Detection of Heart and Respiration Rate with an Organic-Semiconductor-Based Optomechanical MEMS Sensor †

Abstract

:1. Introduction

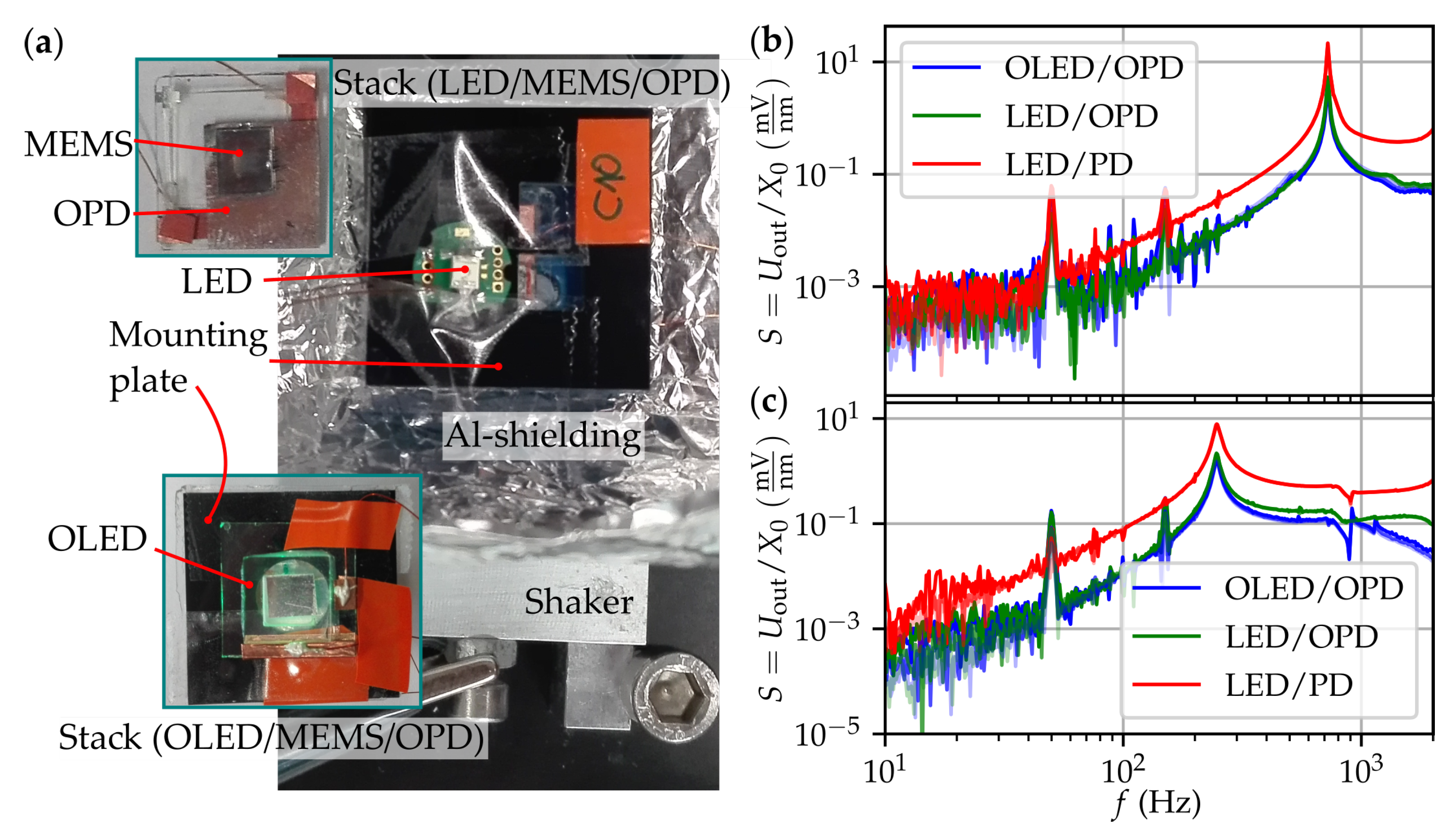

2. Sensor and Components

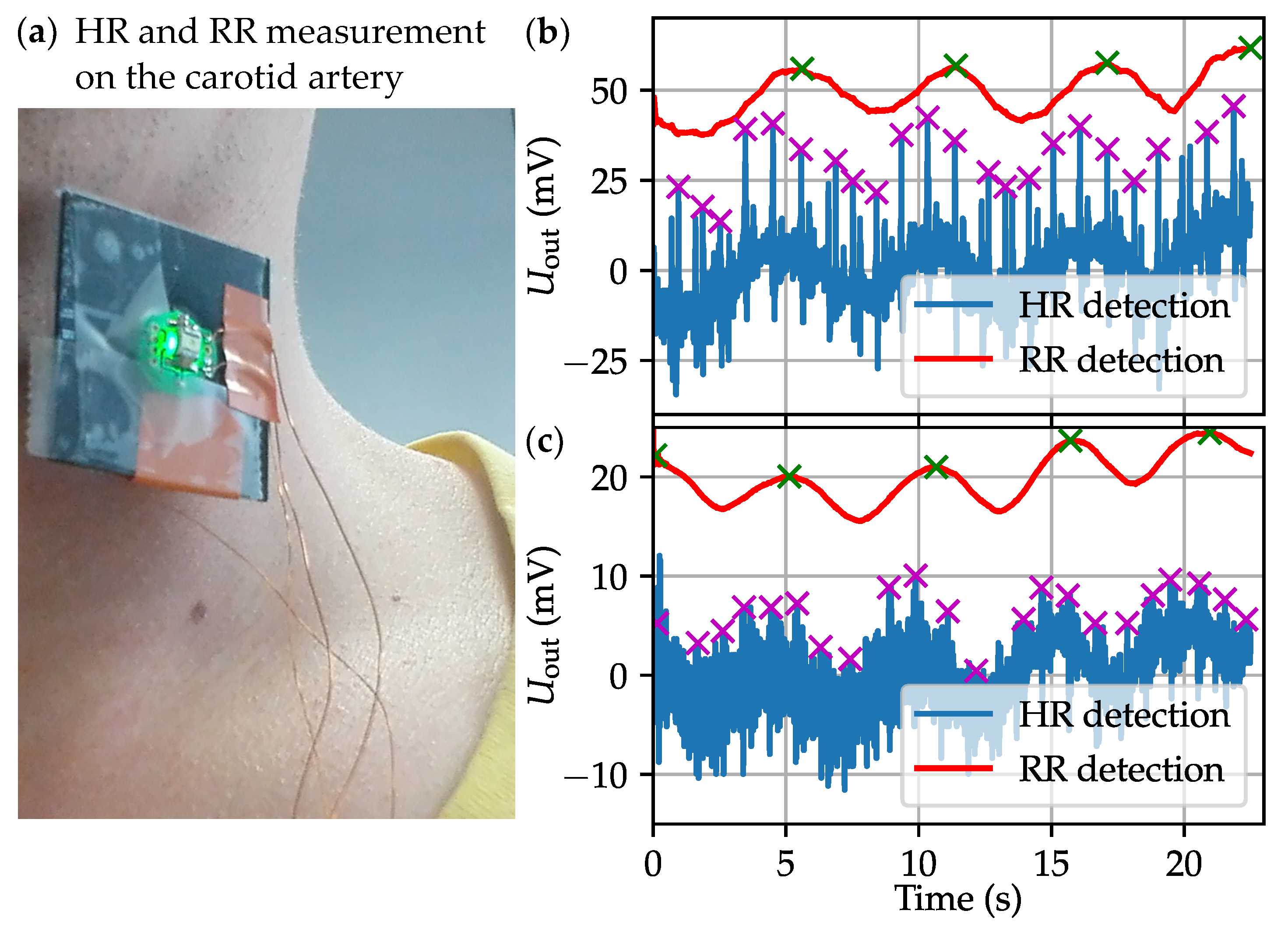

3. Heart and Respiration Rate Measurements

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Bhansali, S.; Vasudev, A. MEMS for Biomedical Applications; Woodhead Publishing: Sawston, UK, 2012. [Google Scholar]

- Kaniusas, E. Biomedical Signals and Sensors I; Springer: Berlin, Germany, 2012. [Google Scholar] [CrossRef]

- Kaniusas, E. Biomedical Signals and Sensors II: Linking Acoustic and Optic Biosignals and Biomedical Sensors (Biological and Medical Physics, Biomedical Engineering); Springer: Berlin, Germany, 2015. [Google Scholar]

- Kainz, A.; Hortschitz, W.; Steiner, H.; Hong, Y.; Chen, C.; Zan, H.; Meng, H.; Sauter, T.; Keplinger, F. MOEMS Vibration Sensor with Organic Semiconductor Readout. Procedia Eng. 2016, 168, 1253–1256. [Google Scholar] [CrossRef]

- Hortschitz, W.; Steiner, H.; Stifter, M.; Kohl, F.; Kahr, M.; Kainz, A.; Raffelsberger, T.; Keplinger, F. Novel high resolution MOEMS inclination sensor. In Proceedings of the 2014 IEEE SENSORS, Valencia, Spain, 2–5 November 2014; pp. 1893–1896. [Google Scholar] [CrossRef]

- Kainz, A.; Hortschitz, W.; Steiner, H.; Schalko, J.; Jachimowicz, A.; Keplinger, F. Accurate analytical model for air damping in lateral MEMS/MOEMS oscillators. Sens. Actuators A Phys. 2017, 255, 154–159. [Google Scholar] [CrossRef]

- Middlemiss, R.; Samarelli, A.; Paul, D.; Hough, J.; Rowan, S.; Hammond, G. Measurement of the Earth tides with a MEMS gravimeter. Nature 2016, 531, 614–617. [Google Scholar] [CrossRef] [PubMed]

- Kainz, A.; Steiner, H.; Schalko, J.; Jachimowicz, A.; Kohl, F.; Stifter, M.; Beigelbeck, R.; Keplinger, F.; Hortschitz, W. Distortion-free measurement of electric field strength with a MEMS sensor. Nat. Electron. 2018, 1, 68. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammer, G.; Kainz, A.; Hortschitz, W.; Zan, H.-W.; Meng, H.-F.; Sauter, T.; Keplinger, F. Detection of Heart and Respiration Rate with an Organic-Semiconductor-Based Optomechanical MEMS Sensor. Proceedings 2018, 2, 715. https://doi.org/10.3390/proceedings2130715

Hammer G, Kainz A, Hortschitz W, Zan H-W, Meng H-F, Sauter T, Keplinger F. Detection of Heart and Respiration Rate with an Organic-Semiconductor-Based Optomechanical MEMS Sensor. Proceedings. 2018; 2(13):715. https://doi.org/10.3390/proceedings2130715

Chicago/Turabian StyleHammer, Günter, Andreas Kainz, Wilfried Hortschitz, Hsiao-Wen Zan, Hsin-Fei Meng, Thilo Sauter, and Franz Keplinger. 2018. "Detection of Heart and Respiration Rate with an Organic-Semiconductor-Based Optomechanical MEMS Sensor" Proceedings 2, no. 13: 715. https://doi.org/10.3390/proceedings2130715

APA StyleHammer, G., Kainz, A., Hortschitz, W., Zan, H.-W., Meng, H.-F., Sauter, T., & Keplinger, F. (2018). Detection of Heart and Respiration Rate with an Organic-Semiconductor-Based Optomechanical MEMS Sensor. Proceedings, 2(13), 715. https://doi.org/10.3390/proceedings2130715