Investigation of Electrochemical Processes in CO2 Sensitive Electrodes †

Abstract

:1. Introduction

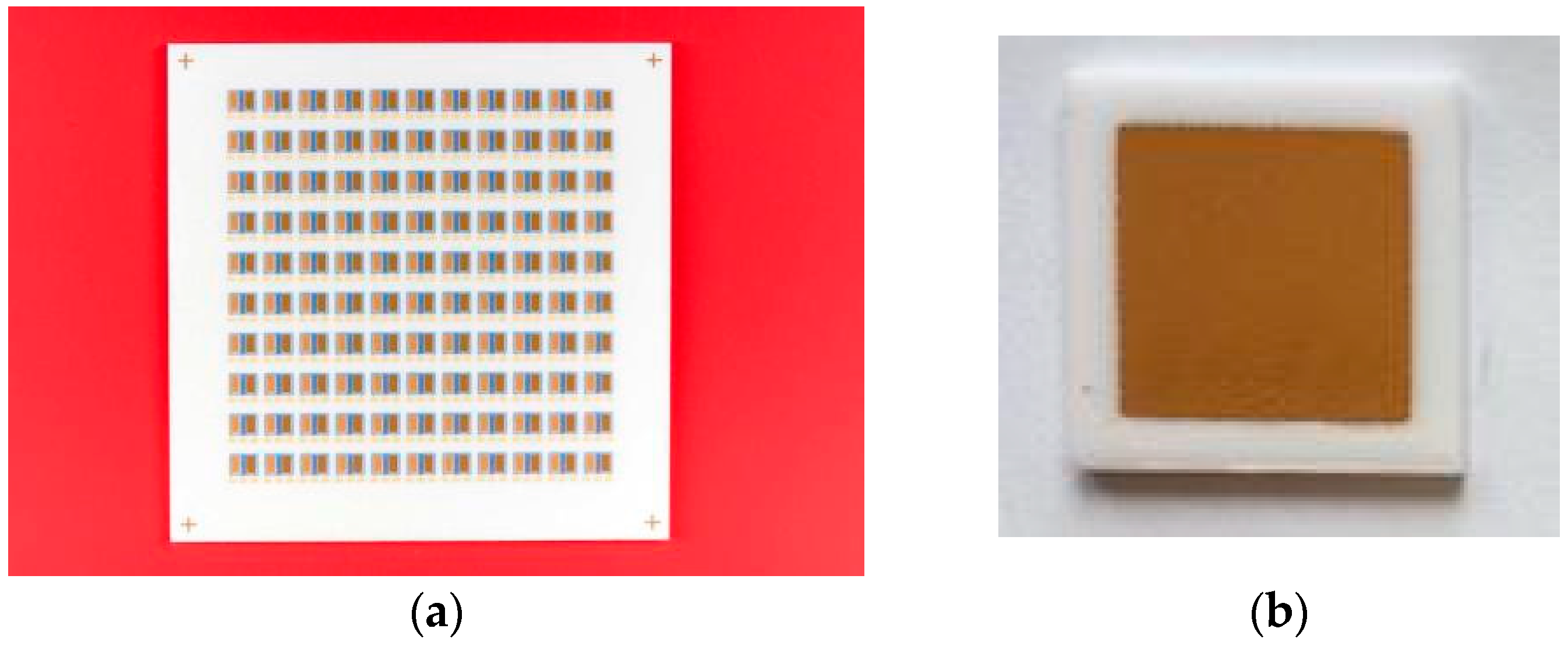

2. Materials and Methods

3. Results and Discussion

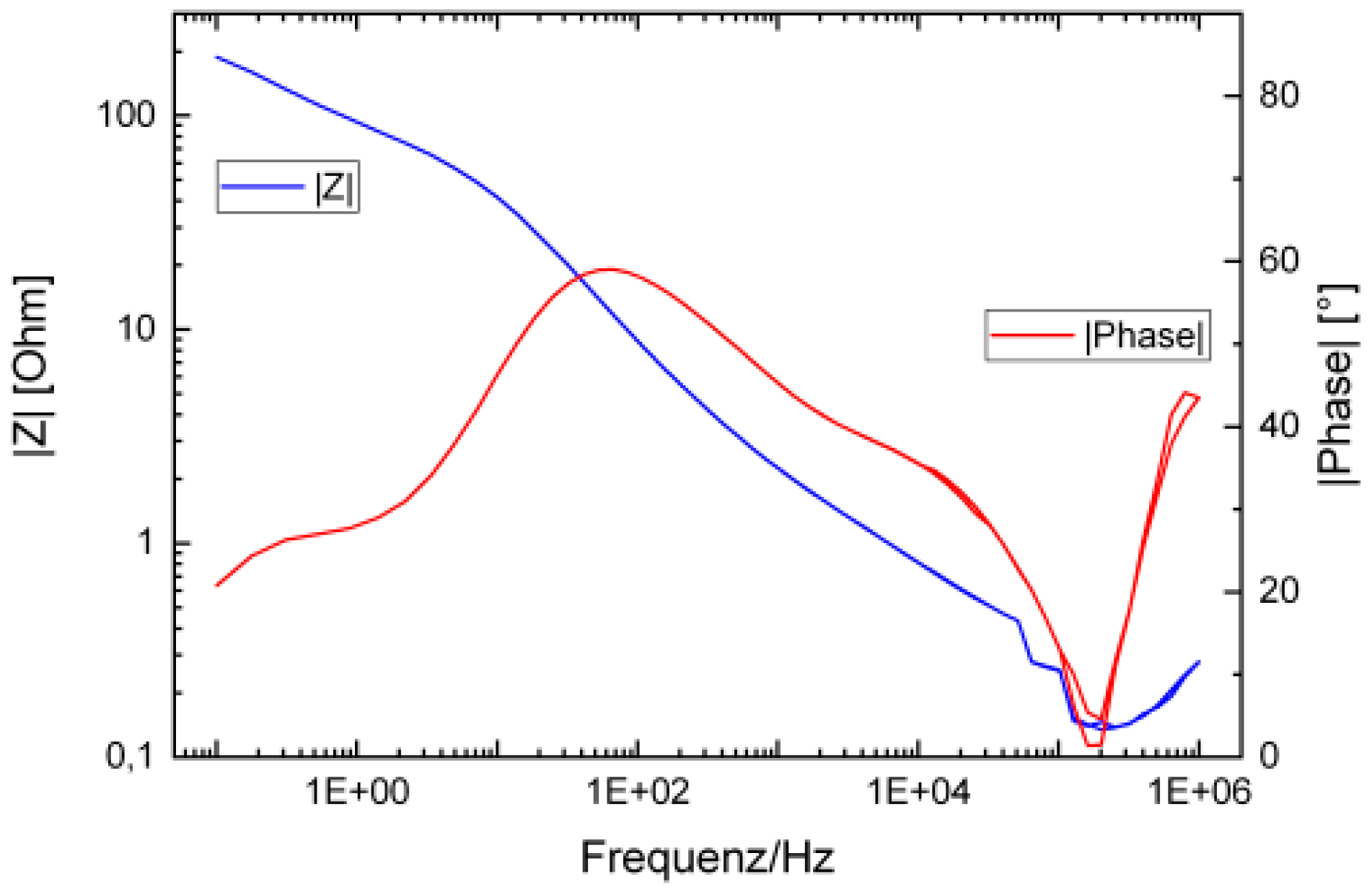

3.1. Sensor Characterization

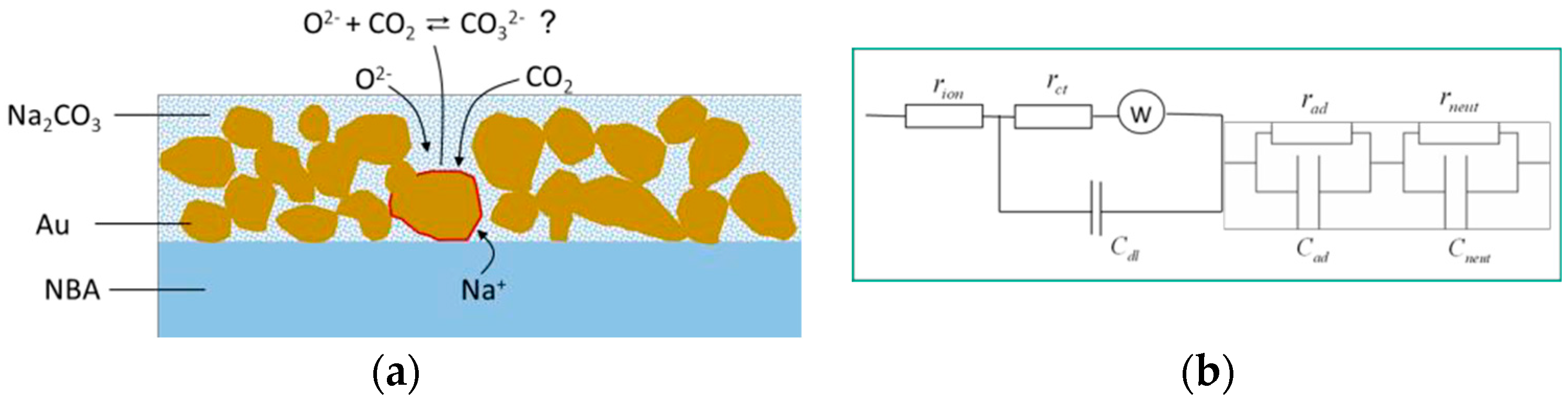

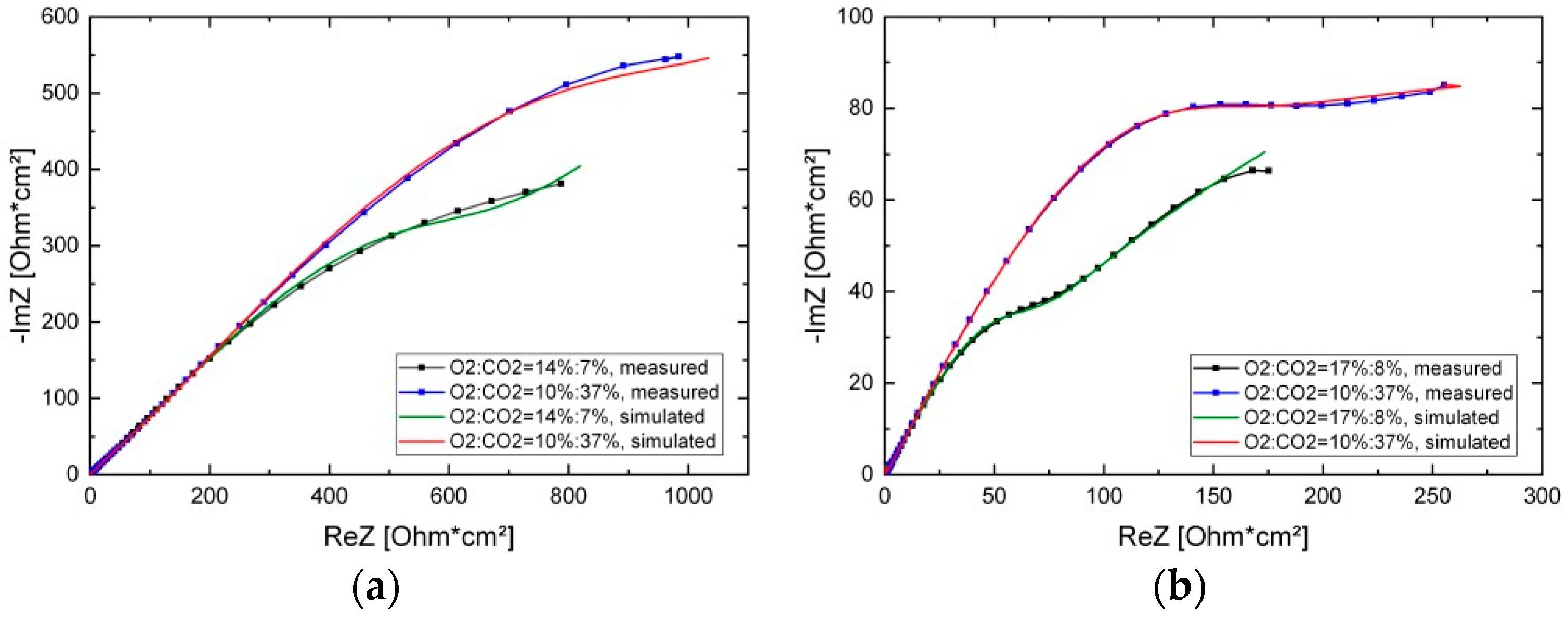

3.2. EIS Measurements

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Meléndez-Ceballos, A.; Albin, V. Kinetic approach on the effect of Cs addition on oxygen reduction for MCFC application. Electrochim. Acta 2015, 184, 295–300. [Google Scholar] [CrossRef]

- Bednarz, M. Mechanistische Untersuchung und Modellierung der Kathodenreaktion in Karbonat-brennstoffzellen (MCFC). Ph.D. Thesis, IPCH Universität Hamburg, Hamburg, Germany, 2002. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dietrich, S.; Kusnezoff, M.; Mosch, S.; Baumgärtner, C. Investigation of Electrochemical Processes in CO2 Sensitive Electrodes. Proceedings 2018, 2, 903. https://doi.org/10.3390/proceedings2130903

Dietrich S, Kusnezoff M, Mosch S, Baumgärtner C. Investigation of Electrochemical Processes in CO2 Sensitive Electrodes. Proceedings. 2018; 2(13):903. https://doi.org/10.3390/proceedings2130903

Chicago/Turabian StyleDietrich, Stefan, Mihails Kusnezoff, Sindy Mosch, and Christoph Baumgärtner. 2018. "Investigation of Electrochemical Processes in CO2 Sensitive Electrodes" Proceedings 2, no. 13: 903. https://doi.org/10.3390/proceedings2130903

APA StyleDietrich, S., Kusnezoff, M., Mosch, S., & Baumgärtner, C. (2018). Investigation of Electrochemical Processes in CO2 Sensitive Electrodes. Proceedings, 2(13), 903. https://doi.org/10.3390/proceedings2130903