Abstract

The exhausted olive pomace (EOP) is the main residue generated year-round after the extraction of the residual oil contained in the olive pomace. Due to its chemical composition, EOP is an interesting bioresource for the production of bioenergy and high added-value products. Therefore, the purpose of this study was to evaluate the extraction of antioxidants from EOP using sequential ultrasound-assisted extraction (UAE) and maceration with constant stirring. Water and 70% acetone were used as solvents. The total phenolic content was determined by the Folin–Ciocalteu method, the antioxidant capacity was investigated and the phenolic extracts were also characterized.

1. Introduction

More than 97% of the world’s olive production is concentrated in the Mediterranean region [1], and Spain is the world’s leading producer and exporter of olive oil [2]. In Spain, the surface area of olive trees was 2,579,001 Ha in 2018 with an olive production of 9,819,569 tons [3]. This activity generates important amounts of residues every year such as olive tree pruning, olive mill leaves, stones, olive pomace, and exhausted olive pomace (EOP). EOP is the residual solid biomass obtained after the extraction of the olive pomace oil. According to the chemical composition of EOP, which can contain up to 35% of carbohydrates and its high content in non-structural components, around 50%, it constitutes a promising feedstock within the context of biorefinery for the production of bioenergy and bioactive compounds extraction, such as phenolic compounds [4]. These compounds are natural antioxidants with applications in the food industry. In this line, the interest of the food industry in replacing synthetic antioxidants with natural antioxidants is increasing [5]. Moreover, these bioactive compounds show potential health benefits, and therefore, their applications for the pharmaceutical and food industries are large.

The aim of this study was to obtain antioxidants from the EOP. In this way, ultrasound-assisted extraction (UAE) was performed using sequential extraction with water and 70% acetone as solvents. UAE is considered an efficient extraction technique because it reduces extraction time, solvent, and energy consumption with increasing yields [5,6], which translates into savings on an industrial scale. Moreover, it was compared with an optimized extraction method using water at 85 °C under agitation [7]. All these experiments were carried out with a 10% (w/v) solid load. The extracts obtained were lyophilized and characterized in terms of the total phenolic content (TPC) by the Folin–Ciocalteu method and their antioxidant activity was determined by two different in vitro tests (2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid (ABTS) radical scavenging). The phenolic extract profiles were identified by capillary zone electrophoresis (CZE).

2. Methods

2.1. Raw Material

EOP was obtained by a local olive pomace industry (Spuny SA, Jaén, Spain). This residue was partially pitted and pelletized, with an average length of 14.5 mm and an average diameter of 4.6 mm. This by-product was characterized in terms of moisture, ash, lignin, and carbohydrates according to the standard National Renewable Energy Laboratory (NREL) procedure [8]. Aqueous and ethanolic extractives were determined using Soxhlet extraction.

2.2. Ultrasound-Assisted Extraction and Maceration with Constant Stirring

Exhausted olive pomace was subjected to three consecutive steps of extraction in ultrasound using the conditions indicated in Table 1. The extraction time of each extraction step was 30 min and two different solvents were used (water and 70% acetone). Additionally, water was used as a solvent for maceration with constant stirring at 85 °C for 90 min. In all experiments, the solid loading was at 10% (w/v). After each extraction, the samples were filtered under vacuum; an aliquot of the extracts was stored in cold and another portion was lyophilized. Liquid and lyophilized extracts were characterized in terms of the TPC, antioxidant activity, and their phenolic profile, which was determined by CZE. The solid recovery yield of each experiment was also determined. The samples were filtered through a 0.45 μm nylon membrane filter (SinerLab Group, Madrid, Spain) before analysis.

Table 1.

Conditions applied to recover antioxidants from exhausted olive pomace.

2.3. Total Phenolic Content

TPC was determined by using the Folin–Ciocalteu colorimetric method according to a procedure described by [9], with some modifications. Briefly, the extract sample (or water for blank) (0.1 mL) was mixed with distilled water (0.4 mL), diluted Folin–Ciocalteu reagent (1:1, v/v) (0.25 mL) and Na2CO3 (20% w/v) (1.25 mL). After 40 min incubation at room temperature, the absorbance was measured at 725 nm with a microplate reader (Multiskan GO, ThermoFisher Scientific, Waltham, MA, USA). A calibration curve of gallic acid was prepared. The measurements were carried out in triplicate.

2.4. Antioxidant Capacity

Two different assays were used to determine the antioxidant activity of the extracts according to previous studies [10,11]: DPPH and ABTS radical scavenging assay. The former is based on the scavenging of DPPH by the antioxidant compound, resulting in a change of color, while the second assay is based on the quantification of the discoloration of the ABTS radical due to its interaction with hydrogen or electron donor species. Then, the absorbance was measured with the aforementioned device at 515 nm and 734 nm, respectively. Trolox was used as the standard for comparison and a calibration curve was prepared. All samples were analyzed in triplicate.

2.5. Phenolic Profile by Capillary Electrophoresis

The extracts were analyzed by CZE using a capillary electrophoresis system from Agilent Technologies (Waldbronn, Germany), equipped with a diode array detector (DAD), an Agilent uncoated fused silica capillary (50 μm) and an effective length of 62/56 cm. The separation buffer was 15 mM sodium tetraborate decahydrate with 8% MeOH, which was used as an organic modifier to improve separation performance, adjusted to pH 9.1. The separation voltage was 30 kV with a ramp of 0.5 min and the current was at 120 μA maximum setting. The capillary temperature was maintained at 30 °C during separations. The samples were injected directly under a pressure of 50 mbar for 5 s into the anode (+). Electropherograms were recorded at 220 nm. The capillary was pre-conditioned between runs by washing with 0.1 M NaOH (3 min) followed by a buffer (3 min). The characterization was performed by the comparison of the migration time and UV spectra with standards from an in-house library using Agilent 3D-CE ChemStation data software (version B.04.01) (Agilent Technologies).

3. Results and Discussion

The chemical composition of the EOP showed that it contained 41.8% of extractives, 20.6% of carbohydrates, and 21.8% of lignin, as major components [7]. This is in line with previous literature [12] and remarks that the extractive fraction should be studied for the further valorization of EOP. For that reason, in this study, two extraction methods were compared to recover the phenolic fraction.

Table 2 shows the results of the TPC and the antioxidant activity of the water and water-acetone extracts of EOP obtained after UAE and maceration with constant stirring. It can be seen that using 10% solids load by UAE at 30 °C it is recommended to perform three sequential extractions in order to recover the highest possible concentration of phenolic compounds. However, using water extraction through maceration at 80 °C, higher amounts of phenolic compounds were solubilized in the liquid fraction in a single step (Table 2), and totally 4.22 acid gallic equivalents (GAE) versus 2.88 GAE using UAE with both solvents. This trend was observed by the total solids recovered, which was higher using the aforementioned method. This means that the lowest extraction yield was obtained by UAE with acetone, 38.53%, and thus the richness of phenolic compounds in these extracts was higher.

Table 2.

Total phenolic content (TPC) and antioxidant activity determined by the 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid (ABTS) radical scavenging assays, of the water and water–acetone extracts from exhausted olive pomace at 10% solid load.

The different extracts, the mixtures obtained by UAE and the water extract obtained by maceration, were subjected to a drying process by lyophilization to check if the antioxidant activity is maintained. This drying process is highly applied to obtain final products of the highest quality [13]. Table 3 shows the results obtained. As before, UAE with water-acetone was revealed to be more effective than with water, with a TPC value of 95.7 versus 74.4 mg GAE/g extract, respectively. The extract obtained in an agitated water bath at 85 °C showed a TPC of 65.9 mg GAE/g extract. The antioxidant activity of the extracts revealed to be in accordance with the TPC, being the results higher for UAE extracts, particularly, using water–acetone. These values are higher than those reported for carob kibbles using UAE [14]; 9.4 mg GAE/g dry mass for water and 20.4 mg GAE/g dry mass for 70% acetone. They were also higher than those for brewer’s spent grains using maceration [15], 3.6 mg GAE/g dry mass for water, and 9.90 mg GAE/g dry mass for 60% acetone. These results also revealed that the phenolic compounds from EOP are highly polar and a large amount can be obtained using water.

Table 3.

Total phenolic content (TPC) and antioxidant activity, determined by the 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid (ABTS) radical scavenging assays, of the lyophilized water and water–acetone extracts obtained from exhausted olive pomace.

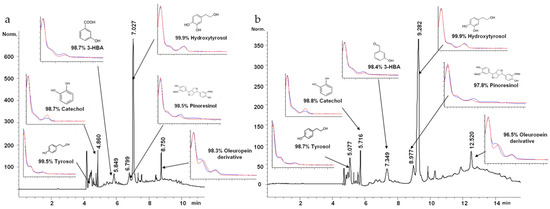

The extracts were also characterized to determine the phenolic composition through CZE. All the extracts showed similar profiles. As an example, Figure 1 shows the electropherograms of the water–acetone extract obtained by UAE and the water extract obtained by maceration with constant stirring. Moreover, it was possible to tentatively identify hydroxytyrosol, tyrosol, catechol, pinoresinol, oleuropein derivative, and 3-hydroxybenzaldehyde with a >95% matching.

Figure 1.

Electropherograms at 200 nm of the water–acetone extract obtained by (a) ultrasound-assisted extraction (UAE) and (b) the water extract obtained by maceration with constant stirring.

Among them, hydroxytyrosol was the major compound found in all the extracts, which is also considered the most powerful and one of the most powerful antioxidants in the olive tree, followed by tyrosol. This is interesting since this compound is one of the antioxidants of olive oil that confers protection of blood lipids from oxidative stress [16]. As a novel food ingredient, hydroxytyrosol has recently been declared safe by the European Food Safety Authority under proposed uses and use levels, i.e., in fish and vegetable oils up to 215 mg/kg and in margarine up to 175 mg/kg [17].

4. Conclusions

Results showed that EOP presents a significant amount of phenolic compounds, independently of the extraction conditions. While the highest solubilization of phenolic compounds was obtained using water extraction at 80 °C, UAE with 70% acetone revealed to be more effective for the obtention of an extract richer in antioxidants. Hydroxytyrosol was the major compound found in all the extracts, which is also considered one of the most powerful antioxidants. Therefore, EOP is a promising source of added-value phenolic compounds with antioxidant activity, in particular of hydroxytyrosol and its obtention is worth-merit before the exploration of this byproduct for bioenergy production.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available on request from the corresponding author.

Acknowledgments

Financial support from Agencia Estatal de Investigación and Fondo Europeo de Desarrollo Regional. Reference project ENE2017-85819-C2-1-R. Irene Gómez-Cruz expresses her gratitude to the Universidad de Jaén for financial support (grant R5/04/2017). Authors also thank the FEDER UJA projects 1260905 funded by “Programa Operativo FEDER 2014-2020” and “Consejería de Economía y Conocimiento de la Junta de Andalucía”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Christoforou, E.; Fokaides, P.A. A review of olive mill solid wastes to energy utilization techniques. Waste Manag. 2016, 49, 346–363. [Google Scholar] [CrossRef] [PubMed]

- AICA—Agencia de Información y Control Alimentarios. Available online: https://www.aica.gob.es/ (accessed on 15 October 2020).

- FAOSTAST. Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 15 October 2020).

- Contreras, M.d.M.; Romero, I.; Moya, M.; Castro, E. Olive-derived biomass as a renewable source of value-added products. Process Biochem. 2020, 97, 43–56. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Gómez-Cruz, I.; Romero, I.; Gullón, B.; Ruiz, E.; Brnčićc, M.; Castro, E. Ultrasound-assisted extraction as a first step in a biorefinery strategy for valorisation of extracted olive pomace. Energies 2019, 12, 2679. [Google Scholar] [CrossRef]

- Picó, Y. Ultrasound-assisted extraction for food and environmental samples. Trends Anal. Chem. 2013, 43, 84–99. [Google Scholar] [CrossRef]

- Gómez-Cruz, I.; Cara, C.; Romero, I.; Castro, E.; Gullón, B. Valorisation of exhausted olive pomace by an eco-friendly solvent extraction process of natural antioxidants. Antioxidants 2020, 9, 1010. [Google Scholar] [CrossRef] [PubMed]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process Samples; NREL/TP-510-42623; National Renewable Energy Laboratory: Golden, CO, USA, 2006. [Google Scholar]

- Singleton, V.L.; Rossi, S.A. Colorimetric of total phenolics with phosphomolibic Phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Manzanares, P.; Ballesteros, I.; Negro, M.J.; González, A.; Oliva, J.M.; Ballesteros, M. Processing of extracted olive oil pomace residue by hydrothermal or dilute acid pretreatment and enzymatic hydrolysis in a biorefinery context. Renew. Energy 2020, 145, 1235–1245. [Google Scholar] [CrossRef]

- Bhatta, S.; Janezic, T.S.; Ratti, C. Freeze-drying of plant-based foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef] [PubMed]

- Roseiro, L.B.; Tavares, C.S.; Roseiro, J.C.; Rauter, A.P. Antioxidants from aqueous decoction of carob pods biomass (Ceretonia siliqua L.): Optimisation using response surface methodology and phenolic profile by capillary electrophoresis. Ind. Crops Prod. 2013, 44, 119–126. [Google Scholar] [CrossRef]

- Meneses, N.G.T.; Martins, S.; Teixeira, J.A.; Mussatto, S.I. Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Sep. Purif. Technol. 2013, 108, 152–158. [Google Scholar] [CrossRef]

- European Commission Commission Regulation (EU). No 1018/2013 of 23 October 2013. Amending Regulation (EU) No 432/2012 establishing a list of permitted health claims made on foods other than those referring to the reduction of disease risk and to children’s development and health. Off. J. Eur. Union 2013, 56, 43–45. Available online: http://eur-lex.europa.eu/pri/en/oj/dat/2003/l_285/l_28520031101en00330037.pdf (accessed on 10 October 2020).

- Dominique, T.; Bresson, J.L.; Burlingame, B.; Dean, T.; Fairweather-Tait, S.; Heinonen, M.; Hirsch-Ernst, K.I.; Mangelsdorf, I.; McArdle, H.J.; Naska, A.; et al. Safety of hydroxytyrosol as a novel food pursuant to Regulation (EC) No 258/97. EFSA J. 2017, 15, e04728. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).