Physics-Based Simulations of Chip Flow over Micro-Textured Cutting Tool in Orthogonal Cutting of Alloy Steel

Abstract

:1. Introduction

1.1. Cutting Tool Wear

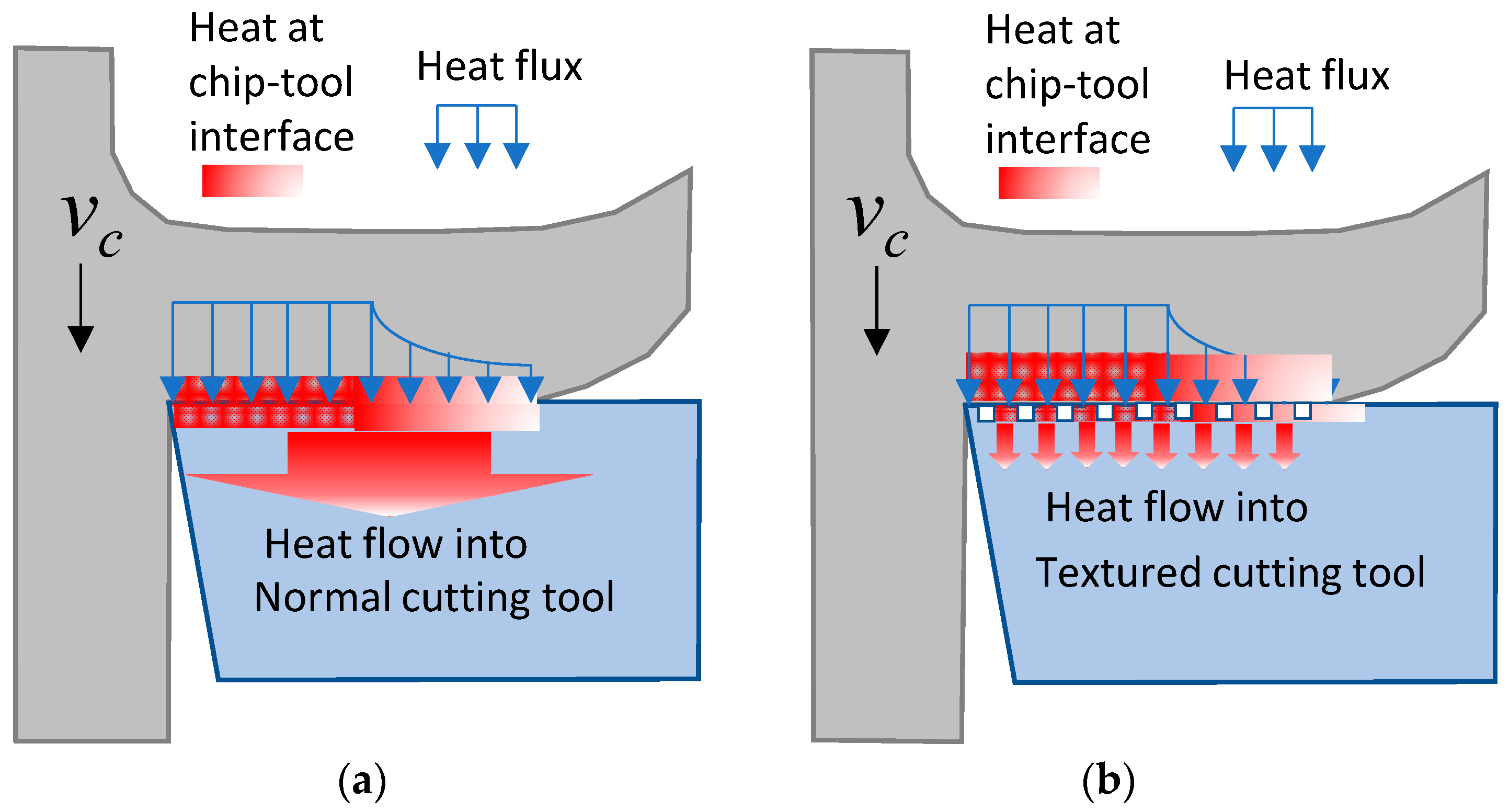

1.2. Chip-Tool Contact Mechanism

1.3. Micro-Textured Cutting Tool

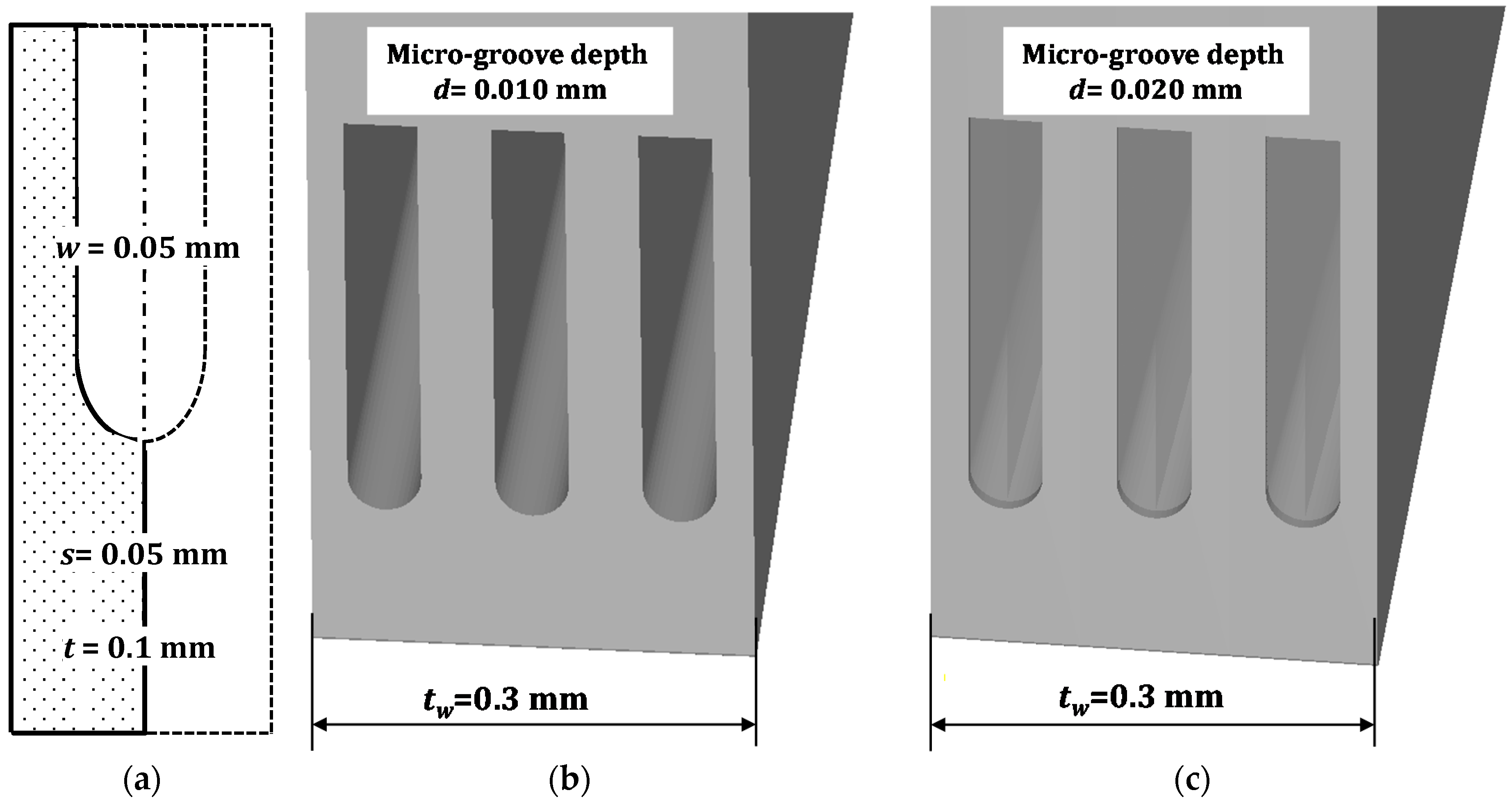

2. Materials and Methods

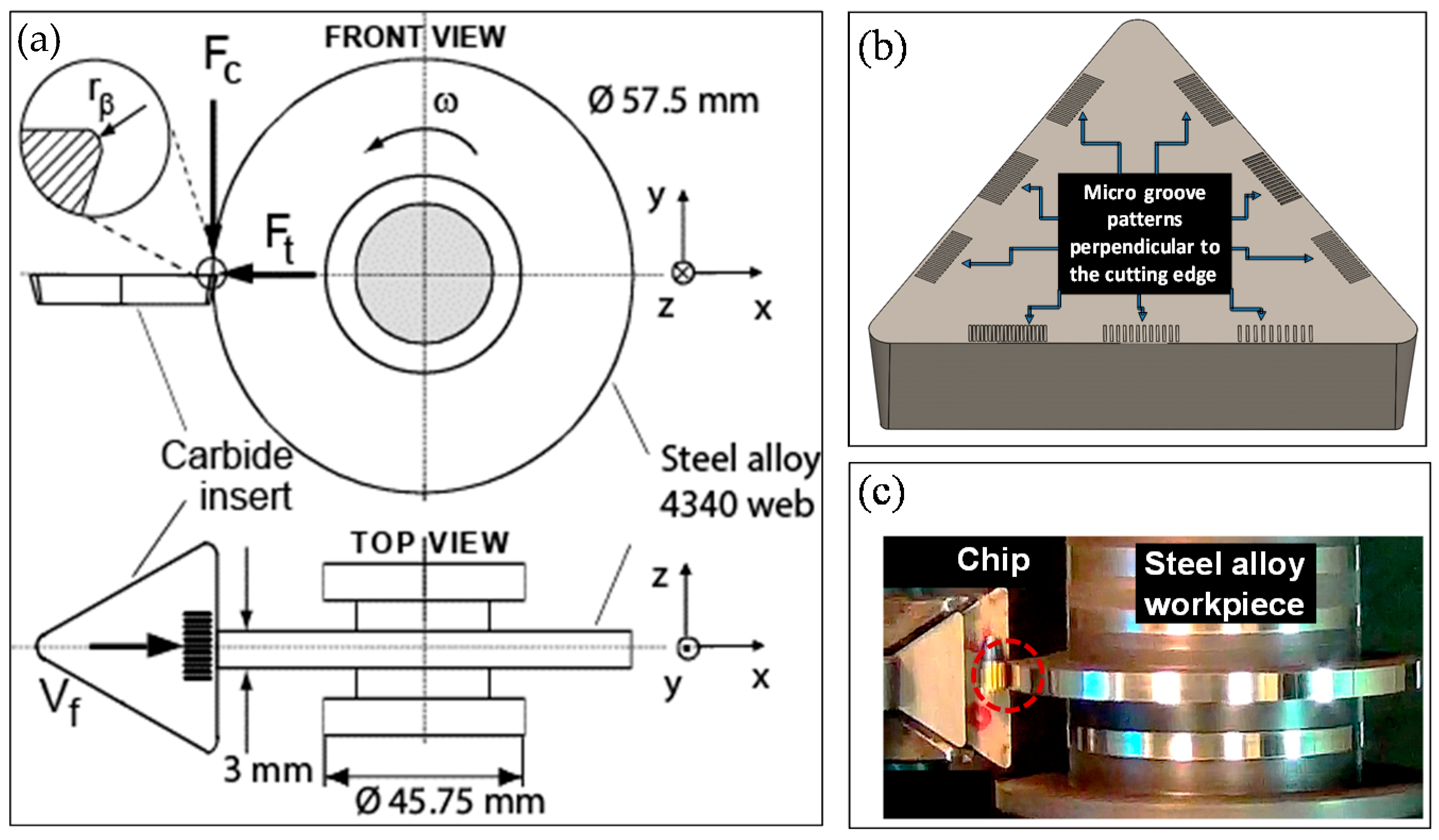

2.1. Orthogonal Cutting Experiments

2.2. Chip-Tool Contact Analysis

3. Results and Discussion

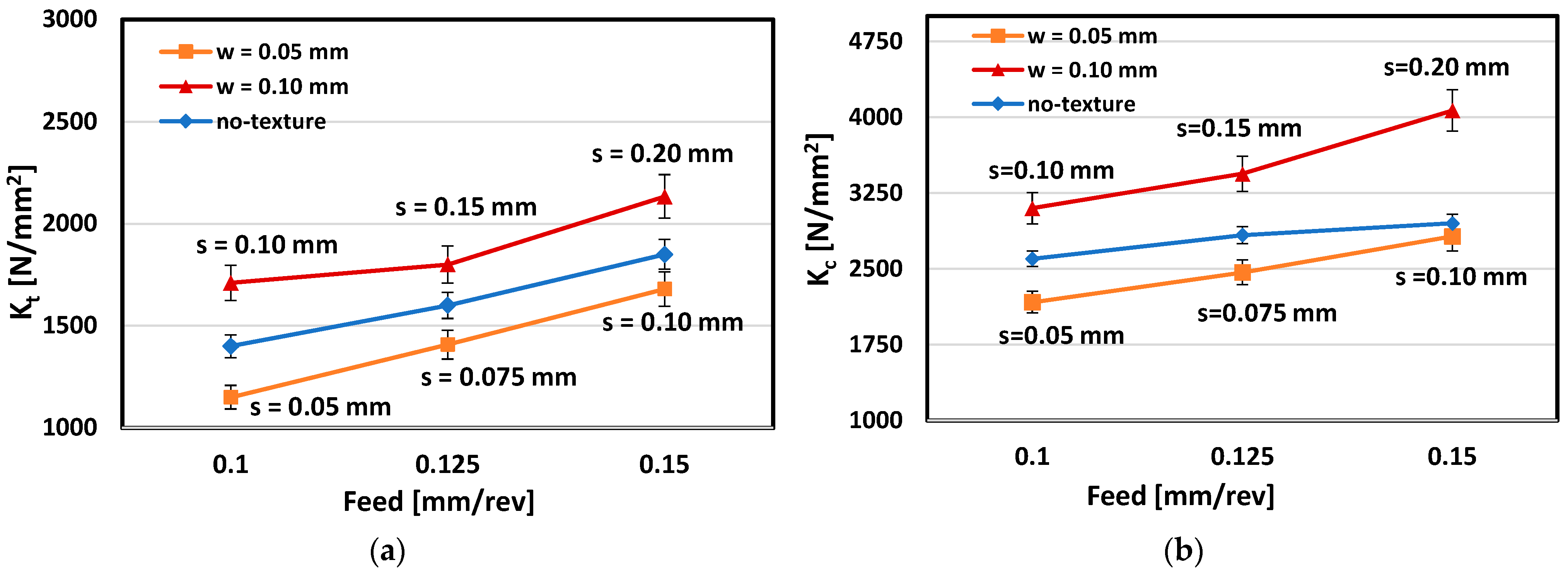

3.1. Effects of Micro-Texture on Cutting Forces

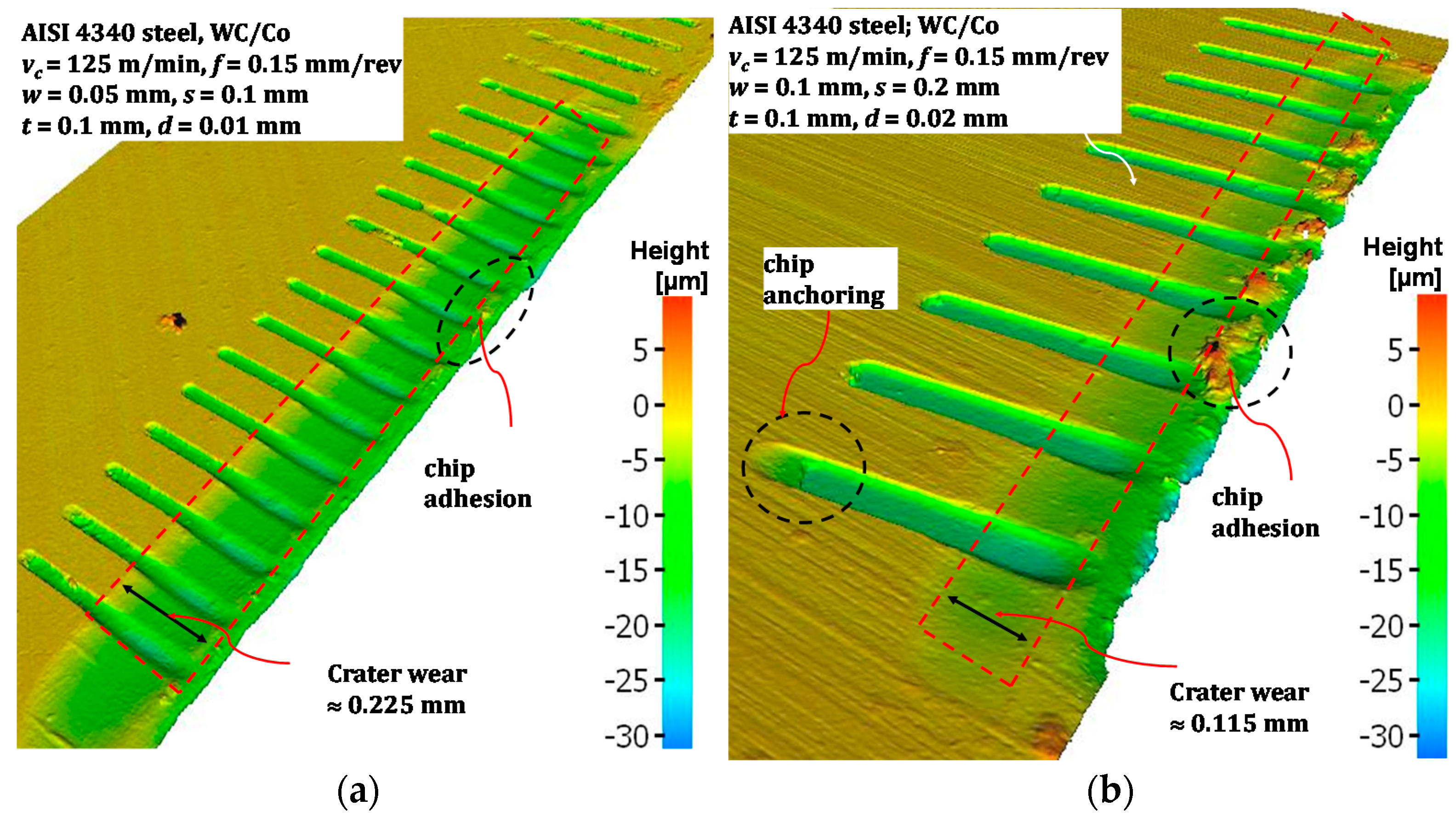

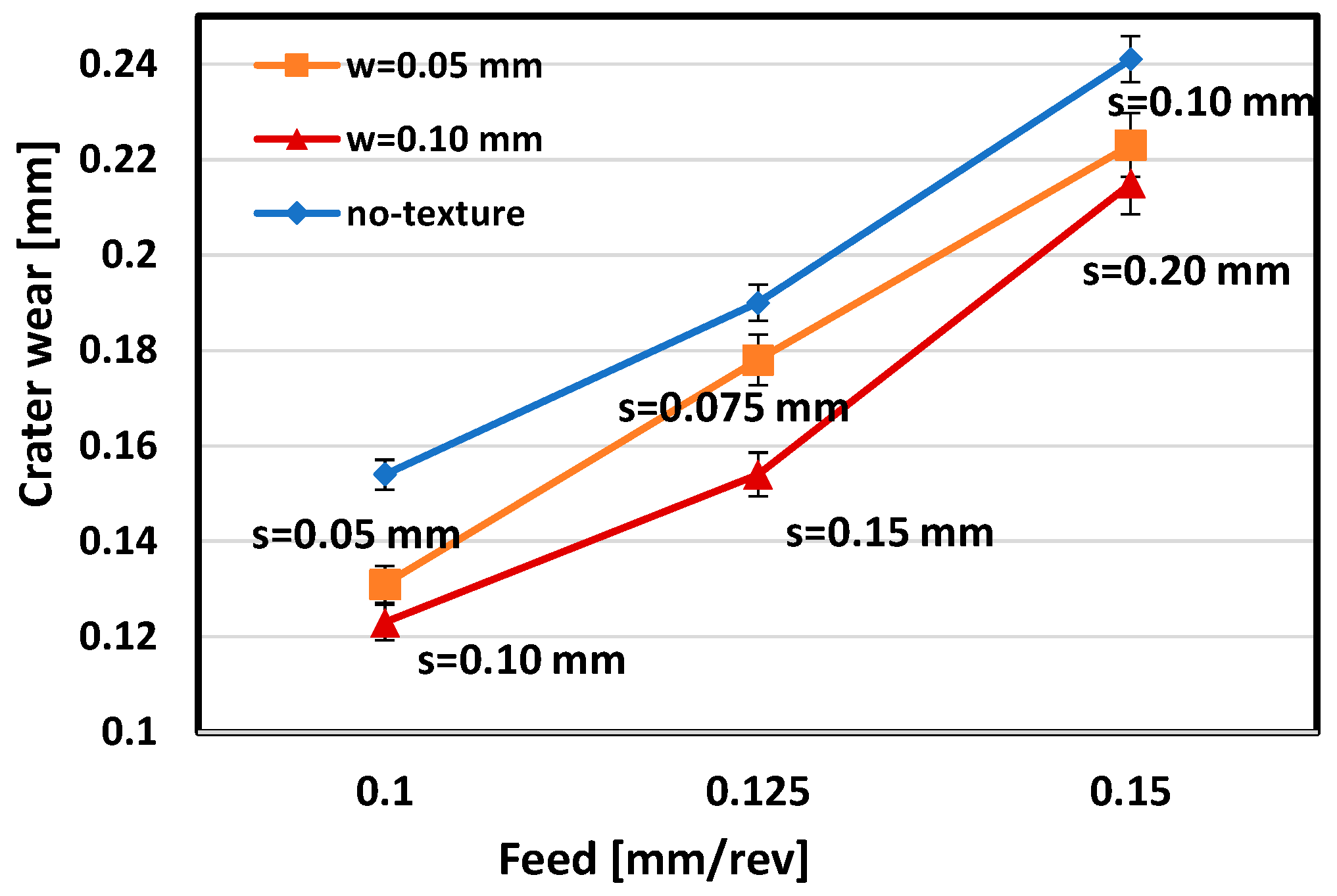

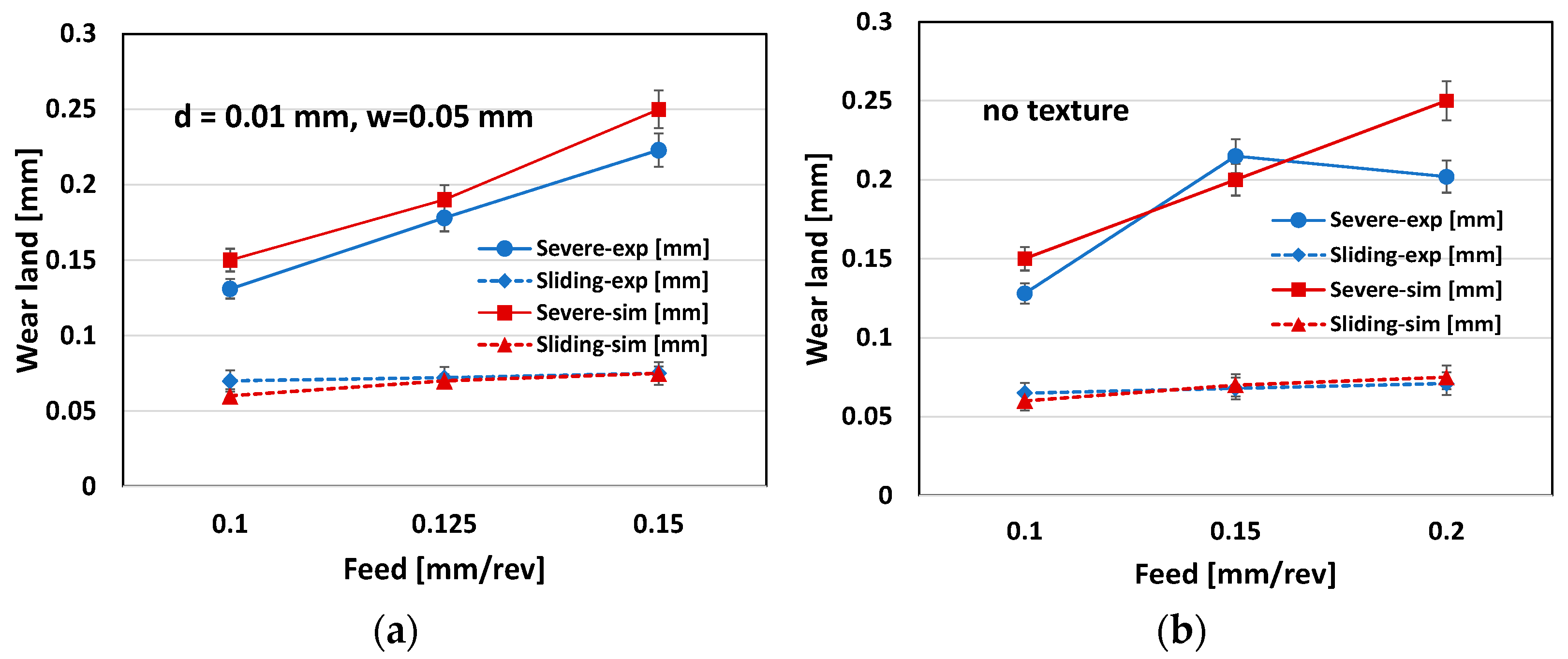

3.2. Effects of Micro-Texture on Tool Wear and Chip Adhesion

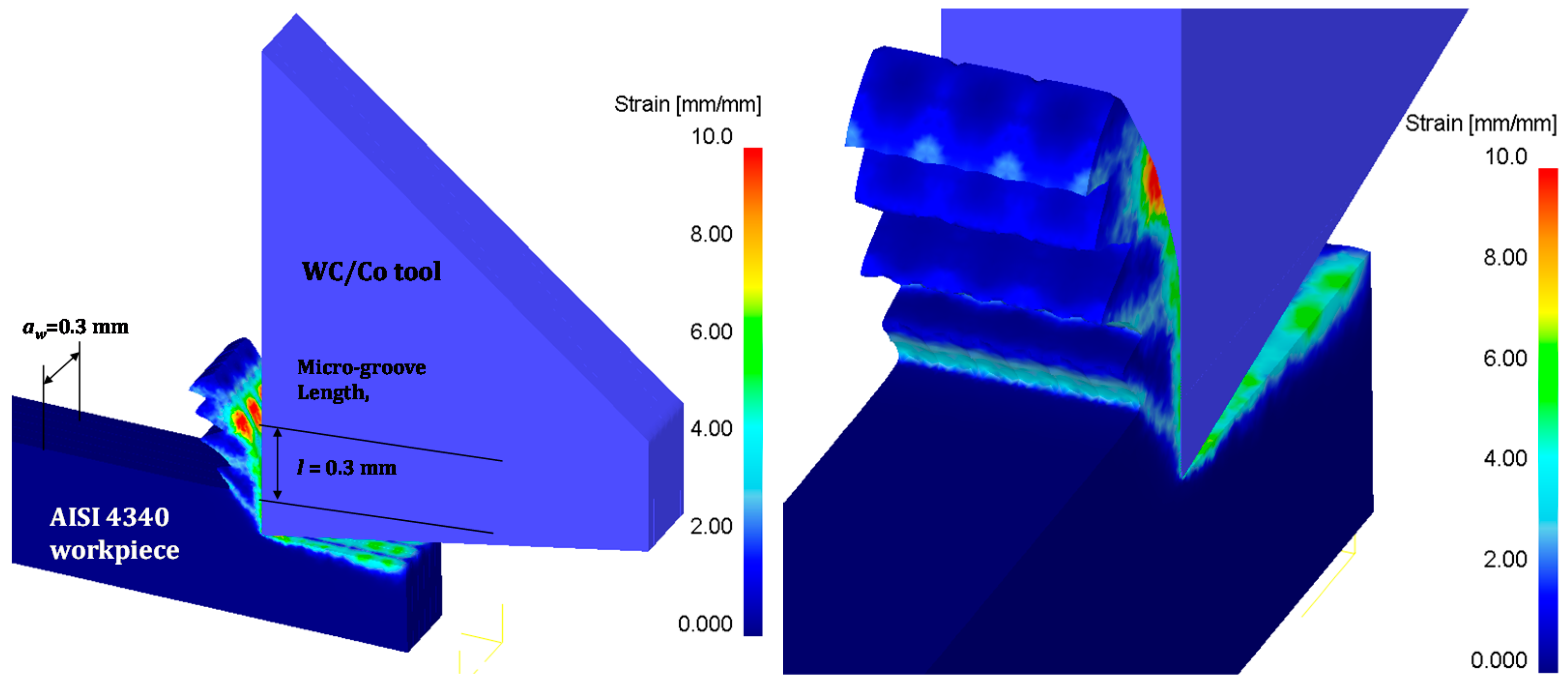

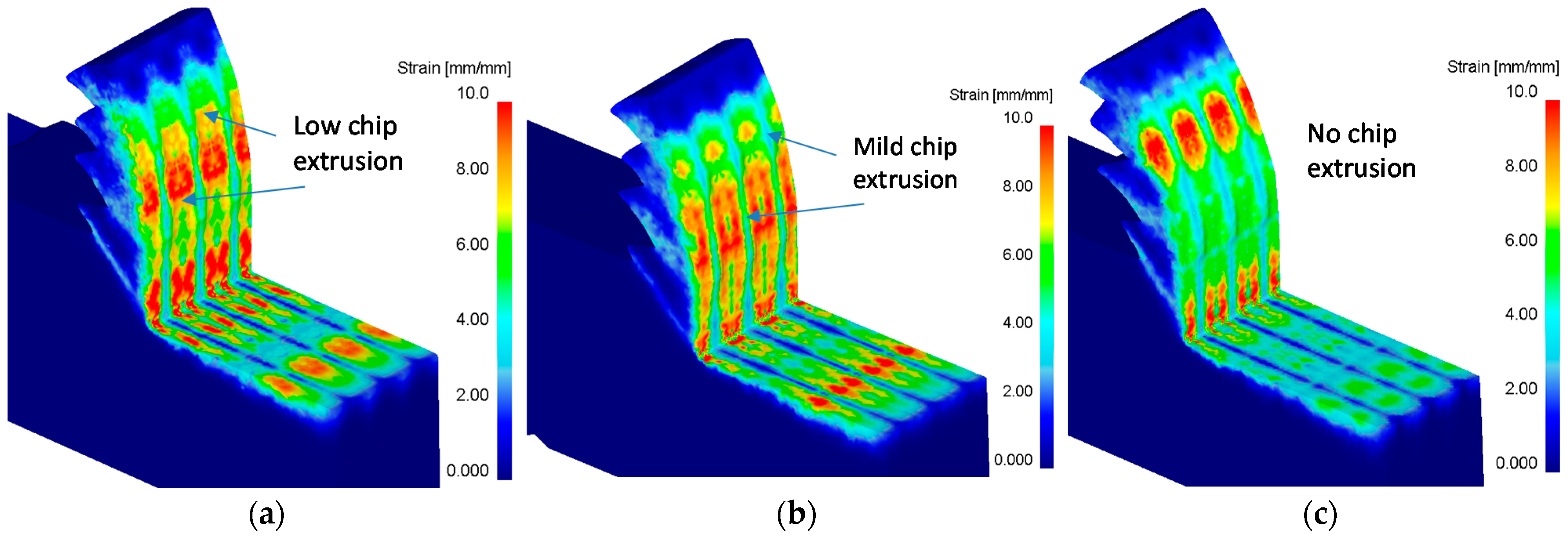

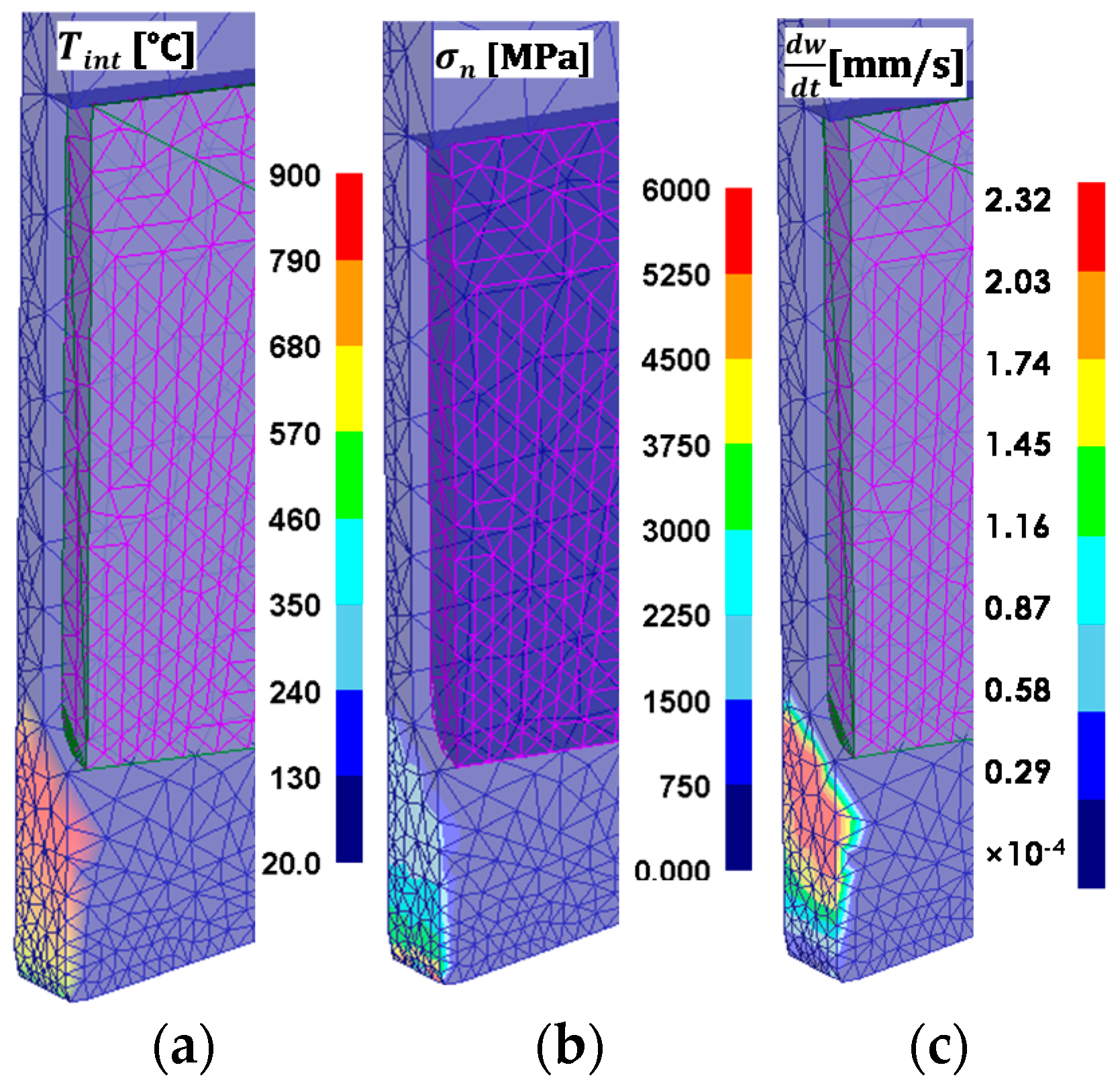

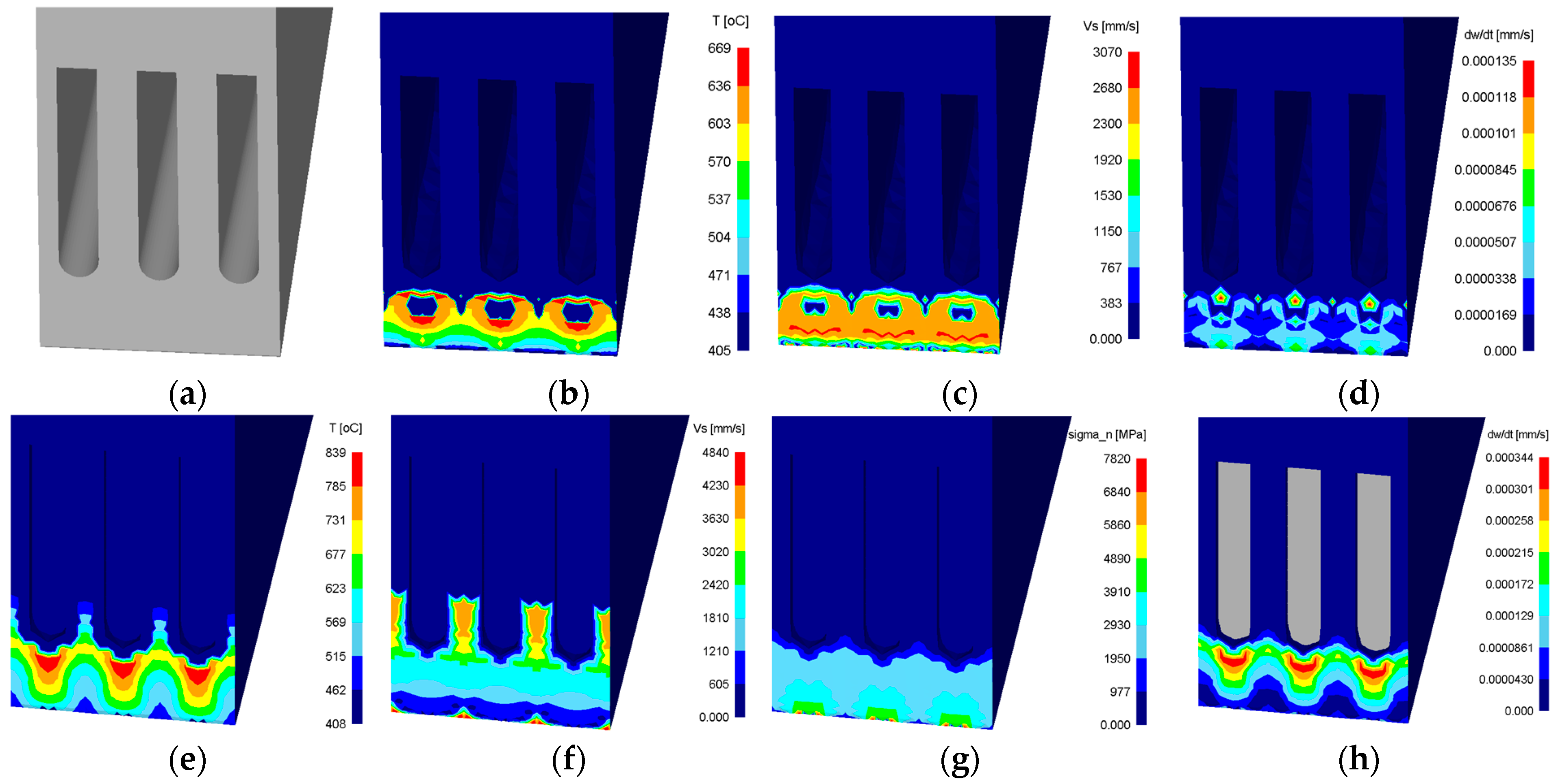

3.3. Simulation of Cutting with Micro-Textured Tool

4. Conclusions

- Micro-texture patterns fabricated in cutting tools show some geometrical irregularities, but may also result in certain subsurface alterations to cemented carbide substrate, subsequently affecting its wear behavior;

- Micro-textures perpendicular to the cutting edge influence the chip flow and material adhesion along the open and closed sections of the micro-grooves;

- Measured areas of the adhered material and worn areas of the textured cutting tool surface indicate that physical chip material accumulations or tool material losses are affected by chip flow, its speed, and the contact pressure that forms between the chip and textured tool surface;

- Physics-based FEM simulations reveal actual contact pressure, contact temperature, and sliding velocity profiles that reflect the amount of material accumulating on the tool surface, as well as tool volume loss due to active wear mechanisms. This information should be valuable for developing a digital twin for textured cutting tools for design and optimization purposes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, D.H.; Kim, T.J.; Wang, X.; Kim, M.; Quan, Y.J.; Oh, J.W.; Ahn, S.H. Smart machining process using machine learning: A review and perspective on machining industry. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 555–568. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Botkina, D.; Hedlind, M.; Olsson, B.; Henser, J.; Lundholm, T. Digital twin of a cutting tool. Procedia CIRP 2018, 72, 215–218. [Google Scholar] [CrossRef]

- Poulachon, G.; Moisan, A.; Jawahir, I.S. Tool-wear mechanisms in hard turning with polycrystalline cubic boron nitride tools. Wear 2001, 250, 576–586. [Google Scholar] [CrossRef]

- Luo, S.; Liao, Y.; Tsai, Y. Wear characteristics in turning high hardness alloy steel by ceramic and CBN tools. J. Mater. Process. Technol. 1999, 88, 114–121. [Google Scholar] [CrossRef]

- Jianxin, D.; Jiantou, Z.; Hui, Z.; Pei, Y. Wear mechanisms of cemented carbide tools in dry cutting of precipitation hardening semi-austenitic stainless steels. Wear 2011, 270, 520–527. [Google Scholar] [CrossRef]

- Diniz, E.; Machado, A.R.; Corrêa, J.G. Tool wear mechanisms–in the machining of steels and stainless steels. Int. J. Adv. Manuf. Technol. 2016, 87, 3157–3168. [Google Scholar] [CrossRef]

- Corrêa, J.G.; Schroeter, R.B.; Machado, A.R. Tool life and wear mechanism analysis of carbide tools used in the machining of martensitic and supermartensitic stainless steels. Tribol. Int. 2017, 105, 102–117. [Google Scholar] [CrossRef]

- Breidenstein, B.; Grove, T.; Krödel, A.; Sitab, R. Influence of hexagonal phase transformation in laser prepared PcBN cutting tools on tool wear in machining of Inconel 718. Met. Powder Rep. 2019, 74, 237–243. [Google Scholar] [CrossRef]

- Childs, T.H.C. Friction Modelling in Metal Cutting. Wear 2006, 260, 310–318. [Google Scholar] [CrossRef]

- Özel, T.; Biermann, D.; Enomoto, T.; Mativenga, P. Structured and textured cutting tool surfaces for machining applications. CIRP Ann. Manuf. Technol. 2021, 70, in press. [Google Scholar]

- Huang, Y.; Chou, Y.K.; Liang, S.Y. CBN tool wear in hard turning: A survey on research progresses. Int. J. Adv. Manuf. Technol. 2007, 35, 443–453. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Development of a cutting tool with a nano/micro-textured surface-Improvement of anti-adhesive effect by considering the texture patterns. Precis. Eng. 2009, 33, 425–429. [Google Scholar] [CrossRef]

- Sawant, M.S.; Jain, N.K.; Palani, I.A. Influence of dimple and spot-texturing of HSS cutting tool on machining of Ti-6Al-4V. J. Mater. Process. Technol. 2018, 261, 1–11. [Google Scholar] [CrossRef]

- Alagan, N.T.; Zeman, P.; Hoier, P.; Beno, T.; Klement, U. Investigation of micro-textured cutting tools used for face turning of alloy 718 with high-pressure cooling. J. Manuf. Proc. 2019, 37, 606–616. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Crater and flank wear resistance of cutting tools having micro textured surfaces. Precis. Eng. 2017, 37, 888–896. [Google Scholar] [CrossRef]

- Sugihara, T.; Nishimoto, Y.; Enomoto, T. Development of a novel cubic boron nitride cutting tool with a textured flank face for high-speed machining of Inconel 718. Precis. Eng. 2017, 48, 75–82. [Google Scholar] [CrossRef]

- Kim, D.M.; Lee, I.; Kim, S.K.; Kim, B.H.; Park, H.W. Influence of a micropatterned insert on characteristics of the tool-workpiece interface in a hard turning process. J. Mater. Process. Technol. 2016, 229, 160–171. [Google Scholar] [CrossRef]

- Durairaj, S.; Guo, J.; Aramcharoen, A.; Castagne, S. An experimental study into the effect of micro-textures on the performance of cutting tool. Int. J. Adv. Manuf. Technol. 2018, 98, 1011–1130. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Performance of cutting tools with dimple textured surfaces: A comparative study of different texture patterns. Precis. Eng. 2017, 49, 52–60. [Google Scholar] [CrossRef]

- Enomoto, T.; Sugihara, T.; Yukinaga, S.; Hirose, K.; Satake, U. Highly wear-resistant cutting tools with textured surfaces in steel cutting. CIRP Ann. Manuf. Technol. 2012, 61, 571–574. [Google Scholar] [CrossRef]

- Hao, X.; Cui, W.; Li, L.; Li, H.; Khan, A.M.; He, N. Cutting performance of textured polycrystalline diamond tools with composite lyophilic/lyophobic wettabilities. J. Mater. Process. Technol. 2018, 260, 1–8. [Google Scholar] [CrossRef]

- Patel, K.V.; Shah, S.R.; Özel, T. Orthogonal cutting of alloy steel 4340 with micro-grooved cutting tools. Procedia CIRP 2019, 82, 178–183. [Google Scholar] [CrossRef]

- Polvorosa, R.; de Lacalle, L.N.L.; Egea, A.S.; Fernandez, A.; Esparta, M.; Zamakona, I. Cutting edge control by monitoring the tapping torque of new and resharpened tapping tools in Inconel 718. Int. J. Adv. Manuf. Technol. 2020, 106, 3799–3808. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Hameed, S.; Egea, A.J.S.; Pérez, D.; Canales, J.; de Lacalle, L.N.L. Wear and MnS Layer Adhesion in Uncoated Cutting Tools When Dry and Wet Turning Free-Cutting Steels. Metals 2019, 9, 556. [Google Scholar] [CrossRef] [Green Version]

- Fatima, A.; Mativenga, P.T. Femtosecond Laser Surface Structuring of Carbide Tooling for Modifying Contact Phenomena. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 228, 1325–1337. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Kumawat, V. Effect of micro-textured tools on machining of Ti–6Al–4 V alloy: An experimental and numerical approach. Int. J. Refract. Met. Hard Mater. 2016, 54, 165–177. [Google Scholar] [CrossRef]

- Kim, D.M.; Bajpai, V.; Kim, B.H.; Park, H.W. Finite element modeling of hard turning process via a micro-textured tool. Int. J. Adv. Manuf. Technol. 2015, 78, 1393–1405. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. 3D finite element investigations on textured tools with different geometrical shapes for dry machining of titanium alloys. Int. J. Mech. Sci. 2018, 14, 424–449. [Google Scholar] [CrossRef]

- Liu, G.; Huang, C.; Su, R.; Özel, T.; Liu, Y.; Xu, L. 3D FEM simulation of the turning process of stainless steel 17-4PH with differently texturized cutting tools. Int. J. Mech. Sci. 2019, 155, 417–429. [Google Scholar] [CrossRef]

- Patel, K.; Liu, G.; Shah, S.R.; Özel, T. Effect of Micro-textured tool parameters on forces, stresses, wear rate, and variable friction in titanium alloy machining. J. Manuf. Sci. Eng. 2020, 142, 021007. [Google Scholar] [CrossRef]

- Karpat, Y.; Özel, T. Mechanics of high speed cutting with curvilinear edge tools. Int. J. Mach. Tool Manuf. 2008, 48, 195–208. [Google Scholar] [CrossRef]

- Usui, E.; Shirakashi, T.; Kitagawa, T. Analytical prediction of three dimensional cutting process. Part 3. Cutting temperature and crater wear of carbide tool. J. Eng. Ind. 1978, 100, 236–243. [Google Scholar]

- Kitagawa, T.; Maekawa, K.; Shirakashi, T.; Usui, E. Analytical prediction of flank wear of carbide tools in turning plain carbon steels. Part 2. Prediction of flank wear. Bull. Jpn. Soc. Precis. Eng. 1989, 23, 126–134. [Google Scholar]

| Test No. | Cutting Parameters | Micro-Texture Parameters | Chip-Tool Contact | Friction Coef. | ||||

|---|---|---|---|---|---|---|---|---|

| vc [m/min] | f [mm/rev] | w [mm] | s [mm] | d [mm] | lf [mm] | Ap [mm2] | μ | |

| 1 | 125 | 0.100 | No-texture | 0.193 | 0.527 | 0.54 | ||

| 2 | 125 | 0.150 | No-texture | 0.283 | 0.773 | 0.56 | ||

| 3 | 125 | 0.200 | No-texture | 0.273 | 0.745 | 0.63 | ||

| 4 | 125 | 0.100 | 0.05 | 0.05 | 0.01 | 0.201 | 878.8 | 0.53 |

| 5 | 125 | 0.125 | 0.05 | 0.075 | 0.01 | 0.250 | 1009.8 | 0.57 |

| 6 | 125 | 0.150 | 0.05 | 0.10 | 0.01 | 0.298 | 1151.2 | 0.60 |

| 7 | 125 | 0.100 | 0.10 | 0.10 | 0.02 | 0.192 | 0.312 | 0.55 |

| 8 | 125 | 0.125 | 0.10 | 0.15 | 0.02 | 0.246 | 0.456 | 0.52 |

| 9 | 125 | 0.150 | 0.10 | 0.20 | 0.02 | 0.310 | 0.624 | 0.52 |

| Test No. | Cutting Parameters | Micro-Texture Parameters | Measured Forces | Simulated Forces | |||||

|---|---|---|---|---|---|---|---|---|---|

| vc [m/min] | f [mm/rev] | w [mm] | s [mm] | d [mm] | Fc [N/mm] | Ft [N/mm] | Fc [N/mm] | Ft [N/mm] | |

| 1 | 125 | 0.100 | No-texture | 260 | 140 | 240 | 116 | ||

| 2 | 125 | 0.150 | No-texture | 425 | 240 | 340 | 152 | ||

| 3 | 125 | 0.200 | No-texture | 590 | 370 | 494 | 196 | ||

| 4 | 125 | 0.100 | 0.05 | 0.05 | 0.01 | 217 | 115 | 216 | 106 |

| 5 | 125 | 0.125 | 0.05 | 0.075 | 0.01 | 308 | 176 | 300 | 138 |

| 6 | 125 | 0.150 | 0.05 | 0.10 | 0.01 | 423 | 252 | 380 | 210 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, K.V.; Jarosz, K.; Özel, T. Physics-Based Simulations of Chip Flow over Micro-Textured Cutting Tool in Orthogonal Cutting of Alloy Steel. J. Manuf. Mater. Process. 2021, 5, 65. https://doi.org/10.3390/jmmp5030065

Patel KV, Jarosz K, Özel T. Physics-Based Simulations of Chip Flow over Micro-Textured Cutting Tool in Orthogonal Cutting of Alloy Steel. Journal of Manufacturing and Materials Processing. 2021; 5(3):65. https://doi.org/10.3390/jmmp5030065

Chicago/Turabian StylePatel, Kaushalendra V., Krzysztof Jarosz, and Tuğrul Özel. 2021. "Physics-Based Simulations of Chip Flow over Micro-Textured Cutting Tool in Orthogonal Cutting of Alloy Steel" Journal of Manufacturing and Materials Processing 5, no. 3: 65. https://doi.org/10.3390/jmmp5030065

APA StylePatel, K. V., Jarosz, K., & Özel, T. (2021). Physics-Based Simulations of Chip Flow over Micro-Textured Cutting Tool in Orthogonal Cutting of Alloy Steel. Journal of Manufacturing and Materials Processing, 5(3), 65. https://doi.org/10.3390/jmmp5030065