Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review

Abstract

:1. Introduction

- Substrate concrete must be strong enough, without any major cracks or unsoundness;

- Moisture content and temperature of the substrate has to be suitable;

- Substrate surface must be clean of any dust or dirt [8].

2. Influential Factors on Bond Performance

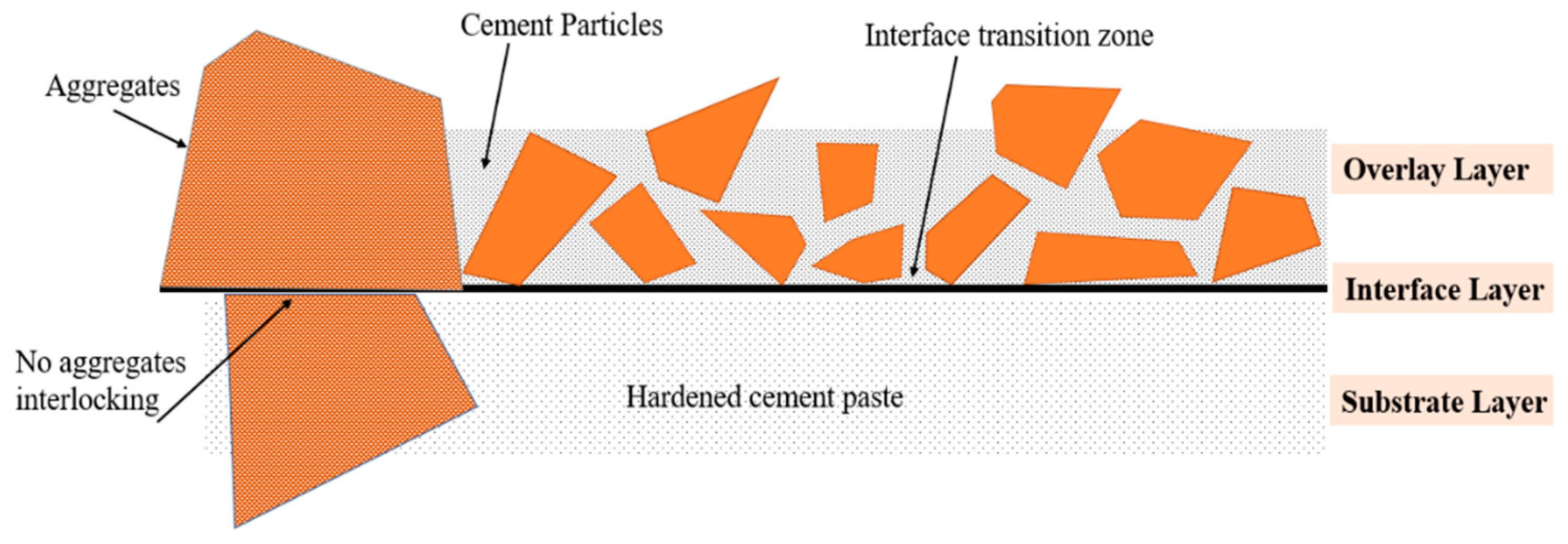

2.1. Influential Features of Concrete Layers

2.1.1. Compressive Strength

2.1.2. Shrinkage

- Formation of microcracks in the interface because of the inner tensile stresses induced by shrinkage;

- Enlargement of bigger pores to enhance the overall volume and interconnections between the pores and a higher amount of permeability;

- Drying out and partial collapsing of Calcium–Silicate–Hydrate (CSH) sheets in concrete, which cause an expansion of capillary pores, resulting in a “coarser” microstructure [27].

2.1.3. Supplementary Cementitious Materials

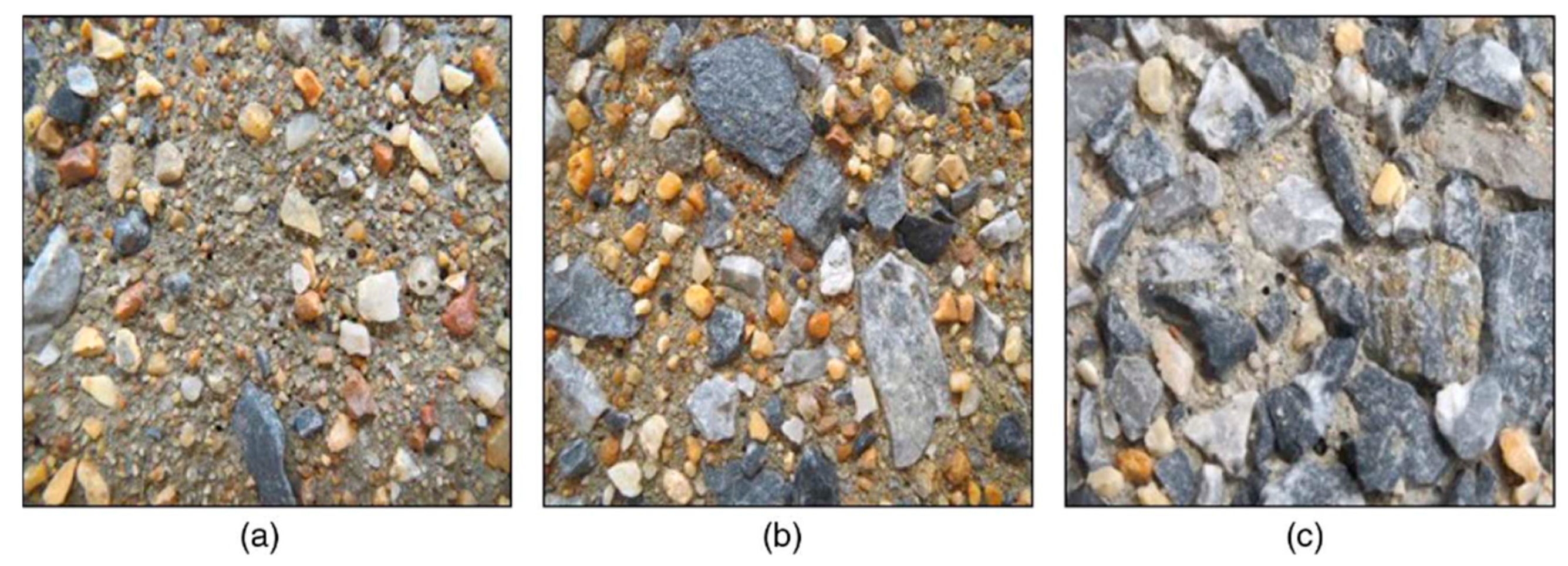

2.1.4. Aggregates

2.1.5. Age of Layers

2.1.6. Density

2.1.7. Overlay Thickness

2.1.8. Overlay Workability

2.1.9. Other Factors

2.2. The Role of Concrete Types on Bond Properties

2.2.1. Ultra-High-Performance Concrete (UHPC)

2.2.2. Lightweight Concrete (LWC)

2.2.3. Self-Consolidating Concrete (SCC)

2.2.4. Recycled Aggregate Concrete (RAC)

2.3. Substrate Moisture Content

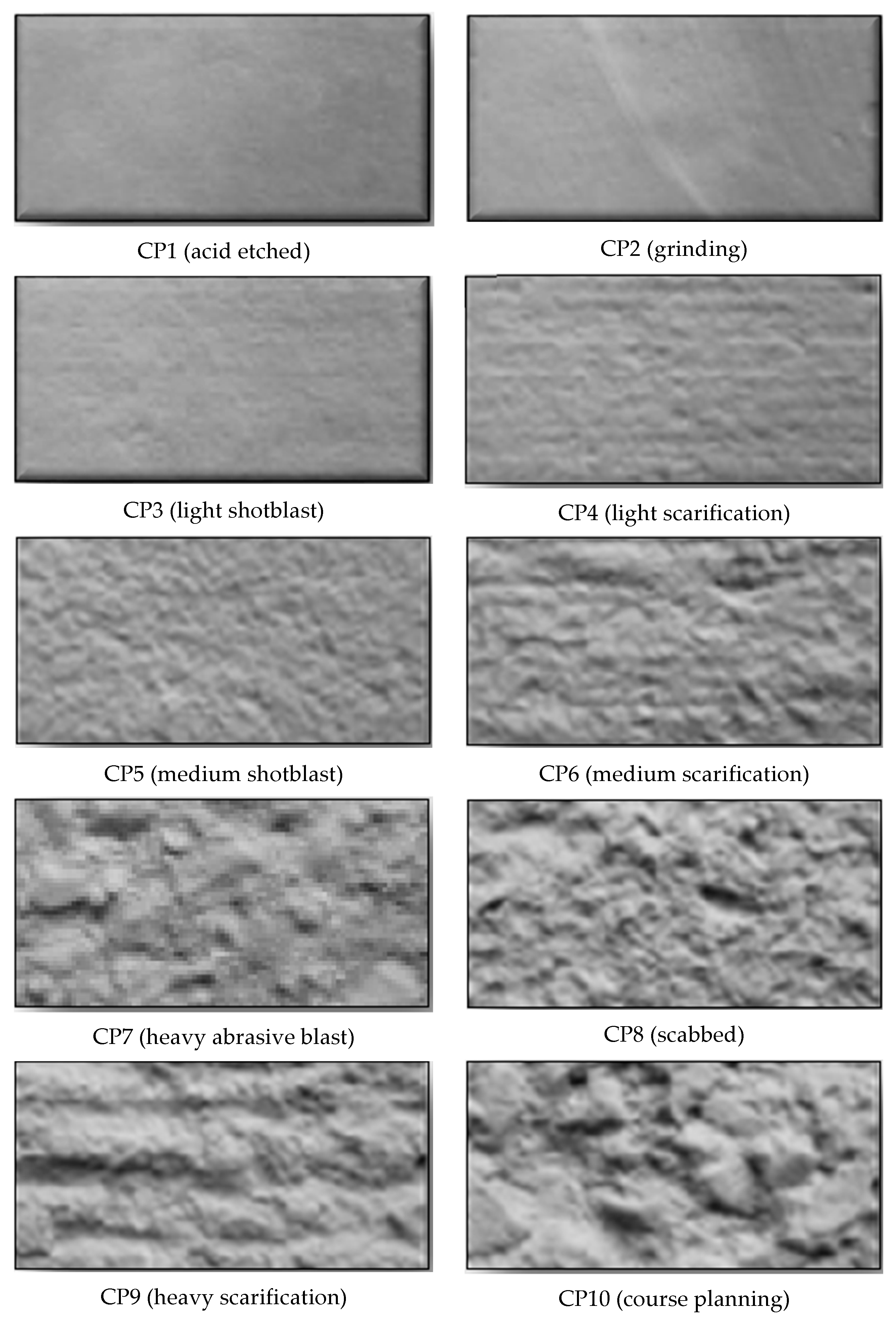

2.4. Surface Preparation Methods

2.4.1. In-Form Retarders

- Lignosulfonates, which are ligno-sulfonic aid salts;

- Carboxylic acid salts;

- Some kinds of inorganic salts;

- Some sugar derivatives [128].

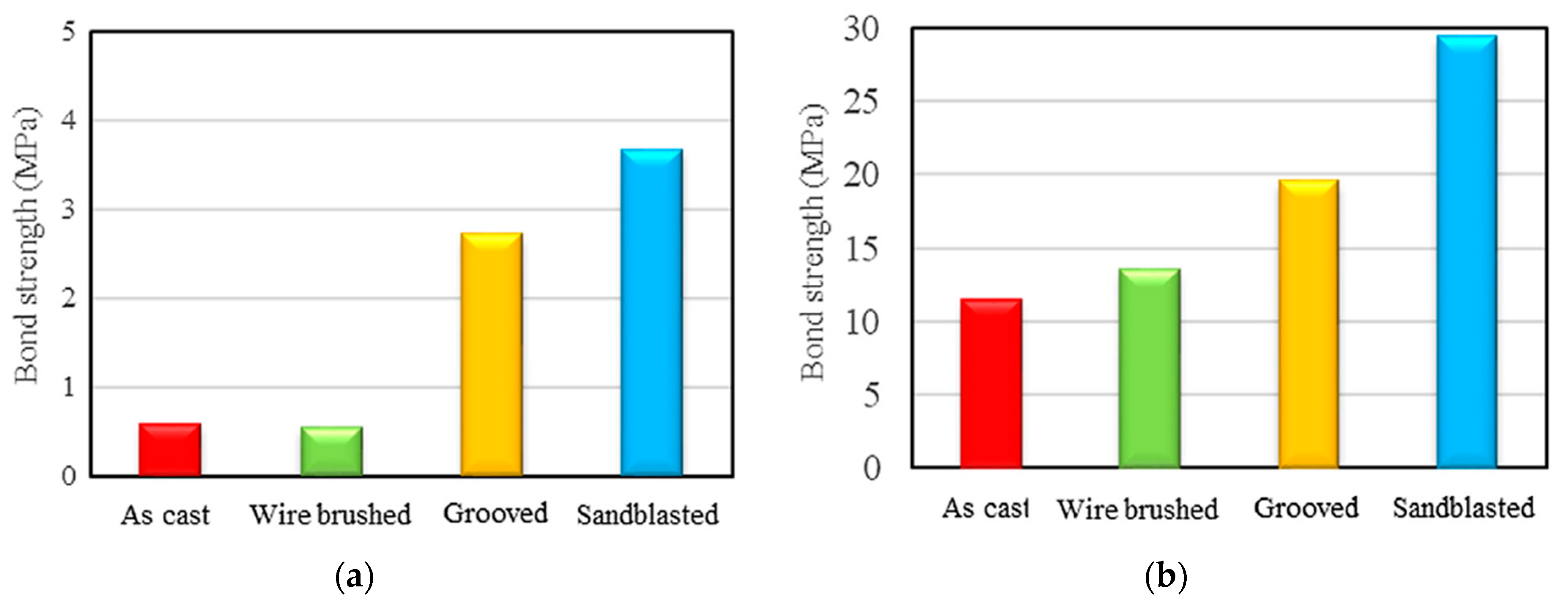

2.4.2. Sandblasting

2.4.3. Shotblasting or Bead Blasting

2.4.4. Hydro-Demolition

2.4.5. Waterblasting

2.4.6. Chipping

2.4.7. Grinding

2.4.8. Milling or Scarification

2.5. The Impact of Bonding Agents on Bond Behavior

2.6. Curing Conditions

3. Durability of Concrete-to-Concrete Bond in Extreme Conditions

3.1. Freeze–Thaw Cycles

3.2. Chemical Attack

3.3. Fire and High Temperatures

4. Types of Tests Carried out on Concrete Bond

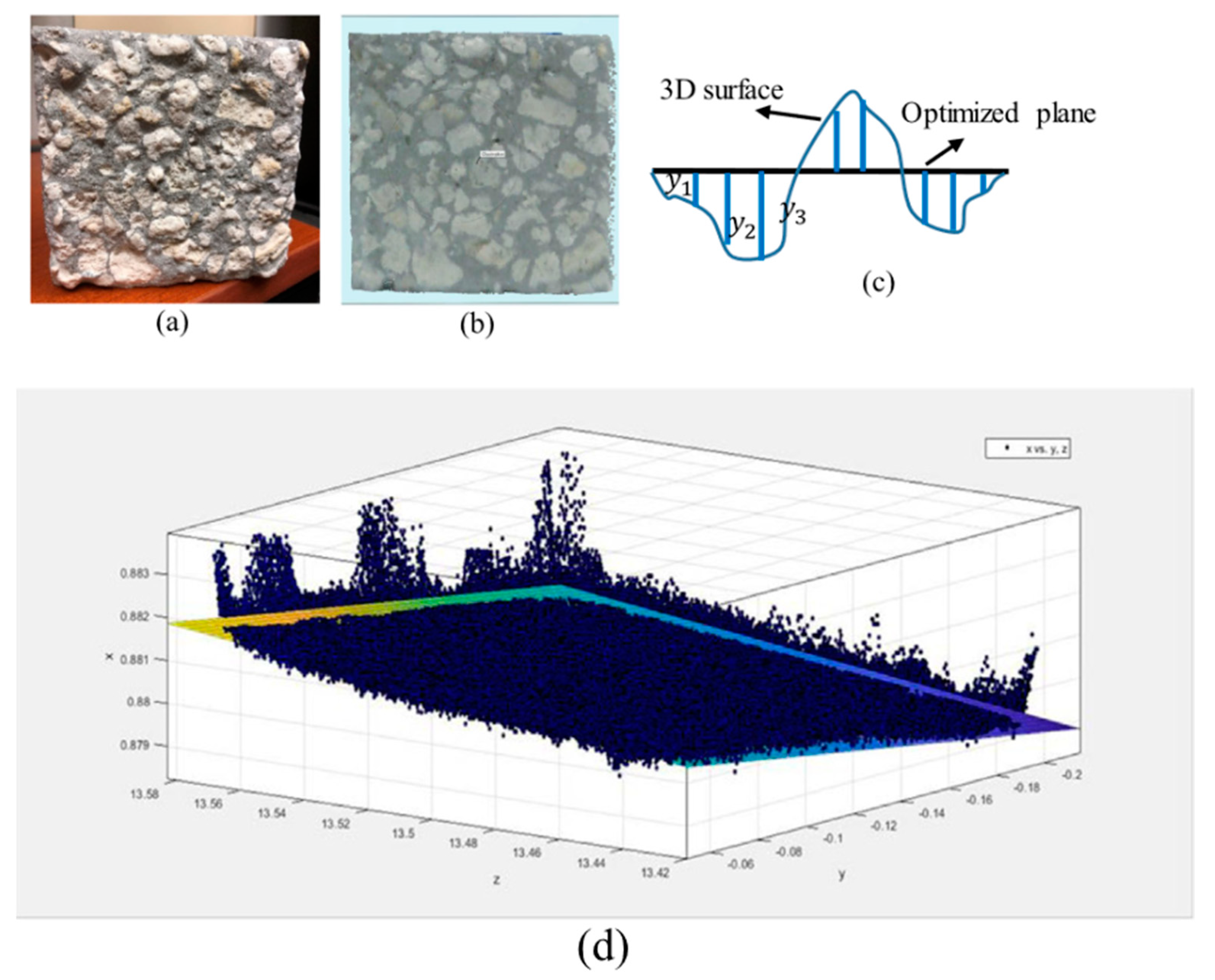

4.1. Surface Roughness Tests

4.1.1. Sand Patch Method

4.1.2. Circular Texture Meter (CT Meter)

4.1.3. 2D and 3D Laser Roughness Analyzer (LRA) Method

4.2. Characterization Methods for Assessing Bond Properties

4.2.1. Microstructural Analysis (MSA)

4.2.2. Measuring Bond Resistance

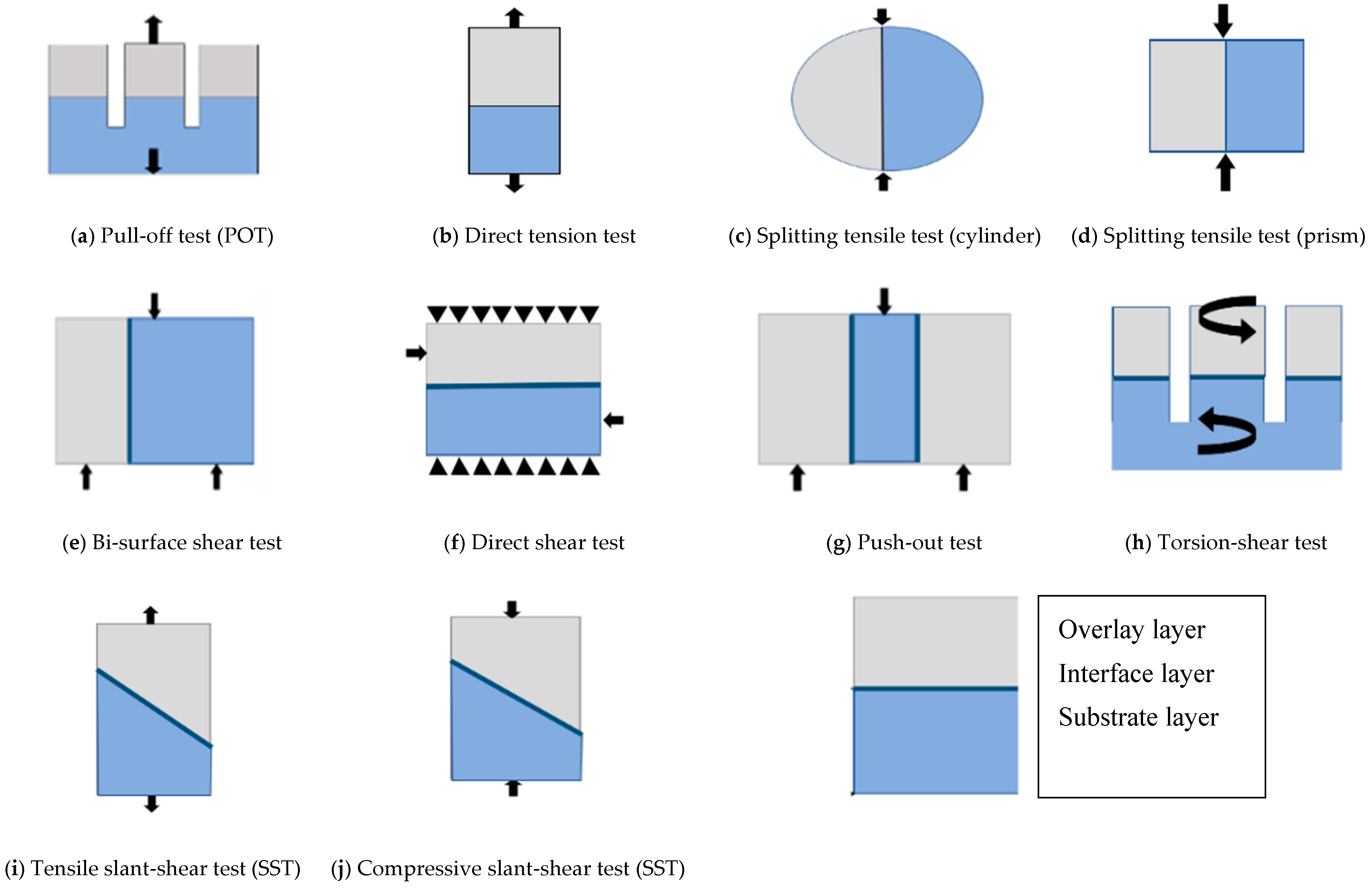

Tension Tests

Shear Tests

Shear and Compression Tests

5. Summary and Conclusions

- There are three different failure mechanisms that can take place in a concrete-to-concrete connection, i.e., adhesive, cohesive and mixed, among which the cohesive is preferable since it allows the full usage of structural capacity, and making a suitable bond between concrete layers can effectively prevent the adhesive failure which occurs in the bond.

- Bond strength is highly influenced by the properties of both concrete layers, such as their compressive strength, age, level of shrinkage, thickness and types of aggregates. The curing conditions of concrete substrate and overlay, such as temperature and moisture, also impact the bond performance to a great extent.

- Bonding between concrete layers in construction techniques where two layers of concrete are cast at different times, such as the prefabrication of structural elements and connecting them by grouting the void between them by fresh concrete, can be improved to ensure that a brittle bond failure does not jeopardize the entire structure safety and service life.

- While surface preparation techniques, which comprise cleaning, roughening and deteriorated concrete removal, are used to enhance bond shear resistance, bond agents can be applied on the surface to make an even stronger connection between concrete layers.

- Various tests encompassing microstructural and mechanical types are available to measure the bond strength, including microscopy, push-off, push-out, bi-shear, slant shear tests and so forth, with different setups and specimen configurations. An appropriate one must be selected by considering the concrete element properties, such as direction, loading, support conditions and bonding complexity. Nevertheless, it is recommended to specify an average bond strength by using multiple test types to obtain more precise and representative results.

6. Recommendations for Future Studies

- Evaluation of performance changes in different bond configurations, such as more than two layers of concrete, and anchored by various mechanical connectors.

- Developing a mechanical apparatus for examining the bond strength under the combined effect of tension, torsion and shear or compression, torsion and shear.

- A comprehensive comparison between the effect of different kinds of bond agents and the criteria for selecting the most suitable one according to the case study.

- The effect of overlay thickness by measuring the bond strength for various thicknesses on both rough and smooth substrates and different bond strength tests.

- Long-term performance of concrete-to-concrete bond during the service life of the structure.

- Bond performance under cyclic loads

- Bond strength between concrete and non-shrink grouts that are common in accelerated bridge technology (ABC) and other prefabrication practices

- Developing a numerical model by machine learning based on existing literature and new experimental results to predict bond shear strength based on features of substrate and overlay, such as roughness, relative humidity, strength, etc.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ARTBA Bridge Report. American Road and Transportation Builders Association, Washington, DC, USA. 2022. Available online: https://artbabridgereport.org/ (accessed on 5 April 2024).

- Vaysburd, A.M.; Emmons, P.H. Concrete repair a composite system: Philosophy, engineering and practice. Restor. Build. Monum. Bauinstandsetz. Baudenkmalpflege 2006, 12, 423–436. [Google Scholar]

- Santos, D.S.; Santos, P.M.D.; Dias-da-Costa, D. Effect of surface preparation and bonding agent on the concrete-to-concrete interface strength. Constr. Build. Mater. 2012, 37, 102–110. [Google Scholar] [CrossRef]

- Rabehi, B.; Ghernouti, Y.; Li, A.; Boumchedda, K. Comparative behavior under compression of concrete columns repaired by fiber reinforced polymer (FRP) jacketing and ultra high-performance fiber reinforced concrete (UHPFRC). J. Adhes. Sci. Technol. 2014, 28, 2327–2346. [Google Scholar] [CrossRef]

- Cusson, D. Durability of repaired concrete structures. In Failure, Distress and Repair of Concrete Structures; Elsevier: Amsterdam, The Netherlands, 2009; pp. 296–321. [Google Scholar]

- Pulkit, K.; Saini, B.; Chalak, H. Effect of various interface bond tests and their failure behavior on substrate and overlay concrete —A Review. Res. Eng. Struct. Mater. 2023. [Google Scholar] [CrossRef]

- Stander, H. Interfacial Bond Properties for ECC Overlay Systems. Ph.D. Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2007. [Google Scholar]

- Courard, L.; Bissonnette, B.; Garbacz, A.; Vaysburd, A.M.; Von Fay, K.F. Guidelines for concrete surface preparation: 10 years research and experience. MATEC Web Conf. 2018, 199, 08004. [Google Scholar] [CrossRef]

- Soares, S.; Sena-Cruz, J.; Cruz, J.R.; Fernandes, P. Influence of Surface Preparation Method on the Bond Behavior of Externally Bonded CFRP Reinforcements in Concrete. Materials 2019, 12, 414. [Google Scholar] [CrossRef]

- Carbonell Muñoz, M.A.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond performance between ultrahigh-performance concrete and normal-strength concrete. J. Mater. Civ. Eng. 2014, 26, 04014031. [Google Scholar] [CrossRef]

- De la Varga, I.; Haber, Z.B.; Graybeal, B.A. Enhancing Shrinkage Properties and Bond Performance of Prefabricated Bridge Deck Connection Grouts: Material and Component Testing. J. Mater. Civ. Eng. 2018, 30, 04018053. [Google Scholar] [CrossRef]

- Randl, N. Investigations on Transfer of Forces between Old and New Concrete at Different Joint Roughness. Ph.D. Thesis, University of Innsbruck, Innsbruck, Austria, 1997. [Google Scholar]

- Bonaldo, E.; Barros, J.A.; Lourenço, P.B. Bond characterization between concrete substrate and repairing SFRC using pull-off testing. Int. J. Adhes. Adhes. 2005, 25, 463–474. [Google Scholar] [CrossRef]

- Júlio, E.N.B.S.; Branco, F.A.B.; Silva, V.D.; Lourenço, J.F. Influence of added concrete compressive strength on adhesion to an existing concrete substrate. Build. Environ. 2006, 41, 1934–1939. [Google Scholar] [CrossRef]

- Haber, Z.B.; Munoz, J.F.; De La Varga, I.; Graybeal, B.A. Bond characterization of UHPC overlays for concrete bridge decks: Laboratory and field testing. Constr. Build. Mater. 2018, 190, 1056–1068. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Gao, Z. Bond behavior between lightweight aggregate concrete and normal weight concrete based on splitting-tensile test. Constr. Build. Mater. 2019, 209, 306–314. [Google Scholar] [CrossRef]

- Costa, H.; Carmo, R.; Júlio, E. Influence of lightweight aggregates concrete on the bond strength of concrete-to-concrete interfaces, Constr. Constr. Build. Mater. 2018, 180, 519–530. [Google Scholar] [CrossRef]

- Manawadu, A.; Qiao, P.; Wen, H. Characterization of Substrate-to-Overlay Interface Bond in Concrete Repairs: A Review, Constr. Constr. Build. Mater. 2023, 373, 130828. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, M.; Peyerl, M. Sustainable strengthening of RC members with high performance concrete overlays. In Maintenance, Monitoring, Safety, Risk and Resilience of Bridges and Bridge Networks; CRC Press: Boca Raton, FL, USA, 2016; Volume 370. [Google Scholar]

- Feng, S.; Xiao, H.; Liu, R.; Liu, M. The bond properties between ultra-high-performance concrete and normal strength concrete substrate: Bond macro-performance and overlay transition zone microstructure. Cem. Concr. Compos. 2022, 128, 104436. [Google Scholar] [CrossRef]

- Valikhani, A.; Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application. Constr. Build. Mater. 2020, 238, 117753. [Google Scholar] [CrossRef]

- Iavarone, F.; Vecchio, F.J.; Plizzari, G.; Minelli, F. Shear bond between existing concrete and high-strength fiber reinforced overlay: Influence of substrate strength and interface roughness. Struct. Concr. 2023, 25, 526–536. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Zhu, Y.; Cao, J.; Shao, X. An experimental study: Various influence factors affecting interfacial shear performance of UHPC-NSC. Constr. Build. Mater. 2020, 236, 117480. [Google Scholar] [CrossRef]

- Beushausen, H.; Alexander, M.G. Bond strength development between concretes of different ages. Mag. Concr. Res. 2008, 60, 65–74. [Google Scholar] [CrossRef]

- Momani, Y.; Alawadi, R.; Taqieddin, Z.N.; Tarawneh, A.; Rezeq, W.; Aljuneidi, A. Bond strength prediction of UHPC-NSC interface. J. Appl. Eng. Sci. 2023, 21, 618–628. [Google Scholar] [CrossRef]

- Moelich, G.; Kruger, P.; Combrinck, R. The effect of restrained early age shrinkage on the interlayer bond and durability of 3D printed concrete. J. Build. Eng. 2021, 43, 102857. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Beushausen, H.; Alexander, M.G. Failure mechanisms and tensile relaxation of bonded concrete overlays subjected to differential shrinkage. Cem. Concr. Res. 2006, 36, 1908–1914. [Google Scholar] [CrossRef]

- Daneshvar, D.; Behnood, A.; Robisson, A. Interfacial bond in concrete-to-concrete composites: A review. Constr. Build. Mater. 2022, 359, 129195. [Google Scholar] [CrossRef]

- Silfwerbrand, J. Stresses and strains in composite concrete beams subjected to differential shrinkage. Struct. J. 1997, 94, 347–353. [Google Scholar]

- Qin, R.; Hao, H.; Rousakis, T.; Lau, D. Effect of shrinkage reducing admixture on new-to-old concrete interface. Compos. Part B Eng. 2019, 167, 346–355. [Google Scholar] [CrossRef]

- Burkart, I.; Müller, H.S. Creep and shrinkage characteristics of ultra high strength concrete (UHPC). In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 469–476. [Google Scholar]

- Toledo, W.K.; Davila, L.; Al-Basha, A.J.; Newtson, C.M.; Weldon, B.D. Assessment of Ultra-High Performance Concrete Overlays on Concrete Bridge Decks. In Proceedings of the Tran-SET 2020, American Society of Civil Engineers, Albuquerque, New Mexico, 1–2 September 2021; pp. 278–286. [Google Scholar] [CrossRef]

- Padavala, S.S.A.B.; Kode, V.R.; Dey, S. Bond strength of fly ash and silica fume blended concrete mixes. Asian J. Civ. Eng. 2024, 25, 895–909. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Momayez, A.; Ehsani, M.R.; Ramezanianpour, A.A.; Rajaie, H. Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Kuroda, M.; Watanabe, T.; Terashi, N. Increase of bond strength at interfacial transition zone by the use of fly ash. Cem. Concr. Res. 2000, 30, 253–258. [Google Scholar] [CrossRef]

- Yamei, Z.; Wei, S.; Lianfei, S. Mechanical Properties of High Performance Concrete Made with High Calcium High Sulfate Fly Ash. Cem. Concr. Res. 1997, 27, 1093–1098. [Google Scholar] [CrossRef]

- Al-Azzawi, M.; Yu, T.; Hadi, M.N.S. Factors Affecting the Bond Strength Between the Fly Ash-based Geopolymer Concrete and Steel Reinforcement. Structures 2018, 14, 262–272. [Google Scholar] [CrossRef]

- Li, G. A new way to increase the long-term bond strength of new-to-old concrete by the use of fly ash. Cem. Concr. Res. 2003, 33, 799–806. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Sata, V.; Hanjitsuwan, S.; Ridtirud, C.; Hatanaka, S.; Chindaprasirt, P. High calcium fly ash geopolymer mortar containing Portland cement for use as repair material. Constr. Build. Mater. 2015, 98, 482–488. [Google Scholar] [CrossRef]

- Kramar, S.; Šajna, A.; Ducman, V. Assessment of alkali activated mortars based on different precursors with regard to their suitability for concrete repair. Constr. Build. Mater. 2016, 124, 937–944. [Google Scholar] [CrossRef]

- Tasong, W.A.; Lynsdale, C.J.; Cripps, J.C. Aggregate-cement paste interface. II: Influence of aggregate physical properties. Cem. Concr. Res. 1998, 28, 1453–1465. [Google Scholar] [CrossRef]

- Caliskan, S.; Karihaloo, B.L.; Barr, B.I.G. Study of rock–mortar interfaces. Part II: Strength of interface. Mag. Concr. Res. 2002, 54, 463–472. [Google Scholar] [CrossRef]

- Caliskan, S.; Karihaloo, B.L. Effect of Surface Roughness, Type and Size of Model Aggregates on the Bond Strength of Aggregate/Mortar Interface. Interface Sci. 2004, 12, 361–374. [Google Scholar] [CrossRef]

- Kozul, R.; Darwin, D. Effects of Aggregate Type, Size, and Content on Concrete Strength and Fracture Energy; University of Kansas Center for Research, Inc.: Lawrence, KS, USA, 1997. [Google Scholar]

- Akçaoğlu, T.; Tokyay, M.; Çelik, T. Effect of coarse aggregate size on interfacial cracking under uniaxial compression. Mater. Lett. 2002, 57, 828–833. [Google Scholar] [CrossRef]

- Momayez, A.; Ramezanianpour, A.A.; Rajaie, H.; Ehsani, M.R. Bi-surface shear test for evaluating bond between existing and new concrete. Mater. J. 2004, 101, 99–106. [Google Scholar]

- Chen, B.; Liu, J. Effect of aggregate on the fracture behavior of high strength concrete. Constr. Build. Mater. 2004, 18, 585–590. [Google Scholar] [CrossRef]

- Popovics, S. Strength and Related Properties of Concrete: A Quantitative Approach; John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

- Dehghan, A.; Maher, M.L.J.; Navarra, M. The Effects of Aggregate Properties on Concrete Mix Design and Behaviour. In Canadian Society of Civil Engineering Annual Conference; Springer: Berlin/Heidelberg, Germany, 2021; pp. 457–468. [Google Scholar]

- Yazdi, M.A.; Dejager, E.; Debraekeleer, M.; Gruyaert, E.; Van Tittelboom, K.; De Belie, N. Bond strength between concrete and repair mortar and its relation with concrete removal techniques and substrate composition. Constr. Build. Mater. 2020, 230, 116900. [Google Scholar] [CrossRef]

- Kaplan, M.F. Flexural and compressive strength of concrete as affected by the properties of coarse aggregates. J. Proc. 1959, 55, 1193–1208. [Google Scholar]

- Morimoto, H.; Koyanagi, W. 12 Estimation of Stress Relaxation in Concrete at Early Ages. In Thermal Cracking in Concrete at Early Ages: Proceedings of the International RILEM Symposium; CRC Press: Boca Raton, FL, USA, 1994; p. 95. [Google Scholar]

- Santos, P.M.D. Factors Affecting Bond between New and Old Concrete. ACI Mater. J. 2011, 108, 449–456. [Google Scholar]

- ACI 318R-08; Building Code Requirements for Structural Concrete and Commentary. ACI—American Concrete Institute: Farmington Hills, MI, USA, 2008.

- CSA A23.3; Design of Concrete Structures. Canadian Standards Association, Toronto, ON, Canada, 2004.

- Shaw, D.M.; Sneed, L.H. Interface shear transfer of lightweight-aggregate concretes cast at different times. PCI J. 2014, 59, 130–144. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; van Breugel, K. Autogenous shrinkage in high-performance cement paste: An evaluation of basic mechanisms. Cem. Concr. Res. 2003, 33, 223–232. [Google Scholar] [CrossRef]

- Costa, H.; Júlio, E.; Lourenço, J. New approach for shrinkage prediction of high-strength lightweight aggregate concrete. Constr. Build. Mater. 2012, 35, 84–91. [Google Scholar] [CrossRef]

- Teng, L.; Khayat, K.H. Effect of overlay thickness, fiber volume, and shrinkage mitigation on flexural behavior of thin bonded ultra-high-performance concrete overlay slab. Cem. Concr. Compos. 2022, 134, 104752. [Google Scholar] [CrossRef]

- Safdar, M.; Matsumoto, T.; Kakuma, K. Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC). Compos. Struct. 2016, 157, 448–460. [Google Scholar] [CrossRef]

- Teng, L.; Valipour, M.; Khayat, K.H. Design and performance of low shrinkage UHPC for thin bonded bridge deck overlay. Cem. Concr. Compos. 2021, 118, 103953. [Google Scholar] [CrossRef]

- Pulkit, K.; Saini, B.; Chalak, H.D. Factors Affecting the Bond Between Substrate-Overlay Material. A Review. J. Eng. Sci. Technol. Rev. 2022, 15, 55–69. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J.; Xia, M. Method of enhancing interlayer bond strength in construction scale 3D printing with mortar by effective bond area amplification. Mater. Des. 2019, 169, 107684. [Google Scholar] [CrossRef]

- Megid, W.A.; Khayat, K.H. Effect of structural buildup at rest of self-consolidating concrete on mechanical and transport properties of multilayer casting. Constr. Build. Mater. 2018, 196, 626–636. [Google Scholar] [CrossRef]

- Secrieru, E.; Khodor, J.; Schröfl, C.; Mechtcherine, V. Formation of lubricating layer and flow type during pumping of cement-based materials. Constr. Build. Mater. 2018, 178, 507–517. [Google Scholar] [CrossRef]

- Zanotti, C.; Borges, P.H.; Bhutta, A.; Banthia, N. Bond strength between concrete substrate and metakaolin geopolymer repair mortar: Effect of curing regime and PVA fiber reinforcement. Cem. Concr. Compos. 2017, 80, 307–316. [Google Scholar] [CrossRef]

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Zanotti, C.; Randl, N. Are concrete-concrete bond tests comparable? Cem. Concr. Compos. 2019, 99, 80–88. [Google Scholar] [CrossRef]

- Zanotti, C.; Rostagno, G.; Tingley, B. Further evidence of interfacial adhesive bond strength enhancement through fiber reinforcement in repairs. Constr. Build. Mater. 2018, 160, 775–785. [Google Scholar] [CrossRef]

- Valikhani, A.; Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. Effect of mechanical connectors on interface shear strength between concrete substrates and UHPC: Experimental and numerical studies and proposed design equation. Constr. Build. Mater. 2021, 267, 120587. [Google Scholar] [CrossRef]

- Zhan, P.; He, Z. Application of shrinkage reducing admixture in concrete: A review. Constr. Build. Mater. 2019, 201, 676–690. [Google Scholar] [CrossRef]

- Skominas, R.; Gurskis, V.; Sadzevicius, R.; Damulevicius, V.; Radzevicius, A. Evaluation of cement mortar suitability for repairing concrete in hydraulic structures. KSCE J. Civ. Eng. 2017, 21, 2814–2820. [Google Scholar] [CrossRef]

- Ouyang, X.; Shi, C.; Wu, Z.; Li, K.; Shan, B.; Shi, J. Experimental investigation and prediction of elastic modulus of ultra-high performance concrete (UHPC) based on its composition. Cem. Concr. Res. 2020, 138, 106241. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2006.

- Farzad, M.; Shafieifar, M.; Azizinamini, A. Experimental and numerical study on bond strength between conventional concrete and Ultra High-Performance Concrete (UHPC). Eng. Struct. 2019, 186, 297–305. [Google Scholar] [CrossRef]

- Jahromi, A.J.; Valikhani, A.; Mantawy, I.M.; Azizinamini, A. Service Life Design of Deck Closure Joints in ABC Bridges: Guidelines and Practical Implementation. Front. Built Environ. 2020, 5, 152. [Google Scholar] [CrossRef]

- Harris, D.K.; Sarkar, J.; Ahlborn, T.T.M. Characterization of Interface Bond of Ultra-High-Performance Concrete Bridge Deck Overlays. Transp. Res. Rec. J. Transp. Res. Board 2011, 2240, 40–49. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.; Johari, M.M.; Voo, Y.L. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay. Constr. Build. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Johari, M.A.M. Characterization of the interfacial bond between old concrete substrate and ultra high performance fiber concrete repair composite. Mater. Struct. 2013, 46, 743–753. [Google Scholar] [CrossRef]

- Harris, D.K.; Muñoz, M.A.C.; Gheitasi, A.; Ahlborn, T.M.; Rush, S.V. The Challenges Related to Interface Bond Characterization of Ultra-High-Performance Concrete With Implications for Bridge Rehabilitation Practices. Adv. Civ. Eng. Mater. 2015, 4, 75–101. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Ma, M.; Zhang, S. Experimental study on bonding behaviour of interface between UHPC and concrete substrate. Constr. Build. Mater. 2021, 311, 125360. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Ahmad, S.; Al-Madani, M.K.; Khalid, H.R.; Al-Huri, M.; Al-Fakih, A. Performance of bond strength between ultra-high-performance concrete and concrete substrates (concrete screed and self-compacted concrete): An experimental study. J. Build. Eng. 2022, 51, 104291. [Google Scholar] [CrossRef]

- Zhou, A.; Büyüköztürk, O.; Lau, D. Debonding of concrete-epoxy interface under the coupled effect of moisture and sustained load. Cem. Concr. Compos. 2017, 80, 287–297. [Google Scholar] [CrossRef]

- Ferrándiz-Mas, V.; Sarabia, L.; Ortiz, M.; Cheeseman, C.; García-Alcocel, E. Design of bespoke lightweight cement mortars containing waste expanded polystyrene by experimental statistical methods. Mater. Des. 2016, 89, 901–912. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Abd Elrahman, M.; Sikora, P.; Rucinska, T.; Horszczaruk, E.; Stephan, D. Evaluation of the Effects of Crushed and Expanded Waste Glass Aggregates on the Material Properties of Lightweight Concrete Using Image-Based Approaches. Materials 2017, 10, 1354. [Google Scholar] [CrossRef]

- Vargas, P.; Restrepo-Baena, O.; Tobón, J.I. Microstructural analysis of interfacial transition zone (ITZ) and its impact on the compressive strength of lightweight concretes. Constr. Build. Mater. 2017, 137, 381–389. [Google Scholar] [CrossRef]

- Diamond, S.; Huang, J. The ITZ in concrete—A different view based on image analysis and SEM observations. Cem. Concr. Compos. 2001, 23, 179–188. [Google Scholar] [CrossRef]

- Tschegg, E.K.; Ingruber, M.; Surberg, C.H.; Munger, F. Factors influencing fracture behavior of old-new concrete bonds. Mater. J. 2000, 97, 447–453. [Google Scholar]

- Lo, T.Y.; Cui, H.Z. Interfacial-zone microstructure of lightweight aggregate concrete. Mater. Res. Innov. 2005, 9, 37–39. [Google Scholar] [CrossRef]

- De la Varga, I.; Spragg, R.P.; Muñoz, J.F.; Nickel, C.A.; Graybeal, B.A. Application of Internal Curing in Cementitious Grouts for Prefabricated Bridge Concrete Elements Connections. Adv. Civ. Eng. Mater. 2018, 7, 628–643. [Google Scholar] [CrossRef]

- De la Varga, I.; Spragg, R.P.; Muñoz, J.F.; Helsel, M.A.; Graybeal, B.A. Cracking, Bond, and Durability Performance of Internally Cured Cementitious Grouts for Prefabricated Bridge Element Connections. Sustainability 2018, 10, 3881. [Google Scholar] [CrossRef]

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef]

- Figueiredo, P.; Garcia, S.L.; Cossetti, R.; Leite, A. Bond Performance between Normal-Strength Concrete and Sand-Lightweight Concrete. ACI Struct. J. 2022, 119, 199–213. [Google Scholar]

- Farrag, S.; Yehia, S. Impact of Mix Preparation on Strength and Workability of High Strength Self-Consolidated Lightweight Concrete. IOSR J. Mech. Civ. Eng. 2014, 11, 58–69. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Luo, Y.; Wang, L. Effects of Interface Orientations on Bond Strength between Old Conventional Concrete and New Self-Consolidating Concrete. ACI Struct. J. 2020, 117, 191–201. [Google Scholar]

- Yehia, S.; Abudayyeh, O.; Bhusan, B.; Maurovich, M.; Zalt, A. Self-consolidating concrete mixture with local materials: Proportioning and evaluation. Mater. Sci. Res. J. 2009, 3, 41–64. [Google Scholar]

- Kassimi, F. Development and Performance of Fiber-Reinforced Self-Consolidating Concrete for Repair Applications. Ph.D. Dissertation, University of Sherbrooke, Sherbrooke, QC, Canada, 2013.

- Diab, A.M.; Elmoaty, A.E.M.A.; Eldin, M.R.T. Slant shear bond strength between self compacting concrete and old concrete. Constr. Build. Mater. 2017, 130, 73–82. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Wirkman, C.; Volz, J.S. Performance of Fiber-reinforced Self-consolidating Concrete for Repair of Bridge Substructures. Structures 2018, 15, 320–328. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Verian, K.P. Using Recycled Concrete as Coarse Aggregate in Pavement Concrete. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2012. [Google Scholar]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Gomes, M.; de Brito, J. Structural concrete with incorporation of coarse recycled concrete and ceramic aggregates: Durability performance. Mater. Struct. 2009, 42, 663–675. [Google Scholar] [CrossRef]

- Ceia, F.; Raposo, J.; Guerra, M.; Júlio, E.; de Brito, J. Shear strength of recycled aggregate concrete to natural aggregate concrete interfaces. Constr. Build. Mater. 2016, 109, 139–145. [Google Scholar] [CrossRef]

- Robalo, K.; Carmo, R.D.; Costa, H.; Júlio, E. Experimental study on the interface between low cement recycled aggregates concrete and ultra-high durability concrete. Constr. Build. Mater. 2021, 304, 124603. [Google Scholar] [CrossRef]

- Beushausen, H.; Höhlig, B.; Talotti, M. The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ. Cem. Concr. Res. 2017, 92, 84–91. [Google Scholar] [CrossRef]

- Beushausen, H. The influence of precast surface moisture condition on overlay bond strength. Concr. Plant Int. 2015, 1, 144–147. [Google Scholar]

- Shearrer, A.J.; Riding, K.A.; Peterman, R.J. Effects of Concrete Moisture on Polymer Overlay Bond over New Concrete, Kansas; Department of Transportation, Bureau of Materials & Research: Washington, DC, USA, 2015.

- Omar, B.; Fattoum, K.; Maissen, B.; Farid, B. Influence of the roughness and moisture of the substrate surface on the bond between old and new concrete. Contemp. Eng. Sci. 2010, 3, 139–147. [Google Scholar]

- De la Varga, I.; Muñoz, J.; Bentz, D.; Spragg, R.; Stutzman, P.; Graybeal, B. Grout-concrete interface bond performance: Effect of interface moisture on the tensile bond strength and grout microstructure. Constr. Build. Mater. 2018, 170, 747–756. [Google Scholar] [CrossRef]

- Bissonnette, B.; Vaysburd, A.M.; von Fay, K.F. Best practices for Preparing Concrete Surfaces Prior to Repairs and Overlays. 2012. Available online: https://www.studocu.com/en-za/document/durban-university-of-technology/civil-engineering-practice-ii/best-practices-for-preparing-concrete-surfaces-prior-to-repairs-and-overlays/9309633 (accessed on 13 March 2024).

- Courard, L.; Lenaers, J.-F.; Michel, F.; Garbacz, A. Saturation level of the superficial zone of concrete and adhesion of repair systems. Constr. Build. Mater. 2011, 25, 2488–2494. [Google Scholar] [CrossRef]

- Iovinella, I.; Prota, A.; Mazzotti, C. Influence of surface roughness on the bond of FRP laminates to concrete. Constr. Build. Mater. 2013, 40, 533–542. [Google Scholar] [CrossRef]

- Savoia, M.; Mazzotti, C.; Ferracuti, B. Mode II fracture energy and interface law for FRP concrete bonding with different concrete surface preparations. In Proceedings of the FRAMCOS-6 Conference Proceedings, Catania, Italy, 17–22 June 2007. [Google Scholar]

- Garbacz, A.; Górka, M.; Courard, L. Effect of concrete surface treatment on adhesion in repair systems. Mag. Concr. Res. 2005, 57, 49–60. [Google Scholar] [CrossRef]

- Austin, S.; Robins, P.; Pan, Y. Shear bond testing of concrete repairs. Cem. Concr. Res. 1999, 29, 1067–1076. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Hooton, R.; Zhang, X. Effects of interface roughness and interface adhesion on new-to-old concrete bonding. Constr. Build. Mater. 2017, 151, 582–590. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.; Johari, M.M.; Ratnam, M. The relationship between substrate roughness parameters and bond strength of ultra high-performance fiber concrete. J. Adhes. Sci. Technol. 2013, 27, 1790–1810. [Google Scholar] [CrossRef]

- EL Afandi, M.; Yehia, S.; Landolsi, T.; Qaddoumi, N.; Elchalakani, M. Concrete-to-concrete bond Strength: A review. Constr. Build. Mater. 2023, 363, 129820. [Google Scholar] [CrossRef]

- Fiebrich, M.H. Influence of the surface roughness on the adhesion between concrete and gunite mortars overlays. In Proceedings of the 2nd Bolomey Workshop Adherence Young Old Concrete Wittmann Aedification Verl. Unterengstringen, Freiburg, Germany, 1 April 1994; pp. 107–114. [Google Scholar]

- British Standards Institution. Eurocode 2: Design of Concrete Structures; BSI: London, UK, 1992. [Google Scholar]

- 3102 R-2013; Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays, and Concrete Repair, Guidel. International C.R. Institute: Los Angeles, CA, USA, 2013.

- Júlio, E.N.B.S.; Branco, F.A.B.; Silva, V.D. Concrete-to-concrete bond strength. Influence of the roughness of the substrate surface. Constr. Build. Mater. 2004, 18, 675–681. [Google Scholar] [CrossRef]

- Abu-Tair, A.I.; Rigden, S.R.; Burley, E. Testing the bond between repair materials and concrete substrate. Mater. J. 1996, 93, 553–558. [Google Scholar]

- Yamamoto, Y. Retarders for Concrete, and Their Effects on Setting-Time and Shrinkage. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 1972. [Google Scholar]

- Aïtcin, P.-C. Retarders. In Science and Technology of Concrete Admixtures; Elsevier: Amsterdam, The Netherlands, 2016; pp. 395–404. [Google Scholar] [CrossRef]

- C09 Committee, Specification for Chemical Admixtures for Concrete, ASTM International, n.d. Available online: https://www.astm.org/c0494_c0494m-19.html (accessed on 12 January 2024).

- Zhang, Z.; Chen, H.; Zhang, Y. Surface treatment of concrete by retarder: Investigation of pattern change and preliminary application. J. Build. Eng. 2021, 36, 102123. [Google Scholar] [CrossRef]

- Santos, P.M.D.; Júlio, E.N.B.S.; Silva, V.D. Correlation between concrete-to-concrete bond strength and the roughness of the substrate surface. Constr. Build. Mater. 2007, 21, 1688–1695. [Google Scholar] [CrossRef]

- Semendary, A.A.; Svecova, D. Factors affecting bond between precast concrete and cast in place ultra high performance concrete (UHPC). Eng. Struct. 2020, 216, 110746. [Google Scholar] [CrossRef]

- Dąbrowski, M.; Glinicki, M.A.; Gibas, K.; Antolik, A.; Dziedzic, K. Influence of Surface Retarders on Texture Profile and Durability of Upper Layer of Exposed Aggregate Concrete Pavement. 2019. Available online: https://docs.lib.purdue.edu/icdcs/2018/pse/16/ (accessed on 25 January 2024).

- Darter, M.I.; Barenberg, E.J. Bonded Concrete Overlays: Construction and Performance; US Army Engineer Waterways Experiment Station, Geotechnical Laboratory: Vicksburg, MI, USA, 1980. [Google Scholar]

- Schroeder, C.J.; Britson, R.A.; Bergren, J.V. Bonded, Thin-Lift, Non-Reinforced Portland Cement Concrete Resurfacing. 1977. Available online: https://trid.trb.org/View/483744 (accessed on 27 December 2023).

- Felt, E.J. Resurfacing and patching concrete pavements with bonded concrete. In Proceedings of the Highway Research Board Proceedings, Washington, DC, USA, 17–20 January 1956. [Google Scholar]

- Santos, P.M.D.; Júlio, E.N.B.S. A state-of-the-art review on roughness quantification methods for concrete surfaces. Constr. Build. Mater. 2013, 38, 912–923. [Google Scholar] [CrossRef]

- ElKhatib, L.W.; Elkordi, A.; Khatib, J. Methods and Surface Materials Repair for Concrete Structures—A Review. BAU J. Sci. Technol. 2023, 4, 7. [Google Scholar] [CrossRef]

- Bissonnette, B.; Courard, L.; Garbacz, A. Concrete Surface Engineering, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Hydrodemolition, A.O. Use of Hydrodemolition. To Remove Deteriorated Concrete from Bridge Decks. Transp. Res. Rec. 1490, 83. Available online: https://onlinepubs.trb.org/Onlinepubs/trr/1995/1490/1490-011.pdf (accessed on 2 February 2024).

- Sakota, K. Bond Characteristics of Construction Joint of the Concrete Treated Surface by Water Jet Method. J. Jet Flow Eng. 2005, 22, 16–20. [Google Scholar]

- Habel, K.; Denarié, E.; Brühwiler, E. Experimental Investigation of Composite Ultra-High-Performance Fiber-Reinforced Concrete and Conventional Concrete Members. ACI Struct. J. 2007, 104, 93–101. [Google Scholar] [CrossRef]

- Silfwerbrand, J.; Paulsson, J. Better bonding of bridge deck overlays. Concr. Int. 1998, 20, 56–61. [Google Scholar]

- Sono, T.; Tanikura, I.; Sainoki, A.; Schwartzkopff, A.K.; Obara, Y. Optimization of chipping parameters to mitigate the damage in a concrete substrate using a discontinuum modelling approach. Constr. Build. Mater. 2020, 258, 119658. [Google Scholar] [CrossRef]

- Austin, S.; Robins, P.; Pan, Y. Tensile bond testing of concrete repairs. Mater. Struct. 1995, 28, 249–259. [Google Scholar] [CrossRef]

- Tanikura, I.; Shintani, R.; Sainoki, A.; Watanabe, S.; Obara, Y. Quantitative comparison of chipping- and hydrodemolition-induced microscopic damage evolution in concrete substrates. Constr. Build. Mater. 2018, 164, 193–205. [Google Scholar] [CrossRef]

- Son, J.-S.; Song, C.; Chin, W.-J.; Kim, Y.-J.; Lee, J.-Y. Experimental Evaluation of Bond Strength between Setting Retarder Added Concrete and Normal Concrete. Adv. Civ. Eng. 2023, 2023, 1597449. [Google Scholar] [CrossRef]

- Bissonnette, B.; Courard, L.; Fowler, D.W.; Granju, J.-L. Bonded Cement-Based Material Overlays for the Repair, the Lining or the Strengthening of Slabs or Pavements: State-of-the-Art Report of the RILEM Technical Committee 193-RLS; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Kumar, P.; Patnaik, A.; Chaudhary, S. A review on application of structural adhesives in concrete and steel–concrete composite and factors influencing the performance of composite connections. Int. J. Adhes. Adhes. 2017, 77, 1–14. [Google Scholar] [CrossRef]

- Al-Zu’bi, M.; Fan, M.; Anguilano, L. Advances in bonding agents for retrofitting concrete structures with fibre reinforced polymer materials: A review. Constr. Build. Mater. 2022, 330, 127115. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Quan, D.; Urdániz, J.L.; Ivanković, A. Enhancing mode-I and mode-II fracture toughness of epoxy and carbon fibre reinforced epoxy composites using multi-walled carbon nanotubes. Mater. Des. 2018, 143, 81–92. [Google Scholar] [CrossRef]

- Park, J.K.; Kim, M.O. The effect of different exposure conditions on the pull-off strength of various epoxy resins. J. Build. Eng. 2021, 38, 102223. [Google Scholar] [CrossRef]

- Çolak, A.; Çoşgun, T.; Bakırcı, A.E. Effects of environmental factors on the adhesion and durability characteristics of epoxy-bonded concrete prisms. Constr. Build. Mater. 2009, 23, 758–767. [Google Scholar] [CrossRef]

- Lau, D.; Büyüköztürk, O. Fracture characterization of concrete/epoxy interface affected by moisture. Mech. Mater. 2010, 42, 1031–1042. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Aziz, O.Q. Stresses, deformations and damages of various joints in precast concrete segmental box girder bridges subjected to direct shear loading. Eng. Struct. 2020, 206, 110151. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Aziz, O.Q. Shear behavior of dry and epoxied joints in precast concrete segmental box girder bridges under direct shear loading. Eng. Struct. 2019, 182, 89–100. [Google Scholar] [CrossRef]

- Frigione, M.; Aiello, M.A.; Naddeo, C. Water effects on the bond strength of concrete/concrete adhesive joints. Constr. Build. Mater. 2006, 20, 957–970. [Google Scholar] [CrossRef]

- Daneshvar, D.; Deix, K.; Robisson, A. Effect of casting and curing temperature on the interfacial bond strength of epoxy bonded concretes. Constr. Build. Mater. 2021, 307, 124328. [Google Scholar] [CrossRef]

- Modesti, L.A.; de Vargas, A.S.; Schneider, E.L. Repairing concrete with epoxy adhesives. Int. J. Adhes. Adhes. 2020, 101, 102645. [Google Scholar] [CrossRef]

- Xiong, G.; Luo, B.; Wu, X.; Li, G.; Chen, L. Influence of silane coupling agent on quality of interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Compos. 2006, 28, 97–101. [Google Scholar] [CrossRef]

- Newlands, M.; Khosravi, N.; Jones, R.; Chernin, L. Mechanical performance of statically loaded flat face epoxy bonded concrete joints. Mater. Struct. 2018, 51, 49. [Google Scholar] [CrossRef]

- Yeon, J.; Song, Y.; Kim, K.K.; Kang, J. Effects of Epoxy Adhesive Layer Thickness on Bond Strength of Joints in Concrete Structures. Materials 2019, 12, 2396. [Google Scholar] [CrossRef] [PubMed]

- Delatte, N.J.; Williamson, M.S.; Fowler, D.W. Bond Strength Development with Maturity of High-Early-Strength Bonded Concrete Overlays. ACI Mater. J. 2000, 97, 201–207. [Google Scholar] [CrossRef]

- Al-Madani, M.K.; Al-Osta, M.A.; Ahmad, S.; Khalid, H.R.; Al-Huri, M. Interfacial bond behavior between ultra high performance concrete and normal concrete substrates. Constr. Build. Mater. 2022, 320, 126229. [Google Scholar] [CrossRef]

- Ray, I.; Davalos, J.F.; Luo, S. Interface evaluations of overlay-concrete bi-layer composites by a direct shear test method. Cem. Concr. Compos. 2005, 27, 339–347. [Google Scholar] [CrossRef]

- Ganesh, P.; Murthy, A.R. Simulation of surface preparations to predict the bond behaviour between normal strength concrete and ultra-high performance concrete. Constr. Build. Mater. 2020, 250, 118871. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Li, Y. Influence of interfacial parameters and testing methods on UHPC–NSC bond strength: Slant shear vs. direct tensile testing. Cem. Concr. Compos. 2022, 131, 104568. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Peng, G.; Niu, D.; Hu, X.; Pan, B.; Zhong, S. Experimental study of the interfacial bond strength between cementitious grout and normal concrete substrate. Constr. Build. Mater. 2020, 273, 122057. [Google Scholar] [CrossRef]

- Courard, L.; Piotrowski, T.; Garbacz, A. Near-to-surface properties affecting bond strength in concrete repair. Cem. Concr. Compos. 2014, 46, 73–80. [Google Scholar] [CrossRef]

- Rith, M.; Kim, Y.K.; Lee, S.W.; Park, J.Y.; Han, S.H. Analysis of in situ bond strength of bonded concrete overlay. Constr. Build. Mater. 2016, 111, 111–118. [Google Scholar] [CrossRef]

- Yıldırım, G.; Şahmaran, M.; Al-Emam, M.K.M.; Hameed, R.K.H.; Al-Najjar, Y.; Lachemi, M. Effects of Compressive Strength, Autogenous Shrinkage, and Testing Methods on Bond Behavior of High-Early-Strength Engineered Cementitious Composites. ACI Mater. J. 2015, 112, 409–418. [Google Scholar] [CrossRef]

- Holland, R.; Du, J.; Obeidah, A.; Meng, W.; Nassif, H. Early-age crack-free ultra-high-performance concrete under restrained ring test for large-scale production as an overlay. Constr. Build. Mater. 2023, 409, 133949. [Google Scholar] [CrossRef]

- Decter, M. Durable concrete repair—Importance of compatibility and low shrinkage. Constr. Build. Mater. 1997, 11, 267–273. [Google Scholar] [CrossRef]

- Petcherdchoo, A.; Hongubon, T.; Thanasisathit, N.; Punthutaecha, K.; Jang, S.-H. Effect of Curing Time on Bond Strength between Reinforcement and Fly-ash Geopolymer Concrete. Appl. Sci. Eng. Prog. 2020, 13, 127–135. [Google Scholar] [CrossRef]

- Tanyildizi, H. Variance analysis of crack characteristics of structural lightweight concrete containing silica fume exposed to high temperature. Constr. Build. Mater. 2013, 47, 1154–1159. [Google Scholar] [CrossRef]

- Behforouz, B.; Tavakoli, D.; Gharghani, M.; Ashour, A. Bond strength of the interface between concrete substrate and overlay concrete containing fly ash exposed to high temperature. Structures 2023, 49, 183–197. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.M.; Hao, H. Effect of aggregate size on bond behaviour between basalt fibre reinforced polymer sheets and concrete. Compos. Part B Eng. 2019, 158, 459–474. [Google Scholar] [CrossRef]

- Hu, J.; Wang, K. Effect of coarse aggregate characteristics on concrete rheology. Constr. Build. Mater. 2011, 25, 1196–1204. [Google Scholar] [CrossRef]

- Kumar, P.; Patnaik, A.; Chaudhary, S. Effect of bond layer thickness on behaviour of steel-concrete composite connections. Eng. Struct. 2018, 177, 268–282. [Google Scholar] [CrossRef]

- Laskar, S.M.; Talukdar, S. Preparation and tests for workability, compressive and bond strength of ultra-fine slag based geopolymer as concrete repairing agent. Constr. Build. Mater. 2017, 154, 176–190. [Google Scholar] [CrossRef]

- Bentz, D.P.; De la Varga, I.; Muñoz, J.F.; Spragg, R.P.; Graybeal, B.A.; Hussey, D.S.; Jacobson, D.L.; Jones, S.Z.; LaManna, J.M. Influence of substrate moisture state and roughness on interface microstructure and bond strength: Slant shear vs. pull-off testing. Cem. Concr. Compos. 2017, 87, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Wen, J.; Li, X.; Yang, X. Permeability of the bonding interface between strain-hardening cementitious composite and normal concrete. AIP Adv. 2019, 9, 055107. [Google Scholar] [CrossRef]

- Lukovic, M.; Ye, G. Effect of Moisture Exchange on Interface Formation in the Repair System Studied by X-ray Absorption. Materials 2015, 9, 2. [Google Scholar] [CrossRef]

- Emmons, P.H. Concrete Repair and Maintenance Illustrated: Problem Analysis; Repair Strategy; Techniques; John Wiley & Sons: Hoboken, NJ, USA, 1992. [Google Scholar]

- Sabah, S.A.; Hassan, M.; Bunnori, N.M.; Johari, M.M. Bond strength of the interface between normal concrete substrate and GUSMRC repair material overlay. Constr. Build. Mater. 2019, 216, 261–271. [Google Scholar] [CrossRef]

- Pultorak, A.S. The Effects of Common Surface Pretreatments on the Shear Strength of Bonded Concrete Overlays. Master’s Thesis, University of Colorado at Denver, Denver, CO, USA, 2016. [Google Scholar]

- Silfwerbrand, J. Shear bond strength in repaired concrete structures. Mater. Struct. 2003, 36, 419–424. [Google Scholar] [CrossRef]

- Jafarinejad, S.; Rabiee, A.; Shekarchi, M. Experimental investigation on the bond strength between Ultra high strength Fiber Reinforced Cementitious Mortar & conventional concrete. Constr. Build. Mater. 2019, 229, 116814. [Google Scholar] [CrossRef]

- Mirmoghtadaei, R.; Mohammadi, M.; Samani, N.A.; Mousavi, S. The impact of surface preparation on the bond strength of repaired concrete by metakaolin containing concrete. Constr. Build. Mater. 2015, 80, 76–83. [Google Scholar] [CrossRef]

- Naresh, J.; Lavanya, B.; Kumar, K.S. A Study on bond strength of normal concrete to high volume fly ash concrete. IOP Conf. Series: Mater. Sci. Eng. 2021, 1057, 012082. [Google Scholar] [CrossRef]

- Mack, V.; Salehfard, R.; Habibnejad Korayem, A. Comparative study of the effects of key factors on concrete-to-concrete bond strength. Civ. Eng. Infrastruct. J. 2023, 57, 205–223. [Google Scholar] [CrossRef]

- Xiong, G.; Liu, J.; Li, G.; Xie, H. A way for improving interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Res. 2002, 32, 1877–1881. [Google Scholar] [CrossRef]

- Youssef, G.; Loulou, L.; Chataigner, S.; Caré, S.; Flety, A.; Le Roy, R.; Bornert, M.; Aubagnac, C. Analysis of the behaviour of a bonded joint between laminated wood and ultra high performance fibre reinforced concrete using push-out test. Constr. Build. Mater. 2014, 53, 381–391. [Google Scholar] [CrossRef]

- Rashid, K.; Ahmad, M.; Ueda, T.; Deng, J.; Aslam, K.; Nazir, I.; Sarwar, M.A. Experimental investigation of the bond strength between new to old concrete using different adhesive layers. Constr. Build. Mater. 2020, 249, 118798. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Liu, R.; Dong, X.; Liu, Z.; Liu, H. The influence of different bond primers on the bond strength of concrete overlays and the microstructure of the overlays transition zone. Cem. Concr. Compos. 2021, 119, 104023. [Google Scholar] [CrossRef]

- Zhao, K.; Hu, Z.; Wang, B.; Li, Q.; Xu, Y. Effect of roughness and adhesive on the strength of concrete-to-concrete interfaces cast from 3D-printed prefabricated plastic formworks. Constr. Build. Mater. 2023, 368, 130423. [Google Scholar] [CrossRef]

- Oktavia, A.; Pratiwi, A.Y.; Chairunnisa, N. Performance Of Concrete-To-Concrete Bond Strength in Wetland Area. E3S Web Conf. 2024, 476, 01062. [Google Scholar] [CrossRef]

- Xia, J.; Shan, K.-Y.; Wu, X.-H.; Gan, R.-L.; Jin, W.-L. Shear-friction behavior of concrete-to-concrete interface under direct shear load. Eng. Struct. 2021, 238, 112211. [Google Scholar] [CrossRef]

- Ju, Y.; Shen, T.; Wang, D. Bonding behavior between reactive powder concrete and normal strength concrete. Constr. Build. Mater. 2020, 242, 118024. [Google Scholar] [CrossRef]

- Mohamad, M.E.; Ibrahim, I.S. Interface Shear Strength of Concrete-to-Concrete Bond with and without Projecting Steel Reinforcement. J. Teknol. 2015, 75. [Google Scholar] [CrossRef]

- Rashid, M.H.; Molla, M.; Taki, I.M. Effect of Elevated Temperature on Bond Strength of Concrete. Mater. Sci. Forum 2019, 972, 26–33. [Google Scholar] [CrossRef]

- Dybeł, P.; Wałach, D. Evaluation of the Development of Bond Strength between Two Concrete Layers. IOP Conf. Series: Mater. Sci. Eng. 2017, 245, 032056. [Google Scholar] [CrossRef]

- Baloch, W.L.; Siad, H.; Lachemi, M.; Sahmaran, M. A review on the durability of concrete-to-concrete bond in recent rehabilitated structures. J. Build. Eng. 2021, 44, 103315. [Google Scholar] [CrossRef]

- Şahin, Y.; Akkaya, Y.; Taşdemir, M.A. Effects of freezing conditions on the frost resistance and microstructure of concrete. Constr. Build. Mater. 2021, 270, 121458. [Google Scholar] [CrossRef]

- Pigeon, M.; Gagné, R.; Aïtcin, P.-C.; Banthia, N. Freezing and thawing tests of high-strength concretes. Cem. Concr. Res. 1991, 21, 844–852. [Google Scholar] [CrossRef]

- Zhang, W.; Pi, Y.; Kong, W.; Zhang, Y.; Wu, P.; Zeng, W.; Yang, F. Influence of damage degree on the degradation of concrete under freezing-thawing cycles. Constr. Build. Mater. 2020, 260, 119903. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of recycled aggregate concrete containing low- and high-volume fly ash against the combined action of freeze–thaw cycles and sulfate attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

- Jiang, L.; Niu, D.; Yuan, L.; Fei, Q. Durability of concrete under sulfate attack exposed to freeze–thaw cycles. Cold Reg. Sci. Technol. 2015, 112, 112–117. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Khoshkbijari, R.K. Bonding durability of polymer-modified concrete repair overlays under freeze–thaw conditions. Mag. Concr. Res. 2017, 69, 1268–1275. [Google Scholar] [CrossRef]

- Xie, N.; Akin, M.; Shi, X. Permeable concrete pavements: A review of environmental benefits and durability. J. Clean. Prod. 2019, 210, 1605–1621. [Google Scholar] [CrossRef]

- Zhong, S.; Hu, X.; Yang, B.; Peng, G. Bond performance between cementitious grout and normal concrete subjected to freeze–thaw damage. Constr. Build. Mater. 2023, 405, 133344. [Google Scholar] [CrossRef]

- Tian, J.; Wu, X.; Zheng, Y.; Hu, S.; Ren, W.; Du, Y.; Wang, W.; Sun, C.; Ma, J.; Ye, Y. Investigation of damage behaviors of ECC-to-concrete interface and damage prediction model under salt freeze-thaw cycles. Constr. Build. Mater. 2019, 226, 238–249. [Google Scholar] [CrossRef]

- Fan, J.; Wu, L.; Zhang, B. Influence of Old Concrete Age, Interface Roughness and Freeze-Thawing Attack on New-to-Old Concrete Structure. Materials 2021, 14, 1057. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.S.; Qudoos, A.; Jakhrani, S.H.; Lee, J.B.; Kim, H.G. Influence of Coarse Aggregates and Silica Fume on the Mechanical Properties, Durability, and Microstructure of Concrete. Materials 2019, 12, 3324. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Hu, Y.; Tang, Z.; Wang, K.; Li, Y.; Li, W. Deterioration of concrete under coupled aggressive actions associated with load, temperature and chemical attacks: A comprehensive review. Constr. Build. Mater. 2022, 322, 126466. [Google Scholar] [CrossRef]

- Maes, M.; De Belie, N. Resistance of concrete and mortar against combined attack of chloride and sodium sulphate. Cem. Concr. Compos. 2014, 53, 59–72. [Google Scholar] [CrossRef]

- Gao, S.; Jin, J.; Hu, G.; Qi, L. Experimental investigation of the interface bond properties between SHCC and concrete under sulfate attack. Constr. Build. Mater. 2019, 217, 651–663. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Iqbal, H.W.; Khushnood, R.A.; Baloch, W.L.; Nawaz, A.; Tufail, R.F. Influence of graphite nano/micro platelets on the residual performance of high strength concrete exposed to elevated temperature. Constr. Build. Mater. 2020, 253, 119029. [Google Scholar] [CrossRef]

- Aseem, A.; Baloch, W.L.; Khushnood, R.A.; Mushtaq, A. Structural health assessment of fire damaged building using non-destructive testing and micro-graphical forensic analysis: A case study. Case Stud. Constr. Mater. 2019, 11, e00258. [Google Scholar] [CrossRef]

- Memon, S.A.; Shah, S.F.A.; Khushnood, R.A.; Baloch, W.L. Durability of sustainable concrete subjected to elevated temperature—A review. Constr. Build. Mater. 2019, 199, 435–455. [Google Scholar] [CrossRef]

- Abo Sabah, S.H.; Zainal, N.L.; Muhamad Bunnori, N.; Megat Johari, M.A.; Hassan, M.H. Interfacial behavior between normal substrate and green ultra-high-performance fiber-reinforced concrete under elevated temperatures. Struct. Concr. 2019, 20, 1896–1908. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, X.; Qiao, J.; Guo, Y.; Hu, G. Study on the bonding properties of Engineered Cementitious Composites (ECC) and existing concrete exposed to high temperature. Constr. Build. Mater. 2019, 196, 330–344. [Google Scholar] [CrossRef]

- Santos, P.M.D.; Júlio, E.N.B.S. Development of a laser roughness analyser to predict in situ the bond strength of concrete-to-concrete interfaces. Mag. Concr. Res. 2008, 60, 329–337. [Google Scholar] [CrossRef]

- E965 Committee, Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique, ASTM International. 2019. Available online: https://www.astm.org/e0965-15r19.html (accessed on 10 April 2024).

- Abe, H.; Sawa, T.; Kasahara, A. Road Surface Roughness Measuring Device. Google Patents Patent No. US6679106B1, 20 January 2004. Available online: https://patents.google.com/patent/US6679106/sv (accessed on 12 January 2024).

- E17 Committee, Test Method for Measuring Pavement Macrotexture Properties Using the Circular Track Meter, ASTM International, n.d. Available online: https://www.astm.org/e2157-15r19.html (accessed on 10 March 2024).

- Lees, G.; Katekhda, I.-D. Outflow Meter for Measuring Surface Drainage Characteristics. Google Patents Patent No. US4070903A, 31 January 1978. Available online: https://patents.google.com/patent/US4070903A/en (accessed on 17 May 2024).

- Mohammed, A.; Abdullah, A. Scanning electron microscopy (SEM): A review. In Proceedings of the 2018 International Conference on Hydraulics and Pneumatics, Baile Govora, Romania, 7–9 November 2018; pp. 7–9. [Google Scholar]

- Williams, D.B.; Carter, C.B.; Williams, D.B.; Carter, C.B. The Transmission Electron Microscope; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Bankhead, P. Analyzing fluorescence microscopy images with ImageJ. ImageJ 2014, 1, 10-1109. [Google Scholar]

- Scrivener, K.L. Backscattered electron imaging of cementitious microstructures: Understanding and quantification. Cem. Concr. Compos. 2004, 26, 935–945. [Google Scholar] [CrossRef]

- Hindo, K.R. In-place bond testing and surface preparation of concrete. Concr. Int. 1990, 12, 46–48. [Google Scholar]

- Long, A.E.; Murray, A.M. The “Pul l-Off” Partially Destructive Test for Concrete. Spec. Publ. 1984, 82, 327–350. [Google Scholar]

- Guide for Using In-Situ Tensile Pulloff Tests to Evaluate Concrete Surface Repairs and Bonded Overlays; International Concrete Repair Institute, Inc.: Minneapolis, MI, USA, 2022.

- Valipour, M.; Khayat, K.H. Debonding test method to evaluate bond strength between UHPC and concrete substrate. Mater. Struct. 2020, 53, 15. [Google Scholar] [CrossRef]

- Akazawa, S. Splitting tensile test of cylindrical specimens. J. Jpn. Civ. Eng. Inst. 1943, 6, 12–19. [Google Scholar]

- Carneiro, F.L. Tensile strength of concretes. Rilem. Bull. 1953, 13, 103–107. [Google Scholar]

- Zhu, H.; Li, C.; Gao, D.; Yang, L.; Cheng, S. Study on mechanical properties and strength relation between cube and cylinder specimens of steel fiber reinforced concrete. Adv. Mech. Eng. 2019, 11, 1687814019842423. [Google Scholar] [CrossRef]

- Espeche, A.D.; León, J. Estimation of bond strength envelopes for old-to-new concrete interfaces based on a cylinder splitting test. Constr. Build. Mater. 2010, 25, 1222–1235. [Google Scholar] [CrossRef]

- Hu, B.; Meng, T.-F.; Li, Y.; Li, D.-Z.; Chen, L. Dynamic splitting tensile bond behavior of new-to-old concrete interfaces. Constr. Build. Mater. 2021, 281, 122570. [Google Scholar] [CrossRef]

- Figueira, D.; Sousa, C.; Calçada, R.; Neves, A.S. Push-Off Tests in the Study of Cyclic Behavior of Interfaces between Concretes Cast at Different Times. J. Struct. Eng. 2016, 142, 04015101. [Google Scholar] [CrossRef]

- Zanotti, C.; Banthia, N.; Plizzari, G. A study of some factors affecting bond in cementitious fiber reinforced repairs. Cem. Concr. Res. 2014, 63, 117–126. [Google Scholar] [CrossRef]

- C09 Committee, Test Method for Compressive Strength of Cylindrical Concrete Specimens, ASTM International, n.d. Available online: https://www.astm.org/c0039_c0039m-12.html (accessed on 12 May 2024).

- Lee, H.-S.; Jang, H.-O.; Cho, K.-H. Evaluation of Bonding Shear Performance of Ultra-High-Performance Concrete with Increase in Delay in Formation of Cold Joints. Materials 2016, 9, 362. [Google Scholar] [CrossRef]

- Al-Rubaye, M.M.; Yousef, R.F.; Muteb, H.H. Experimental evaluation of bond strength performance between normal concrete substrate and different overlay materials. J. Eng. Sci. Technol. 2020, 15, 4367–4382. [Google Scholar]

- Wang, B.; Li, Q.; Liu, F.; Wang, J.; Xu, S. Shear bond assessment of UHTCC repair using push-out test. Constr. Build. Mater. 2018, 164, 206–216. [Google Scholar] [CrossRef]

- Júlio, E.; Branco, F.A.; Silva, V.D. Reinforced concrete jacketing-interface influence on cyclic loading response. ACI Struct. J. 2008, 105, 471. [Google Scholar]

- Rizzo, E.M.; Sobelman, M.B. Selection criteria for concrete repair materials. Concr. Int. 1989, 11, 46–49. [Google Scholar]

- Zambas, C. Structural Repairs to the Monuments of the Acropolis—The Parthenon. Proc. Inst. Civ. Eng.—Civ. Eng. 1992, 92, 166–176. [Google Scholar] [CrossRef]

- C09 Committee, Test Method for Bond Strength of Epoxy-Resin Systems Used with Concrete By Slant Shear, ASTM International, n.d. Available online: https://www.astm.org/c0882_c0882m-20.html (accessed on 22 June 2024).

- Hu, B.; Li, Y.; Liu, Y. Dynamic slant shear bond behavior between new and old concrete. Constr. Build. Mater. 2020, 238, 117779. [Google Scholar] [CrossRef]

| Surface Preparation Method | Risk of Microcrack Formation | Average Cutting Depth (µm) | ||

|---|---|---|---|---|

| Low | Moderate | High | ||

| Sandblasting | × | 200 | ||

| Shotblasting | × | 1000–2500 (based on time) | ||

| Hydro-demolition | × | N/A | ||

| Waterblasting | × | N/A | ||

| Chipping | × | N/A | ||

| Grinding | × | 200 | ||

| Milling | × | × | 250–800 (based on hand or machine) | |

| Group | Studied Parameter | Type of Bond Test | Major Conclusions | Reference |

|---|---|---|---|---|

| Concrete layer | Compressive strength | Direct shear test | Higher shear capacity in the bond in case of using UHPC as overlay, | [23,166,167] |

| Slant shear test | Stronger connection between concrete layers due to substrate with higher compressive strength, more significant effect of substrate strength than overlay on bond performance | [14,55,77,80,100,168,169,170] | ||

| Pull-off test | Insignificant effect of substrate compressive strength in case of roughening surface | [70,171,172,173] | ||

| Shrinkage and cracking | Three-point bending test, slant shear test, pull-off test | Higher bond durability because of reducing shrinkage, reduction of bond strength by decreasing early-age shrinkage, less significant effect of lower shrinkage on bond rather than overlay thickness | [11,20,26,28,30,31,42,55,61,63,173,174,175] | |

| Binder | Slant shear, pullout and pull-off test | Beneficial impact of geopolymer on bond strength, sensitivity of bond strength of fly ash geopolymer to curing condition, higher bond strength with greater amount of silica fume | [36,40,41,176,177,178] | |

| Aggregates | Pull-off test, slant shear test | Effectiveness of aggregate size on efficiency of surface preparation, increase in bond strength by stiffer aggregates | [17,43,45,46,47,52,179,180] | |

| Age | Direct shear test, slant shear test, splitting tensile test | Significant increase in shear strength of bond by growth of concrete age, increase in bond strength with a higher differential age | [23,54,55,58,121,164] | |

| Density | Slant shear test, splitting tensile test | Lower bond strength with reduction of concrete density | [16,17,58,91,95,107] | |

| Thickness | Pull-off test | Improvement of bond performance as a result of a thicker substrate | [26,52,61,62,63,181] | |

| Workability | Slant shear test, splitting tensile test | Better influence of using superplasticizers on bond strength for increasing workability compared to water content | [64,65,176,182] | |

| Bond state | Moisture content | Slant shear test, pull-off test | Higher bond strength with SSD condition of substrate, negative impact of a wet substrate on bond performance in some cases | [29,63,64,85,108,109,110,112,114,155,158,183,184,185,186] |

| Roughness | Pull-off test | Negative impact of scarification and hammering on bond, monotonic behavior of specimens with sand-blasted substrate surface, necessity of cleaning surface before adding new layer of concrete | [10,15,36,52,120,125,131,132,172,187,188,189,190] | |

| Slant shear test | Interfacial failure of specimens with smooth substrate, effectiveness of wire brushing in increasing bond strength, better applicability of using in-form retarders compared to mechanical surface roughening methods | [25,79,84,100,118,120,125,147,168,169,190,191,192] | ||

| Bonding agent | Slant shear test, bi-surface shear test, flexural test | Good adhesion of epoxy to concrete surface and improvement inthe bond, low early-age shear strength of bond because of using epoxy as bonding agent, reduction of cohesion between ultra-high-performance and normal concrete because of bonding agent | [21,100,150,160,163,170,190,192,193,194,195,196,197,198,199] | |

| Reinforcement and fibers | Direct shear test, splitting tensile test, bi-surface shear test, single-shear test, push-out test | No brittle failure by adding reinforcement crossing the interface, increase in bond strength with higher volume of fiber usage, effectiveness of type of fiber on bond | [21,22,61,83,199,200,201] | |

| Curing conditions | Curing method | Slant shear test, splitting tensile test, flexural test | Beneficial impact of heat and water curing on bond strength, zero strength of bond at curing temperatures of higher than 400 degrees Celsius, higher shear resistance of bond with a longer curing time | [23,68,84,159,178,179,194,202,203,204,205] |

| Environmental Condition | Test Method | Material of Substrate | Material of Overlay | Investigated Parameters | Reference |

|---|---|---|---|---|---|

| Freeze-thaw cycles | Splitting tensile and slant shear test | NC | Cementitious grout | Interfacial shear strength, slant shear angle, number of freeze–thaw cycles, substrate compressive strength | [213] |

| Splitting tensile test | NC | NC | Surface roughness, substrate age, number of freeze–thaw cycles | [216] | |

| Pull-off test | NC | Polymer modified concrete | Number of freeze–thaw cycles, amount of added silica fume, type of modifier polymer, | [211] | |

| Splitting tensile, slant shear test and pull-off test | NC | UHPC | Surface roughness degree, concrete age, number of freeze–thaw cycles, moisture content | [10] | |

| Chemical attack | Splitting tensile and slant shear test | NC | Strain-hardening cementitious composite, RC | Number of sulphate wet–dry cycles, type of overlay | [219] |

| Fire and high temperature | Splitting tensile and slant shear test | NC | Engineered cementitious composite, NC | Ambient temperature, type of overlay, sequence of heating specimens (before and after jacketing) | [225] |

| Splitting tensile, slant shear test, pull-off test, | NC | Green Universiti Sains Malaysia Reinforced Concrete | Temperature, surface roughening method, moisture content | [224] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mokhtari, S.; Hassan, M. Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review. Infrastructures 2024, 9, 171. https://doi.org/10.3390/infrastructures9100171

Mokhtari S, Hassan M. Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review. Infrastructures. 2024; 9(10):171. https://doi.org/10.3390/infrastructures9100171

Chicago/Turabian StyleMokhtari, Sahar, and Munzer Hassan. 2024. "Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review" Infrastructures 9, no. 10: 171. https://doi.org/10.3390/infrastructures9100171

APA StyleMokhtari, S., & Hassan, M. (2024). Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review. Infrastructures, 9(10), 171. https://doi.org/10.3390/infrastructures9100171