Abstract

This work presents a non-destructive methodology to estimate the residual porosity and mechanical properties of titanium foams produced via Hot Isostatic Pressing (HIP) followed by solid-state foaming (SSF). Pulsed laser-spot thermography was employed to measure thermal diffusivity in compact and foamed Ti6Al4V-ELI samples derived from powders of different granulometries. A power-law correlation between thermal diffusivity and porosity was used to estimate post-foaming porosity, which was then used to predict elastic modulus, yield strength, and ultimate tensile strength. Results highlight the potential of thermal diffusivity as a reliable indicator of structural performance, offering a rapid and fully non-destructive route for evaluating metallic foams in biomedical and aerospace applications.

1. Introduction

Titanium alloys, particularly Ti6Al4V-ELI, are key materials in biomedical and aerospace engineering due to their superior mechanical performance and biocompatibility [1]. In implant design, engineered porosity is often introduced to reduce stiffness mismatch with bone and improve osseointegration. A promising route to obtain controlled porosity is the combination of HIP and SSF, enabling fully dense starting components to be selectively foamed through thermal treatment [2,3].

Assessing porosity and mechanical properties is crucial, but conventional methods are destructive and time-consuming. Non-destructive methods such as ultrasonic testing are more suitable, but are limited by surface accessibility and spatial resolution.

IR thermography offers full-field, contactless, and fast analysis capabilities, especially with laser excitation. Although widely applied to detect damage or defects in polymers and composites, its application to quantify porosity and predict mechanical performance in metallic foams remains underexplored. This work proposes a thermographic-based framework for estimating porosity and deriving key mechanical properties from thermal diffusivity measurements in foamed titanium alloys.

2. Materials and Methods

This study analyzed two different specimens produced through the Hot Isostatic Pressing (HIP) process [2,3]. As shown in previous studies [3], starting with Ti powders of different average sizes, it is possible to obtain blanks with low and comparable residual porosity after HIP consolidation. However, as later discussed by Guglielmi et al. [2], starting with HIP-processed blanks, additional heat treatment can be applied to induce a controlled increase in porosity (in terms of both percentage and average size). This is commonly referred to as solid-state foaming (SSF), and alters specimens’ thermal and mechanical properties.

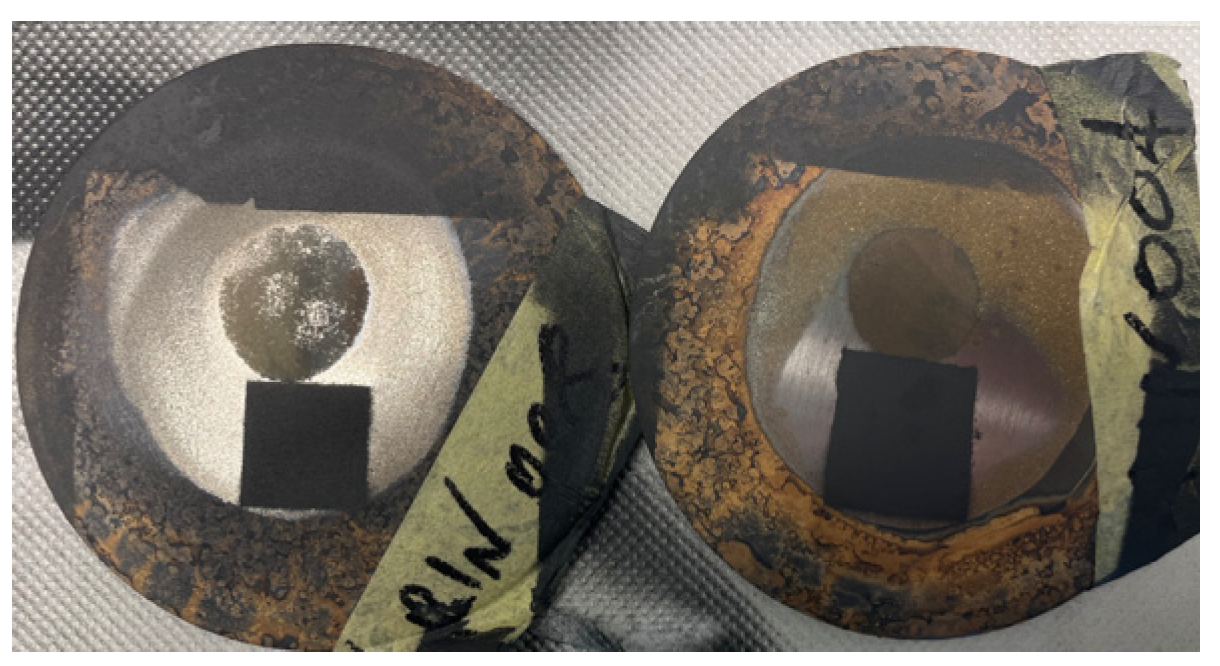

Therefore, the two base specimens were subjected to isothermal SSF at 1020 °C for 120 min, as detailed in [2]. Following this treatment, significant deformation was observed in the blanks (Figure 1). In addition, the surface condition changed markedly, presenting localized alterations that resulted in non-uniform emissivity across the surface, which is particularly critical for thermographic analysis.

Figure 1.

Analyzed specimens after SSF.

A thin layer of graphite spray was applied to the selected surface region prior to thermographic testing. The pulsed laser spot thermography technique was used in a reflection setup to measure thermal diffusivity [4,5]. This method is based on the solution of the heat conduction equation for a localized laser-heating event. The model assumes a laser spot of radius R, a Dirac-type thermal pulse, and a homogeneous body of finite thickness L under adiabatic boundary conditions. In this study, only in-depth thermal diffusivity was considered, as the goal was to assess internal porosity, which primarily affects heat propagation along the thickness direction. Measurement is feasible because a regression fit through the physical model of the resulting curve yields the dimensionless parameter α/L2, from which the through-thickness thermal diffusivity can be directly obtained, given the known thickness of the sample.

Experiments were carried out in reflection mode using a CW 1064 nm laser with a spot diameter of ~5 mm to heat the specimen surface for 500 µs. Surface temperature evolution was recorded using a FLIR X6981 SLS LW infrared camera (Teledyne FLIR LLC, Wilsonville, OR, USA), calibrated between –20 °C and 150 °C, with a frame rate of 3600 Hz over a total acquisition time of 1.25 s. Each test was repeated three times on the same ROI for each specimen. Measurements were analyzed following the procedure cited earlier.

The porosity P of the SSFed specimens was indirectly estimated from the volumetric expansion ratios reported in [2] based on geometric measurements and metallographic image analysis. These porosity values served as the basis for the subsequent mechanical property estimations. Starting from the compact state, the mechanical properties of the foamed materials were estimated using empirical power-law models as functions of porosity. Specifically, the elastic modulus after foaming was estimated using the relation where E0 is the elastic modulus of the compact material, and the exponent n was calculated directly from previously published experimental values of E and P for each specimen [3]. A reverse logarithmic interpolation was performed, and the final exponent was taken as the average of the two individual values.

Yield strength and ultimate tensile strength were estimated using:

where σᵧ0 and UTS0 are the properties in the compact state. The exponents m1 and m2 were selected based on the technical literature for porous titanium alloys: m1 = 2.2, in line with studies on sintered and cellular Ti6Al4V, and m2 = 2.5, a value commonly adopted to reflect the more significant reduction in ultimate strength compared to yield strength in porous structures. The consistency between porosity and thermal diffusivity was evaluated using the model where α0 is the average value measured on compact specimens. The exponent s was assumed to be 1.5, in analogy with simplified forms of the Maxwell–Eucken model for porous metals with homogeneous pore distributions [6].

3. Results and Discussion

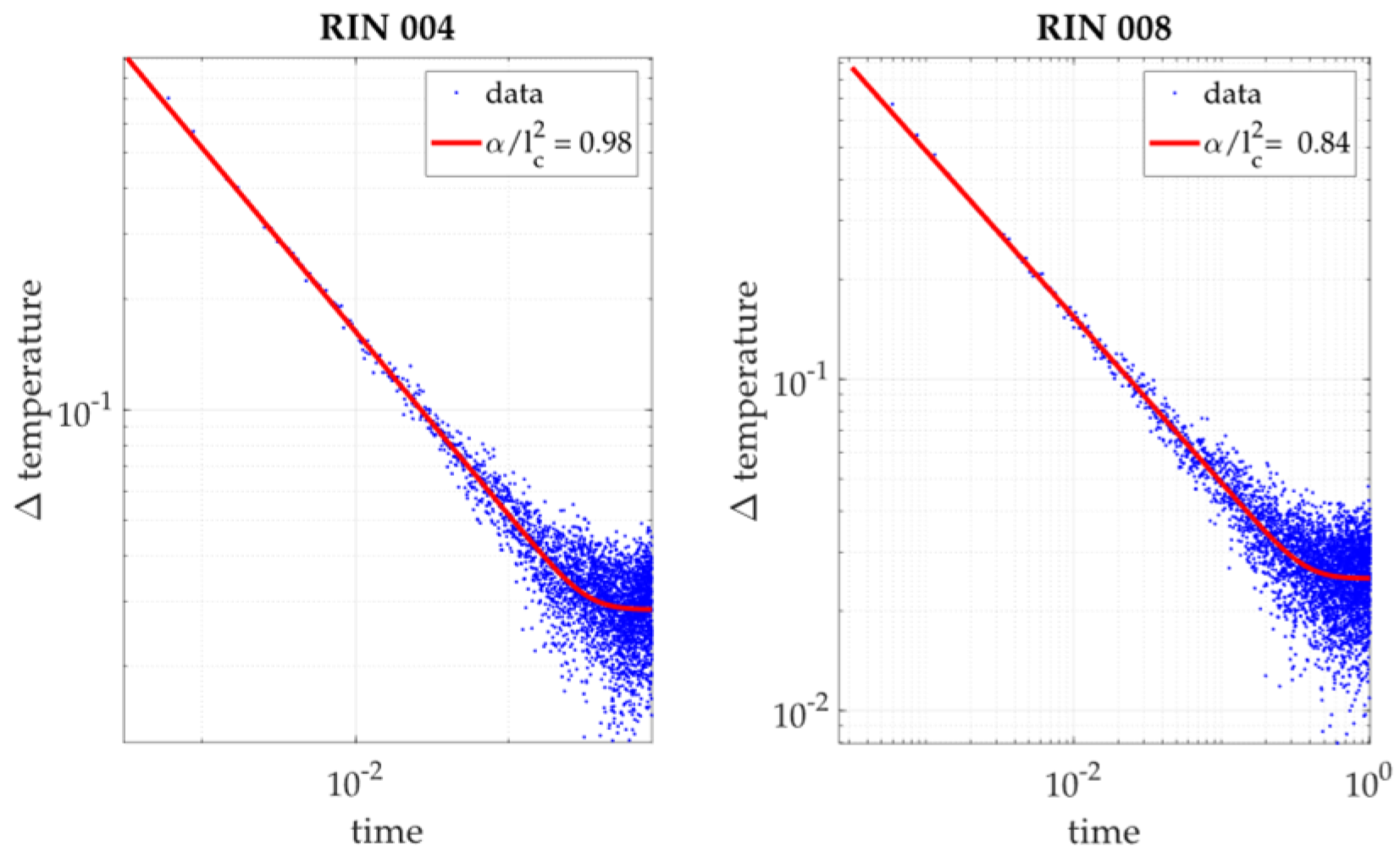

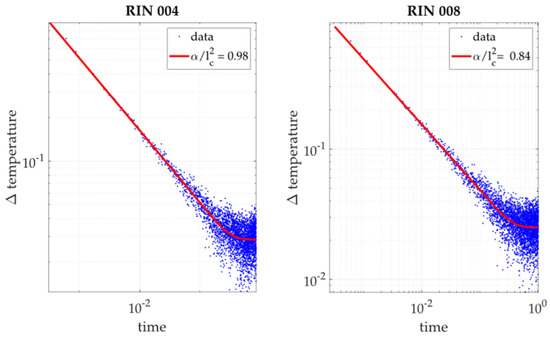

Thermal diffusivity (α) measurements were carried out on both specimens in the compact state and after SSF. The average diffusivity in the compact state was approximately 3.0 × 10−6 m2/s for both samples. Figure 2 shows representative curves for the two different SSFed conditions evaluated, RIN004 (characterized by an initial Ti powder size of 50 µm) and RIN008 (100 µm), from which α/l2 ratios were extracted and used to compute through-thickness thermal diffusivity.

Figure 2.

Results of experimental curves fitted by model for in-depth α measurements.

After SSF, a decrease in α was observed, consistent with the formation of a distributed porous structure within the metallic matrix. Specifically, for sample RIN004, a post-foaming value of 2.2 × 10−6 m2/s was measured, while RIN008 showed a further 15% reduction, with a value of approximately 1.87 × 10−6 m2/s. The larger reduction observed in RIN008 suggests a more effective foaming process, which aligns with metallographic observations and previously reported volumetric expansion data [2,3].

Using the relation α = α0 (1 − P)s with s = 1.5, the porosity of the post-foamed samples was estimated to be 18% for RIN004 and 27% for RIN008. These values are consistent with previous studies and confirm that thermal treatment is more effective in generating porosity in specimens derived from coarser powders (RIN008).

Mechanical properties in the foamed state were estimated from those in the compact state (E0 = 111.6 GPa, σy0 = 696.6 MPa, UTS0 = 779.8 MPa) using power-law models based on porosity. These results are summarized in Table 1 below.

Table 1.

Estimated mechanical properties based on thermal diffusivity measurements.

These results show that foaming reduces mechanical performance, which may be acceptable when weighed against topological and biological benefits. The more pronounced reduction in UTS compared to σy, and both relative to E, was expected and reflects the increasingly brittle behavior associated with distributed porosity.

Notably, these estimates were obtained non-destructively, solely from thermal diffusivity measurements. This supports the potential for an entirely NDT procedure to assess mechanical performance in components manufactured via HIP + SSF. The following direct estimation models are proposed, where α_r = α/α0 is the normalized post-foaming thermal diffusivity:

These expressions enable the quantitative prediction of residual mechanical properties based solely on post-foaming thermal diffusivity. This approach offers immediate applicability for quality control in porous metallic components for biomedical and advanced structural applications and represents a clear innovation over conventional sectioning and destructive testing techniques.

4. Conclusions

This study demonstrated the feasibility of non-destructively estimating porosity and key mechanical properties (E, σy, UTS) in foamed titanium alloys, using only thermal diffusivity measurements obtained through pulsed laser spot thermography. The proposed correlations, based on literature models and adjusted using prior experimental data, showed good internal consistency and effectively captured the influence of foaming in samples produced from different powder granulometries.

Future developments will include (i) direct validation of porosity through metallographic and macrographic analyses, (ii) the use of contact ultrasonic testing to experimentally estimate the elastic modulus on analyzed specimens, and (iii) implementation of multivariate models to improve the accuracy of mechanical property predictions.

Author Contributions

Conceptualization, G.D., A.C. and P.G.; methodology, G.D. and A.C.; software, V.P. and P.B.; validation, G.D. and P.B.; formal analysis, G.D., A.C., S.R., P.B. and P.G.; investigation, G.D., S.R., V.P. and A.C.; resources, G.F. and P.G.; data curation, G.D., A.C., P.B. and P.G.; writing—original draft preparation, G.D. and A.C.; writing—review and editing, G.F. and P.G.; visualization, G.D. and A.C.; supervision, P.B.; project administration, P.G. and G.F.; funding acquisition, A.C. and G.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rosenthal, S.; Maaß, F.; Kamaliev, M.; Hahn, M.; Gies, S.; Tekkaya, A.E. Lightweight in Automotive Components by Forming Technology. Automot. Innov. 2020, 3, 195–209. [Google Scholar] [CrossRef]

- Guglielmi, P.; Palumbo, G. Production of Porous Titanium Structures by Combining Hot Isostatic Pressing and Solid-State Foaming. CIRP J. Manuf. Sci. Technol. 2024, 52, 58–72. [Google Scholar] [CrossRef]

- Guglielmi, P.; Castellano, A.; Cusanno, A.; Palumbo, G. Correlation between Porosity Level and Elastic Modulus in a Foamed Hiped Ti Alloy. In Proceedings of the Materials Research Proceedings, Kraków, Poland, 19–21 April 2023; Association of American Publishers: Washington, DC, USA, 2023; Volume 28, pp. 1427–1434. [Google Scholar]

- Bison, P.; Cernuschi, F.; Grinzato, E. In-Depth and in-Plane Thermal Diffusivity Measurements of Thermal Barrier Coatings by IR Camera: Evaluation of Ageing. Int. J. Thermophys. 2008, 29, 2149–2161. [Google Scholar] [CrossRef]

- Cernuschi, F.; Russo, A.; Lorenzoni, L.; Figari, A. In-Plane Thermal Diffusivity Evaluation by Infrared Thermography. Rev. Sci. Instrum. 2001, 72, 3988–3995. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, J. Thermal Conductivity Prediction of Closed-Cell Aluminum Alloy Considering Micropore Effect. Adv. Mech. Eng. 2015, 7, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).