1. Introduction

Due to the layer-wise build-up of parts by means of laser beam melting, surface roughness is often higher than what is generally acceptable due to the stair-step effect. This characteristically high roughness of additively manufactured parts requires finishing by means of various processes to meet the quality requirements of functional surfaces. Experience confirms that the required surface quality cannot always be achieved in one finishing process step [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16].

Often, the use of several processes, such as particle blasting, vibratory grinding or polishing becomes necessary for a sufficient final result [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38]. Each of these processes is characterized by its technological parameters and is only effective in some specific applications. For technologically related reasons, it is possible to achieve only a certain surface structure and roughness at an optimum cost with a respective finish method.

First of all, additively manufactured parts are usually blasted with particles of hard materials in order to clean the surfaces of the material residue on the one hand and to smooth the peaks of roughness on the other [

18,

19]. Since this process is not very controlled, the final quality of the component requires further finishing steps [

20,

21].

Vibratory grinding is a well-known abrasive process for machining complex metal components. By using this method, coarse metal surfaces can be machined by tumbling the part with abrasive grains, and usually additives, in an aqueous solution in a container. Roughness can be significantly reduced, and geometric deviations can also occur. Lower material removal means that the process takes a relatively long time. For example, to ensure a roughness of Ra < 1 µm, the process should run for at least 3 h [

22]. The machining of additively manufactured components with complex geometry places especially high demands on the process, whereby the accessibility of the grinding particles to all areas should be ensured for homogeneous surface roughness [

23,

24]. This process can be used effectively in series production.

Polishing offers further potential for the production of smooth surfaces on manufactured parts. Various applications are known from publications [

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39]. With laser polishing, roughness peaks on the surface can be quickly heated to melting temperature and thus made to flow. After solidification of the molten bath, a balanced topography is created [

25,

26,

27]. With this process, in addition to the surface roughness, properties of the material can also be changed or affected [

28,

29]. Although a roughness (Ra) of 75 nm can be achieved on the manufactured steel part with this method, the process takes a relatively long time since every surface area is to be scanned with a laser beam [

30]. In addition, reaching all functional surfaces on the component with a laser beam is a technological problem in itself.

In contrast, plasma electrolytic polishing (PeP) offers a contour-independent process. Since the process takes place in an aqueous medium, any geometries can be polished [

31,

32]. Achieving a surface roughness (Ra) < 0.1 µm is possible with adapted technological conditions [

33,

34]. Since the process is carried out at a low temperature of the medium, there is no thermal influence on the part. Impairment of the shape accuracy of the component contour is limited due to short processing times. Another advantage of this process is the use of ecologically friendly process components compared to other polishing processes [

35]. The above-mentioned advantages make the investigation of this process attractive for the finishing of AM parts.

The extent of post-processing of additively manufactured parts with the above-mentioned current methods depends not only on the quality of the finished surfaces to be achieved, but also on the condition of the initial surfaces. The difference between the roughness of the initial surface and the finished part determines the duration of the finishing process. Surfaces of LBM manufactured components do not always offer optimal starting conditions for the finishing methods mentioned above. For example, a direct reduction of workpiece roughness to Ra < 1µm with vibratory finishing usually takes significantly longer than with combined finishing methods used to reduce the initial surfaces roughness values.

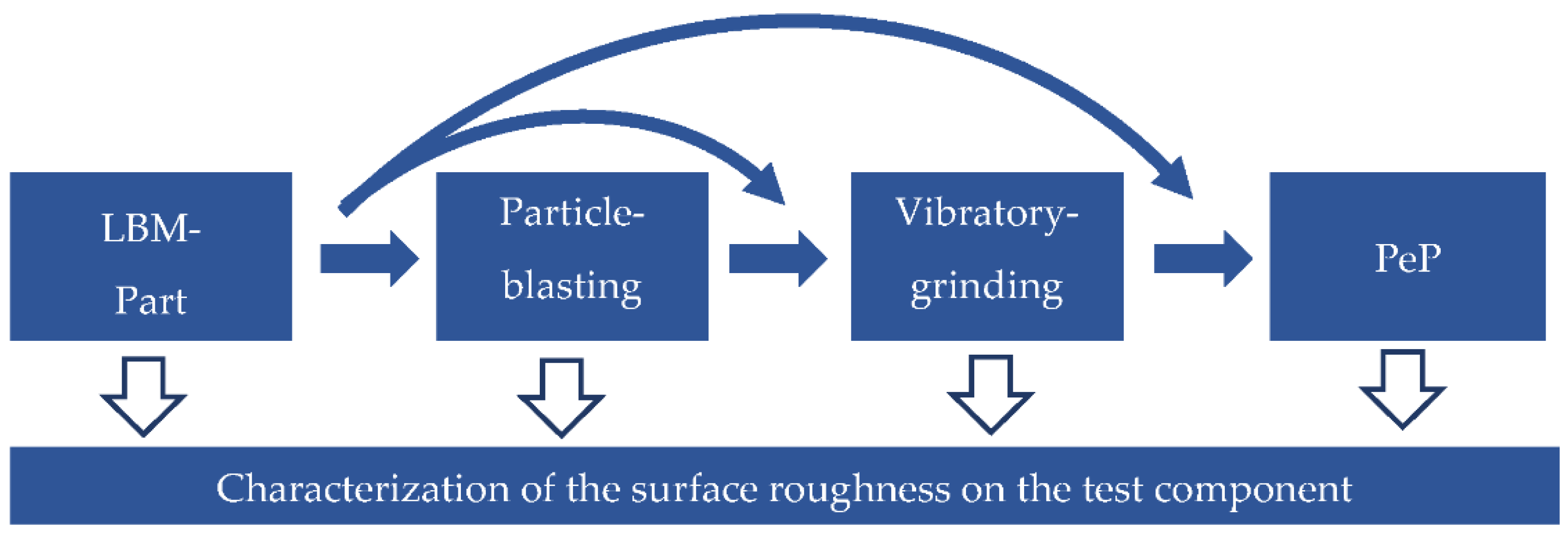

The use of several process steps in the finishing process requires the coordination of individual steps to achieve the final quality with little effort. Depending on the manufacturing task, different process chains can be realized through combinations of post-processing methods (

Figure 1).

An effectively designed finishing process enables the advantages of laser beam melting based on the few design restrictions to be reasonably exploited. With a broader knowledge base for finishing, planning of the entire process chain can be positively influenced. The presented state-of-the-art reviews have demonstrated that few studies are available on the design of a process chain for effective and efficient finishing of additively manufactured parts. Therefore, the present work is of great importance for minimizing the total effort required in the additive manufacturing (AM) process.

In this study, the limits of individual processes and their combination for the finishing of surfaces, produced additively with laser beam melting, were experimentally investigated on various test geometries in the framework of different process chains and subsequently verified on a stainless steel propeller. The optimal combination of various finishing methods met the criterion of minimum production time of the entire finishing process chain.

2. Processing and Experimental Methods

When additive manufacturing (AM) of real components is performed, geometrically varying surface normals are created, which are reflected in the development of geometric deviations. To differentiate these effects, the terms upskin surfaces with positive angles and downskin surfaces with negative angles of inclination to the building platform are used. Technological knowledge regarding the development of roughness of these surfaces within the building process in relation to part orientation and positioning enables a sound base for planning the laser beam melting (LBM) process, the results of which play a decisive role in the finishing process.

For this reason, this study performed several experiments on differently inclined platelets. The design of the test platelets referred to the guidelines of DIN EN ISO/ASTM 52902 standard to identify the directional roughness.

Figure 2 presents the arrangement of the test platelets. They consist of strips oriented in different angles to the building platform and were fixed by struts. These platelets were easy to measure and the different angles allowed conclusions to be drawn regarding curved surfaces or free-form surfaces on real components, which are usually difficult to measure.

The test specimens were additively manufactured from steel powder (316 L) in an EOS M 290 system using laser beam melting in standard setting. Identical process parameters were used to carry out the tests. After the support structure was removed using conventional methods, the surfaces were finished with selected manufacturing processes (

Figure 3). In view of the suitability for machining of complex geometries, the following processes were used for the finishing:

Particle blasting with glass beads, silicon carbide, and zirconium oxide balls;

Vibratory grinding;

Plasma electrolytic polishing (PeP).

Each of these processes leads to a reduction in surface roughness due to its special material removal mechanism, which can be further increased by combining the described processes [

2,

13,

24,

39]. To investigate this effect, different finishing chains were realized. The parameters of the finishing processes are presented in

Table 1.

The shape deviations of the surfaces on the test specimens were measured after each processing with Keyence VR3200 and VK-X 120 devices and evaluated according to the guidelines of DIN EN ISO 4287. For a better characterization of the shape deviations of the surfaces, the roughness parameter Sa was considered. With this planar representation of the surface parameters, the formation of individual profile shapes using different finishing processes could be better explained.

3. Experimental Research

During the tests, 3D parameters of the surface were analyzed in order to gain more information about the surface structure. This allows more statistical certainty compared to 2D measurements [ISO25178]. For the characterization of surfaces according to ISO 25178, it is advisable to use the arithmetical mean height Sa, which is considered as an extension of the line roughness parameter Ra of the surface. These parameters are suitable for evaluating the functionally relevant surface parameters and are therefore used in this study.

Before finishing, roughness of the manufactured test platelets was measured and graphically represented in relation to the surface’s inclination angle to the building platform (

Figure 4) as a dispersion of the determined values of S

a.

As expected, the significant influence of inclination angle can be observed in the graph, which clearly exhibits the stair step effect in the researched areas. Here, the shape deviations on downskin and upskin surfaces differed due to technology. Large roughness values on downskin surfaces were caused by the LBM support structure. The quality of support removal also determined the surface roughness, which was reduced through the following processes. Thus, support removal has a considerable influence on the process design for finishing in addition to the other factors.

3.1. Process step: Particle Blasting

The additively manufactured platelets were finished with different blasting media to determine an effective blasting medium. Due to the specifics of the methods, the surfaces exhibited different optics (

Figure 5).

The surfaces of the machined test plates were optically measured.

Figure 6 presents a comparison of all of the blasting media used in terms of surface roughness improvement. The relative roughness reduction indicates the effectiveness of individual blasting media. The figure clearly indicates that S

iC was an effective blasting medium for upskin surfaces. For reducing the shape deviations of the downskin surfaces at a micro level, ZrO

2 was the most suitable medium. Since Z

rO

2 balls cause greater plastic deformation at crash in the contact area due to their greater hardness, they lead to faster and more effective smoothing of the additive-manufactured surfaces. Therefore, it makes sense to finish the complete component only with Z

rO

2 blasting balls to achieve greater surface quality.

3.2. Process Step: Vibratory Grinding

In the planned trials for vibratory finishing, the extent to which rotating and vibrating abrasive particles are suitable for finishing printed surfaces was investigated. Several test platelets were processed together. To investigate the relationship between the process steps, the printed surfaces were finished with and without blasting with Z

rO

2 balls. The results of the trials without blasting are presented in

Figure 7, where the curves demonstrate that roughness reduction depends on the inclination angle of the platelets to the building platform. Finishing of all upskin surfaces revealed an average Sa roughness < 4 µm after three hours, but Sa roughness values > 15 µm were still present in the downskin area. The flattening of the machining curves over time in the diagram was due to the change (smoothing) of the surface roughness with time. For example, a very long grinding time is required to process rough downskin surfaces to achieve average Sa roughness values < 5 µm. For a homogeneous machining result, preparing these surfaces using blasting is meaningful.

The results of the particle blasting and vibratory grinding experiments are presented in

Figure 8. By combining blasting and vibratory grinding in the upskin areas, the average S

a roughness could be reduced to <3 μm. However, the roughness values of the downskin areas indicated that the surfaces built on supports still had an S

a roughness > 5 μm even after the processes were combined. The total material removal of both methods was insufficient for smoothing the rough initial surfaces and, therefore, the two areas had different roughness.

3.3. Process Step: Plasma Electrolytic Polishing

This tool-less process is highly suitable for the finishing of additive-manufactured complex geometries [

39]. PeP cleans and smoothens the surfaces of metallic components in a relatively short time, where processing time strongly relates to initial roughness and material properties. For initial roughness arising from milling, the process usually takes a few minutes (<10 min). The method is based on an electrolytic process that ensures the formation of a plasma layer between the electrolyte and workpiece surfaces. Then, material removal occurs in that plasma zone, following the electric field lines (and therefore focusing on peaks and burrs). It removes small peaks very quickly but slows down when large wavy areas are to be flattened; hence, high material volume is to be removed.

Investigations were conducted on test plates built at 15°, 45°, and 90° angles. This investigation area covered the upskin surfaces as well as the roughest downskin surfaces. The direct finishing of the surfaces with PeP only did not provide a significant reduction in roughness in a short time due to the fact that the high initial roughness high material volume must be removed. The experiments showed that after one hour of polishing, a reduction of Sa from 40 µm to 10 µm was achieved. This is due to the decrease of material removal rate with time. Hence, the direct and only use of PeP was not continued in this work.

On the basis of the aforementioned knowledge regarding the effect of single finishing processes on roughness reduction, this study investigated the effect of combining PeP with other finishing processes. The experimental investigations on the test platelets revealed a clear improvement in surface quality with certain combinations. The preparation of printed platelets with particle blasting or vibratory grinding (or both of these methods) was especially effective (

Table 2).

The combination of the processes of blasting, grinding, and polishing made it possible to gradually reduce the peaks of the surface mountains along this chain (

Figure 9). The favourable input variable of surface shape became noticeable after only 2 min of polishing. Despite long finishing, the roughness of the downskin surfaces was greater than that of the upskin surfaces. This indicated that the hereditary effect of the downskin surfaces continued until the final stage. This negative interaction on downskin surfaces could only be eliminated with a significantly longer polishing time, thus achieving the same roughness as that for upskin surfaces.

In summary, it was observed that the reduction of Sa roughness to <1 μm required a combination of the three considered finishing methods. The realization of this process chain can, however, only be successful if the dimensional changes during the reworking are considered. This dimensional change can be up to 10% in the combination of blasting, grinding, and polishing.

4. Edge Rounding

The finishing of the parts’ surfaces leads to edge rounding. This change in the shape of test platelets depends not only on the technological parameters of finishing but also on the quality of the edge building using LBM [

40,

41]. It is known that no homogeneous weld pool is formed at the edges of the surfaces due to line-like exposure. Instead, small drops are formed. These weak areas are creating edge radii of different sizes during finishing, depending on the type of method. When blasting with ZrO

2 balls, for example, a burr can be observed at the edges, which is influenced by the acute angle of the edge (

Figure 10). In contrast, in vibratory grinding, a small burr can be observed, which can be completely eliminated through PeP processes. These influences were explained by finishing and characterising test pieces with different acute angles.

Figure 11 demonstrates how the combination of the aforementioned methods influenced the size of these form errors. The size of the edge rounding correlated strongly with the tip angle. Furthermore, duration and type of machining played a significant role. As previously described, a combination of several processes is necessary for achieving excellent surface quality. In particular, the experimental investigations revealed that this process chain caused increased rounding. This negative effect should be considered when designing the finishing process. One way to do this is to compensate for the undesired material removal through additional allowances in necessary areas.

5. Verification of the Results

To verify the experimental knowledge gained from the test platelets, several stainless-steel propellers were LBM produced. This was aimed at enabling the identification of not only influences of orientation but also of positioning the parts on the build platform. Roughness values were recorded at several areas of the propeller surface, which helped to better illustrate the relationships (

Figure 12).

The measurement results revealed higher roughness values at the outer edge of the propeller surface in the upskin area than in the inside area. This tendency was caused by varying angles of inclination of the wing surfaces due to rotation around the propeller axis. This was reflected in the process-specific formation of the surface shape. As expected, the roughness values were significantly higher in the downskin area. In both cases, the evaluated roughness values tended to agree with the experimental results.

The effect of the combination of the blasting, vibratory grinding, and PeP processes, already defined during the finishing of the test plates, was demonstrated when the propeller surfaces were machined. Roughness of the polished surfaces was in the range of Sa 1.7–2.1 µm. The roughness on the downskin surfaces could only be reduced to Sa 3.5–4.2 µm.

Figure 13 depicts the propeller processed through blasting, vibratory grinding, and PeP. The picture indicates that the macroscopic waviness of the component was still present, especially in the downskin area.

6. Conclusions

In the present study, it was first possible to identify the technological limits of individual finishing processes with regard to roughness reduction on test specimens manufactured using LBM. The experimental investigations revealed that treatment of the surfaces with ZrO2 balls reduced unevenness of the surfaces to a certain degree and can only be used in the preparation of demanding parts.

Processing of initial surfaces with vibratory grinding had several advantages due to the abrasive medium used (which had countless grains). The direct application reduced the roughness values of the surfaces but left irregularities on the rough surfaces (Sa > 10 µm). To achieve a final quality <1 µm, it was necessary to further process the test surfaces with PeP. The experiments demonstrated that a high surface quality could only be achieved through the stepwise reduction of surface roughness.

In this respect, the combination of particle blasting and vibratory grinding with PeP achieved the optimal results. Once finishing was complete, the surfaces of the test parts (i.e., the propellers) had a maximum roughness Sa < 5 µm.

The experimental results presented the following technological knowledge:

When designing the finishing process chain, attention should be paid to the constrained sequence of each method which relate to their material removal mechanisms. This depends on the tool used for removal. Coarse processes can remove a lot of material quickly, but cannot produce a fine surface. This is to be supplemented by intelligent combination with fine removal processes.

The total duration of the post-processing chain depends strongly on the quality of the additively manufactured surface. A lower quality of the initial surface requires more effort in post-processing than a significantly better printed component surface. A further approach towards best efficiency, including optimal interaction between LBM and post-processing parameters, requires complete viewing of the process chain from pre-processing to finishing, considering the interrelationships between the individual process steps and is the subject of ongoing and future research.

Author Contributions

Conceptualization, H.Z. and R.A.; methodology, R.A.; validation, H.Z., R.A. and F.G.; formal analysis, H.Z. and F.G.; investigation, F.G.; resources, H.Z. and F.G.; data curation, F.G. and R.A.; writing—original draft preparation, H.Z., R.A. and F.G.; writing—review and editing, H.Z. and R.A.; visualization, R.A. and F.G.; supervision, R.A.; All authors have read and agreed to the published version of the manuscript.

Funding

Open Access Funding by the Publication Fund of TU Bergakademie Freiberg.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the support of EOS GmbH, Krailing, Germany, who provided the LBM parts.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bagehorn, S.; Wehr, J.; Maier, H.J. Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti-6Al-4V parts. Int. J. Fatigue 2017, 102, 135–142. [Google Scholar] [CrossRef]

- Han, S.; Salvatore, F.; Rech, J.; Bajolet, J.; Courbon, J. Effect of abrasive flow machining (AFM) finish of selective laser melting (SLM) internal channels on fatigue performance. J. Manuf. Process. 2020, 59, 248–257. [Google Scholar] [CrossRef]

- Hung, W. Postprocessing of Additively Manufactured Metal Parts. J. Mater. Eng. Perform. 2021, 30, 6439–6460. [Google Scholar] [CrossRef]

- Kaynak, Y.; Tascioglu, E. Post-processing effects on the surface characteristics of Inconel 718 alloy fabricated by selective laser melting additive manufacturing. Prog. Addit. Manuf. 2020, 5, 221–234. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kıtay, Ö. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2019, 26, 84–93. [Google Scholar] [CrossRef]

- Kosche, T. Nachbearbeitung additiv gefertigter Bauteile. In Additive Serienfertigung; Lachmayer, R., Lippert, R., Kaierle, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Lane, B.M.; Moylan, S.P.; Whitenton, E.P. Post-process machining of additive manufactured stainless steel. In Proceedings of the 2015 ASPE Spring Topical Meeting: Achieving Precision Tolerances in Additive Manufacturing, Raleigh, NC, USA, 26–29 April 2015; p. 27. [Google Scholar]

- Seltzman, A.H.; Wukitch, S.J. Surface roughness and finishing techniques in selective laser melted GRCop-84 copper for an additive manufactured lower hybrid current drive launcher. Fusion Eng. Des. 2020, 160, 111801. [Google Scholar] [CrossRef]

- Stucker, B.; Rosen, D.; Gibson, I.; Khorasani, M. Additive Manufacturing Technologies; Springer International Publishing: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Simoni, F.; Huxol, A.; Villmer, F.J. Improving surface quality in selective laser melting based tool making. J. Intell. Manuf. 2021, 32, 1927–1938. [Google Scholar] [CrossRef]

- Rudolph, J.-P.; Emmelmann, C. Organisation von Nachbearbeitungsprozessen in additiven Produktionsstrukturen. Z. Wirtsch. Fabr.—ZWF 2018, 113, 738–741. [Google Scholar] [CrossRef]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. India Ser. 2018, C99, 481–487. [Google Scholar] [CrossRef]

- Alrbaeya, A. Improvement to the Surface Finish of Additive Layer Manufacturing Parts Made by Selective Laser Melting. Ph.D. Thesis, De Montfort University, Leicester, UK, 2014. [Google Scholar]

- Löber, L.; Flache, C.; Petters, R.; Kühn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 316l steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar] [CrossRef]

- Cao, Q.; Bai, Y.; Zhang, J.; Shi, Z.; Fuh, J.Y.H.; Wang, H. Removability of 316L stainless steel cone and block support structures fabricated by Selective Laser Melting(SLM). Mater. Des. 2020, 191, 108691. [Google Scholar] [CrossRef]

- Lia, Y.; Wu, Y.; Zhou, L.; Fujimoto, M. Vibration-assisted dry polishing of fused silica using a fixed-abrasive polisher. Int. J. Mach. Tools Manuf. 2014, 77, 93–102. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.; Liew, P.J. Material Removal in Ultrasonic Abrasive Polishing of Additive Manufactured Com-ponents. Appl. Sci. 2019, 9, 535. [Google Scholar] [CrossRef]

- Abbott, K.E. Dry media blasting for the removal of paint coatings on aerospace surfaces. Met. Finish. 1996, 94, 33–35. [Google Scholar] [CrossRef]

- Fedoryszyn, A.; Zyzak, P. Characteristics of the outer surface layer in casts subjected to shot blasting treatment. Arch. Metall. Mater. 2010, 55, 813–818. [Google Scholar]

- Soja, A.; Li, J.; Tredinnick, S.; Woodfield, T. Surface finishing of additively manufactured stainless steel surgical instruments. Rapid Prototyp. J. 2021, 27, 59–70. [Google Scholar] [CrossRef]

- Denti, L.; Sola, A. On the Effectiveness of Different Surface Finishing Techniques on A357.0 Parts Produced by Laser-Based Powder Bed Fusion: Surface Roughness and Fatigue Strength. Metals 2019, 9, 1284. [Google Scholar] [CrossRef]

- Jamal, M.; Morgan, M.N. Design Process Control for Improved Surface Finish of Metal Additive Manufactured Parts of Complex Build Geometry. Inventions 2017, 2, 36. [Google Scholar] [CrossRef]

- Domblesky, J.; Cariapa, V.; Evans, R. Investigation of vibratory bowl finishing. Int. J. Prod. Res. 2003, 41, 3943–3953. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Veniali, F. Post-Processing of Complex SLM Parts by Barrel Finishing. Appl. Sci. 2020, 10, 1382. [Google Scholar] [CrossRef]

- Wang, Q.; Morrow, J.D.; Ma, C.; Duffie, N.A.; Pfefferkorn, F.E. Surface prediction model for thermocapillary regime pulsed laser micro polishing of metals. J. Manuf. Process. 2015, 20, 340–348. [Google Scholar] [CrossRef]

- Ukar, E.; Lamikiz, A.; Liebana, F.; Martinez, S.; Tabernero, I.; Mentxaka, A.L. An industrial approach of laser polishing with different laser sources. Mater. Werkst. 2015, 46, 661–667. [Google Scholar] [CrossRef]

- Chen, L.; Richter, B.; Zhang, X.; Bertsch, K.B.; Thoma, D.J.; Pfefferkorn, F.E. Effect of laser polishing on the microstructure and mechanical properties of stainless steel 316L fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2021, 802, 140579. [Google Scholar] [CrossRef]

- Ma, C.; Guan, Y.; Zhou, W. Laser polishing of additive manufactured Ti alloys. Opt. Lasers Eng. 2017, 93, 171–177. [Google Scholar] [CrossRef]

- Lamikiz, A.; Sánchez, J.; de Lacalle, L.L.; Arana, J. Laser polishing of parts built up by selective laser sintering. Int. J. Mach. Tools Manuf. 2007, 47, 2040–2050. [Google Scholar] [CrossRef]

- Mai, T.A.; Lim, G.C. Micromelting and its effects on surface topography and properties in laser polishing of stainless steel. J. Laser Appl. 2004, 16, 221–228. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, C.; Ding, F.; Yang, Y.; Zhang, T.; He, X.; Zheng, L.; Li, N. Principle, process, and application of metal plasma electrolytic polishing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1893–1912. [Google Scholar] [CrossRef]

- Belkin, P.M.; Kusmanov, S.A.; Parfenov, E.F. Mechanism and technological opportunity of plasma electrolytic polishing of metals and alloys surfaces. Appl. Surf. Sci. Adv. 2020, 1, 100016. [Google Scholar] [CrossRef]

- Zeidler, H.; Böttger-Hiller, F. Surface Finish of Additively Manufactured Parts using Plasma Electrolytic Polishing. In Proceedings of the WCMNM 2018 World Congress on Micro and Nano Manufacturing, Portorož, Slovenia, 18–20 September 2018. [Google Scholar] [CrossRef][Green Version]

- Nestler, K.; Böttger-Hiller, F.; Adamitzki, W.; Glowa, G.; Zeidler, H.; Schubert, A. Plasma electrolytic polishing—An overview of applied technologies and current challenges to extend the polishable material Range. Procedia CIRP 2016, 42, 503–507. [Google Scholar] [CrossRef]

- Tyagi, P.; Goulet, T.; Riso, C.; Stephenson, R.; Chuenprateep, N.; Schlitzer, J.; Benton, C.; Garcia-Moreno, F. Reducing the roughness of internal surface of an additive manufacturing produced 316 steel component by chempolishing and electropolishing. Addit. Manuf. 2019, 25, 32–38. [Google Scholar] [CrossRef]

- Zhang, J.; Tai, W.; Wang, H.; Kumar, A.S.; Lu, W.; Fuh, J.Y.H. Magnetic abrasive polishing of additively manufactured 316L stainless steel parts. In Proceedings of the 18th International Conference of the European Society for Precision Engineering and Nanotechnology EUSPEN 2018, Venice, Italy, 4–8 June 2018; pp. 401–402. [Google Scholar]

- Zhang, J.; Toh, A.Y.X.; Wang, H.; Lu, W.F.; Fuh, J.Y.H. Vibration-assisted conformal polishing of additively manufactured structured surface. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 233, 4154–4164. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Yang, J.; Fuh, J.Y.H.; Lu, W.F.; Weng, C.; Wang, H. Dry mechanical-electrochemical polishing of selective laser melted 316L stainless steel. Mater. Des. 2020, 193, 108840. [Google Scholar] [CrossRef]

- Zeidler, H.; Böttger-Hiller, F.; Krinke, S.; Parenti, P.; Annoni, M. Surface finish of additively manufactured parts using plasma electrolytic polishing. In Proceedings of the 19th International Conference & Exhibition, Bilbao, Spain, 3–7 June 2019. [Google Scholar]

- Metelkova, J.; Haitjema, H.; Witvrouw, A.; Pfleging, W.; Van Hooreweder, B. Elevated edges of metal parts produced by laser powder bed fusion: Characterization and post-process correction. In Proceedings of the Special Interest Group Meeting on Advancing Precision in Additive Manufacturing Euspen, Nantes, France, 16–18 September 2019; pp. 12–15. [Google Scholar]

- Gebhardt, A.; Hötter, J.; Ziebura, D. Impact of SLM build parameters on the surface quality. RTejournal—Forum Rapid Technol. 2014, 11, 1–14. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).