Research on the Protection Scheme of a High-Speed Railway Crossing 1000 KV Ultra-High Voltage Transmission Line

Abstract

:1. Introduction

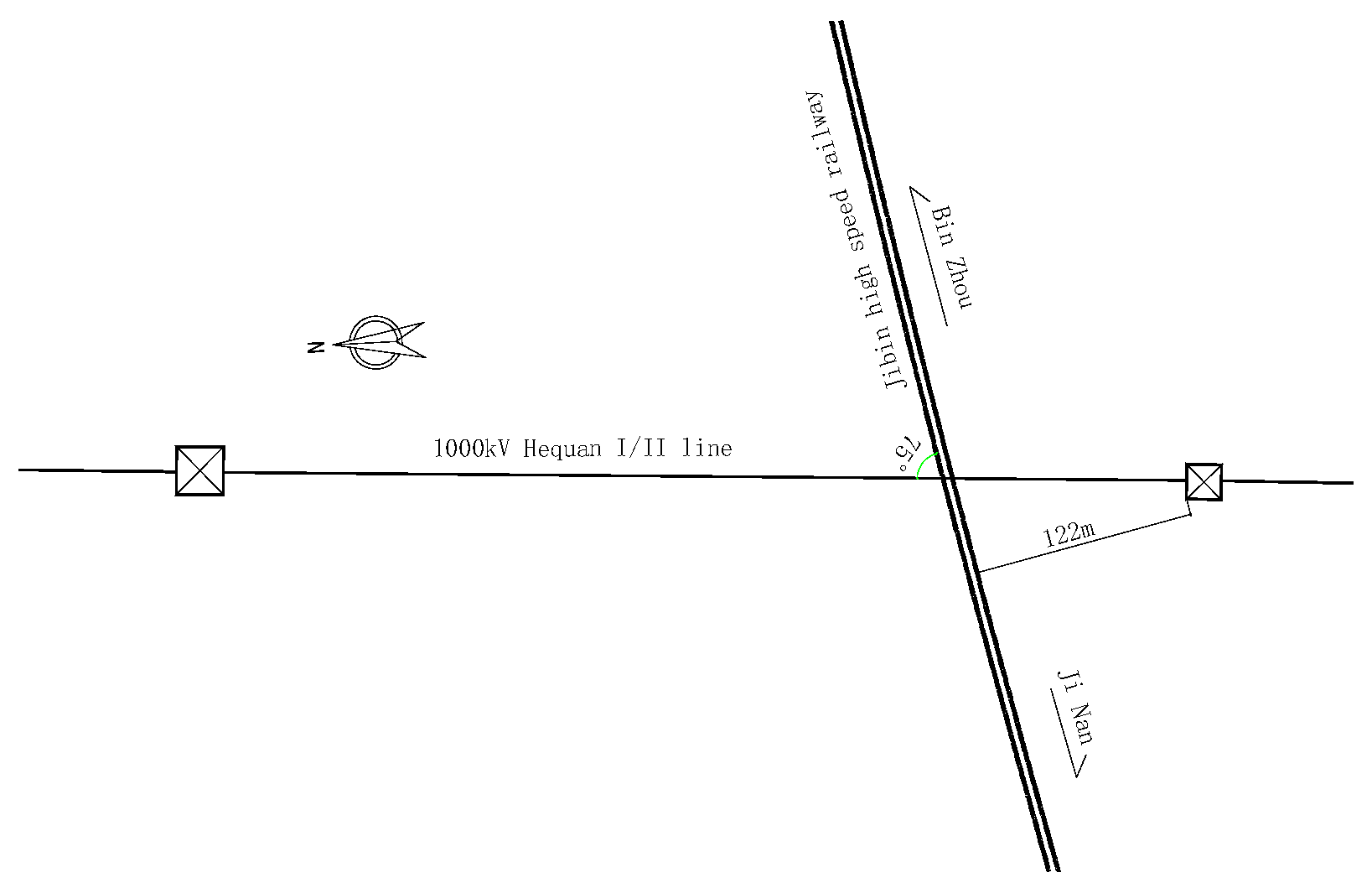

Project Overview

2. Study of the Scope of High-Speed Rail Protection and Line-Break Load

2.1. Study of the Scope of Protection of High-Speed Rail

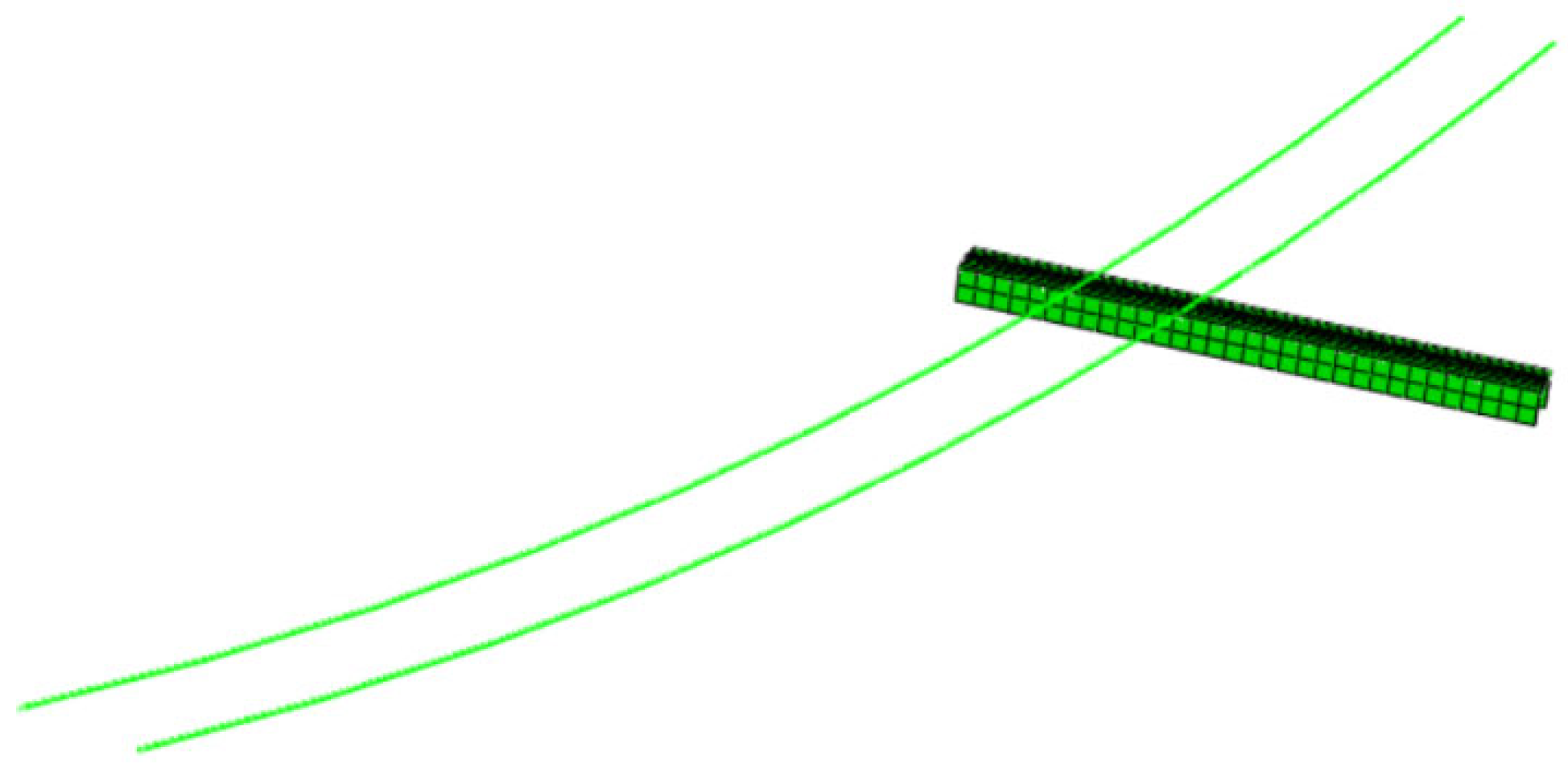

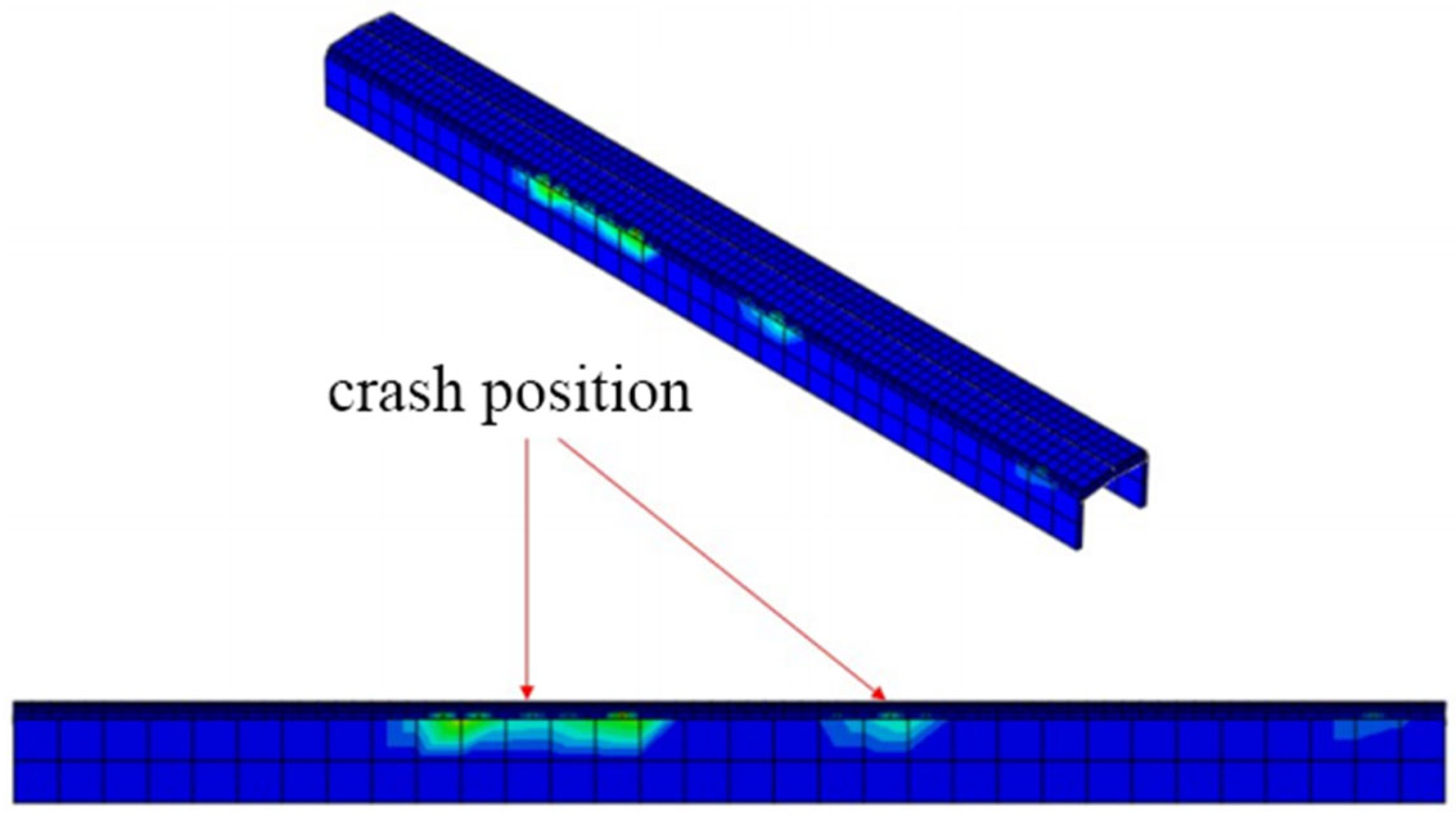

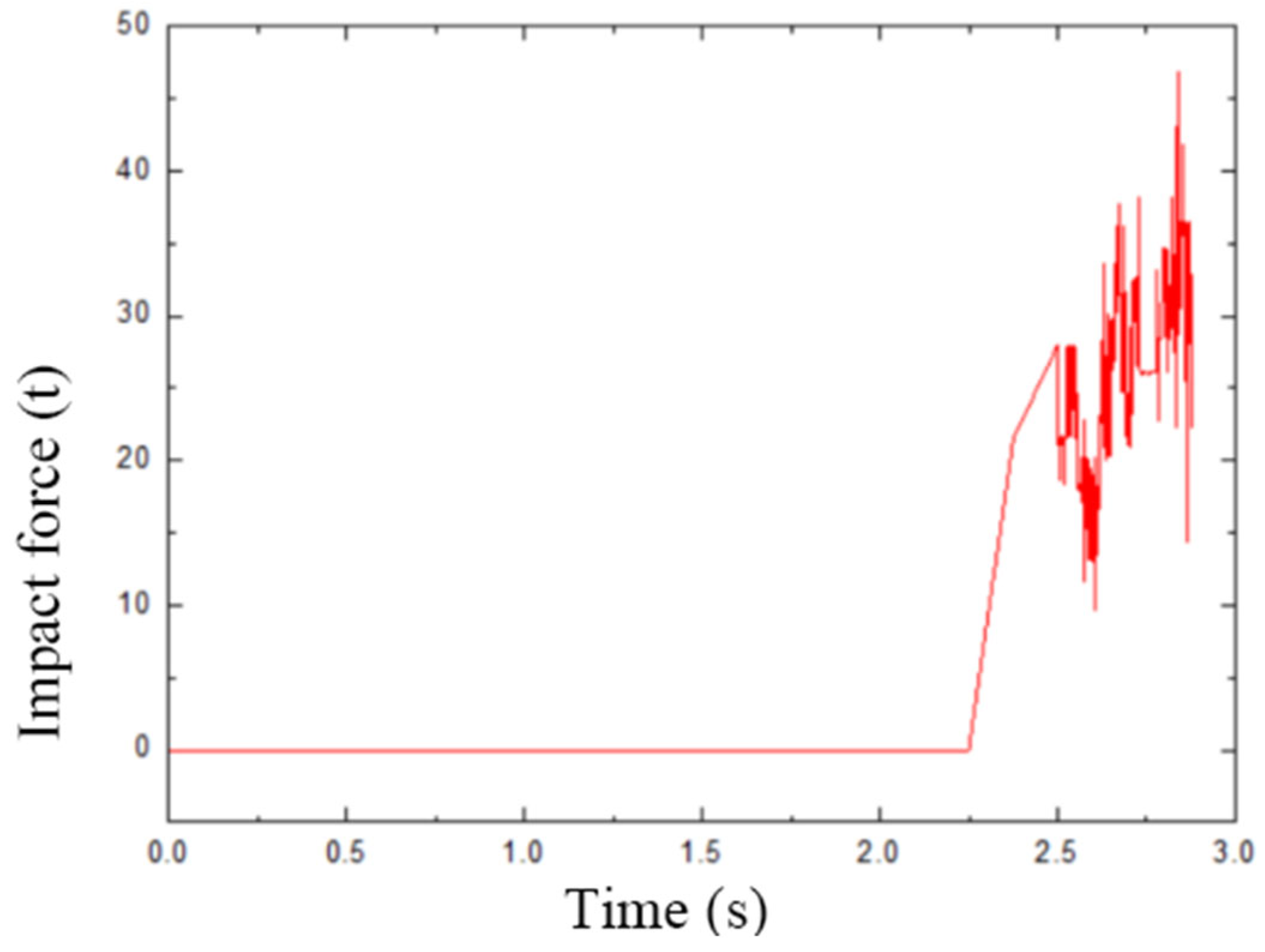

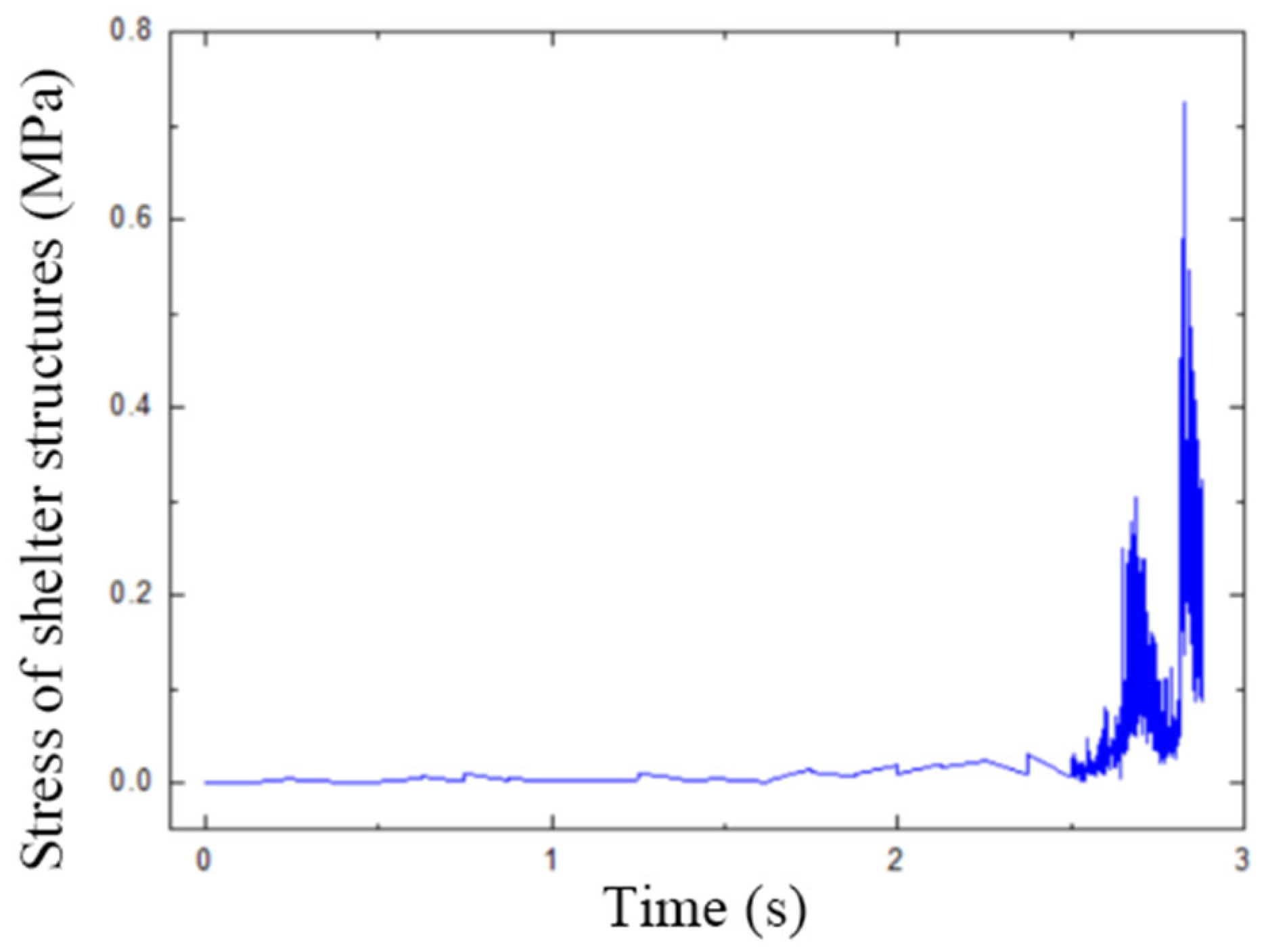

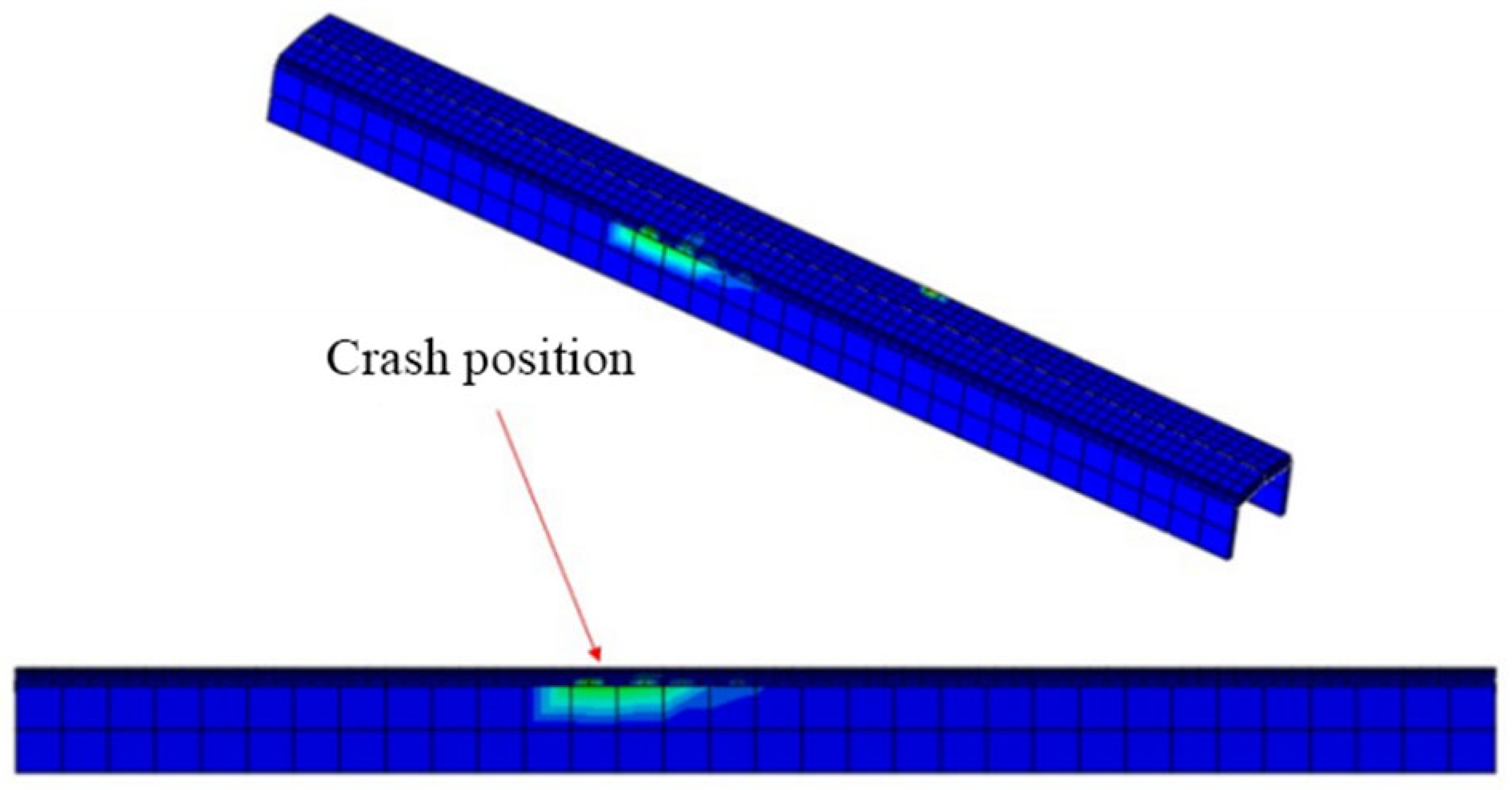

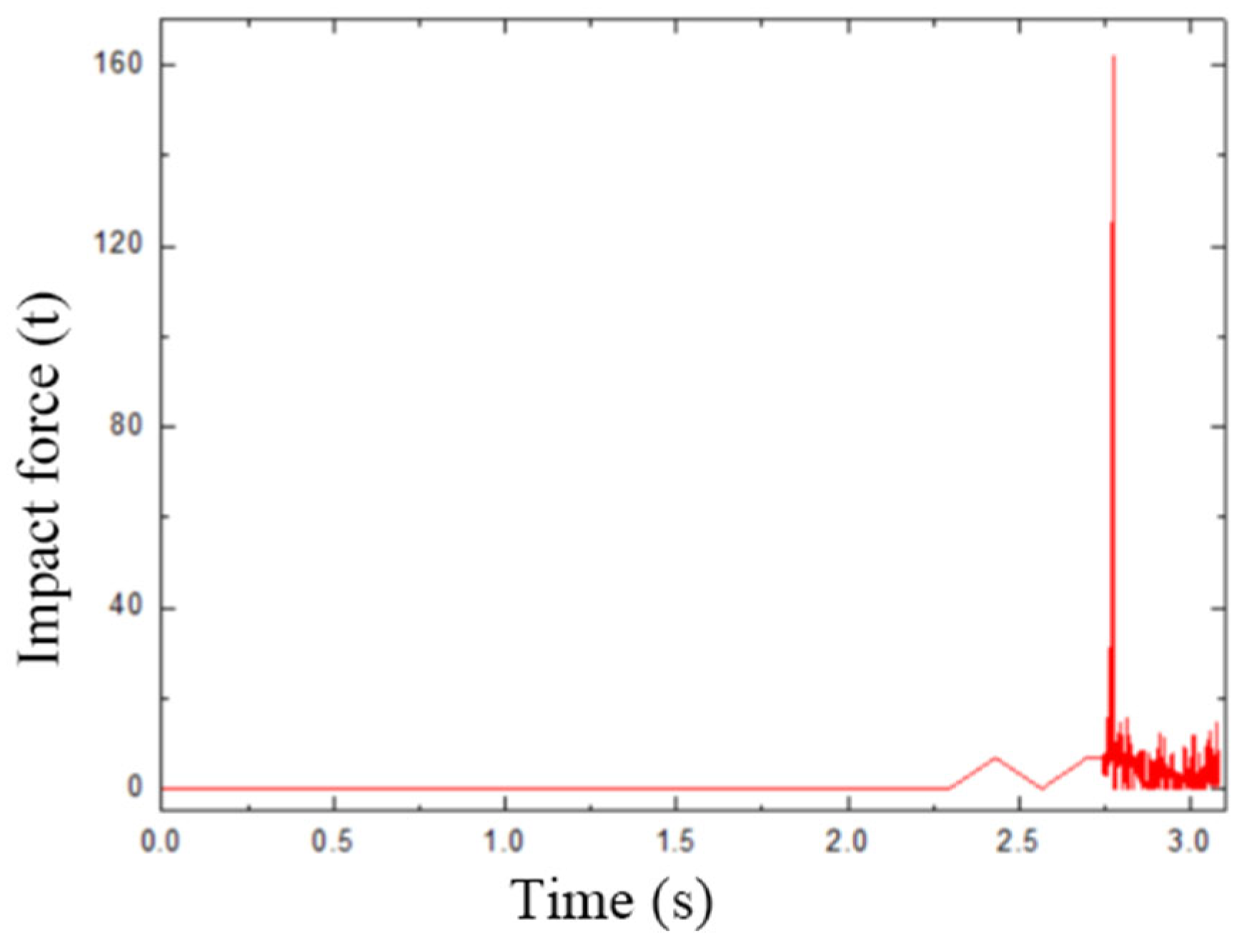

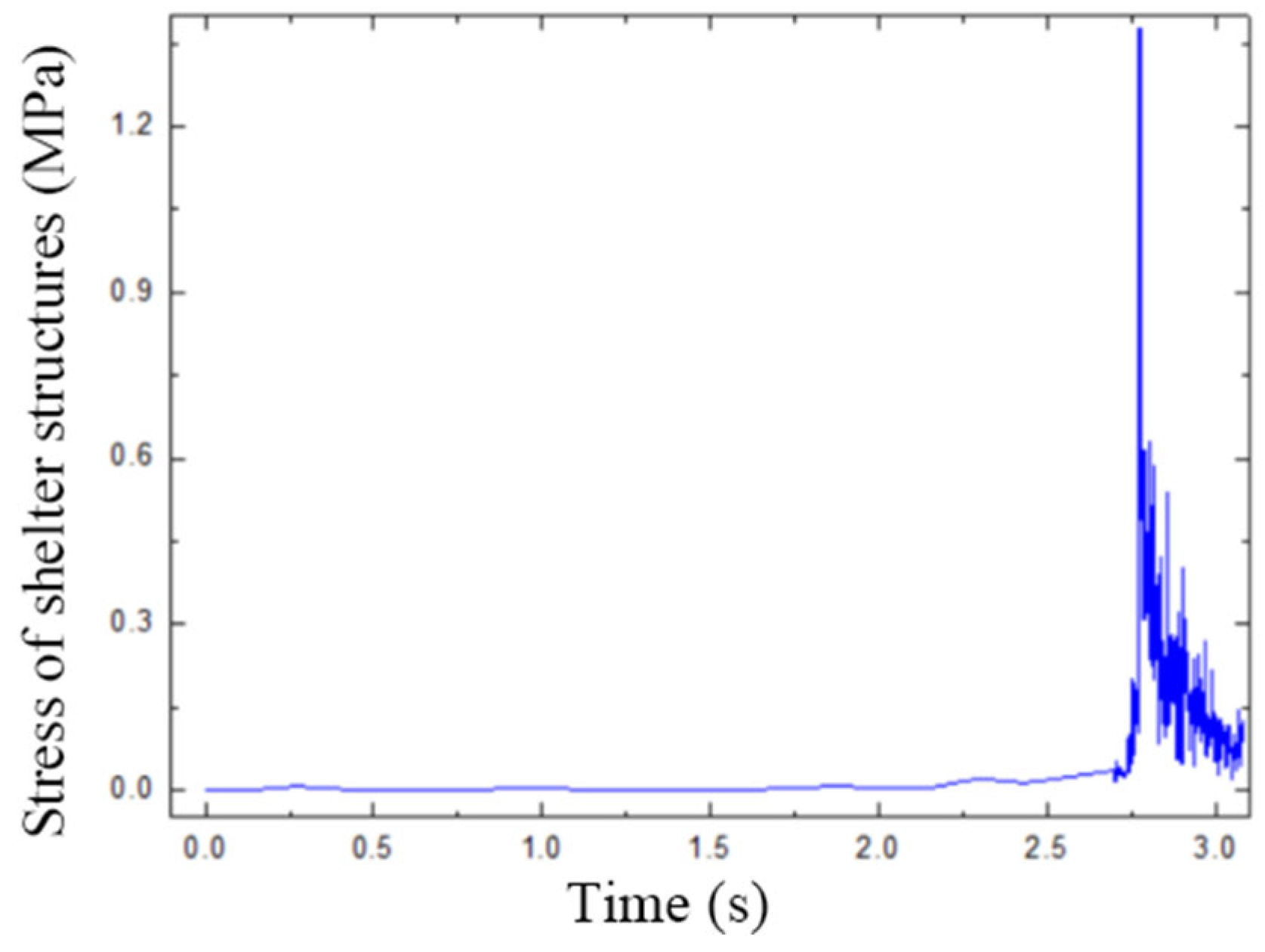

2.2. Study of Impact Loads on Transmission Line Breaks

3. Study of the Form of Protective Structures and Construction Measures

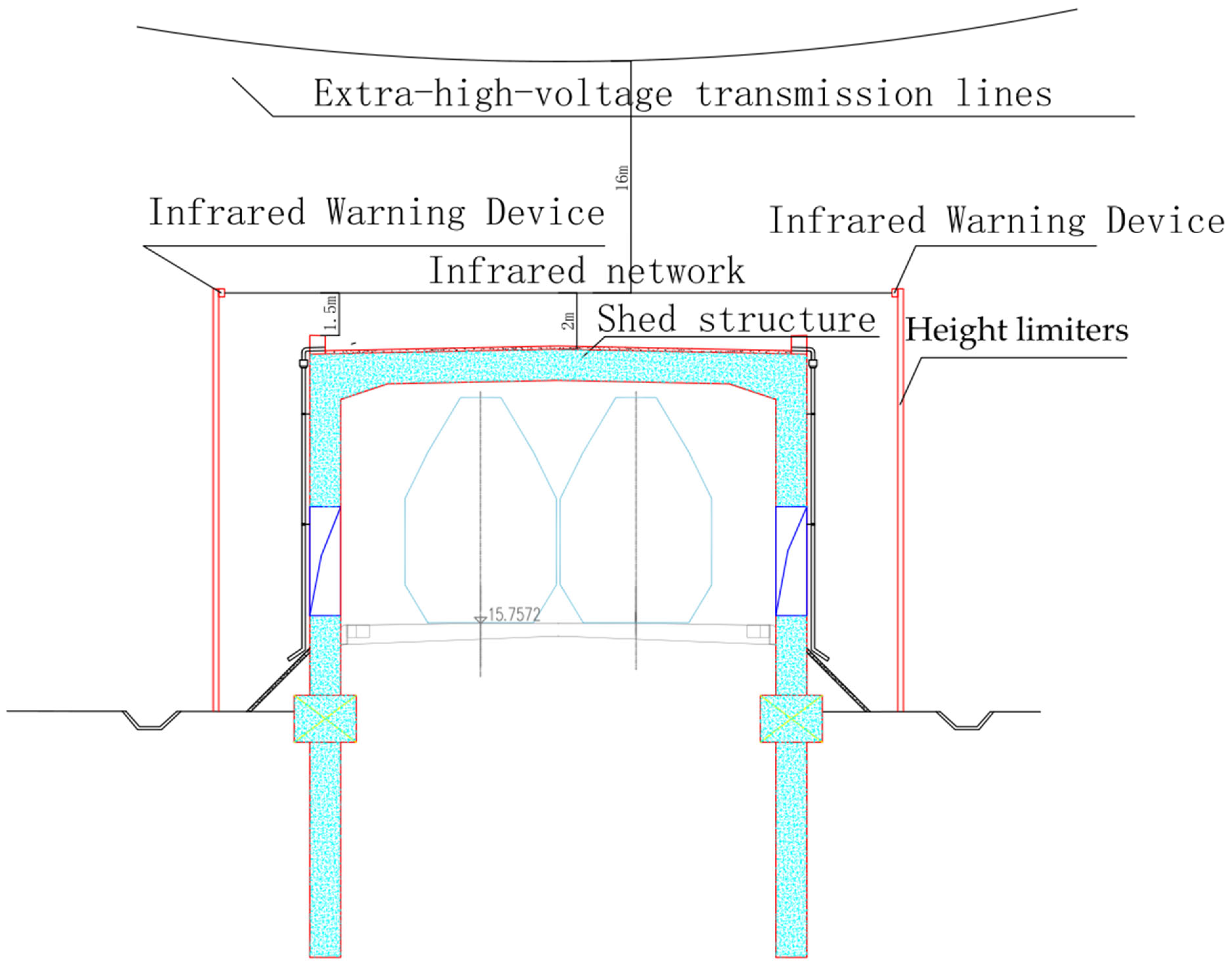

3.1. Study of the Design of Protective Structures for High-Speed Rail

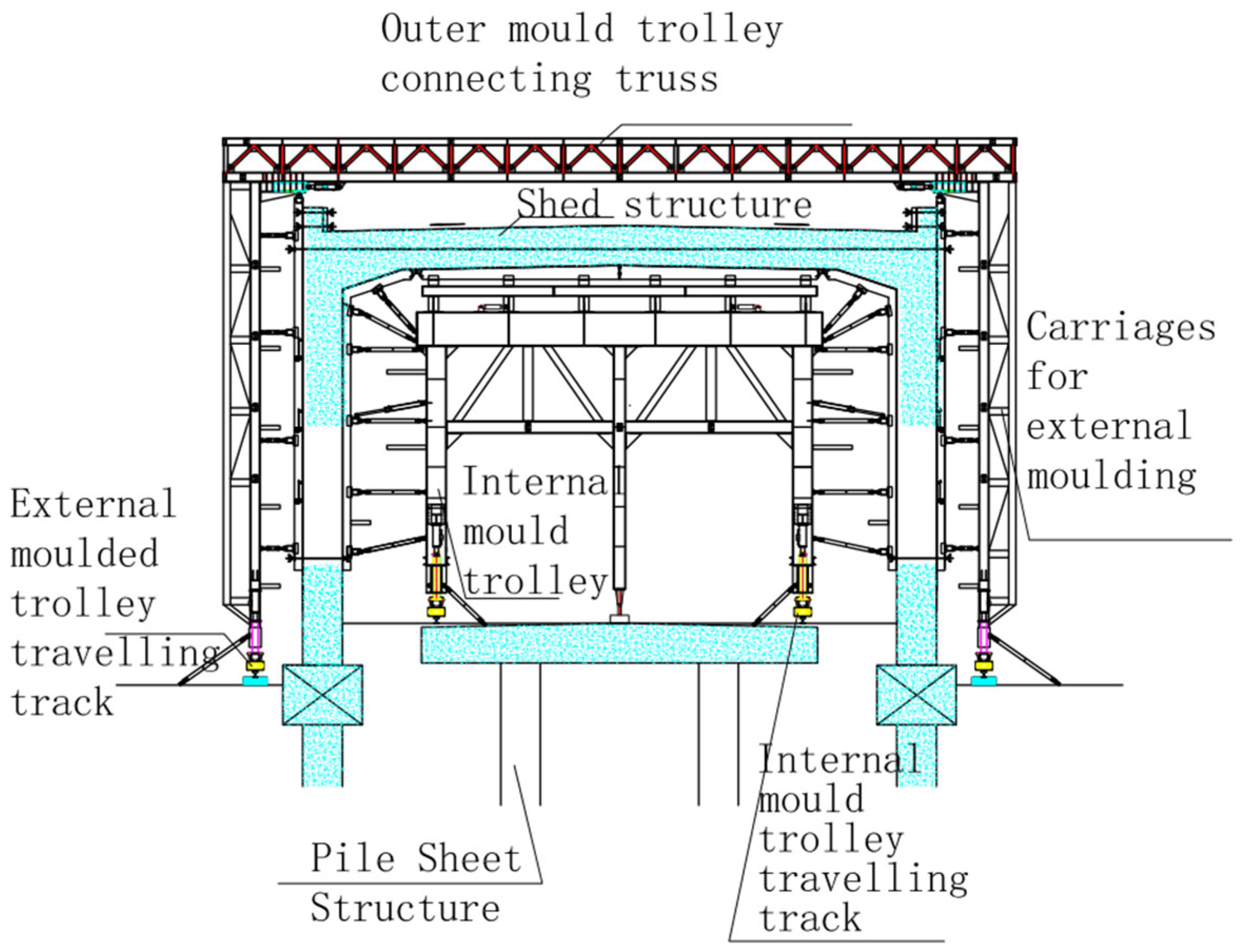

3.2. Study of Construction Measures for Protective Structures

4. Conclusions

- (1)

- During the design of the UHV transmission line, the safety factor of the tower is set to be extremely high. Therefore, the protection of the high-speed rail under the 1000 KV UHV line primarily emphasizes safeguarding against line-break accidents in extreme conditions.

- (2)

- The structural form of the C35-reinforced concrete shed hole can not only meet the force requirements under disconnected conditions but also reduce the mutual influence with the UHV transmission line.

- (3)

- The structural form of a straight wall, flat roof, and side wall window can also prevent the structure from intruding into the safety control area of the transmission line while meeting the headroom requirement.

- (4)

- The construction measures, such as establishing an automatic warning protection corridor and utilizing an overall movable cart molding, can guarantee the safe and efficient construction of the high-speed rail protection shelter structure within the safety zone of the adjacent ultra-high-voltage transmission line. The implementation has shown positive results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Chen, J.; Zhang, L.; Zhang, Y.; Teng, C.; Huang, X. Opportunity for developing ultra-high voltage transmission technology under the emission peak, carbon neutrality, and new infrastructure. High Volt. Eng. 2021, 47, 2396–2408. [Google Scholar]

- Li, X. New infrastructure construction and policy orientation for a smart society. Reform 2020, 5, 34–48. [Google Scholar]

- Sun, J.; Jiang, Z.; Yang, J.; Zheng, L.; Zhao, P.F.; Mu, Q.; Cong, X. Research on the line-break influence range of power line crossing electrified railway. China Railw. 2023, 9, 117–124. [Google Scholar] [CrossRef]

- Liu, B. Discussion on the scheme of adding protective sheds to the corridor of the new railway crossing the UHV transmission line. Electr. Railw. 2019, 30, 72–76. [Google Scholar]

- GB 50665-2011; Code for Design of 1000kV Overhead Transmission Line. China Planning Press: Beijing, China, 2011.

- GB 50790-2013; Code for Designing of ±800kV DC Overhead Transmission Line. China Planning Press: Beijing, China, 2019.

- DL/T5486-2020; Technical Specification for the Design of Steel Supporting Structures of Overhead Transmission Line. China Planning Press: Beijing, China, 2020.

- DL/T5301-2013; Construction Technology Guide for Tension Stringing of Overhead Transmission Line When Over-Crossing Live Lines without Cross Frame. China Electric Power Press: Beijing, China, 2014.

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture Publishing & Media Co., Ltd.: Beijing, China, 2015.

- Mo, Z.-L.; Zhang, Z.-F.; Hu, G.-Y. Experimental Research for Broken Conductor Wire of ±800 kV DC EHV Suspension Tower Model. Electr. Power Constr. 2010, 31, 30–33. [Google Scholar]

- He, S.-M.; Shen, J.; Wu, Y. Rock shed dynamic response to impact of rock-fall. Rock Soil Mech. 2011, 32, 781–787. [Google Scholar]

- Jiang, J.; Yang, X.; Luo, Y.; Zhou, Y. Summarize about traditional shed hole compared with flexible shed hole in application research. Build. Struct. 2016, 46 (Suppl. S1), 249–252. [Google Scholar]

- Jiang, D.; Zhou, X.; Tang, J.; Liu, K. Mechanical response of large span arched open cut tunnel structure under rockfall impaction. Railw. Stand. Des. 2021, 65, 122–127. [Google Scholar]

- Wang, Y.; Li, S.; Li, W.; Tan, J.; Guo, Z. Study on the Characteristics and Protection Design of Tuyu Tunnel Rockfall on Zhangjiajie-Jishou-Huaihua Railway. Railw. Stand. Des. 2023, 67, 126–133. [Google Scholar]

- Wen, X.; Pei, X.; Pei, Z.; Yang, H.; Chen, Z.; Zhang, Y. Study on structural design and safety of shed tunnels in the scenic area of Changbai mountains. Mod. Tunn. Technol. 2021, 58, 151–157. [Google Scholar]

- Yang, C. Study on protection scheme of dangerous rock falling on high steep slope of chizhou-huangshan high speed railway tunnel. Railw. Eng. 2023, 63, 124–126. [Google Scholar]

- Wang, K.; Gao, C.; Zhou, Y. Research on Design of Railway Bridge-shed Integrated Structure for Preventing Falling Rocks. Railw. Stand. Des. 2023, 67, 106–112+154. [Google Scholar]

- Li, X.; Lin, C.; Li, J. New Construction Method for Secondary Lining of Railway Tunnel and Design of Lining Trolley Scheme. Tunn. Constr. 2021, 41, 293. [Google Scholar]

- Zhang, M.; Jia, D.; Wang, S.; Gao, C. New Automatic Pouring and Vibrating Techniques for the Construction of Railway Tunnel Lining. Mod. Tunn. Technol. 2022, 59, 29–34+41. [Google Scholar]

- Zhang, H. Research on rapid construction technology for arch wall lining inopen-cut hole of large-section loess tunnel. Railw. Constr. Technol. 2020, 1, 93–96. [Google Scholar] [CrossRef]

| Programme I (Beam-Slab-Column Structure) | Programme II (Straight-Wall Vaulted Structure) | Programme III (Straight-Wall, Flat-Roofed Structure) | |

|---|---|---|---|

| Structural Form | To meet the requirements of traffic clearance, the beam-slab-column rectangular structure does not intrude into the transmission line safety protection zone. | The straight wall arch structure is designed to meet headroom requirements. However, the upper arch occupies more space, causing the structure to intrude into the safety protection zone of the transmission line. | A straight-wall, flat-roofed structure that meets headroom requirements and does not intrude into the transmission line safety protection zone. |

| Structural Dimensions | Beams and columns are the main load-bearing members designed to support the upper loads, and the structure has small structural dimensions. | Smaller dimensions are required for the arched structure at the top, while larger dimensions are needed for the side wall structure. | The structure features a flat roof at the top, with greater forces and larger dimensions in the center, and larger dimensions in the side wall structure. |

| Structural Force Transmission | The structural force transfer occurs through a clear path from the slab to the beam, column, and foundation. | The arch loads are transferred to the side walls, which are subjected to significant vertical and horizontal forces. | The load of the roof slab is transferred to the side walls, which experience significant vertical forces and minimal horizontal forces. |

| Construction Condition | Construction can be carried out using cast-in-place or the pre-supported erection of supports, both of which require large lifting machinery and pose the risk of construction machinery encroaching into the protected area. | It can be constructed using cast-in-place or integral formwork with bracing, which helps prevent the intrusion of construction machinery into the protected area. | It can be constructed by cast-in-place or integral formwork with bracing, which can avoid the intrusion of construction machinery into the protected area. |

| Analysis | Not recommended | Not recommended | Recommended |

| Position | Thickness (m) | Fundamental Combination | Nominal Combination | Accidental Combination | Calculate Reinforcement Area (mm2) | Actual Reinforcement Area (mm2) | |||

|---|---|---|---|---|---|---|---|---|---|

| Bending Moment (KN*m) | Axial Force (KN) | Bending Moment (KN*m) | Axial Force (KN) | Bending Moment (KN*m) | Axial Force (KN) | ||||

| roof | 1.0 | 828 | 108 | 513 | 66 | 407 | 335 | 2417 | 4909 |

| left side wall | 1.0 | 384 | 809 | 244 | 547 | 1832 | 1112 | 4224 | 6158 |

| right side wall | 1.0 | 399 | 809 | 244 | 547 | 2043 | 691 | 5417 | 6158 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Xiao, W. Research on the Protection Scheme of a High-Speed Railway Crossing 1000 KV Ultra-High Voltage Transmission Line. Infrastructures 2024, 9, 110. https://doi.org/10.3390/infrastructures9070110

Song Y, Xiao W. Research on the Protection Scheme of a High-Speed Railway Crossing 1000 KV Ultra-High Voltage Transmission Line. Infrastructures. 2024; 9(7):110. https://doi.org/10.3390/infrastructures9070110

Chicago/Turabian StyleSong, Yi, and Wei Xiao. 2024. "Research on the Protection Scheme of a High-Speed Railway Crossing 1000 KV Ultra-High Voltage Transmission Line" Infrastructures 9, no. 7: 110. https://doi.org/10.3390/infrastructures9070110

APA StyleSong, Y., & Xiao, W. (2024). Research on the Protection Scheme of a High-Speed Railway Crossing 1000 KV Ultra-High Voltage Transmission Line. Infrastructures, 9(7), 110. https://doi.org/10.3390/infrastructures9070110