Effects of the Ratio of Porosity to Volumetric Cement Content on the Unconfined Compressive Strength of Cement Bound Fine Grained Soils

Abstract

:1. Introduction

2. Materials and Experiments

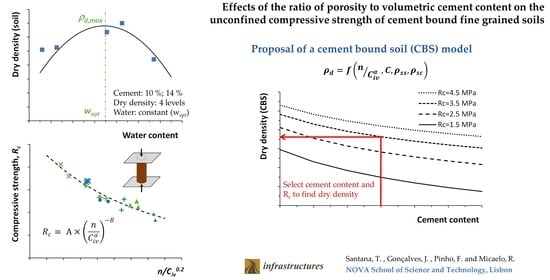

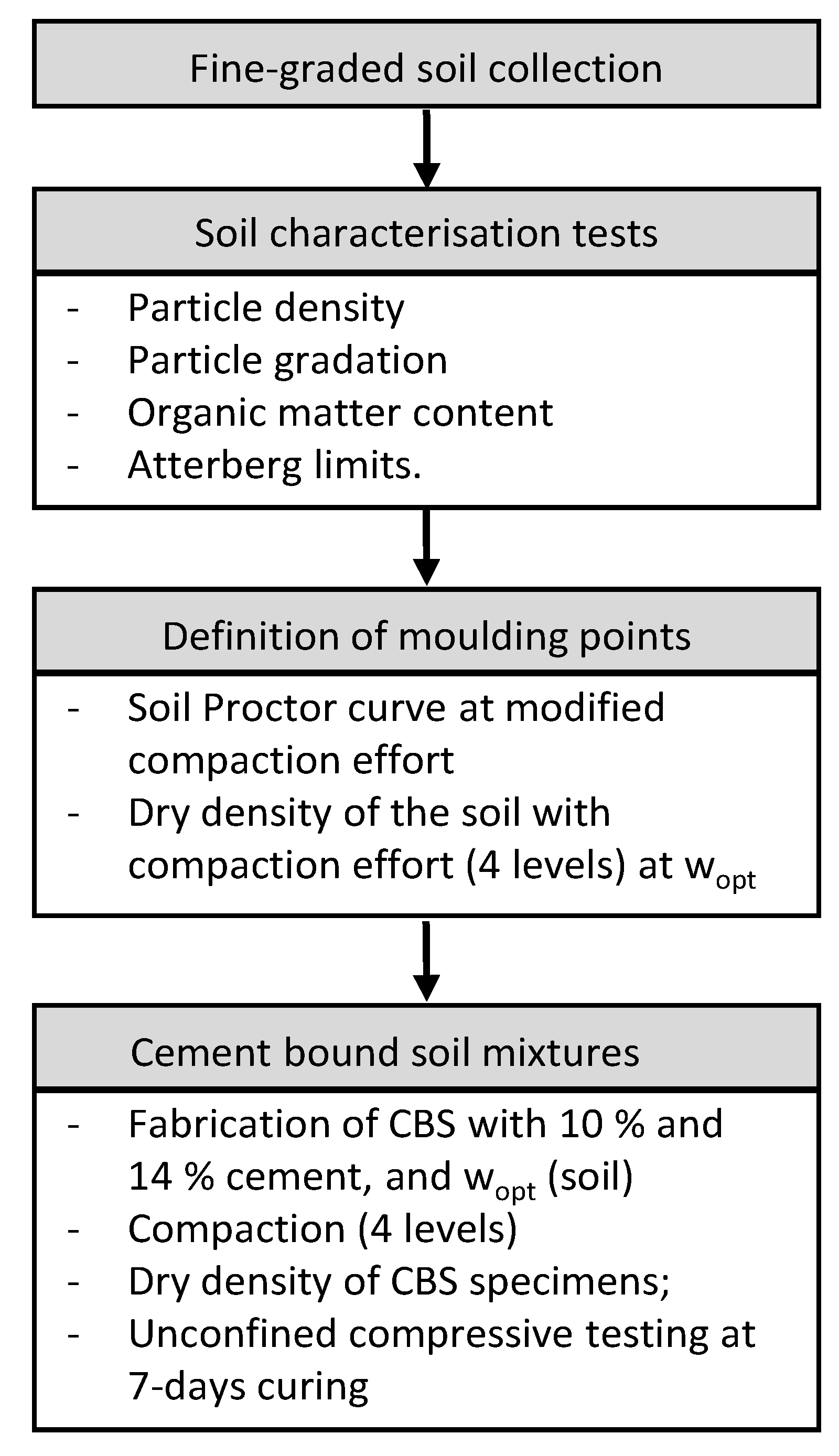

2.1. Experimental Plan

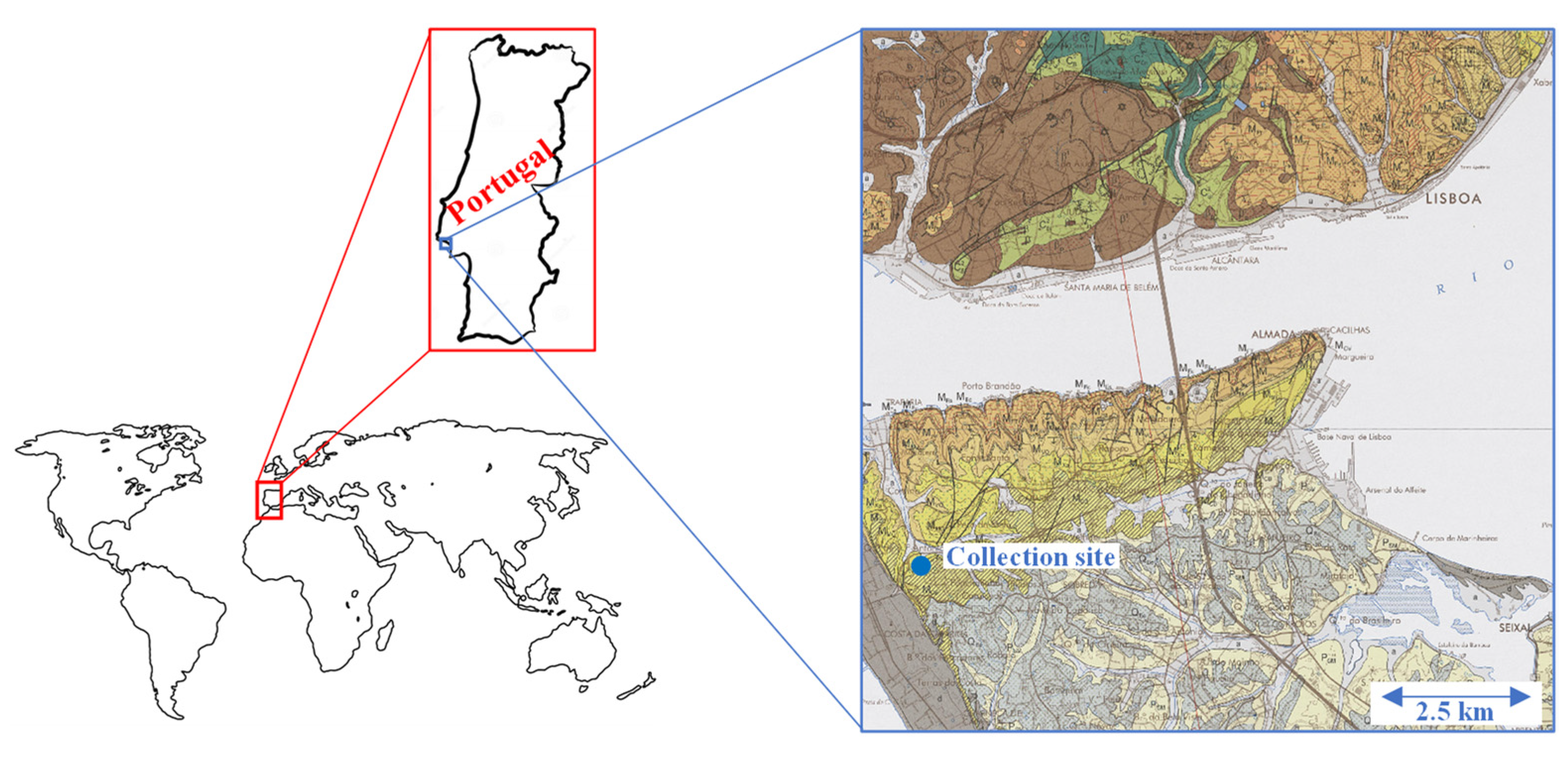

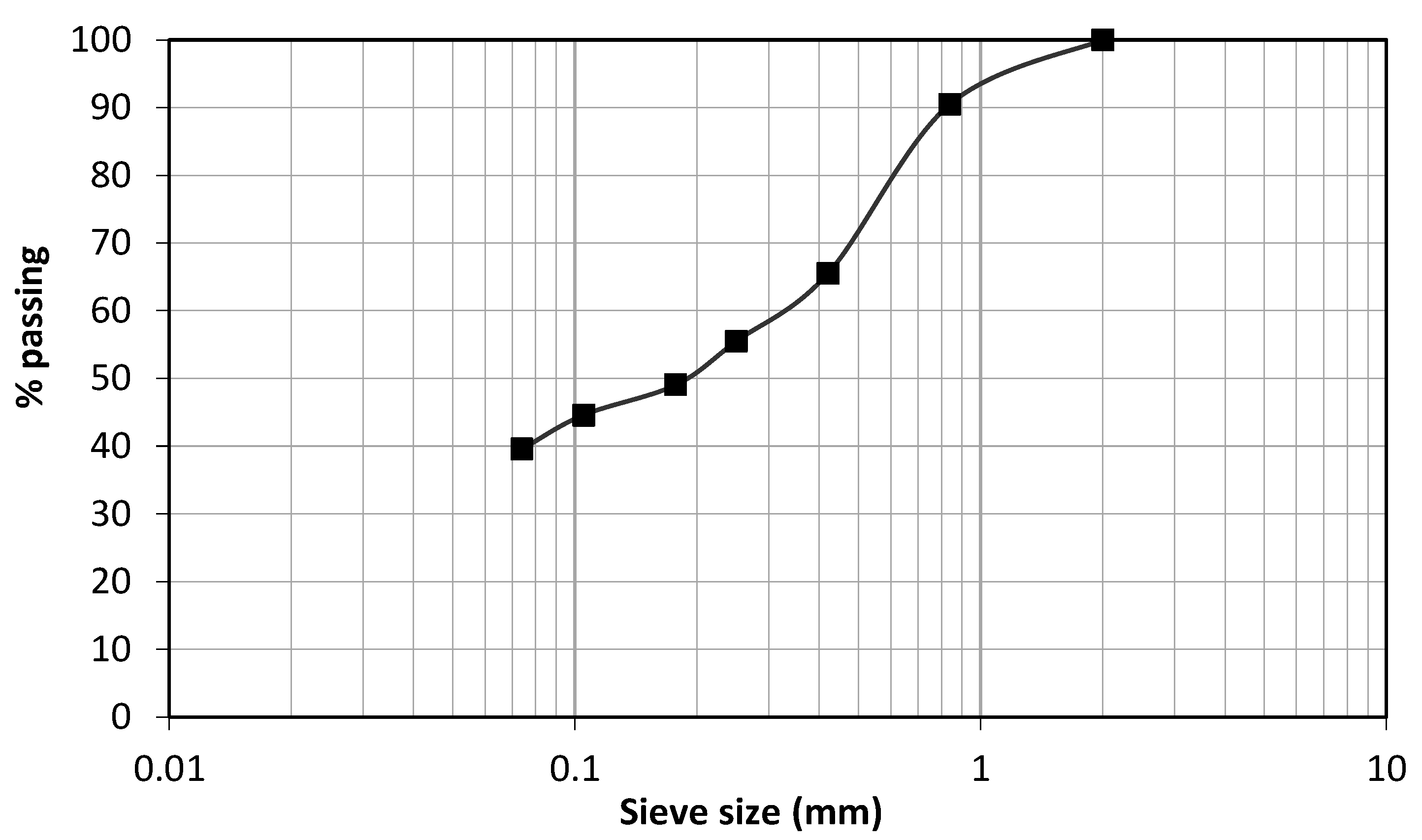

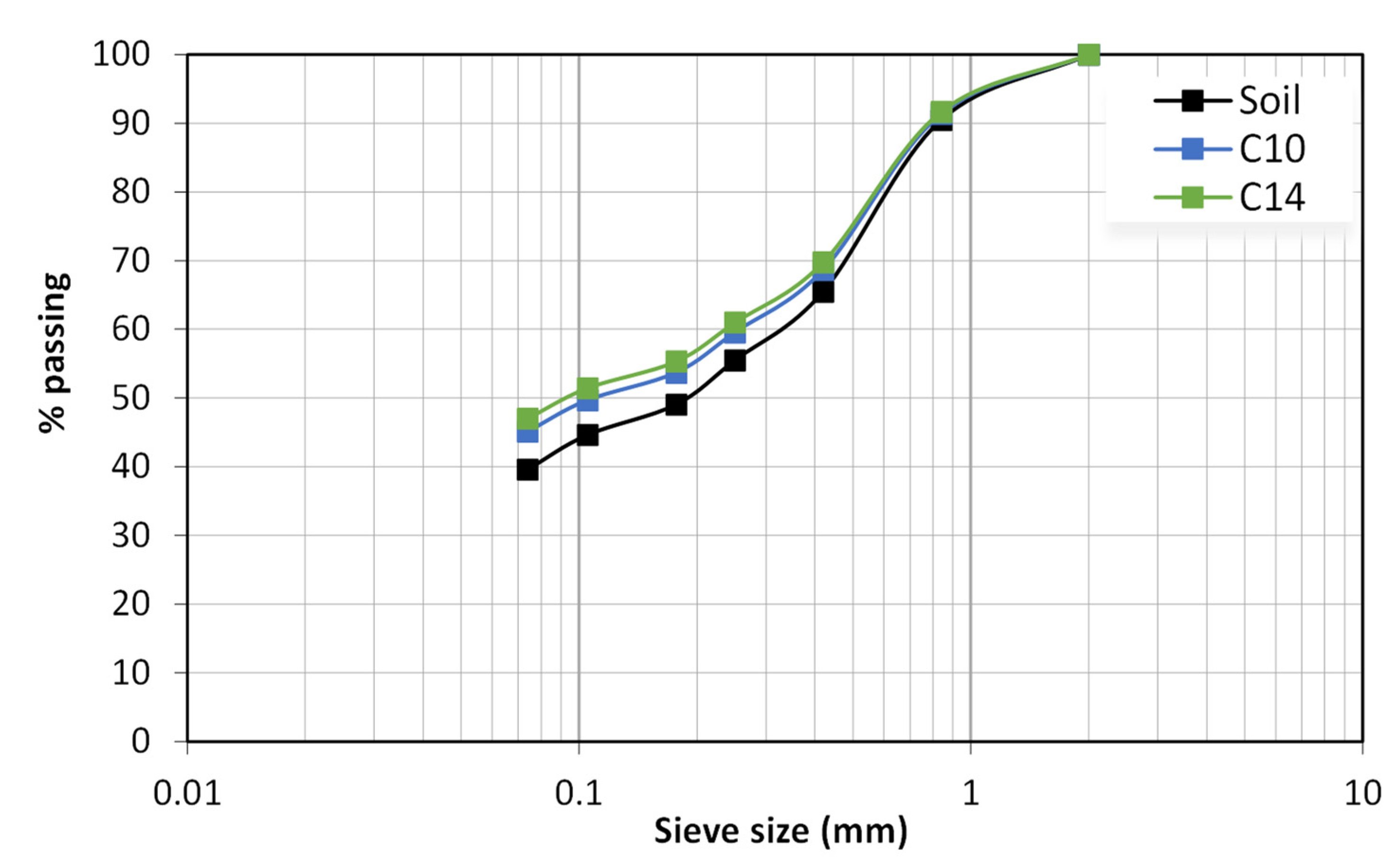

2.2. Materials

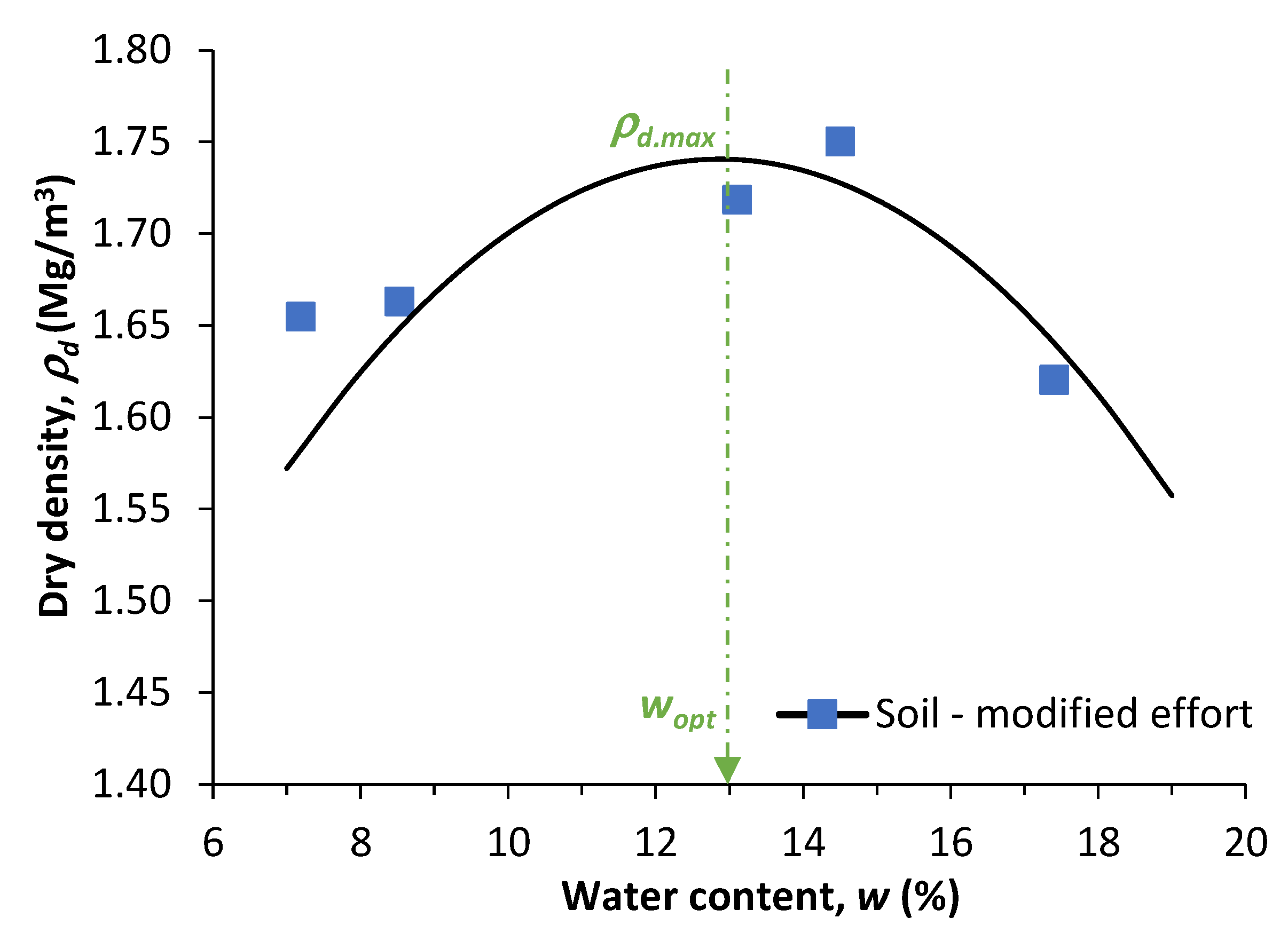

2.3. Definition of the Moulding Points

2.4. Moulding the Specimens for the Unconfined Compression Tests

2.5. Unconfined Compression Tests

3. Results

3.1. Physical Properties of CBS Specimens

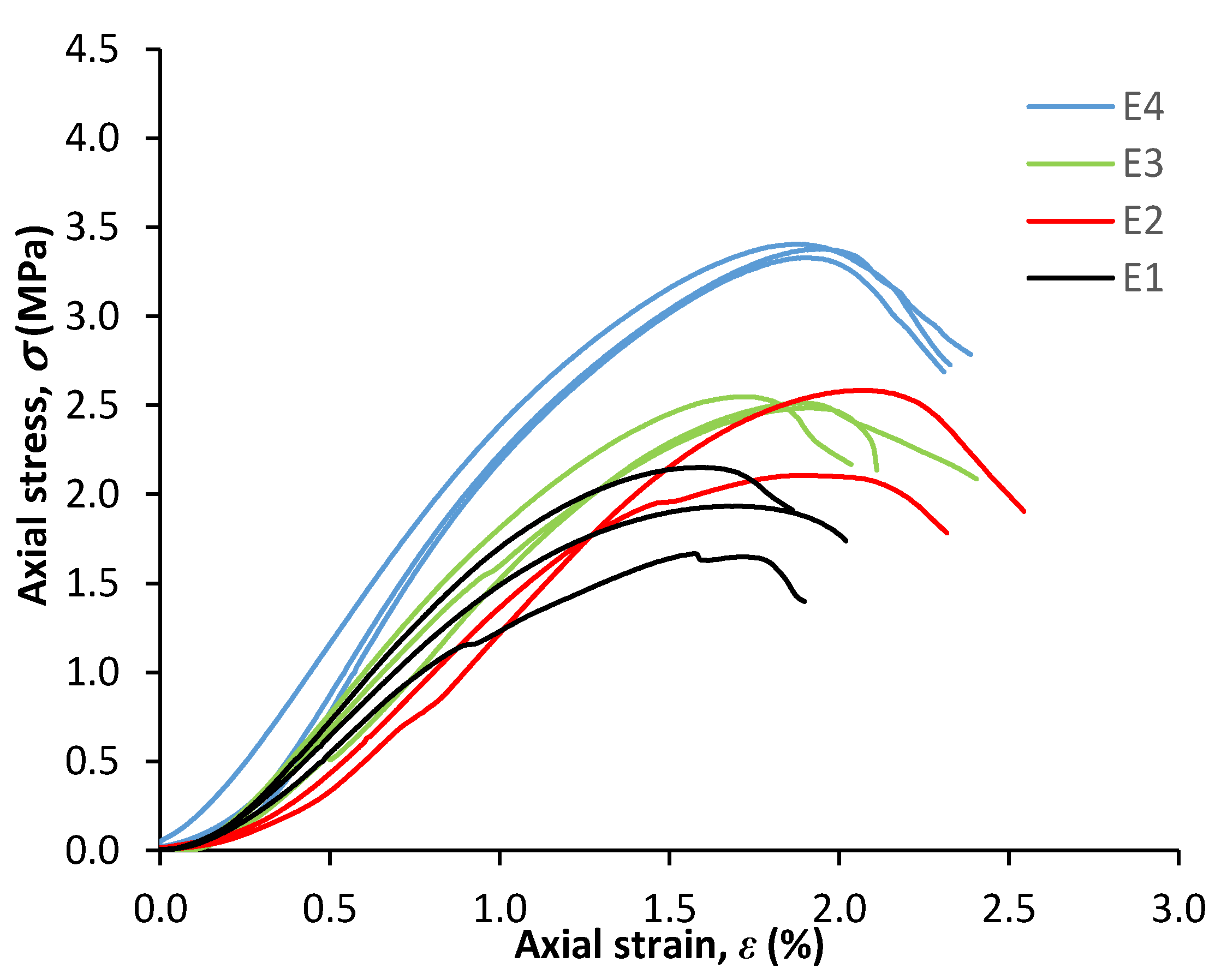

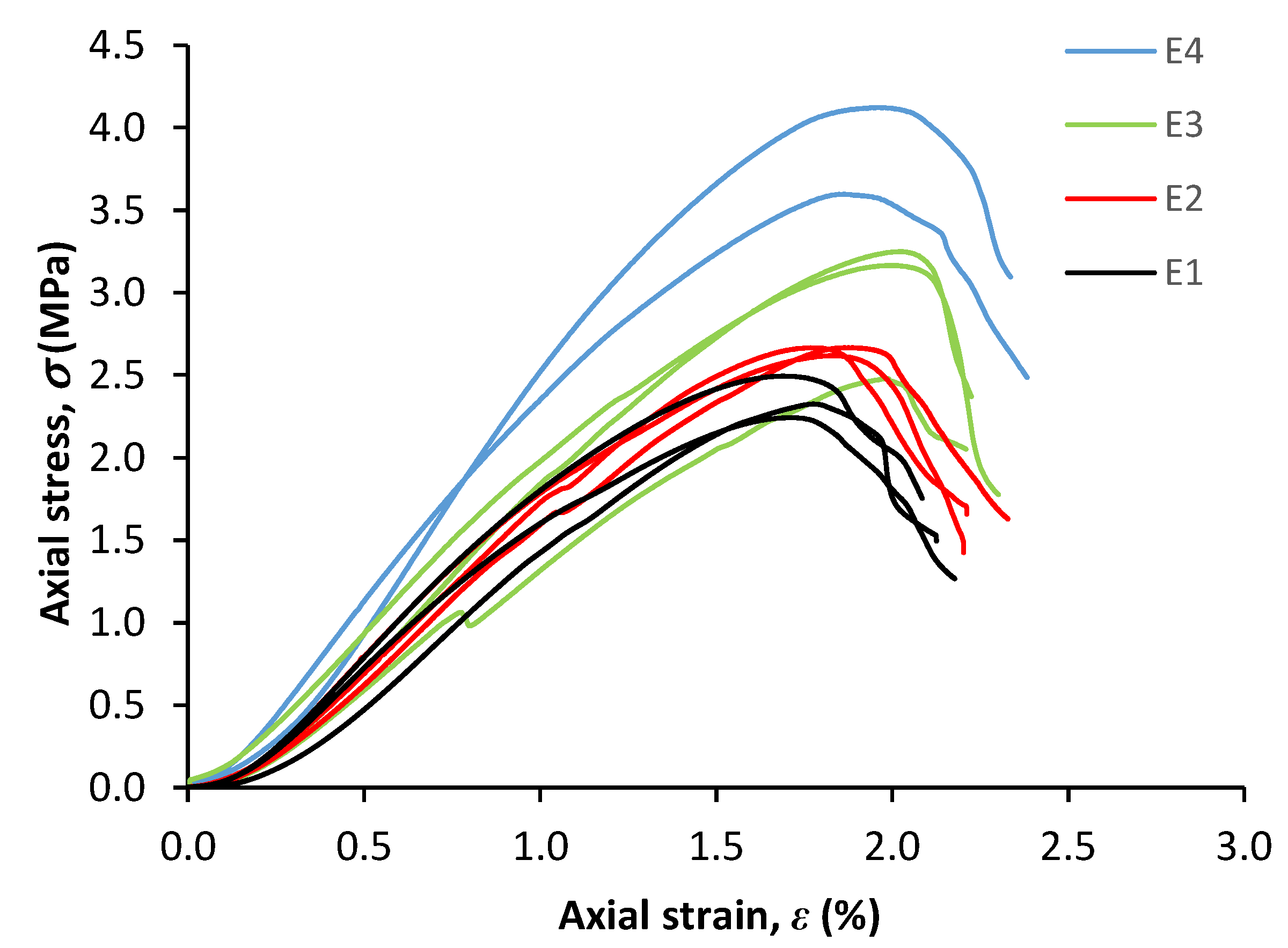

3.2. Unconfined Compression Tests

4. Discussion

4.1. CBS Specimens

4.2. Unconfined Compressive Strength

4.3. CBS Volumetric Normalisation

5. CBS Design Procedure

5.1. Description

5.2. Determination of CBS Model

- Build the soil Proctor curve for the determination of the maximum dry density and the optimum water content of the soil;

- Establish the adequate limits of cement content for the soil type (minimum range 4%), using, for example, recommendations in [33];

- Establish the limits of laboratory compaction, for example, E4 and E2;

- Produce CBS specimens with minimum and maximum values of cement content at the soil optimum water content, compacted at E4 and E2;

- Test CBS specimens cured for 7 days for unconfined compression strength;

- Determine n and Civ;

- Fit Equation (6) to versus Rc results to obtain A, B and α; in the literature, the best fit model is obtained for an α between 0.18 and 0.4.

6. Conclusions

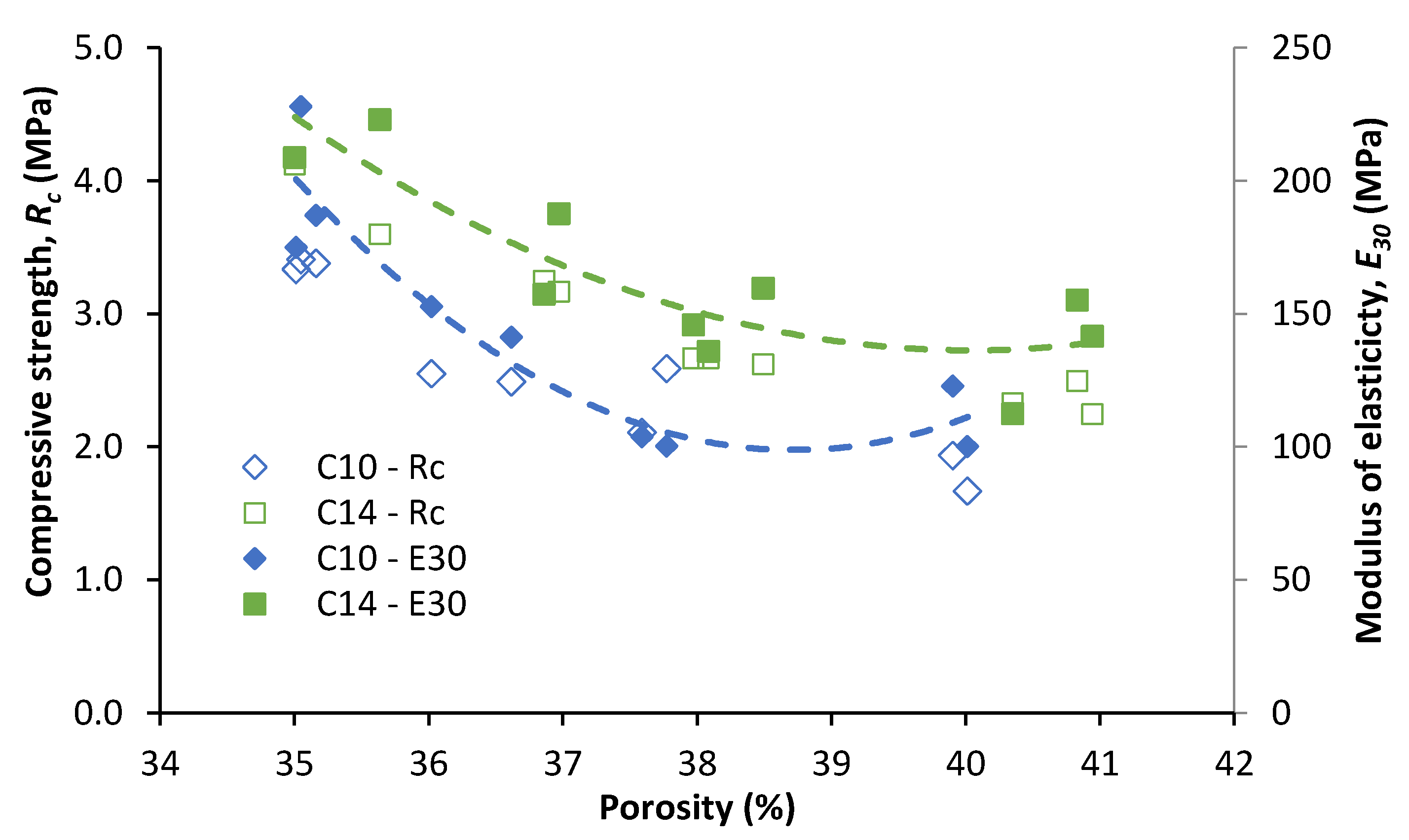

- The unconfined compressive stress–strain behavior of CBS is affected by the cement content and compaction effort used in the production of the specimens. Increasing cement content and compaction effort leads to higher peak stress (compression strength, Rc) and less deformation at peak, which results in higher modulus of elasticity, E30, values. For a certain cement content, the Rc and E30 had the same variation trend as the specimen porosity.

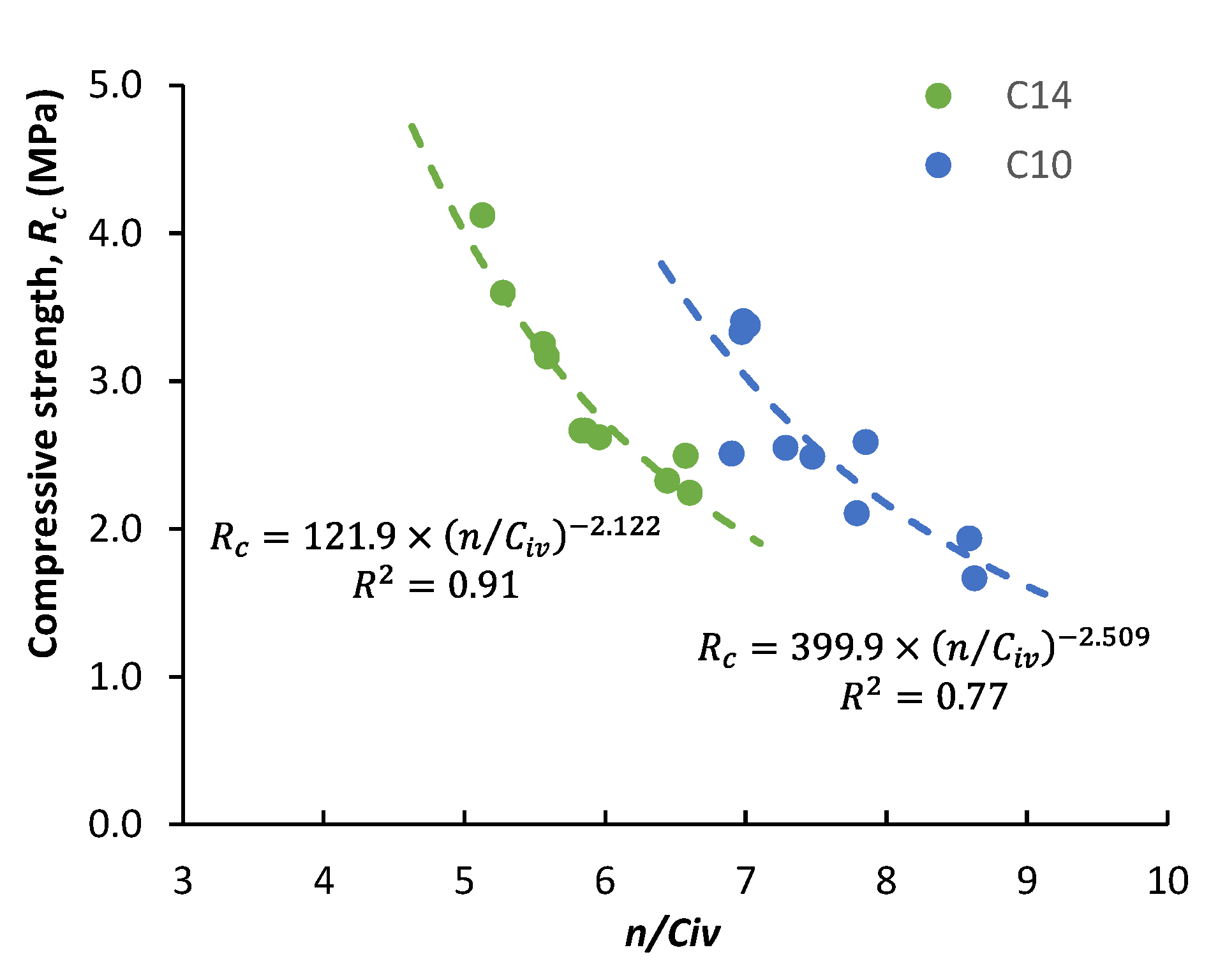

- The compressive strength is strongly affected by the modified porosity to volumetric cement content ratio (n/). The exponent value of 0.2 is in agreement with other studies found in literature for different fine-graded soils. It was also found that by normalizing the compressive strength of CBS to a certain n/ value, the results of CBS with different parent soils and cements fit a single model.

- The Rc–n/ model allows the determination of the cement content and the dry density required in the field to obtain a certain Rc value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Solihu, H. Cement Soil Stabilization as an Improvement Technique for Rail Track Subgrade, and Highway Subbase and Base Courses: A Review. J. Civ. Environ. Eng. 2020, 10, 1–6. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Consoli, N.C.; Ferreira, P.; Tang, C.-S.; Veloso Marques, S.F.; Festugato, L.; Corte, M.B. A unique relationship determining strength of silty/clayey soils—Portland cement mixes. Soils Found. 2016, 56, 1082–1088. [Google Scholar] [CrossRef]

- Consoli, N.C.; Marques, S.F.V.; Sampa, N.C.; Bortolotto, M.S.; Siacara, A.T.; Nierwinski, H.P.; Pereira, F.; Festugato, L. A general relationship to estimate strength of fibre-reinforced cemented fine-grained soils. Geosynth. Int. 2017, 24, 435–441. [Google Scholar] [CrossRef]

- Rios, S.; da Fonseca, A.V.; Baudet, B.A. Effect of the Porosity/Cement Ratio on the Compression of Cemented Soil. J. Geotech. Geoenviron. Eng. 2012, 138, 1422–1426. [Google Scholar] [CrossRef] [Green Version]

- Sariosseiri, F.; Muhunthan, B. Effect of cement treatment on geotechnical properties of some Washington State soils. Eng. Geol. 2009, 104, 119–125. [Google Scholar] [CrossRef]

- Ismail, A.; Baghini, M.S.; Karim, M.R.; Shokri, F.; Al-Mansob, R.A.; Firoozi, A.A. Laboratory Investigation on the Strength Characteristics of Cement-Treated Base. Appl. Mech. Mater. 2014, 507, 353–360. [Google Scholar] [CrossRef]

- Moreira, E.B.; Baldovino, J.A.; Rose, J.L.; Izzo, R.L.d.S. Effects of porosity, dry unit weight, cement content and void/cement ratio on unconfined compressive strength of roof tile waste-silty soil mixtures. J. Rock Mech. Geotech. Eng. 2019, 11, 369–378. [Google Scholar] [CrossRef]

- Rosone, M.; Ferrari, A.; Celauro, C. On the hydro-mechanical behaviour of a lime-treated embankment during wetting and drying cycles. Geomech. Energy Environ. 2018, 14, 48–60. [Google Scholar] [CrossRef]

- França, B.R.; Azevedo, A.; Monteiro, S.N.; Filho, F.D.C.G.; Marvila, M.T.; Alexandre, J.; Zanelato, E.B. Durability of Soil-Cement Blocks with the Incorporation of Limestone Residues from the Processing of Marble. Mater. Res. 2018, 21, 21. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, A.; Xavier, G.D.C.; Alexandre, J.; Pedroti, L.G.; Azevedo, A.; Vieira, C.M.F.; Monteiro, S.N. Environmental Durability of Soil-Cement Block Incorporated with Ornamental Stone Waste. Mater. Sci. Forum 2014, 798–799, 548–553. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Herzog, A.; Mitchell, J.K. Reactions Accompanying Stabilization of Clay with Cement. Highw. Res. Rec. 1963, 36, 146–171. [Google Scholar]

- Rakhimova, N.R.; Rakhimov, R.; Morozov, V.; Eskin, A. Calcined Low-grade Clays as Sources for Zeolite Containing Material. Period. Polytech. Civ. Eng. 2020, 65, 204–214. [Google Scholar] [CrossRef]

- Consoli, N.C.; Quiñónez, R.A.; González, L.E.; López, R.A. Influence of Molding Moisture Content and Porosity/Cement Index on Stiffness, Strength, and Failure Envelopes of Artificially Cemented Fine-Grained Soils. J. Mater. Civ. Eng. 2017, 29, 04016277. [Google Scholar] [CrossRef]

- Chen, X.; Yu, F.; Hong, Z.-M.; Pan, L.-F.; Liu, X.-W.; Li, Y. Comparative Investigation on the Curing Behavior of GS-Stabilized and Cemented Soils at Macromechanical and Microstructural Scales. J. Test. Eval. 2021, 51. [Google Scholar] [CrossRef]

- Attah, I.C.; Okafor, F.O.; Ugwu, O.O. Optimization of California bearing ratio of tropical black clay soil treated with cement kiln dust and metakaolin blend. Int. J. Pavement Res. Technol. 2021, 14, 655–667. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation. EN 14227-10 Hydraulically Bound Mixtures Specifications. Part 10: Soil Treated by Cement; Comité Européen de Normalisation: Brussels, Belgium, 2013. [Google Scholar]

- PCA American’s Cement Manufacturers. Cement Stabilized Subgrade (CSS) Soils; PCA American’s Cement Manufacturers: Washington, DC, USA, 2021. [Google Scholar]

- Nusit, K.; Jitsangiam, P.; Kodikara, J.; Bui, H.H.; Leung, G.L.M. Advanced Characteristics of Cement-Treated Materials with respect to Strength Performance and Damage Evolution. J. Mater. Civ. Eng. 2017, 29, 04016255. [Google Scholar] [CrossRef]

- Horpibulsk, S.; Rachan, R.; Suddeepong, A.; Chinkulkijniwat, A. Strength Development in Cement Admixed Bangkok Clay: Laboratory and Field Investigations. Soils Found. 2011, 51, 239–251. [Google Scholar] [CrossRef] [Green Version]

- Consoli, N.C.; Rosa, D.A.; Cruz, R.C.; Rosa, A.D. Water content, porosity and cement content as parameters controlling strength of artificially cemented silty soil. Eng. Geol. 2011, 122, 328–333. [Google Scholar] [CrossRef]

- Rios, S.; Viana da Fonseca, A. Porosity/Cement Index to Evaluate Geomechanical Properties of an Artificial Cemented Soil. In Proceedings of the18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013. [Google Scholar]

- Costa, C.; Manuppella, G.; Clavijo, E.; Moniz, C.; Dias, R.P.; Machado, S. Geological Map of Portugal; National Laboratory of Energy and Geology (LNEG): Amadora, Portugal, 2005. [Google Scholar]

- Antunes, M.; Pais, J.; Legoinha, P. Neogene Deposits of Lisbon and Setúbal Peninsula, Excursion A. Ciências da Terra; Universidade Nova de Lisboa: Lisbon, Portugal, 1992; Special number 2; pp. 29–35. [Google Scholar]

- International Organization for Standardization. EN ISO 17892-4 Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- International Organization for Standardization. EN ISO 17892-12 Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Liquid and Plastic Limits; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- American Association of State and Highway Transportation Officials. ASTM D 2487-06 Standard Classification of Soils for Engineering Purposes; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2006. [Google Scholar]

- American Association of State and Highway Transportation Officials. AASHTO M 145-91 Standard Specification for Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2017. [Google Scholar]

- Gross, J.; Adaska, W. Guide to Cement-Stabilized Subgrade Soils; Portland Cement Association: Washington, DC, USA; National Concrete Pavement Technology Center, Iowa State University: Ames, IA, USA, 2020. [Google Scholar]

- Instituto Português da Qualidade. NP EN 197-1 Composition, Specifications and Conformity Criteria for Common Cements; Instituto Português da Qualidad: Lisbon, Portugal, 2012. [Google Scholar]

- Faustino, P.; Gonçalves, F.; Bras, A.; Nunes, Â. Lifetime Prediction of Reinforced Concrete Structures in Carbonation Environments Carbonation Modelling vs Air Permeability Modelling. J. Civ. Eng. Manag. 2017, 23, 283–291. [Google Scholar] [CrossRef]

- American Concrete Institute. Report on Soil Cement, ACI 230.1R-09; American Concrete Institute: Indianapolis, IN, USA, 2009. [Google Scholar]

- Ikhlef, N.-S.; Ghembaza, M.S.; Dadouch, M. Effect of Treatment with Cement on the Mechanical Characteristics of Silt from Telagh Region of Sidi Belabes, Algeria. Geotech. Geol. Eng. 2015, 33, 1067–1079. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation. EN 13286-50 Unbound and Hydraulically Bound Mixtures. Part 50: Method for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Proctor Equipment or Vibrating Table Compaction; Comité Européen de Normalisation: Brussels, Belgium, 2004. [Google Scholar]

- Comité Européen de Normalisation. EN 13286-41 Unbound and Hydraulically Bound Mixtures. Part 41: Test Method for the Determination of the Compressive Strength of Hydraulically Bound Mixtures; Comité Européen de Normalisation: Brussels, Belgium, 2013. [Google Scholar]

- Pinho, F.F.S.; Lúcio, V.; Baião, M.F.C. Rubble Stone Masonry Walls Strengthened by Three-Dimensional Steel Ties and Textile-Reinforced Mortar Render, Under Compression and Shear Loads. Int. J. Arch. Herit. 2014, 9, 844–858. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation. EN 13286-43 Unbound and Hydraulically Bound Mixtures. Part 41: Test Method for the Determination of the Modulus of Elasticity of Hydraulically Bound Mixtures; Comité Européen de Normalisation: Brussels, Belgium, 2013. [Google Scholar]

- Pham, T.A.; Koseki, J.; Dias, D. Optimum material ratio for improving the performance of cement-mixed soils. Transp. Geotech. 2021, 28, 100544. [Google Scholar] [CrossRef]

- Aïtcin, P.-C. 2-Phenomenology of cement hydration. In Science and Technology of Concrete Admixtures; Aïtcin, P.-C., Flatt, R.J., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 15–25. ISBN 978-0-08-100693-1. [Google Scholar]

- Baldovino, J.D.J.A.; Moreira, E.B.; Carazzai, É.; Rocha, E.V.D.G.; Izzo, R.D.S.; Mazer, W.; Rose, J.L. Equations controlling the strength of sedimentary silty soil–cement blends: Influence of voids/cement ratio and types of cement. Int. J. Geotech. Eng. 2021, 15, 359–372. [Google Scholar] [CrossRef]

- Vitali, O. Effect of the Composition of Soil-Cement Mixtures on Stiffness and Strength Parameters. Master’s Thesis, University of Porto, Porto, Portugal, 2008. (In Portuguese). [Google Scholar]

- Consoli, N.C.; Prietto, P.D.M.; Lopes, L.D.S.; Winter, D. Control factors for the long term compressive strength of lime treated sandy clay soil. Transp. Geotech. 2014, 1, 129–136. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Liquid limit (EN ISO 17892-12 2016) | 32% |

| Plastic Limit (EN ISO 17892-12 2016) | 21% |

| Plastic index (EN ISO 17892-12 2016) | 11% |

| Particle density (ρss) (EN ISO 17892-3 2016) | 2.64 Mg/m3 |

| Coarse sand (2.0–4.75 mm) (EN ISO 17892-4 2016) | - |

| Medium sand (0.42–2.0 mm) (EN ISO 17892-4 2016) | 34.5% |

| Fine sand (0.074–0.42 mm) (EN ISO 17892-4 2016) | 25.9% |

| Fines content (<0.074 mm) (EN ISO 17892-4 2016) | 39.6% |

| Mean particle diameter (D50) (EN ISO 17892-4 2016) | 0.2 mm |

| Unified soil classification (ASTM D 2487) | SC |

| ASHTO soil classification (AASHTO M145-42) | A-6 (14) |

| Properties | Values |

|---|---|

| Constituents | >69% K |

| >26% FA | |

| Ignition loss | 2.3% |

| Insoluble residue | 26.3% |

| Specific surface area (Blaine) (cm2/g) (EN 196-6) | 4292 |

| Compression strength 28d (MPa) (EN 196-1) | 44.3 |

| Setting time (min) (EN 196-3) | >75 |

| CBS | C (%) | wopt (%) | Blows Per Layer | E (MN.m/m3) |

|---|---|---|---|---|

| C10-E1 | 10 | 13 | 10 | 0.98 |

| C10-E2 | 15 | 1.47 | ||

| C10-E3 | 20 | 1.97 | ||

| C10-E4 | 25 | 2.50 | ||

| C14-E1 | 14 | 10 | 0.98 | |

| C14-E2 | 15 | 1.47 | ||

| C14-E3 | 20 | 1.97 | ||

| C14-E4 | 25 | 2.50 |

| Material | w | ρd | n | ||

|---|---|---|---|---|---|

| Mean (%) | CV (%) | Mean (Mg/m3) | CV (%) | (%) | |

| C10-E1 | 12.2 | 3.9 | 1.61 | 0.5 | 39.8 |

| C10-E2 | 12.4 | 6.5 | 1.68 | 0.7 | 37.4 |

| C10-E3 | 12.1 | 2.7 | 1.72 | 1.5 | 35.8 |

| C10-E4 | 12.6 | 1.7 | 1.74 | 0.1 | 35.1 |

| C14-E1 | 11.9 | 2.2 | 1.60 | 0.5 | 40.7 |

| C14-E2 | 11.5 | 3.4 | 1.67 | 0.4 | 38.2 |

| C14-E3 | 12.4 | 2.7 | 1.71 | 0.7 | 36.6 |

| C14-E4 | 12.4 | 4.1 | 1.74 | 0.5 | 35.3 |

| Specimen | Rc | ε at Rc | E30 | |||

|---|---|---|---|---|---|---|

| Mean (MPa) | CV (%) | Mean (%) | CV (%) | Mean (MPa) | CV (%) | |

| Soil-E4 | 0.22 | 11 | 1.62 | 7.7 | 2 | 14 |

| C10-E1 | 1.80 | 11 | 1.62 | 4 | 111.4 | 14 |

| C10-E2 | 2.35 | 14 | 1.96 | 7 | 102.0 | 2 |

| C10-E3 | 2.52 | 1 | 1.84 | 6 | 137.4 | 13 |

| C10-E4 | 3.37 | 1 | 1.91 | 2 | 196.5 | 14 |

| C14-E1 | 2.35 | 5 | 1.73 | 3 | 136.4 | 16 |

| C14-E2 | 2.65 | 1 | 1.82 | 3 | 147.0 | 8 |

| C14-E3 | 3.21 | 2 | 2.01 | 1 | 172.4 | 12 |

| C14-E4 | 3.86 | 10 | 1.91 | 4 | 215.8 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santana, T.; Gonçalves, J.; Pinho, F.; Micaelo, R. Effects of the Ratio of Porosity to Volumetric Cement Content on the Unconfined Compressive Strength of Cement Bound Fine Grained Soils. Infrastructures 2021, 6, 96. https://doi.org/10.3390/infrastructures6070096

Santana T, Gonçalves J, Pinho F, Micaelo R. Effects of the Ratio of Porosity to Volumetric Cement Content on the Unconfined Compressive Strength of Cement Bound Fine Grained Soils. Infrastructures. 2021; 6(7):96. https://doi.org/10.3390/infrastructures6070096

Chicago/Turabian StyleSantana, Teresa, João Gonçalves, Fernando Pinho, and Rui Micaelo. 2021. "Effects of the Ratio of Porosity to Volumetric Cement Content on the Unconfined Compressive Strength of Cement Bound Fine Grained Soils" Infrastructures 6, no. 7: 96. https://doi.org/10.3390/infrastructures6070096

APA StyleSantana, T., Gonçalves, J., Pinho, F., & Micaelo, R. (2021). Effects of the Ratio of Porosity to Volumetric Cement Content on the Unconfined Compressive Strength of Cement Bound Fine Grained Soils. Infrastructures, 6(7), 96. https://doi.org/10.3390/infrastructures6070096