Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes †

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. 3D Printing Conditions of the Reference Grade

2.3. Mechanical Recycling of the Materials

2.4. Characterization Techniques

3. Results and Discussion

3.1. Intrinsic Viscosity

3.2. Thermal Properties

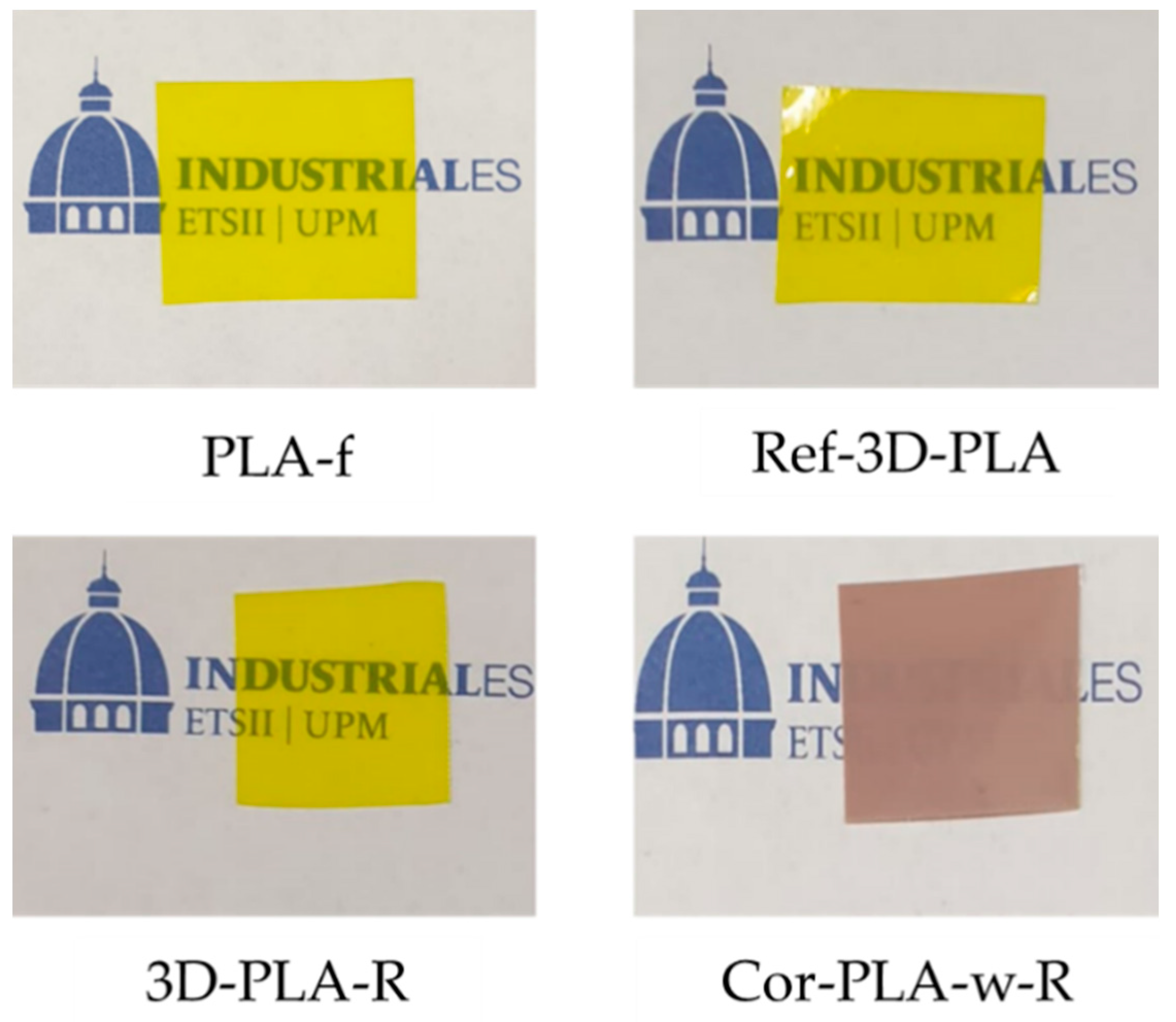

3.3. Visual Properties

4. Conclusions

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PLA | Poly(lactic acid) |

References

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D printing filament as a second life of waste plastics—A review. Environ. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Tan, H.W.; Patel, D.C.; Choong, W.T.N.; Chen, C.; Low, H.Y.; Tan, M.J.; Patel, C.D.; Chua, C.K. The global rise of 3D printing during the COVID-19 pandemic. Nat. Rev. Mater. 2020, 5, 637–639. [Google Scholar] [CrossRef] [PubMed]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, K.A. Recycled poly(lactic acid)–based 3D printed sustainable biocomposites: a comparative study with injection molding. Mater. Today Sustain. 2020, 7–8, 100027. [Google Scholar] [CrossRef]

- De Andrade, M.F.C.; Souza, P.M.S.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Ong, T.K.; Choo, H.L.; Choo, W.J.; Koay, S.C.; Pang, M.M. Recycling of Polylactic Acid (PLA) Wastes from 3D Printing Laboratory. In Advances in Manufacturing Engineering; Emamian, S., Awang, M., Yusof, F., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Lorenzo, V.; Acosta, J.; de la Orden, M.U.; Urreaga, J.M. Effect of simulated mechanical recycling processes on the structure and properties of poly(lactic acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Agüero, A.; Morcillo, D.M.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [PubMed]

- Peeters, B.; Kiratli, N.; Semeijn, J. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. J. Clean. Prod. 2019, 241, 118313. [Google Scholar] [CrossRef]

- Chariyachotilert, C.; Joshi, S.; Selke, S.E.M.; Auras, R. Assessment of the properties of poly(L-lactic acid) sheets produced with differing amounts of postconsumer recycled poly(L-lactic acid). J. Plast. Film Sheeting 2012, 28, 314–335. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Beltrán, F.R.; Infante, C.; de la Orden, M.U.; Urreaga, J.M. Mechanical recycling of poly(lactic acid): Evaluation of a chain extender and a peroxide as additives for upgrading the recycled plastic. J. Clean. Prod. 2019, 219, 46–56. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Processing of poly(lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

| Sample | Description |

|---|---|

| PLA-f | Non-used PLA 3D filament (Smartfil® PLA) |

| Ref-3D-PLA | PLA-f subjected to printing under controlled conditions |

| 3D-PLA-R | 3D printing wastes coming from PLA-f, subjected to mechanical recycling |

| Cor-PLA-w-R | 3D printing wastes coming from the coronamakers association, subjected to mechanical recycling |

| Sample | Tcrist (°C) | ∆Hcrist (J/g) | T10 (°C) |

|---|---|---|---|

| PLA-f | 92.3 | 1 | 315.2 |

| Ref-3D-PLA | 94.3 | 1 | 313.1 |

| 3D-PLA-R | 94.1 | 1 | 314.7 |

| Cor-PLA-w-R | 105.3 | 21 | 299.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno, E.; Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; Muneta, L.M.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; Orden, M.U.d.l.; Urreaga, J.M. Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes. Proceedings 2021, 69, 19. https://doi.org/10.3390/CGPM2020-07187

Moreno E, Beltrán FR, Arrieta MP, Gaspar G, Muneta LM, Carrasco-Gallego R, Yáñez S, Hidalgo-Carvajal D, Orden MUdl, Urreaga JM. Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes. Proceedings. 2021; 69(1):19. https://doi.org/10.3390/CGPM2020-07187

Chicago/Turabian StyleMoreno, Eduardo, Freddys R. Beltrán, Marina P. Arrieta, Gerald Gaspar, Luisa M. Muneta, Ruth Carrasco-Gallego, Susana Yáñez, David Hidalgo-Carvajal, María U. de la Orden, and Joaquín Martínez Urreaga. 2021. "Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes" Proceedings 69, no. 1: 19. https://doi.org/10.3390/CGPM2020-07187

APA StyleMoreno, E., Beltrán, F. R., Arrieta, M. P., Gaspar, G., Muneta, L. M., Carrasco-Gallego, R., Yáñez, S., Hidalgo-Carvajal, D., Orden, M. U. d. l., & Urreaga, J. M. (2021). Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes. Proceedings, 69(1), 19. https://doi.org/10.3390/CGPM2020-07187