. However, there are conditions in which excessive centrifugal force can lead to vapor–liquid separation, thereby causing a decrease in the heat transfer performance of PHPs. It is necessary to introduce suitable centrifugal force according to different working fluids and conditions to improve the start-up characteristics and heat transfer performance of PHPs.

- In visualization experiments, new technologies, such as IR and LIF, are adopted for the observation of phenomena in PHPs, such as the morphology and motion of liquid or vapor slugs, to obtain information that is not available through optic observation. However, the non-interference measurement of the temperature of the working fluid to lessen the influence of sensors on the thermal and fluid process in PHPs is still a challenge for visualization experiments.

- PHPs are particularly suitable for applications with high heat flux, space constraints, microgravity, and flexible layout. It is still necessary to investigate the mechanism of PHPs, to observe the phenomena that occur in PHPs, and to evaluate the start-up and heat transfer performances of PHPs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qu, W.; Ma, H.B. Theoretical Analysis of Startup of a Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2007, 50, 2309–2316. [Google Scholar] [CrossRef]

- Rahman, M.L.; Mir, F.; Nawrin, S.; Sultan, R.A.; Ali, M. Effect of Fin and Insert on the Performance Characteristics of Open Loop Pulsating Heat Pipe (OLPHP). Procedia Eng. 2015, 105, 105–112. [Google Scholar] [CrossRef]

- Feng, C.; Wan, Z.; Mo, H.; Tang, H.; Lu, L.; Tang, Y. Heat Transfer Characteristics of a Novel Closed-Loop Pulsating Heat Pipe with a Check Valve. Appl. Therm. Eng. 2018, 141, 558–564. [Google Scholar] [CrossRef]

- Alizadeh, H.; Alhuyi Nazari, M.; Ghasempour, R.; Shafii, M.B.; Akbarzadeh, A. Numerical Analysis of Photovoltaic Solar Panel Cooling by a Flat Plate Closed-Loop Pulsating Heat Pipe. Sol. Energy 2020, 206, 455–463. [Google Scholar] [CrossRef]

- Ebrahimi Dehshali, M.; Nazari, M.A.; Shafii, M.B. Thermal Performance of Rotating Closed-Loop Pulsating Heat Pipes: Experimental Investigation and Semi-Empirical Correlation. Int. J. Therm. Sci. 2018, 123, 14–26. [Google Scholar] [CrossRef]

- Zhu, Y.; Xie, J.; Pei, A.; Liu, B.; Wu, Y.; Lin, D.; Li, J.; Wang, H.; Chen, H.; Xu, J.; et al. Fast Lithium Growth and Short Circuit Induced by Localized-Temperature Hotspots in Lithium Batteries. Nat. Commun. 2019, 10, 2067. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, J. A Dumbbell-Shaped 3D Flat Plate Pulsating Heat Pipe Module Augmented by Capillarity Gradient for High-Power Server CPU Onsite Cooling. Energy Convers. Manag. 2023, 292, 117384. [Google Scholar] [CrossRef]

- Mangini, D.; Mameli, M.; Georgoulas, A.; Araneo, L.; Filippeschi, S.; Marengo, M. A Pulsating Heat Pipe for Space Applications: Ground and Microgravity Experiments. Int. J. Therm. Sci. 2015, 95, 53–63. [Google Scholar] [CrossRef]

- Mameli, M.; Araneo, L.; Filippeschi, S.; Marelli, L.; Testa, R.; Marengo, M. Thermal Response of a Closed Loop Pulsating Heat Pipe under a Varying Gravity Force. Int. J. Therm. Sci. 2014, 80, 11–22. [Google Scholar] [CrossRef]

- Chang, X.; Yokouchi, T.; Odagiri, K.; Ogawa, H.; Nagano, H.; Nagai, H. Design Optimization and Experimental Demonstration of a Gravity-Assisted Cryogenic Loop Heat Pipe. Int. J. Heat Mass Transf. 2024, 221, 125037. [Google Scholar] [CrossRef]

- Zhang, J.; Song, G.; Qiu, Z.; Li, H. Thermal Analysis and Effects Study of Evaporator Exit Vapor Quality in a Separate Heat Pipe. Appl. Therm. Eng. 2020, 181, 115716. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, X.; Yu, H.; Huang, S.; Zhang, Y.; Su, G.H.; Deng, J.; Chai, X.; Hu, W. Capillary Limit of a Sodium Screen-Wick Heat Pipe. Appl. Therm. Eng. 2023, 232, 120972. [Google Scholar] [CrossRef]

- Anand, R.S.; Li, A.; Huang, W.; Chen, J.; Li, Z.; Ma, Q.; Jiang, F. Super-Long Gravity Heat Pipe for Geothermal Energy Exploitation—A Comprehensive Review. Renew. Sustain. Energy Rev. 2024, 193, 114286. [Google Scholar] [CrossRef]

- Han, X.; Wang, X.; Zheng, H.; Xu, X.; Chen, G. Review of the Development of Pulsating Heat Pipe for Heat Dissipation. Renew. Sustain. Energy Rev. 2016, 59, 692–709. [Google Scholar] [CrossRef]

- Bastakoti, D.; Zhang, H.; Li, D.; Cai, W.; Li, F. An Overview on the Developing Trend of Pulsating Heat Pipe and Its Performance. Appl. Therm. Eng. 2018, 141, 305–332. [Google Scholar] [CrossRef]

- Xu, Y.; Xue, Y.; Qi, H.; Cai, W. An Updated Review on Working Fluids, Operation Mechanisms, and Applications of Pulsating Heat Pipes. Renew. Sustain. Energy Rev. 2021, 144, 110995. [Google Scholar] [CrossRef]

- Saha, N.; Das, P.K.; Sharma, P.K. Influence of Process Variables on the Hydrodynamics and Performance of a Single Loop Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2014, 74, 238–250. [Google Scholar] [CrossRef]

- Kang, S.W.; Wang, Y.C.; Liu, Y.C.; Lo, H.M. Visualization and Thermal Resistance Measurements for a Magnetic Nanofluid Pulsating Heat Pipe. Appl. Therm. Eng. 2017, 126, 1044–1050. [Google Scholar] [CrossRef]

- Karthikeyan, V.K.; Ramachandran, K.; Pillai, B.C.; Brusly Solomon, A. Understanding Thermo-Fluidic Characteristics of a Glass Tube Closed Loop Pulsating Heat Pipe: Flow Patterns and Fluid Oscillations. Heat Mass Transf. 2015, 51, 1669–1680. [Google Scholar] [CrossRef]

- Pachghare, P.R.; Mahalle, A.M. Thermo-Hydrodynamics of Closed Loop Pulsating Heat Pipe: An Experimental Study. J. Mech. Sci. Technol. 2014, 28, 3387–3394. [Google Scholar] [CrossRef]

- Mahapatra, B.N.; Das, P.K.; Sahoo, S.S. Scaling Analysis and Experimental Investigation of Pulsating Loop Heat Pipes. Appl. Therm. Eng. 2016, 108, 358–367. [Google Scholar] [CrossRef]

- Cecere, A.; De Cristofaro, D.; Savino, R.; Ayel, V.; Sole-Agostinelli, T.; Marengo, M.; Romestant, C.; Bertin, Y. Experimental Analysis of a Flat Plate Pulsating Heat Pipe with Self-ReWetting Fluids during a Parabolic Flight Campaign. Acta Astronaut. 2018, 147, 454–461. [Google Scholar] [CrossRef]

- Pachghare, P.R.; Mahalle, A.M. Effect of Pure and Binary Fluids on Closed Loop Pulsating Heat Pipe Thermal Performance. Procedia Eng. 2013, 51, 624–629. [Google Scholar] [CrossRef]

- Han, H.; Cui, X.; Zhu, Y.; Sun, S. A Comparative Study of the Behavior of Working Fluids and Their Properties on the Performance of Pulsating Heat Pipes (PHP). Int. J. Therm. Sci. 2014, 82, 138–147. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, P.; Xu, H.; Ma, W.; Sheng, J. Visualization of Thermo-Hydrodynamic Behavior in Flat-Plate Pulsating Heat Pipe with HFE-347. J. Therm. Sci. 2021, 30, 926–938. [Google Scholar] [CrossRef]

- Ahmad, H.; Kim, S.K.; Jung, S.Y. Analysis of Thermally Driven Flow Behaviors for Two-Turn Closed-Loop Pulsating Heat Pipe in Ambient Conditions: An Experimental Approach. Int. J. Heat Mass Transf. 2020, 150, 119245. [Google Scholar] [CrossRef]

- Jun, S.; Kim, S.J. Experimental Study on a Criterion for Normal Operation of Pulsating Heat Pipes in a Horizontal Orientation. Int. J. Heat Mass Transf. 2019, 137, 1064–1075. [Google Scholar] [CrossRef]

- Ilinca, A.; Mangini, D.; Mameli, M.; Fioriti, D.; Filippeschi, S.; Araneo, L.; Roth, N.; Marengo, M. Fluid-Flow Pressure Measurements and Thermo-Fluid Characterization of a Single Loop Two-Phase Passive Heat Transfer Device. J. Phys. Conf. Ser. 2017, 923, 012022. [Google Scholar] [CrossRef]

- Yoon, A.; Kim, S.J. A Deep-Learning Approach for Predicting Oscillating Motion of Liquid Slugs in a Closed-Loop Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2021, 181, 121860. [Google Scholar] [CrossRef]

- Markal, B.; Candere, A.; Avci, M.; Aydin, O. Investigation of Flat Plate Type Pulsating Heat Pipes via Flow Visualization-Assisted Experiments: Effect of Cross Sectional Ratio. Int. Commun. Heat Mass Transf. 2021, 125, 105289. [Google Scholar] [CrossRef]

- Markal, B.; Candere, A.C.; Avci, M.; Aydin, O. Effect of Double Cross Sectional Ratio on Performance Characteristics of Pulsating Heat Pipes. Int. Commun. Heat Mass Transf. 2021, 127, 105583. [Google Scholar] [CrossRef]

- Kwon, G.H.; Kim, S.J. Experimental Investigation on the Thermal Performance of a Micro Pulsating Heat Pipe with a Dual-Diameter Channel. Int. J. Heat Mass Transf. 2015, 89, 817–828. [Google Scholar] [CrossRef]

- Czajkowski, C.; Nowak, A.I.; Błasiak, P.; Ochman, A.; Pietrowicz, S. Experimental Study on a Large Scale Pulsating Heat Pipe Operating at High Heat Loads, Different Adiabatic Lengths and Various Filling Ratios of Acetone, Ethanol, and Water. Appl. Therm. Eng. 2020, 165, 114534. [Google Scholar] [CrossRef]

- Hao, T.; Ma, H.; Ma, X. Heat Transfer Performance of Polytetrafluoroethylene Oscillating Heat Pipe with Water, Ethanol, and Acetone as Working Fluids. Int. J. Heat Mass Transf. 2019, 131, 109–120. [Google Scholar] [CrossRef]

- Bastakoti, D.; Zhang, H.; Cai, W.; Li, F. An Experimental Investigation of Thermal Performance of Pulsating Heat Pipe with Alcohols and Surfactant Solutions. Int. J. Heat Mass Transf. 2018, 117, 1032–1040. [Google Scholar] [CrossRef]

- Sun, X.; Li, S.; Wang, B.; Jiao, B.; Pfotenhauer, J.; Miller, F.; Gan, Z. Numerical Study of the Thermal Performance of a Hydrogen Pulsating Heat Pipe. Int. J. Therm. Sci. 2022, 172, 107302. [Google Scholar] [CrossRef]

- Sun, X.; Li, S.; Jiao, B.; Gan, Z.; Pfotenhauer, J. Experimental Study on a Hydrogen Closed-Loop Pulsating Heat Pipe with Two Turns. Cryogenics 2019, 97, 63–69. [Google Scholar] [CrossRef]

- Sun, X.; Li, S.; Jiao, B.; Gan, Z.; Pfotenhauer, J.; Wang, B.; Zhao, Q.; Liu, D. Experimental Study on Hydrogen Pulsating Heat Pipes under Different Number of Turns. Cryogenics 2020, 111, 103174. [Google Scholar] [CrossRef]

- Li, S.; Sun, X.; Liu, D.; Jiao, B.; Pfotenhauer, J.; Gan, Z.; Qiu, M. Experimental Study on a Hydrogen Pulsating Heat Pipe in Different Heating Modes. Cryogenics 2022, 123, 103440. [Google Scholar] [CrossRef]

- Lyu, B.; Xu, D.; Wang, W.; Xin, J.; Shi, Y.; Fang, Z.; Huang, C.; Huang, R.; Li, L. Experimental Investigation of a Serial-Parallel Configuration Helium Pulsating Heat Pipe. Cryogenics 2023, 131, 103668. [Google Scholar] [CrossRef]

- Guo, R.; Xu, D.; Shi, Y.; Huang, C.; Li, L. Effect of Large Redundant Volume on the Performance of Multiple Turns Helium Pulsating Heat Pipe. Cryogenics 2023, 134, 103726. [Google Scholar] [CrossRef]

- Li, M.; Li, L.; Xu, D. Effect of Filling Ratio and Orientation on the Performance of a Multiple Turns Helium Pulsating Heat Pipe. Cryogenics 2019, 100, 62–68. [Google Scholar] [CrossRef]

- Xu, D.; Li, L.; Liu, H. Experimental Investigation on the Thermal Performance of Helium Based Cryogenic Pulsating Heat Pipe. Exp. Therm. Fluid Sci. 2016, 70, 61–68. [Google Scholar] [CrossRef]

- Fonseca, L.D.; Pfotenhauer, J.; Miller, F. Results of a Three Evaporator Cryogenic Helium Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2018, 120, 1275–1286. [Google Scholar] [CrossRef]

- Li, M.; Li, L.; Xu, D. Effect of Number of Turns and Configurations on the Heat Transfer Performance of Helium Cryogenic Pulsating Heat Pipe. Cryogenics 2018, 96, 159–165. [Google Scholar] [CrossRef]

- Kossel, L.; Pfotenhauer, J.; Kashani, A.; Miller, F. A Novel Thermal Bus Architecture for Large Cryogenic Space Telescopes Utilizing Helium Pulsating Heat Pipes. Cryogenics 2024, 139, 103807. [Google Scholar] [CrossRef]

- Li, S.; Bu, Z.; Fang, T.; Wang, Y.; Shen, Y.; Tao, X.; Jiao, B.; Gan, Z. Experimental Study on the Thermo-Hydrodynamic Characteristics of a Nitrogen Pulsating Heat Pipe. Int. Commun. Heat Mass Transf. 2023, 146, 106920. [Google Scholar] [CrossRef]

- Li, S.; Pei, H.; Liu, D.; Shen, Y.; Tao, X.; Gan, Z. Visualization Study on the Flow Characteristics of a Nitrogen Pulsating Heat Pipe. Int. Commun. Heat Mass Transf. 2023, 143, 106722. [Google Scholar] [CrossRef]

- Shi, Y.; Xu, D.; Yan, J.; Guo, R.; Lyu, B.; Huang, C.; Li, L. Visualized Investigation of a Nitrogen Pulsating Heat Pipe. Cryogenics 2024, 138, 103783. [Google Scholar] [CrossRef]

- Singh, B.P.; Atrey, M.D. Numerical Investigation of a Nitrogen Based Cryogenic Pulsating Heat Pipe. Cryogenics 2021, 115, 103246. [Google Scholar] [CrossRef]

- Sagar, K.R.; Naik, H.B.; Mehta, H.B. Numerical Study of Liquid Nitrogen Based Pulsating Heat Pipe for Cooling Superconductors. Int. J. Refrig. 2021, 122, 33–46. [Google Scholar] [CrossRef]

- Fonseca, L.D.; Miller, F.; Pfotenhauer, J. Experimental Heat Transfer Analysis of a Cryogenic Nitrogen Pulsating Heat Pipe at Various Liquid Fill Ratios. Appl. Therm. Eng. 2018, 130, 343–353. [Google Scholar] [CrossRef]

- Bruce, R.; Barba, M.; Bonelli, A.; Baudouy, B. Thermal Performance of a Meter-Scale Horizontal Nitrogen Pulsating Heat Pipe. Cryogenics 2018, 93, 66–74. [Google Scholar] [CrossRef]

- Yi, H.; Changcheng, M.; Jun, Z.; Rui, H.; Rui, G. Experimental Studies on the Heat Transfer Characteristics of Helium-Based Cryogenic Oscillating Heat Pipes. In Radiation Detection Technology and Methods; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Riehl, R.R.; Murshed, S.M.S. Performance Evaluation of Nanofluids in Loop Heat Pipes and Oscillating Heat Pipes. Int. J. Thermofluids 2022, 14, 100147. [Google Scholar] [CrossRef]

- Babu, E.R.; Reddy, N.C.; Babbar, A.; Chandrashekar, A.; Kumar, R.; Bains, P.S.; Alsubih, M.; Islam, S.; Joshi, S.K.; Rizal, A.; et al. Characteristics of Pulsating Heat Pipe with Variation of Tube Diameter, Filling Ratio, and SiO2 Nanoparticles: Biomedical and Engineering Implications. Case Stud. Therm. Eng. 2024, 55, 104065. [Google Scholar] [CrossRef]

- Jajarm, A.R.A.; Goshayeshi, H.R.; Bashirnezhad, K.; Chaer, I.; Toghraie, D.; Salahshour, S. Combined Effect of the Magnetic Field, Orientation, and Filling Ratio on Cylindrical Pulsating Heat Pipe Using Distilled Water and Distilled Water/Fe3O4 Nanofluid. J. Magn. Magn. Mater. 2024, 590, 171712. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, Z.; Guo, J.; Ma, D.; Yang, W. Capture of Kinetic Behavior of Ethanol-Based Copper Oxides in Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2024, 225, 125392. [Google Scholar] [CrossRef]

- Kharat, P.B.; Kounsalye, J.S.; Shisode, M.V.; Jadhav, K.M. Preparation and Thermophysical Investigations of CoFe2O4-Based Nanofluid: A Potential Heat Transfer Agent. J. Supercond. Nov. Magn. 2019, 32, 341–351. [Google Scholar] [CrossRef]

- Zhang, D.; He, Z.; Guan, J.; Tang, S.; Shen, C. Heat Transfer and Flow Visualization of Pulsating Heat Pipe with Silica Nanofluid: An Experimental Study. Int. J. Heat Mass Transf. 2022, 183, 122100. [Google Scholar] [CrossRef]

- Ali, H.M.; Sajid, M.U.; Arshad, A. Heat Transfer Applications of TiO2 Nanofluids. In Application of Titanium Dioxide; Intech: London, UK, 2017. [Google Scholar]

- Choi, S.U.S.; Zhang, Z.G.; Yu, W.; Lockwood, F.E.; Grulke, E.A. Anomalous Thermal Conductivity Enhancement in Nanotube Suspensions. Appl. Phys. Lett. 2001, 79, 2252–2254. [Google Scholar] [CrossRef]

- Eastman, J.A.; Choi, S.U.S.; Li, S.; Yu, W.; Thompson, L.J. Anomalously Increased Effective Thermal Conductivities of Ethylene Glycol-Based Nanofluids Containing Copper Nanoparticles. Appl. Phys. Lett. 2001, 78, 718–720. [Google Scholar] [CrossRef]

- Das, S.K.; Putra, N.; Thiesen, P.; Roetzel, W. Temperature Dependence of Thermal Conductivity Enhancement for Nanofluids. J. Heat Transf. 2003, 125, 567–574. [Google Scholar] [CrossRef]

- Gonzalez, M.; Kim, Y.J. Experimental Study of a Pulsating Heat Pipe Using Nanofluid as a Working Fluid. In Proceedings of the Fourteenth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 27–30 May 2014; pp. 541–546. [Google Scholar] [CrossRef]

- Park, K.; Ma, H.B. Nanofluid Effect on the Heat Transport Capability in a Well-Balanced Oscillating Heat Pipe. J. Thermophys. Heat Transf. 2012, 21, 443–445. [Google Scholar] [CrossRef]

- Karthikeyan, V.K.; Ramachandran, K.; Pillai, B.C.; Brusly Solomon, A. Effect of Nanofluids on Thermal Performance of Closed Loop Pulsating Heat Pipe. Exp. Therm. Fluid Sci. 2014, 54, 171–178. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mohammadi, M.; Shafii, M.B. Experimental Investigation of a Pulsating Heat Pipe Using Ferrofluid (Magnetic Nanofluid). J. Heat Transfer. 2012, 134, 014504. [Google Scholar] [CrossRef]

- Zhao, N.; Zhao, D.; Ma, H. Experimental Investigation of Magnetic Field Effect on the Magnetic Nanofluid Oscillating Heat Pipe. J. Therm. Sci. Eng. Appl. 2013, 5, 011005. [Google Scholar] [CrossRef]

- Tanshen, M.R.; Lee, S.; Kim, J.; Kang, D.; Noh, J.; Chung, H.; Jeong, H.; Huh, S. Pressure Distribution inside Oscillating Heat Pipe Charged with Aqueous Al2O3 Nanoparticles, MWCNTs and Their Hybrid. J. Cent. South Univ. 2014, 21, 2341–2348. [Google Scholar] [CrossRef]

- Zufar, M.; Gunnasegaran, P.; Kumar, H.M.; Ng, K.C. Numerical and Experimental Investigations of Hybrid Nanofluids on Pulsating Heat Pipe Performance. Int. J. Heat Mass Transf. 2020, 146, 118887. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Maleki, A.; Ahmadi, M.H. The Effect of Some Metal Oxide Nanocomposites on the Pulsating Heat Pipe Performance. Energy Rep. 2021, 7, 8825–8833. [Google Scholar] [CrossRef]

- Smrity, A.M.A.; Yin, P. Design and Performance Evaluation of Pulsating Heat Pipe Using Metallic Nanoparticles Based Hybrid Nanofluids. Int. J. Heat Mass Transf. 2024, 218, 124773. [Google Scholar] [CrossRef]

- Shao, Y.; Iliut, M.; Dierking, I.; Vijayaraghavan, A. Hybrid Molecular/Mineral Lyotropic Liquid Crystal System of CTAB and Graphene Oxide in Water. Carbon 2021, 173, 105–114. [Google Scholar] [CrossRef]

- Bao, K.; Wang, X.; Fang, Y.; Ji, X.; Han, X.; Chen, G. Effects of the Surfactant Solution on the Performance of the Pulsating Heat Pipe. Appl. Therm. Eng. 2020, 178, 115678. [Google Scholar] [CrossRef]

- Ayel, V.; Slobodeniuk, M.; Bertossi, R.; Karmakar, A.; Martineau, F.; Romestant, C.; Bertin, Y.; Khandekar, S. Thermal Performances of a Flat-Plate Pulsating Heat Pipe Tested with Water, Aqueous Mixtures and Surfactants. Int. J. Therm. Sci. 2022, 178, 107599. [Google Scholar] [CrossRef]

- Xing, M.; Wang, R.; Yu, J. The Impact of Gravity on the Performance of Pulsating Heat Pipe Using Surfactant Solution. Int. J. Heat Mass Transf. 2020, 151, 119466. [Google Scholar] [CrossRef]

- Basatakoti, D.; Zhang, H.; Li, X.; Cai, W.; Li, F. Visualization of Bubble Mechanism of Pulsating Heat Pipe with Conventional Working Fluids and Surfactant Solution. Exp. Comput. Multiph. Flow 2020, 2, 22–30. [Google Scholar] [CrossRef]

- Zhang, D.; Duan, C.; Guan, J.; Yu, Y.; Tang, S.; Wu, X.; Liu, D.; Wang, L.; Lei, Y. Experimental Study on Heat Transfer Performance Enhancement of Pulsating Heat Pipes Induced by Surfactants. Appl. Therm. Eng. 2024, 245, 122857. [Google Scholar] [CrossRef]

- Patel, V.M.; Gaurav; Mehta, H. B. Influence of Working Fluids on Startup Mechanism and Thermal Performance of a Closed Loop Pulsating Heat Pipe. Appl. Therm. Eng. 2017, 110, 1568–1577. [Google Scholar] [CrossRef]

- Wang, X.H.; Zheng, H.C.; Si, M.Q.; Han, X.H.; Chen, G.M. Experimental Investigation of the Influence of Surfactant on the Heat Transfer Performance of Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2015, 83, 586–590. [Google Scholar] [CrossRef]

- Han, H.; Cui, X.; Zhu, Y.; Xu, T.; Sui, Y.; Sun, S. Experimental Study on a Closed-Loop Pulsating Heat Pipe (CLPHP) Charged with Water-Based Binary Zeotropes and the Corresponding Pure Fluids. Energy 2016, 109, 724–736. [Google Scholar] [CrossRef]

- Santhi Sree, N.; Sudheer, N.V.V.S.; Bhramara, P.; Venkatesh, A.; Tharun, V.; Arjun, M. Comparative Analysis of CLPHP Working with Binary Mixtures in Different Concentrations. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Heat Transfer Enhancement in Pulsating Heat Pipe by Alcohol-Water Based Self-Rewetting Fluid. Therm. Sci. Eng. Prog. 2021, 22, 100809. [Google Scholar] [CrossRef]

- Shi, S.; Cui, X.; Han, H.; Weng, J.; Li, Z. A Study of the Heat Transfer Performance of a Pulsating Heat Pipe with Ethanol-Based Mixtures. Appl. Therm. Eng. 2016, 102, 1219–1227. [Google Scholar] [CrossRef]

- Xu, Y.; Xue, Y.; Qi, H.; Cai, W. Experimental Study on Heat Transfer Performance of Pulsating Heat Pipes with Hybrid Working Fluids. Int. J. Heat Mass Transf. 2020, 157, 724–736. [Google Scholar] [CrossRef]

- Zamani, R.; Kalan, K.; Shafii, M.B. Experimental Investigation on Thermal Performance of Closed Loop Pulsating Heat Pipes with Soluble and Insoluble Binary Working Fluids and a Proposed Correlation. Heat Mass Transf. 2019, 55, 375–384. [Google Scholar] [CrossRef]

- Wei, A.; Qu, J.; Qiu, H.; Wang, C.; Cao, G. Heat Transfer Characteristics of Plug-in Oscillating Heat Pipe with Binary-Fluid Mixtures for Electric Vehicle Battery Thermal Management. Int. J. Heat Mass Transf. 2019, 135, 746–760. [Google Scholar] [CrossRef]

- Mameli, M.; Marengo, M.; Khandekar, S. Local Heat Transfer Measurement and Thermo-Fluid Characterization of a Pulsating Heat Pipe. Int. J. Therm. Sci. 2014, 75, 140–152. [Google Scholar] [CrossRef]

- Cui, X.; Qiu, Z.; Weng, J.; Li, Z. Heat Transfer Performance of Closed Loop Pulsating Heat Pipes with Methanol-Based Binary Mixtures. Exp. Therm. Fluid Sci. 2016, 76, 253–263. [Google Scholar] [CrossRef]

- Markal, B.; Varol, R. Investigation of the Effects of Miscible and Immiscible Binary Fluids on Thermal Performance of Pulsating Heat Pipes. Heat Mass Transf. 2021, 57, 1527–1542. [Google Scholar] [CrossRef]

- Dilawar, M.; Pattamatta, A. A Parametric Study of Oscillatory Two-Phase Flows in a Single Turn Pulsating Heat Pipe Using a Non-Isothermal Vapor Model. Appl. Therm. Eng. 2013, 51, 1328–1338. [Google Scholar] [CrossRef]

- Qu, J.; Wu, H.; Cheng, P. Start-up, Heat Transfer and Flow Characteristics of Silicon-Based Micro Pulsating Heat Pipes. Int. J. Heat Mass Transf. 2012, 55, 6109–6120. [Google Scholar] [CrossRef]

- Yang, C.; Tao, Q.; Zheng, J.; Qiu, L.; Chen, Y.; Yan, H.; Min, Y.; Fan, Y. Thermal Evaluation of Photovoltaic Panels Combined Pulsating Heat Pipe with Phase Change Materials: Numerical Study and Experimental Validation. Energy Build. 2024, 303, 113806. [Google Scholar] [CrossRef]

- Wu, L.; Chen, J.; Wang, S. Experimental Study on Thermal Performance of a Pulsating Heat Pipe Using R1233zd(E) as Working Fluid. Int. Commun. Heat Mass Transf. 2022, 135, 106152. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.J. Effect of Channel Geometry on the Operating Limit of Micro Pulsating Heat Pipes. Int. J. Heat Mass Transf. 2017, 107, 204–212. [Google Scholar] [CrossRef]

- Yang, K.S.; Cheng, Y.C.; Jeng, M.S.; Chien, K.H.; Shyu, J.C. An Experimental Investigation of Micro Pulsating Heat Pipes. Micromachines 2014, 5, 385–395. [Google Scholar] [CrossRef]

- Chien, K.H.; Lin, Y.T.; Chen, Y.R.; Yang, K.S.; Wang, C.C. A Novel Design of Pulsating Heat Pipe with Fewer Turns Applicable to All Orientations. Int. J. Heat Mass Transf. 2012, 55, 5722–5728. [Google Scholar] [CrossRef]

- Ishida, R.; Youn, Y.; Muramatsu, K.; Kohara, K.; Han, Y.; Shikazono, N. Heat Transfer and Flow Characteristics of Thermally Induced Two-Phase Oscillating Flow in Micro Tubes. J. Therm. Sci. Technol. 2016, 11, JTST0042. [Google Scholar] [CrossRef][Green Version]

- Lee, Y.J.; Kim, S.J. Experimental Investigation on the Effect of Transverse Grooves in a Channel on the Thermal Performance of a Flat-Plate Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2024, 218, 124759. [Google Scholar] [CrossRef]

- Wang, J.; Ma, H.; Zhu, Q. Effects of the Evaporator and Condenser Length on the Performance of Pulsating Heat Pipes. Appl. Therm. Eng. 2015, 91, 1018–1025. [Google Scholar] [CrossRef]

- Su, Z.; Hu, Y.; Zheng, S.; Dang, C.; Liu, K.; Chen, J.; Huang, J. Study on Heat Transfer Characteristics of Annular Pulsating Heat Pipe with Temperature Oscillation Characteristic. Int. Commun. Heat Mass Transf. 2023, 144, 106779. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.J. Experimental Investigation on the Effect of the Condenser Length on the Thermal Performance of a Micro Pulsating Heat Pipe. Appl. Therm. Eng. 2018, 130, 439–448. [Google Scholar] [CrossRef]

- Lee, J.; Joo, Y.; Kim, S.J. Effects of the Number of Turns and the Inclination Angle on the Operating Limit of Micro Pulsating Heat Pipes. Int. J. Heat Mass Transf. 2018, 124, 1172–1180. [Google Scholar] [CrossRef]

- Panyoyai, N.; Terdtoon, P.; Sakulchangsatjatai, P. Effects of Aspect Ratios and Number of Meandering Turns on Performance Limit of an Inclined Closed-Loop Oscillating Heat Pipe. Energy Res. J. 2010, 1, 91–95. [Google Scholar] [CrossRef]

- Charoensawan, P.; Khandekar, S.; Groll, M.; Terdtoon, P. Closed Loop Pulsating Heat Pipes: Part A: Parametric Experimental Investigations. Appl. Therm. Eng. 2003, 23, 2009–2020. [Google Scholar] [CrossRef]

- Charoensawan, P.; Terdtoon, P. Thermal Performance of Horizontal Closed-Loop Oscillating Heat Pipes. Appl. Therm. Eng. 2008, 28, 460–466. [Google Scholar] [CrossRef]

- Xie, K.; Ji, Y.; Yu, C.; Wu, M.; Yi, H. Experimental Investigation on an Aluminum Oscillating Heat Pipe Charged with Water. Appl. Therm. Eng. 2019, 162, 114182. [Google Scholar] [CrossRef]

- Kim, J.Y.; Cho, H.; Jung, S.Y. Improvements in Performance and Durability through Surface Modification of Aluminum Micro-Pulsating Heat Pipe Using Water as Working Fluid. Int. J. Heat Mass Transf. 2023, 214, 124445. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Liu, X. Investigation of Wettability on Performance of Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2020, 150, 119354. [Google Scholar] [CrossRef]

- Hao, T.; Ma, X.; Lan, Z.; Li, N.; Zhao, Y.; Ma, H. Effects of Hydrophilic Surface on Heat Transfer Performance and Oscillating Motion for an Oscillating Heat Pipe. Int. J. Heat Mass Transf. 2014, 72, 50–65. [Google Scholar] [CrossRef]

- Leu, T.S.; Wu, C.H. Experimental Studies of Surface Modified Oscillating Heat Pipes. Heat Mass Transf. 2017, 53, 3329–3340. [Google Scholar] [CrossRef]

- Wu, S.; Chen, S.; Xiao, N.; Sheng, J.; Chen, Y.; Liu, X. Thermo-Hydrodynamic Performance of Tubular Pulsating Heat Pipes with Integral Sintered Powder Wicks. Int. Commun. Heat Mass Transf. 2023, 141, 106573. [Google Scholar] [CrossRef]

- Qu, J.; Li, X.; Wang, Q.; Liu, F.; Guo, H. Heat Transfer Characteristics of Micro-Grooved Oscillating Heat Pipes. Exp. Therm. Fluid Sci. 2017, 85, 75–84. [Google Scholar] [CrossRef]

- Cheng, T.W.; Lin, T.L. Characteristics of Gas–Liquid Two-Phase Flow in Small Diameter Inclined Tubes. Chem. Eng. Sci. 2001, 56, 6393–6398. [Google Scholar] [CrossRef]

- Bhusan, S.; Ghosh, S.; Das, G.; Das, P.K. Rise of Taylor Bubbles through Narrow Rectangular Channels. Chem. Eng. J. 2009, 155, 326–332. [Google Scholar] [CrossRef]

- Qu, J.; Zuo, A.; Liu, H.; Zhao, J.; Rao, Z. Three-Dimensional Oscillating Heat Pipes with Novel Structure for Latent Heat Thermal Energy Storage Application. Appl. Therm. Eng. 2021, 187, 116574. [Google Scholar] [CrossRef]

- Xue, Z.H.; Qu, W. Experimental and Theoretical Research on a Ammonia Pulsating Heat Pipe: New Full Visualization of Flow Pattern and Operating Mechanism Study. Int. J. Heat Mass Transf. 2017, 106, 149–166. [Google Scholar] [CrossRef]

- Markal, B.; Varol, R. Experimental Investigation and Force Analysis of Flat-Plate Type Pulsating Heat Pipes Having Ternary Mixtures. Int. Commun. Heat Mass Transf. 2021, 121, 105084. [Google Scholar] [CrossRef]

- Betancur-Arboleda, L.A.; Flórez Mera, J.P.; Mantelli, M. Experimental Study of Channel Roughness Effect in Diffusion Bonded Pulsating Heat Pipes. Appl. Therm. Eng. 2020, 166, 114734. [Google Scholar] [CrossRef]

- Xue, Z.; Qu, W. Experimental Study on Effect of Inclination Angles to Ammonia Pulsating Heat Pipe. Chin. J. Aeronaut. 2014, 27, 1122–1127. [Google Scholar] [CrossRef]

- Mangini, D.; Mameli, M.; Fioriti, D.; Filippeschi, S.; Araneo, L.; Marengo, M. Hybrid Pulsating Heat Pipe for Space Applications with Non-Uniform Heating Patterns: Ground and Microgravity Experiments. Appl. Therm. Eng. 2017, 126, 1029–1043. [Google Scholar] [CrossRef]

- Abela, M.; Mameli, M.; Nikolayev, V.; Filippeschi, S. Experimental Analysis and Transient Numerical Simulation of a Large Diameter Pulsating Heat Pipe in Microgravity Conditions. Int. J. Heat Mass Transf. 2022, 187, 122532. [Google Scholar] [CrossRef]

- Slobodeniuk, M.; Bertossi, R.; Ayel, V.; Ravichandran, R.; Thyagarajan, K.; Romestant, C.; Bertin, Y. Experimental Study of the Flat Plate Pulsating Heat Pipe Operation during Dry-out and Flow Re-Activation Periods under Microgravity Conditions. Int. J. Multiph. Flow 2022, 147, 103888. [Google Scholar] [CrossRef]

- Sun, Q.; Qu, J.; Wang, Q.; Yuan, J. Operational Characteristics of Oscillating Heat Pipes under Micro-Gravity Condition. Int. Commun. Heat Mass Transf. 2017, 88, 28–36. [Google Scholar] [CrossRef]

- Qian, N.; Marengo, M.; Jiang, F.; Chen, X.; Fu, Y.; Xu, J. Pulsating Heat Pipes Filled with Acetone and Water under Radial Rotation Conditions: Heat Transfer Performance and Semi-Empirical Correlation. Int. Commun. Heat Mass Transf. 2024, 150, 107172. [Google Scholar] [CrossRef]

- Aboutalebi, M.; Nikravan Moghaddam, A.M.; Mohammadi, N.; Shafii, M.B. Experimental Investigation on Performance of a Rotating Closed Loop Pulsating Heat Pipe. Int. Commun. Heat Mass Transf. 2013, 45, 137–145. [Google Scholar] [CrossRef]

- On-ai, K.; Kammuang-lue, N.; Terdtoon, P.; Sakulchangsatjatai, P. Implied Physical Phenomena of Rotating Closed-Loop Pulsating Heat Pipe from Working Fluid Temperature. Appl. Therm. Eng. 2019, 148, 1303–1309. [Google Scholar] [CrossRef]

- Qian, N.; Marengo, M.; Chen, J.; Fu, Y.; Zhang, J.; Xu, J. Heat Transfer and Temperature Characteristics of Single-Loop Oscillating Heat Pipe under Axial-Rotation Conditions. Int. J. Heat Mass Transf. 2022, 197, 123308. [Google Scholar] [CrossRef]

- Qian, N.; Fu, Y.; Chen, J.; Marengo, M.; Zhang, J.; Xu, J. Thermal Performance Analysis of Axial-Rotating Oscillating Heat Pipe and Its Prediction Model Based on Grey System Theory. Therm. Sci. Eng. Prog. 2022, 29, 101210. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, C.; Rao, Z. Numerical Study on Heat Transfer Enhancement of Closed Loop Oscillating Heat Pipe through Active Incentive Method. Int. Commun. Heat Mass Transf. 2020, 115, 104612. [Google Scholar] [CrossRef]

- Xian, H.; Xu, W.; Zhang, Y.; Du, X.; Yang, Y. Thermal Characteristics and Flow Patterns of Oscillating Heat Pipe with Pulse Heating. Int. J. Heat Mass Transf. 2014, 79, 332–341. [Google Scholar] [CrossRef]

- Xian, H.; Xu, W.; Zhang, Y.; Du, X.; Yang, Y. Experimental Investigations of Dynamic Fluid Flow in Oscillating Heat Pipe under Pulse Heating. Appl. Therm. Eng. 2015, 88, 376–383. [Google Scholar] [CrossRef]

- Wang, C.; Yuan, K.; Song, Q.; Yu, J.; Yang, J.; Qu, J.; Zhu, Y. Performance of Pulsating Heat Pipe with a Stimulus of Auxiliary Heat Load for Battery Thermal Management System. Int. J. Heat Mass Transf. 2024, 223, 125190. [Google Scholar] [CrossRef]

- Jiansheng, W.; Zhenchuan, W.; Meijun, L. Thermal Performance of Pulsating Heat Pipes with Different Heating Patterns. Appl. Therm. Eng. 2014, 64, 209–212. [Google Scholar] [CrossRef]

- Ma, H.B.; Hanlon, M.A.; Chen, C.L. An Investigation of Oscillating Motions in a Miniature Pulsating Heat Pipe. Microfluid. Nanofluidics 2006, 2, 171–179. [Google Scholar] [CrossRef]

- Liang, S.B.; Ma, H.B. Oscillating Motions of Slug Flow in Capillary Tubes. Int. Commun. Heat Mass Transf. 2004, 31, 365–375. [Google Scholar] [CrossRef]

- Ma, H.B.; Borgmeyer, B.; Cheng, P.; Zhang, Y. Heat Transport Capability in an Oscillating Heat Pipe. J. Heat Transfer. 2008, 130, 081501. [Google Scholar] [CrossRef]

- Spinato, G.; Borhani, N.; Thome, J.R. Understanding the Self-Sustained Oscillating Two-Phase Flow Motion in a Closed Loop Pulsating Heat Pipe. Energy 2015, 90, 889–899. [Google Scholar] [CrossRef]

- Gürsel, G.; Frijns, A.J.H.; Homburg, F.G.A.; Van Steenhoven, A.A. A Mass-Spring-Damper Model of a Pulsating Heat Pipe with a Non-Uniform and Asymmetric Filling. Appl. Therm. Eng. 2015, 91, 80–90. [Google Scholar] [CrossRef]

- Khandekar, S.; Dollinger, N.; Groll, M. Understanding Operational Regimes of Closed Loop Pulsating Heat Pipes: An Experimental Study. Appl. Therm. Eng. 2003, 23, 707–719. [Google Scholar] [CrossRef]

- Peng, H.; Pai, P.F.; Ma, H. Nonlinear Thermomechanical Finite-Element Modeling, Analysis and Characterization of Multi-Turn Oscillating Heat Pipes. Int. J. Heat Mass Transf. 2014, 69, 424–437. [Google Scholar] [CrossRef]

- Yoon, A.; Kim, S.J. Experimental and Theoretical Studies on Oscillation Frequencies of Liquid Slugs in Micro Pulsating Heat Pipes. Energy Convers. Manag. 2019, 181, 48–58. [Google Scholar] [CrossRef]

- Shafii, M.B.; Faghri, A.; Zhang, Y. Thermal Modeling of Unlooped and Looped Pulsating Heat Pipes. J. Heat Transf. 2001, 123, 1159–1172. [Google Scholar] [CrossRef]

- Zhang, Y.; Faghri, A.; Shafii, M.B. Analysis of Liquid–Vapor Pulsating Flow in a U-Shaped Miniature Tube. Int. J. Heat Mass Transf. 2002, 45, 2501–2508. [Google Scholar] [CrossRef]

- Zhang, Y.; Faghri, A. Heat Transfer in a Pulsating Heat Pipe with Open End. Int. J. Heat Mass Transf. 2001, 45, 755–764. [Google Scholar] [CrossRef]

- Shafii, M.B.; Faghri, A.; Zhang, Y. Analysis of Heat Transfer in Unlooped and Looped Pulsating Heat Pipes. Int. J. Numer. Methods Heat Fluid Flow 2002, 12, 585–609. [Google Scholar] [CrossRef]

- Yuan, D.; Qu, W.; Ma, T. Flow and Heat Transfer of Liquid Plug and Neighboring Vapor Slugs in a Pulsating Heat Pipe. Int. J. Heat Mass Transf. 2010, 53, 1260–1268. [Google Scholar] [CrossRef]

- Holley, B.; Faghri, A. Analysis of Pulsating Heat Pipe with Capillary Wick and Varying Channel Diameter. Int. J. Heat Mass Transf. 2005, 48, 2635–2651. [Google Scholar] [CrossRef]

- Mameli, M.; Marengo, M.; Zinna, S. Thermal Simulation of a Pulsating Heat Pipe: Effects of Different Liquid Properties on a Simple Geometry. Heat Transf. Eng. 2012, 33, 1177–1187. [Google Scholar] [CrossRef]

- Mameli, M.; Marengo, M.; Zinna, S. Numerical Investigation of the Effects of Orientation and Gravity in a Closed Loop Pulsating Heat Pipe. Microgravity Sci. Technol. 2012, 24, 79–92. [Google Scholar] [CrossRef]

- Mameli, M.; Marengo, M.; Zinna, S. Numerical Model of a Multi-Turn Closed Loop Pulsating Heat Pipe: Effects of the Local Pressure Losses Due to Meanderings. Int. J. Heat Mass Transf. 2012, 55, 1036–1047. [Google Scholar] [CrossRef]

- Manzoni, M.; Mameli, M.; De Falco, C.; Araneo, L.; Filippeschi, S.; Marengo, M. Non Equilibrium Lumped Parameter Model for Pulsating Heat Pipes: Validation in Normal and Hyper-Gravity Conditions. Int. J. Heat Mass Transf. 2016, 97, 473–485. [Google Scholar] [CrossRef]

- Nikolayev, V.S. A Dynamic Film Model of the Pulsating Heat Pipe. J. Heat Transfer 2011, 133, 081504. [Google Scholar] [CrossRef]

- Nekrashevych, I.; Nikolayev, V.S. Effect of Tube Heat Conduction on the Pulsating Heat Pipe Start-Up. Appl. Therm. Eng. 2017, 117, 24–29. [Google Scholar] [CrossRef]

- Senjaya, R.; Inoue, T. Oscillating Heat Pipe Simulation Considering Bubble Generation Part I: Presentation of the Model and Effects of a Bubble Generation. Int. J. Heat Mass Transf. 2013, 60, 816–824. [Google Scholar] [CrossRef]

- Senjaya, R.; Inoue, T. Oscillating Heat Pipe Simulation Considering Dryout Phenomena. Heat Mass Transf. 2014, 50, 1429–1441. [Google Scholar] [CrossRef]

- Bae, J.; Lee, S.Y.; Kim, S.J. Numerical Investigation of Effect of Film Dynamics on Fluid Motion and Thermal Performance in Pulsating Heat Pipes. Energy Convers. Manag. 2017, 151, 296–310. [Google Scholar] [CrossRef]

- Rittidech, S.; Terdtoon, P.; Murakami, M.; Kamonpet, P.; Jompakdee, W. Correlation to Predict Heat Transfer Characteristics of a Closed-End Oscillating Heat Pipe at Normal Operating Condition. Appl. Therm. Eng. 2003, 23, 497–510. [Google Scholar] [CrossRef]

- Khandekar, S.; Charoensawan, P.; Groll, M.; Terdtoon, P. Closed Loop Pulsating Heat Pipes Part B: Visualization and Semi-Empirical Modeling. Appl. Therm. Eng. 2003, 23, 2021–2033. [Google Scholar] [CrossRef]

- Katpradit, T.; Wongratanaphisan, T.; Terdtoon, P.; Kamonpet, P.; Polchai, A.; Akbarzadeh, A. Correlation to Predict Heat Transfer Characteristics of a Closed End Oscillating Heat Pipe at Critical State. Appl. Therm. Eng. 2005, 25, 2138–2151. [Google Scholar] [CrossRef]

- Qu, J.; Wang, Q. Experimental Study on the Thermal Performance of Vertical Closed-Loop Oscillating Heat Pipes and Correlation Modeling. Appl. Energy 2013, 112, 1154–1160. [Google Scholar] [CrossRef]

- Goshayeshi, H.R.; Izadi, F.; Bashirnezhad, K. Comparison of Heat Transfer Performance on Closed Pulsating Heat Pipe for Fe3O4 and ɤFe2O3 for Achieving an Empirical Correlation. Phys. E Low-Dimens. Syst. Nanostructures 2017, 89, 43–49. [Google Scholar] [CrossRef]

- Kholi, F.K.; Mucci, A.; Kallath, H.; Ha, M.Y.; Chetwynd-Chatwin, J.; Min, J.K. An Improved Correlation to Predict the Heat Transfer in Pulsating Heat Pipes over Increased Range of Fluid-Filling Ratios and Operating Inclinations. J. Mech. Sci. Technol. 2020, 34, 2637–2646. [Google Scholar] [CrossRef]

- Wang, J.; Ma, H.; Zhu, Q.; Dong, Y.; Yue, K. Numerical and Experimental Investigation of Pulsating Heat Pipes with Corrugated Configuration. Appl. Therm. Eng. 2016, 102, 158–166. [Google Scholar] [CrossRef]

- Xie, F.; Li, X.; Qian, P.; Huang, Z.; Liu, M. Effects of Geometry and Multisource Heat Input on Flow and Heat Transfer in Single Closed-Loop Pulsating Heat Pipe. Appl. Therm. Eng. 2020, 168, 114856. [Google Scholar] [CrossRef]

- Wang, W.W.; Wang, L.; Cai, Y.; Yang, G.B.; Zhao, F.Y.; Liu, D.; Yu, Q.H. Thermo-Hydrodynamic Model and Parametric Optimization of a Novel Miniature Closed Oscillating Heat Pipe with Periodic Expansion-Constriction Condensers. Int. J. Heat Mass Transf. 2020, 152, 119460. [Google Scholar] [CrossRef]

- Li, Q.; Wang, C.; Wang, Y.; Wang, Z.; Li, H.; Lian, C. Study on the Effect of the Adiabatic Section Parameters on the Performance of Pulsating Heat Pipes. Appl. Therm. Eng. 2020, 180, 115813. [Google Scholar] [CrossRef]

- Choi, J.; Zhang, Y. Numerical Simulation of Oscillatory Flow and Heat Transfer in Pulsating Heat Pipes with Multi-Turns Using OpenFOAM. Numer. Heat Transf. Part A Appl. 2020, 77, 761–781. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Lian, C.; Li, H.; He, X. Effect of Micro Encapsulated Phase Change Material on the Anti-Dry-out Ability of Pulsating Heat Pipes. Appl. Therm. Eng. 2019, 159, 113854. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, W.; Liu, C.; Rao, Z. Thermal Performance Enhancement of an Oscillating Heat Pipe with External Expansion Structure for Thermal Energy Recovery and Storage. Appl. Therm. Eng. 2019, 155, 667–675. [Google Scholar] [CrossRef]

- Pouryoussefi, S.M.; Zhang, Y. Numerical Investigation of Chaotic Flow in a 2D Closed-Loop Pulsating Heat Pipe. Appl. Therm. Eng. 2016, 98, 617–627. [Google Scholar] [CrossRef]

- Bao, K.; Liu, Y.; Yan, Y.; Ye, G.; Han, X. Partial Visualization Study on Flow, Startup and Heat Transfer Characteristics of Closed-Loop Pulsating Heat Pipe with R1336mzz(Z). Appl. Therm. Eng. 2023, 226, 120218. [Google Scholar] [CrossRef]

- Ayel, V.; Slobodeniuk, M.; Bertossi, R.; Romestant, C.; Bertin, Y. Flat Plate Pulsating Heat Pipes: A Review on the Thermohydraulic Principles, Thermal Performances and Open Issues. Appl. Therm. Eng. 2021, 197, 117200. [Google Scholar] [CrossRef]

- Vo, D.T.; Kim, H.T.; Ko, J.; Bang, K.H. An Experiment and Three-Dimensional Numerical Simulation of Pulsating Heat Pipes. Int. J. Heat Mass Transf. 2020, 150, 119317. [Google Scholar] [CrossRef]

- Markal, B.; Varol, R. Thermal Investigation and Flow Pattern Analysis of a Closed-Loop Pulsating Heat Pipe with Binary Mixtures. J. Brazilian Soc. Mech. Sci. Eng. 2020, 42, 549. [Google Scholar] [CrossRef]

- Karthikeyan, V.K.; Khandekar, S.; Pillai, B.C.; Sharma, P.K. Infrared Thermography of a Pulsating Heat Pipe: Flow Regimes and Multiple Steady States. Appl. Therm. Eng. 2014, 62, 470–480. [Google Scholar] [CrossRef]

- Jo, J.; Kim, J.; Kim, S.J. Experimental Investigations of Heat Transfer Mechanisms of a Pulsating Heat Pipe. Energy Convers. Manag. 2019, 181, 331–341. [Google Scholar] [CrossRef]

- Su, Z.; Hu, Y.; Zheng, S.; Wu, T.; Liu, K.; Zhu, M.; Huang, J. Recent Advances in Visualization of Pulsating Heat Pipes: A Review. Appl. Therm. Eng. 2023, 221, 119867. [Google Scholar] [CrossRef]

- Kim, Y.B.; Kim, H.; Sung, J. Investigation of Thermal Enhancement Factor in Micro Pulsating Heat Exchanger Using LIF Visualization Technique. Int. J. Heat Mass Transf. 2020, 159, 120121. [Google Scholar] [CrossRef]

- Ishii, K.; Fumoto, K. Temperature Visualization and Investigation inside Evaporator of Pulsating Heat Pipe Using Temperature-Sensitive Paint. Appl. Therm. Eng. 2019, 155, 575–583. [Google Scholar] [CrossRef]

- Dai, C.W.; Ding, W.F.; Zhu, Y.J.; Xu, J.H.; Yu, H.W. Grinding Temperature and Power Consumption in High Speed Grinding of Inconel 718 Nickel-Based Superalloy with a Vitrified CBN Wheel. Precis. Eng. 2018, 52, 192–200. [Google Scholar] [CrossRef]

- Chen, J.; Fu, Y.; Qian, N.; Ching, C.Y.; Ewing, D.; He, Q. A Study on Thermal Performance of Revolving Heat Pipe Grinding Wheel. Appl. Therm. Eng. 2021, 182, 116065. [Google Scholar] [CrossRef]

- Liang, F.; Gao, J.; Xu, L. Investigation on a Grinding Motorized Spindle with Miniature-Revolving-Heat-Pipes Central Cooling Structure. Int. Commun. Heat Mass Transf. 2020, 112, 104502. [Google Scholar] [CrossRef]

- Li, F.; Gao, J.; Shi, X.; Liang, F.; Zhu, K. Experimental Investigation of Single Loop Thermosyphons Utilized in Motorized Spindle Shaft Cooling. Appl. Therm. Eng. 2018, 134, 229–237. [Google Scholar] [CrossRef]

- Czajkowski, C.; Nowak, A.I.; Pietrowicz, S. Flower Shape Oscillating Heat Pipe—A Novel Type of Oscillating Heat Pipe in a Rotary System of Coordinates—An Experimental Investigation. Appl. Therm. Eng. 2020, 179, 115702. [Google Scholar] [CrossRef]

- Liu, L.; Feng, X.; Rahe, C.; Li, W.; Lu, L.; He, X.; Sauer, D.U.; Ouyang, M. Internal Short Circuit Evaluation and Corresponding Failure Mode Analysis for Lithium-Ion Batteries. J. Energy Chem. 2021, 61, 269–280. [Google Scholar] [CrossRef]

- Zhou, Z.; Lv, Y.; Qu, J.; Sun, Q.; Grachev, D. Performance Evaluation of Hybrid Oscillating Heat Pipe with Carbon Nanotube Nanofluids for Electric Vehicle Battery Cooling. Appl. Therm. Eng. 2021, 196, 117300. [Google Scholar] [CrossRef]

- Qu, J.; Zhao, J.; Rao, Z. Experimental Investigation on the Thermal Performance of Three-Dimensional Oscillating Heat Pipe. Int. J. Heat Mass Transf. 2017, 109, 589–600. [Google Scholar] [CrossRef]

- Ling, Y.Z.; She, X.H.; Zhang, X.S.; Chen, T.T.; Lin, X.R.; Feng, J.K. A PCM-Based Thermal Management System Combining Three-Dimensional Pulsating Heat Pipe with Forced-Air Cooling. Appl. Therm. Eng. 2022, 213, 118732. [Google Scholar] [CrossRef]

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal Issues about Li-Ion Batteries and Recent Progress in Battery Thermal Management Systems: A Review. Energy Convers. Manag. 2017, 150, 304–330. [Google Scholar] [CrossRef]

- Hongkun, L.; Noor, M.M.; Wenlin, Y.; Kadirgama, K.; Badruddin, I.A.; Kamangar, S. Experimental Research on Heat Transfer Characteristics of a Battery Liquid-Cooling System with ⊥-Shaped Oscillating Heat Pipe under Pulsating Flow. Int. J. Heat Mass Transf. 2024, 224, 125363. [Google Scholar] [CrossRef]

- Wang, Q.; Rao, Z.; Huo, Y.; Wang, S. Thermal Performance of Phase Change Material/Oscillating Heat Pipe-Based Battery Thermal Management System. Int. J. Therm. Sci. 2016, 102, 9–16. [Google Scholar] [CrossRef]

- Li, C.; Li, J. Thermal Characteristics of a Flat Plate Pulsating Heat Pipe Module for Onsite Cooling of High Power Server CPUs. Therm. Sci. Eng. Prog. 2023, 37, 101542. [Google Scholar] [CrossRef]

- Jang, D.S.; Kim, D.; Hong, S.H.; Kim, Y. Comparative Thermal Performance Evaluation between Ultrathin Flat Plate Pulsating Heat Pipe and Graphite Sheet for Mobile Electronic Devices at Various Operating Conditions. Appl. Therm. Eng. 2019, 149, 1427–1434. [Google Scholar] [CrossRef]

- Chen, X.; Chen, S.; Zhang, Z.; Sun, D.; Liu, X. Heat Transfer Investigation of a Flat-Plate Oscillating Heat Pipe with Tandem Dual Channels under Nonuniform Heating. Int. J. Heat Mass Transf. 2021, 180, 121830. [Google Scholar] [CrossRef]

- Chen, X.; Li, H.; Han, X.; Liu, X. Thermo-Hydrodynamic Characteristics of a Novel Flat-Plate Micro Pulsating Heat Pipe with Asymmetric Converging-Diverging Channels. Int. Commun. Heat Mass Transf. 2024, 152, 107282. [Google Scholar] [CrossRef]

- Mameli, M.; Catarsi, A.; Mangini, D.; Pietrasanta, L.; Fioriti, D.; La Foresta, M.; Caporale, L.; Marengo, M.; Di Marco, P.; Filippeschi, S. Large Diameter Pulsating Heat Pipe for Future Experiments on the International Space Station. In Proceedings of the Joint 19th IHPC (International Heat Pipe Conference) and the 13th IHPS (International Heat Pipe Symposium), Pisa, Italy, 10–14 June 2018. [Google Scholar]

| Single Working Fluids | Effect | Refs. |

|---|---|---|

| Water | Low boiling point, low dynamic viscosity, and low surface tension make them easy to start. High boiling point, high liquid specific heat, and high latent heat lead to greater anti-dry-out ability. | [17,18,19,20,21,22] |

| Methanol | [17,20,23,24] | |

| Ethanol | [25,26,27,28,29,30,31,32,33] | |

| Acetone | [7,23,24,33] | |

| Hydrogen | [36,37,38,39] | |

| Helium | [40,41,42,43,44,45,46] | |

| Nitrogen | [47,48,49,50,51,52,53] |

| Mixed Working Fluids | Effects | Refs. |

|---|---|---|

| Ethanol + Water | Delay of dry-out and heat transfer enhancement at low filling ratio | [23,76,83,84,86,88] |

| Methanol + Water | [23,83,90] | |

| Acetone + Water | [23,83,86] | |

| Methanol + Ethanol | No effective improvement in thermal performance | [90] |

| Methanol + Acetone | [85,90] | |

| Acetone + Ethanol | Improvement in heat transfer at low filling ratio | [85,90] |

| Condition | Phenomenon | Refs. |

|---|---|---|

| Horizontal | Challenges include working fluid reflux and modification of oscillation characteristics. Performance can be improved by micro-slot structure, magnetic field assistance, capillary structure, etc. | [17,93,104,113,118,119,120] |

| Incline (from 0 to 90) | Optimum inclination angle for heat transfer performance. | [17,117] |

| Vertical | Influenced by gravity. Performance can be improved by capillary and proper adoption of the working fluid. | [57,113,114,118] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, S.; Zhou, C.; Zhu, Y.; Qian, Z.; Wang, C. Review on Research Progress of Pulsating Heat Pipes. Inventions 2024, 9, 86. https://doi.org/10.3390/inventions9040086

Fang S, Zhou C, Zhu Y, Qian Z, Wang C. Review on Research Progress of Pulsating Heat Pipes. Inventions. 2024; 9(4):86. https://doi.org/10.3390/inventions9040086

Chicago/Turabian StyleFang, Shiqiang, Chong Zhou, Ye Zhu, Zhong Qian, and Cheng Wang. 2024. "Review on Research Progress of Pulsating Heat Pipes" Inventions 9, no. 4: 86. https://doi.org/10.3390/inventions9040086

APA StyleFang, S., Zhou, C., Zhu, Y., Qian, Z., & Wang, C. (2024). Review on Research Progress of Pulsating Heat Pipes. Inventions, 9(4), 86. https://doi.org/10.3390/inventions9040086