Top Surface Roughness Modeling for Robotic Wire Arc Additive Manufacturing

Abstract

1. Introduction

- A machine learning method based on GPR is developed to model the top surface roughness for robotic weaving path;

- The proposed method is tested experimentally, and the results demonstrate that about 50 m accuracy of the top surface roughness is achieved.

2. Materials and Methods

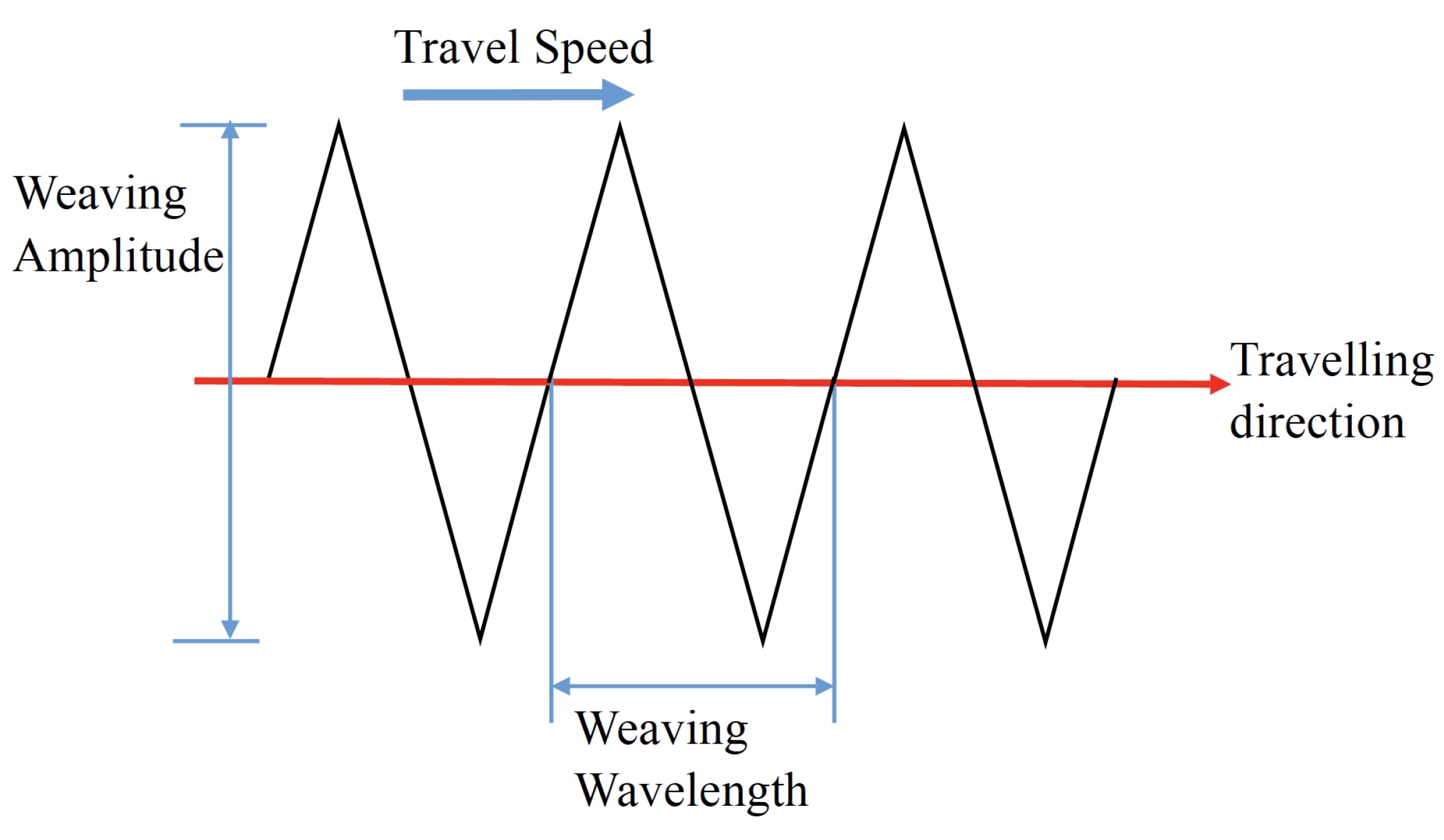

2.1. Robotic WAAM Process

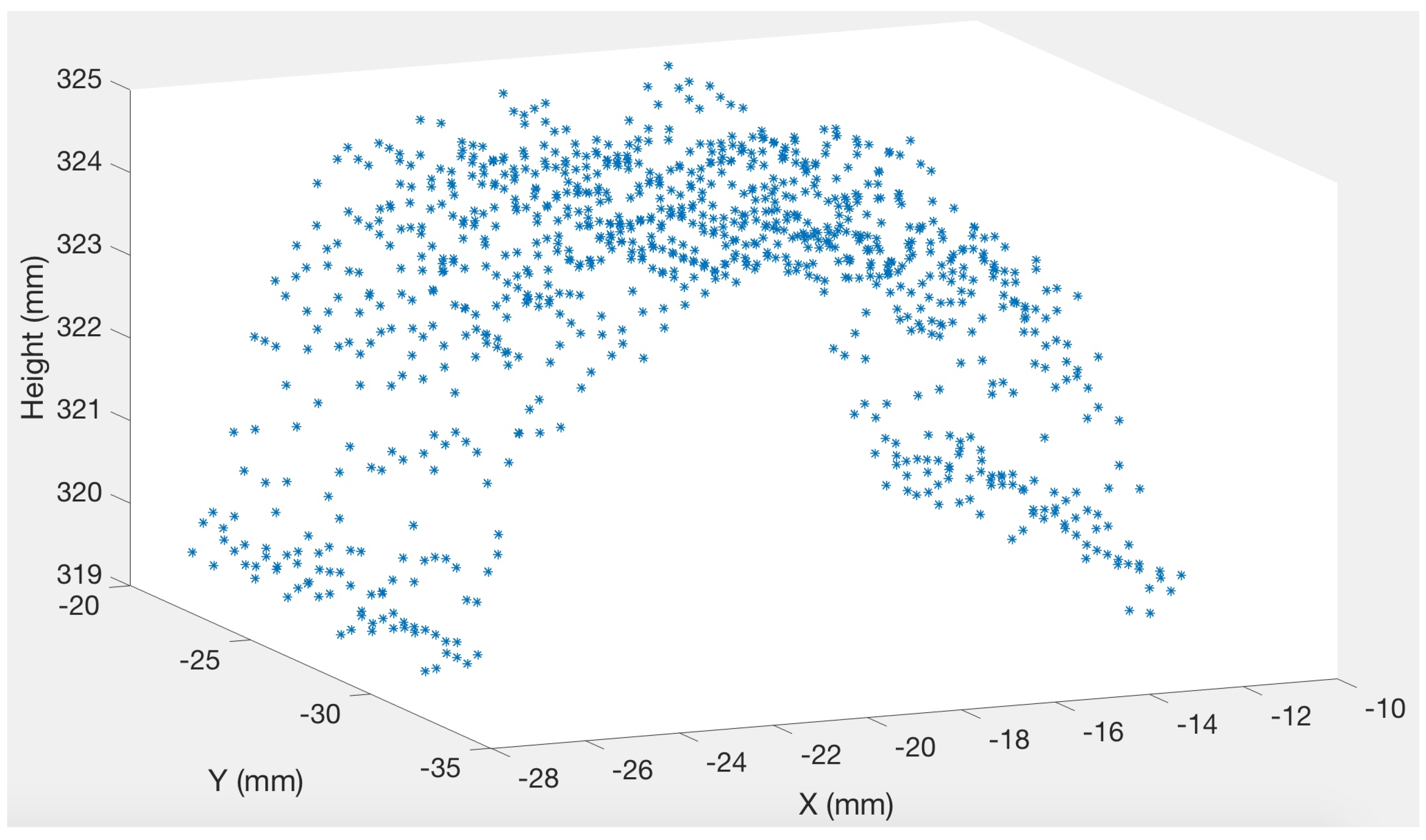

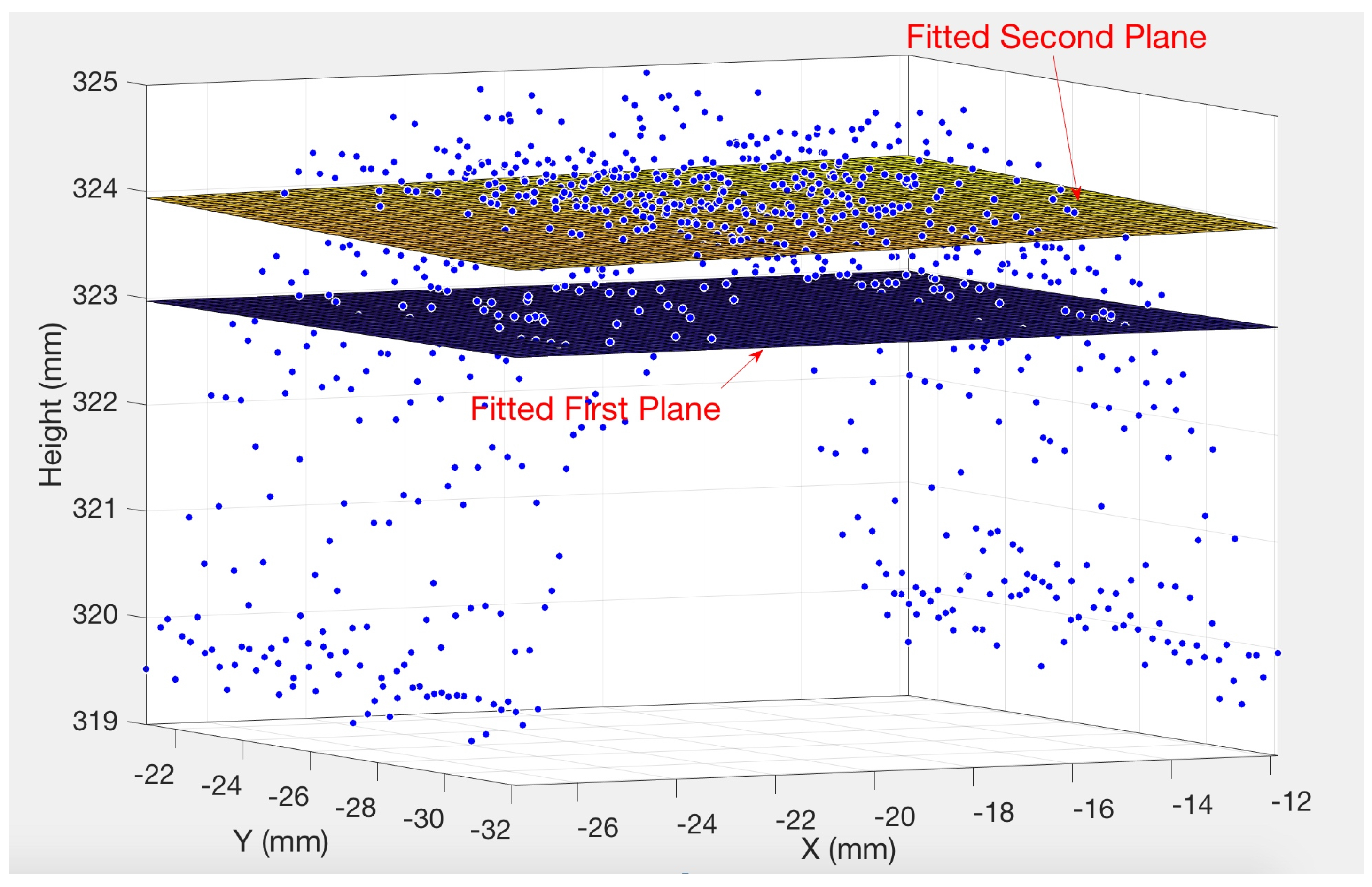

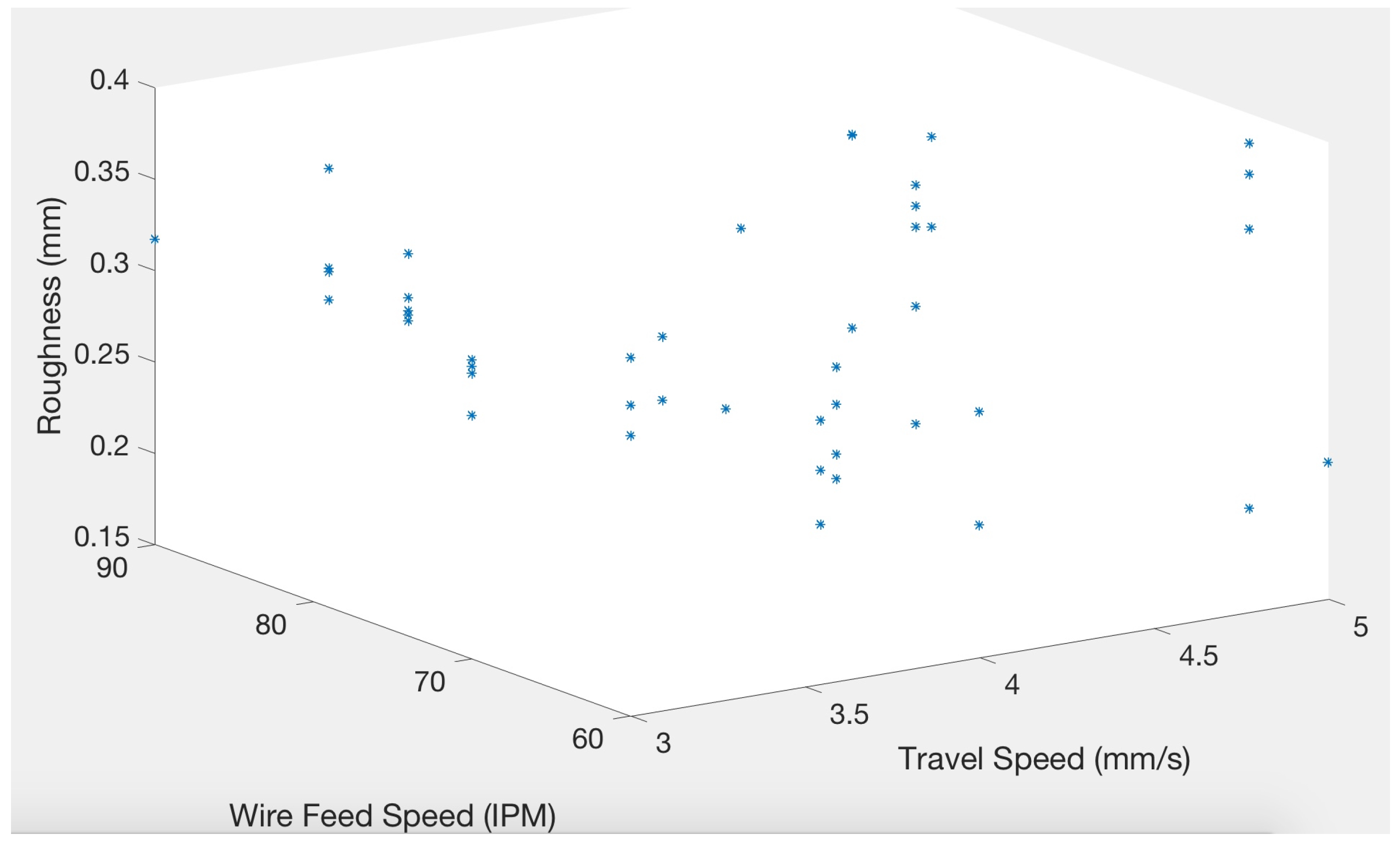

2.2. Data Collection and Roughness Measurement

2.3. Modeling Method

3. Results and Discussions

| Algorithm 1: Model Construction and Testing Procedures Based on GPR. |

procedure Read experimental datasets from a file Randomly divide the datasets into 40 training datasets and 5 testing datasets Construct a model based on GPR using the training datasets loop the 40 training datasets: Input the robotic WAAM process parameters in the training dataset into the constructed model and obtain the predicted top surface roughness Compute RMS error using the predicted top surface roughness and the actual top surface roughness Record the maximum top surface roughness goto loop. loop the 5 testing datasets: Input the robotic WAAM process parameters in the testing dataset into the constructed model and obtain the predicted top surface roughness Compute the RMS error using the predicted top surface roughness and the actual top surface roughness Record the maximum top surface roughness goto loop. close |

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Li, Y.; Su, C.; Zhu, J. Comprehensive review of wire arc additive manufacturing: Hardware system, physical process, monitoring, property characterization, application and future prospects. Results Eng. 2022, 13, 100330. [Google Scholar] [CrossRef]

- Popov, V.V.; Fleisher, A. Hybrid additive manufacturing of steels and alloys. Manuf. Rev. 2020, 7, 6. [Google Scholar] [CrossRef]

- Ding, D.; He, F.; Yuan, L.; Pan, Z.; Wang, L.; Ros, M. The first step towards intelligent wire arc additive manufacturing: An automatic bead modelling system using machine learning through industrial information integration. J. Ind. Inf. Integr. 2021, 23, 100218. [Google Scholar] [CrossRef]

- Yaseer, A.; Chen, H. Machine learning based layer roughness modeling in robotic additive manufacturing. J. Manuf. Process. 2021, 70, 543–552. [Google Scholar] [CrossRef]

- Dordlofva, C.; Torlind, P. Evaluating design uncertainties in additive manufacturing using design artefacts: Examples from space industry. Des. Sci. 2020, 6, e12. [Google Scholar] [CrossRef]

- Yehorov, Y.; da Silva, L.J.; Scotti, A. Balancing WAAM Production Costs and Wall Surface Quality through Parameter Selection: A Case Study of an Al-Mg5 Alloy Multilayer-Non-Oscillated Single Pass Wall. J. Manuf. Mater. Process. 2019, 3, 32. [Google Scholar] [CrossRef]

- Li, B.; Wang, B.; Zhu, G.; Zhang, L.; Lu, B. Low-Roughness-Surface Additive Manufacturing of Metal-Wire Feeding with Small Power. Materials 2021, 14, 4265. [Google Scholar] [CrossRef]

- Urhal, P.; Weightman, A.; Diver, C.; Bartolo, P. Robot assisted additive manufacturing: A review. Robot. Comput.-Integr. Manuf. 2019, 59, 335–345. [Google Scholar] [CrossRef]

- Yaseer, A.; Chen, H. A Review of Path Planning for Wire Arc Additive Manufacturing (WAAM). J. Adv. Manuf. Syst. 2021, 20, 589–609. [Google Scholar] [CrossRef]

- Suryakumar, S.; Karunakaran, K.; Bernard, A.; Chandrasekhar, U.; Raghavender, N.; Sharma, D. Weld bead modeling and process optimization in Hybrid Layered Manufacturing. Comput.-Aided Des. 2011, 43, 331–344. [Google Scholar] [CrossRef]

- Aldalur, E.; Veiga, F.; Suarez, A.; Bilbao, J.; Lamikiz, A. Analysis of the Wall Geometry with Different Strategies for High Deposition Wire Arc Additive Manufacturing of Mild Steel. Metals 2020, 10, 892. [Google Scholar] [CrossRef]

- Deng, Y.; Mao, Z.; Yang, N.; Niu, X.; Lu, X. Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting. Materials 2020, 13, 1601. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Lu, Z.; Li, F.; Chen, S. Predictive Modeling of Surface Roughness Based on Response Surface Methodology after WAAM. In Proceedings of the International Conference on Electronical, Mechanical and Materials Engineering (ICE2ME 2019), Wuhan, China, 20–21 January 2019. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting. Appl. Sci. 2019, 9, 1256. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S. Modelling and prediction of surface roughness in wire arc additive manufacturing using machine learning. J. Intell. Manuf. 2021, 1–16. [Google Scholar] [CrossRef]

- Vasudevan, S.; Ramos, F.; Nettleton, E.; Durrant-Whyte, H. Gaussian process modeling of large-scale terrain. J. Field Robot. 2009, 26, 812–840. [Google Scholar] [CrossRef]

- Frank, B.; Stachniss, C.; Abdo, N.; Burgard, W. Using Gaussian Process Regression for Efficient Motion Planning in Environments with Deformable Objects. In Proceedings of the Twenty-Fifth AAAI Conference on Artificial Intelligence, San Francisco, CA, USA, 7–8 August 2011. [Google Scholar]

- Schneider, M.; Ertel, W. Robot Learning by Demonstration with local Gaussian process regression. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 255–260. [Google Scholar]

- Jadaliha, M.; Xu, Y.; Choi, J.; Johnson, N.; Li, W. Gaussian Process Regression for Sensor Networks Under Localization Uncertainty. Signal Process. IEEE Trans. 2013, 61, 223–237. [Google Scholar] [CrossRef]

- Grancharova, A.; Kocijan, J.; Johansen, T.A. Explicit stochastic predictive control of combustion plants based on Gaussian process models. Automatica 2008, 44, 1621–1631. [Google Scholar] [CrossRef]

- Jiang, J.; Ma, Y. Path Planning Strategies to Optimize Accuracy, Quality, Build Time and Material Use in Additive Manufacturing: A Review. Micromachines 2020, 11, 633. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, G.; Li, Z.; Xiao, W. A Path Planning Method for Robotic Wire and Arc Additive Manufacturing of Thin-Walled Structures with Varying Thickness. IOP Conf. Ser. Mater. Sci. Eng. 2019, 470, 012018. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Process Planning Strategy for Wire and Arc Additive Manufacturing. In Robotic Welding, Intelligence and Automation. RWIA 2014. Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2014; Volume 363. [Google Scholar]

- Chen, H.; Zhang, B.; Fuhlbrigge, T. Welding Process Optimization Methods: A Review. Trans. Intell. Weld. Manuf. 2020, 3–21. [Google Scholar] [CrossRef]

| Name | Equation |

|---|---|

| Noise Function | |

| Linear Function | |

| Squared Exponential Function | |

| Gaussian Radial Basis Function | |

| Sigmoid Function | |

| Polynomial Function |

| Input Parameters | Minimum Values | Maximum Values |

|---|---|---|

| (inches/minute) | 60 | 90 |

| (mm/s) | 3 | 5 |

| (mm) | 2 | 4 |

| (mm) | 6 | 12 |

| Trial | RMS1 (m) | Max1 (m) | RMS2 (m) | Max2 (m) |

|---|---|---|---|---|

| 1 | 0.064 | 0.178 | 22.830 | 41.001 |

| 2 | 0.096 | 0.269 | 27.102 | 45.626 |

| 3 | 0.834 | 2.153 | 22.238 | 34.499 |

| 4 | 0.065 | 0.149 | 28.407 | 46.845 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen , H.; Yaseer, A.; Zhang , Y. Top Surface Roughness Modeling for Robotic Wire Arc Additive Manufacturing. J. Manuf. Mater. Process. 2022, 6, 39. https://doi.org/10.3390/jmmp6020039

Chen H, Yaseer A, Zhang Y. Top Surface Roughness Modeling for Robotic Wire Arc Additive Manufacturing. Journal of Manufacturing and Materials Processing. 2022; 6(2):39. https://doi.org/10.3390/jmmp6020039

Chicago/Turabian StyleChen , Heping, Ahmed Yaseer, and Yuming Zhang . 2022. "Top Surface Roughness Modeling for Robotic Wire Arc Additive Manufacturing" Journal of Manufacturing and Materials Processing 6, no. 2: 39. https://doi.org/10.3390/jmmp6020039

APA StyleChen , H., Yaseer, A., & Zhang , Y. (2022). Top Surface Roughness Modeling for Robotic Wire Arc Additive Manufacturing. Journal of Manufacturing and Materials Processing, 6(2), 39. https://doi.org/10.3390/jmmp6020039