Difficult Cutting Property of NiTi Alloy and Its Mechanism

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material Properties

2.2. Cutting Conditions

2.3. Experimental Measurements

3. Result and Discussion

3.1. Cutting Characteristics and Difficult to Cut Property of NiTi Alloy

3.2. Examination of the Cause for Cutting Difficulty by Orthogonal Cutting

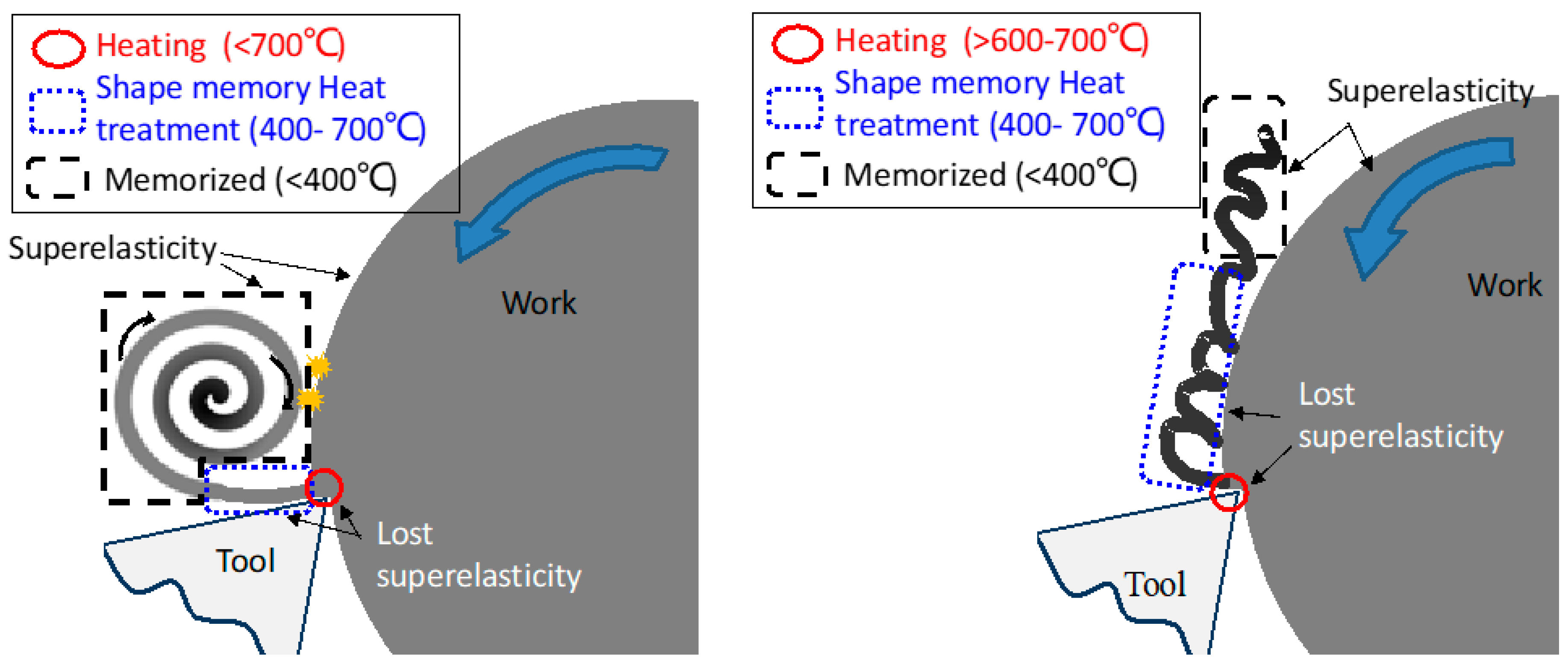

3.3. The Cause of the Very Low Chip Discharging Property in Cutting of NiTi Alloy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fadlallah, A.S.; El-Bagoury, N.; Gad, E.-R.M.S.; Ahmed, A.R.; El-Ousamii, G. An Overview of NiTi Shape Memory Alloy: Corrosion Resistance and Antibacterial Inhibition for Dental Application. J. Alloys Compd. 2014, 583, 455–464. [Google Scholar]

- Shabalovskaya, A.S. On the Nature of the Biocompatibility and on Medical Applications of NiTi Shape Memory and Superelastic Alloys. Biomed. Mater. Eng. 1996, 6, 267–289. [Google Scholar]

- Mishra, C.S. Applications of Shape Memory Alloys: A Review. J. Thin Films Coat. Sci. Technol. Appl. 2015, 2, 1–7. [Google Scholar]

- Maffiodo, D.; Raparelli, T. Three-Fingered Gripperwith Flexure Hinges Actuated by Shape Memory AlloyWires. Int. J. Autom. Technol. 2017, 11, 355–360. [Google Scholar]

- Morgan, B.N. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar]

- Miyazaki, S.; Otsuka, K. Development of Shape Memory Alloys. ISIJ Int. 1989, 29, 253–377. [Google Scholar] [CrossRef]

- Mori, Y.; Ishida, S.; Satow, T.; Konnno, T.; Ohkawa, A.; Honma, T. Mechanical Working of a TiNi Shape Memory Alloy and It’s Application; Departmental Bulletin Paper of Tohoku University: Tohoku, Honshu, Japan, 1987; Volume 43, pp. 171–178. (In Japanese) [Google Scholar]

- Wu, K.S.; Lin, C.H.; Chen, C.C. A study on the machinability of a Ti49.6 Ni50.4 shape memory alloy. Mater. Lett. 1999, 40, 27–32. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, E.H.; Noebe, D.R.; Jawahir, S.I. Tool-wear analysis in cryogenic machining of NiTi shape memory alloys, A comparison of tool-wear performance with dry and MQL machining. Wear 2013, 306, 51–63. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. Tool wear progression of PCD and PCBN cutting tools in high speed machining of NiTi shape memory alloy under various cutting speeds. Diam. Relat. Mater. 2020, 105, 1–10. [Google Scholar]

- Altas, E.; Gokkaya, H.; Ozkan, D. Investigation Of The Effects Of Machining Parameters On Tool Life And Surface Roughness During The Face Milling Of The NiTi Shape Memory Alloy With Uncoated Tools. Preprints 2020, 1, 2020080383. [Google Scholar]

- Weinert, K.; Petzoldt, V. Machining of NiTi based shape memory alloys. Mater. Sci. Eng. A 2004, 378, 180–184. [Google Scholar] [CrossRef]

- Weinert, K.; Petzoldt, V.; Kotter, D. Turning and Drilling of NiTi Shape Memory Alloys. CIRP Ann. 2004, 53, 65–68. [Google Scholar] [CrossRef]

- Weinert, K.; Petzoldt, V. Machining NiTi micro-parts by micro-milling. Mater. Sci. Eng. A 2008, 481, 672–675. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, E.H.; Noebe, D.R.; Jawahir, S.I. The Effect of Active Phase of the Work Material on Machining Performance of a NiTi Shape Memory Alloy. Metall. Mater. Trans. A 2015, 46, 2625–2636. [Google Scholar] [CrossRef]

- Kaynak, Y.; Robertson, W.S.; Karaca, E.H.; Jawahir, S.I. Progressive tool-wear in machining of room-temperature austenitic NiTi alloys, the influence of cooling/lubricating, melting, and heat treatment conditions. J. Mater. Process. Technol. 2015, 215, 95–104. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, E.H.; Jawahir, S.I. Cutting Speed Dependent Microstructure and Transformation Behavior of NiTi Alloy in Dry and Cryogenic Machining. J. Mater. Eng. Perform. 2015, 24, 452–460. [Google Scholar] [CrossRef]

- Kaynak, Y. Machining and Phase Transformation Response of Room-Temperature Austenitic NiTi Shape Memory Alloy. J. Mater. Eng. Perform. 2014, 23, 3354–3360. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, E.H.; Noebe, D.R.; Jawahir, S.I. Analysis of Tool-wear and Cutting Force Components in Dry, Preheated, and Cryogenic Machining of NiTi Shape Memory Alloys. Procedia CIRP 2013, 8, 498–503. [Google Scholar] [CrossRef] [Green Version]

- Kaynak, Y.; Karaca, E.H.; Jawahir, S.I. Cryogenic Machining of NiTi Shape Memory Alloys. In Proceedings of the 6th International Conference and Exhibition on Design and Production of Machines and Dies/Molds, Ankara, Turkey, 23–26 June 2011. [Google Scholar]

- Kaynak, Y.; Huang, B.; Karaca, E.H.; Jawahir, S.I. Surface Characteristics of Machined NiTi Shape Memory Alloy, The Effects of Cryogenic Cooling and Preheating Conditions. J. Mater. Eng. Perform. 2017, 26, 3597–3606. [Google Scholar] [CrossRef]

- Shaw, C.M. Metal Cutting Principles; Oxford University Press: Oxford, UK, 2012; ISBN 0198086113. [Google Scholar]

- Sekiya, K.; Yamane, Y.; Narutaki, N. Tool Wear under High Speed End Milling of Nickel-Base Superalloy Inconel 718. J. Jpn. Soc. Precis. Eng. 2004, 70, 1086–1090. [Google Scholar] [CrossRef] [Green Version]

- Itakura, K.; Kuroda, M.; Omokawa, H.; Itani, H.; Yamamoto, K.; Ariura, Y. Wear Mechanism of Coated Cemented Carbide Tool in Cutting of Super Heat Resisting Alloy Inconel 718. J. Jpn. Soc. Precis. Eng. 1999, 65, 976–981. [Google Scholar] [CrossRef]

- Kuppuswamy, R.; Yui, A. High-speed Micromachining Characteristics for the NiTi Shape Memory Alloys. Int. J. Adv. Manuf. Technol. 2017, 93, 11–21. [Google Scholar] [CrossRef]

- Elahinia, M.; Moghaddam, S.N.; Andani, T.M.; Amerinatanzi, A.; Bimber, A.B.; Hamilton, F.R. Fabrication of NiTi through Additive Manufacturing: A Review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Wu, Q.; Kang, H.J.; Winfree, A.N. Compressive superelastic behavior of a NiTi shape memory alloy at strain rates of 0.001–750 s−1. Int. J. Solids Struct. 2001, 38, 8989–8998. [Google Scholar] [CrossRef]

- Terui, A.; Tateishi, T.; Miyamoto, H.; Suki, Y. Study of Stress Relaxation Properties of NiTi Shape Memory Alloy. Trans. Jpn. Soc. Mech. Eng. C 1985, 51, 288–292. [Google Scholar]

- Müller, K. Extrusion of nickel–titanium alloys Nitinol to hollow shapes. J. Mater. Process. Technol. 2001, 111, 122–126. [Google Scholar] [CrossRef]

- Mazzolai, M.F.; Biscarini, A.; Coluzzi, B.; Mazzolai, G.; Villa, E.; Tuissi, A. Low-frequency internal friction of hydrogen-free and hydrogen-doped NiTi alloys. Acta Mater. 2007, 55, 4243–4252. [Google Scholar] [CrossRef]

- Motohashi, Y.; Ohsawa, K.; Hoshiya, T.; Okamoto, Y.; Ohmori, M. Grain Refinement of a Ti-Ni Shape Memory Alloy and Its Influence on Phase Transformation Characteristics. J. Jpn. Inst. Met. Mater. 1991, 52, 132–140. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Cao, S.; Li, Y.Y.; Zhao, X.Z.; Zhu, W.Z.; Wang, X.D.; Ma, X.; Zhang, P.X. Two-step constrained aging treatment enabled superior two-way shape memory effect and elevated R-phase transformation temperatures in a rapidly solidified Ni51Ti49 alloy. J. Alloys Compd. 2019, 785, 1180–1188. [Google Scholar] [CrossRef]

- Lopes, N.; Silva, L.; Santos, L.; Buono, V. Surface Characterization of NiTi Superelastic and Shape Memory Alloys after Electrolytic Polishing. Mater. Res. 2017, 20, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Adharapurapu, R.; Jiang, F.; Vecchio, S.K.; Gray, T.G. Response of NiTi shape memory alloy at high strain rate: A systematic investigation of temperature effects in tension-compression asymmetry. Acta Mater. 2006, 54, 4609–4620. [Google Scholar] [CrossRef]

- Benafan, O.; Noebe, D.R.; Padula, A.S.; Garg, A.; Clausen, B.; Vogel, S.; Vaidyanathan, R. Temperature dependent deformation of the B2 austenite phase of a NiTi shape memory alloy. Int. J. Plast. 2013, 51, 103–121. [Google Scholar] [CrossRef]

| Turning | Orthogonal Cutting | |

|---|---|---|

| Cutting speed (m/min) | 25, 50, 75, 100 | 10–130 |

| Feed (mm/rev) | 0.1 | 0.1 |

| Depth of cut (mm) | 1 | 2 |

| Atmosphere | Dry | |

| Tool | Carbide (non-coated, K10) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shizuka, H.; Sakai, K.; Yang, H.; Sonoda, K.; Nagare, T.; Kurebayashi, Y.; Hayakawa, K. Difficult Cutting Property of NiTi Alloy and Its Mechanism. J. Manuf. Mater. Process. 2020, 4, 124. https://doi.org/10.3390/jmmp4040124

Shizuka H, Sakai K, Yang H, Sonoda K, Nagare T, Kurebayashi Y, Hayakawa K. Difficult Cutting Property of NiTi Alloy and Its Mechanism. Journal of Manufacturing and Materials Processing. 2020; 4(4):124. https://doi.org/10.3390/jmmp4040124

Chicago/Turabian StyleShizuka, Hiroo, Katsuhiko Sakai, Hao Yang, Kazuki Sonoda, Tetsuo Nagare, Yuji Kurebayashi, and Kunio Hayakawa. 2020. "Difficult Cutting Property of NiTi Alloy and Its Mechanism" Journal of Manufacturing and Materials Processing 4, no. 4: 124. https://doi.org/10.3390/jmmp4040124

APA StyleShizuka, H., Sakai, K., Yang, H., Sonoda, K., Nagare, T., Kurebayashi, Y., & Hayakawa, K. (2020). Difficult Cutting Property of NiTi Alloy and Its Mechanism. Journal of Manufacturing and Materials Processing, 4(4), 124. https://doi.org/10.3390/jmmp4040124