AlN-on-Si Square Diaphragm Piezoelectric Micromachined Ultrasonic Transducer with Extended Range of Detection †

Abstract

:1. Introduction

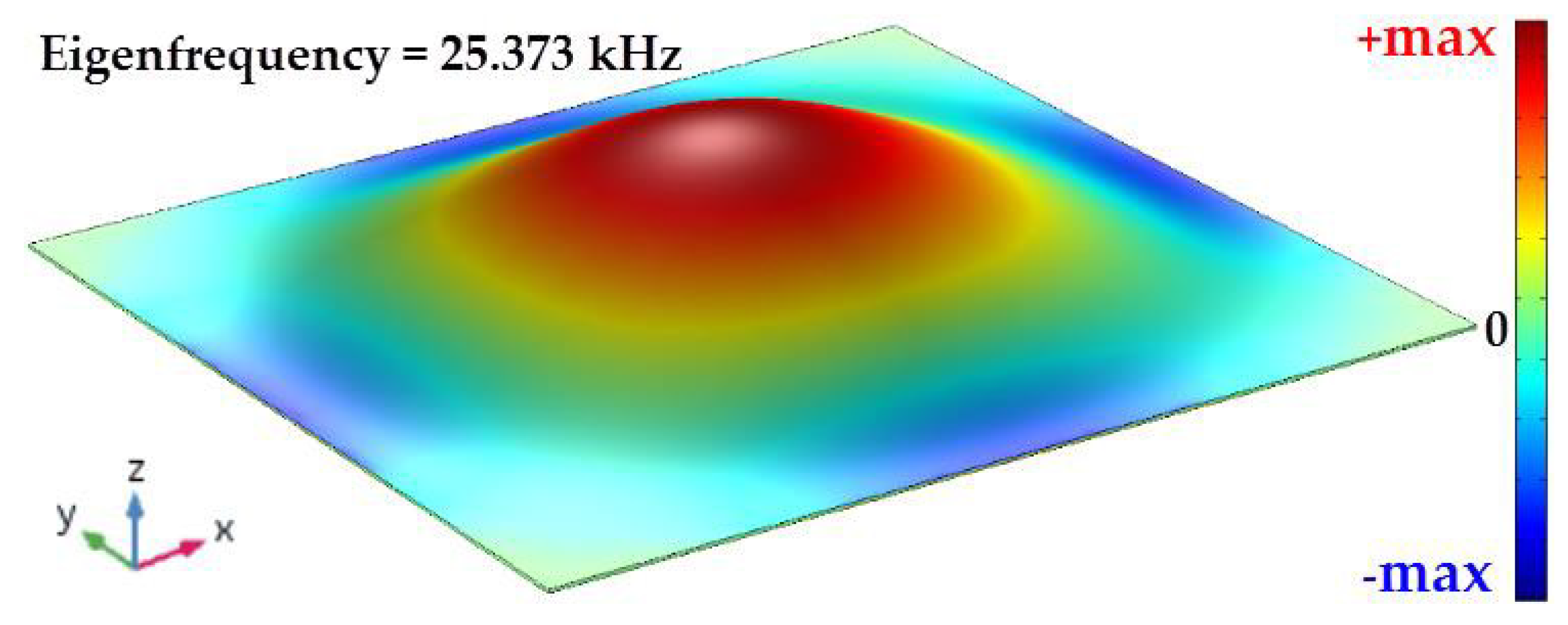

2. Device Implementation and Simulation

3. Device Characterization and Experimental Results

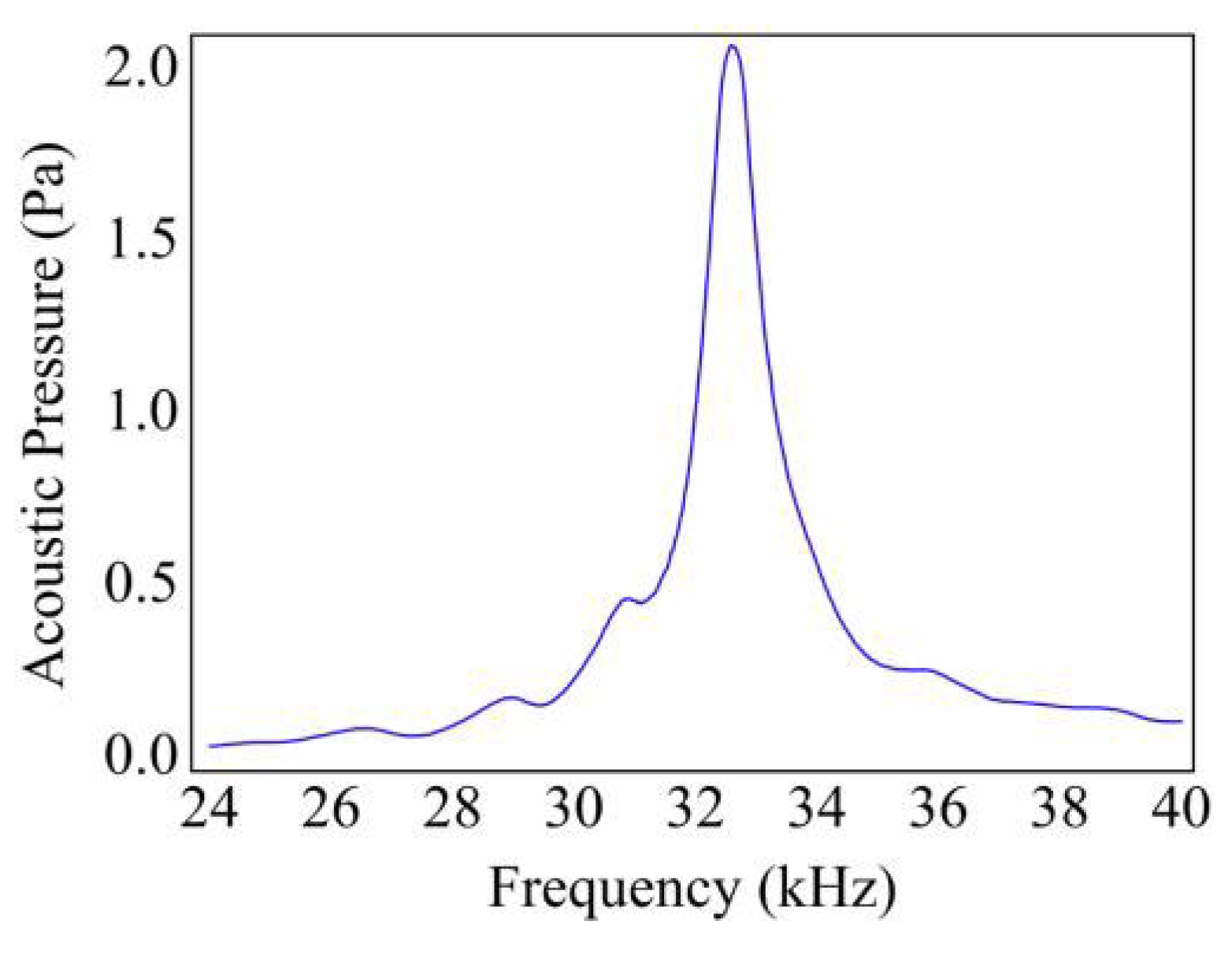

3.1. Electrical and Acoustic Characterization

3.2. Range-Detection Demonstration and Calibration

4. Conclusions

Author Contributions

Acknowledgments

References

- Przybyla, R.J.; Shelton, S.E.; Guedes, A.; Izyumin, I.I.; Kline, M.H.; Horsley, D.A.; Boser, B.E. In-air rangefinding with an AlN piezoelectric micromachined ultrasound transducer. IEEE Sensors 2011, 11, 2690–2697. [Google Scholar] [CrossRef]

- Przybyla, R.; Flynn, A.; Jain, V.; Shelton, S.; Guedes, A.; Izyumin, I.; Horsley, D.; Boser, B.A. Micromechanical ultrasonic distance sensor with >1 m range. In Proceedings of the IEEE 16th International Solid-State Sensors, Actuators and Microsystems Conference (Transducers), Beijing, China, 5–9 June 2011. [Google Scholar]

- Wang, T.; Kobayashi, T.; Yang, B.; Wang, H.; Lee, C. Highly sensitive piezoelectric micromachined ultrasonic transducer (pMUT) operated in air. In Proceedings of the IEEE 11th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Sendai, Japan, 17–20 April 2016. [Google Scholar]

- Rozen, O.; Block, S.T.; Mo, X.; Bland, W.; Hurst, P.; Tsai, J.M.; Daneman, M.; Amirtharajah, R.; Horsley, D.A. Monolithic MEMS-CMOS ultrasonic rangefinder based on dual-electrode PMUTs. In Proceedings of the IEEE 29th International Conference on MEMS, Shanghai, China, 24–28 Jan 2016. [Google Scholar]

- Cowen, A.; Hames, G.; Glukh, K.; Hardy, B. PiezoMUMPs Design Handbook; MEMSCAP Inc.: Durham, NC, USA, 2014. [Google Scholar]

- Guedes, A.; Shelton, S.; Przybyla, R.; Izyumin, I.; Boser, B.; Horsley, D.A. Aluminum nitride pMUT based on a flexurally-suspended membrane. In Proceedings of the IEEE 16th International Solid-State Sensors, Actuators and Microsystems Conference (Transducers), Beijing, China, 5–9 June 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alasatri, S.; Rufer, L.; Lee, J.E.-Y. AlN-on-Si Square Diaphragm Piezoelectric Micromachined Ultrasonic Transducer with Extended Range of Detection. Proceedings 2018, 2, 913. https://doi.org/10.3390/proceedings2130913

Alasatri S, Rufer L, Lee JE-Y. AlN-on-Si Square Diaphragm Piezoelectric Micromachined Ultrasonic Transducer with Extended Range of Detection. Proceedings. 2018; 2(13):913. https://doi.org/10.3390/proceedings2130913

Chicago/Turabian StyleAlasatri, Suresh, Libor Rufer, and Joshua En-Yuan Lee. 2018. "AlN-on-Si Square Diaphragm Piezoelectric Micromachined Ultrasonic Transducer with Extended Range of Detection" Proceedings 2, no. 13: 913. https://doi.org/10.3390/proceedings2130913

APA StyleAlasatri, S., Rufer, L., & Lee, J. E.-Y. (2018). AlN-on-Si Square Diaphragm Piezoelectric Micromachined Ultrasonic Transducer with Extended Range of Detection. Proceedings, 2(13), 913. https://doi.org/10.3390/proceedings2130913