Theoretical Assessment of the Environmental Impact of the Preheating Stage in Thermoplastic Composite Processing: A Step toward Sustainable Manufacturing

Abstract

:1. Introduction

2. Goal and Scope

3. Inventory Analysis

3.1. Thermal Simulation of Preheating Stage

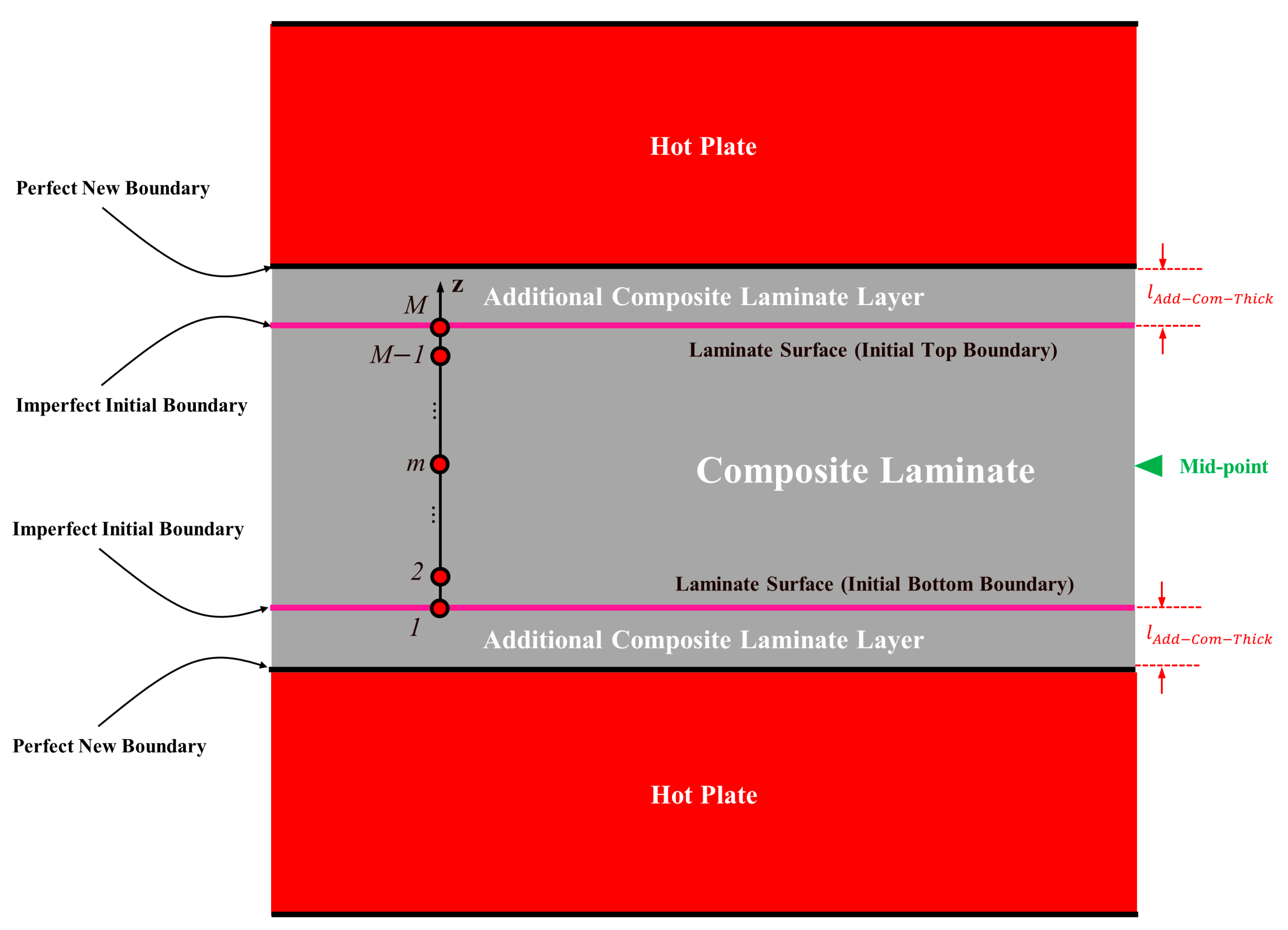

3.1.1. Analysis of Boundary Nodes

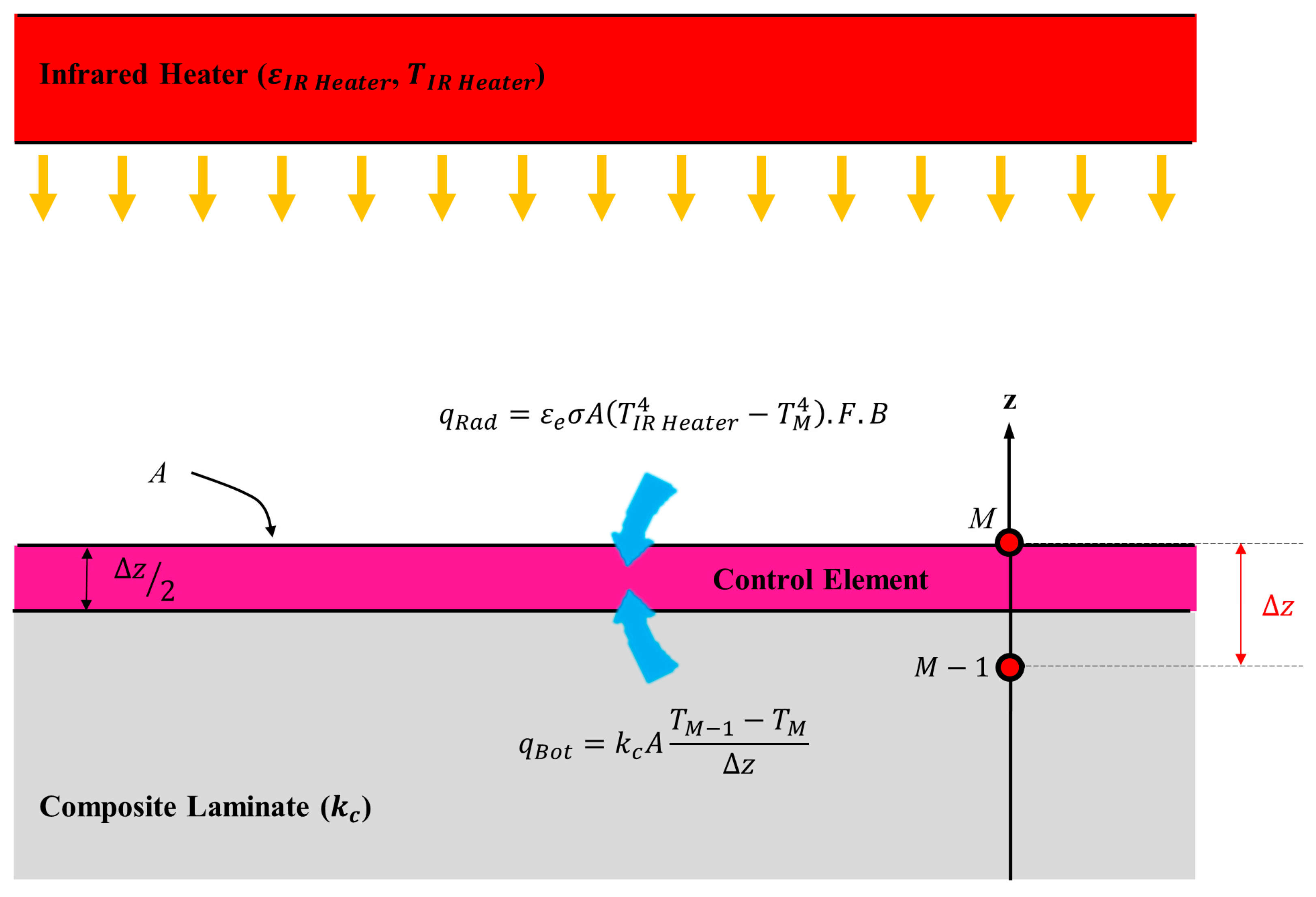

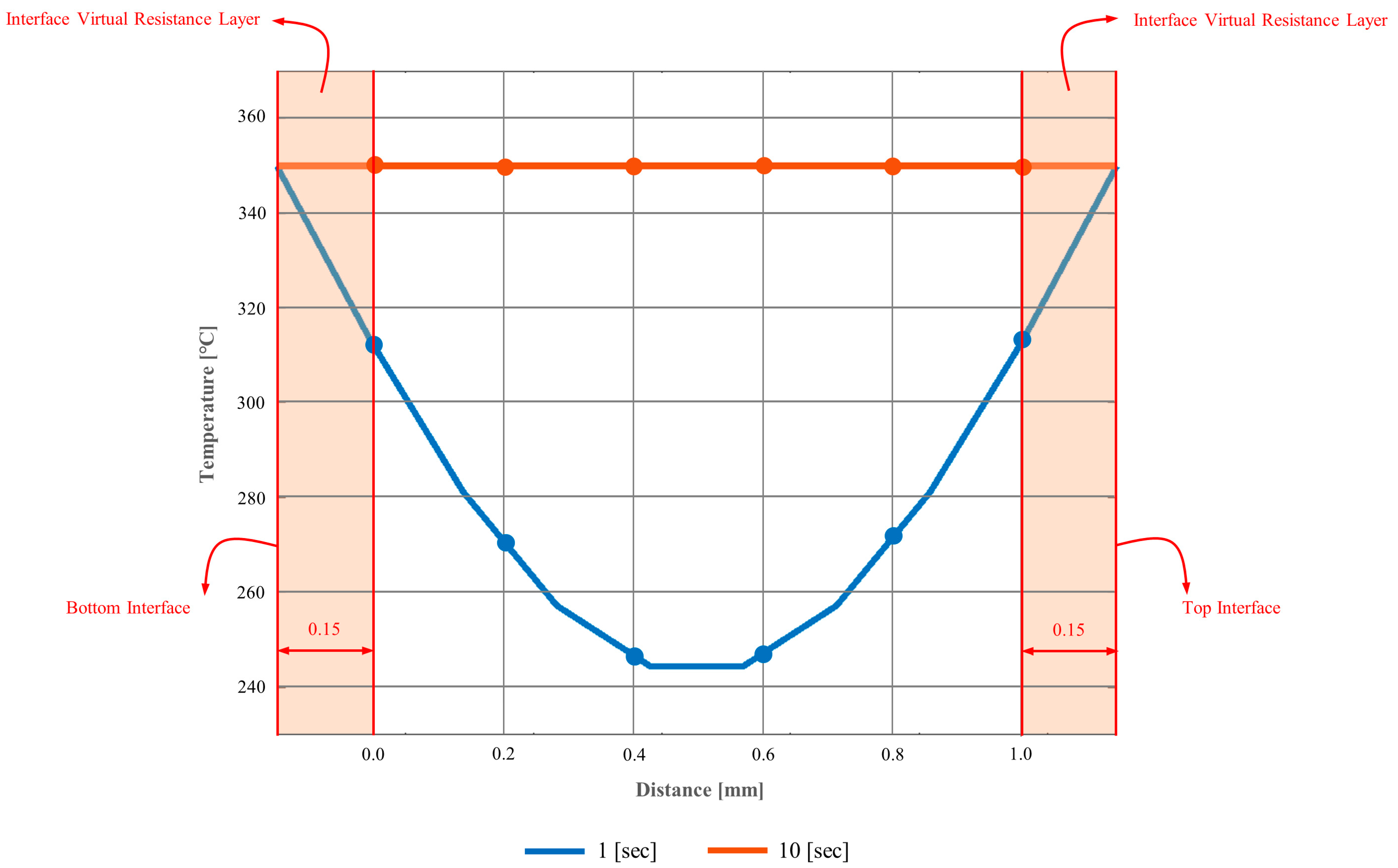

Boundary Nodes of the Conductive Mode of Preheating

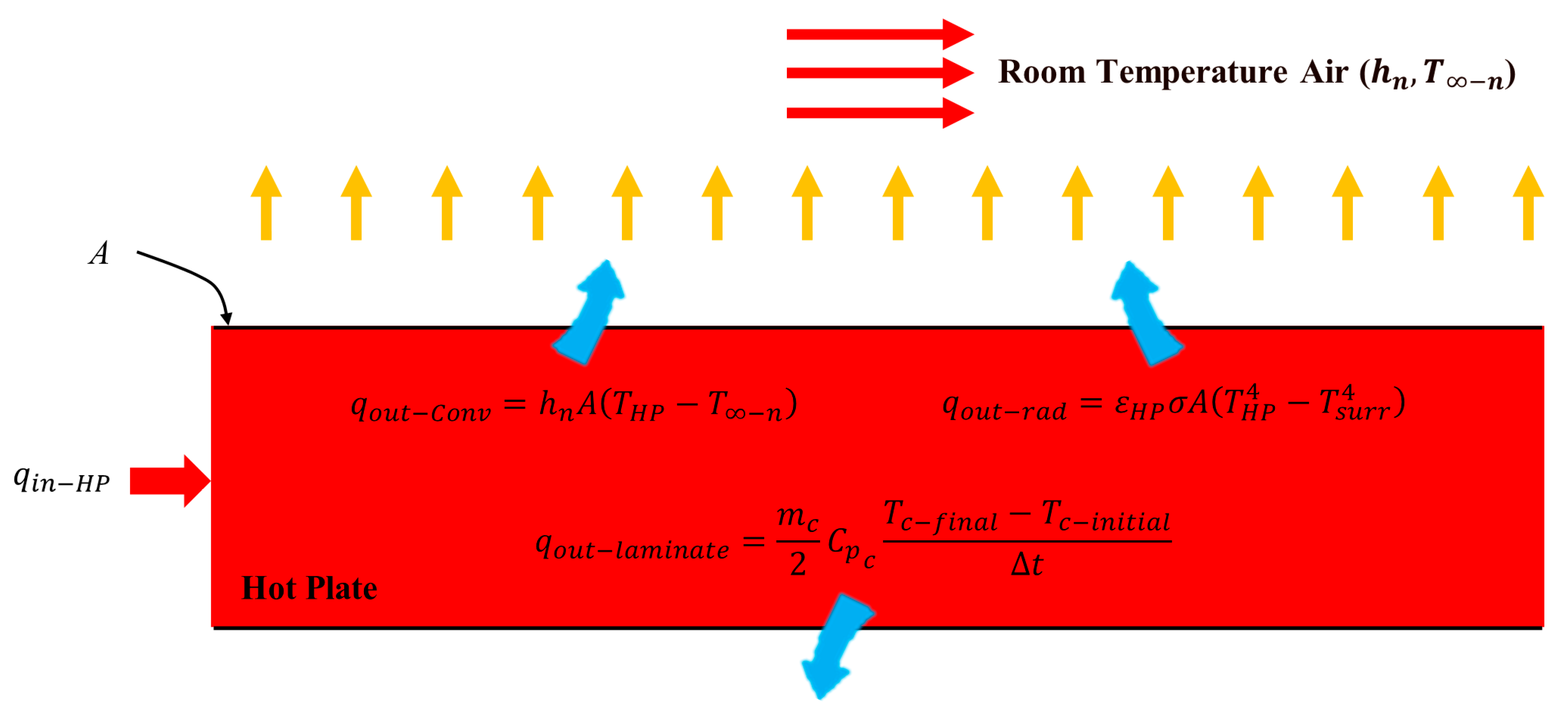

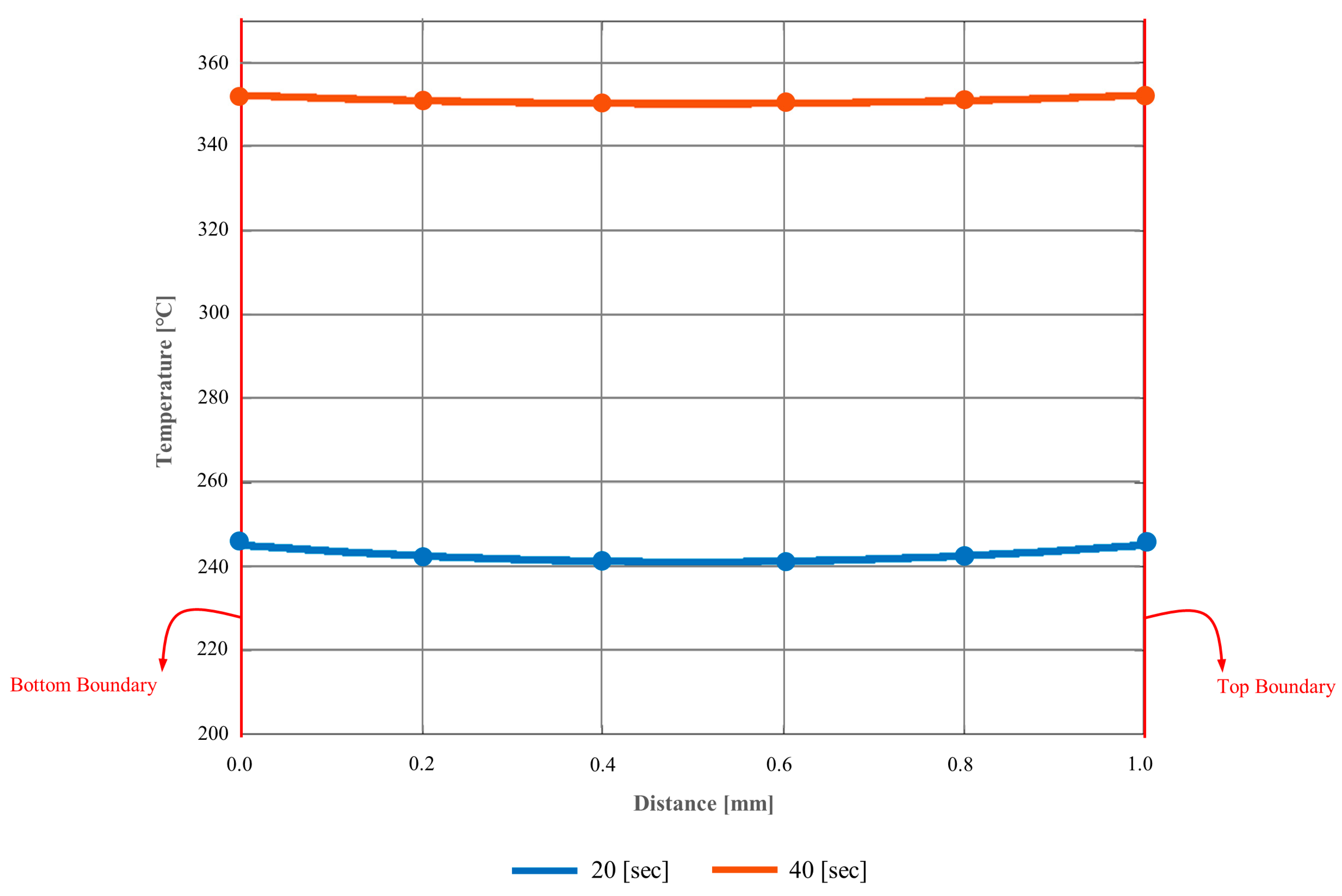

Boundary Nodes of the Convective Mode of Preheating

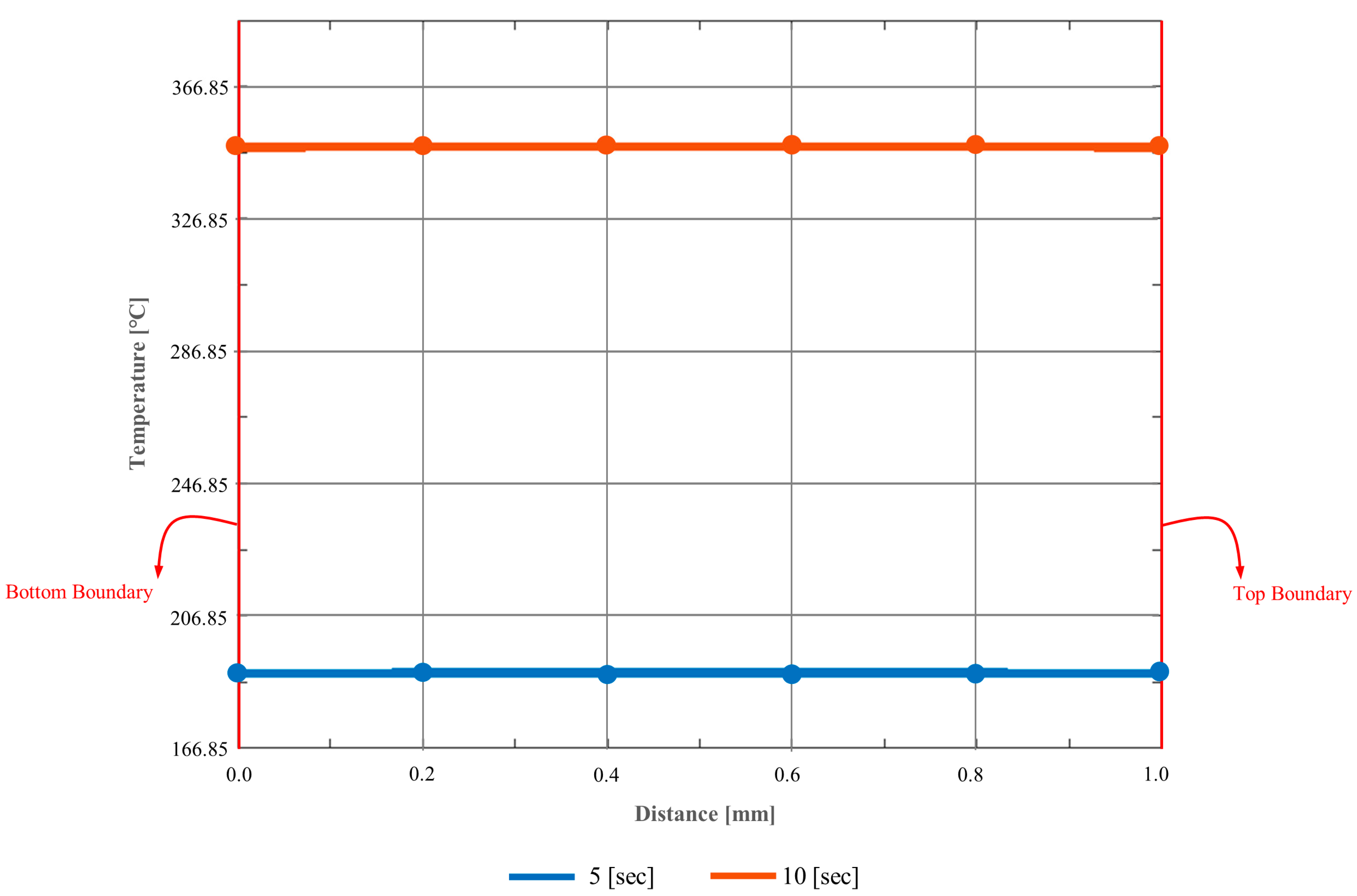

Boundary Nodes of the Radiative Mode of Preheating

3.1.2. Analysis of Interior Nodes

Interior Nodes of the Conductive and Convective Modes of Preheating

Interior Nodes of the Radiative Modes of Preheating

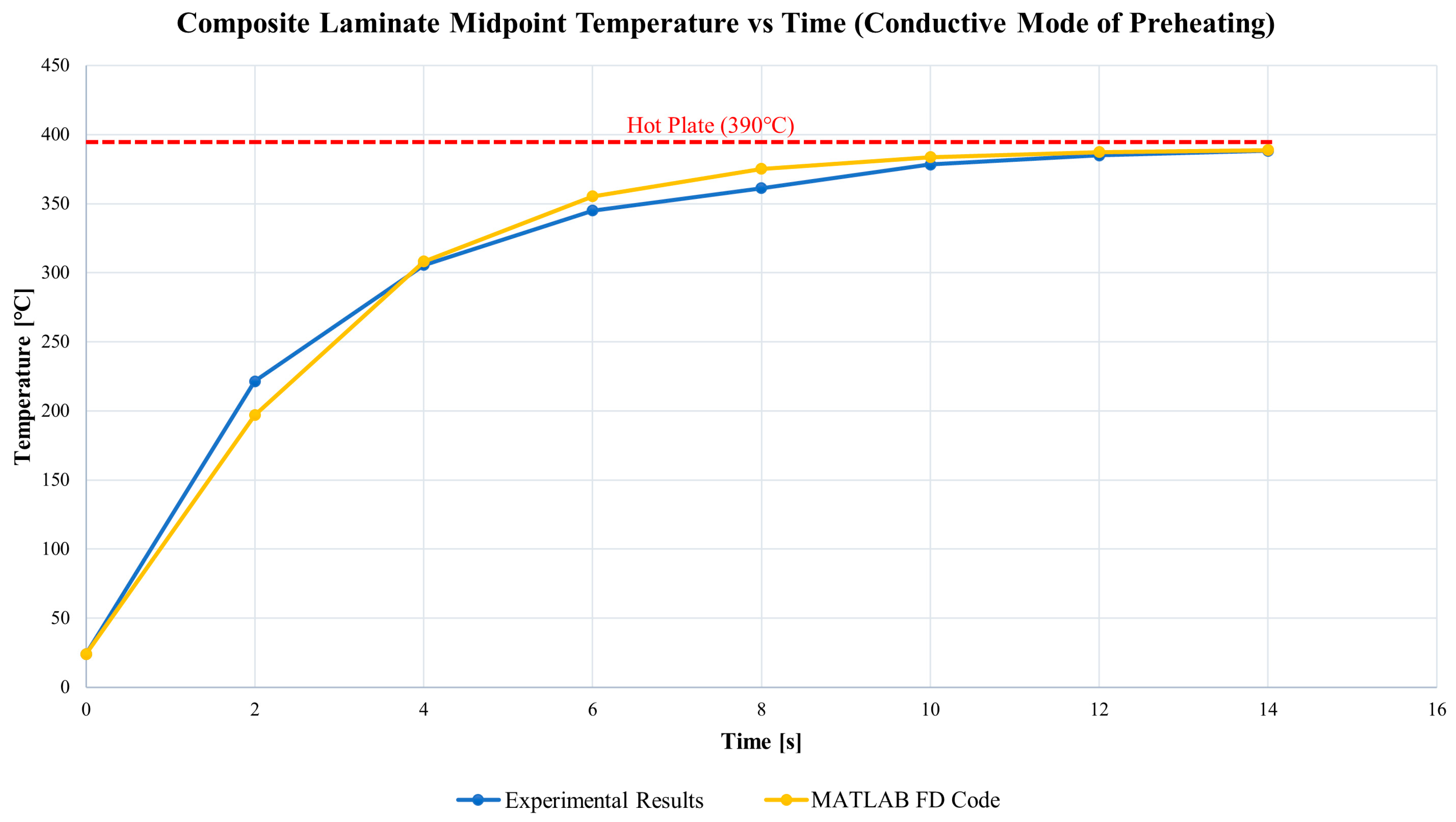

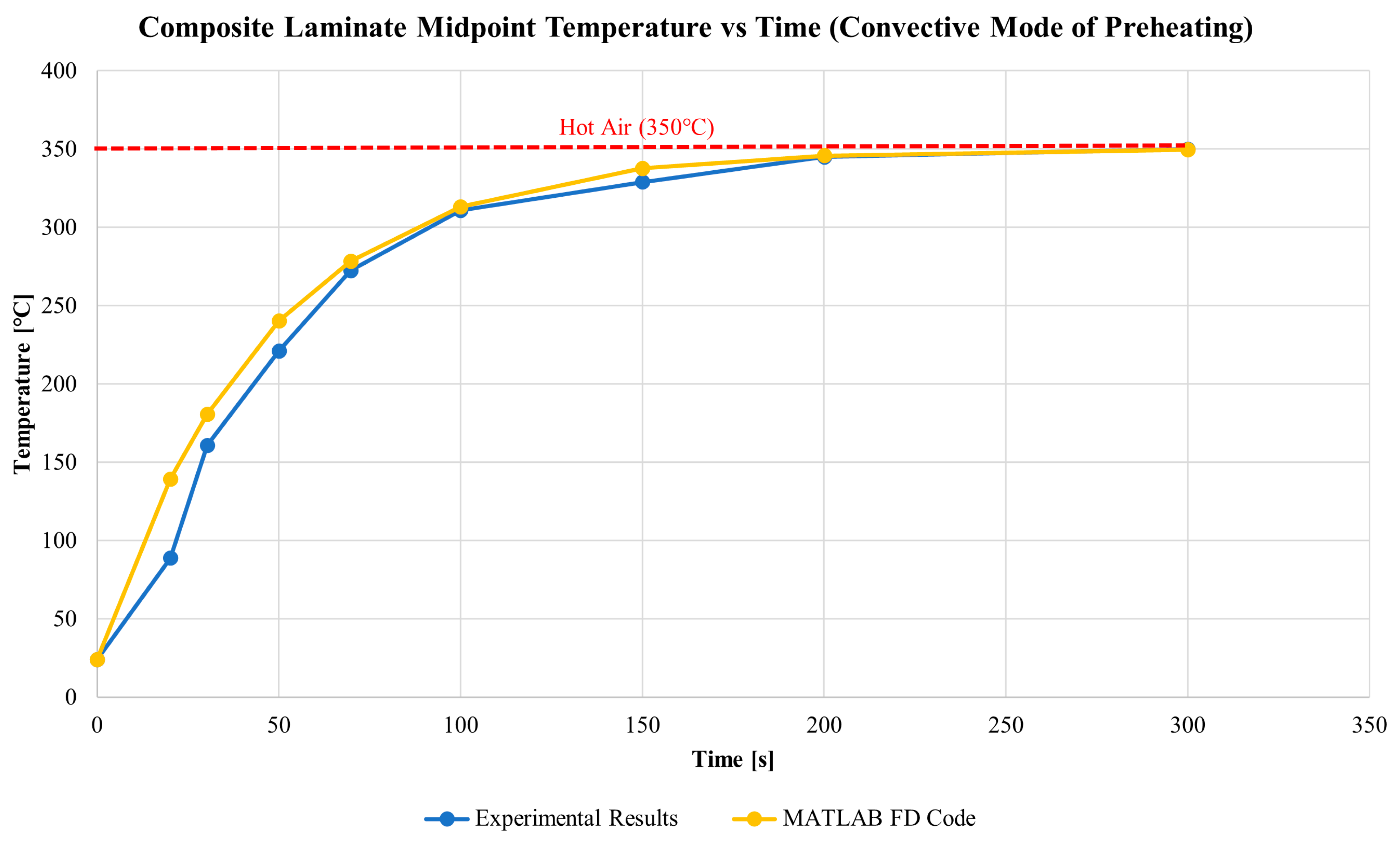

3.1.3. Finite Difference Model Validation

3.2. Consumed Energy of the Preheating Stage

3.2.1. Material

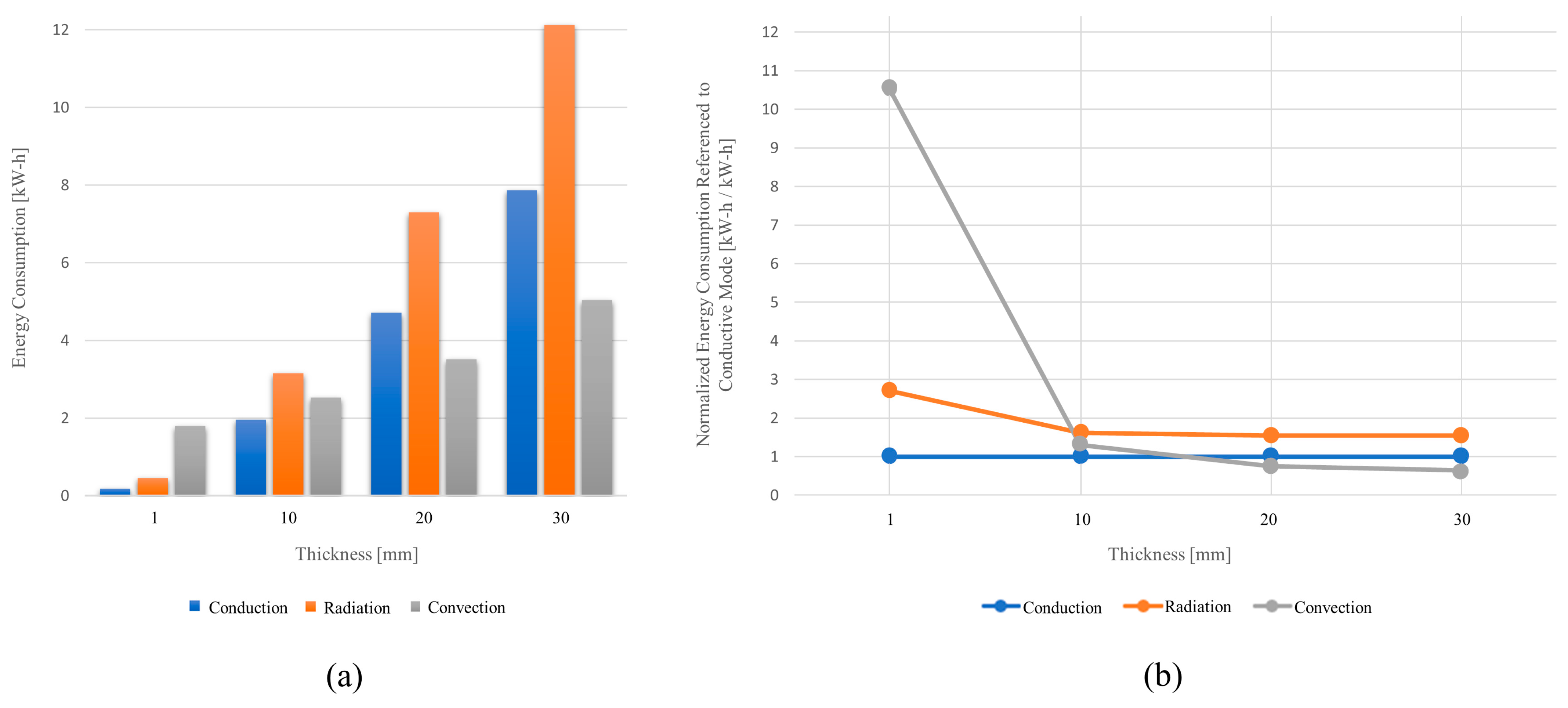

3.2.2. Analysis of Energy Consumption of Modes of Preheating

Energy Consumption of the Conductive Mode of Preheating

Energy Consumption of the Convective Mode of Preheating

Energy Consumption of the Radiative Mode of Preheating

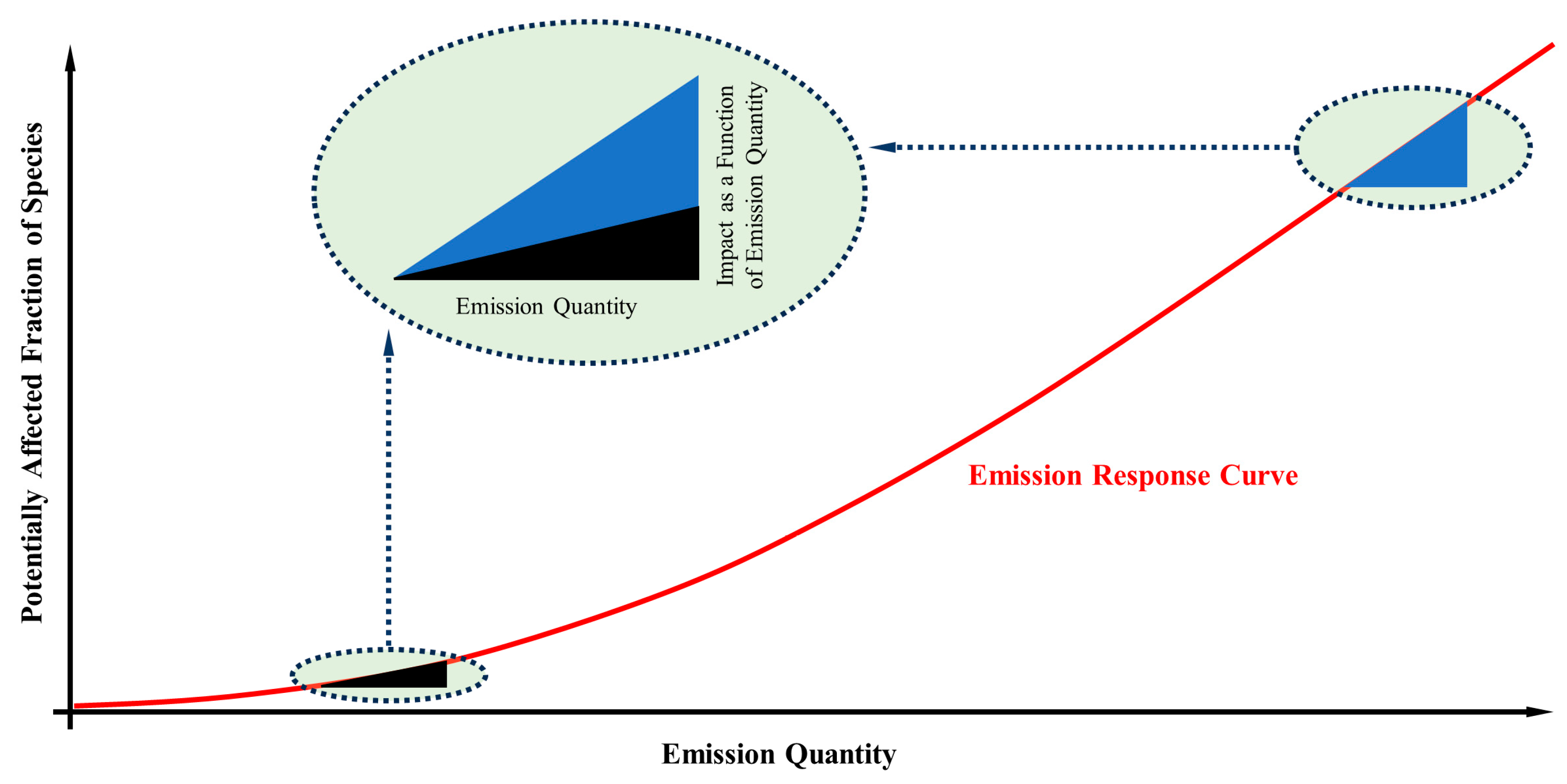

4. Impact Assessment of Modes of Preheating

5. Results and Discussion

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Rate of heat transfer from top to the control element | |

| Rate of heat transfer from bottom to the control element | |

| Rate of heat generated in the control element | |

| Density of the composite laminate | |

| Specific heat capacity of the composite laminate | |

| Density of the hot plate | |

| Specific heat capacity of the hot plate | |

| Time interval | |

| Nodal temperature | |

| Time step counter | |

| Surface area of the laminate interface | |

| Space interval | |

| Thermal conductivity of the hot plate | |

| Thermal conductivity of the composite laminate | |

| Thermal contact resistance | |

| Thermal contact conductance | |

| Additional composite laminate thickness at the interface | |

| Rate of heat transfer from the free stream to the control element | |

| Convective heat transfer coefficient | |

| Temperature of the free stream | |

| Radiative absorption rate of boundary layer | |

| Effective emissivity | |

| Stefan–Boltzmann constant | |

| View factor | |

| Absorbed fraction of radiation striking boundary layer of the laminate | |

| Coefficient of emissivity of the infrared heater | |

| Emissivity of the composite laminate | |

| Absorption coefficient of the material | |

| Respective radiative heat transfer rates from top boundary layer to control element | |

| Respective radiative heat transfer rates from bottom boundary layer to control element | |

| Rate of heat transfer entering the hot plate | |

| Rate of heat transfer existing the hot plate due to natural convection | |

| Rate of heat transfer existing the hot plate due to radiation | |

| Rate of heat transfer exiting the hot plate to heat up the composite laminate | |

| Coefficient of natural convection heat transfer | |

| Ambient temperature | |

| Coefficient of emissivity of the aluminum hot plate | |

| Final temperature of the laminate | |

| Initial temperature of the laminate | |

| Energy required to fulfill one functional unit in a convection oven | |

| Energy needed to heat up the laminate | |

| Heat loss occurring in the oven during the process | |

| Energy required by fans to generate necessary air velocity for hot air to obtain required h | |

| Characteristic flow length | |

| Thermal conductivity of hot air | |

| Reynolds number | |

| Prandtl number | |

| Density of hot air | |

| Average velocity of the hot air | |

| Viscosity of hot air | |

| Airflow velocity generated by an axial fan | |

| Power of the fan’s motor | |

| Cross-sectional flow area of the fan | |

| Cross-sectional area of the oven | |

| Surface area of the infrared heater | |

| Output parameter at the base value of the input | |

| Change in the output parameter | |

| Base value of the input parameter | |

| Change in the input parameter from the base value |

References

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable bio composites for aircraft components. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK, 2018; pp. 109–123. [Google Scholar]

- Sun, X.; Wang, P.; Ferris, T.; Lin, H.; Dreyfus, G.; Gu, B.; Zaelke, D.; Wang, Y. Fast action on short-lived climate pollutants and nature-based solutions to help countries meet carbon neutrality goals. Adv. Clim. Chang. Res. 2022, 13, 564–577. [Google Scholar] [CrossRef]

- Liu, N.; Wang, Y.; Bai, Q.; Liu, Y.; Wang, P.S.; Xue, S.; Yu, Q.; Li, Q. Road life-cycle carbon dioxide emissions and emission reduction technologies: A review. J. Traffic Transp. Eng. 2022, 9, 532–555. [Google Scholar] [CrossRef]

- Narayanan, R.G.; Gunasekera, J.S. Sustainable Manufacturing Processes; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Singh, M.; Ohji, T.; Asthana, R. Progress and Prospect. In Green and Sustainable Manufacturing of Advanced Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 3–10. [Google Scholar]

- Choi, A.C.K.; Kaebernick, H.; Lai, W.H. Manufacturing processes modelling for environmental impact assessment. J. Mater. Process. Technol. 1997, 70, 231–238. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Francioso, V.; Lopez-Arias, M.; Moro, C.; Jung, N.; Velay-Lizancos, M. Impact of curing temperature on the life cycle assessment of sugarcane bagasse ash as a partial replacement of cement in mortars. Sustainability 2023, 15, 142. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Vijayan, D. Life Cycle Assessment (LCA) of Epoxy-Based Materials. In Micro- and Nanostructured Epoxy/Rubber Blends; Wiley: Hoboken, NJ, USA, 2014; pp. 421–432. [Google Scholar]

- Chatzipanagiotou, K.R.; Antypa, D.; Petrakli, F.; Karatza, A.; Pik, K.; Bogacka, M.; Poranek, N.; Werle, S.; Amanatides, E.; Mataras, D.; et al. Life Cycle Assessment of Composites Additive Manufacturing Using Recycled Materials. Sustainability 2023, 15, 12843. [Google Scholar] [CrossRef]

- Zhao, M.; Dong, Y.; Guo, H. Comparative life cycle assessment of composite structures incorporating uncertainty and global sensitivity analysis. Eng. Struct. 2021, 242, 112394. [Google Scholar] [CrossRef]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China-Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef]

- Richard, D.; Hong, T.; Hastak, M.; Mirmiran, A.; Salem, O. Life-cycle performance model for composites in construction. Compos. Part B 2007, 38, 236–246. [Google Scholar] [CrossRef]

- Ramachandran, K.; Constance, L.; Gnanasagaran, A.V. Life cycle assessment of carbon fiber and bio-fiber composites prepared via vacuum bagging technique. J. Manuf. Process. 2023, 89, 124–131. [Google Scholar] [CrossRef]

- Al-Lami, A.; Hilmer, P.; Sinapius, M. Eco-efficiency assessment of manufacturing carbon fiber reinforced polymers (CFRP) in aerospace industry. Aerosp. Sci. Technol. 2018, 79, 669–678. [Google Scholar] [CrossRef]

- Khalil, Y.F. Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry. Sustain. Prod. Consum. 2017, 12, 16–26. [Google Scholar] [CrossRef]

- Hosseini, A.; Kashani, M.H.; Sassani, F.; Milani, A.; Ko, F.K. A mesoscopic analytical model to predict the onset of wrinkling in plain woven preforms under bias extension shear deformation. Materials 2017, 10, 1184. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Zindani, D.; Davim, J.P. Sustainable Manufacturing and Design; Woodhead Publishing: Sawston, UK, 2021. [Google Scholar]

- Längauer, M.; Zitzenbacher, G.; Stadler, H.; Hochenauer, C. Enhanced simulation of infrared heating of thermoplastic composites prior to forming under consideration of anisotropic thermal conductivity and deconsolidation by means of novel physical material models. Polymers 2022, 14, 3331. [Google Scholar] [CrossRef] [PubMed]

- Kirby, M.; Naderi, A.; Palardy, G. Predictive thermal modeling and characterization of ultrasonic consolidation process for thermoplastic composites. J. Manuf. Sci. Eng. 2023, 145, 031009. [Google Scholar] [CrossRef]

- Koerdt, M.; Koerdt, M.; Grobrug, T.; Skowronek, M.; Herrmann, A. Modelling and analysis of the thermal characteristic of thermoplastic composites from hybrid textiles during compression moulding. J. Thermoplast. Compos. Mater. 2022, 35, 127–146. [Google Scholar] [CrossRef]

- Längauer, M.; Brunnthaller, F.; Zitzenbacher, G.; Burgstaller, C.; Hochenauer, C. Modeling of the anisotropic thermal conductivity of fabrics embedded in a thermoplastic matrix system. Polym. Compos. 2021, 42, 2050–2060. [Google Scholar] [CrossRef]

- Moghadamazad, M.; Hoa, S.V. Models for heat transfer in thermoplastic composites made by automated fiber placement using hot gas torch. Compos. Part C Open Access 2022, 7, 100214. [Google Scholar] [CrossRef]

- Cunningham, J.E.; Monaghan, P.F.; Brogan, M.T.; Cassidy, S.F. Modelling of pre-heating of flat panels prior to press forming. Compos. Part A 1997, 28, 17–24. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Ghajar, A.J. Heat and Mass Transfer: Fundamentals & Applications; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Gibbins, J. Thermal Contact Resistance of Polymer Interfaces. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2006. [Google Scholar]

- Watlow Electric Manufacturing Company. Radiant Heating with Infrared: A Technical Guide to Understanding and Applying Infrared Heaters; Watlow Electric Manufacturing Company: Saint Louis, MO, USA, 1997. [Google Scholar]

- Ajersch, M. Modeling and Real-Time Control of Sheet Reheat Phase in Thermoforming. Master’s Thesis, McGill University, Montreal, QC, USA, 2004. [Google Scholar]

- Nardi, D.; Sinke, J. Design analysis for thermoforming of thermoplastic composites: Prediction and machine learning-based optimization. Compos. Part C Open Access 2021, 5, 100126. [Google Scholar] [CrossRef]

- Fernlund, G.; Mobuchon, C.; Zobeiry, N. Autoclave Processing. In Comprehensive Composite Materials II; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 42–62. [Google Scholar]

- Young, W.C.; Budynas, R.G.; Sadegh, A.M. Roark’s Formulas for Stress and Strain; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- OpenLCA Nexus. OpenLCA Nexus. [Online]. Available online: https://nexus.openlca.org/database/Environmental%20Footprints (accessed on 13 October 2023).

- Fazio, S.; Zampori, L.; Schryver, A.D. Guide for EF Compliant Data Sets; Joint Research Centre (JRC) of the European Commission’s Science and Knowledge Service: Luxembourg, 2020. [Google Scholar]

- Thermoplastic Composites Market Size, Share & Trends Analysis Report By Resin (PA, PP), By Fiber (Carbon, Glass), By Product (SFT, LFT), By End-Use (Transportation, Aerospace & Defense), By Region, and Segment Forecasts, 2022–2030. Grand View Research. 2022. Available online: https://www.gii.tw/report/grvi1133334-thermoplastic-composites-market-size-share-trends.html (accessed on 1 February 2024).

- Biron, M. Thermoplastics and Thermoplastic Composites. In Thermoplastic Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 821–882. [Google Scholar]

- Schmidt, F.; Maoult, Y.; Monteix, S. Modelling of infrared heating of thermoplastic sheet used in thermoforming process. J. Mater. Process. Technol. 2003, 143–144, 225–231. [Google Scholar] [CrossRef]

- Hertwich, E. The seeds of sustainable consumption patterns. In Proceedings of the 1st International Workshop on Sustainable Consumption, Tokyo, Japan, 19–20 May 2003. [Google Scholar]

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

- Sweeney, G.; Monaghan, P.; Brogan, M.; Cassidy, S. Reduction of infra-red heating cycle time in processing of thermoplastic composites using computer modelling. Compos. Manuf. 1995, 6, 255–262. [Google Scholar] [CrossRef]

- Cachon, G.; Terwiesch, C. Matching Supply with Demand: An Introduction to Operations Management; McGraw Hill: New York, NY, USA, 2024. [Google Scholar]

| Parameters | Simulation | Hot Plate (Mold) | Composite Laminate | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Nodes | Initial Temperature of Laminate | Material | Conductive Heat Transfer Coefficient ) | Temperature ) | Density ) | Specific Heat Capacity ) | Steel-Composite Laminate Interface Conductance | Material | Thickness | Thermal Conductivity ) | Density) | Specific Heat ) | |

| Values | 10 | 24 | Steel | 45 | 390 | 7850 | 490 | 650 | APC-2/S4 | 0.0009 | 0.36 | 1615 | 1288 |

| Units | N.A. | [] | N.A. | [] | N.A. | [] | |||||||

| Parameters | Simulation | Free Stream (Hot Air) | Composite Laminate | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Nodes | Initial Temperature of Laminate | Convective Heat Transfer Coefficient ) | Temperature ) | Material | Thickness | Thermal Conductivity ) | Density ) | Specific Heat Capacity ) | |

| Values | 10 | 24 | 20 | 350 | APC-2/S4 | 0.0009 | 0.36 | 1615 | 1288 |

| Units | N.A. | [] | [] | N.A. | [] | ||||

| Parameters | Simulation | Infrared Heater | Composite Laminate | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Nodes | Initial Temperature of Laminate | Effective Emissivity ) | Stefan–Boltzmann Constant ) | View Factor ) | Surface Temperature ) | Material | Thickness | Thermal Conductivity ) | Density ) | Specific Heat Capacity ) | Absorption Coefficient () | |

| Values | 10 | 297.15 | 0.81 | 5.67 | 0.60 | 773.15 | GF/PEI | 0.0005 | 0.40 | 1910 | 890 | 980 |

| Units | N.A. | [] | N.A. | N.A. | [] | N.A. | [] | |||||

| Parameters | Constituents | Dimensions | Thermal Conductivity ) | Density ) | Specific Heat ) | Absorption Coefficient |

|---|---|---|---|---|---|---|

| Values | GF/PEI | 1 × 1 × 0.001 | 0.40 | 1910 | 890 | 980 |

| Units | N.A. | [] |

| Parameters | Simulation | Hot Plate (Mold) | ||||||

|---|---|---|---|---|---|---|---|---|

| Number of Nodes | Initial Temperature of Laminate | Material | Conductive Heat Transfer Coefficient ) | Temperature ) | Density ) | Specific Heat Capacity ) | Aluminum-Composite Laminate Interface Conductance | |

| Values | 10 | 24 | Aluminum | 237 | 350 | 2700 | 897 | 2600 |

| Units | N.A. | [] | N.A. | [] | ||||

| Parameters | Environment | Hot Plate (Mold) | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature ) | Natural Convective Heat Transfer Coefficient ) | Material | Dimensions | Temperature ) | Density ) | Specific Heat Capacity ) | Emissivity ) | |

| Values | 24 or 297.15 | 5 | Aluminum | 1 × 1 × 0.010 | 350 | 2700 | 897 | 0.1 |

| Units | [] or [K] | N.A. | [] | N.A. | ||||

| Parameters | Simulation | Free Stream (Hot Air) | ||

|---|---|---|---|---|

| Number of Nodes | Initial Temperature of Laminate | Convective Heat Transfer Coefficient ) | Temperature ) | |

| Values | 10 | 24 | 30 | 459 |

| Units | N.A. | [] | [] | |

| Parameters | Convective Oven | |||||||

|---|---|---|---|---|---|---|---|---|

| Heat Loss | Hot Air Viscosity ) | Hot Air Density ) | Oven-to-Fan Area Ratio ) | Characteristic Flow Length ) | Hot Air Thermal Conductivity ) | Cross-Sectional Area of Oven ) | Hot Air Specific Heat Capacity ) | |

| Values | 5 | 34.2 | 0.4822 | 30 | 1 | 0.054 | 1 | 1082 |

| Units | [%] | [kg/m·s] | N.A. | |||||

| Parameters | Simulation | Infrared Heater | ||||

|---|---|---|---|---|---|---|

| Number of Nodes | Initial Temperature of Laminate | Effective Emissivity ) | Stefan–Boltzmann Constant ) | View Factor ) | Surface Temperature ) | |

| Values | 10 | 297.15 | 0.81 | 5.67 | 0.60 | 1143.15 |

| Units | N.A. | [] | N.A. | N.A. | [] | |

| Parameters | Radiative Heater | Environment | ||||

|---|---|---|---|---|---|---|

| Infrared Heater Emissivity ) | Surface Area of Infrared Heater ) | Temperature of Infrared Heater ) | Initial Temperature of Composite Laminate ) | Convective Heat Transfer Coefficient ) | Temperature ) | |

| Values | 0.85 | 1.00 | 1143.15 | 297.15 | 5 | 24 |

| Units | N.A. | [] | ||||

| Preheating Modes | Conduction | Radiation | Convection | |

|---|---|---|---|---|

| Reference Flow: Electrical Energy Required to Fulfill One Functional Unit | 0.17 | 0.46 | 1.79 | |

| Impact Categories | Climate Change | 1.525 | 4.126 | 1.606 |

| Ozon Depletion | 5.603 | 1.516 | 5.900 | |

| Acidification | 3.959 | 1.071 | 4.169 | |

| Ecotoxicity—Freshwater | 5.440 | 1.472 | 5.728 | |

| Eutrophication—Marine | 8.427 | 2.280 | 8.873 | |

| Eutrophication—Freshwater | 3.454 | 9.346 | 3.637 | |

| Eutrophication—Terrestrial | 8.911 | 2.411 | 9.383 | |

| Human Toxicity—Cancer | 1.196 | 3.237 | 1.259 | |

| Human Toxicity—Non-Cancer | 2.663 | 7.206 | 2.804 | |

| Land Use | 1.362 | 3.686 | 1.435 | |

| Water Use | 1.955 | 5.290 | 2.059 | |

| Ionizing Radiation—Human Health | 6.324 | 1.711 | 6.659 | |

| Particulate Matter | 3.733 | 1.010 | 3.930 | |

| Photochemical Ozone Formation—Human Health | 2.349 | 6.356 | 2.473 | |

| Resource Use—Fossils | 2.595 | 7.022 | 2.732 | |

| Resource Use—Minerals and Metals | 5.064 | 1.370 | 5.332 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosseini, A. Theoretical Assessment of the Environmental Impact of the Preheating Stage in Thermoplastic Composite Processing: A Step toward Sustainable Manufacturing. J. Manuf. Mater. Process. 2024, 8, 120. https://doi.org/10.3390/jmmp8030120

Hosseini A. Theoretical Assessment of the Environmental Impact of the Preheating Stage in Thermoplastic Composite Processing: A Step toward Sustainable Manufacturing. Journal of Manufacturing and Materials Processing. 2024; 8(3):120. https://doi.org/10.3390/jmmp8030120

Chicago/Turabian StyleHosseini, Abbas. 2024. "Theoretical Assessment of the Environmental Impact of the Preheating Stage in Thermoplastic Composite Processing: A Step toward Sustainable Manufacturing" Journal of Manufacturing and Materials Processing 8, no. 3: 120. https://doi.org/10.3390/jmmp8030120

APA StyleHosseini, A. (2024). Theoretical Assessment of the Environmental Impact of the Preheating Stage in Thermoplastic Composite Processing: A Step toward Sustainable Manufacturing. Journal of Manufacturing and Materials Processing, 8(3), 120. https://doi.org/10.3390/jmmp8030120