Bi2Te3 and Sb2Te3 Thin Films with Enhanced Thermoelectric Properties for Flexible Thermal Sensors †

Abstract

:1. Introduction

2. Material and Methods

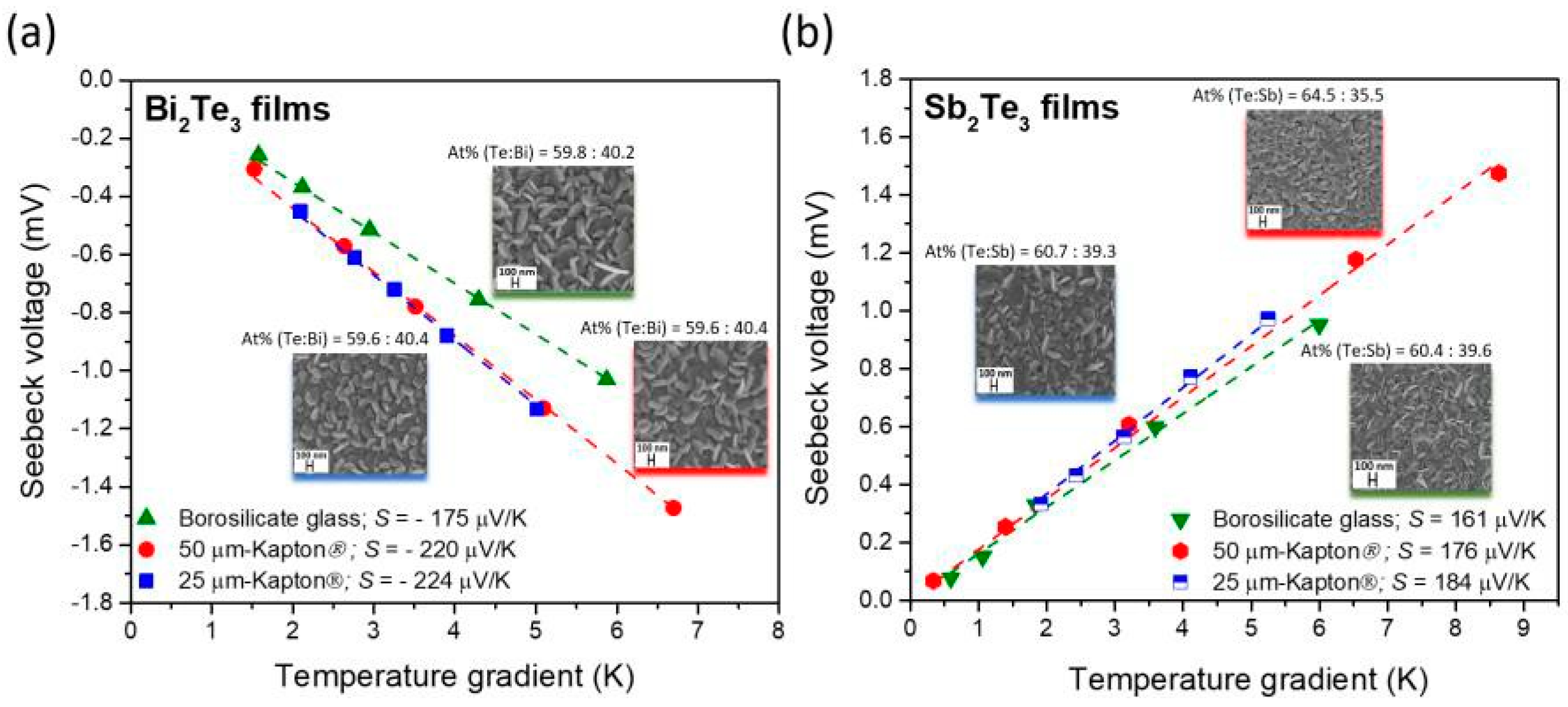

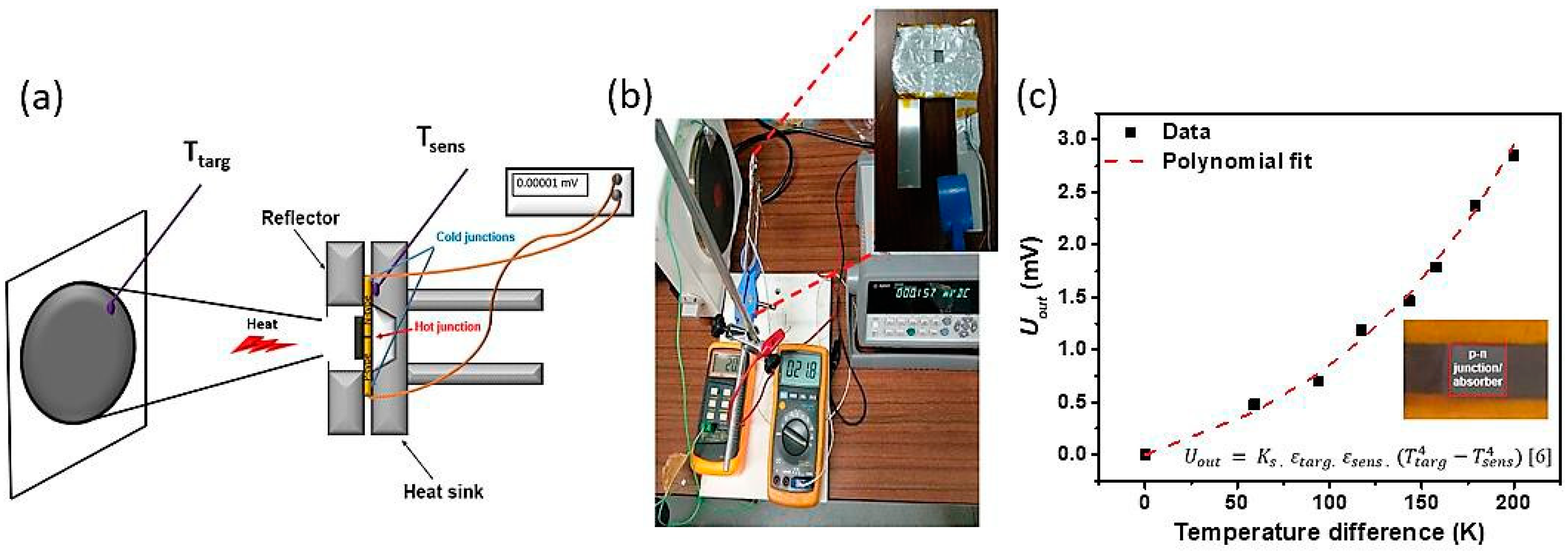

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Mamur, H.; Bhuiyan, M.R.A.; Korkmaz, F.; Nil, M. A review on bismuth telluride (Bi2Te3) nanostructure for thermoelectric applications. Renew. Sustain. Energy Rev. 2018, 82, 4159–4169. [Google Scholar] [CrossRef]

- Xu, D.; Xiong, B.; Wang, Y. Micromachined thermoelectric IR sensors fabricated by a self-aligned process. Smart. Mater. Struct. 2011, 20, 015013-21. [Google Scholar] [CrossRef]

- Shen, S.; Zhu, W.; Deng, Y.; Zhao, H.; Peng, Y.; Wang, C. Enhancing thermoelectric properties of Sb2Te3 flexible thin film through microstructure control and crystal preferential orientation engineering. Appl. Surf. Sci. 2017, 414, 197–204. [Google Scholar] [CrossRef]

- Nuthongkum, P.; Sakdanuphab, R.; Horprathum, M.; Sakulkalavek, A. [Bi]:[Te] Control, Structural and Thermoelectric Properties of Flexible BixTey Thin Films Prepared by RF Magnetron Sputtering at Different Sputtering Pressures. J. Electron. Mater. 2017, 46, 6444–6450. [Google Scholar] [CrossRef]

- Cao, Z.; Tudor, M.J.; Torah, R.N.; Beeby, S.P. Screen Printable Flexible BiTe–SbTe-Based Composite Thermoelectric Materials on Textiles for Wearable Applications. IEEE Trans. Electron. Devices 2016, 63, 4024–4030. [Google Scholar] [CrossRef]

- Sebastián, E.; Armiens, C.; Gómez-Elvira, J. Infrared temperature measurement uncertainty for unchopped thermopile in presence of case thermal gradients. Infrared Phys. Technol. 2011, 54, 75–83. [Google Scholar] [CrossRef]

| Film | Thickness (µm) | Substrate | 𝑺 (µVK−1) | 𝝈RT (Ω m)−1 | 𝑷𝑭(× 10−3 W K−2 m−1) |

|---|---|---|---|---|---|

| Bi2Te3/Sb2Te3 | 0.4 | glass/polyimide | −224/176 | 5.3 × 104/4.6 × 104 | 2.7/1.4 |

| Sb2Te3 [3] | - | polyimide | 135 | 2.8 × 104 | 0.5 |

| Bi2Te3 [4] | 1.3 | polyimide | 119 | 7.0 × 104 | 1 (Bi2Te3) |

| Sb2Te3/Bi1.8Te3.2 [5] | 70 | Glass-textile/polyimide | −138/120 | 1.0 × 104/1.0 × 104 | 0.3/0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vieira, E.; Figueira, J.; Pires, A.L.; Grilo, J.; Silva, M.F.; Pereira, A.M.; Goncalves, L.M. Bi2Te3 and Sb2Te3 Thin Films with Enhanced Thermoelectric Properties for Flexible Thermal Sensors. Proceedings 2018, 2, 815. https://doi.org/10.3390/proceedings2130815

Vieira E, Figueira J, Pires AL, Grilo J, Silva MF, Pereira AM, Goncalves LM. Bi2Te3 and Sb2Te3 Thin Films with Enhanced Thermoelectric Properties for Flexible Thermal Sensors. Proceedings. 2018; 2(13):815. https://doi.org/10.3390/proceedings2130815

Chicago/Turabian StyleVieira, Eliana, Joana Figueira, Ana Lucia Pires, José Grilo, Manuel Fernando Silva, André Miguel Pereira, and Luís Miguel Goncalves. 2018. "Bi2Te3 and Sb2Te3 Thin Films with Enhanced Thermoelectric Properties for Flexible Thermal Sensors" Proceedings 2, no. 13: 815. https://doi.org/10.3390/proceedings2130815