Printed Anisotropic Magnetoresistive Sensors on Flexible Polymer Foils †

Abstract

1. Introduction

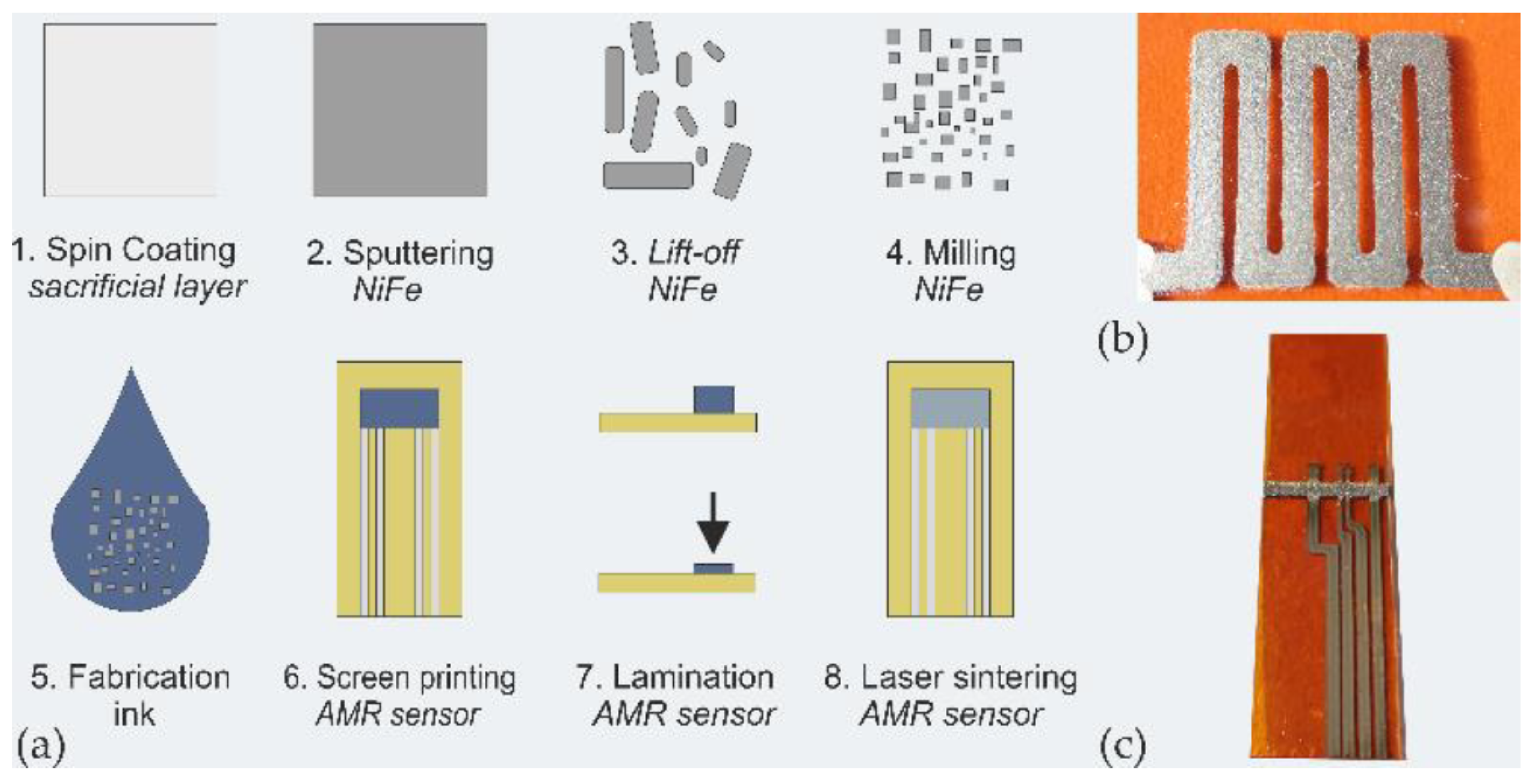

2. Materials and Methods

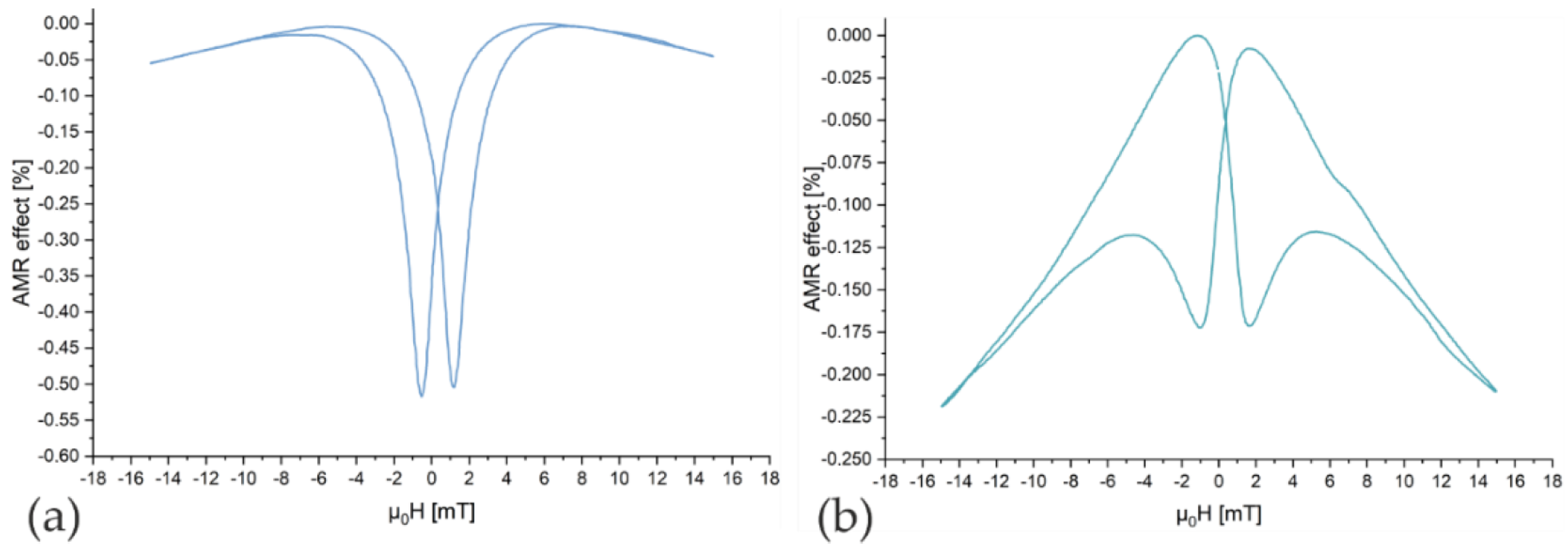

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wurz, M.C.; Prediger, M.S. Physical Sensors: Magnetic Sensors. In Reference Module in Biomedical Sciences; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Oliveros-Mata, E.S.; Voigt, C.; Cañón Bermúdez, G.S.; Zabila, Y.; Valdez-Garduño, N.M.; Fritsch, M.; Mosch, S.; Kusnezoff, M.; Fassbender, J.; Vinnichenko, M.; et al. Dispenser Printed Bismuth-Based Magnetic Field Sensors with Non-Saturating Large Magnetoresistance for Touchless Interactive Surfaces. Adv. Mater. Technol. 2022, 7, 2200227. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voigt, C.; Mosch, S.; Oliveros-Mata, E.S.; Makarov, D.; Schubert, C.; Ott, M.; Preußner, T.; Vinnichenko, M. Printed Anisotropic Magnetoresistive Sensors on Flexible Polymer Foils. Proceedings 2024, 97, 177. https://doi.org/10.3390/proceedings2024097177

Voigt C, Mosch S, Oliveros-Mata ES, Makarov D, Schubert C, Ott M, Preußner T, Vinnichenko M. Printed Anisotropic Magnetoresistive Sensors on Flexible Polymer Foils. Proceedings. 2024; 97(1):177. https://doi.org/10.3390/proceedings2024097177

Chicago/Turabian StyleVoigt, Clemens, Sindy Mosch, Eduardo Sergio Oliveros-Mata, Denys Makarov, Conrad Schubert, Morris Ott, Thomas Preußner, and Mykola Vinnichenko. 2024. "Printed Anisotropic Magnetoresistive Sensors on Flexible Polymer Foils" Proceedings 97, no. 1: 177. https://doi.org/10.3390/proceedings2024097177

APA StyleVoigt, C., Mosch, S., Oliveros-Mata, E. S., Makarov, D., Schubert, C., Ott, M., Preußner, T., & Vinnichenko, M. (2024). Printed Anisotropic Magnetoresistive Sensors on Flexible Polymer Foils. Proceedings, 97(1), 177. https://doi.org/10.3390/proceedings2024097177