External Wall Technological Solutions for Carbon Zero Schools in Italy †

Abstract

:1. Introduction

2. Method and Input Data

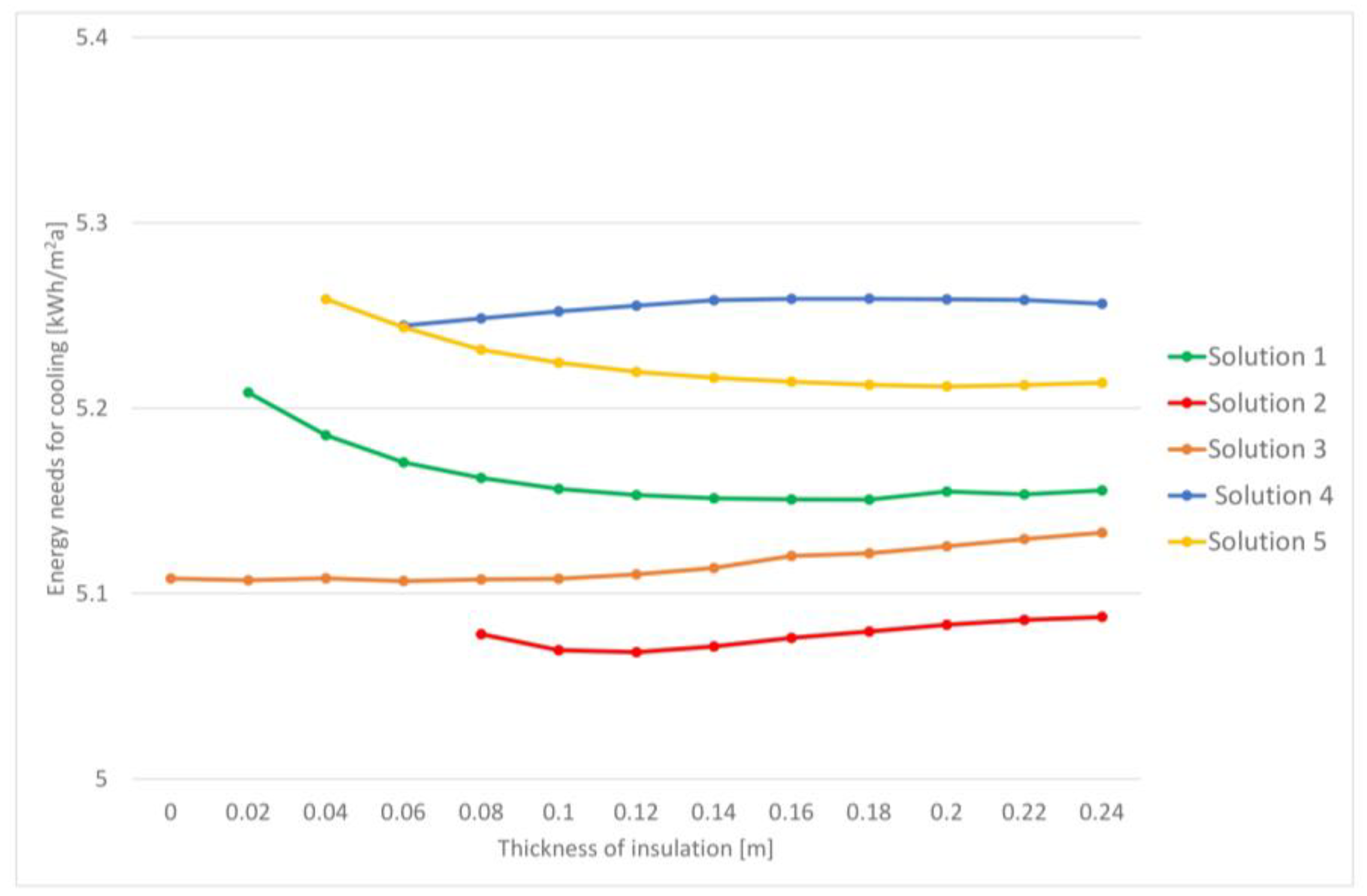

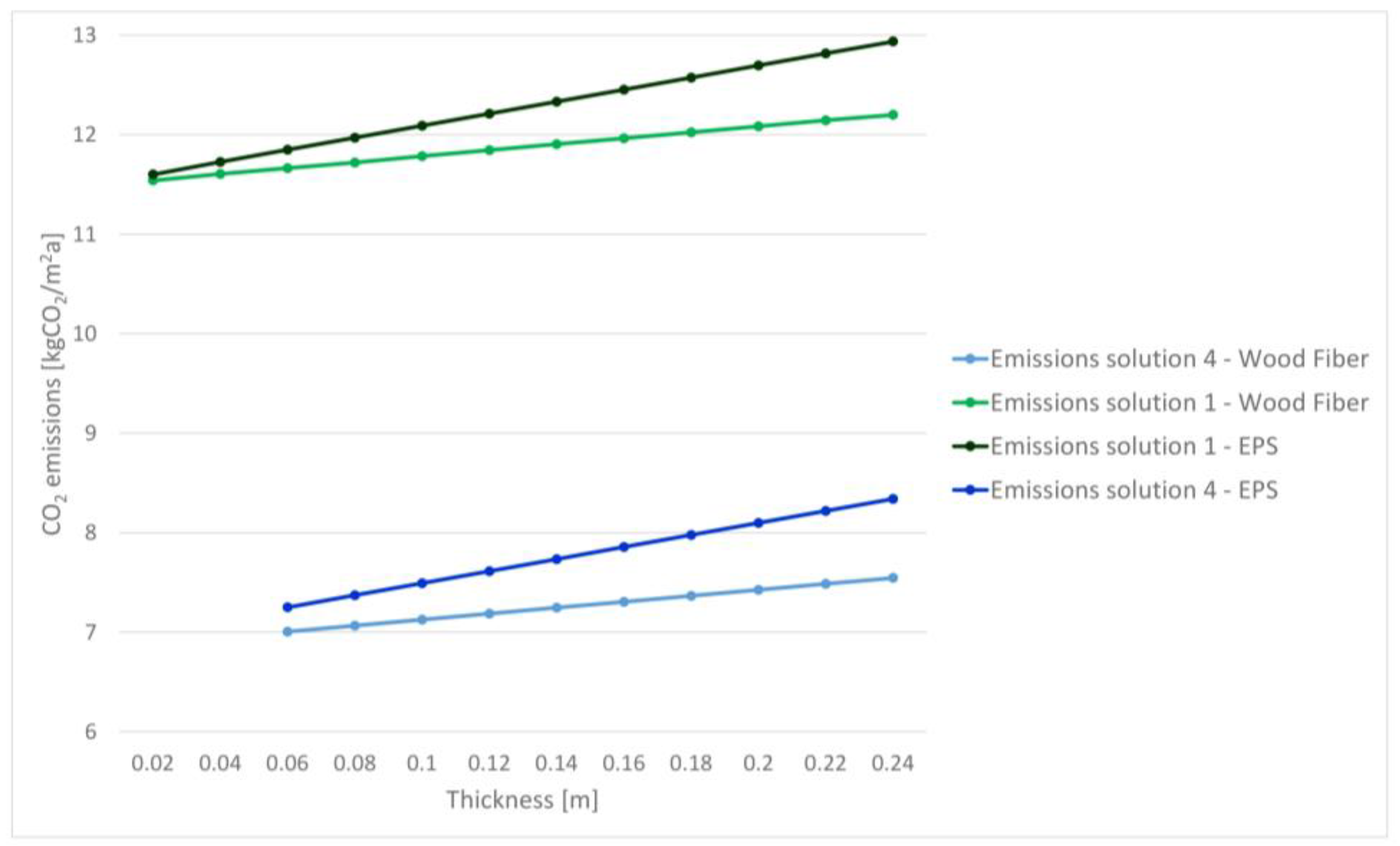

- Solution 1: reinforced concrete frame structure, with load bearing layer in lightweight bricks (0.30 m), external insulation (0.02 m), and a false wall constituted by a double plasterboard panel (0.015 m) and rock wool insulation layer (0.05) to ensure the right acoustic insulation required by regulation.

- Solution 2: steel frame structure, external wall made of dry solution with cement board external panel (0.0125 m), waterproofing sheet (0.0018 m), insulation layer (0.08), plasterboard panel (0.015 m), and false wall, as in Solution 1.

- Solution 3: steel frame structure, load bearing layer in aerated autoclaved concrete blocks (0.30 m), and false wall, as in Solution 1.

- Solution 4: wooden platform frame structure, external insulation (0.02 m) applied on a single oriented strand board (OSB) (0.02 m), internal insulation layer (0.06), waterproofing sheet (0.0018 m), single OSB panel (0.02 m), and false wall, as in Solution 1.

- Solution 5: XLAM wooden structure, external insulation applied on XLAM wall (0.04 m), and false wall as in Solution 1.

3. Results and Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Rad, E.A.; Fallahi, E. Optimizing the insulation thickness of external wall by a novel 3E (energy, environmental, economic) method. Constr. Build. Mater. 2019, 205, 196–212. [Google Scholar] [CrossRef]

- Agostino, D.D.; De Rossi, F.; Marigliano, M. Evaluation of the optimal thermal insulation thickness for an office building in different climates by means of the basic and modified “cost-optimal” methodology. J. Build. Eng. 2019, 24, 100743. [Google Scholar] [CrossRef]

- Fodoup, F.; Vincelas, C.; Ghislain, T. The determination of the most economical combination between external wall and the optimum insulation material in Cameroonian’s buildings. J. Build. Eng. 2017, 9, 155–163. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Hou, C. Optimization analysis of thermal insulation layer attributes of building envelope exterior wall based on DeST and life cycle economic evaluation. Case Stud. Therm. Eng. 2019, 14, 1–9. [Google Scholar] [CrossRef]

- Rosti, B.; Omidvar, A.; Monghasemi, N. Optimal insulation thickness of common classic and modern exterior walls in different climate zones of Iran. J. Build. Eng. 2020, 27, 100954. [Google Scholar] [CrossRef]

- Governo Italiano. Decreto Ministeriale del 26 Giugno 2015. Applicazione Delle Metodologie di Calcolo Delle Prestazioni Energetiche e Definizione Delle Prescrizioni e dei Requisiti Minimi Degli Edifici; Governo Italiano: Rome, Italy, 2015. [Google Scholar]

| Insulation | Wood Fiber | EPS | Mineral Wool | Glass Wool | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solution | YIE | Φ | t | YIE | φ | t | YIE | φ | t | YIE | φ | t |

| 1 | 0.009 | 18.47 | 0.02 | 0.009 | 18.31 | 0.02 | 0.009 | 18.36 | 0.02 | 0.008 | 18.37 | 0.02 |

| 1A | ||||||||||||

| 2 | 0.207 | 4.69 | 0.08 | 0.216 | 2.23 | 0.08 | 0.239 | 2.80 | 0.08 | 0.236 | 2.75 | 0.08 |

| 2A | 0.087 | 8.14 | 0.14 | 0.095 | 8.10 | 0.32 | 0.058 | 8.27 | 0.24 | 0.059 | 8.08 | 0.24 |

| 3 | 0.018 | 15.89 | - | 0.018 | 15.89 | - | 0.018 | 15.89 | - | 0.018 | 15.89 | - |

| 3A | ||||||||||||

| 4 | 0.05 | 11.88 | 0.04 | 0.101 | 9.19 | 0.04 | 0.099 | 9.33 | 0.04 | 0.099 | 9.18 | 0.04 |

| 4A | 0.079 | 9.76 | 0.06 | |||||||||

| 5 | 0.02 | 14.36 | 0.04 | 0.02 | 13.82 | 0.04 | 0.02 | 13.94 | 0.04 | 0.02 | 13.95 | 0.04 |

| 5A | ||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciacci, C.; Bazzocchi, F.; Di Naso, V. External Wall Technological Solutions for Carbon Zero Schools in Italy. Proceedings 2020, 51, 13. https://doi.org/10.3390/proceedings2020051013

Ciacci C, Bazzocchi F, Di Naso V. External Wall Technological Solutions for Carbon Zero Schools in Italy. Proceedings. 2020; 51(1):13. https://doi.org/10.3390/proceedings2020051013

Chicago/Turabian StyleCiacci, Cecilia, Frida Bazzocchi, and Vincenzo Di Naso. 2020. "External Wall Technological Solutions for Carbon Zero Schools in Italy" Proceedings 51, no. 1: 13. https://doi.org/10.3390/proceedings2020051013

APA StyleCiacci, C., Bazzocchi, F., & Di Naso, V. (2020). External Wall Technological Solutions for Carbon Zero Schools in Italy. Proceedings, 51(1), 13. https://doi.org/10.3390/proceedings2020051013