1. Introduction

Numerous manufacturing processes like honing, deep rolling, burnishing, or shot peening are used to beneficially influence the surface and subsurface properties of highly stressed parts across different industries such as automotive engineering, aerospace technologies, mechanical engineering, and life science engineering. Depending on the process, different aspects of the surface or subsurface area are addressed.

Honing, for example, is used as one of the last processes in the manufacturing chain of cylinder bores in conventional combustion engines, not only to correct deviations in the cylindrical shape but also to generate a functional surface with the potential to hold a specific amount of lubricant [

1]. The process can be adjusted to meet specific requirements for surface roughness, the resulting geometrical shape, and coolant storing volume on honed surfaces. Honing is a specific grinding process, the cooling storing volume is adjustable though the “real” volume can only be statistically determined because of the abrasive tool material [

2]. Form-honing is a more advanced concept to generate more complex cylinder shapes compared to conventional honing but is limited to cylindrical shapes [

3].

Deep rolling (also referred to as burnishing) instead is used to generate compressive residual stresses with a high depth effect, to reduce the roughness of the manufactured part, and (depending on the used material) to increase the hardness of the surface [

4,

5]. Due to strain hardening and compressive residual stresses, an improvement of component fatigue strength and lifetime can be achieved [

6,

7,

8,

9]. The reduced surface roughness as well as strain hardening contribute to a delayed crack formation and crack propagation is slowed down by compressive residual stresses [

10]. In addition to conventional deep rolling, there are also several modified process variants like ultrasonic supported deep rolling [

11] or deep rolling with milling kinematics [

12] which are investigated.

For shot peening, in general, the main aspect is to induce residual compressive stresses and to increase the hardness of the used material [

4]. Since it is thereby possible to improve the fatigue performance of a component [

13], shot peeing is used, for example, in the manufacturing process of high-performance turbines, enabling the safe use of highly stressed parts and increasing the service life of components [

14]. As failure-facilitating surface cracks may also be introduced by shot peening, an additional smoothing process is required [

15]. After shot peening, compressive residual stresses result, and the surface is statistically evenly dented with the impact points of the shot peening material.

Machine hammer peening is performed with periodic contact of tool and workpiece and depending on the actuation principle, different process variants and impact velocities can be realized [

5]. For example, one study [

16] describes piezoelectric machine hammer tools with impact frequencies up to 700 Hz. The workpiece is routed with the tool in multiple lines, generating a geometrically defined area with multiple impacts [

17]. It also enables an increase in hardness and the introduction of residual compressive stresses. Performing hammer peening investigations on C45E, Adjassoho et al. determined compressive residual stresses up to −700 MPa and a 15% hardness increase in the near-surface area [

18]. They further analyzed the mechanism of surface modification due to machine hammer peening using a carbide tip with an electromagnetic actuator system and were able to show a good agreement between a simplified unidirectional model and the real system [

19].

All four processes, honing (smooth, functional surface), deep rolling (smooth, hardened surface with induced compressive residual stresses), machine hammer peening (single impacts, regular structured, hardened surface with induced compressive residual stresses), and shot peening (single impacts, irregular surface with induced compressive residual stresses), result in specific surface and or subsurface properties and are used to improve the technical function and or increase the durability of the machined part. An overview of the characteristics as well as the surface and subsurface properties of all four processes are shown in

Table 1.

Nevertheless, none of the processes presented here is suitable to generate a designated specific functional surface structure and induce compressive residual stresses in the subsurface layer while maintaining a constant tool–workpiece contact. This paper presents a first approach in the design of a new process capable of doing both. PMST is a purely mechanical process with constant tool–workpiece contact. It could be used to generate a functional and geometrical determined surface while also inducing compressive residual stresses in the surface and subsurface layer. Due to the constant tool–workpiece contact, a constant minimum amount of hardness increase and residual stresses can be expected in the material independent from the exact desired surface topography. The resulting surface could, for example, be optimized to hold a specific amount of lubricant or to improve the flow properties of the surface. Thus, it combines the advantages of the material-removing process of honing with the strain hardening effects of deep rolling or machine hammer peening.

1.1. Description of the Process Design and Comparison to Deep Rolling and Shot Peening

PMST is a process with a predominant mechanical impact on the workpiece and constant tool–workpiece contact. The process is designed to combine the pulsed character of shot peening or machine hammer peening with the continuous contact between workpiece and tool as in a deep rolling process with the possibility to directly determine the surface topography of the workpiece.

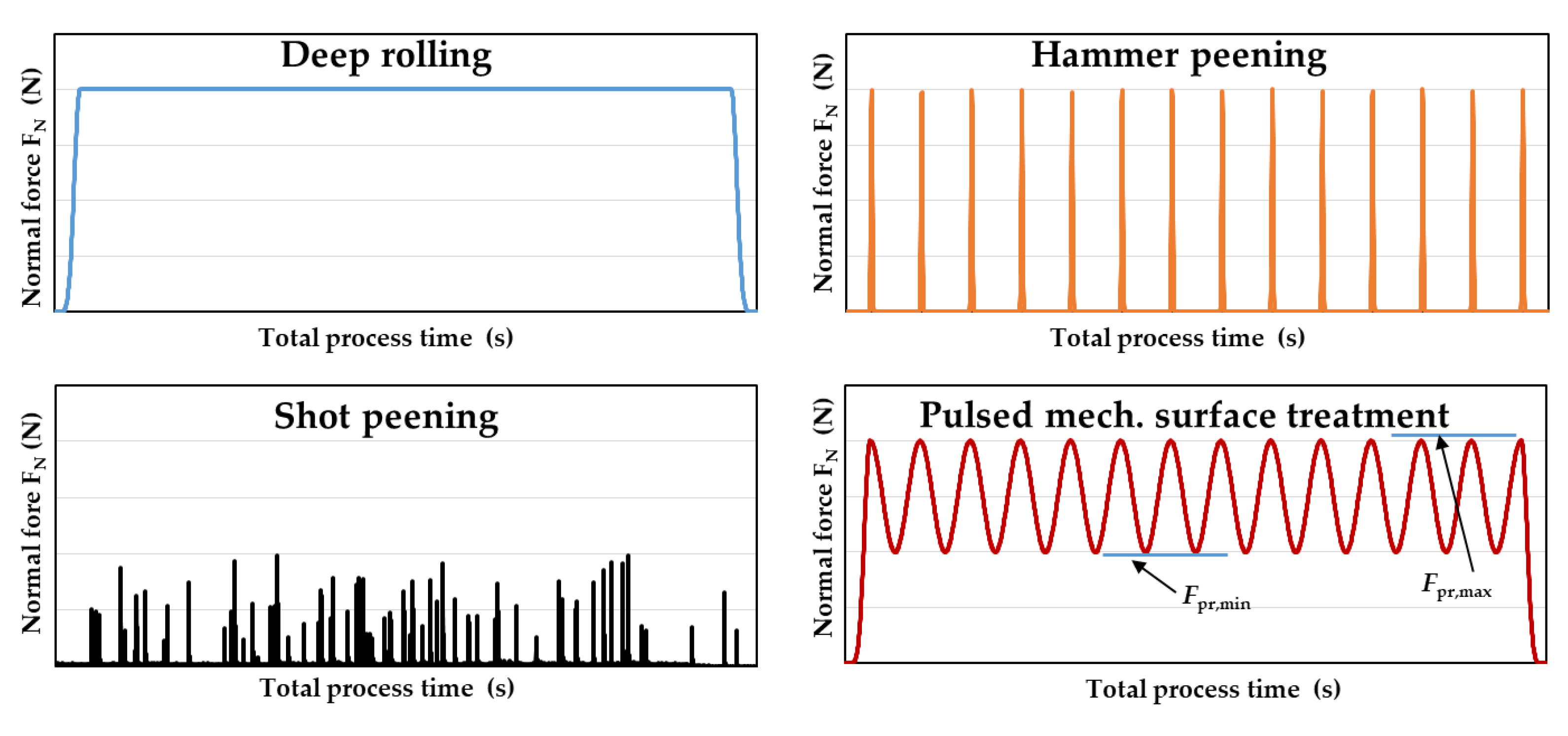

Figure 1 shows a time-based theoretical analysis of the occurring normal forces for deep rolling, shot peening, machine hammer peening, and PMST during the process. For deep rolling, the normal force (deep rolling force) is constant after an initial phase during the whole process and when using a hydrostatical deep rolling tool. The entire workpiece is influenced by the same force, based on the chosen process parameters. A process variation of conventional deep rolling is deep rolling with ultrasonic support as done in [

11]. The frequencies used to induce the deep rolling process are in a significantly higher frequency range (multiple kHz) compared to the ones utilized during PMST (0.5 to 5 Hz). During shot peening, there are multiple force spikes visible in the diagram. Each of these spikes represents an impact generated by a single shot peening particle. Between these impacts, there is no additional influence on the workpiece. For shot peening, the processing of the workpiece is based on a statistical distribution since the impact location of an individual particle cannot be controlled exactly. Machine hammer peening is also composed of single mechanical impacts on the workpiece but reaches higher normal forces than shot peening and the single impacts occur regularly.

The last graph shows the estimated normal force-time sequence for a PMST process. After the process begins, the normal force alternates between a minimum force Fpr,min, and a maximum force Fpr,max. Compared to deep rolling, PMST also has a permanent normal force (Fpr,min, or higher) affecting the workpiece during the process although the amount of force is not constant during the process. Compared to shot peening, the workpiece is continuously affected by a normal force but there are also visible spikes (Fpr,max). Different to shot peening, this maximum force occurs on a geometrically specific spot of the workpiece which can be controlled by the process parameters.

1.2. Process Fundamentals

Experiments in this paper were performed as a path-controlled process. Process parameters were the radius of the tool

rpr (mm), the minimum process normal force

Fpr,min(N), the amplitude

pramp (mm), and frequency

f (1/s) for the strokes, as well as the process velocity

vpr and the feed rate

fpr (mm/min), which influence the offset between each stroke in processing direction

cr (mm) and perpendicular to the processing direction

cf (mm).

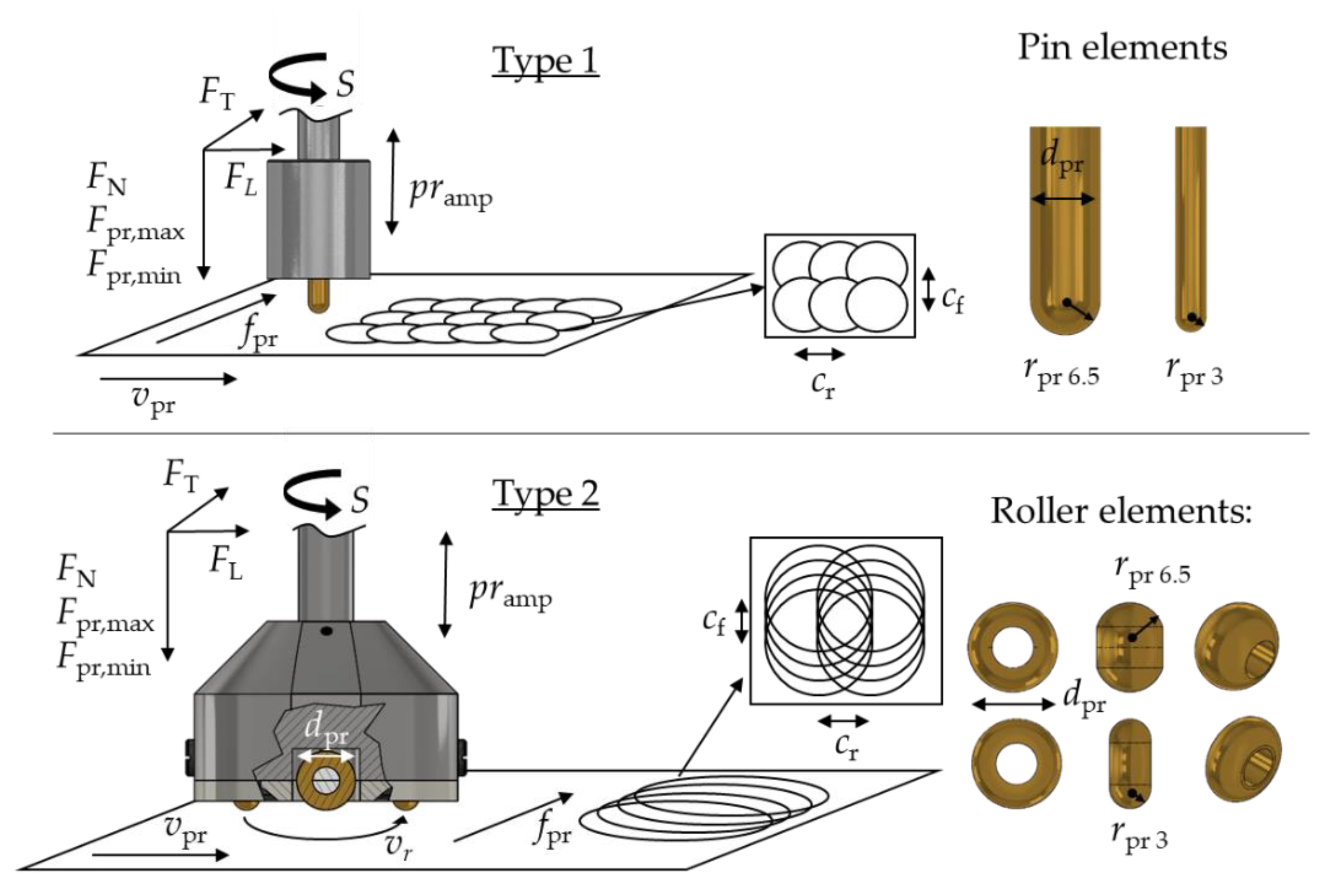

Figure 2 gives an overview of these process parameters for the pulsed mechanical surface treatment.

As a first approach, two different types of PMST tools were developed. Type 1 is closely related to a burnishing process that uses carbide pin elements centered to the tool to generate single impacts on the surface while maintaining constant tool–workpiece contact and being routed over the surface. Tool type 1 does not roll over the surface in lateral and transversal directions but is rotating around its own axis. Type 2 uses roller elements that are arranged eccentric to the tool axis and therefore generate a pulsating rolling movement. In general, the kinematics of PMST type 1 are less complicated than type 2. Therefore, the experiments in this paper were conducted using type 1 to approach the concept and reach a stable process. The process for tool type 2 is characterized by a much more complex kinematic and will be examined systematically in further investigations. To generate a pulsed normal force, a MITIS® tool holder (by MITIS, Bouguenais, France) normally used for vibration drilling was utilized. This tool holder is used to create the amplitude and frequency of the strokes. It uses the tool revolutions supplied by the CNC manufacturing center to generate an additional stroke amplitude normal to the manufactured surface, thereby allowing the amplitude to be adjusted in the operating range of the tool holder. The frequency can be varied by choosing different tool holders but is fixed for each of them. The maximum process-normal-force Fpr,max is directly dependent on Fpr,min, and the chosen amplitude. For this setup, Fpr,max can only be determined based on experience.

The topography of the resulting surface and the location of each impact can be controlled by adjusting both offsets

cf and

cr. Therefore, the revolutions determine the total amount of strokes per minute when multiplied with the tool holder frequency. The total amount of strokes per minute multiplied with the process velocity and the process feed results in strokes per mm on the surface. The perpendicular feed

fpr is equal to the offset c

f. The depth of the impacts can be controlled with the chosen amplitude and the minimum process normal force

Fpr,min. The relations between the different variables are also described by the equations in

Table 2.

2. Materials and Methods

2.1. Material

The workpiece material analyzed within this work was S235. Its chemical composition is displayed in

Table 3. After homogenization, the workpieces exhibited a hardness of 158 HV1. Heat treatment included heating up to 900 °C and holding this temperature for one hour. It resulted in a ferritic pearlitic microstructure (cf. Figure 11b). S235 was chosen in this state because of its lower hardness and good deformability. Both properties are beneficial for a first approach to a material-forming process like PMST.

2.2. Experimental Setup

As a basis for the experimental investigation, two different tool concepts were designed using a tool radius

rpr of either 3 mm or 6.5 mm.

Figure 3 shows both tool concepts.

For type 1, a fine-grain carbide (C: 10%, WC: 90%; Carbidur 902 by Carbidur AG, Benzstraße 6, 75210 Keltern-Dietlingen, Germany) pin is inserted in a base body made of 42CrMo4. The half-sphere contacting the workpiece has a radius rpr of either 3 mm or 6.5 mm. The tool is mounted in a MITIS® tool holder using a 12 mm mounting shaft at the top of the base body. Although the pin rotates around its axis, this process variant is called “static” in comparison to type 2 because there is no rolling motion on the specimen surface.

To integrate the rolling movement into the pulsed mechanical surface treatment, the second “dynamic” tool concept uses rollers (medium grain carbide of quality K30, supplied by Renzelmann Werkzeugtechnik GmbH, Bremen, Germany) running on small steel shafts. The steel shafts are mounted between a tool cover and the base body. Small flat head screws are used to secure these shafts. Spacers made of PTFE are used to center the rollers on the shafts. The base body is made of 42CrMo4 and up to two pairs of rolling spheres with two effective rolling diameters can be used.

To reduce friction, an 8% emulsion was used as a coolant for both tool concepts. While it was applied on the workpiece surface for type 1, for type 2, it was additionally supplied by the CNC machine center and transported to the spheres using a central coolant supply bore and individual cooling channels in the base body. All experiments were performed on a conventional 4-axis CNC machining center (DMC 65V by Deckel Maho, Pfronten, Germany); the whole experimental setup for the static tool, including a specimen, the MITIS

® tool holder, and the measuring devices is shown in

Figure 3.

The MITIS® tool holder (by MITIS, rue Johannes Gutenberg 12, 44340 Bouguenais, France) used for these experiments has an adjustable amplitude from 0.005 mm to 0.240 mm and a fixed stroke frequency of f = 1.5 per revolution. The amplitude pramp was set to 0.042 mm for all experiments performed. The tool holder was attached directly to the CNC manufacturing center, all tools were mounted directly in the tool holder.

As specimen metal plates made of S235 (1.0038, cf.

Section 2.1) with dimensions of 120 × 150 × 25 mm are used. To minimize clamping errors and ensure a plane orientation of the machining center and the specimen, each plate was milled down by 0.2 mm (

S = 800 (1/min); feed 500 (mm/min), cutting depth 0.1 (mm)) in the same clamping before usage.

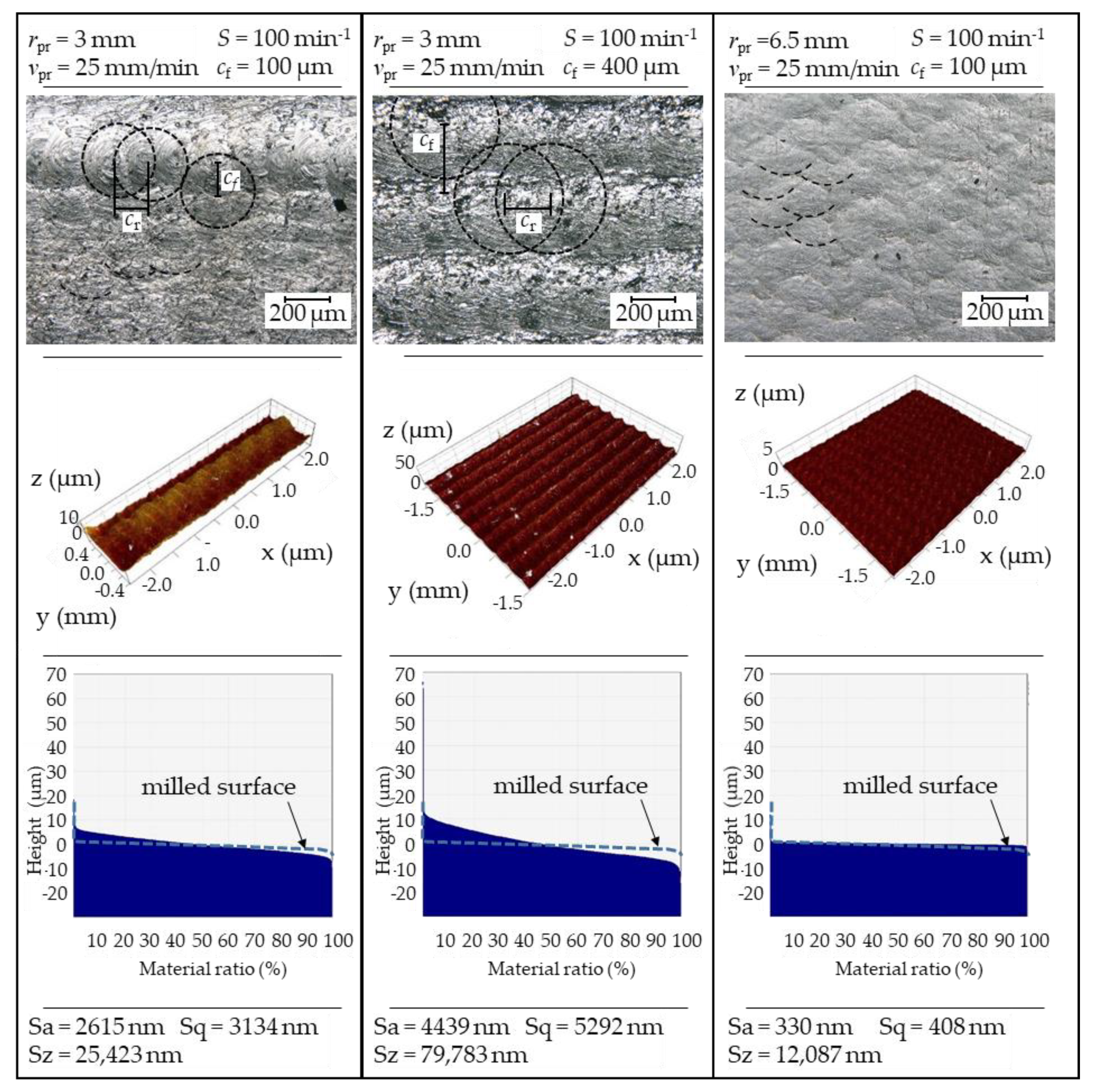

Figure 4 shows the surface characteristics after milling.

2.3. Measuring Devices

The process forces normal to the surface (FN), in as well as perpendicular to the processing direction, were measured utilizing a piezoelectric 3-component dynamometer (Typ 9257 B, Kistler Instrumente GmbH, Sindelfingen, Germany) equipped by a Kistler charge amplifier Typ 5019 A. A 500 Hz low pass filter was used to reduce the noise of the signal and the sampling rate was selected to 2500 Hz.

The analysis of the surface topographies (track as well as area) was carried out with the help of the Keyence digital microscope VHX—S 15 (KEYENCE DEUTSCHLAND GmbH, Neu-Isenburg, Germany). The images were captured with a 200x magnification.

The use and the coherence scanning interferometer Talysurf CCI HD (AMETEK GmbH, BU Taylor Hobson, Weiterstadt, Germany) enabled the determination of 3D images and Abbott curves.

Conventional hardness measurements (HV0.5) were performed for a depth up to 2 mm below the surface. In addition to that, universal micro hardness measurements were performed with the Fischerscope H100C testing device (Fischer Technology Inc., Windsor, CT, USA). Therefore, individual processed areas were separated by eroding. The samples were embedded, ground, and subsequently polished before testing on the cross-sections with a maximum indentation force of 10 mN. Starting at a distance to the surface of 6 µm, indentations were carried out at distances of approximately 15 µm. The measurements had a distance of approximately 100 µm parallel to the surface (cf. Figure 13).

5. Discussion

The results presented in

Section 4 confirm the ability of the chosen experimental setup to superimpose a higher load on a constant load. Therefore, both the surface and the subsurface properties of the component can be influenced. Taking into consideration the resistant but still lubricious surface aimed at utilizing the presented new process, Abbott curves from

Figure 9 (

rdr = 3 mm;

S = 100 min

−1) were compared with the curve of the milled surface in

Figure 14. The areas of high (1.) and low (2.) profile height are displayed in higher magnification.

Profile heights of around 10 µm already show a material ratio of approximately 10%. With decreasing profile height, the dark red curve shows a steeper increase in material ratio. Under load, 10% of the surface area is in contact at first and presumably deformed before the profile around 0 µm resists the load due to the higher material ratio. The maximum material ratio is reached at negative profile heights, which is due to the “downs” of the surface topography. These indentations could accommodate cooling lubricant. An ideally lubricatable surface should have only slight profile elevations but sufficient (in size and depth) indentations for the cooling lubricant. Since the presented pulsed mechanical surface treatment is a forming and not a subtractive process, indentations can only be created by deformation. Thus, the profile high increases at the same time. By variation of the process parameters, the surface could be adjusted, such that higher topography areas also show a higher material ratio and thus a higher resistance. The choice of a smaller tool could help to generate a flat Abbott curve in the area of slightly increased profile heights and a steeper slope in the area of negative profile heights.

To enable a quantification of the influence of the process parameters, on the right side of

Figure 14, the areal material ratios Smr1 and Smr2 are additionally displayed. Since an increase in surface roughness is achieved by choosing higher center offsets and results in separated indentations, a decrease in the areal material ratios is expected for increasing center offsets.

Almost independent of the center offset, Smr1 values were around 10%. While an Smr1 value increasing from 10 to 13% was visible for an increasing center offset at a velocity of 50 mm/min, a slight decrease from 14% to 8% could be seen at first before the values increased up to 20% at a velocity of 25 mm/min. Smr2 was above 88% for all parameter combinations. For both velocities, Smr2 first decreased before reaching its highest value.

Due to the increase in hardness of the surface and subsurface area associated with the plastic deformation (cf.

Figure 11 and

Figure 13), it can be assumed that the higher profile areas also offer increased resistance to wear. The actual behavior of the surfaces generated by a pulsed mechanical surface treatment in different applications must, therefore, be examined.

6. Conclusions and Outlook

The main aspect of this paper is the presentation of a new manufacturing process to generate geometrically defined surfaces with functional properties and a positively influenced surface and subsurface layer. The process, therefore, is characterized by a constant tool–workpiece contact and a continuous normal force affecting the surface. This normal force alternates between a minimum and a maximum value, depending on the process parameters. Two different processes with two tool types (1 and 2) were successfully designed. Tool type 1 was implemented and tested with two different tools sizes. The resulting surface topography was directly correlated to the process parameters and therefore could be designed for specific purposes like holding a specific amount of lubricant while still having a mechanically enhanced surface and subsurface layer.

This could be used to enhance the lifetime of highly stressed parts like ship propellers which are exposed to high mechanical punctual loads due to cavitation during their service life. A hardened, structured surface could minimize the occurring cavitation and improve the resistance of the parts against mechanical loads. Other applications could be hardened surfaces which are structured and optimized for aerodynamic purposes or fluid transport. A structured surface could improve the friction between the fluid and pipe walls or minimize fluid turbulences.

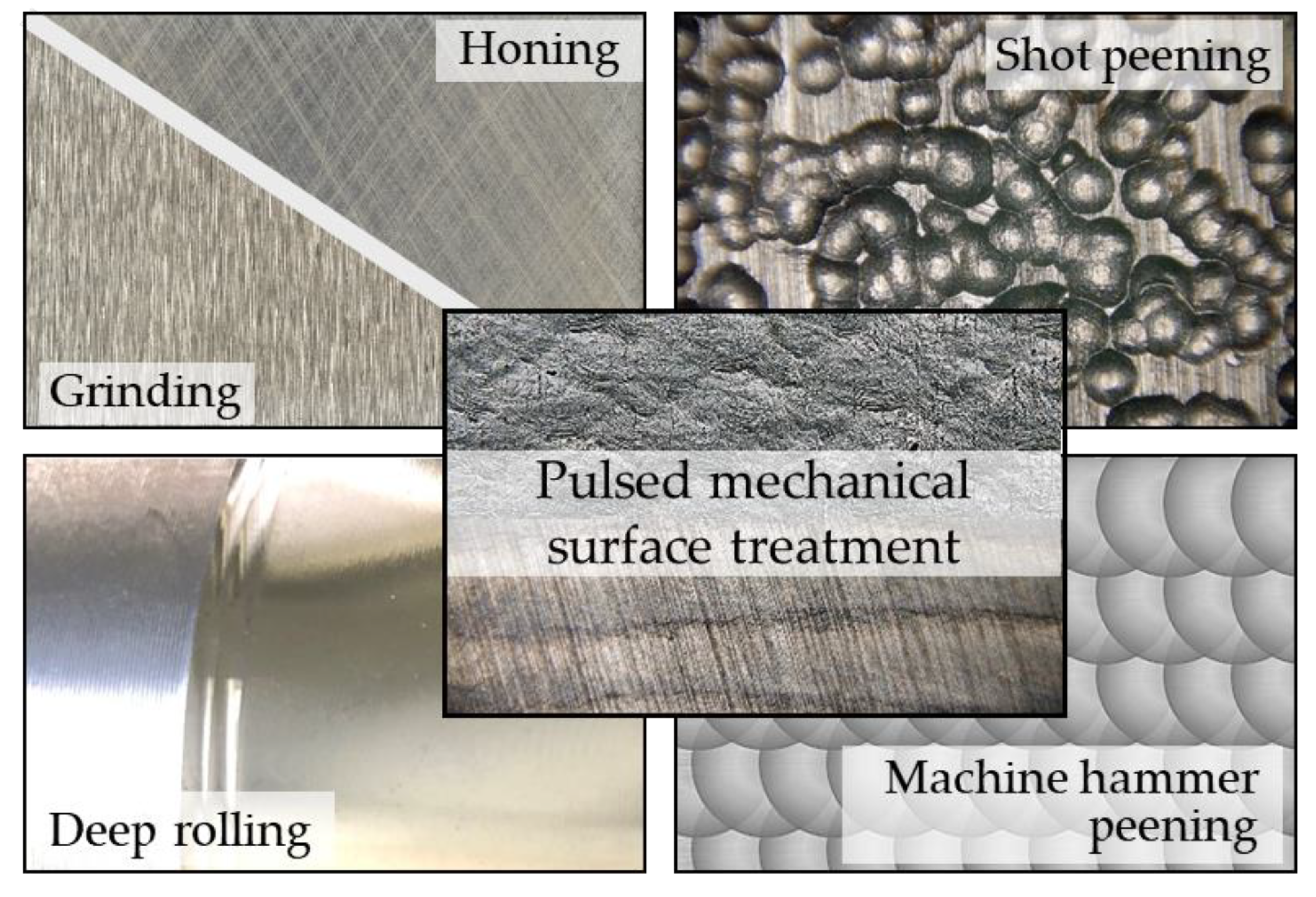

The process can be classified between other processes which generate final functional surfaces like honing, grinding, deep rolling, shot peening, or machine hammer peening.

Figure 15 gives a quick overview of the resulting surfaces of each of these processes and the classification of pulsed mechanical surface treatment. In addition to a geometrically defined surface topography, the process resulted in a general increase of hardness in the surface and subsurface layer of about 300 HM with spikes up to 1800 HM higher than the bulk material. The results are promising and indicate a high potential for PMST to be evaluated in further investigations.

In addition to the experiments with tool type 1, a first approach was also made to implement the process with the tool type 2. Only selected parameter combinations were used based on experiments performed with tool type 1. Results presented in the following were generated with a spindle speed S of 100 (1/min) and process feeds fpr of 25 or 50 (mm/min). This resulted in a rolling speed vr of 11 (m/min).

The experiments performed resulted in surfaces characterized by overlapping circular tracks as shown exemplarily in

Figure 16. Due to the rotating tool movement and the forces (in processing direction and perpendicular to the processing direction), the influence on the workpiece was much more complex. The feed force chosen in the presented example resulted in almost parallel rolling tracks in the upper and lower section, which varied in their track depth depending on the pulsed lift-off of the tool. In the area of track overlay (enlarged right red marked picture), multiple rollovers of the tool occurred in a single spot. These multiple rollovers could generate different properties in the surface and subsurface area, which will be investigated in further research.

Following the current work, tests with higher rolling forces and thus more pronounced plastic deformations will be carried out for a more detailed analysis of the surface topography.

The conducted experiments showed that the process is challenging to implement. Although the measured forces, offsets, and feeds met the calculated values the use of a mechanical tool holder to implement the pulsating movement leaves room for improvement. In a highly dynamic industrial environment, variables such as the stroke amplitude could be useful as a quick adjustable process parameter. Moreover, the maximum normal force which could only be determined experimentally in this research should be a controlled process parameter to maximize the possible benefits of PMST. These improvements could be achieved when instead of the mechanical MITIS tool holder, a magnetic beared and controlled tool spindle (by, e.g., KEBA AG, Linz, Austria) is used.

Further research will deal with of the process itself, such as the complex kinematics of the rolling process (type 2) when manufacturing bigger, overlapping areas, the possible amount of the minimum normal force Fpr,min, and the possible dynamic of the process will be addressed. In addition, further investigations on other surface and subsurface properties such as resulting residual stresses will be conducted.