Biochar Characteristics and Application: Effects on Soil Ecosystem Services and Nutrient Dynamics for Enhanced Crop Yields

Abstract

:1. Introduction

2. Biochar Definition and Generation

2.1. Methods of Biochar Production

2.1.1. Fast Pyrolysis

2.1.2. Slow Pyrolysis

2.2. How Production Conditions Influence Produced Biochar’s Physicochemical Properties

2.2.1. Pre-Treatment Techniques

2.2.2. Post-Treatment Techniques

2.2.3. Feedstock Materials

2.2.4. Pyrolysis Parameters

3. Biochar Characteristics and Their Influence on Delivery of Soil Ecosystem Services

3.1. Biochar Characterization Techniques

3.1.1. Nuclear Magnetic Resonance (NMR) Spectroscopy

3.1.2. Thermal Analysis

3.1.3. Scanning Electron Microscopy (SEM)

3.1.4. X-Ray Diffraction (XRD)

3.1.5. Fourier-Transform Infrared Spectroscopy (FTIR)

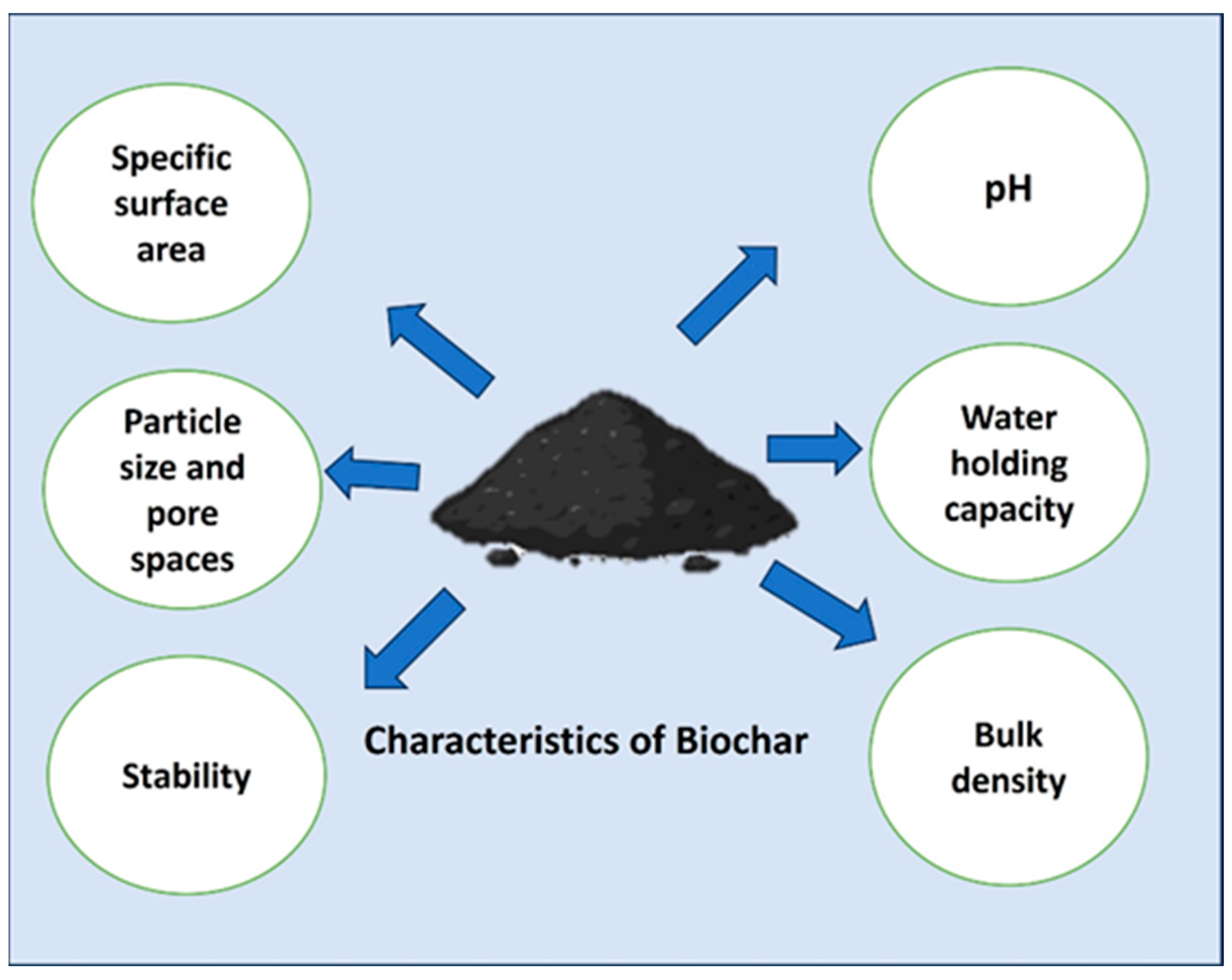

3.2. Biochar Characteristics Influencing Delivery of Soil Ecosystem Services

3.2.1. Specific Surface Area

3.2.2. Porosity, Particle Size, and Pore Distribution

3.2.3. Stability

3.2.4. Water-Holding Capacity

3.2.5. pH

3.2.6. Bulk Density

3.3. Optimizing Process Parameters in Biochar Pyrolysis

3.3.1. Thermodynamic Equilibrium (TE) Models

3.3.2. Kinetic Models

3.3.3. Fixed Data (FD) Models

3.3.4. Limitations of the Models

4. Factors That Influence Biochar Action on Ecosystem Services and Their Evaluation

4.1. Biochar Factors That Influence Action on Ecosystem Functioning

4.1.1. Biochar Feedstock

4.1.2. Pyrolysis Temperature

4.1.3. Application Rate

4.1.4. Biochar Properties

4.1.5. Soil Properties

4.1.6. Climate

4.1.7. Other Factors

4.2. Evaluation of Biochar Influence on Soil Ecosystem Services

4.2.1. Defining Prioritization Narratives

- (a)

- Improving Soil Quality: Focuses on regions where biochar can enhance soil structure, pH balance, and nutrient retention.

- (b)

- Crop Resilience: Targets areas where biochar’s moisture retention and stress mitigation effects can improve crop performance.

- (c)

- Reducing Nitrogen Leaching: Prioritizes regions where biochar can minimize nitrogen loss to groundwater.

4.2.2. Criteria Selection

4.2.3. Criteria Prioritization via AHP

4.2.4. Weighted Linear Combination (WLC)

4.3. Cascading Effects of Biochar Characteristics on Ecosystem Processes

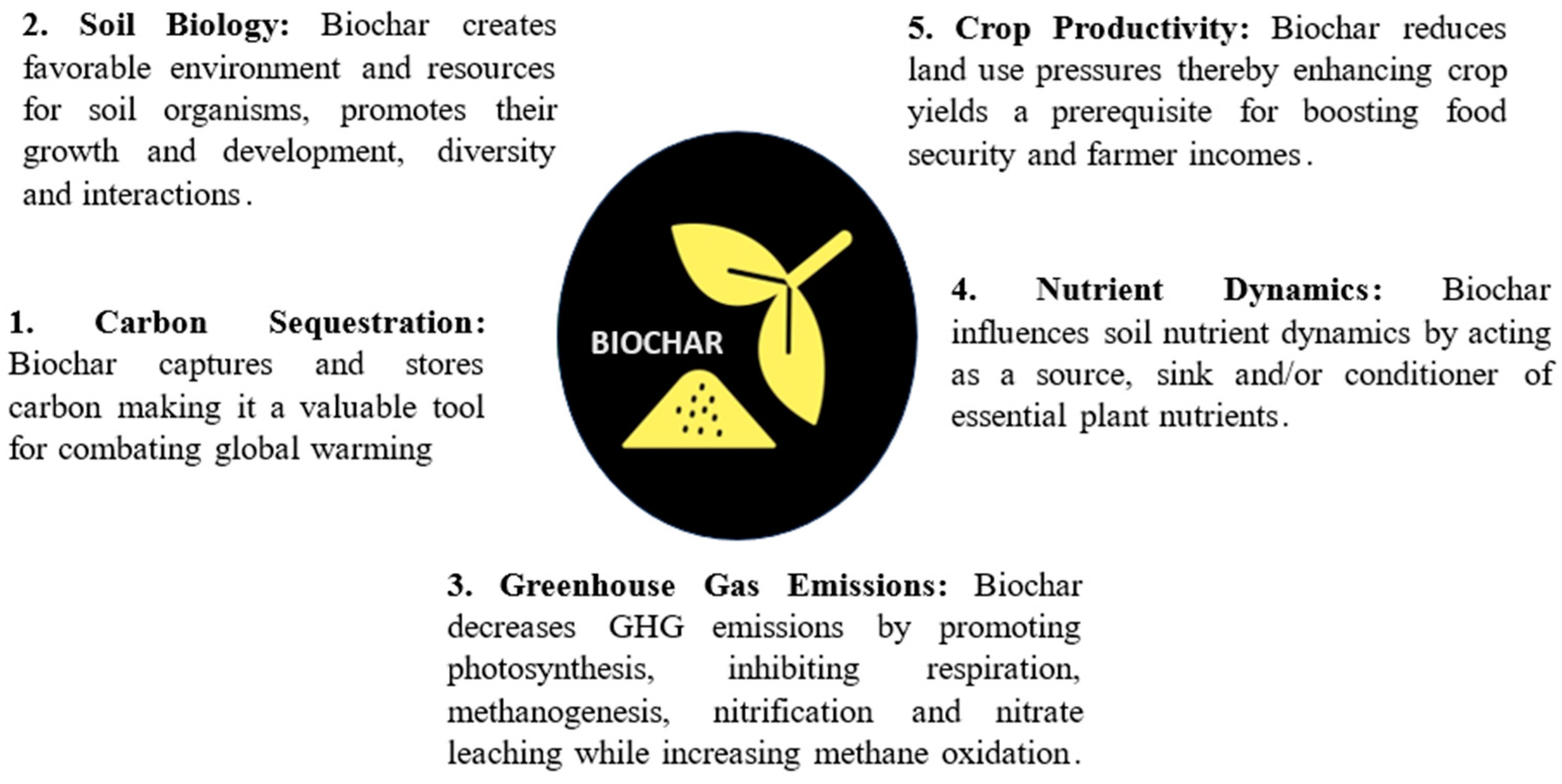

5. Effects of Biochar on Nutrient Dynamics for Enhanced Crop Yields

5.1. Carbon Sequestration

5.2. Effect on Greenhouse Gas Dynamics in Soil

5.3. Effect on Soil Biology

5.4. Effects on Nutrient Dynamics

5.4.1. Nutrient Retention

5.4.2. Nutrient Leaching

Nitrogen

Phosphorus

Potassium

5.4.3. Nutrient Use Efficiency

5.5. Effects of Biochar on Enhancing Crop Yield and Productivity

6. Conclusions and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AHP | Analytical Hierarchy Process |

| ATR-FTIR | Attenuated Total Reflectance Fourier-Transform Infrared |

| BET | Brunauer–Emmett–Teller |

| BUIM | Biochar Use Indication Map |

| CCS | Carbon capture and storage |

| CEC | Cation exchange capacity |

| DRIFTS | Diffuse reflectance infrared Fourier-transform spectroscopy |

| EDX | Energy-Dispersive X-Ray |

| ESs | Ecosystem services |

| FD | Field data |

| FTIR | Fourier-transform infrared spectroscopy |

| GHG | Greenhouse gas |

| HTC | Hydrothermal carbonization |

| MCA | Multiple criteria analysis |

| MGFE | Minimum Gibbs free energy |

| NMR | Nuclear magnetic resonance |

| NUE | Nutrient use efficiency |

| SEM | Scanning electron microscopy |

| SOC | Soil organic matter |

| SSA | Specific surface area |

| TE | Thermodynamic equilibrium |

| TGA | Thermogravimetric analysis |

| WHC | Water-holding capacity |

| WLC | Weighted Linear Combination |

| XRD | X-ray diffraction |

References

- Manono, B. Agro-ecological role of earthworms (Oligochaetes) in sustainable agriculture and nutrient use efficiency: A review. J. Agric. Ecol. Res. Int. 2016, 8, 1–18. [Google Scholar] [CrossRef]

- Pereira, P.; Bogunovic, I.; Muñoz-Rojas, M.; Brevik, E.C. Soil ecosystem services, sustainability, valuation and management. Curr. Opin. Environ. Sci. Health 2018, 5, 7–13. [Google Scholar] [CrossRef]

- Manono, B.O. New Zealand dairy farm effluent, irrigation and soil biota management for sustainability: Farmer priorities and monitoring. Cogent Food Agric. 2016, 2, 1221636. [Google Scholar] [CrossRef]

- MEA (Millennium Ecosystem Assessment). Ecosystems and Human Well-Being: Synthesis; Island Press: Washington, DC, USA, 2005. [Google Scholar]

- Rehman, A.; Farooq, M.; Lee, D.J.; Siddique, K.H. Sustainable agricultural practices for food security and ecosystem services. Environ. Sci. Pollut. Res. 2022, 29, 84076–84095. [Google Scholar] [CrossRef]

- Sadiq, F.K.; Maniyunda, L.M.; Anumah, A.O.; Adegoke, K.A. Variation of soil properties under different landscape positions and land use in Hunkuyi, Northern Guinea savanna of Nigeria. Environ. Monit. Assess. 2021, 193, 178. [Google Scholar] [CrossRef] [PubMed]

- Manono, B.O. Carbon dioxide, nitrous oxide and methane emissions from the Waimate District (New Zealand) pasture soils as influenced by irrigation, effluent dispersal and earthworms. Cogent Environ. Sci. 2016, 2, 1256564. [Google Scholar] [CrossRef]

- Bellè, S.L.; Riotte, J.; Backhaus, N.; Sekhar, M.; Jouquet, P.; Abiven, S. Tailor-made biochar systems: Interdisciplinary evaluations of ecosystem services and farmer livelihoods in tropical agro-ecosystems. PLoS ONE 2022, 17, e0263302. [Google Scholar] [CrossRef]

- Manono, B.O.; Moller, H.; Benge, J.; Carey, P.; Lucock, D.; Manhire, J. Assessment of soil properties and earthworms in organic and conventional farming systems after seven years of dairy farm conversions in New Zealand. Agroecol. Sustain. Food Syst. 2019, 43, 678–704. [Google Scholar] [CrossRef]

- Song, W.; Deng, X. Land-use/land-cover change and ecosystem service provision in China. Sci. Total Environ. 2017, 576, 705–719. [Google Scholar] [CrossRef]

- Nair, V.D.; Mukherjee, A. The use of biochar for reducing carbon footprints in land-use systems: Prospects and problems. Carbon Footpr. 2022, 2, 6. [Google Scholar] [CrossRef]

- Amonette, J.E.; Archuleta, J.G.; Fuchs, M.R.; Hills, K.M.; Yorgey, G.G.; Flora, G.; Hunt, J.; Han, H.-S.; Jobson, B.T.; Miles, T.R.; et al. Biomass to Biochar: Maximizing the Carbon Value; Washington State University, Center for Sustaining Agriculture and Natural Resources: Pullman, WA, USA, 2021; 166p, Available online: https://csanr.wsu.edu/biomass2biochar/ (accessed on 15 March 2025).

- Bolan, N.; Sarmah, A.K.; Bordoloi, S.; Bolan, S.; Padhye, L.P.; Van Zwieten, L.; Sooriyakumar, P.; Khan, B.A.; Ahmad, M.; Solaiman, Z.M.; et al. Soil acidification and the liming potential of biochar. Environ. Pollut. 2023, 317, 120632. [Google Scholar] [CrossRef] [PubMed]

- Diatta, A.A.; Fike, J.H.; Battaglia, M.L.; Galbraith, J.M.; Baig, M.B. Effects of biochar on soil fertility and crop productivity in arid regions: A review. Arab. J. Geosci. 2020, 13, 595. [Google Scholar] [CrossRef]

- Ippolito, J.A.; Cui, L.; Kammann, C.; Wrage-Mönnig, N.; Estavillo, J.M.; Fuertes-Mendizabal, T.; Cayuela, M.L.; Sigua, G.; Novak, J.; Spokas, K.; et al. Feedstock choice, pyrolysis temperature and type influence biochar characteristics: A comprehensive meta-data analysis review. Biochar 2020, 2, 421–438. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K. Soil hydro-physical properties affected by biomass-derived biochar and organic manure: A low-cost technology for managing acidic mountain sandy soils of north eastern region of India. Biomass Convers. Biorefin. 2024, 14, 6621–6635. [Google Scholar] [CrossRef]

- Blanco-Canqui, H. Does biochar improve all soil ecosystem services? GCB Bioenergy 2020, 13, 291–304. [Google Scholar] [CrossRef]

- Tiong, Y.W.; Sharma, P.; Xu, S.; Bu, J.; An, S.; Foo, J.B.L.; Wee, B.K.; Wang, Y.; Lee, J.T.E.; Zhang, J.; et al. Enhancing sustainable crop cultivation: The impact of renewable soil amendments and digestate fertilizer on crop growth and nutrient composition. Environ. Pollut. 2024, 342, 123132. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Wu, J.; Zhao, K.; Zhang, X. The interaction between biochar and earthworms: Revealing the potential ecological risks of biochar application and the feasibility of their co-application. Sci. Total Environ. 2024, 950, 175240. [Google Scholar] [CrossRef]

- David, E.; Kopac, J. Valorization of poultry manure into biochar, bio-oil and gas product by co-pyrolysis with residual biomass and the effects analysis of the feedstock on products yield and their characteristics. J. Anal. Appl. Pyrolysis 2025, 186, 106978. [Google Scholar] [CrossRef]

- He, D.; Luo, Y.; Zhu, B. Feedstock and pyrolysis temperature influence biochar properties and its interactions with soil substances: Insights from a DFT calculation. Sci. Total Environ. 2024, 922, 171259. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Majewska, M.; Hanaka, A. Biochar in the Bioremediation of Metal-Contaminated Soils. Agronomy 2025, 15, 273. [Google Scholar] [CrossRef]

- Daneshvar, S.; Mosaddeghi, M.R.; Afyuni, M. Effect of biochar and hydrochar of pistachio residues on physical quality indicators of a sandy loam soil. Geoderma Reg. 2024, 36, e00740. [Google Scholar] [CrossRef]

- Dong, X.; Lin, Q. Biochar effect on soil physical properties: A review. Chin. J. Eco-Agric. 2018, 26, 1846–1854. [Google Scholar]

- Haider, F.U.; Khan, I.; Farooq, M.; Cai, L.; Li, Y. Co-application of biochar and plant growth regulators improves maize growth and decreases Cd accumulation in cadmium-contaminated soil. J. Clean. Prod. 2024, 440, 140515. [Google Scholar] [CrossRef]

- Ye, L.; Camps-Arbestain, M.; Shen, Q.; Lehmann, J.; Singh, B.; Sabir, M. Biochar effects on crop yields with and without fertilizer: A meta-analysis of field studies using separate controls. Soil Use Manag. 2020, 36, 2–18. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Biochar from biomass: A review of its production, properties, and applications. Renew. Sustain. Energy Rev. 2018, 81, 112–120. [Google Scholar]

- Xiong, Q.; Li, Y.; Hou, C.; Ma, X.; Zhou, X.; Zuo, X.; Chen, C. An efficient and simple approach to remove Cd (II) in aqueous solution by using rice straw biochar: Performance and mechanisms. Environ. Sci. Pollut. Res. 2024, 31, 16782–16794. [Google Scholar] [CrossRef]

- Zahida, S.; Saeed, M.; Khan, M.A. Biochar: A review of its production, characterization, and applications. J. Agric. Sci. Technol. 2017, 17, 531–544. [Google Scholar]

- Daassi, R.; Khasa, D.P.; Stevanovic, T. Effect of ramial chipped wood and poultry manure amendments on soil chemical properties and fungal communities in Benin. Soil Tillage Res. 2024, 237, 105974. [Google Scholar] [CrossRef]

- Ascher, S.; Gordon, J.; Bongiovanni, I.; Watson, I.; Hermannsson, K.; Gillespie, S.; Sarangi, S.; Biakhmetov, B.; Bhargava, P.C.; Bhaskar, T.; et al. Trigeneration based on the pyrolysis of rural waste in India: Environmental impact, economic feasibility and business model innovation. Sci. Total Environ. 2024, 921, 170718. [Google Scholar] [CrossRef]

- Anyebe, O.; Uyovbisere, E.O.; Sadiq, F.K.; Adegoke, K.A.; Anumah, A.O. The Phytoextraction by Zea mays of Residual Metals in Ethylenediaminetetraacetic Acid-Washed Soils. Chem. Afr. 2022, 5, 395–404. [Google Scholar] [CrossRef]

- Amalina, F.; Abd Razak, A.S.; Krishnan, S.; Sulaiman, H.; Zularisam, A.W.; Nasrullah, M. Advanced techniques in the production of biochar from lignocellulosic biomass and environmental applications. Clean. Mater. 2022, 6, 100137. [Google Scholar] [CrossRef]

- Do, P.T.M.; Nguyen, L.X. A review of thermochemical decomposition techniques for biochar production. Environ. Dev. Sustain. 2024, 1–57. [Google Scholar] [CrossRef]

- Goswami, M.; Pant, G.; Mansotra, D.K.; Sharma, S.; Joshi, P.C. Biochar: A carbon negative technology for combating climate change. Adv. Carbon Capture Util. 2021, 251–272. [Google Scholar] [CrossRef]

- Layek, J.; Narzari, R.; Hazarika, S.; Das, A.; Rangappa, K.; Devi, S.; Balusamy, A.; Saha, S.; Mandal, S.; Idapuganti, R.G.; et al. Prospects of biochar for sustainable agriculture and carbon sequestration: An overview for Eastern Himalayas. Sustainability 2022, 14, 6684. [Google Scholar] [CrossRef]

- Zhu, X.; Tong, S.; Li, X.; Gao, Y.; Xu, Y.; Dacres, O.D.; Miura, K.; Liu, W.; Yao, H. Conversion of biomass into high-quality bio-oils by degradative solvent extraction combined with subsequent pyrolysis. Energy Fuels 2017, 31, 3987–3994. [Google Scholar] [CrossRef]

- Adhikari, S.; Moon, E.; Timms, W. Identifying biochar production variables to maximise exchangeable cations and increase nutrient availability in soils. J. Clean. Prod. 2024, 446, 141454. [Google Scholar] [CrossRef]

- Lataf, A.; Jozefczak, M.; Vandecasteele, B.; Viaene, J.; Schreurs, S.; Carleer, R.; Yperman, J.; Marchal, W.; Cuypers, A.; Vandamme, D. The effect of pyrolysis temperature and feedstock on biochar agronomic properties. J. Anal. Appl. Pyrolysis 2022, 168, 105728. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, P.; Yuan, X.; Li, Y.; Han, L. Effect of pyrolysis temperature and correlation analysis on the yield and physicochemical properties of crop residue biochar. Bioresour. Technol. 2020, 296, 122318. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K.; Avasthe, R.K.; Sinha, K. Compositional heterogeneity of different biochar: Effect of pyrolysis temperature and feedstocks. J. Environ. Manag. 2021, 278, 111501. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Patuzzi, F.; Rashid, U.; Shahabz, M.; Ngamcharussrivichai, C.; Baratieri, M. Exploring untapped effect of process conditions on biochar characteristics and applications. Environ. Technol. Innov. 2021, 21, 101310. [Google Scholar] [CrossRef]

- Sharma, T.; Hakeem, I.G.; Gupta, A.B.; Joshi, J.; Shah, K.; Vuppaladadiyam, A.K.; Sharma, A. Parametric influence of process conditions on thermochemical techniques for biochar production: A state-of-the-art review. J. Energy Inst. 2024, 113, 101559. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Pyrolysis of biomass in a fixed bed reactor: A review. Renew. Sustain. Energy Rev. 2015, 41, 1077–1087. [Google Scholar]

- Anand, A.; Gautam, S.; Ram, L.C. Feedstock and pyrolysis conditions affect suitability of biochar for various sustainable energy and environmental applications. J. Anal. Appl. Pyrolysis 2023, 170, 105881. [Google Scholar] [CrossRef]

- Ahuja, V.; Palai, A.K.; Kumar, A.; Patel, A.K.; Farooque, A.A.; Yang, Y.H.; Bhatia, S.K. Biochar: Empowering the future of energy production and storage. J. Anal. Appl. Pyrolysis 2024, 177, 106370. [Google Scholar] [CrossRef]

- Brownsort, P.A. Biomass pyrolysis: A review of the literature. J. Sci. Ind. Res. 2009, 68, 288–297. [Google Scholar]

- Pelagalli, V.; Langone, M.; Matassa, S.; Race, M.; Tuffi, R.; Papirio, S.; Lens, P.N.; Lazzazzara, M.; Frugis, A.; Petta, L.; et al. Pyrolysis of municipal sewage sludge: Challenges, opportunities and new valorization routes for biochar, bio-oil, and pyrolysis gas. Environ. Sci. Water Res. Technol. 2024, 10, 2282–2312. [Google Scholar] [CrossRef]

- Mong, G.R.; Chong, C.T.; Chong, W.W.F.; Ng, J.H.; Ong, H.C.; Ashokkumar, V.; Tran, M.-V.; Karmakar, S.; Goh, B.H.H.; Yasin, M.F.M. Progress and challenges in sustainable pyrolysis technology: Reactors, feedstocks and products. Fuel 2022, 324, 124777. [Google Scholar] [CrossRef]

- Rahimpour, M.R.; Makarem, M.A.; Meshksar, M. (Eds.) Advances in Synthesis Gas: Methods, Technologies and Applications: Syngas Production and Preparation; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Namaswa, T.; Burslem, D.F.; Smith, J. Emerging trends in appropriate kiln designs for small-scale biochar production in low to middle income countries. Bioresour. Technol. Rep. 2023, 24, 101641. [Google Scholar] [CrossRef]

- Thomsen, T. Introduction to Production and Use of Biochar 2022: Working Towards a More Circular and Bio-Based Danish Economy; Roskilde Universitet: Roskilde, Danemark, 2022. [Google Scholar]

- Chandraratne, M.R.; Daful, A.G. Advances in Bioenergy Production Using Fast Pyrolysis and Hydrothermal Processing. In Biomass, Biorefineries and Bioeconomy; IntechOpen: London, UK, 2022. [Google Scholar]

- Makepa, D.C.; Chihobo, C.H.; Musademba, D. Advances in sustainable biofuel production from fast pyrolysis of lignocellulosic biomass. Biofuels 2023, 14, 529–550. [Google Scholar] [CrossRef]

- Cai, N.; Zhang, H.; Nie, J.; Deng, Y.; Baeyens, J. Biochar from biomass slow pyrolysis. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 586, p. 012001. [Google Scholar]

- Sekar, M.; Mathimani, T.; Alagumalai, A.; Chi, N.T.L.; Duc, P.A.; Bhatia, S.K.; Brindhadevi, K.; Pugazhendhi, A. A review on the pyrolysis of algal biomass for biochar and bio-oil–Bottlenecks and scope. Fuel 2021, 283, 119190. [Google Scholar] [CrossRef]

- Laougé, Z.B.; Çorbacıoğlu, C.; Merdun, H. Fast pyrolysis of greenhouse waste into bio-oil and optimization of process conditions using response surface methodology. Biomass Convers. Biorefin. 2023, 13, 9807–9819. [Google Scholar] [CrossRef]

- Singh, A.; Nanda, S.; Guayaquil-Sosa, J.F.; Berruti, F. Pyrolysis of Miscanthus and characterization of value-added bio-oil and biochar products. Can. J. Chem. Eng. 2021, 99, S55–S68. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; Shahbaz, M.; Mckay, G.; Mackey, H.; Al-Ansari, T. A review of pyrolysis technologies and feedstock: A blending approach for plastic and biomass towards optimum biochar yield. Renew. Sustain. Energy Rev. 2022, 167, 112715. [Google Scholar] [CrossRef]

- Husk, B.; Major, J. Bio-oil and biochar production by fast pyrolysis of biomass. J. Anal. Appl. Pyrolysis 2010, 89, 249–257. [Google Scholar]

- Wang, H.; Nan, Q.; Waqas, M.; Wu, W. Stability of biochar in mineral soils: Assessment methods, influencing factors and potential problems. Sci. Total Environ. 2022, 806, 150789. [Google Scholar] [CrossRef]

- Chun, Y.; Lee, S.K.; Yoo, H.Y.; Kim, S.W. Recent advancements in biochar production according to feedstock classification, pyrolysis conditions, and applications: A review. BioResources 2021, 16, 6512. [Google Scholar] [CrossRef]

- Bolan, N.; Hoang, S.A.; Beiyuan, J.; Gupta, S.; Hou, D.; Karakoti, A.; Joseph, S.; Jung, S.; Kim, K.H.; Kirkham, M.B.; et al. Multifunctional applications of biochar beyond carbon storage. Int. Mater. Rev. 2022, 67, 50–200. [Google Scholar] [CrossRef]

- Rodrigues, L.; Budai, A.; Elsgaard, L.; Hardy, B.; Keel, S.G.; Mondini, C.; Plaza, C.; Leifeld, J. The importance of biochar quality and pyrolysis yield for soil carbon sequestration in practice. Eur. J. Soil Sci. 2023, 74, e13396. [Google Scholar] [CrossRef]

- Rasaq, W.A.; Okpala, C.O.R.; Igwegbe, C.A.; Białowiec, A. Navigating pyrolysis implementation—A tutorial review on consideration factors and thermochemical operating methods for biomass conversion. Materials 2024, 17, 725. [Google Scholar] [CrossRef]

- Kamarudin, N.S.; Dahalan, F.A.; Hasan, M.; An, O.S.; Parmin, N.A.; Ibrahim, N.; Hamdzah, M.; Zain, N.A.; Muda, K.; Wikurendra, E.A. Biochar: A review of its history, characteristics, factors that influence its yield, methods of production, application in wastewater treatment and recent development. Biointerface Res. Appl. Chem. 2022, 12, 7914–7926. [Google Scholar] [CrossRef]

- Elkhlifi, Z.; Iftikhar, J.; Sarraf, M.; Ali, B.; Saleem, M.H.; Ibranshahib, I.; Bispo, M.D.; Meili, L.; Ercisli, S.; Torun Kayabasi, E.; et al. Potential role of biochar on capturing soil nutrients, carbon sequestration and managing environmental challenges: A review. Sustainability 2023, 15, 2527. [Google Scholar] [CrossRef]

- Pandey, D.; Daverey, A.; Arunachalam, K. Biochar: Production, properties and emerging role as a support for enzyme immobilization. J. Clean. Prod. 2020, 255, 120267. [Google Scholar] [CrossRef]

- Tan, H.; Lee, C.T.; Ong, P.Y.; Wong, K.Y.; Bong, C.P.C.; Li, C.; Gao, Y. A Review On The Comparison Between Slow Pyrolysis And Fast Pyrolysis On The Quality Of Lignocellulosic And Lignin-Based Biochar. IOP Conf. Ser. 2021, 012075. [Google Scholar] [CrossRef]

- Cakin, I.; Pap, S.; Gaffney, P.P.; Taggart, M.A. Designing a biochar-based pretreatment method for distillery effluents entering constructed wetlands. J. Clean. Prod. 2024, 476, 143790. [Google Scholar] [CrossRef]

- Liao, W.; Thomas, S.C. Biochar particle size and post-pyrolysis mechanical processing affect soil pH, water retention capacity, and plant performance. Soil Syst. 2019, 3, 14. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Singh, M.V.; Fransila, B.; Kumar, R.P.; Devi, G.K. A review on influencing parameters of biodiesel production and purification processes. Curr. Res. Green Sustain. Chem. 2020, 1, 1–6. [Google Scholar] [CrossRef]

- Thomas, S.C. Post-processing of biochars to enhance plant growth responses: A review and meta-analysis. Biochar 2021, 3, 437–455. [Google Scholar] [CrossRef]

- Laghari, M.; Müller-Stöver, D.S.; Puig-Arnavat, M.; Thomsen, T.P.; Henriksen, U.B. Evaluation of Biochar Post-Process Treatments to Produce Soil Enhancers and Phosphorus Fertilizers at a Single Plant. Waste Biomass Valor 2021, 12, 5517–5532. [Google Scholar] [CrossRef]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Singh, S.V.; Dhyani, V.C.; Govindaraju, K.; Vinu, R.; Mandal, S. Characterization, bioenergy value, and thermal stability of biochars derived from diverse agriculture and forestry lignocellulosic wastes. Biomass Conv. Bioref. 2023, 13, 879–892. [Google Scholar] [CrossRef]

- Werdin, J.; Fletcher, T.D.; Rayner, J.P.; Williams, N.S.; Farrell, C. Biochar made from low density wood has greater plant available water than biochar made from high density wood. Sci. Total Environ. 2020, 25, 135856. [Google Scholar] [CrossRef]

- Shrivastava, P.; Kumar, A.; Tekasakul, P.; Lam, S.S.; Palamanit, A. Comparative investigation of yield and quality of bio-oil and biochar from pyrolysis of woody and non-woody biomasses. Energies 2021, 14, 1092. [Google Scholar] [CrossRef]

- Abhishek, K.; Shrivastava, A.; Vimal, V.; Gupta, A.K.; Bhujbal, S.K.; Biswas, J.K.; Singh, L.; Ghosh, P.; Pandey, A.; Sharma, P.; et al. Biochar application for greenhouse gas mitigation, contaminants immobilization and soil fertility enhancement: A state-of-the-art review. Sci. Total Environ. 2022, 853, 158562. [Google Scholar] [CrossRef] [PubMed]

- Amin, F.R.; Huang, Y.; He, Y.; Zhang, R.; Liu, G.; Chen, C. Biochar applications and modern techniques for characterization. Clean Technol. Environ. Policy 2016, 18, 1457–1473. [Google Scholar] [CrossRef]

- Rutherford, D.W.; Wershaw, R.L.; Rostad, C.E.; Kelly, C.N. Effect of formation conditions on biochars: Compositional and structural properties of cellulose, lignin, and pine biochars. Biomass Bioenergy 2012, 46, 693–701. [Google Scholar] [CrossRef]

- Jiang, T.J.; Morgan Jr, H.M.; Tsai, W.T.; Chien, H.; Yen, T.B.; Lee, Y.R. Thermochemical Conversion of Biomass into Biochar: Enhancing Adsorption Kinetics and Pore Properties for Environmental Sustainability. Sustainability 2024, 16, 6623. [Google Scholar] [CrossRef]

- Akmal, M.; Maqbool, Z.; Khan, K.S.; Hussain, Q.; Ijaz, S.S.; Iqbal, M.; Aziz, I.; Hussain, A.; Abbas, M.S.; Rafa, H.U. Integrated use of biochar and compost to improve soil microbial activity, nutrient availability, and plant growth in arid soil. Arab J. Geosci. 2019, 12, 232. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Conradie, J.; Ohoro, C.R.; Amaku, J.F.; Oyedotun, K.O.; Maxakato, N.W.; Akpomie, K.G.; Okeke, E.S.; Olisah, C.; Malloum, A.; et al. Biochar from coconut residues: An overview of production, properties, and applications. Ind. Crops Prod. 2023, 204, 117300. [Google Scholar] [CrossRef]

- Singh, B.; Singh, B.P.; Cowie, A.L. Characterisation and evaluation of biochars for their application as a soil amendment. Soil Res. 2010, 48, 516–525. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; Melo, I.C.; Melo, L.C.; Magriotis, Z.M.; Sánchez-Monedero, M.A. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef] [PubMed]

- Murtaza, G.; Usman, M.; Ahmed, Z.; Rizwan, M.; Iqbal, R. Non-wood-based biochars as promising and eco-friendly adsorbents for chromium hexavalent Cr (VI) removal from aquatic systems: State-of-the-art, limitations, and potential future directions. Environ. Pollut. Bioavailab. 2024, 36, 2387680. [Google Scholar] [CrossRef]

- Custodis, V.B.; Karakoulia, S.A.; Triantafyllidis, K.S.; van Bokhoven, J.A. Catalytic fast pyrolysis of lignin over high-surface-area mesoporous aluminosilicates: Effect of porosity and acidity. ChemSusChem 2016, 9, 1134–1145. [Google Scholar] [CrossRef]

- Munera-Echeverri, J.L.; Martinsen, V.; Strand, L.T.; Zivanovic, V.; Cornelissen, G.; Mulder, J. Cation exchange capacity of biochar: An urgent method modification. Sci. Total Environ. 2018, 642, 190–197. [Google Scholar] [CrossRef] [PubMed]

- Mukome, F.N.; Six, J.; Parikh, S.J. The effects of walnut shell and wood feedstock biochar amendments on greenhouse gas emissions from a fertile soil. Geoderma 2013, 1, 90–98. [Google Scholar] [CrossRef]

- Mukherjee, A.; Zimmerman, A.R.; Harris, W. Surface chemistry variations among a series of laboratory-produced biochars. Geoderma 2011, 163, 247–255. [Google Scholar] [CrossRef]

- El-Gamal, E.; Saleh, M.; Elsokkary, I.; Rashad, M.; Mona, M.; Mona, M. Comparison between properties of biochar produced by traditional and controlled pyrolysis. Alex. Sci. Exch. J. 2017, 38, 412–425. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, R.K.; Zhang, H. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef]

- Chen, W.H.; Wang, C.W.; Ong, H.C.; Show, P.L.; Hsieh, T.H. Torrefaction, pyrolysis and two-stage thermodegradation of hemicellulose, cellulose and lignin. Fuel 2019, 258, 116168. [Google Scholar] [CrossRef]

- Fu, P.; Yi, W.; Bai, X.; Li, Z.; Hu, S.; Xiang, J. Effect of temperature on gas composition and char structural features of pyrolyzed agricultural residues. Bioresour. Technol. 2011, 102, 8211–8219. [Google Scholar] [CrossRef]

- Domingues, R.R.; Sánchez-Monedero, M.A.; Spokas, K.A.; Melo, L.C.; Trugilho, P.F.; Valenciano, M.N.; Silva, C.A. Enhancing cation exchange capacity of weathered soils using biochar: Feedstock, pyrolysis conditions and addition rate. Agronomy 2020, 10, 824. [Google Scholar] [CrossRef]

- Chatterjee, S.; Saito, T. Lignin-derived advanced carbon materials. ChemSusChem 2015, 23, 3941–3958. [Google Scholar] [CrossRef] [PubMed]

- Clurman, A.M.; Rodríguez-Narvaez, O.M.; Jayarathne, A.; De Silva, G.; Ranasinghe, M.I.; Goonetilleke, A.; Bandala, E.R. Influence of surface hydrophobicity/hydrophilicity of biochar on the removal of emerging contaminants. Chem. Eng. J. 2020, 402, 126277. [Google Scholar] [CrossRef]

- Banik, C.; Lawrinenko, M.; Bakshi, S.; Laird, D.A. Impact of pyrolysis temperature and feedstock on surface charge and functional group chemistry of biochars. J. Environ. Qual. 2018, 47, 452–461. [Google Scholar] [CrossRef]

- Newalkar, G.; Iisa, K.; D’Amico, A.D.; Sievers, C.; Agrawal, P. Effect of temperature, pressure, and residence time on pyrolysis of pine in an entrained flow reactor. Energy Fuels 2014, 28, 5144–5157. [Google Scholar] [CrossRef]

- Patil, S.A.; Hebbal, O.D.; Hotti, S.R. Bio-oil production by pyrolysis of hibiscus cannabinus (Deccan Hemp) and pongamia pinnata (Karanja) seed cake and its characterization. Int. J. Adv. Technol. Eng. Explor. 2023, 10, 87–104. [Google Scholar] [CrossRef]

- Mukherjee, A.; Patra, B.R.; Podder, J.; Dalai, A.K. Synthesis of biochar from lignocellulosic biomass for diverse industrial applications and energy harvesting: Effects of pyrolysis conditions on the physicochemical properties of biochar. Front. Mater. 2022, 9, 870184. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, F.; Li, Z.; Tan, H. Formation and emission characteristics of PAHs during pyrolysis and combustion of coal and biomass. Fuel 2024, 378, 132935. [Google Scholar] [CrossRef]

- Gezahegn, A.G.; Selassie, Y.; Agegnehu, G.; Addisu, S.; Asargew Mihretie, F.; Kohira, Y.; Sato, S. Pyrolysis temperature changes the physicochemical characteristics of water hyacinth-based biochar as a potential soil amendment. Biomass Convers. Biorefin. 2024, 15, 3737–3752. [Google Scholar] [CrossRef]

- Zheng, Q.; Zhang, D.; Fu, P.; Wang, A.; Sun, Y.; Li, Z.; Fan, Q. Insight into the fast pyrolysis of lignin: Unraveling the role of volatile evolving and char structural evolution. Chem. Eng. J. 2022, 437, 135316. [Google Scholar] [CrossRef]

- Lin, J.; Xu, Z.; Zhang, Q.; Cao, Y.; Mašek, O.; Lei, H.; Tsang, D.C. Enhanced adsorption of aromatic VOCs on hydrophobic porous biochar produced via microwave rapid pyrolysis. Bioresour. Technol. 2024, 393, 130085. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, E.; Mishra, R.; Kumar, S. Biochar as environmental armour and its diverse role towards protecting soil, water and air. Sci. Total Environ. 2022, 806, 150444. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.G.; Chun, J.H.; Yun, Y.U.; Lee, J.Y.; Sung, J.; Oh, T.K. Pyrolysis temperature and time of rice husk biochar potentially control ammonia emissions and Chinese cabbage yield from urea-fertilized soils. Sci. Rep. 2024, 14, 5692. [Google Scholar] [CrossRef]

- Raczkiewicz, M.; Ostolska, I.; Mašek, O.; Oleszczuk, P. Effect of the pyrolysis conditions and type of feedstock on nanobiochars obtained as a result of ball milling. J. Clean. Prod. 2024, 458, 142456. [Google Scholar] [CrossRef]

- Adhikari, S.; Mahmud, M.P.; Nguyen, M.D.; Timms, W. Evaluating fundamental biochar properties in relation to water holding capacity. Chemosphere 2023, 328, 138620. [Google Scholar] [CrossRef] [PubMed]

- Reza, M.S.; Iskakova, Z.B.; Afroze, S.; Kuterbekov, K.; Kabyshev, A.; Bekmyrza, K.Z.; Kubenova, M.M.; Bakar, M.S.A.; Azad, A.K.; Roy, H.; et al. Influence of catalyst on the yield and quality of bio-oil for the catalytic pyrolysis of biomass: A comprehensive review. Energies 2023, 16, 5547. [Google Scholar] [CrossRef]

- Xie, T.; Reddy, K.R.; Wang, C.; Yargicoglu, E.; Spokas, K. Characteristics and applications of biochar for environmental remediation: A review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 939–969. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P. Review of process parameters for biodiesel production from different feedstocks. Renew. Sustain. Energy Rev. 2016, 62, 1063–1071. [Google Scholar] [CrossRef]

- Igalavithana, A.D.; Mandal, S.; Niazi, N.K.; Vithanage, M.; Parikh, S.J.; Mukome, F.N.; Rizwan, M.; Oleszczuk, P.; Al-Wabel, M.; Bolan, N.; et al. Advances and future directions of biochar characterization methods and applications. Crit. Rev. Environ. Sci. Technol. 2017, 47, 2275–2330. [Google Scholar] [CrossRef]

- Ennis, C.; Evans, A.G.; Islam, M.; Ralebitso-Senior, T.K.; Senior, E. Biochar: Carbon sequestration, land remediation, and impacts on soil microbiology. Crit. Rev. Environ. Sci. Technol. 2012, 42, 2311–2364. [Google Scholar] [CrossRef]

- Wong, J.W.; Webber, J.B.; Ogbonnaya, U.O. Characteristics of biochar porosity by NMR and study of ammonium ion adsorption. J. Anal. Appl. Pyrolysis 2019, 143, 104687. [Google Scholar] [CrossRef]

- Li, S.; Chen, G. Thermogravimetric, thermochemical, and infrared spectral characterization of feedstocks and biochar derived at different pyrolysis temperatures. Waste Manag. 2018, 78, 198–207. [Google Scholar] [CrossRef]

- Jegan, J.; Praveen, S.; Pushpa, T.B.; Gokulan, R. Biodecolorization of basic violet 03 using biochar derived from agricultural wastes: Isotherm and kinetics. J. Biobased Mater. Bioenergy 2020, 14, 316–326. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, B.; Budai, A.; Jeng, A.; Hao, X.; Wei, D.; Zhang, Y.; Rasse, D. Study of biochar properties by scanning electron microscope–energy dispersive X-ray spectroscopy (SEM-EDX). Commun. Soil Sci. Plant Anal. 2016, 47, 593–601. [Google Scholar] [CrossRef]

- Oleszczuk, P.; Ćwikła-Bundyra, W.; Bogusz, A.; Skwarek, E.; Ok, Y.S. Characterization of nanoparticles of biochars from different biomass. J. Anal. Appl. Pyrolysis 2016, 121, 165–172. [Google Scholar] [CrossRef]

- Bekiaris, G.; Peltre, C.; Jensen, L.S.; Bruun, S. Using FTIR-photoacoustic spectroscopy for phosphorus speciation analysis of biochars. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 168, 29–36. [Google Scholar] [CrossRef]

- Tsolis, V.; Barouchas, P. Biochar as soil amendment: The effect of biochar on soil properties using VIS-NIR diffuse reflectance spectroscopy, biochar aging and soil microbiology—A review. Land 2023, 12, 1580. [Google Scholar] [CrossRef]

- Shen, D.; Liu, G.; Zhao, J.; Xue, J.; Guan, S.; Xiao, R. Thermo-chemical conversion of lignin to aromatic compounds: Effect of lignin source and reaction temperature. J. Anal. Appl. Pyrolysis 2015, 112, 56–65. [Google Scholar] [CrossRef]

- Munira, S.; Dynes, J.J.; Islam, M.; Khan, F.; Adesanya, T.; Regier, T.Z.; Spokas, K.A.; Farenhorst, A. Relative proportions of organic carbon functional groups in biochars as influenced by spectral data collection and processing. Chemosphere 2021, 283, 131023. [Google Scholar] [CrossRef]

- Haider, F.U.; Coulter, J.A.; Liqun, C.A.I.; Hussain, S.; Cheema, S.A.; Jun, W.U.; Zhang, R. An overview on biochar production, its implications, and mechanisms of biochar-induced amelioration of soil and plant characteristics. Pedosphere 2022, 32, 107–130. [Google Scholar] [CrossRef]

- Singh, H.; Northup, B.K.; Rice, C.W.; Prasad, P.V. Biochar applications influence soil physical and chemical properties, microbial diversity, and crop productivity: A meta-analysis. Biochar 2022, 4, 8. [Google Scholar] [CrossRef]

- Ullah, M.S.; Malekian, R.; Randhawa, G.S.; Gill, Y.S.; Singh, S.; Esau, T.J.; Zaman, Q.U.; Afzaal, H.; Du, D.L.; Farooque, A.A. The potential of biochar incorporation into agricultural soils to promote sustainable agriculture: Insights from soil health, crop productivity, greenhouse gas emission mitigation and feasibility perspectives—A critical review. Rev. Environ. Sci. Bio/Technol. 2024, 23, 1105–1130. [Google Scholar] [CrossRef]

- Ayaz, M.; Muntaha, S.T.; Baltrėnaitė-Gedienė, E.; Kriaučiūnienė, Z. Biochar and carbon-negative technologies: Exploring opportunities for climate change mitigation. Biochar 2025, 7, 17. [Google Scholar] [CrossRef]

- Ayaz, M.; Feizienė, D.; Tilvikienė, V.; Akhtar, K.; Stulpinaitė, U.; Iqbal, R. Biochar role in the sustainability of agriculture and environment. Sustainability 2021, 13, 1330. [Google Scholar] [CrossRef]

- Janu, R.; Mrlik, V.; Ribitsch, D.; Hofman, J.; Sedláček, P.; Bielská, L.; Soja, G. Biochar surface functional groups as affected by biomass feedstock, biochar composition and pyrolysis temperature. Carbon Resour. Convers. 2021, 4, 36–46. [Google Scholar] [CrossRef]

- Bushra, B.; Remya, N. Biochar from pyrolysis of rice husk biomass—Characteristics, modification and environmental application. Biomass Convers. Biorefin. 2024, 14, 5759–5770. [Google Scholar] [CrossRef]

- Chen, X.; Meng, J.; Shen, J.; Chen, L. Effects of pyrolysis temperature on the surface area and porosity of biochar. J. Anal. Appl. Pyrolysis 2019, 137, 102–109. [Google Scholar]

- Yang, W.; Shang, J.; Li, B.; Flury, M. Surface and colloid properties of biochar and implications for transport in porous media. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2484–2522. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Adebiyi, A.O.; Ahmed, M. Biochar’s effects on soil physical and hydraulic properties: A review. J. Environ. Manag. 2018, 227, 209–218. [Google Scholar]

- Li, J.; Cao, L.; Yuan, Y.; Wang, R.; Wen, Y.; Man, J. Comparative study for microcystin-LR sorption onto biochars produced from various plant-and animal-wastes at different pyrolysis temperatures: Influencing mechanisms of biochar properties. Bioresour. Technol. 2018, 247, 794–803. [Google Scholar] [CrossRef]

- Muzyka, R.; Misztal, E.; Hrabak, J.; Banks, S.W.; Sajdak, M. Various biomass pyrolysis conditions influence the porosity and pore size distribution of biochar. Energy 2023, 263, 126128. [Google Scholar] [CrossRef]

- Li, Q.; Jia, Z.; Fu, J.; Yang, X.; Shi, X.; Chen, R. Biochar enhances partial denitrification/anammox by sustaining high rates of nitrate to nitrite reduction. Bioresour. Technol. 2022, 349, 126869. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.W.; Yibeltal, M.; Kim, Y.H.; Oh, S.J.; Lee, J.C.; Kwon, E.E.; Lee, S.S. Enhancement of soil physical properties and soil water retention with biochar-based soil amendments. Sci. Total Environ. 2022, 836, 155746. [Google Scholar] [CrossRef]

- Luo, L.; Wang, G.; Shi, G.; Zhang, M.; Zhang, J.; He, J.; Xiao, Y.; Tian, D.; Zhang, Y.; Deng, S.; et al. The characterization of biochars derived from rice straw and swine manure, and their potential and risk in N and P removal from water. J. Environ. Manag. 2019, 245, 1–7. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, Y.; Wu, Z.; Yan, X.; Gunina, A.; Kuzyakov, Y.; Xiong, Z. Effects of six-year biochar amendment on soil aggregation, crop growth, and nitrogen and phosphorus use efficiencies in a rice-wheat rotation. J. Clean. Prod. 2020, 242, 118435. [Google Scholar] [CrossRef]

- Rajendran, K.; Ravindran, B.; Zhang, Z. Biochar amendment reduced nitrogen loss from a sandy loam soil. J. Environ. Qual. 2017, 46, 657–674. [Google Scholar]

- Kumar, A.; Bhattacharya, T.; Shaikh, W.A.; Roy, A. Sustainable soil management under drought stress through biochar application: Immobilizing arsenic, ameliorating soil quality, and augmenting plant growth. Environ. Res. 2024, 259, 119531. [Google Scholar] [CrossRef]

- Lu, H.L.; Li, K.W.; Nkoh, J.N.; He, X.; Hong, Z.N.; Xu, R.K. Effects of the increases in soil pH and pH buffering capacity induced by crop residue biochars on available Cd contents in acidic paddy soils. Chemosphere 2022, 301, 134674. [Google Scholar] [CrossRef]

- Murtaza, G.; Ahmed, Z.; Usman, M. Feedstock type, pyrolysis temperature and acid modification effects on physiochemical attributes of biochar and soil quality. Arab. J. Geosci. 2022, 15, 305. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, P.; Luo, Y. Effects of pyrolysis temperature on biochar’s pH and ash content. J. Anal. Appl. Pyrolysis 2015, 113, 268–275. [Google Scholar]

- Figueredo, R.A.; Santos, P.R.S.; Maia, P.F. pH and ash content of biochar from different feedstocks and pyrolysis temperatures. J. Environ. Manag. 2017, 203, 143–149. [Google Scholar]

- Gholizadeh, M.; Meca, S.; Zhang, S.; Clarens, F.; Hu, X. Understanding the dependence of biochar properties on different types of biomass. Waste Manag. 2024, 182, 142–163. [Google Scholar] [CrossRef] [PubMed]

- Qi, F.; Zhang, Y.; Shen, X.; Hou, Y. Effects of feedstock type on biochar’s pH and nutrient content. J. Environ. Manag. 2017, 203, 135–142. [Google Scholar]

- Freitas, A.M.; Nair, V.D.; Harris, W.G. Biochar as influenced by feedstock variability: Implications and opportunities for phosphorus management. Front. Sustain. Food Syst. 2020, 4, 510982. [Google Scholar] [CrossRef]

- Nkoh, J.N.; Ajibade, F.O.; Atakpa, E.O.; Abdulaha-Al Baquy, M.; Mia, S.; Odii, E.C.; Xu, R. Reduction of heavy metal uptake from polluted soils and associated health risks through biochar amendment: A critical synthesis. J. Hazard. Mater. Adv. 2022, 6, 100086. [Google Scholar] [CrossRef]

- Banu, M.R.; Rani, B.; Kavya, S.R.; Nihala Jabin, P.P. Biochar: A black carbon for sustainable agriculture. Int. J. Environ. Clim. Change 2023, 13, 418–432. [Google Scholar] [CrossRef]

- Yao, Y.; Panahi, A.; Schiemann, M.; Levendis, Y.A. Determination of size and porosity of chars during combustion of biomass particles. Combust. Flame 2022, 242, 112182. [Google Scholar] [CrossRef]

- Nsamba, H.K.; Hale, S.E.; Cornelissen, G.; Bachmann, R.T. Sustainable Technologies for Small-Scale Biochar Production—A Review. J. Sustain. Bioenergy Syst. 2015, 5, 10–31. [Google Scholar] [CrossRef]

- Raclavská, H.; Corsaro, A.; Juchelková, D.; Sassmanová, V.; Frantík, J. Effect of temperature on the enrichment and volatility of 18 elements during pyrolysis of biomass, coal, and tires. Fuel Process. Technol. 2015, 131, 330–337. [Google Scholar] [CrossRef]

- Basu, P.; Kaushal, P. Modeling of pyrolysis and gasification of biomass in fluidized beds: A review. Chem. Prod. Process Model. 2009, 4, 1. [Google Scholar] [CrossRef]

- Lestinsky, P.; Palit, A. Wood pyrolysis using aspen plus simulation and industrially applicable model. GeoScience Eng. 2016, 62, 11. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Performance investigation of biomass gasification for syngas and hydrogen production using Aspen Plus. Open J. Model. Simul. 2022, 10, 71–87. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Performance analysis of power generation by wood and woody biomass gasification in a downdraft gasifier. Int. J. Appl. 2021, 10, 80–88. [Google Scholar] [CrossRef]

- Peters, J.F.; Banks, S.W.; Bridgwater, A.V.; Dufour, J. A kinetic reaction model for biomass pyrolysis processes in Aspen Plus. Appl. Energy 2017, 188, 595–603. [Google Scholar] [CrossRef]

- Vikram, S.; Rosha, P.; Kumar, S. Recent modeling approaches to biomass pyrolysis: A review. Energy Fuels 2021, 35, 7406–7433. [Google Scholar] [CrossRef]

- Zaini, I.N.; Sophonrat, N.; Sjöblom, K.; Yang, W. Creating values from biomass pyrolysis in Sweden: Co-production of H2, biocarbon and bio-oil. Processes 2021, 9, 415. [Google Scholar] [CrossRef]

- Visconti, A.; Miccio, M.; Juchelková, D. An Aspen Plus® tool for simulation of lignocellulosic biomass pyrolysis via equilibrium and ranking of the main process variables. Int. J. Math. Models Methods Appl. Sci. 2015, 9, 71–86. [Google Scholar]

- Jaroenkhasemmeesuk, C.; Tippayawong, N.; Ingham, D.B.; Pourkashanian, M. Process modelling and simulation of fast pyrolysis plant of lignocellulosic biomass using improved chemical kinetics in Aspen Plus®. CET J.-Chem. Eng. Trans. 2020, 1, 78. [Google Scholar]

- Mosa, A.; Mansour, M.M.; Soliman, E.; El-Ghamry, A.; El Alfy, M.; El Kenawy, A.M. Biochar as a soil amendment for restraining greenhouse gases emission and improving soil carbon sink: Current situation and ways forward. Sustainability 2023, 15, 1206. [Google Scholar] [CrossRef]

- He, R.; Hui, K.; Zhang, X.; Yao, H. Insight into the Role of the Pore Structure and Surface Functional Groups in Biochar on the Adsorption of Sulfamethoxazole from Synthetic Urine. Appl. Sci. 2024, 14, 1715. [Google Scholar] [CrossRef]

- Marshall, J.; Muhlack, R.; Morton, B.J.; Dunnigan, L.; Chittleborough, D.; Kwong, C.W. Pyrolysis temperature effects on biochar–water interactions and application for improved water holding capacity in vineyard soils. Soil Syst. 2019, 3, 27. [Google Scholar] [CrossRef]

- Murtaza, G.; Ahmed, Z.; Usman, M.; Tariq, W.; Ullah, Z.; Shareef, M.; Iqbal, H.; Waqas, M.; Tariq, A.; Wu, Y.; et al. Biochar induced modifications in soil properties and its impacts on crop growth and production. J. Plant Nutr. 2021, 44, 1677–1691. [Google Scholar] [CrossRef]

- Liang, J.; Li, Y.; Si, B.; Wang, Y.; Chen, X.; Wang, X.; Chen, H.; Wang, H.; Zhang, F.; Bai, Y.; et al. Optimizing biochar application to improve soil physical and hydraulic properties in saline-alkali soils. Sci. Total Environ. 2021, 771, 144802. [Google Scholar] [CrossRef]

- Lustosa Carvalho, M.; Tuzzin de Moraes, M.; Cerri, C.E.P.; Cherubin, M.R. Biochar amendment enhances water retention in a tropical sandy soil. Agriculture 2020, 10, 62. [Google Scholar] [CrossRef]

- Feng, J.; Yu, D.; Sinsabaugh, R.L.; Moorhead, D.L.; Andersen, M.N.; Smith, P.; Song, Y.; Li, X.; Huang, Q.; Liu, Y.-R.; et al. Trade-offs in carbon-degrading enzyme activities limit long-term soil carbon sequestration with biochar addition. Biol. Rev. 2023, 98, 1184–1199. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Chen, Y. Biochar’s potential for carbon sequestration in different climate zones. Environ. Sci. Technol. 2016, 50, 10356–10364. [Google Scholar]

- Chagas, J.K.M.; de Figueiredo, C.C.; Ramos, M.L.G. Biochar increases soil carbon pools: Evidence from a global meta-analysis. J. Environ. Manag. 2022, 305, 114403. [Google Scholar] [CrossRef] [PubMed]

- Bamminger, C.; Poll, C.; Marhan, S. Offsetting global warming-induced elevated greenhouse gas emissions from an arable soil by biochar application. Glob. Change Biol. 2018, 24, e318–e334. [Google Scholar] [CrossRef]

- Zanli, B.L.G.L.; Gbossou, K.C.; Tang, W.; Kamoto, M.; Chen, J. A review of biochar potential in Cote d’Ivoire in light of the challenges facing Sub-Saharan Africa. Biomass Bioenergy 2022, 165, 106581. [Google Scholar] [CrossRef]

- Karan, S.K.; Osslund, F.; Azzi, E.S.; Karltun, E.; Sundberg, C. A spatial framework for prioritizing biochar application to arable land: A case study for Sweden. Resour. Conserv. Recycl. 2023, 189, 106769. [Google Scholar] [CrossRef]

- Paiva, I.D.; Morais, E.G.; Silva, C.A. Biochar and Ammonium Nitrate Synergies: Enhancing Nitrogen Availability and Maize Growth in Oxisols. Agronomy 2025, 15, 633. [Google Scholar] [CrossRef]

- Saaty, T.L. What is the Analytic Hierarchy Process? In Mathematical Models for Decision Support; Mitra, G., Greenberg, H.J., Lootsma, F.A., Rijkaert, M.J., Zimmermann, H.J., Eds.; NATO ASI Series; Springer: Berlin/Heidelberg, Germany, 1998; Volume 48. [Google Scholar] [CrossRef]

- Drobne, S.; Lisec, A. Multi-attribute decision analysis in GIS: Weighted linear combination and ordered weighted averaging. Informatica 2009, 33, 459–474. [Google Scholar]

- Daunoras, J.; Kačergius, A.; Gudiukaitė, R. Role of soil microbiota enzymes in soil health and activity changes depending on climate change and the type of soil ecosystem. Biology 2024, 13, 85. [Google Scholar] [CrossRef] [PubMed]

- Tusar, H.M.; Uddin, M.K.; Mia, S.; Suhi, A.A.; Wahid, S.B.; Kasim, S.; Sairi, N.A.; Alam, Z.; Anwar, F. Biochar-acid soil interactions—A review. Sustainability 2023, 15, 13366. [Google Scholar] [CrossRef]

- Jeffery, S.; Verheijen, F.G.; van der Velde, M.; Bastos, A.C. A quantitative review of the effects of biochar application to soils on crop productivity using meta-analysis. Agric. Ecosyst. Environ. 2011, 144, 175–187. [Google Scholar] [CrossRef]

- Egyir, M.; Luyima, D.; Park, S.J.; Lee, K.S.; Oh, T.K. Volatilisations of ammonia from the soils amended with modified and nitrogen-enriched biochars. Sci. Total Environ. 2022, 835, 155453. [Google Scholar] [CrossRef]

- Biederman, L.A.; Harpole, W.S. Biochar and its effects on plant productivity and nutrient cycling: A meta-analysis. GCB Bioenergy 2013, 5, 202–214. [Google Scholar] [CrossRef]

- Fachini, J.; Coser, T.R.; Araujo, A.S.; Vale, A.T.; Jindo, K.; Figueiredo, C.C. One year residual effect of sewage sludge biochar as a soil amendment for maize in a Brazilian Oxisol. Sustainability 2021, 13, 2226. [Google Scholar] [CrossRef]

- Lehmann, J.; Gaunt, J.; Rondon, M. Bio-char sequestration in terrestrial ecosystems–a review. Mitig. Adapt. Strateg. Glob. Change 2006, 11, 403–427. [Google Scholar] [CrossRef]

- ESRI. ArcGIS Pro, Version 3.0. Band Collection Statistics Tool. Environmental Systems Research Institute (ESRI): Redlands, CA, USA, 2022.

- Qiu, M.; Liu, L.; Ling, Q.; Cai, Y.; Yu, S.; Wang, S.; Fu, D.; Hu, B.; Wang, X. Biochar for the removal of contaminants from soil and water: A review. Biochar 2021, 4, 19. [Google Scholar] [CrossRef]

- Gwenzi, W.; Nyambishi, T.J.; Chaukura, N.; Mapope, N. Synthesis and nutrient release patterns of a biochar-based N–P–K slow-release fertilizer. Int. J. Environ. Sci. Technol. 2018, 15, 405–414. [Google Scholar] [CrossRef]

- Mukherjee, A.; Lal, R. Biochar impacts on soil physical properties and greenhouse gas emissions. Agronomy 2013, 3, 313–339. [Google Scholar] [CrossRef]

- Yu, L.; Tang, J.; Zhang, R.; Wu, Q.; Gong, M. Effects of biochar application on soil methane emission at different soil moisture levels. Biol. Fertil. Soils 2013, 49, 119–128. [Google Scholar] [CrossRef]

- Troy, S.M.; Lawlor, P.G.; O’Flynn, C.J.; Healy, M.G. Impact of biochar addition to soil on greenhouse gas emissions following pig manure application. Soil Biol. Biochem. 2013, 60, 173–181. [Google Scholar] [CrossRef]

- Baiamonte, G.; Crescimanno, G.; Parrino, F.; De Pasquale, C. Effect of biochar on the physical and structural properties of a sandy soil. Catena 2019, 175, 294–303. [Google Scholar] [CrossRef]

- Antonangelo, J.A.; Sun, X.; Eufrade-Junior, H.J. Biochar impact on soil health and tree-based crops: A review. Biochar 2025, 7, 51. [Google Scholar] [CrossRef]

- Farhangi-Abriz, S.; Torabian, S.; Qin, R.; Noulas, C.; Lu, Y.; Gao, S. Biochar effects on yield of cereal and legume crops using meta-analysis. Sci. Total Environ. 2021, 775, 145869. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.R.; Loos, M. Carbon capture and storage: A review of the current state of the art. Energy Environ. Sci. 2005, 2, 1–13. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Climate change 2007: Mitigation. Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Fagorite, V.I.; Chijioke, C.F.; Opara, A.I.; Onyekuru, S.O.; Oguzie, E.E. Environmental and safety issues associated with geological carbon storage: A review. Euro-Mediterr. J. Environ. Integr. 2022, 7, 445–461. [Google Scholar] [CrossRef]

- Li, S.; Tasnady, D. Biochar for soil carbon sequestration: Current knowledge, mechanisms, and future perspectives. C 2023, 9, 67. [Google Scholar] [CrossRef]

- Xu, H.; Cai, A.; Wu, D.; Liang, G.; Xiao, J.; Xu, M.; Colinet, G.; Zhang, W. Effects of biochar application on crop productivity, soil carbon sequestration, and global warming potential controlled by biochar C: N ratio and soil pH: A global meta-analysis. Soil Tillage Res. 2021, 213, 105125. [Google Scholar] [CrossRef]

- Khan, S.; Irshad, S.; Mehmood, K.; Hasnain, Z.; Nawaz, M.; Rais, A.; Gul, S.; Wahid, M.A.; Hashem, A.; Abd_Allah, E.F.; et al. Biochar production and characteristics, its impacts on soil health, crop production, and yield enhancement: A review. Plants 2024, 13, 166. [Google Scholar] [CrossRef] [PubMed]

- Cayuela, M.L.; van Zwieten, L.; Singh, B.P.; Jeffery, S.; Roig, A.; Sánchez-Monedero, M.A. Biochar’s role in mitigating soil nitrous oxide emissions: A review and meta-analysis. Agric. Ecosyst. Environ. 2014, 191, 5–16. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Ma, Y. Biochar increases nitrogen uptake and use efficiency in crops. J. Environ. Qual. 2019, 48, 657–674. [Google Scholar]

- Manono, B.O. Effects of Irrigation, Effluent Dispersal and Organic Farming on Earthworms and Soil Microbes in New Zealand Dairy Farms. Ph.D. Thesis, University of Otago, Dunedin, New Zealand, 2014. Available online: https://hdl.handle.net/10523/5097 (accessed on 15 March 2025).

- Pan, S.Y.; Dong, C.D.; Su, J.F.; Wang, P.Y.; Chen, C.W.; Chang, J.S.; Kim, H.; Huang, C.-P.; Hung, C.M. The role of biochar in regulating the carbon, phosphorus, and nitrogen cycles exemplified by soil systems. Sustainability 2021, 13, 5612. [Google Scholar] [CrossRef]

- Alkharabsheh, H.M.; Seleiman, M.F.; Battaglia, M.L.; Shami, A.; Jalal, R.S.; Alhammad, B.A.; Almutairi, K.F.; Al-Saif, A.M. Biochar and its broad impacts in soil quality and fertility, nutrient leaching and crop productivity: A review. Agronomy 2021, 11, 993. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K.; Avasthe, R. Biochar application for environmental management and toxic pollutant remediation. Biomass Convers. Biorefin. 2023, 13, 555–566. [Google Scholar] [CrossRef]

- Hussain, M.; Farooq, M.; Wakeel, A. Biochar effects on soil nutrient availability and crop yield: A review. J. Environ. Qual. 2017, 46, 687–696. [Google Scholar]

- Fatima, S.; Riaz, M.; Al-Wabel, M.I.; Arif, M.S.; Yasmeen, T.; Hussain, Q.; Roohi, M.; Fahad, S.; Ali, K.; Arif, M. Higher biochar rate strongly reduced decomposition of soil organic matter to enhance C and N sequestration in nutrient-poor alkaline calcareous soil. J. Soils Sediments 2021, 21, 148–162. [Google Scholar] [CrossRef]

- Marcińczyk, M.; Oleszczuk, P. Biochar and engineered biochar as slow-and controlled-release fertilizers. J. Clean. Prod. 2022, 339, 130685. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, Y.; Cao, X.; Ma, Y.; Li, X. Biochar effects on nutrient leaching in soil. J. Environ. Qual. 2018, 47, 657–674. [Google Scholar]

- Viancelli, A.; Michelon, W. Climate change and nitrogen dynamics: Challenges and strategies for a sustainable future. Nitrogen 2024, 5, 688–701. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, Y.; Liu, Q.; Chen, S.; Hou, P.; Poinern, G.; Jiang, Z.; Fawcett, D.; Xue, L.; Lam, S.S.; et al. How does biochar aging affect NH3 volatilization and GHGs emissions from agricultural soils? Environ. Pollut. 2022, 294, 118598. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, X.; Li, G.; Liu, X. Mechanism of biochar on nitrification and denitrification to N2O emissions based on isotope characteristic values. Environ. Res. 2022, 212, 113219. [Google Scholar] [CrossRef]

- Kaur, N.; Kieffer, C.; Ren, W.; Hui, D. How much is soil nitrous oxide emission reduced with biochar application? An evaluation of meta-analyses. GCB Bioenergy 2023, 15, 24–37. [Google Scholar] [CrossRef]

- Yao, Y.; Yang, W.; Ma, Y. Biochar increases nitrogen use efficiency in rice. J. Environ. Qual. 2019, 48, 675–686. [Google Scholar]

- Chen, X.; Yang, S.H.; Jiang, Z.W.; Ding, J.; Sun, X. Biochar as a tool to reduce environmental impacts of nitrogen loss in water-saving irrigation paddy field. J. Clean. Prod. 2021, 290, 125811. [Google Scholar] [CrossRef]

- Yang, L.; Wu, Y.; Wang, Y.; An, W.; Jin, J.; Sun, K.; Wang, X. Effects of biochar addition on the abundance, speciation, availability, and leaching loss of soil phosphorus. Sci. Total Environ. 2021, 758, 143657. [Google Scholar] [CrossRef]

- Ghodszad, L.; Reyhanitabar, A.; Oustan, S.; Alidokht, L. Phosphorus sorption and desorption characteristics of soils as affected by biochar. Soil Tillage Res. 2022, 216, 105251. [Google Scholar] [CrossRef]

- Shi, Y.; Yu, Y.; Chang, E.; Wang, R.; Hong, Z.; Cui, J.; Zhang, F.; Jiang, J.; Xu, R. Effect of biochar incorporation on phosphorus supplementation and availability in soil: A review. J. Soils Sediments 2023, 23, 672–686. [Google Scholar] [CrossRef]

- Ajmal, Z.; Muhmood, A.; Dong, R.; Wu, S. Probing the efficiency of magnetically modified biomass-derived biochar for effective phosphate removal. J. Environ. Manag. 2020, 253, 109730. [Google Scholar] [CrossRef] [PubMed]

- Angst, T.E. Biochar and nutrient leaching in soils. J. Environ. Qual. 2014, 43, 631–644. [Google Scholar]

- Major, J.; Angst, T.E.; Dalal, R.C.; Menzies, N.W. Wood biochar effects on nutrient leaching in an acidic and low-fertile soil. J. Environ. Qual. 2012, 41, 657–674. [Google Scholar]

- Hardie, M.; Haynes, P.M.; Quirk, R.J.; Dalal, R.C.; Menzies, N.W. Biochar effects on potassium leaching in soil. J. Environ. Qual. 2015, 44, 657–674. [Google Scholar]

- Sarkar, B.; Mandal, S.; Singh, R.K. Biochar’s potential in reducing nitrogen loss from soils. J. Environ. Qual. 2016, 45, 657–674. [Google Scholar]

- Gavrilescu, M. Water, soil, and plants interactions in a threatened environment. Water 2021, 13, 2746. [Google Scholar] [CrossRef]

- Arif, M.; Ashraf, M.; Shahid, M.; Zubair, M.; Riaz, M.; Saif, M. Wood biochar improves phosphorus use efficiency in alkaline soil. J. Environ. Qual. 2017, 46, 631–644. [Google Scholar] [CrossRef]

- Prapagdee, S.; Sittibut, C.; Kovaejarat, C. Biochar reduced nitrogen leaching in a sandy soil. J. Environ. Qual. 2017, 46, 645–656. [Google Scholar]

- Zhang, T.; Tang, Y.; Gao, W.; Lee, X.; Li, H.; Hu, W.; Cheng, J. Combined effects of biochar and inhibitors on greenhouse gas emissions, global warming potential, and nitrogen use efficiency in the tobacco field. Sustainability 2023, 15, 6100. [Google Scholar] [CrossRef]

- Haider, G.; Murtaza, G.; Usman, M.; Khan, M.R.; Shah, M.S. Mixed biochar reduces nitrogen use efficiency due to polyaromatic hydrocarbons. J. Environ. Qual. 2017, 46, 645–656. [Google Scholar]

- Xu, L.; Fang, H.; Deng, X.; Ying, J.; Lv, W.; Shi, Y.; Zhou, G.; Zhou, Y. Biochar application increased ecosystem carbon sequestration capacity in a Moso bamboo forest. For. Ecol. Manag. 2020, 475, 118447. [Google Scholar] [CrossRef]

- Jeffery, S.; Abalos, D.; Prodana, M.; Bastos, A.C.; Van Groenigen, J.W.; Hungate, B.A.; Verheijen, F. Biochar boosts tropical but not temperate crop yields. Environ. Res. Lett. 2017, 12, 053001. [Google Scholar] [CrossRef]

- Bonanomi, G.; De Filippis, F.; Zotti, M.; Idbella, M.; Cesarano, G.; Al-Rowaily, S.; Abd-ElGawad, A. Repeated applications of organic amendments promote beneficial microbiota, improve soil fertility and increase crop yield. Appl. Soil Ecol. 2020, 156, 103714. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Yan, X.; Li, J.; Jiao, N.; Hu, S. Biochar amendments increase the yield advantage of legume-based intercropping systems over monoculture. Agric. Ecosyst. Environ. 2017, 237, 16–23. [Google Scholar] [CrossRef]

- Mosharrof, M.; Uddin, M.K.; Sulaiman, M.F.; Mia, S.; Shamsuzzaman, S.M.; Haque, A.N.A. Combined application of biochar and lime increases maize yield and accelerates carbon loss from an acidic soil. Agronomy 2021, 11, 1313. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anyebe, O.; Sadiq, F.K.; Manono, B.O.; Matsika, T.A. Biochar Characteristics and Application: Effects on Soil Ecosystem Services and Nutrient Dynamics for Enhanced Crop Yields. Nitrogen 2025, 6, 31. https://doi.org/10.3390/nitrogen6020031

Anyebe O, Sadiq FK, Manono BO, Matsika TA. Biochar Characteristics and Application: Effects on Soil Ecosystem Services and Nutrient Dynamics for Enhanced Crop Yields. Nitrogen. 2025; 6(2):31. https://doi.org/10.3390/nitrogen6020031

Chicago/Turabian StyleAnyebe, Ojone, Fatihu Kabir Sadiq, Bonface Ombasa Manono, and Tiroyaone Albertinah Matsika. 2025. "Biochar Characteristics and Application: Effects on Soil Ecosystem Services and Nutrient Dynamics for Enhanced Crop Yields" Nitrogen 6, no. 2: 31. https://doi.org/10.3390/nitrogen6020031

APA StyleAnyebe, O., Sadiq, F. K., Manono, B. O., & Matsika, T. A. (2025). Biochar Characteristics and Application: Effects on Soil Ecosystem Services and Nutrient Dynamics for Enhanced Crop Yields. Nitrogen, 6(2), 31. https://doi.org/10.3390/nitrogen6020031