1. Introduction

An important aspect for improved competitiveness in cross-country skiing often claimed by many athletes and coaches is weight reduction of poles, commonly achieved by a composite laminate design. High-end composite poles are today lighter but also stiffer than previous generations in e.g., aluminium. A negative aspect is however that ski poles have become increasingly brittle, which can have devastating consequences in competition. Thus, there is a strong need to find the best design of composite ski poles with a good balance between weight/inertia, stiffness and strength. To avoid resource expensive development on a “trial and error” basis, a better understanding of the mechanisms of failure in these poles under impact and transverse loadings is needed. There is also an apparent need to establish a predictive simulation driven design process in which different pole concepts can be tested and compared virtually.

In the current study, we have investigated existing pole designs by mechanical testing and by microscopy. The pole models investigated were Skigo Race 2.0 (from 2016 and from 2017 denoted SKIGO1 and SKIGO2 below, both with a weight per unit length of approx. 0.62 g/mm), Fischer RCS Carbonlite (0.54 g/mm), Fischer RCS Speedmax (0.6 g/mm) and Swix Triac 2.5 (0.55 g/mm). The weight of each pole is given in g/mm since the lengths and shapes (cross-section variation along the length) were different for different poles. The purpose of the mechanical tests was both to characterise material properties and to better understand how the material architecture, e.g., fibre orientation of the different layers (or plies), influence the material response. We have also developed numerical tools which accurately can predict the bending and stress state in ski poles under axial as well as transverse loading conditions. Thus, we here present a first step towards a simulation driven design process which when fully developed allows for finding an optimal balance between competing requirements on weight, stiffness and strength.

2. Method

2.1. Mechanical Tests Methods of SKIGO1 and SKIGO2

To determine the material stiffness in the composite plies of SKIGO1 and SKIGO2 in the direction of fibres, , and the in-plane shear modulus of each ply, , a tension/torsion test was conducted using an MTS 809 Axial/Torsional machine. Since the fibre orientation was not entirely unidirectional through the thickness of the poles, classical laminate theory was used to calculate the actual ply properties. A biaxial extensometer was mounted to measure the torsion angle and the tensile strains. To install the specimens in the tension/torsion machine, steel inserts were manufactured and glued in the specimens using Adekit a140 epoxy glue. The depth of the inserts was set to 40 mm, with a total specimen length of 134 mm. A total of 3 specimens per pole type were used for this test.

To determine the ultimate compressive strength needed for failure predictions in the simulations, a compressive test was performed using an INSTRON 4505 5500R test frame with a 10 kN load cell. Strains were measured using linear strain gauges (CEA-06-240UZ-120) glued to the specimens. Furthermore, the testing was guided by the ASTM D5449 standard. However, in contrast to the standard, the specimens had a larger outer diameter of 16 mm (compared to 11.4 mm). In accordance with the standard, fixtures were used to distribute the compressive load and to avoid crushing of the specimen ends. However, to fit the strain gauges and compression fixtures the specimens were made 34 mm long. A hot-melting adhesive was used as a potting material to fill in and reduce the cavities in the contact zones between the fixtures and the specimens.

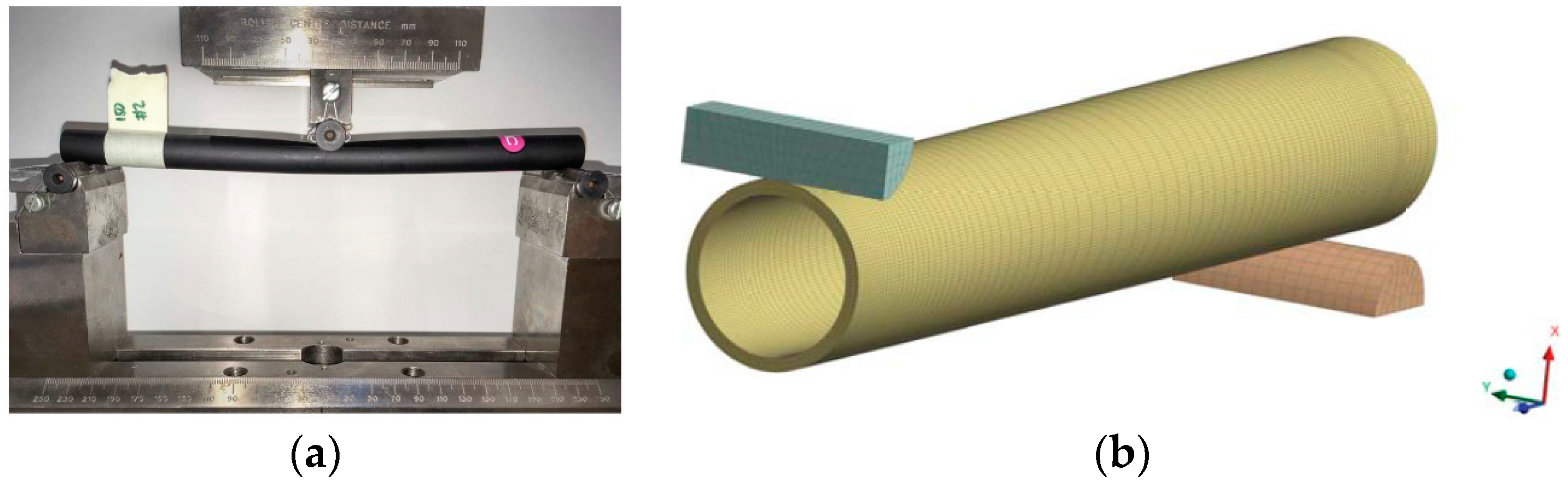

In the interest of evaluating the amount of damage initialised by a side impact, a 3-point bending (3PB) test was performed for all poles, see

Figure 1a. This was done based on the assumption that the impact load of ski poles can, under realistic circumstances, be well approximated as a quasi-static event, see [

1] for a detailed motivation. In the 3PB test, specimens of length 230 mm were supported by two steel cylinders. The load was applied by a third steel cylinder, displaced at a rate of 1 mm/min at the middle of the span until failure. This test allowed to compare the different pole strengths and to see how their material architecture is affecting their performance and damage tolerance.

2.2. Microscopy Analysis of All Ski Poles

The optical characterisation in a microscope helped to determine the fibre orientations through the thickness, the fibres volume fraction, the fibres diameters, the lamina thicknesses and the voids content in the poles considered in this study. For this analysis, 5 mm long specimens were cast in epoxy and polished to a fine surface finish.

2.3. Numerical Modelling and Simulation of SKIGO1 and SKIGO2

Two FE-models were developed. Firstly, a full ski pole bending model to mimic the test setup of the bending test carried out by SKIGO using the test method described in [

2]. The model was parameterised to enable simulation of the bending of both

SKIGO1 and

SKIGO2 poles as well as of the proposed concepts for design improvement. Secondly, a 3PB model for a comparison with the 3PB experiment and for evaluation of the strength of the proposed new design concepts. The FE-analysis was performed using the commercial software ANSYS Mechanical v17.

In the simulations of the full scale bending test—a test where the poles are placed horizontally in a test rig and then loaded in compression by pulling the hand strap while the basket tip was mounted in a ball joint—very detailed modelling of the boundary conditions at the handle and basket tip were necessary for good correlation between simulated and experimental results. The total bending of the pole was taken as the maximum displacement in the transverse vertical direction. The full-scale model of the pole was simulated using 9568 SHELL181 shell elements (plane stress, bilinear first order shear deformation theory elements), which guaranteed mesh convergent results.

To reduce the computational time of the simulations of the 3PB test, symmetry was utilised and thus only half of the assembly was analysed. Although the

SKIGO1 ski pole has one interior 45° ply which makes the structure asymmetric around its lengthwise midpoint, this asymmetry was neglected in the analysis since this ply does not significantly contribute to the bending stiffness nor does it significantly affect the outcome of the failure predictions. The supporting cylinders were set as fixed and the loading was carried out by a prescribed displacement of the top cylinder. The contact between the cylinders and the pole was set as frictionless. For all 3PB analyses, except for the proposed sandwich concept (see below), the same shell elements were used as for the longitudinal compression loading case. Also here, mesh convergence studies were conducted to guarantee low approximation errors in the simulations. See

Figure 1b for an illustration of the model.

The actual composite lay-up (fibre orientation in the plies through the thickness) was implemented by means of assigning the same transversely isotropic material properties in all plies, but with varying fibre orientations through the shell thickness according to the lay-ups identified in the microscopy study. Material properties for

SKIGO1 and

SKIGO2 were partly obtained by the experiments described above. The remaining data was estimated based on tabulated data for similar materials in [

3], see [

4] for details. The strength analysis of the composite poles was assessed with the Hashin failure initiation criteria, a set of criteria evaluating the risk of failure initiation for a number of failure modes: fibre direction tensile failure, fibre direction compressive failure, transverse direction matrix tensile failure, transverse direction matrix compressive failure and delamination.

2.4. Numerical Modelling and Simulation of Proposed New Design Concepts

Two new design concepts were analysed. Both were designed using thin ply (<50 µm) CFRP textile reinforced laminates (with or without a foam core), the actual reinforcement textile considered being TeXtreme

®, produced by Oxeon AB. Research has shown that such thin-ply CFRP laminates exhibit a higher ultimate tensile strength and an increased resistance to intralaminar crack propagation comparing to the conventional thick-ply CFRP [

5].

Longitudinal fibres are the main contributor to the ski pole bending stiffness. Based on this fact, and the fact that the 3PB tests (see

Section 3.3) indicated that circumferentially placed fibre reinforcements are important to increase the resistance to transverse and impact loads, an unbalanced 76 gsm plain TeXtreme

® weave impregnated with a M30SC epoxy matrix was considered as a suitable design material. The material considered in the new concepts was decided to have 88% of the fibres in the longitudinal direction and 12% of the fibres in the transverse direction, corresponding well with the fibre distribution in

SKIGO2. The CFRP properties were provided by the manufacturer Oxeon and are classified and can therefore not be given here. For the foam core, the material ROHACELL

® 71 RIMA was chosen and modelled as isotropic with properties taken from [

6]. In the end, the predicted weights of the two concepts very similar to

SKIGO2 (2% higher and 1% lower with and without foam core, respectively).

The full bending model validated for SKIGO1 was modified with the properties for the thin-ply material architecture (and the foam core), and two concepts aiming for a retained bending behaviour (with respect to SKIGO1) were developed. This resulted in a laminate lay-ups as [0F12] for the pure laminate design and [0F4/Core/0F7] for the sandwich design, with a core thickness of 0.6 mm. Note that the lay-ups specified with the unbalanced weave are denoted F. As for the sandwich concept, three solid-shell elements (ANSYS SOLSH190) were used through the thickness of the specimen in order to better capture the significant variation in stiffness between the CFRP face sheets and the foam core. The risk of core failure was assessed by comparing the maximum shear stress to the shear strength of the core.

3. Results and Discussion

3.1. Material Data for SKIGO1 and SKIGO2

The longitudinal stiffness, the in-plane shear stiffness, the compressive strength and compressive strain at failure obtained from the material characterisation tests are given in

Table 1 below. Unfortunately, the adhesive used in the tensile tests was not strong enough to reach tensile failure of the specimens so this value could not be determined.

3.2. Microscopy Results

The average wall thickness for the tested ski poles was about 1 mm. The lay-ups (from inside-out) and fibre volume fractions are summarised in

Table 2 below. More details can be found in [

4].

3.3. Results from Mechanical 3-Point Bending Tests

Results from the 3PB tests in terms of peak transverse force are summarised in

Table 3 for all considered pole brands. Duplicate values are presented for

Skigo Triac 2.5, which has a triangular cross section, since specimens from this pole were loaded both with a flat surface placed down (#1) and up (#2) in the 3PB rig. The reported values are averaged from tests on at least three samples.

Swix Triac 2.5 was the pole type which could carry the highest load until failure when loaded on its curved surface, followed by SKIGO2 and then Fischer RCS Carbonlite and Swix Triac 2.5 loaded on the flat surface. Since all poles fail by local deformation under the loading point (which is likely also the case in e.g., sprint impacts), two things are noted: (i) for impact resistance, it appears beneficial to have supporting plies with fibres in the circumferential direction and (ii) also geometrical stiffening (such as not having circular cross-sections) seems to have a beneficial effect IF the impact occurs in the right place.

3.4. Simulation Results from Full-Scale Bending

The simulated deformed shape of

SKIGO1 at maximum load is shown in

Figure 2a for illustrative purposes. Furthermore, the axial force is plotted versus the maximum deflection for

SKIGO1 and

SKIGO2 in

Figure 2b, together with the experimental results for

SKIGO1 provided by SKIGO. In

Figure 2c, axial force vs. maximum deflection is presented for the two new concept designs, also here together with the experimental data for

SKIGO1.

A comparison of the results from the FE-model with the experimental data given by Skigo for SKIGO1, shows that the FE-model generates accurate results, both in terms of the displacement magnitude and the bending behaviour of the ski pole. The strong correlation between the simulated and experimentally measured data also indicates that the modelling approach is valid and that the same model could be used with an alternated CFRP design in order to get reliable predictions of the stiffness characteristics of new design concepts. As a consequence, it could be used to design the new concepts to have similar bending characteristics while aiming for a more robust design.

The SKIGO2, for which there were no experimental data, was found to be only marginally less stiff than SKIGO1. This is due to the different lay-ups strategies in the ski poles. SKIGO1 had more fibres in the longitudinal direction making it more resilient to bending.

The bending results from simulation of compressive loading of the two new design concepts show that the design requirement of more or less retained axial stiffness characteristics is met for these new concepts.

3.5. Simulation Results from 3-Point Bending (New Concepts vs. SKIGO1 and SKIGO2)

A comparison (for a given load) of the spatial distribution of the failure initiation indices between SKIGO1 and SKIGO2 indicates that SKIGO2 is more resistant to transverse loads, both with respect to fibre and matrix dominated failure. This also confirms the trend found in the 3PB experiments. From the simulation results it can be concluded that the increased strength is due to the higher amount of fibres placed in the circumferential direction of the pole, thereby preserving better its circular cross-section and, consequently, lowering the amount of localised deformation which is the main cause for failure. This is also supported by the fact that, for SKIGO2, most of the fibre failure occurs in the 90° plies.

When comparing the two new concepts to SKIGO2, it was found that less fibre failure in the load carrying 0° plies is predicted for both cases (with and without foam core), which indicates that the two new concepts are probably even more resistant to transverse loads. Most of the fibre failure is predicted to occur in the 90° plies which further implicates the correlation between increased hoop strength and impact resistance. Due to uncertainties in the in-data as well as the fact that only composite failure initiation was considered in this study, no clear results with respect to the importance of the foam core could be obtained with certainty.

4. Conclusions

In this study, the first simulation assisted studies of CFRP ski pole stiffness and strength, with actual consideration of the material architecture and properties, have been conducted. For this purpose, finite element models were developed to characterise the performance of the existing ski pole concepts. After these models were validated against experimental results, they were used to predict the behaviour of new design concepts for ski poles, which according to preliminary results appear to be more resistant to transverse (and likely also impact) loading.

In addition, detailed material analysis (by experiments and microscopy) was used to characterise CFRP materials utilised, and a comparative study on the strength under transverse loading (representative of an impact event) of a number of different ski pole brands was conducted.

From the combined results, we conclude that, to some extent, the strive for optimised weight and bending stiffness has driven the pole design to be sub-optimal, with an increased sensitivity to transverse loading, by having a too pronounced focus on placing fibres for optimal stiffness (i.e., along the pole). We also showed that the same bending and weight characteristics can be retained, but with increased transverse strength simply by selecting other materials and composite lay-ups.