Automated Laser Ablation of Inhomogeneous Metal Oxide Films to Manufacture Uniform Surface Temperature Profile Electrical Heating Elements

Abstract

1. Introduction

2. Methodology

2.1. Metal Oxide Film Composition

2.2. Model of Thermal Profile Uniformization of Electrical Heating Panels through Targeted Current Density Increase

2.3. Resistance Measurement through the Four-Probe Method

2.4. Laser Ablation of Metals and Oxides

3. Film Processing Method

3.1. Laser Ablation Analysis

3.2. The Laser Ablation System with Integrated Infrared Imagery

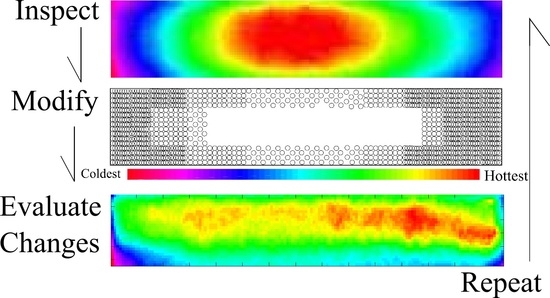

3.3. Control Processes to Increase the Uniformity of the Surface Profile

4. Results

4.1. Control Strategy Comparisons through Thermal Imagery

4.2. Control Process Metrics

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rajendra, P. Global Warming of 1.5 °C; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018. [Google Scholar]

- Department for Business, Energy & Industrial strategy. United Kingdom Energy Statistics 2017; Department for Business, Energy & Industrial Strategy: London, UK, 2017. [Google Scholar]

- Palmer, J.; Cooper, I. United Kingdom:Housing Energy Fact File; Department for Energy and Climate Changes: London, UK, 2013. [Google Scholar]

- Leslie, K. Should we be going off gas? No. 30. Sanctuary Mod. Green Homes; Alternative Technology Association: Melbourne, Australia, 2015; pp. 60–63. [Google Scholar]

- Han, H.J.; Jeon, Y.I.; Lim, S.H.; Kim, W.W.; Chen, K. New developments in illumination, heating and cooling technologies for energy-efficient buildings. Energy 2010, 35, 2647–2653. [Google Scholar] [CrossRef]

- He, R.; Fang, D.; Wang, P.; Zhang, X.; Zhang, R. Electrical properties of ZrB2–SiC ceramics with potential for heating element applications. Ceram. Int. 2014, 40, 9549–9553. [Google Scholar] [CrossRef]

- Neella, N.; Gaddam, V.; Rajanna, K.; Nayak, M.M. Low cost, disposable and wearable body warmer using RGO sheets coated on cloth substrate as heating element. In Proceedings of the 2017 IEEE 12th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Los Angeles, CA, USA, 9–12 April 2017; pp. 177–180. [Google Scholar]

- Pang, E.; Pickering, S.; Chan, A.; Wong, K. Use of recycled carbon fibre as a heating element. J. Compos. Mater. 2013, 47, 2039–2050. [Google Scholar] [CrossRef]

- Isaji, S.; Bin, Y.; Matsuo, M. Electrical conductivity and self-temperature-control heating properties of carbon nanotubes filled polyethylene films. Polymer 2009, 50, 1046–1053. [Google Scholar] [CrossRef]

- Lee, T.-W.; Jeong, Y.G. Regenerated cellulose/multiwalled carbon nanotube composite films with efficient electric heating performance. Carbohydr. Polym. 2015, 133, 456–463. [Google Scholar] [CrossRef] [PubMed]

- Cueff, S.; Labbé, C.; Cardin, J.; Doualan, J.L.; Khomenkova, L.; Hijazi, K.; Jambois, O.; Garrido, B.; Rizk, R. Efficient energy transfer from Si-nanoclusters to Er ions in silica induced by substrate heating during deposition. (Technical report). J. Appl. Phys. 2010, 108, 064302. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, H.; Tao, Y.; Mei, T.; Liu, Q.; Liu, K.; Li, M.; Wang, W.; Wang, D. Polypyrrole/poly(vinyl alcohol-co-ethylene) nanofiber composites on polyethylene terephthalate substrate as flexible electric heating elements. Compos. Part A Appl. Sci. Manuf. 2016, 81, 234–242. [Google Scholar] [CrossRef]

- The Engineering Toolbox. Thermal Conductivity of Metals, Oxides and Alloys. Available online: https://www.engineeringtoolbox.com/thermal-conductivity-metals-d_858.html (accessed on 15 October 2018).

- Zhao, P.; Kim, S.; Yoon, S.; Song, P. Characteristics of indium zinc oxide/silver/indium zinc oxide multilayer thin films prepared by magnetron sputtering as flexible transparent film heaters. (Report). Thin Solid Films 2018, 665, 137–142. [Google Scholar] [CrossRef]

- Warwick, M.E.A.; Binions, R. Electric field assisted aerosol assisted chemical vapor deposition of nanostructured metal oxide thin films. Surf. Coat. Technol. 2013, 230, 28–32. [Google Scholar] [CrossRef]

- Cheong, H.-G.; Song, D.-W.; Park, J.-W. Transparent film heaters with highly enhanced thermal efficiency using silver nanowires and metal/metal-oxide blankets. Microelectron. Eng. 2015, 146, 11–18. [Google Scholar] [CrossRef]

- Duffield, M.E.; Tatlock, G.J.; Lewis, J.F. High-Temperature Decomposition of Fe- and Cr-Doped NiO Produced by a Novel Flame Spray Technique. Oxid. Met. 2017, 88, 351–360. [Google Scholar] [CrossRef]

- Tennenhouse, C. Design and maintenance of electric heating elements. Ind. Heat. 2000, 67, 34. [Google Scholar]

- Hou, M.; Yang, M.; Beehag, A.; Mai, Y.-W.; Ye, L. Resistance welding of carbon fibre reinforced thermoplastic composite using alternative heating element. Compos. Struct. 1999, 47, 667–672. [Google Scholar] [CrossRef]

- Rathjen, C.; Blanchard, S.; Henrist, B.; Koelemeijer, W.; Libera, B.; Lutkiewicz, P. Ultrathin Polyimide-Stainless Steel Heater for Vacuum System Bake-Out. In Proceedings of the 2005 Particle Accelerator Conference, Knoxville, TN, USA, 12–20 May 2005; Volume 2005, pp. 2744–2746. [Google Scholar]

- Jansen, K.M.B.; Flaman, A.A.M. Construction of fast-response heating elements for injection molding applications. Polym. Eng. Sci. 1994, 34, 894–897. [Google Scholar] [CrossRef]

- Lantada, A.D.; Rebollo, M.S. Towards Low-Cost Effective and Homogeneous Thermal Activation of Shape Memory Polymers. Materials 2013, 6, 5447–5465. [Google Scholar] [CrossRef] [PubMed]

- Hemmer, C.; Polidori, G.; Popa, C. Temperature optimization of an electric heater by emissivity variation of heating elements. Case Stud. Therm. Eng. 2014, 4, 187–192. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, W.; He, S.; Ma, Y. An efficient plate heater with uniform surface temperature engineered with effective thermal materials. Opt Express 2014, 22, 17006–17015. [Google Scholar] [CrossRef]

- Zhao, J.; Jian, Q.; Zhang, N.; Luo, L.; Huang, B.; Cao, S. The improvement on drying performance and energy efficiency of a tumbler clothes dryer with a novel electric heating element. Appl. Therm. Eng. 2018, 128, 531–538. [Google Scholar] [CrossRef]

- Heiner, K.; Hans-Georg, L. Recommendations for implementing the strategic initiative Industrie 4.0′. Bus. Inf. Syst. Eng. 2013, 4, 239–242. [Google Scholar]

- Hippensteele, S.A.; Russell, L.M.; Stepka, F.S. Evaluation of a Method for Heat Transfer Measurements and Thermal Visualization Using a Composite of a Heater Element and Liquid Crystals. J. Heat Transf. 1983, 105, 184–189. [Google Scholar] [CrossRef]

- Barrington, S.J.; Eason, R.W. Homogeneous substrate heating using a CO 2 laser with feedback, rastering, and temperature monitoring. Rev. Sci. Instrum. 2000, 71, 4223–4225. [Google Scholar] [CrossRef][Green Version]

- Boeing Co. Methods and Systems for Controlling and Adjusting Heat Distribution over a Part Bed. U.S. Patent No. US7515986B2, 7 April 2009. [Google Scholar]

- Griffiths, D.J. Introduction to Electrodynamics, 4th ed.; Pearson: Boston, MA, USA, 2013. [Google Scholar]

- Park, C.; Kim, J.; Lee, K.; Oh, S.; Kang, H.J.; Park, N.S. Electronic, Optical and Electrical Properties of Nickel Oxide Thin Films Grown by RF Magnetron Sputtering. Appl. Sci. Converg. Technol. 2015, 24, 72–76. [Google Scholar] [CrossRef]

- Serway, R.A.; Gordon, J.R. Principles of Physics; Saunders College Pub: Philadelphia, PA, USA, 1998. [Google Scholar]

- Majumdar, J.D.; Manna, I. Laser processing of materials. Sadhana Acad. Proc. Eng. Sci. 2003, 28, 495–562. [Google Scholar] [CrossRef]

- Indhu, R.; Vivek, V.; Sarathkumar, L.; Bharatish, A.; Soundarapandian, S. Overview of Laser Absorptivity Measurement Techniques for Material Processing. Lasers Manuf. Mater. Process. 2018, 5, 458–481. [Google Scholar] [CrossRef]

- Newman, R.; Chrenko, R.M. Optical Properties of Nickel Oxide. Phys. Rev. 1959, 114, 1507–1513. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Fe | Si | Cu | Mn |

|---|---|---|---|---|---|---|

| wt% | Bal. | 14.9 | 8.6 | 0.55 | 0.3 | 0.13 |

| Material | Resistivity (n·m) |

|---|---|

| Metallic nickel | 69.3 |

| Metallic iron | 96.1 |

| Metallic chromium | 125.1 |

| Nickel oxide | 548.1 |

| Ablation Method | Summary |

|---|---|

| Abrasion Baseline | The abrasion method is carried out by the analysis of the thermal profile of the element and abrading with an abrasive medium of the coolest regions of the element temperature profile. |

| 20% Threshold (20%) | All regions at temperatures lower than the 20th percentile of the temperature distribution were ablated at the optimized output of the pulsed laser beam in a raster pattern. |

| 50% Threshold (50%) | All regions at temperatures lower than the 50th percentile of the temperature distribution were ablated at the optimized output of the pulsed laser beam in a raster pattern. |

| Greyscale (GS) | The element is ablated in a raster pattern with the coldest areas receiving more treatment than hotter areas through altering the duty cycle of the pulsed beam; areas at the highest temperature regions receive 0% of the power output, the coldest region receiving 100% with a linear scale between. |

| Greyscale-Threshold (GT) | The Greyscale algorithm is used to find the levels of treatment in the areas between a threshold value (set at the hottest 20th percentile) and the lowest temperature. |

| GT + Memory (GM) | The GT method was used, but previous treatments (n − 1) considered to reduce the intensity of subsequent treatments (n) by up to 10% of the output of the previous treatment. |

| Metric | 20% Threshold | 50% Threshold | Greyscale | Greyscale Threshold | GT with Memory |

| Abbreviation | 20% | 50% | GS | GT | GM |

| % Standard Deviation Improvement | 62.1 | −25.1 | 57.4 | 65.8 | 71.2 |

| % Standard Deviation Improvement/Cycle | 15.5 | −6.3 | 7.1 | 11.1 | 11.9 |

| Optimized Profile Kurtosis | 2.71 | 2.08 | 3.57 | 3.37 | 2.71 |

| Time/Cycle (mins) | 1.5 | 2.0 | 3.0 | 3.0 | 3.0 |

| Average Number of Cycles | 4 | 8 | 4 | 6 | 6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ingham, J.; Lewis, J.; Cheneler, D. Automated Laser Ablation of Inhomogeneous Metal Oxide Films to Manufacture Uniform Surface Temperature Profile Electrical Heating Elements. J. Manuf. Mater. Process. 2019, 3, 65. https://doi.org/10.3390/jmmp3030065

Ingham J, Lewis J, Cheneler D. Automated Laser Ablation of Inhomogeneous Metal Oxide Films to Manufacture Uniform Surface Temperature Profile Electrical Heating Elements. Journal of Manufacturing and Materials Processing. 2019; 3(3):65. https://doi.org/10.3390/jmmp3030065

Chicago/Turabian StyleIngham, Joshua, John Lewis, and David Cheneler. 2019. "Automated Laser Ablation of Inhomogeneous Metal Oxide Films to Manufacture Uniform Surface Temperature Profile Electrical Heating Elements" Journal of Manufacturing and Materials Processing 3, no. 3: 65. https://doi.org/10.3390/jmmp3030065

APA StyleIngham, J., Lewis, J., & Cheneler, D. (2019). Automated Laser Ablation of Inhomogeneous Metal Oxide Films to Manufacture Uniform Surface Temperature Profile Electrical Heating Elements. Journal of Manufacturing and Materials Processing, 3(3), 65. https://doi.org/10.3390/jmmp3030065