On the Processability and Microstructural Evolution of CuCrZr in Multilayer Laser-Directed Energy Deposition Additive Manufacturing via Statistical and Experimental Methods

Abstract

:1. Introduction

- The successful deposition of multilayer CuCrZr using LDED, which has not been previously reported in the literature.

- Identification of various types of defects in the LDED process of CuCrZr and the development of a comprehensive processability map.

- Characterization of the microstructure of selected samples fabricated with different process parameters to understand the influence of these parameters, and establishment of correlations between the process parameters and the evolution of microstructure.

2. Materials and Methods

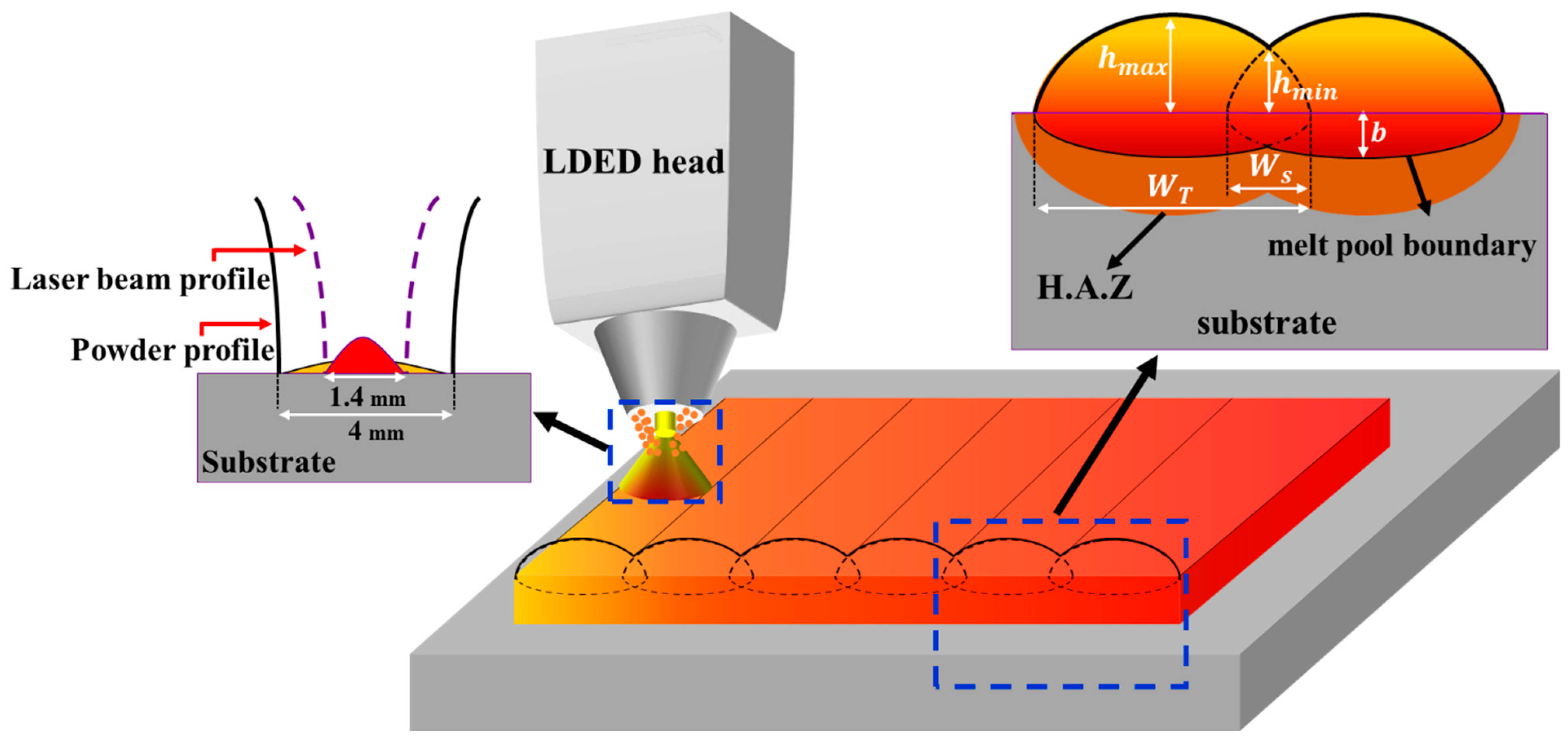

2.1. LDED Process

2.2. Macro- and Micro-Scale Characterization

2.3. Porosity Measurements (XCT)

2.4. Statistical Analysis

3. Results and Discussions

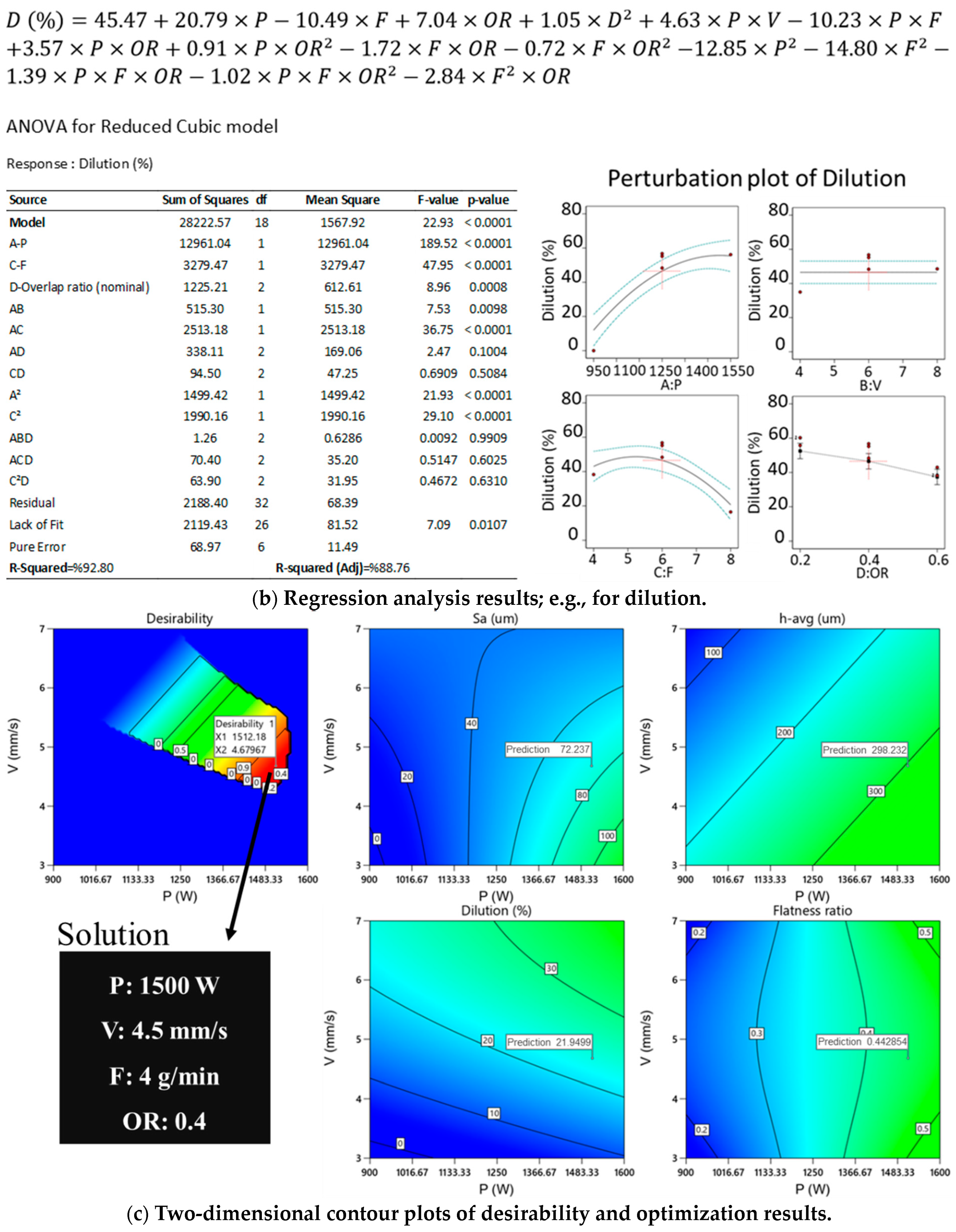

3.1. Process Parameter Optimization of Single-Layer Multitracks

3.2. Multi-Layer Build-Up and Trajectory Planning

3.3. Defects and XCT Results

Vaporization

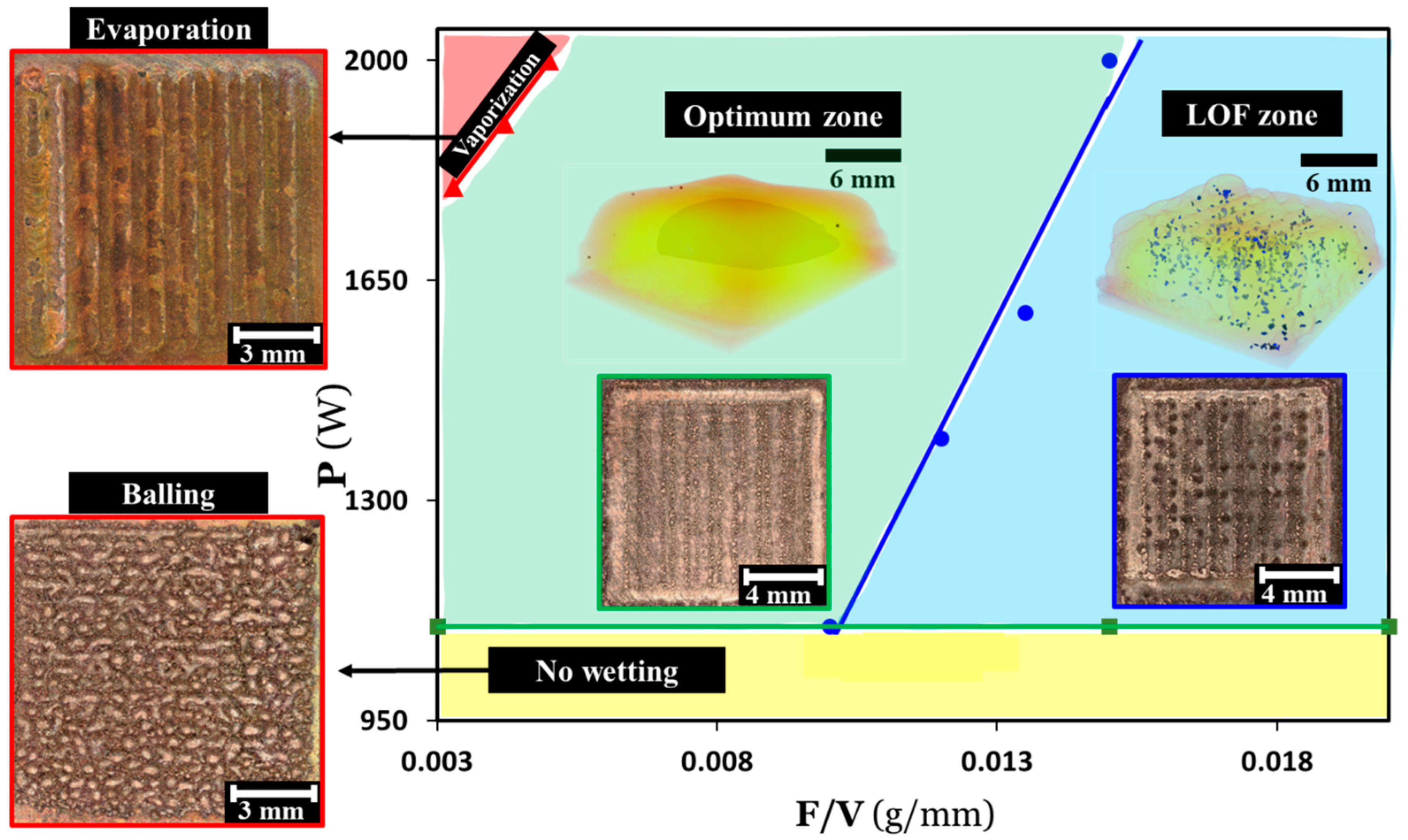

3.4. General Processing Map

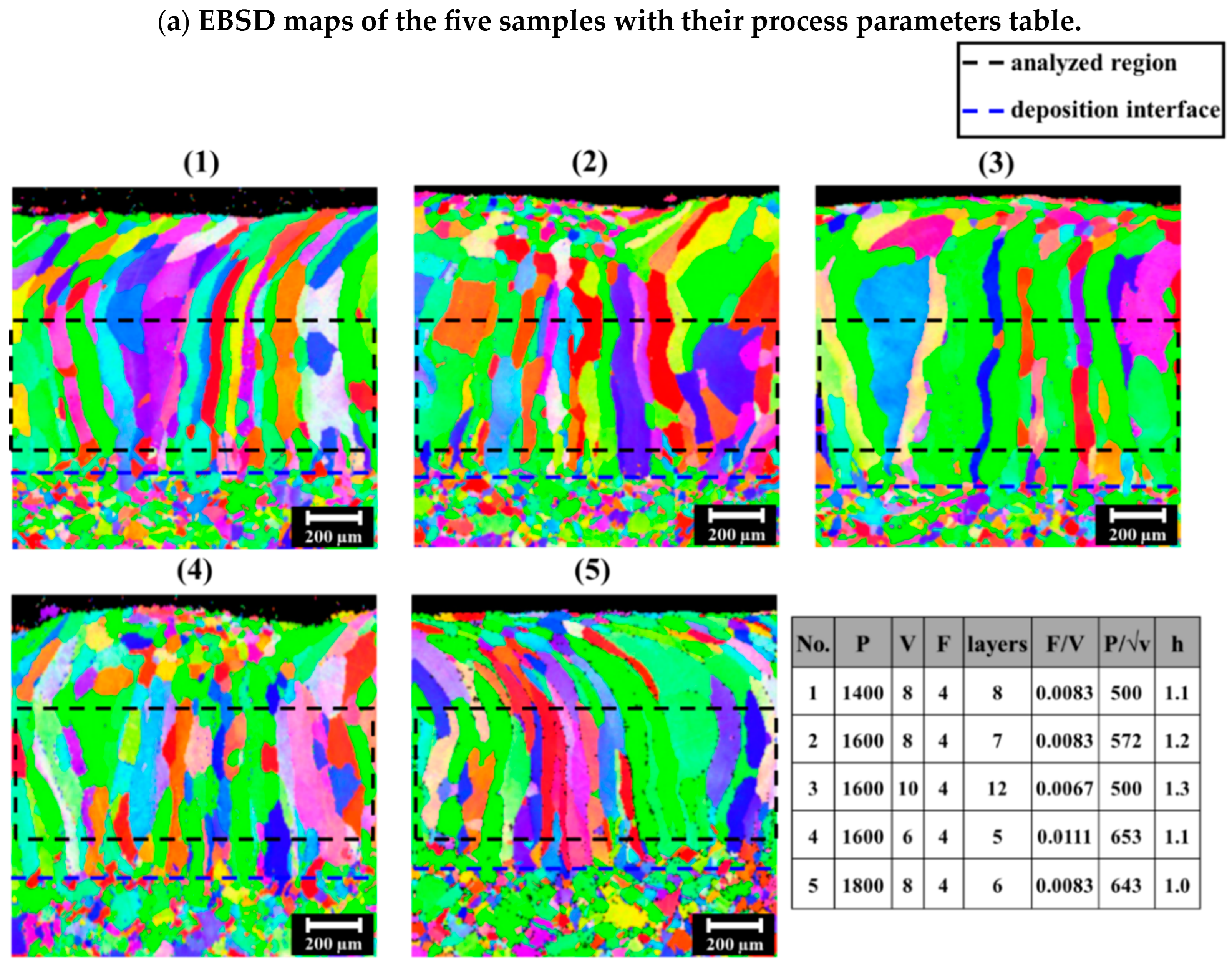

3.5. Microstructural Results

4. Conclusions

- To properly wet the substrate and form a stable melt pool, the minimum laser power of 1100 W is needed, otherwise the balling defect happens as a result of negative values of spreading factors, S.

- The optimum set of parameters for single-layer multitrack is a laser of 1500 W, powder feed rate of 4 g/min, scanning speed of 4.5 mm/s, and overlap ratio of 0.4. The observed responses closely align with the values predicted by the model, demonstrating approximately 95% confidence intervals for both lower and upper bounds.

- Tool path trajectory planning has been conducted to reach the proper build-up strategy that leads to acceptable shape accuracy. For the infill of the geometry, the zigzag strategy with 90° rotation of deposition direction in which the start point also rotates between layers is considered. Further, to compensate for the unfilled perimeter, profile contouring around the perimeter after each infill deposition was considered with a radial pathway at the corners to avoid the bumps that happen as a result of acceleration and deceleration of the robotic arm.

- In order to avoid the LOF defect, the melt pools need to properly overlap each other, both horizontally and vertically. In that regard, the LOF quadrant criterion is employed based on h/b and H/W that define the amount of vertical and horizontal overlap, respectively. Based on the XCT scan results, it was shown that as far as the criterion of is met, no LOF would happen in the multilayer cuboid samples. Therefore, per amount of fed powder to the melt pool (F/V) minimum energy (P) is needed to reach sufficient values of melt pool depth (b) and width (W) to avoid LOF.

- While insufficient values of P per F/V results in LOF defect, too high values are also deleterious and lead to the vaporization of fed powders and substrate material.

- The general processability map was drawn by putting all the data together and based on the P against F/V parameters. The optimum processing window is defined by green color in which only a small amount of gas porosity defects can exist, which are inevitable and common in the LDED process.

- The grain structure of the deposition mainly consists of big columnar grains that nucleated from the fusion zone and grew up to the very top layer through the epitaxial grain growth mechanism. Yet on the very top layer and close to the surface, the fine and equiaxed grain structure has been observed due to the relatively lower values of G vs. R and more nucleation sites. Depositing the new layer provides reheating and cooling for the formerly deposited layer, which leads to grain growth and increases the grain size.

- Utilizing the combinations of process parameters from the optimum processing window for the same deposition height, it was shown that the number of layers as well as the F/V value are influencing the grain size. While the former affects the amount of reheating in the previously deposited material, the latter provides the number of nucleation sites and therefore the number of grains. The higher the number of layers and the lower F/V, the bigger the grain size.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LDED | Laser-directed energy deposition |

| SEM | scanning electron microscope |

| EBSD | electron backscatter diffraction |

| EDS | energy dispersive X-ray spectroscope |

| HAZ | heat affected zone |

| AM | additive manufacturing |

| DOE | design of experiment |

| CCD | central composite design |

| RSM | response surface methodology |

References

- Toyserkani, E.; Sarker, D.; Ibhadode, O.O.; Liravi, F.; Russo, P.; Taherkhani, K. Metal Additive Manufacturing; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Guo, C.; He, S.; Yue, H.; Li, Q.; Hao, G. Prediction modelling and process optimization for forming multi-layer cladding structures with laser directed energy deposition. Opt. Laser Technol. 2021, 134, 106607. [Google Scholar] [CrossRef]

- Chen, C.; Lian, G.; Jiang, J.; Wang, Q. Simplification and experimental investigation of geometrical surface smoothness model for multi-track laser cladding processes. J. Manuf. Process. 2018, 36, 621–628. [Google Scholar] [CrossRef]

- Ng, G.K.L.; Jarfors, A.E.W.; Bi, G.; Zheng, H.Y. Porosity formation and gas bubble retention in laser metal deposition. Appl. Phys. A 2009, 97, 641–649. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Cunningham, R.W. Defect Formation Mechanisms in Powder-Bed Metal Additive Manufacturing. Doctoral Dissertation, Carnegie Mellon University, Pittsburgh, PA, USA, 2018. [Google Scholar]

- Tang, M.; Pistorius, P.C.; Beuth, J.L. Prediction of lack-of-fusion porosity for powder bed fusion. Addit. Manuf. 2017, 14, 39–48. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Kiani, P.; Dupuy, A.D.; Ma, K.; Schoenung, J.M. Directed energy deposition of AlSi10Mg: Single track nonscalability and bulk properties. Mater. Des. 2020, 194, 108847. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Nankali, M.; Akbari, J.; Moradi, M.; Beiranvand, Z.M. Effect of laser additive manufacturing parameters on hardness and geometry of Inconel 625 parts manufactured by direct laser metal deposition. Optik 2022, 249, 168193. [Google Scholar] [CrossRef]

- Mortello, M.; Casalino, G. Transfer mode effects on Ti6Al4V wall building in wire laser additive manufacturing. Manuf. Lett. 2021, 28, 17–20. [Google Scholar] [CrossRef]

- Bonesso, M.; Rebesan, P.; Gennari, C.; Mancin, S.; Dima, R.; Pepato, A.; Calliari, I. Effect of particle size distribution on laser powder bed fusion manufacturability of copper. Berg Huettenmaenn. Mon. 2021, 166, 256–262. [Google Scholar] [CrossRef]

- Agostinetti, P.; Benedetti, E.; Bonifetto, R.; Bonesso, M.; Cavenago, M.; Bello, S.D.; Palma, M.D.; D’Ambrosio, D.; Dima, R.; Favero, G.; et al. Improved Conceptual Design of the Beamline for the DTT Neutral Beam Injector. IEEE Trans. Plasma Sci. 2022, 50, 4027–4032. [Google Scholar] [CrossRef]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and mechanical properties of additive manufactured copper alloy. Mater. Lett. 2016, 179, 38–41. [Google Scholar] [CrossRef]

- Guan, P.; Chen, X.; Liu, P.; Sun, F.; Zhu, C.; Zhou, H.; Fu, S.; Wu, Z.; Zhu, Y. Effect of selective laser melting process parameters and aging heat treatment on properties of CuCrZr alloy. Mater. Res. Exp. 2019, 6, 1165–1166. [Google Scholar] [CrossRef]

- Lassègue, P.; Salvan, C.; De Vito, E.; Soulas, R.; Herbin, M.; Hemberg, A.; Godfroid, T.; Baffie, T.; Roux, G. Laser powder bed fusion (L-PBF) of Cu and CuCrZr parts: Influence of an absorptive physical vapor deposition (PVD) coating on the printing process. Addit. Manuf. 2021, 39, 101888. [Google Scholar] [CrossRef]

- Bergström, D.; Powell, J.; Kaplan, A.F.H. Absorptance of nonferrous alloys to Nd:YLF and Nd:YAG laser light at room temperature. Appl. Opt. 2007, 46, 1290–1301. [Google Scholar] [CrossRef]

- Ordás, N.; Portolés, L.; Azpeleta, M.; Gómez, A.; Blasco, J.R.; Martinez, M.; Ureña, J.; Iturriza, I. Development of CuCrZr via Electron Beam Powder Bed Fusion (EB-PBF). J. Nucl. Mater. 2021, 548, 152841. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protz, C.S. Technology advancements for channel wall nozzle manufacturing in liquid rocket engines. Acta Astronaut. 2020, 174, 148–158. [Google Scholar] [CrossRef]

- Gradl, P.R.; Greene, S.E.; Protz, C.; Bullard, B.; Buzzell, J.; Garcia, C.; Wood, J.; Osborne, R.; Hulka, J.; Cooper, K.G. Additive Manufacturing of Liquid Rocket Engine Combustion Devices: A Summary of Process Developments and Hot-Fire Testing Results. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Horn, T.J.; Gamzina, D. Additive Manufacturing of Copper and Copper Alloys; ASM International: Novelty, OH, USA, 2020; pp. 388–418. [Google Scholar]

- Zardoshtian, A.; Ansari, M.; Esmaeilzadeh, R.; Keshavarzkermani, A.; Jahed, H.; Toyserkani, E. Laser-directed energy deposition of CuCrZr alloy: From statistical process parameter optimization to microstructural analysis. Int. J. Adv. Manuf. Technol. 2023, 126, 4407–4418. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, M. Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd:YAG laser. Opt. Lasers Eng. 2012, 50, 985–995. [Google Scholar] [CrossRef]

- Ansari, M.; Mohamadizadeh, A.; Huang, Y.; Paserin, V.; Toyserkani, E. Laser directed energy deposition of water-atomized iron powder: Process optimization and microstructure of single-tracks. Opt. Laser Technol. 2019, 112, 485–493. [Google Scholar] [CrossRef]

- Ansari, M.; Razavi, R.S.; Barekat, M. An empirical-statistical model for coaxial laser cladding of NiCrAlY powder on Inconel 738 superalloy. Opt. Laser Technol. 2016, 86, 136–144. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Wang, M.; Kashaev, N. On the optimal process window for powder-based laser-directed energy deposition of AA7050 under different robot programs and scanning strategies. J. Manuf. Process. 2023, 90, 286–299. [Google Scholar] [CrossRef]

- Gu, D.D.; Shen, Y.F. Influence of phosphorus element on direct laser sintering of multicomponent Cu-based metal powder. Metall. Mater. Trans. B 2006, 37, 967–977. [Google Scholar] [CrossRef]

- Das, S. Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- Bunnell, D.E. Fundamentals of Selective Laser Sintering of Metals; The University of Texas at Austin: Austin, TX, USA, 1995. [Google Scholar]

- Grange, D.; Queva, A.; Guillemot, G.; Bellet, M.; Bartout, J.D.; Colin, C. Effect of processing parameters during the laser beam melting of Inconel 738: Comparison between simulated and experimental melt pool shape. J. Mater. Process. Technol. 2021, 289, 116897. [Google Scholar] [CrossRef]

- Wei, H.L.; Mukherjee, T.; Debroy, T. Grain growth modeling for additive manufacturing of nickel based superalloys. In Proceedings of the 6th International Conference on Recrystallization and Grain Growth (ReX&GG 2016), Pittsburgh, PA, USA, 17–21 July 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 265–269. [Google Scholar]

- Wei, H.L.; Knapp, G.L.; Mukherjee, T.; DebRoy, T. Three-dimensional grain growth during multi-layer printing of a nickel-based alloy Inconel 718. Addit. Manuf. 2019, 25, 448–459. [Google Scholar] [CrossRef]

- Ansari, M.; Martinez-Marchese, A.; Khamooshi, M.; Keshavarzkermani, A.; Esmaeilizadeh, R.; Toyserkani, E. Analytical modeling of multi-track powder-fed laser directed energy deposition: On the relationships among process, deposition dimensions, and solidification microstructure in additively manufactured near-β titanium alloy. J. Mater. Process. Technol. 2022, 306, 117643. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Marzbanrad, E.; Esmaeilizadeh, R.; Mahmoodkhani, Y.; Ali, U.; Enrique, P.D.; Zhou, N.Y.; Bonakdar, A.; Toyserkani, E. An investigation into the effect of process parameters on melt pool geometry, cell spacing, and grain refinement during laser powder bed fusion. Opt. Laser Technol. 2019, 116, 83–91. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Sadowski, M.; Ladani, L. Direct metal laser melting of Inconel 718: Process impact on grain formation and orientation. J. Alloys Compd. 2018, 736, 297–305. [Google Scholar] [CrossRef]

- Sreekanth, S.; Ghassemali, E.; Hurtig, K.; Joshi, S.; Andersson, J. Effect of Direct Energy Deposition Process Parameters on Single-Track Deposits of Alloy 718. Metals 2020, 10, 96. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Esmaeilizadeh, R.; Ali, U.; Enrique, P.D.; Mahmoodkhani, Y.; Zhou, N.Y.; Bonakdar, A.; Toyserkani, E. Controlling mechanical properties of additively manufactured hastelloy X by altering solidification pattern during laser powder-bed fusion. Mater. Sci. Eng. A 2019, 762, 138081. [Google Scholar] [CrossRef]

| Track NO. | Process Parameters (Input Variables) | Geometrical Measurements (Output Responses) | ||||||

|---|---|---|---|---|---|---|---|---|

| P (W) | V (mm/s) | F (g/min) | OR | (µm) | Sa (µm) | D (%) | S | |

| 1 | 1250 | 6 | 6 | 0.2 | 91.15 | 17.37 | 55.75 | 0.57 |

| 2 | 950 | 4 | 4 | 0.2 | 60 | 41 | 0 | 1 |

| 3 | 1550 | 6 | 6 | 0.4 | 163.47 | 32.25 | 56.15 | 0.61 |

| 4 | 950 | 8 | 4 | 0.6 | 193.23 | 33.13 | 0 | 0.43 |

| 5 | 1250 | 6 | 6 | 0.6 | 232.39 | 47.13 | 38.39 | 0.52 |

| 6 | 1250 | 8 | 6 | 0.2 | 71.13 | 15.83 | 57.70 | 0.50 |

| 7 | 950 | 6 | 6 | 0.4 | 205.59 | 55.7 | 0 | 0.26 |

| 8 | 950 | 8 | 4 | 0.2 | 56.93 | 31.51 | 0 | 1 |

| 9 | 1250 | 6 | 6 | 0.4 | 122.90 | 27.1 | 48.30 | 0.63 |

| 10 | 950 | 4 | 8 | 0.4 | 282.35 | 88.12 | 0 | 0.51 |

| 11 | 1550 | 4 | 8 | 0.6 | 615.88 | 243.17 | 4.34 | 0.88 |

| 12 | 1550 | 4 | 4 | 0.4 | 88.92 | 22.64 | 54.17 | 0.64 |

| 13 | 950 | 6 | 6 | 0.6 | 313.47 | 60 | 0 | 0.44 |

| 14 | 1550 | 8 | 8 | 0.6 | 308.20 | 65.83 | 22.10 | 0.52 |

| 15 | 1250 | 8 | 6 | 0.4 | 102.92 | 20.21 | 48.53 | 0.57 |

| 16 | 1250 | 6 | 6 | 0.4 | 117.44 | 24.73 | 55.22 | 0.66 |

| 17 | 950 | 4 | 8 | 0.2 | 204.32 | 62.15 | 0 | 0.59 |

| 18 | 950 | 4 | 4 | 0.6 | 184.37 | 34.71 | 0 | 0.51 |

| 19 | 1250 | 4 | 6 | 0.4 | 162.44 | 29.81 | 34.98 | 0.56 |

| 20 | 1250 | 4 | 6 | 0.6 | 247.34 | 42.57 | 26.10 | 0.53 |

| 21 | 1550 | 4 | 8 | 0.4 | 387.72 | 91.31 | 6.73 | 0.59 |

| 22 | 1550 | 8 | 8 | 0.4 | 217.29 | 46.55 | 28.70 | 0.62 |

| 23 | 1550 | 6 | 6 | 0.6 | 231.85 | 46.88 | 47.44 | 0.59 |

| 24 | 1250 | 6 | 8 | 0.4 | 188.85 | 39.91 | 16.48 | 0.63 |

| 25 | 1250 | 6 | 4 | 0.4 | 122.01 | 19.79 | 38.27 | 0.52 |

| 26 | 950 | 8 | 8 | 0.2 | 314.77 | 72.25 | 0 | 0.35 |

| 27 | 950 | 4 | 8 | 0.6 | 613.93 | 167.2 | 0 | 0.60 |

| 28 | 1250 | 4 | 6 | 0.2 | 132.34 | 34.19 | 39.77 | 0.69 |

| 29 | 1250 | 6 | 6 | 0.2 | 95.90 | 22.5 | 60.16 | 0.66 |

| 30 | 1250 | 6 | 6 | 0.4 | 110.35 | 30.11 | 56.75 | 0.81 |

| 31 | 1550 | 4 | 8 | 0.2 | 268.99 | 81.82 | 9.42 | 0.69 |

| 32 | 1250 | 8 | 6 | 0.6 | 128.76 | 29.42 | 42.98 | 0.54 |

| 33 | 1250 | 6 | 8 | 0.6 | 393.95 | 124.56 | 8.64 | 0.74 |

| 34 | 950 | 8 | 8 | 0.6 | 1213.51 | 495.21 | 0 | 0.80 |

| 35 | 950 | 8 | 4 | 0.4 | 68.60 | 20.87 | 0 | 0.70 |

| 36 | 1550 | 8 | 4 | 0.4 | 70.18 | 15.77 | 71.27 | 0.67 |

| 37 | 1250 | 6 | 6 | 0.2 | 95.48 | 18 | 60.27 | 0.61 |

| 38 | 1250 | 6 | 6 | 0.6 | 192.06 | 45.45 | 42.99 | 0.79 |

| 39 | 950 | 8 | 8 | 0.4 | 408.05 | 106.92 | 0 | 0.48 |

| 40 | 950 | 4 | 4 | 0.4 | 96.73 | 26.44 | 0 | 0.59 |

| 41 | 1250 | 6 | 8 | 0.2 | 141.32 | 30.94 | 20.87 | 0.62 |

| 42 | 950 | 6 | 6 | 0.2 | 137.46 | 35.87 | 0 | 0.45 |

| 43 | 1550 | 6 | 6 | 0.2 | 97.60 | 21.79 | 68.20 | 0.73 |

| 44 | 1550 | 4 | 4 | 0.2 | 71.49 | 19.13 | 59.52 | 0.71 |

| 45 | 1550 | 8 | 4 | 0.6 | 154.72 | 25.1 | 52.95 | 0.55 |

| 46 | 1250 | 6 | 4 | 0.2 | 76.86 | 20.79 | 49.60 | 0.70 |

| 47 | 1550 | 8 | 4 | 0.2 | 59.02 | 11.96 | 74.68 | 0.56 |

| 48 | 1550 | 4 | 4 | 0.6 | 186.34 | 43.39 | 36.06 | 0.65 |

| 49 | 1250 | 6 | 4 | 0.6 | 213.10 | 50.9 | 26.19 | 0.60 |

| 50 | 1550 | 8 | 8 | 0.2 | 187.88 | 42.54 | 31.76 | 0.63 |

| 51 | 1250 | 6 | 6 | 0.6 | 235.54 | 52.49 | 38.078 | 0.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zardoshtian, A.; Esmaeilizadeh, R.; Ansari, M.; Keshavarz, M.K.; Jahed, H.; Toyserkani, E. On the Processability and Microstructural Evolution of CuCrZr in Multilayer Laser-Directed Energy Deposition Additive Manufacturing via Statistical and Experimental Methods. J. Manuf. Mater. Process. 2023, 7, 151. https://doi.org/10.3390/jmmp7040151

Zardoshtian A, Esmaeilizadeh R, Ansari M, Keshavarz MK, Jahed H, Toyserkani E. On the Processability and Microstructural Evolution of CuCrZr in Multilayer Laser-Directed Energy Deposition Additive Manufacturing via Statistical and Experimental Methods. Journal of Manufacturing and Materials Processing. 2023; 7(4):151. https://doi.org/10.3390/jmmp7040151

Chicago/Turabian StyleZardoshtian, Ali, Reza Esmaeilizadeh, Mazyar Ansari, Mohsen K. Keshavarz, Hamid Jahed, and Ehsan Toyserkani. 2023. "On the Processability and Microstructural Evolution of CuCrZr in Multilayer Laser-Directed Energy Deposition Additive Manufacturing via Statistical and Experimental Methods" Journal of Manufacturing and Materials Processing 7, no. 4: 151. https://doi.org/10.3390/jmmp7040151

APA StyleZardoshtian, A., Esmaeilizadeh, R., Ansari, M., Keshavarz, M. K., Jahed, H., & Toyserkani, E. (2023). On the Processability and Microstructural Evolution of CuCrZr in Multilayer Laser-Directed Energy Deposition Additive Manufacturing via Statistical and Experimental Methods. Journal of Manufacturing and Materials Processing, 7(4), 151. https://doi.org/10.3390/jmmp7040151