Effect of Drilling Parameters on Surface Roughness and Delamination of Ramie–Bamboo-Reinforced Natural Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

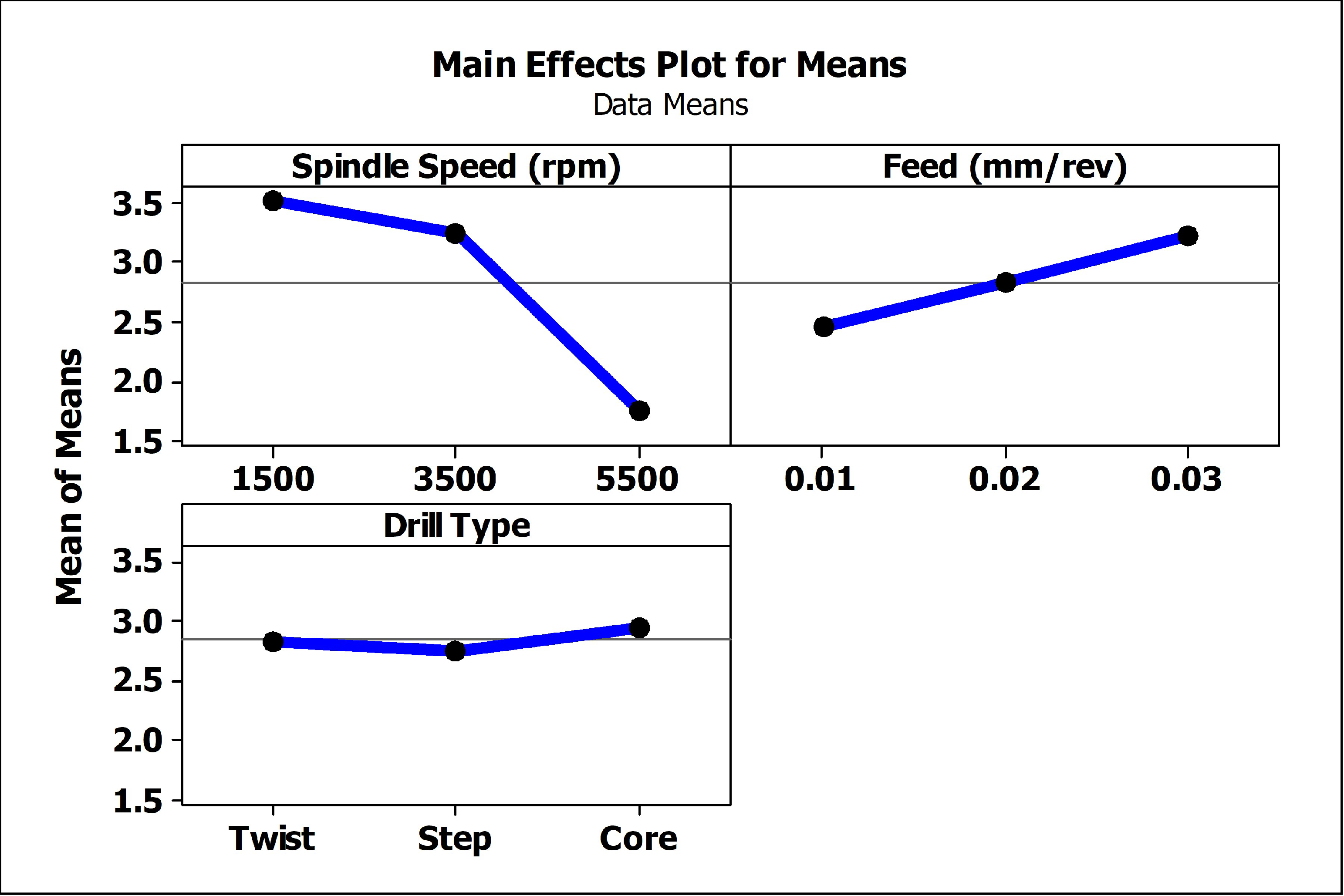

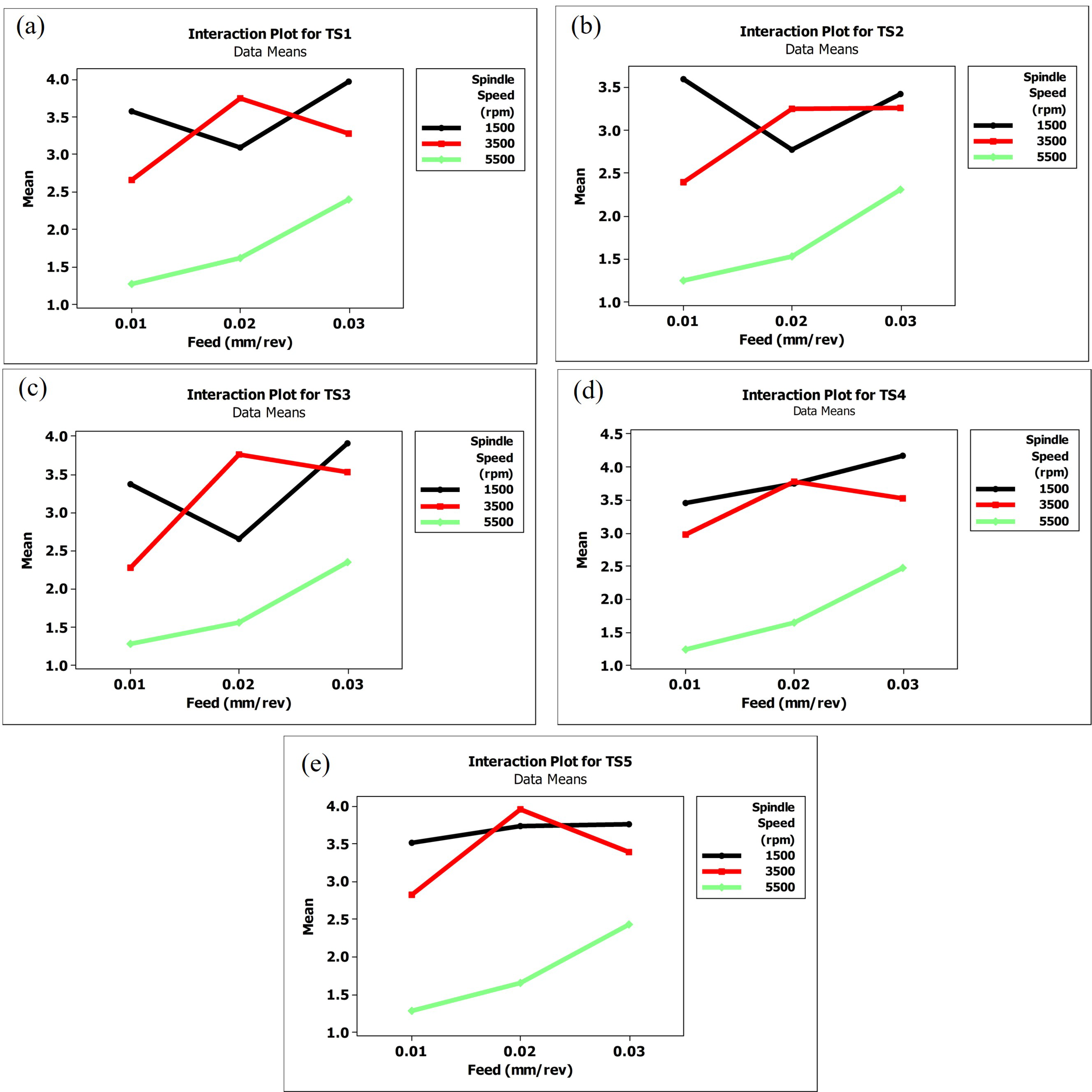

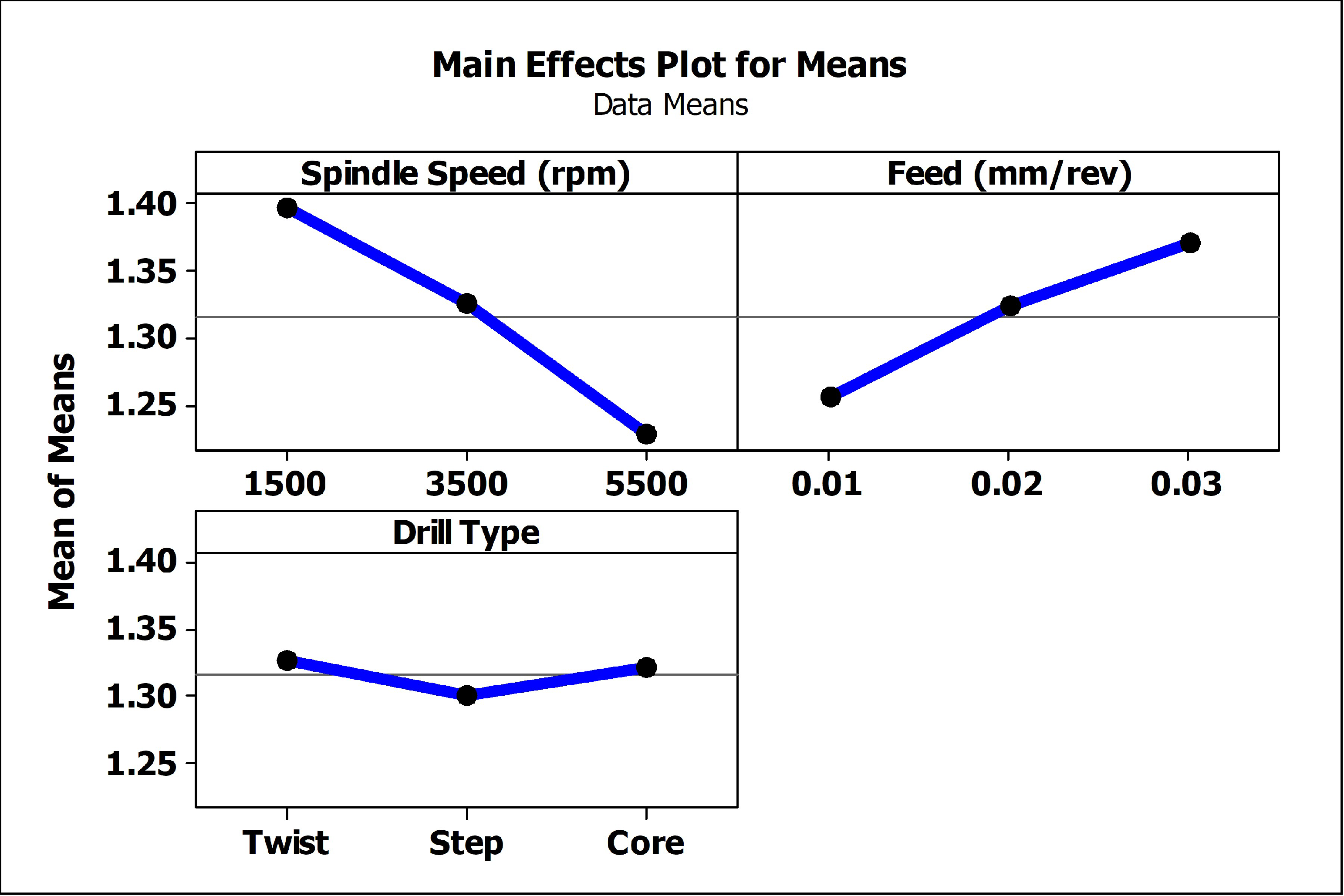

3.1. Surface Roughness Analysis

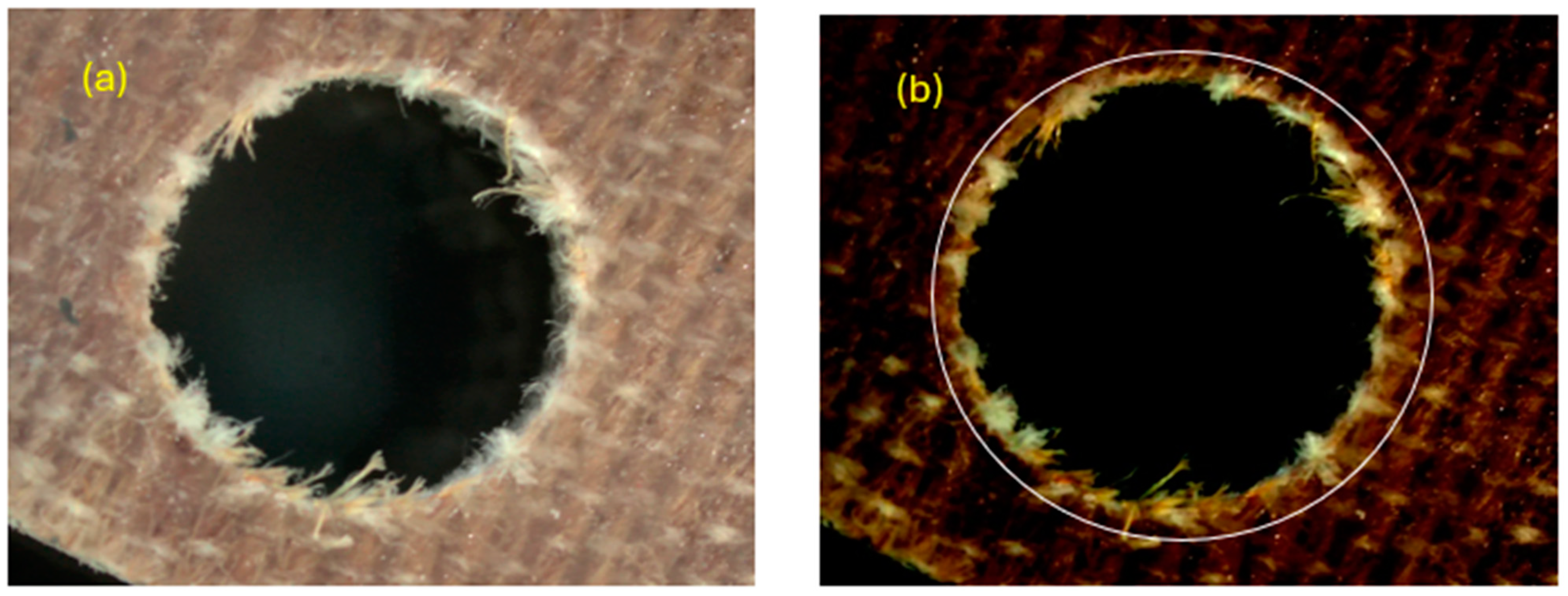

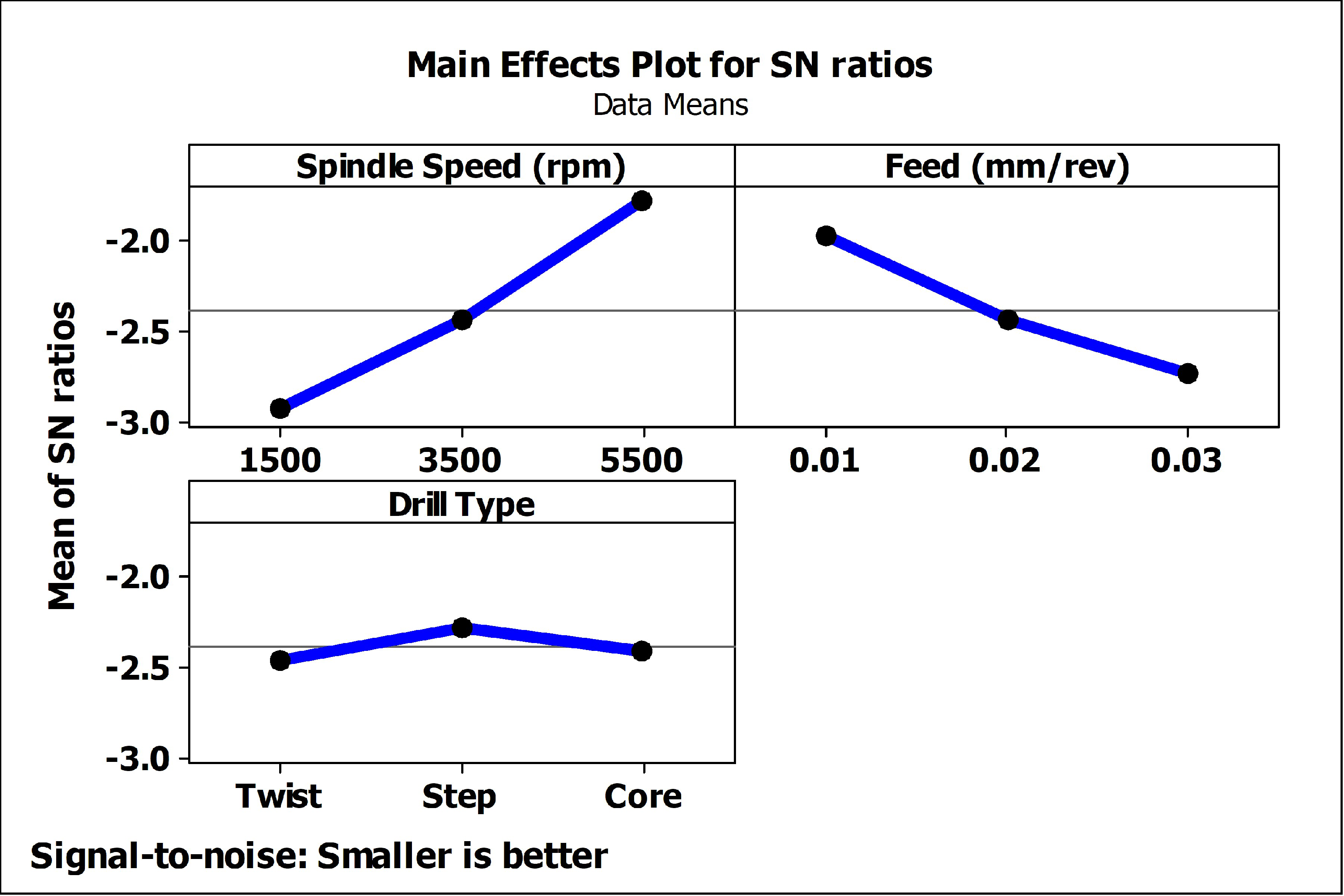

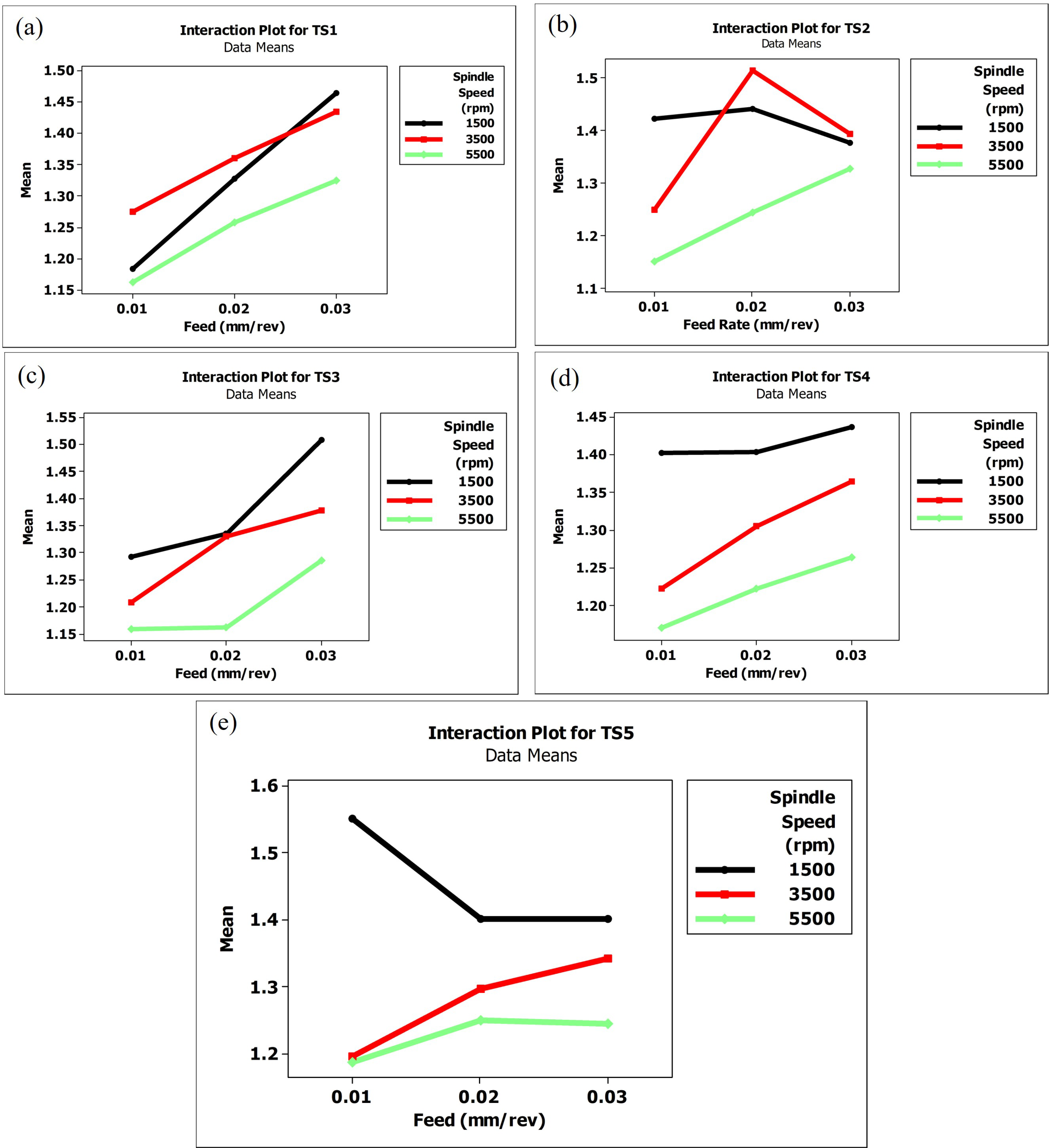

3.2. Delamination Analysis

4. Conclusions

- Surface roughness is mostly affected by spindle speed, followed by feed rate and drill type. Low chisel edge and progressive multi-step cutting action of step drill bits decrease burr formation, all of which contribute to smoother surfaces.

- It is observed that as spindle speed increases, the delamination decreases and also step drills cause less delamination than twist and core drills among drill types.

- Step drill bits are ideal for natural fiber hybrid composites due to their softness and non-abrasiveness, which result in less tool wear and smoother finishes. Synthetic composites, being abrasive, cause rapid tool wear, making them less suitable for step drill bits.

- From observations, to achieve minimum delamination size and good surface roughness when drilling ramie–bamboo-based hybrid laminates, the optimal combination is using a step drill bit, a spindle speed of 5500 rpm, and a feed rate of 0.01 mm/rev.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Syduzzaman, M.; Al Faruque, M.A.; Bilisik, K.; Naebe, M. Plant-based natural fibre reinforced composites: A review on fabrication, properties and applications. Coatings 2020, 10, 973. [Google Scholar] [CrossRef]

- Teja, T.R.; VenkataRao, D.; Naidu, A.L.; Bahubalendruni, M.V.A.R. Mechanical and chemical Properties of Ramie reinforced composites and manufacturing techniques: A Review. Int. J. Res. Dev. Technol. 2017, 8, 21–29. Available online: https://www.researchgate.net/publication/324058516 (accessed on 18 January 2024).

- Rehman, K.; Mohammad, H.; Umer, R. Biomass and Bioenergy Processing and Properties; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y.; Hui, D. Influences of nanoparticles aggregation/agglomeration on the interfacial/interphase and tensile properties of nanocomposites. Compos. B Eng. 2017, 122, 41–46. [Google Scholar] [CrossRef]

- Kumar, L.R.; Madhu, S.; Mothilal, T.; Singh, D.P.; Ali, H.M.; Kamal, M.D.R. Effect of walnut powder reinforcement on the mechanical properties of biodegradable natural flax/hemp fibre-based composites. Mater. Today Proc. 2022, 69, 1387–1393. [Google Scholar] [CrossRef]

- Datta, J.; Kosiorek, P.; Włoch, M. Effect of high loading of titanium dioxide particles on the morphology, mechanical and thermo-mechanical properties of the natural rubber-based composites. Iran. Polym. J. 2016, 25, 1021–1035. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Peng, W.; Zare, Y.; Rhee, K.Y. Effects of Size and Aggregation/Agglomeration of Nanoparticles on the Interfacial/Interphase Properties and Tensile Strength of Polymer Nanocomposites. Nanoscale Res. Lett. 2018, 13, 214. [Google Scholar] [CrossRef]

- Prasad, K.S.; Chaitanya, G. Optimization of process parameters on surface roughness during drilling of GFRP composites using taguchi technique. Mater. Today Proc. 2020, 39, 1553–1558. [Google Scholar] [CrossRef]

- Prasad, K.S.; Chaitanya, G. Analysis of delamination in drilling of GFRP composites using Taguchi Technique. Mater. Today Proc. 2019, 18, 3252–3261. [Google Scholar] [CrossRef]

- Davim, J.P.; Rubio, J.C.; Abrao, A.M. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Tan, C.L.; Azmi, A.I.; Muhammad, N. Delamination and Surface Roughness Analyses in Drilling Hybrid Carbon/Glass Composite. Mater. Manuf. Process. 2016, 31, 1366–1376. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, W.; Chen, D.; Zhang, L. Assessment of the exit defects in carbon fibre-reinforced plastic plates caused by drilling. Key Eng. Mater. 2001, 196, 43–52. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Arunachalam, R.; Alzebdeh, K.I. Machinability of natural fiber reinforced composites: A review. Int. J. Adv. Manuf. Technol. 2017, 88, 2985–3004. [Google Scholar] [CrossRef]

- Xu, J.; An, Q.; Cai, X.; Chen, M. Drilling machinability evaluation on new developed high-strength T800S/250F CFRP laminates. Int. J. Precis. Eng. Manuf. 2013, 14, 1687–1696. [Google Scholar] [CrossRef]

- Debnath, K.; Singh, I.; Dvivedi, A. Drilling characteristics of sisal fiber-reinforced epoxy and polypropylene composites. Mater. Manuf. Process. 2014, 29, 1401–1409. [Google Scholar] [CrossRef]

- Geier, N.; Póka, G.; Jacsó, Á.; Pereszlai, C. A method to predict drilling-induced burr occurrence in chopped carbon fibre reinforced polymer (CFRP) composites based on digital image processing. Compos. B Eng. 2022, 242, 110054. [Google Scholar] [CrossRef]

- Kumar, J.; Singh, Y.; Rakesh, P.K.; Singh, I.; Davim, J.P. The Impact of Hole Diameter on the Molded and Drilled Holes in Jute-Fiber-Reinforced Epoxy Composites. J. Compos. Sci. 2023, 7, 376. [Google Scholar] [CrossRef]

- Debnath, K.; Singh, I.; Dvivedi, A. On the analysis of force during secondary processing of natural fiber-reinforced composite laminates. Polym. Compos. 2017, 38, 164–174. [Google Scholar] [CrossRef]

- Kerrigan, K.; Scaife, R.J. Wet vs dry CFRP drilling: Influence of cutting fluid on tool performance. Procedia CIRP 2018, 77, 315–319. [Google Scholar] [CrossRef]

- Patel, K.; Gohil, P.P.; Chaudhary, V. Investigations on drilling of hemp/glass hybrid composites. Mater. Manuf. Process. 2018, 33, 1714–1725. [Google Scholar] [CrossRef]

- Brahmbhatt, K.; Patel, K.; Bhargav, H. Investigations on Drilling Characteristics of Glass-Bamboo Reinforced Hybrid Composites. Educ. Adm. Theory Pract. 2024, 30, 3122–3127. [Google Scholar] [CrossRef]

- Chandrabakty, S.; Renreng, I.; Djafar, Z.; Arsyad, H. Experimental study and investigation of thrust force and delamination damage of drilled ramie woven reinforced composites. Int. J. Automot. Mech. Eng. 2020, 17, 7618–7628. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Kumar, A.S. An Experimental Study on Drilling of Jute/Epoxy Composites with Ceramic Fillers. J. Eng. Res. Appl. 2018, 59–67. [Google Scholar]

- Nasir, A.A.A.; Azmi, A.I.; Lih, T.C.; Shuaib, N.A. Experimental study towards determination of critical feed for minimization of delamination damage in drilling flax natural fibre composites. Procedia CIRP 2018, 77, 191–194. [Google Scholar] [CrossRef]

- Ramesh, V.; Karthik, K.; Cep, R.; Elangovan, M. Influence of Stacking Sequence on Mechanical Properties of Basalt/Ramie Biodegradable Hybrid Polymer Composites. Polymers 2023, 15, 985. [Google Scholar] [CrossRef]

- Kumar, R.; Ganguly, A.; Purohit, R. Optimization of mechanical properties of bamboo fiber reinforced epoxy hybrid nano composites by response surface methodology. Int. J. Interact. Des. Manuf. 2023, 1–14. [Google Scholar] [CrossRef]

- Shahabaz, S.M.; Mehrotra, P.; Kalita, H.; Sharma, S.; Naik, N.; Noronha, D.J.; Shetty, N. Effect of Al2O3 and SiC Nano-Fillers on the Mechanical Properties of Carbon Fiber-Reinforced Epoxy Hybrid Composites. J. Compos. Sci. 2023, 7, 133. [Google Scholar] [CrossRef]

- Geier, N.; Davim, J.P.; Szalay, T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105552. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Fox-Rabinovich, G.; Paiva, J.M.; Wagg, T.; Veldhuis, S.C. Effect of built-up edge formation during stable state of wear in AISI 304 stainless steel on machining performance and surface integrity of the machined part. Materials 2017, 10, 1230. [Google Scholar] [CrossRef] [PubMed]

- Shahabaz, S.M.; Shetty, N.; Sharma, S.; Jayashree, P.K.; Shetty, S.D.; Naik, N. Optimization of drilling parameters on delamination and burr formation in drilling of neat CFRP and hybrid CFRP nano-composites. Mater. Res. Express 2024, 11, 035006. [Google Scholar] [CrossRef]

- Rashid, K.M.J. Optimize the Taguchi method, the signal-to-noise ratio, and the sensitivity. Int. J. Stat. Appl. Math. 2023, 8, 64–70. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Davim, J.P.; Chen, M.; El Mansori, M. Wear behavior of special tools in the drilling of CFRP composite laminates. Wear 2021, 476, 203738. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, K.; Rakowski, R.; Greenwood, D.; Wale, J. Comparative studies on the effect of pilot drillings with application to high-speed drilling of carbon fibre reinforced plastic (CFRP) composites. Int. J. Adv. Manuf. Technol. 2017, 89, 3243–3255. [Google Scholar] [CrossRef]

- Singh, A.P.; Sharma, M.; Singh, I. A review of modeling and control during drilling of fiber reinforced plastic composites. Compos. B Eng. 2013, 47, 118–125. [Google Scholar] [CrossRef]

- Heidary, H.; Karimi, N.Z.; Minak, G. Investigation on delamination and flexural properties in drilling of carbon nanotube/polymer composites. Compos. Struct. 2018, 201, 112–120. [Google Scholar] [CrossRef]

- Shadrach, A.; Sekaran, J.; Kumar, K.P. Study on Drilling of Woven Sisal and Aloevera Natural Fibre Polymer Composite. Mater. Today Proc. 2019, 16, 640–646. Available online: www.sciencedirect.com (accessed on 2 February 2024). [CrossRef]

- Pankaj; Jawalkar, C.; Kant, S. Study on Mechanical Properties and Delamination Factor Evaluation of Chemically Treated Nettle Fiber Reinforced Polymer Composites. J. Nat. Fibers 2023, 20, 2135053. [Google Scholar] [CrossRef]

| Material | Tensile Strength (MPa) | Young’s Modulus (GPa) | Density (g/cm3) | Diameter (mm) | Cellulose (%) | Lignin (%) | Type |

|---|---|---|---|---|---|---|---|

| Ramie | 180–210 | 1.3 | 1.5 | 0.28 | 68.6 | 0.6 | Woven |

| Bamboo | 180 | 14.2 | 0.3–0.5 | 0.34 | 73.8 | 10 | Woven |

| Material | Density (g/cm3) | Size (nm) | Color |

|---|---|---|---|

| Epoxy Resin | 1.2 | - | Transparent |

| Al2O3 | 3.9 | 20–30 | White |

| SiC | 3.2 | 50 | Grey |

| Test Specimen Configuration | Laminate Configuration | Fiber (wt%) | Epoxy (wt%) | Nano Filler (wt%) |

|---|---|---|---|---|

| TS1 | RRRRRRRR | 30 | 70 | - |

| TS2 | BBBBBBBB | 30 | 70 | - |

| TS3 | RBRBBRBR | 30 | 70 | - |

| TS4 | RBRBBRBR + Al2O3 | 30 | 68 | 2 |

| TS5 | RBRBBRBR + SiC | 30 | 68 | 2 |

| Sl. No. | Parameters | ||

|---|---|---|---|

| Spindle Speed (rpm) | Feed (mm rev−1) | Drill Type | |

| 1 | 1500 | 0.01 | Twist |

| 2 | 3500 | 0.02 | Step |

| 3 | 5500 | 0.03 | Core |

| Spindle Speed (rpm) | Feed (mm rev−1) | Drill Type | TS1 | TS2 | TS3 | TS4 | TS5 |

|---|---|---|---|---|---|---|---|

| 1500 | 0.01 | Twist | 1.173 | 1.564 | 1.312 | 1.384 | 1.534 |

| 1500 | 0.01 | Twist | 1.215 | 1.334 | 1.265 | 1.325 | 1.524 |

| 1500 | 0.01 | Twist | 1.164 | 1.367 | 1.298 | 1.497 | 1.597 |

| 1500 | 0.02 | Step | 1.274 | 1.514 | 1.343 | 1.398 | 1.454 |

| 1500 | 0.02 | Step | 1.306 | 1.437 | 1.365 | 1.464 | 1.398 |

| 1500 | 0.02 | Step | 1.401 | 1.370 | 1.298 | 1.347 | 1.354 |

| 1500 | 0.03 | Core | 1.474 | 1.217 | 1.556 | 1.520 | 1.435 |

| 1500 | 0.03 | Core | 1.456 | 1.500 | 1.465 | 1.365 | 1.354 |

| 1500 | 0.03 | Core | 1.465 | 1.410 | 1.508 | 1.424 | 1.414 |

| 3500 | 0.01 | Step | 1.253 | 1.245 | 1.165 | 1.268 | 1.217 |

| 3500 | 0.01 | Step | 1.302 | 1.267 | 1.205 | 1.245 | 1.204 |

| 3500 | 0.01 | Step | 1.268 | 1.234 | 1.254 | 1.154 | 1.165 |

| 3500 | 0.02 | Core | 1.345 | 1.497 | 1.240 | 1.325 | 1.198 |

| 3500 | 0.02 | Core | 1.348 | 1.504 | 1.345 | 1.268 | 1.335 |

| 3500 | 0.02 | Core | 1.388 | 1.540 | 1.404 | 1.324 | 1.354 |

| 3500 | 0.03 | Twist | 1.409 | 1.400 | 1.380 | 1.405 | 1.314 |

| 3500 | 0.03 | Twist | 1.485 | 1.350 | 1.400 | 1.385 | 1.334 |

| 3500 | 0.03 | Twist | 1.412 | 1.427 | 1.354 | 1.304 | 1.375 |

| 5500 | 0.01 | Core | 1.154 | 1.110 | 1.170 | 1.137 | 1.145 |

| 5500 | 0.01 | Core | 1.163 | 1.190 | 1.114 | 1.178 | 1.198 |

| 5500 | 0.01 | Core | 1.168 | 1.1500 | 1.190 | 1.194 | 1.214 |

| 5500 | 0.02 | Twist | 1.203 | 1.245 | 1.135 | 1.197 | 1.235 |

| 5500 | 0.02 | Twist | 1.263 | 1.226 | 1.165 | 1.267 | 1.227 |

| 5500 | 0.02 | Twist | 1.308 | 1.260 | 1.184 | 1.204 | 1.287 |

| 5500 | 0.03 | Step | 1.265 | 1.324 | 1.274 | 1.298 | 1.254 |

| 5500 | 0.03 | Step | 1.303 | 1.298 | 1.285 | 1.247 | 1.264 |

| 5500 | 0.03 | Step | 1.408 | 1.356 | 1.298 | 1.245 | 1.214 |

| Spindle Speed (rpm) | Feed (mm rev−1) | Drill Type | TS1 | TS2 | TS3 | TS4 | TS5 |

|---|---|---|---|---|---|---|---|

| 1500 | 0.01 | Twist | 3.85 | 3.55 | 3.42 | 3.41 | 3.82 |

| 1500 | 0.01 | Twist | 3.59 | 3.76 | 3.51 | 3.32 | 3.6 |

| 1500 | 0.01 | Twist | 3.31 | 3.49 | 3.19 | 3.63 | 3.14 |

| 1500 | 0.02 | Step | 3.11 | 2.78 | 2.84 | 3.94 | 3.63 |

| 1500 | 0.02 | Step | 3.28 | 2.97 | 2.68 | 3.51 | 3.84 |

| 1500 | 0.02 | Step | 2.91 | 2.57 | 2.46 | 3.8 | 3.75 |

| 1500 | 0.03 | Core | 3.76 | 3.31 | 3.47 | 4.42 | 3.57 |

| 1500 | 0.03 | Core | 3.98 | 3.42 | 3.63 | 4.25 | 3.77 |

| 1500 | 0.03 | Core | 4.19 | 3.54 | 4.63 | 3.84 | 3.95 |

| 3500 | 0.01 | Step | 2.68 | 2.58 | 2.24 | 3.1 | 2.91 |

| 3500 | 0.01 | Step | 2.48 | 2.19 | 2.13 | 2.79 | 2.85 |

| 3500 | 0.01 | Step | 2.82 | 2.43 | 2.47 | 3.03 | 2.72 |

| 3500 | 0.02 | Core | 3.56 | 3.16 | 3.64 | 3.62 | 3.89 |

| 3500 | 0.02 | Core | 3.79 | 3.24 | 3.77 | 3.71 | 4.05 |

| 3500 | 0.02 | Core | 3.92 | 3.36 | 3.88 | 3.97 | 3.95 |

| 3500 | 0.03 | Twist | 3.18 | 3.12 | 3.46 | 3.42 | 3.66 |

| 3500 | 0.03 | Twist | 3.24 | 3.29 | 3.53 | 3.61 | 3.42 |

| 3500 | 0.03 | Twist | 3.41 | 3.39 | 3.62 | 3.55 | 3.12 |

| 5500 | 0.01 | Core | 1.21 | 1.12 | 1.23 | 1.17 | 1.19 |

| 5500 | 0.01 | Core | 1.24 | 1.28 | 1.26 | 1.23 | 1.29 |

| 5500 | 0.01 | Core | 1.35 | 1.35 | 1.34 | 1.31 | 1.35 |

| 5500 | 0.02 | Twist | 1.51 | 1.41 | 1.45 | 1.54 | 1.56 |

| 5500 | 0.02 | Twist | 1.62 | 1.52 | 1.56 | 1.67 | 1.63 |

| 5500 | 0.02 | Twist | 1.73 | 1.64 | 1.67 | 1.72 | 1.76 |

| 5500 | 0.03 | Step | 2.27 | 2.17 | 2.21 | 2.33 | 2.31 |

| 5500 | 0.03 | Step | 2.36 | 2.27 | 2.32 | 2.43 | 2.42 |

| 5500 | 0.03 | Step | 2.58 | 2.49 | 2.53 | 2.66 | 2.57 |

| Level | Spindle Speed (rpm) | Feed (mm rev−1) | Drill Type |

|---|---|---|---|

| 1 | −10.957 | −7.112 | −8.550 |

| 2 | −10.159 | −8.566 | −8.753 |

| 3 | −4.558 | −9.991 | −8.370 |

| Delta | 6.399 | 2.885 | 0.383 |

| Rank | 1 | 2 | 3 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | p Value |

|---|---|---|---|---|---|---|

| Spindle speed (rpm) | 2 | 72.9587 | 72.9587 | 36.4793 | 7.87 | 0.113 |

| Feed (mm rev−1) | 2 | 12.4839 | 12.4839 | 6.2420 | 1.35 | 0.426 |

| Drill type | 2 | 0.2203 | 0.2203 | 0.1102 | 0.02 | 0.977 |

| Residual Error | 2 | 9.2723 | 9.2723 | 4.6361 | ||

| Total | 8 | 94.9352 |

| Level | Spindle Speed (rpm) | Feed (mm rev−1) | Drill Type |

|---|---|---|---|

| 1 | −3.042 | −1.970 | −2.460 |

| 2 | −2.438 | −2.478 | −2.321 |

| 3 | −1.774 | −2.807 | −2.473 |

| Delta | 1.268 | 0.837 | 0.152 |

| Rank | 1 | 2 | 3 |

| Source | Df | Seq SS | Adj SS | Adj MS | F | p Value |

|---|---|---|---|---|---|---|

| Spindle speed | 2 | 2.41203 | 2.41203 | 1.20602 | 25.19 | 0.038 |

| Feed | 2 | 1.06569 | 1.06569 | 0.53284 | 11.13 | 0.082 |

| Drill type | 2 | 0.04247 | 0.04247 | 0.02123 | 0.44 | 0.693 |

| Residual error | 2 | 0.09574 | 0.09574 | 0.04787 | ||

| Total | 8 | 3.61593 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar P, K.; Lokeshwar, G.; Reddy, C.U.K.; Jyotis, A.; Shetty, S.; Acharya, S.; Shetty, N. Effect of Drilling Parameters on Surface Roughness and Delamination of Ramie–Bamboo-Reinforced Natural Hybrid Composites. J. Manuf. Mater. Process. 2024, 8, 195. https://doi.org/10.3390/jmmp8050195

Kumar P K, Lokeshwar G, Reddy CUK, Jyotis A, Shetty S, Acharya S, Shetty N. Effect of Drilling Parameters on Surface Roughness and Delamination of Ramie–Bamboo-Reinforced Natural Hybrid Composites. Journal of Manufacturing and Materials Processing. 2024; 8(5):195. https://doi.org/10.3390/jmmp8050195

Chicago/Turabian StyleKumar P, Krishna, Gaddam Lokeshwar, Chamakura Uday Kiran Reddy, Arun Jyotis, Surendra Shetty, Subash Acharya, and Nagaraja Shetty. 2024. "Effect of Drilling Parameters on Surface Roughness and Delamination of Ramie–Bamboo-Reinforced Natural Hybrid Composites" Journal of Manufacturing and Materials Processing 8, no. 5: 195. https://doi.org/10.3390/jmmp8050195

APA StyleKumar P, K., Lokeshwar, G., Reddy, C. U. K., Jyotis, A., Shetty, S., Acharya, S., & Shetty, N. (2024). Effect of Drilling Parameters on Surface Roughness and Delamination of Ramie–Bamboo-Reinforced Natural Hybrid Composites. Journal of Manufacturing and Materials Processing, 8(5), 195. https://doi.org/10.3390/jmmp8050195