Fractional Transformation-Based Decentralized Robust Control of a Coupled-Tank System for Industrial Applications

Abstract

:1. Introduction

2. Modeling

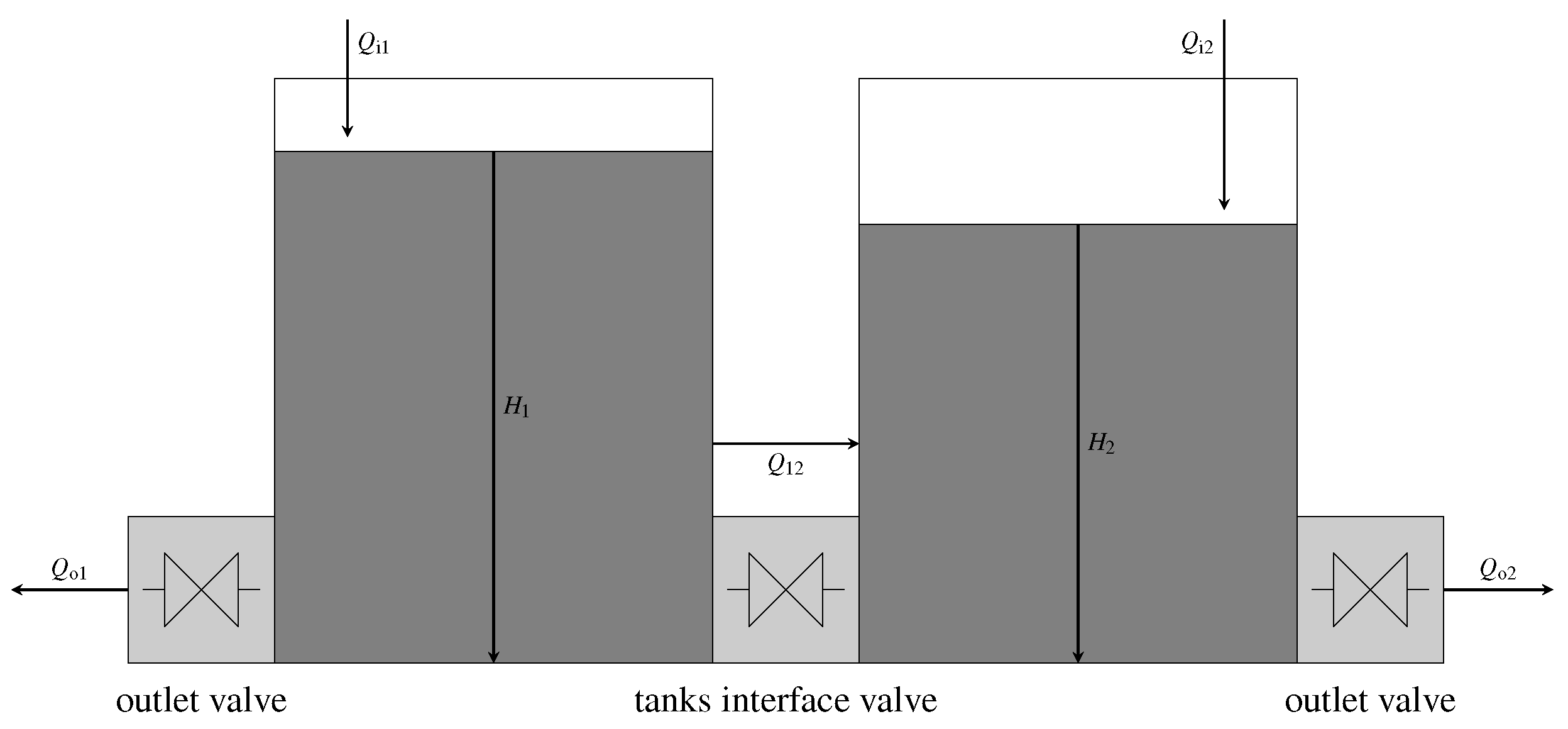

2.1. System’s Description

2.2. Nonlinear MIMO Mathematical Model

2.3. The Perturbed Linearized MIMO Mathematical Model

3. Control Design for the Decoupled MIMO System

3.1. Context

3.2. Traditional PID Design

3.3. Traditional Controller Design

3.4. Design of Fixed-Structure Synthesis

- Block : represents the non-tunable LTI components of the MIMO system.

- Block : contains the tunable components diagonally as . Each of these components has a specific structure and is an LTI control element.

4. Performance Analysis and Discussion

4.1. Context

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, A.P.; Mukherjee, S.; Nikolaou, M. Debottlenecking level control for tanks in series. J. Process Control 2014, 24, 158–171. [Google Scholar] [CrossRef]

- Antimisiaris, S.G.; Kallinteri, P.; Fatouros, D.G. Liposomes and drug delivery. In Pharmaceutical Manufacturing Handbook: Production and Processes; Wiley: Hoboken, NJ, USA, 2008; pp. 443–507. [Google Scholar]

- Saad, M.; Albagul, A.; Abueejela, Y. Performance Comparison between PI and MRAC for Coupled-Tank System. J. Autom. Control Eng. 2014, 2, 316–321. [Google Scholar] [CrossRef] [Green Version]

- Tepljakov, A.; Petlenkov, E.; Belikov, J.; Halas, M. Design and implementation of fractional-order PID controllers for a fluid tank system. In Proceedings of the 2013 American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 1777–1782. [Google Scholar]

- Jaafar, H.I.; Yuslinda, S.; Selamat, N.; Mohd Aras, M.S.; Rashid, M.A.Z. Development of PID Controller for Controlling Desired Level of Coupled Tank System. Int. J. Innov. Technol. Explor. Eng. 2014, 3, 32–36. [Google Scholar]

- Visioli, A. A new design for a PID plus feed forward controller. J. Process Control 2004, 14, 457–463. [Google Scholar] [CrossRef]

- Wu, K.-L.; Yu, C.-C.; Cheng, Y.-C. A two degree of freedom level control. J. Process Control 2001, 11, 311–319. [Google Scholar] [CrossRef]

- Khan, M.K.; Spurgeon, S.K. Robust MIMO water level control in interconnected twin-tanks using second order sliding mode control. Control Eng. Pract. 2006, 14, 375–386. [Google Scholar] [CrossRef]

- Milev, M.; Zlatev, S. A Note about Stability of Fractional Retarded Linear Systems with Distributed Delays. Int. J. Pure Appl. Math. 2017, 115, 873–881. [Google Scholar] [CrossRef] [Green Version]

- Pan, H.; Wong, H.; Kapila, V.; de Queiroz, M.S. Experimental validation of a nonlinear back stepping liquid level controller for a state coupled two tank system. Control Eng. Pract. 2005, 13, 27–40. [Google Scholar] [CrossRef]

- Poulsen, N.K.; Kouvaritakis, B.; Cannon, M. Constrained predictive control and its application to a coupled-tanks apparatus. Int. J. Control 2001, 74, 552–564. [Google Scholar] [CrossRef]

- Murray-Smith, D.; Kocijan, J.; Gong, M. A signal convolution method for estimation of controller parameter sensitivity functions for tuning of feedback control systems by an iterative process. Control Eng. Pract. 2003, 11, 1087–1094. [Google Scholar] [CrossRef]

- Rojas, I.; Anguita, M.; Pomares, H.; Prieto, A. Analysis and electronic implementation of a fuzzy system for the control of a liquid tank. In Proceedings of the 6th International Fuzzy Systems Conference, Barcelona, Spain, 5 July 1997. [Google Scholar]

- Ghwanmeh, S.; Jones, K.; Williams, D. Performance Evaluation of an On-Line Self-Learning Fuzzy Logic Controller Applied to Non-Linear Processes. IFAC Proc. Vol. 1997, 30, 245–250. [Google Scholar] [CrossRef]

- Muftah, M.N.; Faudzi, A.A.M.; Sahlan, S.; Mohamaddan, S. Fuzzy Fractional Order PID Tuned via PSO for a Pneumatic Actuator with Ball Beam (PABB) System. Fractal Fract. 2023, 7, 416. [Google Scholar] [CrossRef]

- Doyle, J.; Glover, K.; Khargonekar, P.P.; Francis, B.A. State-space solutions to standard H2 and H1 control problems. IEEE Trans. Autom. Control 1989, 34, 831–847. [Google Scholar] [CrossRef]

- McFarlane, D.; Glover, K. A loop shaping design procedure using H1 synthesis. IEEE Trans. Autom. Control 1992, 37, 759–769. [Google Scholar] [CrossRef]

- Zhou, K.; Doyle, J.C.; Glover, K. Robust and Optimal Control; Prentice Hall: New York, NY, USA, 1996. [Google Scholar]

- Gahinet, P.; Apkarian, P. Decentralized and fixed-structure H∞ control in MATLAB. In Proceedings of the IEEE Conference on Decision and Control and European Control Conference, Orlando, FL, USA, 12–15 December 2011. [Google Scholar]

- Albalawi, H.; Bakeer, A.; Zaid, S.A.; Aggoune, E.-H.; Ayaz, M.; Bensenouci, A.; Eisa, A. Fractional-order model-free predictive control for voltage source inverters. Fractal Fract. 2023, 7, 433. [Google Scholar] [CrossRef]

- Rahman, M.Z.U.; Leiva, V.; Martin-Barreiro, C.; Mahmood, I.; Usman, M.; Rizwan, M. Fractional transformation-based intelligent H-infinity controller of a direct current servo motor. Fractal Fract. 2022, 7, 29. [Google Scholar] [CrossRef]

- Apkarian, P.; Noll, D. Non-smooth H∞ synthesis. IEEE Trans. Autom. Control 2006, 51, 71–86. [Google Scholar] [CrossRef] [Green Version]

- Apkarian, P.; Bompart, V.; Noll, D. Non-smooth structured control design with application to PID loop-shaping of a process. Int. J. Robust Nonlinear Control 2007, 17, 1320–1342. [Google Scholar] [CrossRef] [Green Version]

- Vázquez, F.; Morilla, F. Tuning Decentralized Pid Controllers for Mimo Systems with Decouplers. IFAC Proc. Vol. 2002, 35, 349–354. [Google Scholar] [CrossRef]

- Sanda Florentina, F. Decoupling in distillation. J. Control Eng. Appl. Inform. 2006, 7, 10–19. [Google Scholar]

- Mashhood, A.; Ali, A.; Choudhry, M.A. Fixed-structure H∞ controller design for two-rotor aerodynamical system. Arab. J. Sci. Eng. 2016, 4, 3619–3630. [Google Scholar]

- Green, M.; Limebeer, D.J.N. Linear Robust Control; Courier Corporation: North Chelmsford, MA, USA, 2012. [Google Scholar]

| Notation | Definition |

|---|---|

| Flow index/control input for tank 1 | |

| Flow index/control input for tank 2 | |

| Height (liquid) in tank 1 | |

| Height (liquid) in tank 2 | |

| Outflow rate through tank 1’s orifice valve | |

| Outflow rate through tank 2’s orifice valve | |

| Coupling flow rate between tanks 1 and 2 through orifice valve | |

| A | Cross-section area of each tank |

| Name | Expression | Value |

|---|---|---|

| Cross-section of tanks 1 and 2 | A | |

| Discharge coefficients | , , | 1, 0.5, 0.5 |

| Cross sections of an orifice valve | , , | |

| Gravitational acceleration | g | |

| Sensor | Ideal | 1 |

| Liquid levels offset | , | m, m |

| Dynamics constant 1 | 4.082249 | |

| Dynamics constant 2 | 5.344471 | |

| Dynamics constant 3 | 6.062148 |

| Symbols | Description | Values for Tracking | Values for Tracking |

|---|---|---|---|

| Proportional gain | 6730 | 4210 | |

| Integral gain | 3230 | 3660 | |

| Derivative gain | −9750 | −8580 | |

| 1st order filter coefficient | 1.64 | 2.44 |

| Controller | Rise Time (s) | Settling Time (s) | Over-Shoot (%) | Steady-State Error | Controller Order |

|---|---|---|---|---|---|

| Traditional | 0.0448 | 0.0801 | 0 | 0% | Third |

| Fixed-structure | 0.0131 | 0.0249 | 0 | 0% | Second |

| PID | 0.0268 | 0.1451 | 10.3289 | 0.1033 | Second |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.Z.U.; Leiva, V.; Ghaffar, A.; Martin-Barreiro, C.; Waleed, A.; Cabezas, X.; Castro, C. Fractional Transformation-Based Decentralized Robust Control of a Coupled-Tank System for Industrial Applications. Fractal Fract. 2023, 7, 590. https://doi.org/10.3390/fractalfract7080590

Rahman MZU, Leiva V, Ghaffar A, Martin-Barreiro C, Waleed A, Cabezas X, Castro C. Fractional Transformation-Based Decentralized Robust Control of a Coupled-Tank System for Industrial Applications. Fractal and Fractional. 2023; 7(8):590. https://doi.org/10.3390/fractalfract7080590

Chicago/Turabian StyleRahman, Muhammad Z. U., Victor Leiva, Asim Ghaffar, Carlos Martin-Barreiro, Aashir Waleed, Xavier Cabezas, and Cecilia Castro. 2023. "Fractional Transformation-Based Decentralized Robust Control of a Coupled-Tank System for Industrial Applications" Fractal and Fractional 7, no. 8: 590. https://doi.org/10.3390/fractalfract7080590