Noise Analysis of MEMS Microphones as a Gas-Sensing Element †

Abstract

:1. Introduction

2. Materials and Methods

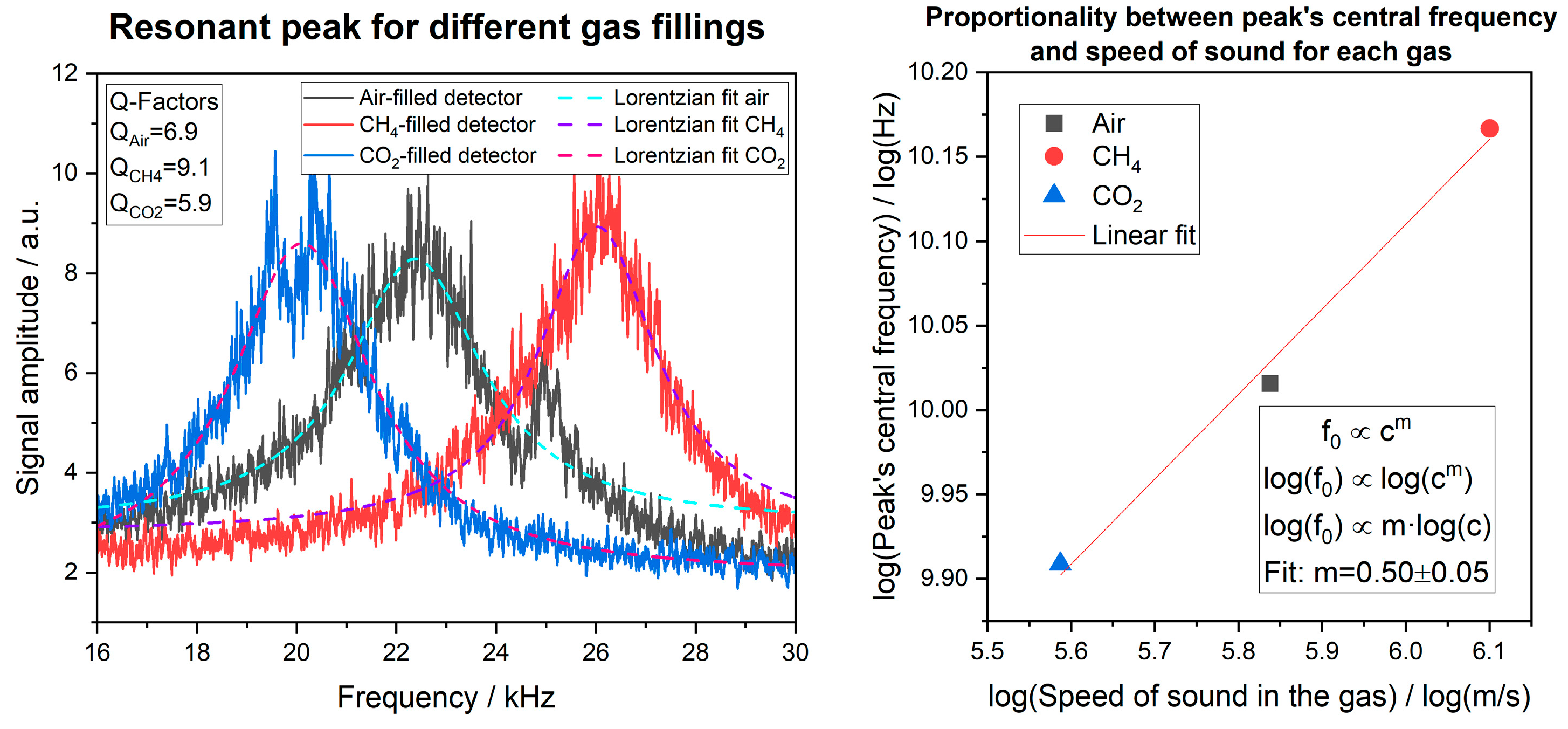

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palzer, S. Photoacoustic-Based Gas Sensing: A Review. Sensors 2020, 20, 2745. [Google Scholar] [CrossRef] [PubMed]

- Scholz, L.; Ortiz Perez, A.; Bierer, B.; Eaksen, P.; Wollenstein, J.; Palzer, S. Miniature Low-Cost Carbon Dioxide Sensor for Mobile Devices. IEEE Sens. J. 2017, 17, 2889–2895. [Google Scholar] [CrossRef]

- Rodríguez Gutiérrez, G.; Palzer, S. Photoacoustic-based, selective, and integrated multigas sensing. In Proceedings of the Eurosensors, Leuven, Belgium, 19–23 September 2022. [Google Scholar]

- Strahl, T.; Steinebrunner, J.; Weber, C.; Wöllenstein, J.; Schmitt, K. Photoacoustic methane detection inside a MEMS microphone. Photoacoustics 2023, 29, 100428. [Google Scholar] [CrossRef] [PubMed]

- Dehé, A. Silicon microphone development and application. Sens. Actuators A Phys. 2007, 133, 283–287. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez Gutierrez, G.; Palzer, S. Noise Analysis of MEMS Microphones as a Gas-Sensing Element. Proceedings 2024, 97, 129. https://doi.org/10.3390/proceedings2024097129

Rodriguez Gutierrez G, Palzer S. Noise Analysis of MEMS Microphones as a Gas-Sensing Element. Proceedings. 2024; 97(1):129. https://doi.org/10.3390/proceedings2024097129

Chicago/Turabian StyleRodriguez Gutierrez, Gabriel, and Stefan Palzer. 2024. "Noise Analysis of MEMS Microphones as a Gas-Sensing Element" Proceedings 97, no. 1: 129. https://doi.org/10.3390/proceedings2024097129

APA StyleRodriguez Gutierrez, G., & Palzer, S. (2024). Noise Analysis of MEMS Microphones as a Gas-Sensing Element. Proceedings, 97(1), 129. https://doi.org/10.3390/proceedings2024097129