Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing

Abstract

:1. Introduction

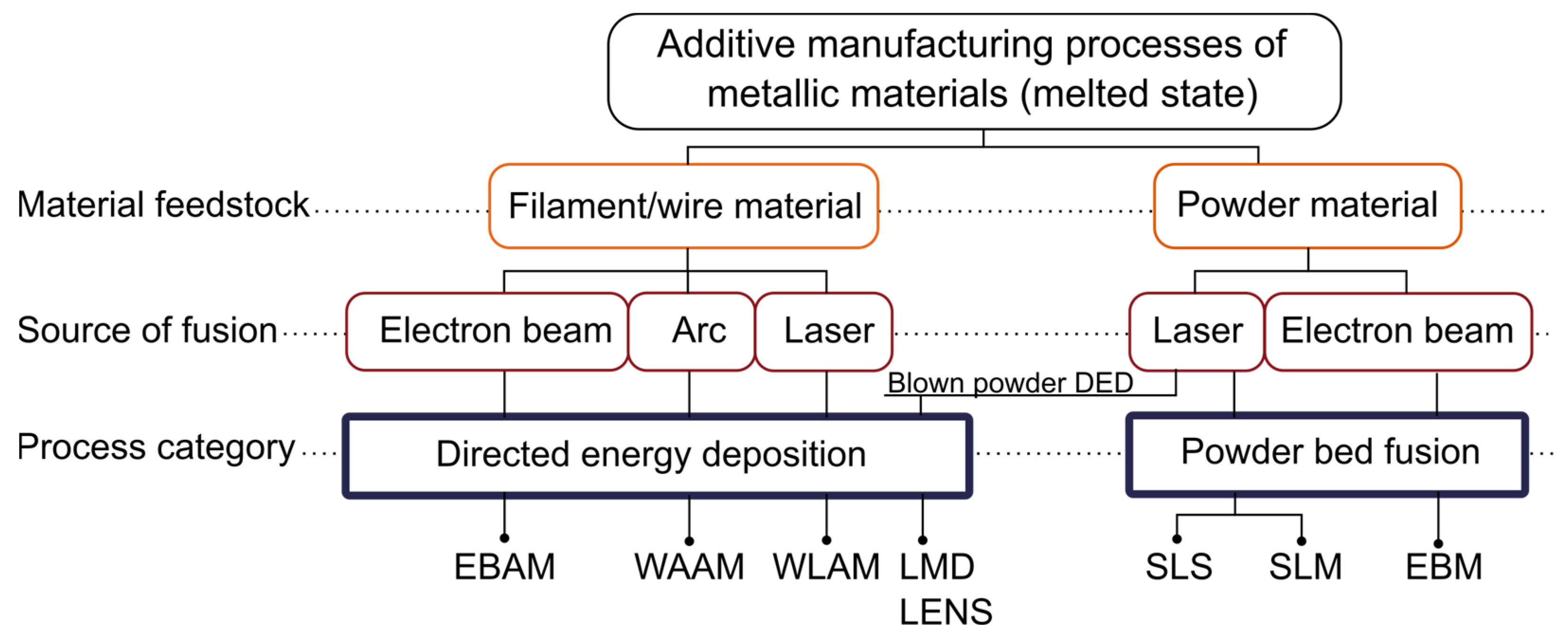

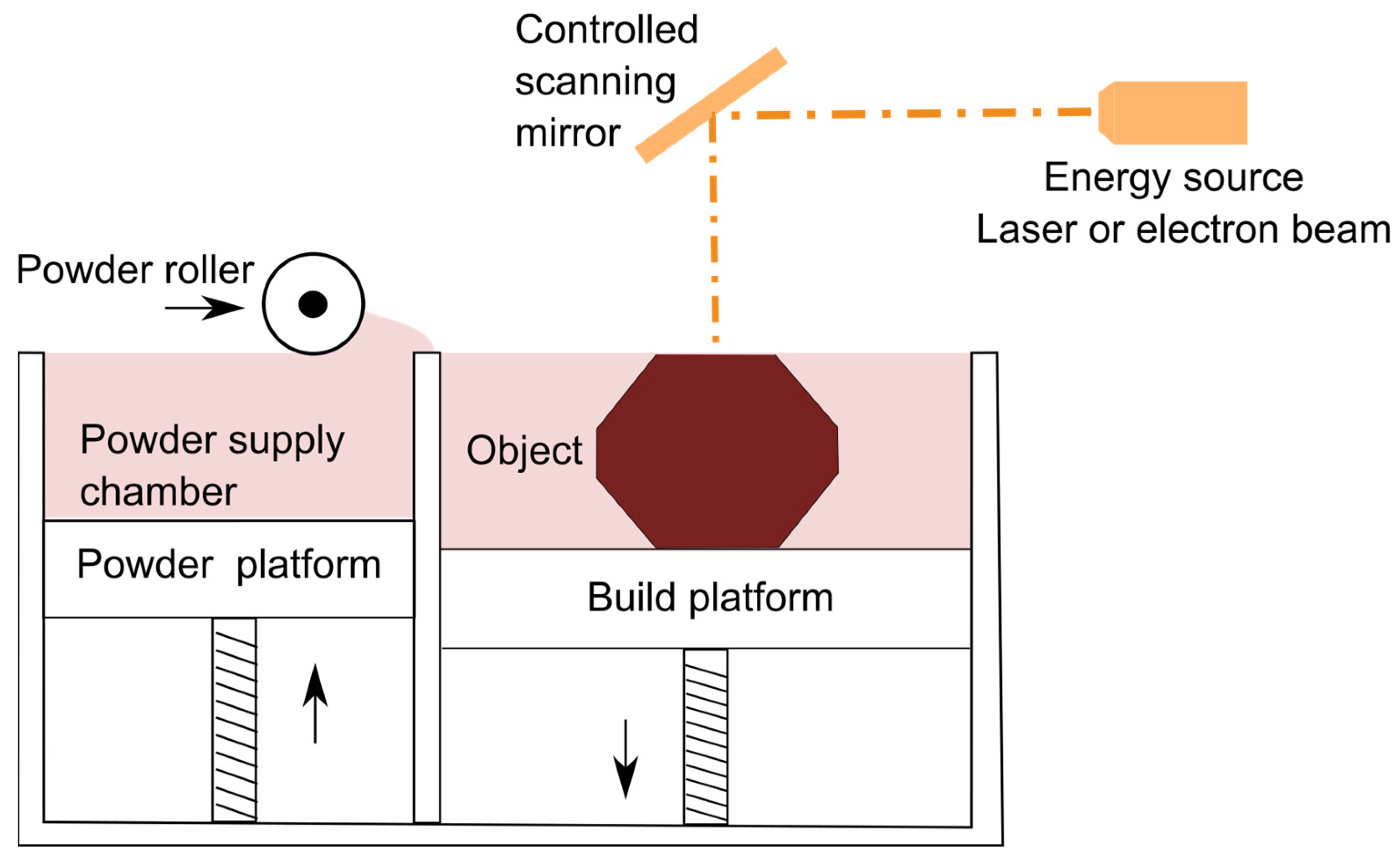

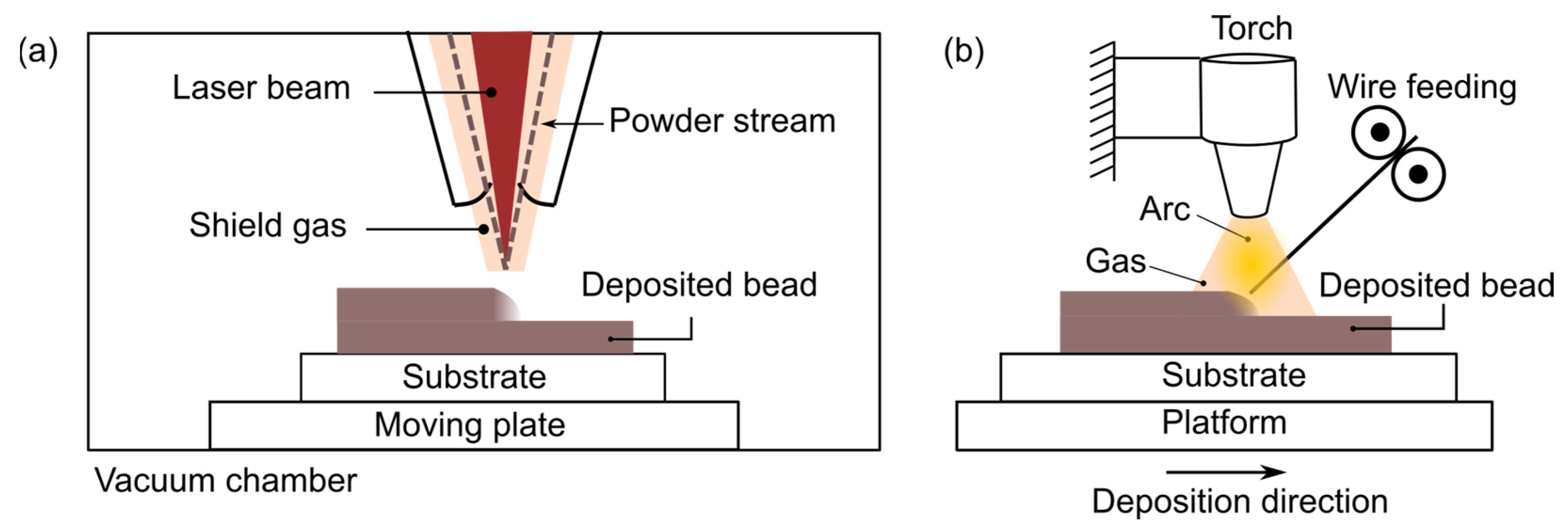

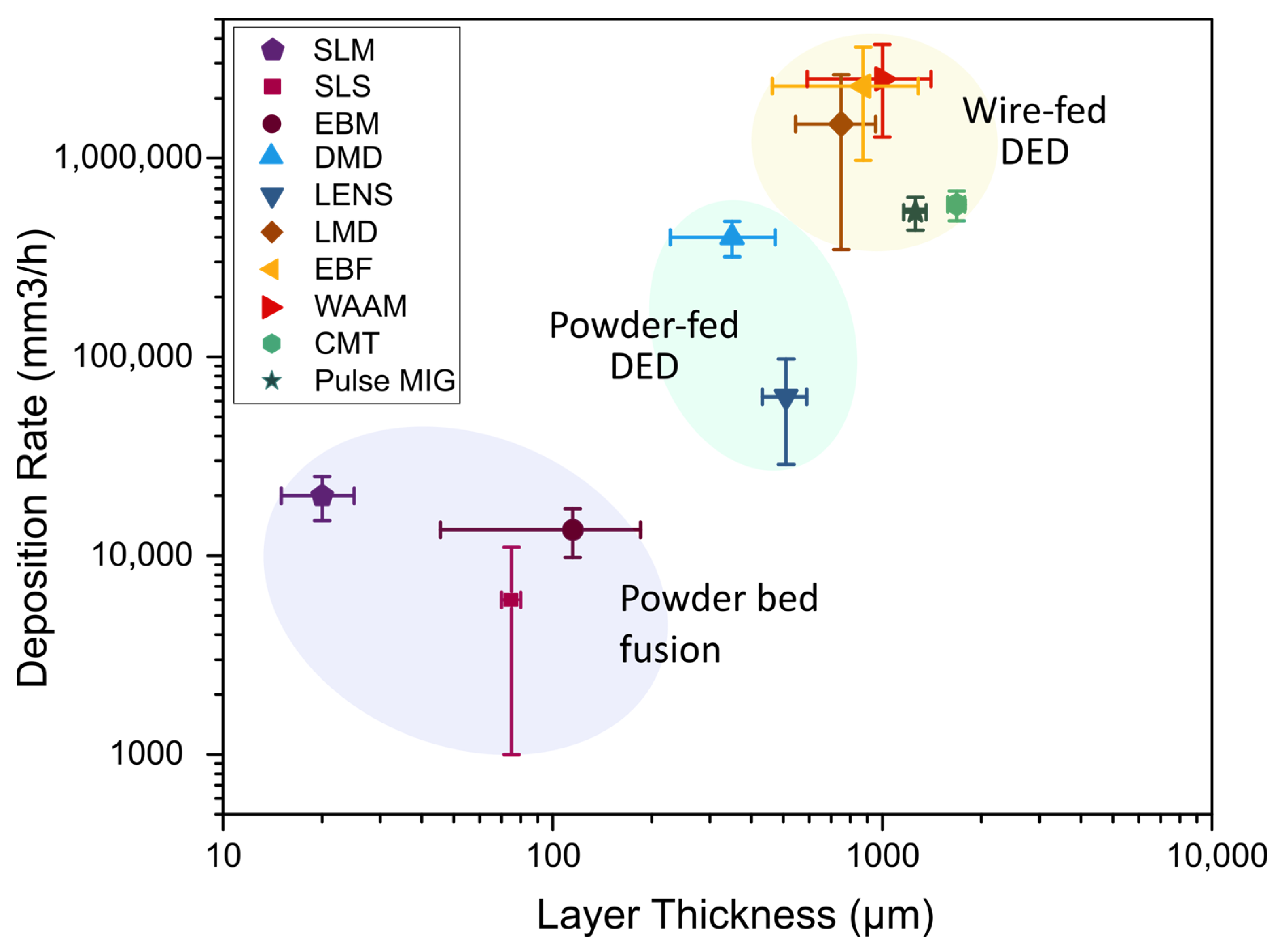

2. Powder Bed Fusion (PBF) and Directed Energy Deposition (DED) Processes

3. Comparison of the DED and PBF Processes

4. Economics of AM

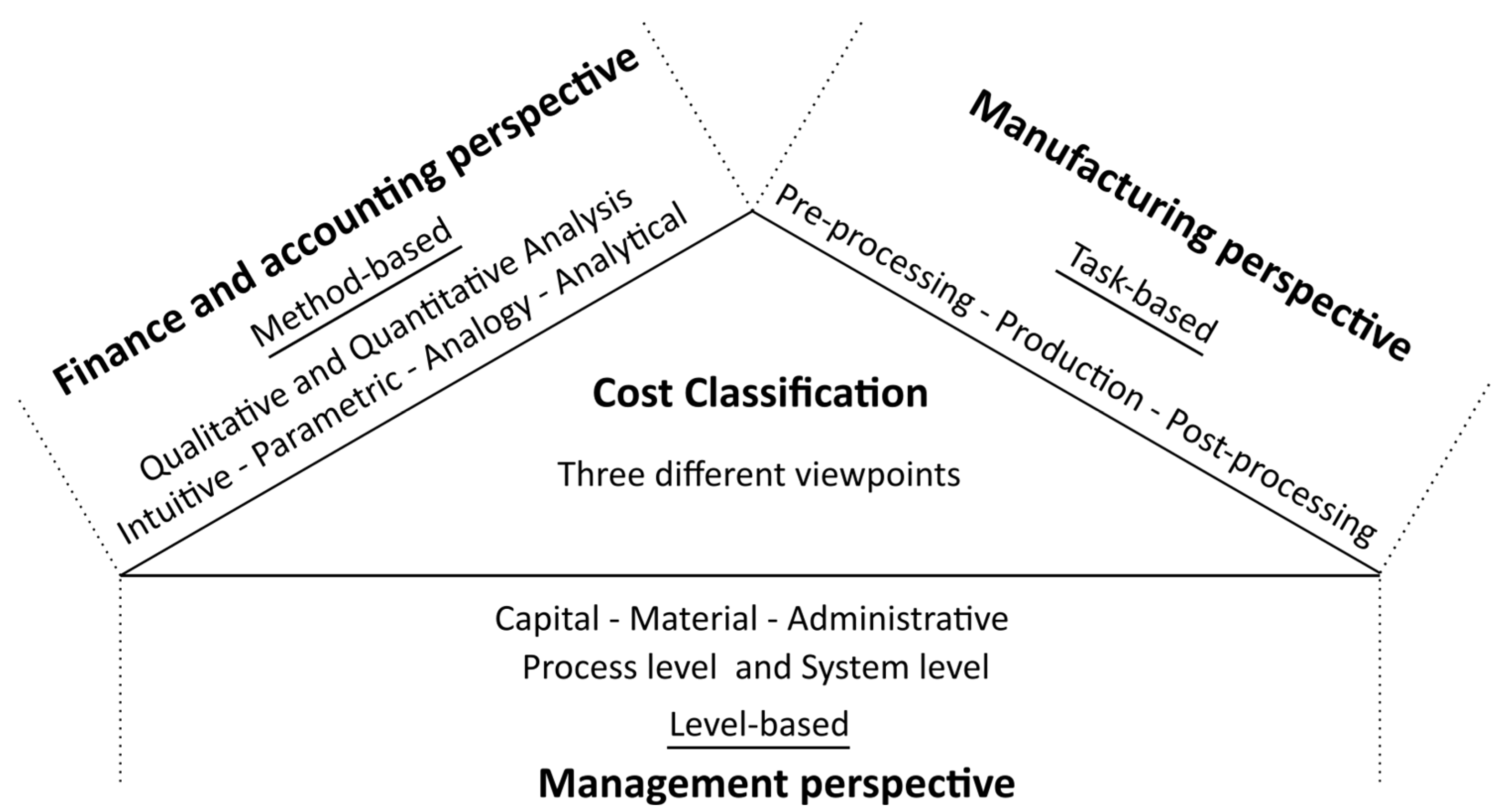

4.1. Cost Estimation Techniques

- Qualitative: Intuitive techniques—the expertise of a domain expert is utilised to estimate the cost based on experience.

- Qualitative: Analogical techniques—this technique is based on previous data where cost estimation is performed by comparing how similar the old and new components are.

- Quantitative: Parametric techniques—this technique calculates the costs based on the process cost drivers.

- Quantitative: Analytical techniques—using this technique, a manufacturing process is divided into its basic components, operations and activities. The overall cost is then calculated by adding the costs for these.

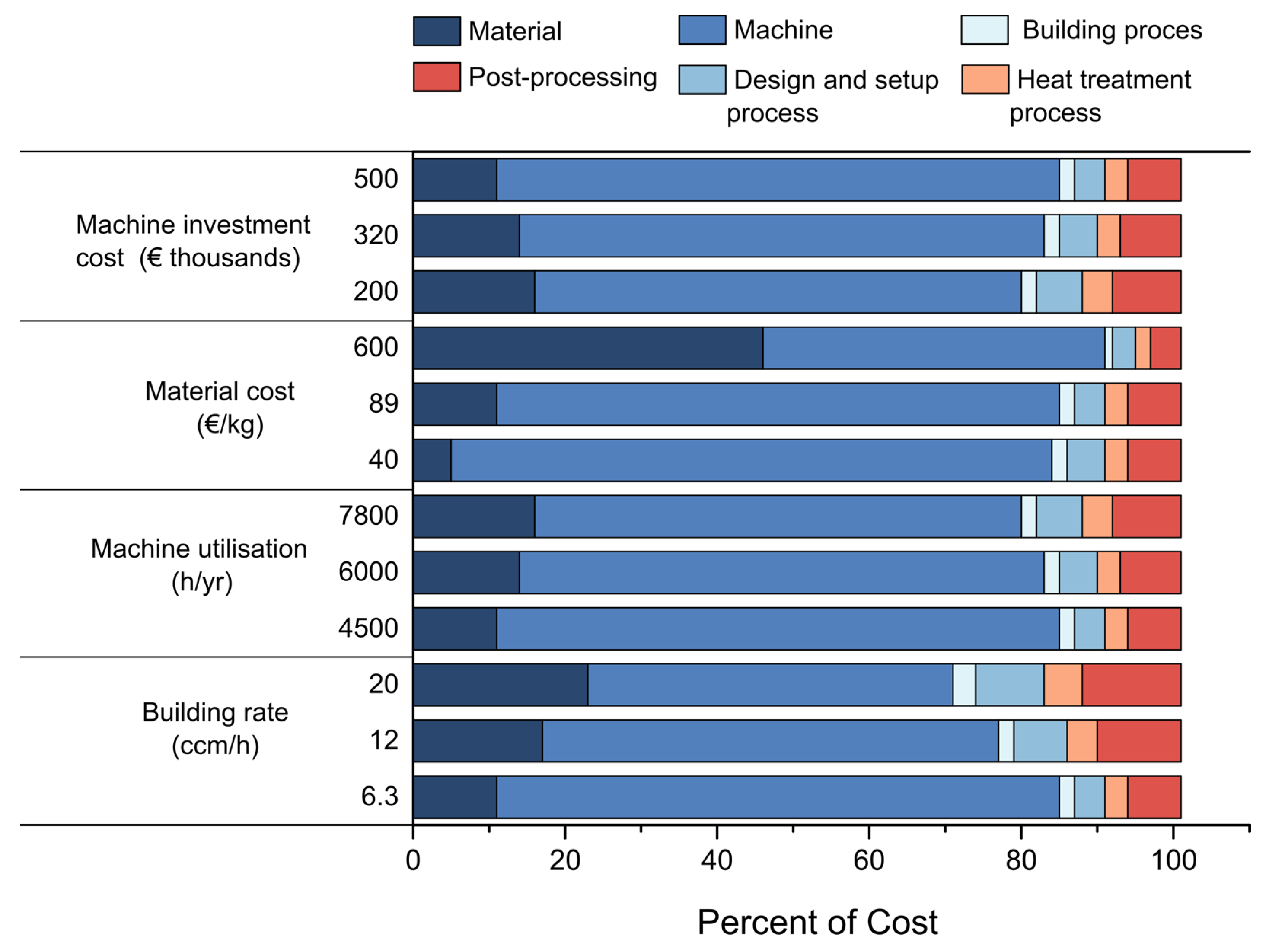

4.2. Cost Contributors in AM

- Machine Costs

- Material Costs

- Energy Costs

- Facility or Infrastructure Costs

- Labour costs

5. Cost Modelling Techniques

- Deterministic Modelling

- Stochastic Modelling

- Software-based Computational Modelling

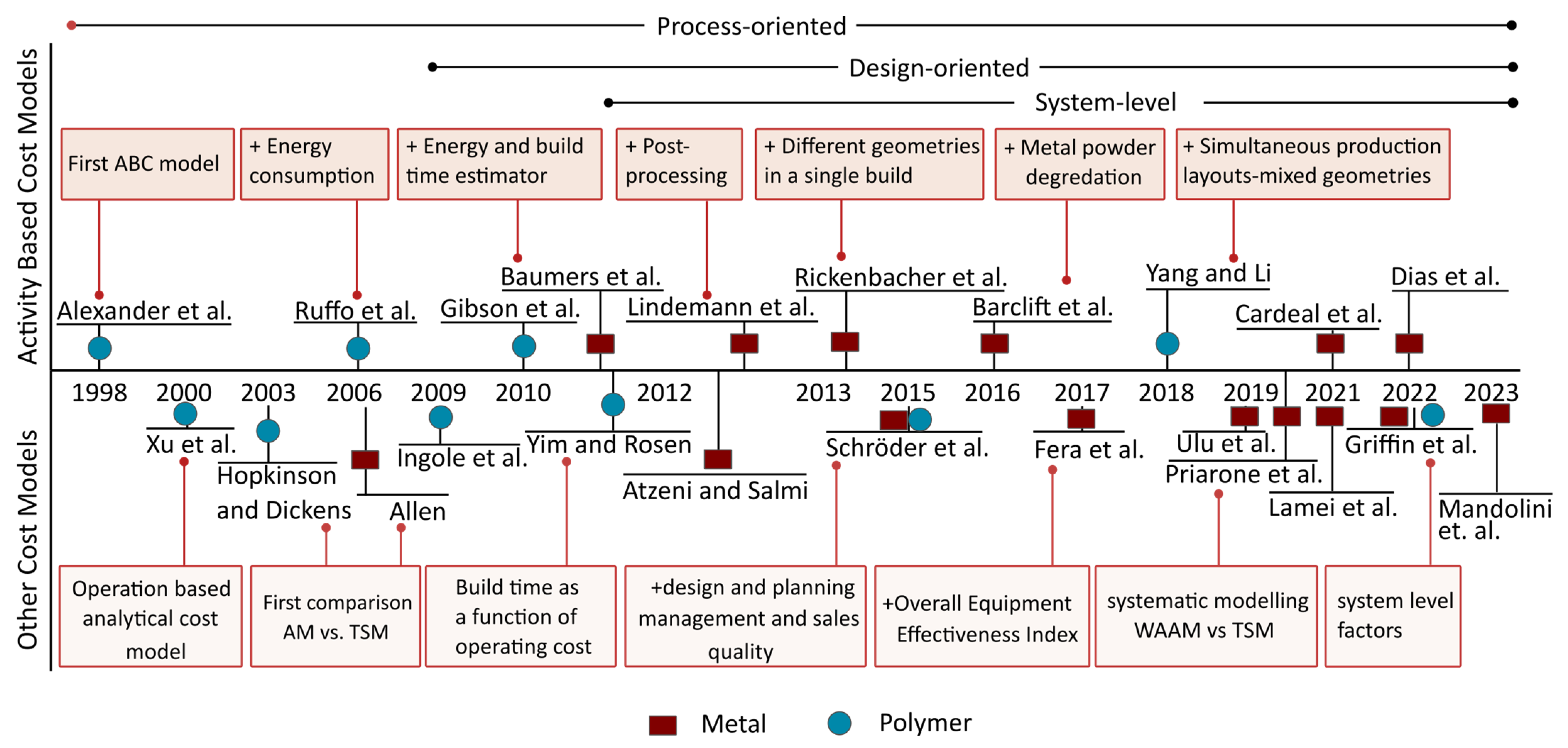

6. Development of Costing and Evaluation of AM Cost Models

6.1. Cost Models for Polymer AM

6.2. Cost Models for Metal AM

- Build job preparation;

- Build;

- Support removal;

- Post-processing.

- Energy and gas are grouped as direct costs.

- Fixed labour and gas costs for each build.

- Modelling many distinct geometries in a single build.

- An algorithm to determine how much time each component of the build will take in proportion.

- A linear regression analysis of 24 separate builds was used to estimate the build time.

- Preparation;

- Build job preparation;

- Machine setup;

- Build job;

- Removal;

- Build plate removal;

- Post-processing.

- Integration of support structures, powder recycling, and waste of material;

- Calculation of the build time;

- Maximising build chamber space;

- Representation of part complexity;

- Post-processing;

- Quality control.

7. Discussion and Future Work

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABC | Activity-based costing |

| AM | Additive manufacturing |

| CMT | Cold Metal Transfer |

| DED | Directed Energy Deposition |

| DMD | Direct Metal Deposition |

| EBAM | Electron Beam Additive Manufacturing |

| EBF | Electron Beam Fabrication |

| EBM | Electron Beam Melting |

| HIP | Hot isostatic pressing |

| LENS | Laser Engineered Net Shaping |

| LMD | Laser Matel Deposition |

| MIG | Metal Inert Gas |

| PBF | Powder Bed Fusion |

| PBF-EB | Powder Bed Fusion—Electron Beam |

| PBF-LB | Powder Bed Fusion—Laser Beam |

| SLM | Selective Laser Melting |

| SLS | Selective Laser Sintering |

| WAAM | Wire Arc Additive Manufacturing |

References

- Bandyopadhyay, A.; Heer, B. Materials Science & Engineering R Additive manufacturing of multi-material structures. Mater. Sci. Eng. R 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; ISBN 9781493921133. [Google Scholar]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Das, S.; Wohlert, M.; Beaman, J.J.; Bourell, D.L. Processing of titanium net shapes by SLS/HIP. Mater. Des. 1999, 20, 115–121. [Google Scholar] [CrossRef]

- Pham, D.T.; Gault, R.S. A comparison of rapid prototyping technologies. Int. J. Mach. Tools Manuf. 1998, 38, 1257–1287. [Google Scholar] [CrossRef]

- Hague, R.; Campbell, I.; Dickens, P. Implications on design of rapid manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 25–30. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Chang. 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Hopkinson, N.; Hague, R.J.M.; Dickens, P.M. Rapid Manufacturing: An Industrial Revolution for the Digital Age; John Wiley & Sons: Chichester, UK, 2005; ISBN 9780470016138. [Google Scholar]

- Thomas, D.S.; Gilbert, S.W. Costs and cost effectiveness of additive manufacturing: A literature review and discussion. In Additive Manufacturing: Costs, Cost Effectiveness and Industry Economics; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2014; pp. 1–96. [Google Scholar] [CrossRef]

- Kadir, A.Z.A.; Yusof, Y.; Wahab, M.S. Additive manufacturing cost estimation models—A classification review. Int. J. Adv. Manuf. Technol. 2020, 107, 4033–4053. [Google Scholar] [CrossRef]

- Chang, K.H. Product Manufacturing and Cost Estimating Using CAD/CAE: A Volume in the Computer Aided Engineering Design Series; Academic Press: Cambridge, MA, USA, 2013; ISBN 9780124017450. [Google Scholar]

- ASTM52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015; Volume 3, p. 5.

- ASTM/ISO 52900. Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2021; Volume 2021, pp. 1–14.

- Youssef, H.A.; El-Hofy, H.A.; Ahmed, M.H. Manufacturing Technology: Materials, Processes, and Equipment, 1st ed.; CRC Press: Boca Raton, FL, USA, 2011; ISBN 9780429184895. [Google Scholar]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing; Springer: New York, NY, USA, 2014. [Google Scholar]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Mirzaali, M.J.; Bobbert, F.S.L.; Li, Y.; Zadpoor, A.A. Additive manufacturing of metals using powder bed-based technologies. In Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2019; pp. 93–145. ISBN 0429466234. [Google Scholar]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Froes, F.H.; Dutta, B. The additive manufacturing (AM) of titanium alloys. Adv Mater Res 2014, 1019, 19–25. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Khanna, N.; Mistry, S.; Rashid, R.A.R.; Gupta, M.K. Investigations on density and surface roughness characteristics during selective laser sintering of Invar-36 alloy. Mater. Res. Express 2019, 6, 086541. [Google Scholar] [CrossRef]

- Gupta, M.K.; Singla, A.K.; Ji, H.; Song, Q.; Liu, Z.; Cai, W.; Mia, M.; Khanna, N.; Krolczyk, G.M. Impact of layer rotation on micro-structure, grain size, surface integrity and mechanical behaviour of SLM Al-Si-10Mg alloy. J. Mater. Res. Technol. 2020, 9, 9506–9522. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Rashid, R.A.R.; Masood, S.H.; Ruan, D.; Palanisamy, S. Mechanical properties of slm-printed aluminium alloys: A review. Materials 2020, 13, 4301. [Google Scholar] [CrossRef]

- Zhang, L.C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Mussatto, A. Research progress in multi-material laser-powder bed fusion additive manufacturing: A review of the state-of-the-art techniques for depositing multiple powders with spatial selectivity in a single layer. Results Eng. 2022, 16, 100769. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Kumar, T.S.S.; Manna, I. Fabrication of Biomedical Implants using Laser Engineered Net Shaping (LENSTM). Trans. Indian Ceram. Soc. 2013, 72, 169–174. [Google Scholar] [CrossRef]

- Balla, V.K. Deposition-Based and Solid-State Additive Manufacturing Technologies for Metals. In Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2019; pp. 147–182. ISBN 0429466234. [Google Scholar]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. A review of metal additive manufacturing technologies. Solid State Phenom. 2018, 278, 1–14. [Google Scholar] [CrossRef]

- Rahman Rashid, R.A.; Palanisamy, S.; Attar, H.; Bermingham, M.; Dargusch, M.S. Metallurgical features of direct laser-deposited Ti6Al4V with trace boron. J. Manuf. Process. 2018, 35, 651–656. [Google Scholar] [CrossRef]

- Rahman Rashid, R.A.; Barr, C.J.; Palanisamy, S.; Nazari, K.A.; Orchowski, N.; Matthews, N.; Dargusch, M.S. Effect of clad orientation on the mechanical properties of laser-clad repaired ultra-high strength 300 M steel. Surf. Coat. Technol. 2019, 380, 125090. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Nicastro, L.; Kent, D.; Chen, Y.; Dargusch, M.S. Optimising the mechanical properties of Ti-6Al-4V components produced by wire + arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 2018, 753, 247–255. [Google Scholar] [CrossRef]

- Jamnikar, N.; Liu, S.; Brice, C.; Zhang, X. Comprehensive molten pool condition-process relations modeling using CNN for wire-feed laser additive manufacturing. J. Manuf. Process. 2023, 98, 42–53. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Thomson-Larkins, J.; St John, D.H.; Dargusch, M.S. Sensitivity of Ti-6Al-4V components to oxidation during out of chamber Wire + Arc Additive Manufacturing. J. Mater. Process. Technol. 2018, 258, 29–37. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Optimization of wire feed for GTAW based additive manufacturing. J. Mater. Process. Technol. 2017, 243, 40–47. [Google Scholar] [CrossRef]

- Sachs, E.; Cima, M.; Cornie, J.; Brancazio, D.; Bredt, J.; Curodeau, A.; Fan, T.; Khanuja, S.; Lauder, A.; Lee, J.; et al. Three-Dimensional Printing: The Physics and Implications of Additive Manufacturing. CIRP Ann. Manuf. Technol. 1993, 42, 257–260. [Google Scholar] [CrossRef]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Watts, C.; Drake, R. A review of Additive Manufacturing technology and Cost Estimation techniques for the defence sector. CIRP J. Manuf. Sci. Technol. 2017, 19, 117–128. [Google Scholar] [CrossRef]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1, 64–76. [Google Scholar] [CrossRef]

- Vartanian, K.; Brewer, L.; Manley, K.; Cobbs, T. Powder bed fusion vs. directed energy deposition benchmark study: Mid-size part with simple geometry. Optomec Corp. 2018, 3–6. Available online: https://www.optomec.com/wp-content/uploads/2018/06/PBF-vs-DED-BENCHMARK-STUDY_7March_2018-03.pdf (accessed on 3 July 2024).

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Leicht, A.; Fischer, M.; Klement, U.; Nyborg, L.; Hryha, E. Increasing the Productivity of Laser Powder Bed Fusion for Stainless Steel 316L through Increased Layer Thickness. J. Mater. Eng. Perform. 2021, 30, 575–584. [Google Scholar] [CrossRef]

- Paradise, P.; Patil, D.; Van Handel, N.; Temes, S.; Saxena, A.; Bruce, D.; Suder, A.; Clonts, S.; Shinde, M.; Noe, C.; et al. Improving Productivity in the Laser Powder Bed Fusion of Inconel 718 by Increasing Layer Thickness: Effects on Mechanical Behavior. J. Mater. Eng. Perform. 2022, 31, 6205–6220. [Google Scholar] [CrossRef]

- Brudler, S.; Medvedev, A.E.; Pandelidi, C.; Piegert, S.; Illston, T.; Qian, M.; Brandt, M. Systematic investigation of performance and productivity in laser powder bed fusion of Ti6Al4V up to 300 µm layer thickness. J. Mater. Process. Technol. 2024, 330, 118450. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Frontiers of additively manufactured metallic materials. Materials 2018, 11, 1566. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The Additive Manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Liu, Z.; He, B.; Lyu, T.; Zou, Y. A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V. JOM 2021, 73, 1804–1818. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.J.; Gibson, I. Wire and arc additive manufacturing: Opportunities and challenges to control the quality and accuracy of manufactured parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Ferreira, B.T.; de Campos, A.A.; Casati, R.; Gonçalves, A.; Leite, M.; Ribeiro, I. Technological Capabilities and Sustainability Aspects of Metal Additive Manufacturing; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; ISBN 0123456789. [Google Scholar]

- Mumtaz, K.A.; Hopkinson, N. Selective Laser Melting of thin wall parts using pulse shaping. J. Mater. Process. Technol. 2010, 210, 279–287. [Google Scholar] [CrossRef]

- Zhu, H.H.; Lu, L.; Fuh, J.Y.H. Development and characterisation of direct laser sintering Cu-based metal powder. J. Mater. Process. Technol. 2003, 140, 314–317. [Google Scholar] [CrossRef]

- Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A.; et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals 2023, 13, 279. [Google Scholar] [CrossRef]

- Wippermann, A.; Gutowski, T.G.; Denkena, B.; Dittrich, M.A.; Wessarges, Y. Electrical energy and material efficiency analysis of machining, additive and hybrid manufacturing. J. Clean. Prod. 2020, 251, 119731. [Google Scholar] [CrossRef]

- Taminger, K.M.; Hafley, R.A. Electron Beam Freeform Fabrication for Cost Effective Near-Net Shape Manufacturing. In Proceedings of the NATO/RTO AVT-139 Specialists’’ Meeting on Cost Effective Manufacture via Net Shape Processing, Amsterdam, The Netherlands, 15–17 May 2006; Volume 19. [Google Scholar]

- Ayed, A.; Bras, G.; Bernard, H.; Michaud, P.; Balcaen, Y.; Alexis, J. Additive manufacturing of Ti6Al4V with wire laser metal deposition process. Mater. Sci. Forum 2021, 1016 MSF, 24–29. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Ding, J. Designing a WAAM based manufacturing system for defence applications. Procedia CIRP 2015, 37, 48–53. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Klocke, F.; Klingbeil, N.; Arntz, K.; Lamikiz, A.; Martinez, S. Evaluation of efficiency and mechanical properties of Inconel 718 components built by wire and powder laser material deposition. Rapid Prototyp. J. 2017, 23, 965–972. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; de Beer, D. Powder Bed Fusion of Multimaterials. J. Manuf. Mater. Process. 2023, 7, 15. [Google Scholar] [CrossRef]

- Breinan, E.M.; Kear, B.H. Rapid Solidification Laser Processing at High Power Density. Mater. Process. Theory Pract. 1983, 3, 235–295. [Google Scholar] [CrossRef]

- Singh, A.; Kapil, S.; Das, M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition. Addit. Manuf. 2020, 35, 101388. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Gouveia, F.M.; Santos, T.G. Micro wire and arc additive manufacturing (µ-WAAM). Addit. Manuf. Lett. 2022, 2, 100032. [Google Scholar] [CrossRef]

- Halisch, C.; Radel, T.; Tyralla, D.; Seefeld, T. Measuring the melt pool size in a wire arc additive manufacturing process using a high dynamic range two-colored pyrometric camera. Weld. World 2020, 64, 1349–1356. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, W.; Li, L. In-process measurement of melt pool cross-sectional geometry and grain orientation in a laser directed energy deposition additive manufacturing process. Opt. Laser Technol. 2020, 129, 106280. [Google Scholar] [CrossRef]

- Sow, M.C.; De Terris, T.; Castelnau, O.; Hamouche, Z.; Coste, F.; Fabbro, R.; Peyre, P. Influence of beam diameter on Laser Powder Bed Fusion (L-PBF) process. Addit. Manuf. 2020, 36, 101532. [Google Scholar] [CrossRef]

- Niazi, A.; Dai, J.S.; Balabani, S.; Seneviratne, L. Product cost estimation: Technique classification and methodology review. J. Manuf. Sci. Eng. 2006, 128, 563–575. [Google Scholar] [CrossRef]

- Chwastyk, P.; Kołosowski, M. Estimating the cost of the new product in development process. In Procedia Engineering; Elsevier: Amsterdam, The Netherlands, 2014; Volume 69, pp. 351–360. [Google Scholar]

- Datta, P.P.; Roy, R. Cost modelling techniques for availability type service support contracts: A literature review and empirical study. CIRP J. Manuf. Sci. Technol. 2010, 3, 142–157. [Google Scholar] [CrossRef]

- Huang, X.X.; Newnes, L.B.; Parry, G.C. The adaptation of product cost estimation techniques to estimate the cost of service. Int. J. Comput. Integr. Manuf. 2012, 25, 417–431. [Google Scholar] [CrossRef]

- Stewart, R.D.; Wyskida, R.M.; Johannes, J.D. Cost Estimator’s Reference Manual; John Wiley & Sons: Hoboken, NJ, USA, 1995; ISBN 0471305103. [Google Scholar]

- Yim, S.; Rosen, D. Build time and cost models for Additive Manufacturing process selection. In Proceedings of the ASME Design Engineering Technical Conference; American Society of Mechanical Engineers, Chicago, IL, USA, 12–15 August 2012; Volume 2, pp. 375–382. [Google Scholar]

- Cooper, R.; Kaplan, R.S. Measure costs right: Make the right decisions. Harv. Bus. Rev. 1988, 66, 96–103. [Google Scholar]

- Özbayrak, M.; Akgün, M.; Türker, A.K. Activity-based cost estimation in a push/pull advanced manufacturing system. Int. J. Prod. Econ. 2004, 87, 49–65. [Google Scholar] [CrossRef]

- Jarrar, Q.; Belkadi, F.; Bernard, A. An Activity-Based Costing Model for Additive Manufacturing. In Proceedings of the IFIP Advances in Information and Communication Technology, Grenoble, France, 10–13 July 2022; Volume 639 IFIP, pp. 492–507. [Google Scholar]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Alexander, P.; Allen, S.; Dutta, D. Part orientation and build cost determination in layered manufacturing. CAD Comput. Aided Des. 1998, 30, 343–356. [Google Scholar] [CrossRef]

- Costabile, G.; Fera, M.; Fruggiero, F.; Lambiase, A.; Pham, D. Cost models of additive manufacturing: A literature review. Int. J. Ind. Eng. Comput. 2016, 8, 263–282. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Lamei, Z. A Comprehensive Cost Estimation for Additive Manufacturing A Thesis by a Comprehensive Cost Estimation for Additive Manufacturing. Ph.D. Thesis, Wichita State University, Wichita, KS, USA, 2021. [Google Scholar]

- Ruffo, M.; Hague, R. Cost estimation for rapid manufacturing—Simultaneous production of mixed components using laser sintering. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1585–1591. [Google Scholar] [CrossRef]

- Atzeni, E.; Iuliano, L.; Minetola, P.; Salmi, A. Redesign and cost estimation of rapid manufactured plastic parts. Rapid Prototyp. J. 2010, 16, 308–317. [Google Scholar] [CrossRef]

- Kokare, S.; Oliveira, J.P.; Godina, R. Life cycle assessment of additive manufacturing processes: A review. J. Manuf. Syst. 2023, 68, 536–559. [Google Scholar] [CrossRef]

- Lindemann, C.; Jahnke, U.; Moi, M.; Koch, R. Analyzing product lifecycle costs for a better understanding of cost drivers in additive manufacturing. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2012, Austin, TX, USA, 6–8 August 2012; pp. 177–188. [Google Scholar]

- Schröder, M.; Falk, B.; Schmitt, R. Evaluation of cost structures of additive manufacturing processes using a new business model. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2015; Volume 30, pp. 311–316. [Google Scholar]

- Wohlers, T.; Diegel, O. Costs and considerations when investing in a metal additive manufacturing system. In Metal Additive Manufacturing; Inovar Communications Ltd.: Shewsbury, UK, 2017; Volume 3, pp. 93–97. [Google Scholar]

- Wiese, M.; Kwauka, A.; Thiede, S.; Herrmann, C. Economic assessment for additive manufacturing of automotive end-use parts through digital light processing (DLP). CIRP J. Manuf. Sci. Technol. 2021, 35, 268–280. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dickens, P. Analysis of rapid manufacturing—Using layer manufacturing processes for production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 31–40. [Google Scholar] [CrossRef]

- Cardeal, G.; Sequeira, D.; Mendonça, J.; Leite, M.; Ribeiro, I. Additive manufacturing in the process industry: A process-based cost model to study life cycle cost and the viability of additive manufacturing spare parts. Procedia CIRP 2021, 98, 211–216. [Google Scholar] [CrossRef]

- Medina, F. Reducing Metal Alloy Powder Costs for Use in Powder Bed Fusion Additive Manufacturing: Improving the Economics for Production. Ph.D. Thesis, University of Texas at El Paso, El Paso, TX, USA, 2013. [Google Scholar]

- Wohlers, T.T. Wohlers Report 2012: Additive Manufacturing and 3D Printing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2012; ISBN 0975442988. [Google Scholar]

- Langelandsvik, G.; Akselsen, O.M.; Furu, T.; Roven, H.J. Review of Aluminum Alloy Development for Wire Arc Additive Manufacturing. Materials 2021, 14, 5370. [Google Scholar] [CrossRef] [PubMed]

- Dias, M.; Pragana, J.P.M.; Ferreira, B.; Ribeiro, I.; Silva, C.M.A. Economic and Environmental Potential of Wire-Arc Additive Manufacturing. Sustainability 2022, 14, 5197. [Google Scholar] [CrossRef]

- Kokare, S.; Oliveira, J.P.; Godina, R. A LCA and LCC analysis of pure subtractive manufacturing, wire arc additive manufacturing, and selective laser melting approaches. J. Manuf. Process. 2023, 101, 67–85. [Google Scholar] [CrossRef]

- Baumers, M. Economic Aspects of Additive Manufacturing: Benefits, Costs and Energy Consumption. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2012; pp. 1–256. [Google Scholar]

- Morrow, W.R.; Qi, H.; Kim, I.; Mazumder, J.; Skerlos, S.J. Environmental aspects of laser-based and conventional tool and die manufacturing. J. Clean. Prod. 2007, 15, 932–943. [Google Scholar] [CrossRef]

- Landi, D.; Zefinetti, F.C.; Spreafico, C.; Regazzoni, D. Comparative life cycle assessment of two different manufacturing technologies: Laser additive manufacturing and traditional technique. Procedia CIRP 2022, 105, 700–705. [Google Scholar] [CrossRef]

- Piili, H.; Happonen, A.; Väistö, T.; Venkataramanan, V.; Partanen, J.; Salminen, A. Cost Estimation of Laser Additive Manufacturing of Stainless Steel. In Physics Procedia; Elsevier: Amsterdam, The Netherlands, 2015; Volume 78, pp. 388–396. [Google Scholar]

- Priarone, P.C.; Pagone, E.; Martina, F.; Catalano, A.R.; Settineri, L. Multi-criteria environmental and economic impact assessment of wire arc additive manufacturing. CIRP Ann. 2020, 69, 37–40. [Google Scholar] [CrossRef]

- Campatelli, G.; Montevecchi, F.; Venturini, G.; Ingarao, G.; Priarone, P.C. Integrated WAAM-Subtractive Versus Pure Subtractive Manufacturing Approaches: An Energy Efficiency Comparison. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 1–11. [Google Scholar] [CrossRef]

- Macaulay, C.S. Fire Risks in Additive Manufacturing: Assessing 3D Printing & Combustible Dust Hazards [White Paper]. TÜV SÜD Global Risk Consultants. 2021. Available online: https://www.tuvsud.com/en-us/resource-centre/white-papers/fire-risks-in-additive-manufacturing (accessed on 3 July 2024).

- CCOHS Safety Hazards Additive Manufacturing. Available online: https://www.ccohs.ca/oshanswers/safety_haz/additive_manufacturing.html#section-3-hdr (accessed on 1 October 2023).

- Franchetti, M.; Kress, C. An economic analysis comparing the cost feasibility of replacing injection molding processes with emerging additive manufacturing techniques. Int. J. Adv. Manuf. Technol. 2017, 88, 2573–2579. [Google Scholar] [CrossRef]

- Feier, A.; Buta, I.; Florica, C.; Blaga, L. Optimization of Wire Arc Additive Manufacturing (WAAM) Process for the Production of Mechanical Components Using a CNC Machine. Materials 2023, 16, 17. [Google Scholar] [CrossRef]

- Romansky, R.P.; Hinov, N.L. Deterministic and Stochastic Approaches in Computer Modeling and Simulation; IGI Global: Hershey, PA, USA, 2023. [Google Scholar]

- Sharma, F.; Dixit, U.S. Fuzzy set based cost model of additive manufacturing with specific example of selective laser sintering. J. Mech. Sci. Technol. 2019, 33, 4439–4449. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef] [PubMed]

- Scott, A.; Harrison, T.P. Additive Manufacturing in an End-to-End Supply Chain Setting. 3D Print. Addit. Manuf. 2015, 2, 65–77. [Google Scholar] [CrossRef]

- Emelogu, A.; Marufuzzaman, M.; Thompson, S.M.; Shamsaei, N.; Bian, L. Additive manufacturing of biomedical implants: A feasibility assessment via supply-chain cost analysis. Addit. Manuf. 2016, 11, 97–113. [Google Scholar] [CrossRef]

- Luo, R.C.; Lan, C.C.; Tzou, J.H.; Chen, C.C. The development of WEB based e-commerce platform for rapid prototyping system. In Proceedings of the IEEE International Conference on Networking, Sensing and Control, Taipei, Taiwan, 21–23 March 2004; IEEE: New York, NY, USA, 2004; Volume 1, pp. 122–127. [Google Scholar]

- Di Angelo, L.; Di Stefano, P. Parametric cost analysis for web-based e-commerce of layer manufactured objects. Int. J. Prod. Res. 2010, 48, 2127–2140. [Google Scholar] [CrossRef]

- Lan, H.; Ding, Y. Price quotation methodology for stereolithography parts based on STL model. Comput. Ind. Eng. 2007, 52, 241–256. [Google Scholar] [CrossRef]

- Barclift, M.; Armstrong, A.; Simpson, T.W.; Joshi, S.B. CAD-Integrated Cost Estimation and Build Orientation Optimization to Support Design for Metal Additive Manufacturing. In Proceedings of the Volume 2A: 43rd Design Automation Conference, American Society of Mechanical Engineers, Cleveland, OH, USA, 6–9 August 2017; Volume 2A-2017. [Google Scholar]

- Dinda, S.; Modi, D.; Simpson, T.W.; Tedia, S.; Williams, C.B. Expediting Build Time, Material, and Cost Estimation for Material Extrusion Processes to Enable Mobile Applications. In Proceedings of the Volume 2A: 43rd Design Automation Conference, American Society of Mechanical Engineers, Cleveland, OH, USA, 6–9 August 2017; Volume 58127. [Google Scholar]

- Campbell, I.; Combrinck, J.; De Beer, D.; Barnard, L. Stereolithography build time estimation based on volumetric calculations. Rapid Prototyp. J. 2008, 14, 271–279. [Google Scholar] [CrossRef]

- Innes, J.; Mitchell, F. The application of activity-based costing in the United Kingdom’s largest financial institutions. Serv. Ind. J. 1997, 17, 190–203. [Google Scholar] [CrossRef]

- Xu, F.; Wong, Y.S.; Loh, H.T. Toward generic models for comparative evaluation and process selection in rapid prototyping and manufacturing. J. Manuf. Syst. 2001, 19, 283–296. [Google Scholar] [CrossRef]

- Ruffo, M.; Tuck, C.; Hague, R. Cost estimation for rapid manufacturing—Laser sintering production for low to medium volumes. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1417–1427. [Google Scholar] [CrossRef]

- Allen, J. An Investigation into the Comparative Costs of Additive Manufacture vs. Machine from Solid for Aero Engine Parts. Cost Eff. Manuf. Net-Shape Process. 2006, 17, 17-1–17-10. [Google Scholar]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Rosamond, E.; Hague, R. Combined build-time, energy consumption and cost estimation for direct metal laser sintering. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2012, Austin, TX, USA, 6–8 August 2012; pp. 932–944. [Google Scholar]

- Hur, S.M.; Choi, K.H.; Lee, S.H.; Chang, P.K. Determination of fabricating orientation and packing in SLS process. J. Mater. Process. Technol. 2001, 112, 236–243. [Google Scholar] [CrossRef]

- Kaplan, R.; Anderson, S. Time-Driven Activity Based Costing: A Simpler and More Powerful Path to Higher Profits. Harvard Business School Press: Boston, MA, USA, 2007. [Google Scholar]

- Rickenbacher, L.; Spierings, A.; Wegener, K. An integrated cost-model for selective laser melting (SLM). Rapid Prototyp. J. 2013, 19, 208–214. [Google Scholar] [CrossRef]

- Ingole, D.S.; Kuthe, A.M.; Thakare, S.B.; Talankar, A.S. Rapid prototyping—A technology transfer approach for development of rapid tooling. Rapid Prototyp. J. 2009, 15, 280–290. [Google Scholar] [CrossRef]

- Barclift, M.; Joshi, S.; Simpson, T.; Dickman, C. Cost modeling and depreciation for reused powder feedstocks in powder bed fusion additive manufacturing. In Proceedings of the Solid Freeform Fabrication 2016: Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2016, Austin, TX, USA, 8–10 August 2016; University of Texas at Austin: Austin, TX, USA, 2016; pp. 2007–2028. [Google Scholar]

- Fera, M.; Fruggiero, F.; Costabile, G.; Lambiase, A.; Pham, D.T. A new mixed production cost allocation model for additive manufacturing (MiProCAMAM). Int. J. Adv. Manuf. Technol. 2017, 92, 4275–4291. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L. Cost modeling and analysis for Mask Image Projection Stereolithography additive manufacturing: Simultaneous production with mixed geometries. Int. J. Prod. Econ. 2018, 206, 146–158. [Google Scholar] [CrossRef]

- Priarone, P.C.; Campatelli, G.; Montevecchi, F.; Venturini, G.; Settineri, L. A modelling framework for comparing the environmental and economic performance of WAAM-based integrated manufacturing and machining. CIRP Ann. 2019, 68, 37–40. [Google Scholar] [CrossRef]

- Ulu, E.; Huang, R.; Kara, L.B.; Whitefoot, K.S. Concurrent Structure and Process Optimization for Minimum Cost Metal Additive Manufacturing. J. Mech. Des. Trans. ASME 2019, 141, 061701. [Google Scholar] [CrossRef]

- Griffin, C.; Hale, J.; Jin, M. A framework for assessing investment costs of additive manufacturing. Prog. Addit. Manuf. 2022, 7, 903–915. [Google Scholar] [CrossRef]

- Mandolini, M.; Sartini, M.; Favi, C.; Germani, M. An Analytical Cost Model for Laser-Directed Energy Deposition (L-DED) BT—Advances on Mechanics, Design Engineering and Manufacturing IV; Gerbino, S., Lanzotti, A., Martorelli, M., Mirálbes Buil, R., Rizzi, C., Roucoules, L., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 993–1004. [Google Scholar]

- Shokrani, A.; Arrazola, P.; Biermann, D.; Mativenga, P.; Jawahir, I.S. Sustainable machining: Recent technological advances. CIRP Ann. 2024, 2. [Google Scholar]

| Properties | PBF-LB (e.g., SLM, SLS) | PBF-EB (e.g., EBM) | Powder-Fed DED (e.g., LMD) | Wire-Fed DED (e.g., WAAM) |

|---|---|---|---|---|

| Beam size | 20–100 μm | 100–200 μm | 0.5–3 mm | 0.9–1.2 mm (wire diameter) |

| Average density of fabricated parts | 99.53% | 99.5% | 99.4% | 99% |

| Layer thickness | 25–75 μm | 50–200 μm | 0.4–1 mm | 1.5 mm |

| Powder particle size | 10–45 μm | 45–106 μm | 50–150 μm | NA |

| Surface finish | Ra 9–12 μm | Ra 25–35 μm | Ra 20–50 μm | Ra 200 μm |

| Melt pool dimension | 0.5–1.5 μm | 2–3 μm | 2–5 mm | 3–12 mm |

| Min. dimensional accuracy | 0.2–0.4 mm | 0.1–4 mm | ||

| Build volume | <200 mm3, can reach 700 mm3 | Can reach above 8000 mm3 | ||

| Method-Based Cost Classification | Advantages | Limitations | |

|---|---|---|---|

| Qualitative | Intuitive |

|

|

| Analogical |

|

| |

| Quantitative | Parametric |

|

|

| Analytical |

|

| |

| Material Feedstock | Titanium | Inconel 718 | Stainless Steel 316 |

|---|---|---|---|

| Wire—1–1.5 mm diameter | USD 92.5 | USD 114.53 | USD 39.9 |

| Powder—AM Grade | USD 429 | USD 198 | USD 135 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanna, N.; Salvi, H.; Karaş, B.; Fairoz, I.; Shokrani, A. Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing. J. Manuf. Mater. Process. 2024, 8, 142. https://doi.org/10.3390/jmmp8040142

Khanna N, Salvi H, Karaş B, Fairoz I, Shokrani A. Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing. Journal of Manufacturing and Materials Processing. 2024; 8(4):142. https://doi.org/10.3390/jmmp8040142

Chicago/Turabian StyleKhanna, Navneet, Harsh Salvi, Büşra Karaş, Ishrat Fairoz, and Alborz Shokrani. 2024. "Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing" Journal of Manufacturing and Materials Processing 8, no. 4: 142. https://doi.org/10.3390/jmmp8040142

APA StyleKhanna, N., Salvi, H., Karaş, B., Fairoz, I., & Shokrani, A. (2024). Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing. Journal of Manufacturing and Materials Processing, 8(4), 142. https://doi.org/10.3390/jmmp8040142