Abstract

High-frequency shock-type vibration (HFV) with a frequency content mainly above 1250 Hz, e.g., from impact wrenches, is likely to cause a significant amount of vibration injuries and even hand-arm vibration syndrome. The objective of this study was to measure vibration up to 100 kHz with a Laser Doppler Vibrometer (LDV) and investigate the variation of vibration over the machine surface, the vibration propagation into finger tissue, and the vibration reduction on the finger tissue due to a foamed polymer layer. Our results showed that the vibration on the handle varies moderately and that the amplitudes are higher on the machine surface. A large proportion of the vibration is transferred into the finger tissue and thereby subjects the finger tissue to high-vibration amplitudes, but it is effectively reduced by a thin layer of foamed polymer.

1. Introduction

The current standard for risk estimation of hand-arm vibration injury omits frequencies above 1400 Hz [1]. Research has long indicated that the risk from high-frequency vibration is underestimated by the current standard, e.g., [2]. A high prevalence of vibration injuries has been found in assembly workers that work with impact wrenches despite being classified as low exposure according to the current risk assessment [3]. In this study, two impact wrenches were measured up to 100 kHz with a Laser Doppler Vibrometer (LDV) at different locations to see the variation of high-frequency vibration. Measurements were also performed on the fingernail to investigate the vibration propagation into and through the finger to the nail surface and its reduction due to a polymer foam.

2. Method

Vibration was measured at different locations on two ½ inch pneumatic impact wrenches with an LDV. The wrenches were run in a brake rig according to ISO 28927-2:2009. The impact wrenches used in the study were the Chicago Pneumatics 734H and the Würth DSS ½ Superior. All sampling and data analysis was performed in MATLAB.

2.1. Measurements

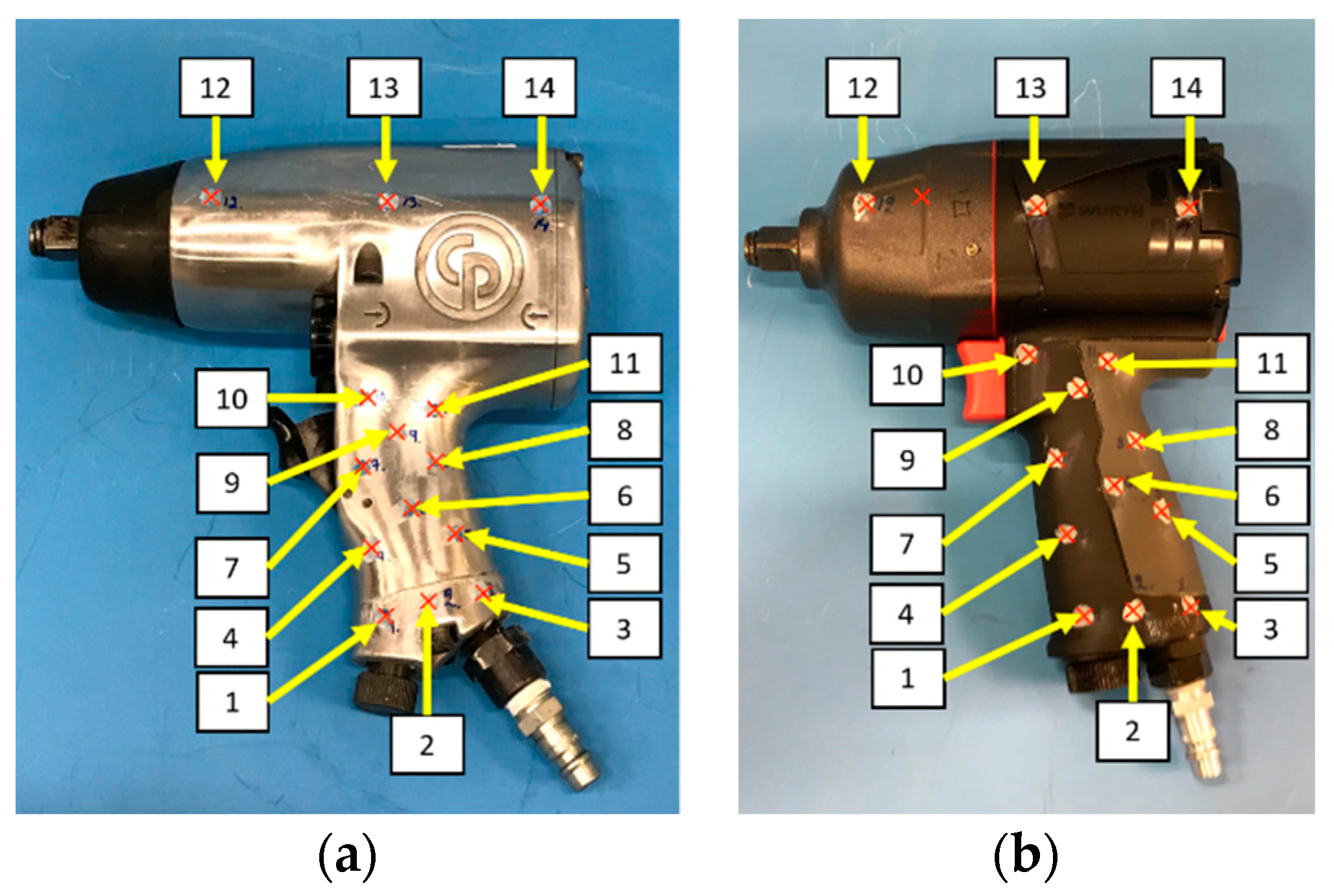

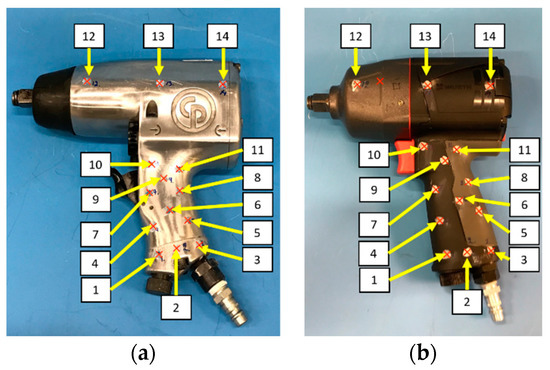

The acceleration was measured at 14 positions on both impact wrenches to map the variation of acceleration over the surface. Ten positions were on the handle and three were on the upper body. The measurement locations can be seen in Figure 1.

Figure 1.

(a) Measurement positions on the CP 734H all-metal impact wrench; (b) measurement positions on the Würth DSS ½” superior composite body impact wrench, except for point 12 (metal).

The acceleration was also measured on the fingernail of the operator’s index finger to see whether the vibration propagates through the finger. The finger was placed on position 9 on the CP 734H while the impact wrench was running, and the laser was kept in the same position to measure the vibration on the fingernail. The measurement was done with the bare finger in contact with the tool surface and with 2 mm of EPDM foam glued to the surface of the tool. The EPDM measurement was performed to investigate the potential of vibration reduction on the finger. The feed force was not measured during the test, but the operator was instructed to try to mimic normal tool griping. The measurement setup with the LDV aimed at the fingernail, as seen in Figure 2.

Figure 2.

Setup for measurements on the fingernail in position 9. The green dot on the fingernail is the pilot laser that shows where the IR laser measures the velocity.

The velocity was measured using an infrared (λ = 1550 nm) LDV. Retroreflective glass beads were fixed at the measurement positions with nail polish to improve the signal quality. The Polytec Vibroflex LDV consists of a -Qtec VFX-I-160 single-point sensor head with a VFX-O-SRI short-range lens. The sensor head was connected to a Connect VXF-F-110 front end with a bandwidth of 100 kHz. The measured velocity is derived from acceleration at the front end. The acceleration signal was recorded using a National Instruments 9223 C series module with a sample rate of 1 MS/s. All positions were measured for 5 s. Position 9 was measured 3 times to investigate repeatability, which is under 10%.

2.2. Data Analysis

Currently, there is no applicable measurement standard for the evaluation of high-frequency shock vibration on hand-held tools. A proposal has been made for algorithms that quantify high-frequency shock vibration on tools [4]. The acceleration measured on the impact wrenches is highly transient. The acceleration is negligible most of the time during an impact cycle, but when the mechanism locks, high-amplitude transients occur. The magnitude of the transients varies; therefore, a method for quantifying the amplitude over time was needed. One suggestion in [4] is to define a Vibration Peak Magnitude (VPM) for a sampled acceleration signal, with N data points, as shown in Equation (1).

The VPM was calculated for all measurements. To investigate the influence of the upper, the VPM was calculated for the same signal with 4 bandwidths: 100 kHz, 30 kHz, 10 kHz, and 1250 Hz. The bandwidth was limited with a 6th order Butterworth low-pass filter.

3. Results

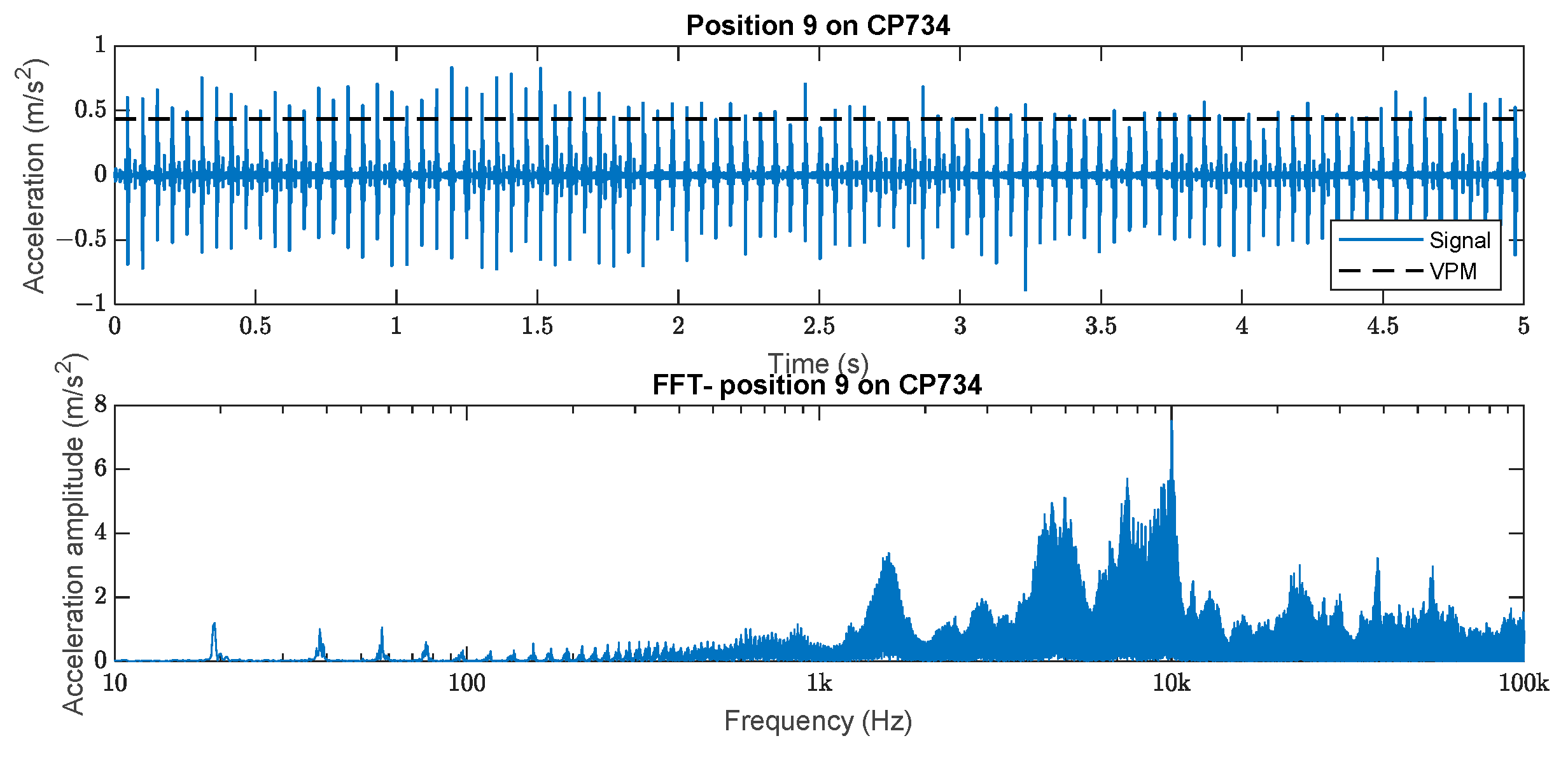

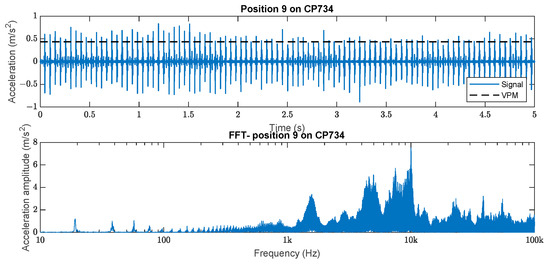

Figure 3 shows the measured signal at position 9 with a VPMVPM of 3800 m/s2.

Figure 3.

Top: Example of the VPM for position 9 on the CP 734H. Signal and the calculated VPM value. Bottom: Frequency spectra of the signal with Hann windowing.

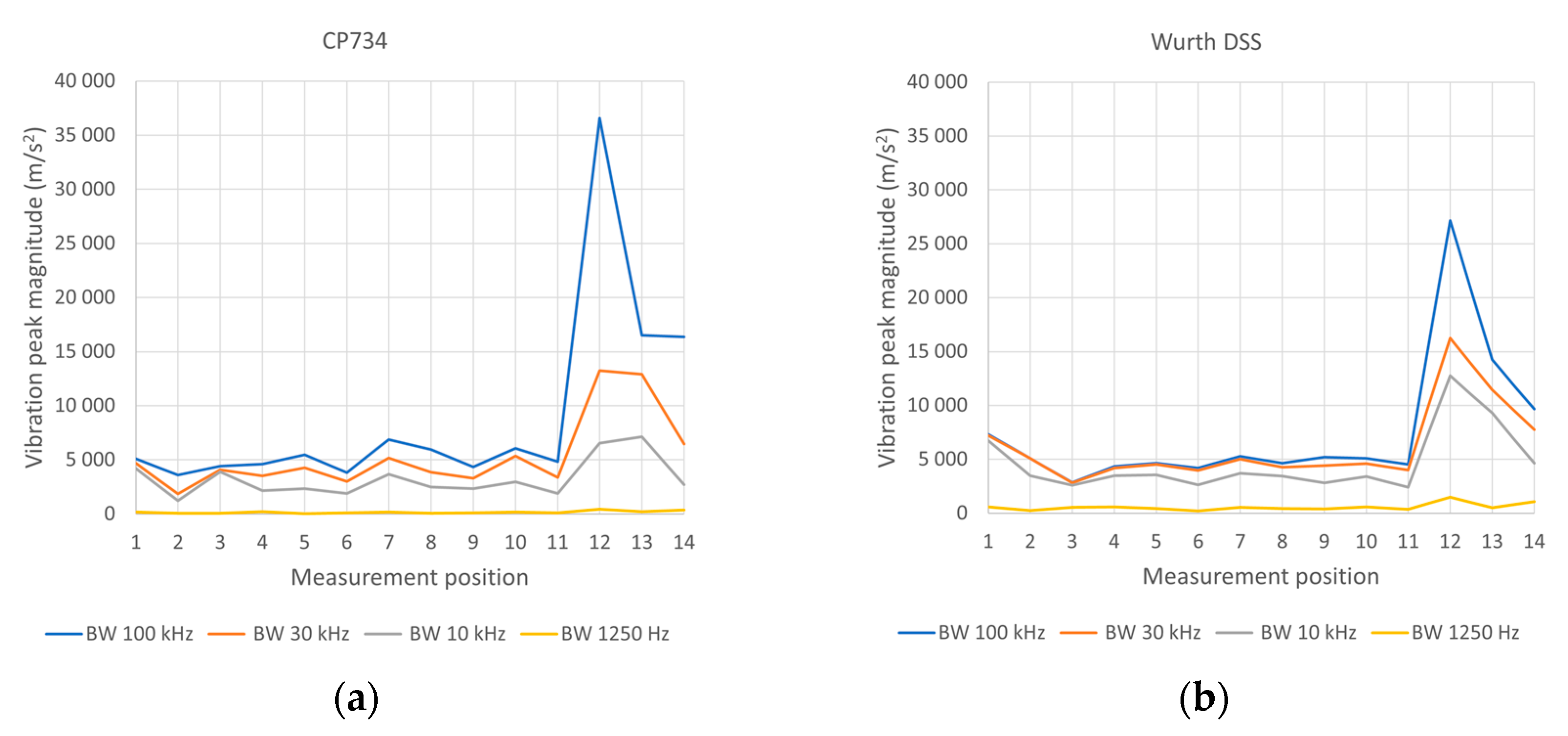

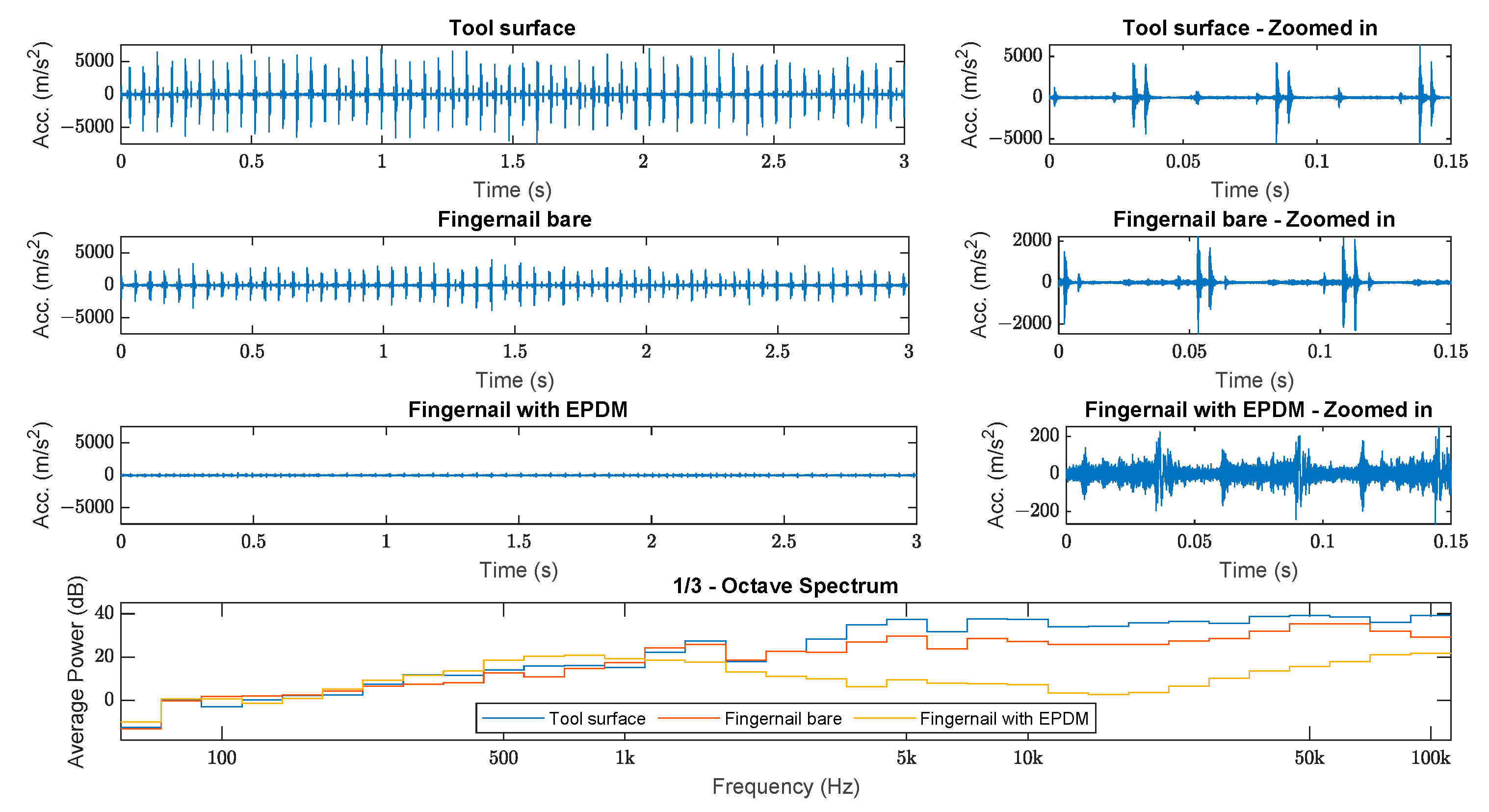

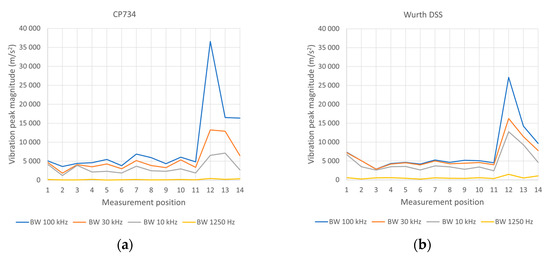

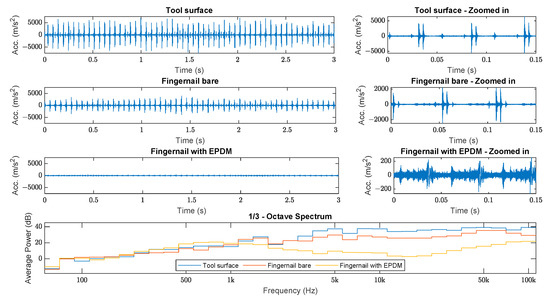

The VPM values from different locations with different bandwidths on both impact wrenches can be seen in Figure 4. A comparison of the measured acceleration for the fingernail and the tool surface at position 9 can be seen in Figure 5. The VPM for the tool surface at position 9 was 4350 m/s2. The VPM for the fingernail was 2270 m/s2 with the finger directly on the tool surface at position 9. The VPM for the fingernail was 220 m/s2 when the EPDM foam was between the finger and the tool at position 9.

Figure 4.

The vibration peak magnitude (VPM) for different measurement positions on the impact wrenches. The curves are calculated from signals that have been low-pass filtered with different cut-off frequencies. (a) The VPM for the CP 734H; (b) the VPM for the Würth DSS ½ superior.

Figure 5.

Comparison of measured signals at position 9 on the CP 734H. Top row: Acceleration for the tool surface. Second row: Acceleration for the fingernail when the bare finger is placed on the tool surface. Third row: Acceleration for the fingernail with 2 mm of EPDM foam between the tool surface and the finger. Bottom row: One-third octave spectrum from 20 Hz to 100 kHz for all three signals.

4. Discussion

The VPM for the handles (positions 1–11) of both impact wrenches is relatively stable around 5000 m/s2 (Figure 4). The VPM is significantly higher (around 30,000 m/s2) for measurement position 12, close to the main shaft. The VPM is also higher for positions 13 and 14 (i.e., the housing around the motor and mechanism).

The measurement on the fingernail showed that the VPM for the fingernail (2270 m/s2) is around half the VPM for the tool surface below (4350 m/s2), which indicates that high frequencies propagate through the finger. When 2 mm of foamed EPDM rubber was placed between the finger and the tool surface, the VPM was reduced by a factor of 10 (220 m/s2), which shows that simple solutions can be used to significantly reduce exposure to high frequencies.

Author Contributions

Conceptualization, methodology, investigation, and writing, H.L. and S.L.G. Software, formal analysis, and visualization, S.L.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Vinnova, which is the Swedish Innovation Agency, and Afa Försäkring.

Informed Consent Statement

Informed consent was obtained from all subjects involved in this study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- ISO 5349-1:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General Requirements. ISO (the International Organization for Standardization): Geneva, Switzerland, 2001.

- Dandanell, R.; Engström, K. Vibration from riveting tools in the frequency range 6 Hz–10 MHz and Raynaud’s phenomenon. Scand. J. Work Environ. Health 1986, 12, 338–342. [Google Scholar] [CrossRef] [PubMed]

- Gerhardsson, L.; Ahlstrand, C.; Ersson, P.; Gustafsson, E. Vibration-induced injuries in workers exposed to transient and high frequency vibrations. J. Occup. Med. Toxicol. 2020, 15, 18. [Google Scholar] [CrossRef] [PubMed]

- Johannisson, P.; Lindell, H. Definition and Quantification of Shock/Impact/Transient Vibrations. arXiv 2022, arXiv:2211.08999. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).