Abstract

This study investigates the need for a quality strategy in metal additive manufacturing (AM) technology effective for batch production. We carried out two surveys aimed at gathering data from industry experts to understand the challenges and the requirements of quality strategies in metal AM. Survey 1 investigated general quality aspects in metal technology, revealing key areas where quality strategies are required, such as process control, material consistency, and post-processing. It also highlighted challenges that directly impact part quality, including process variability, material inconsistencies, and surface finish issues. Survey 2, focused on batch production, showed that 75% of participants strongly agreed with the need for a specific quality strategy to address challenges specific to metal AM. The respondents highlighted critical processes requiring quality strategies, including powder quality, process optimisation, and defect detection, while identifying ongoing issues with process variability and material inconsistency. Both surveys indicate a need for a standardised and effective quality strategy to enhance production consistency, efficiency, and regulatory compliance. Regardless of a limited sample size of 59 respondents, these results emphasise the need for improved quality strategies in metal AM to reduce defects effectively, meet customer expectations, and ensure scalable production. This study provides insights into the strategic development of quality strategies significant for advancing metal AM technology.

1. Introduction

The industrialisation of metal additive manufacturing (AM) is driven by the technology’s capability to overcome traditional manufacturing challenges, such as the production of complex parts in a short lead time and without tooling [1]. This capability positions metal AM as a disruptive technology that could revolutionise industries by enabling more efficient production processes, particularly for batch productions. Design for Additive Manufacturing (DfAM) emerges as a pivotal strategy in this context because the design and production of parts are optimised to fully leverage the benefits of metal AM technology [2]. DfAM has become an essential tool for bridging the gap between the capability of metal AM technology and its operationalisation for industrial growth. DfAM involves designing parts specifically for AM, considering the technology’s unique abilities and the process’s limitations regarding quality [2,3]. From the design and production planning phase, the properties of the metal powder and its behaviour under thermal stresses are considered, as well as the final parts’ required quality [4]. As previously noted, the industrialisation and advancement of metal AM technologies are based on producing highly complex functional parts with maximum quality at minimum cost. However, quality management in batch production for metal AM technology poses a complex challenge, characterised by the scale of production and the complex physics that influence process phenomena, leading to product defects and process variability [5].

Quality challenges in metal AM technology are often compared with challenges in conventional manufacturing technology, such as welding, to understand and define quality strategies for metal AM. Welding and metal AM share some similarities, particularly in their layering process nature, which can lead to similar types of defects and quality challenges. A study by Lee et al. [6] highlighted these similarities and suggested modifying certain quality assurance methods from welding to address issues in metal AM. However, while these similarities provide a valuable starting point for quality assurance in the technology, the unique characteristics of metal AM introduce additional complexities. Unlike welding, metal AM involves intricate geometries, layer-by-layer production, and complex physics that result in greater process variability and a wider range of product anomalies. Colosimo et al. [7] further emphasised these unique challenges by classifying quality issues in metal AM based on the nature of the process, which further presents difficulties in quality measurement and inspection. Process variability in metal AM technology is one of the factors leading to defects.

Quality strategies could play a critical role in addressing the challenges of AM technology, aiding its widespread industrial adoption. One of the significant challenges encountered in metal AM technology is that traditional QA&C (quality assurance and control) methods are not readily applicable to the technology due to the nature of production and the complex physics that leads to process variability and product anomalies. Quality strategies in the manufacturing industry are often applied to reduce process variability and to increase process efficiency and productivity [8]. There is a need for quality strategies specifically tailored for metal AM technology. While drawing inspiration from established manufacturing practices like welding, existing quality strategies must be redefined and adapted to the specific needs of metal AM to address its challenges effectively. This dual perspective emphasises the importance of building on conventional quality approaches while accounting for the distinct requirements of metal AM to ensure its industrial adoption.

Several reasons in metal AM technology, especially in laser powder bed fusion (LPBF), influence the inapplicability of traditional QA&C to metal AM technology; firstly, in LPBF for metal part fabrication, the process’s rapid heating and cooling nature creates melt-pool instability and also introduces residual stresses, which may decrease the quality of the final product [9]. Secondly, the layer-by-layer variation, which is influenced by particle distribution, powder flowability, and the interaction of the powder and the laser during manufacturing, also impacts the quality of the part [10]. Lastly, the by-products of the production process, such as spatter particles in batch productions, influence surface texture and, therefore, affect the quality of the resulting products [11,12]. The above issues emphasise the need for a quality strategy in metal AM technology and further highlight the necessity of understanding how the AM community perceives the need for a tailored quality strategy, as this understanding is essential for designing quality strategies appropriate to address the observed issues effectively. Therefore, this study aims to define the need for a quality strategy for batch production across industries by assessing the perceptions of individuals involved in metal AM technology rather than a quantitative evaluation of existing practices in specific industries. To achieve this, this study employs a survey questionnaire to collect and verify the perceptions and insights of these individuals regarding quality issues in metal AM technology.

2. Materials and Methods

This study adopted a mixed-method research approach comprising multiple-choice, open-ended, and Likert scale assessments. It applied a survey research methodology to answer the research question, aiming to lay the groundwork for a systematic quality strategy for batch production in metal AM technology. A cross-sectional research design, chosen for its ability to observe and collect data in a defined population at a particular time, was employed [13]. As Kesmodel [14] points out, a cross-sectional study design is ideal for assessing and describing a population’s best practices, attitudes, knowledge, and beliefs about a particular phenomenon at a point in time. This study leverages the cross-sectional research design to evaluate the knowledge, beliefs, and perceptions of individuals working with metal AM technology about quality issues, strategies that can be applied, and the requirements for quality in metal AM production. Furthermore, this study aims to guide the development of a QA&C framework for batch production by outlining the imperative for assurance and control in metal AM technology.

2.1. Participants

This study targeted the AM community, focusing on two groups: attendees of Formnext, Germany’s largest annual AM event, and experts in metal AM technologies from academic and industrial backgrounds. Formnext serves as a central hub for AM technology, attracting industrial personnel, experts, and production professionals from around the globe. Its status as a premier gathering for the AM community made it an ideal platform to engage participants for this study. The event takes place annually in November and is a week long, bringing together professionals from diverse industries who are either interested in or actively involved in various AM technologies for industrial applications, including material, post-processing service providers, 3D printer manufacturers, and specialists in measurement technologies for AM parts. The questionnaire was administered to the respondents from the 7th to the 8th of November 2023.

Inclusion: the survey sent to Formnext included personnel in the metal section of the exhibition. Participants were selected from both visitors and exhibitors in the Metal AM section, utilising random sampling. At least one expert from each booth was approached to participate in the survey. The second group consists of experts specialising in metal AM in academia and industry. These experts were identified and accessed through LinkedIn, a global professional networking platform. The participants were selected based on their LinkedIn profiles, which indicated their involvement in metal AM technology. They were then invited to participate in the study by completing an online survey via a provided link. Exclusion: This study excluded personnel specialising in materials other than metals for AM technology, such as polymers. For the second survey, PhDs and sales professionals were manually filtered out from this pool, leaving only researchers in technical roles such as engineers, operators, and technical personnel working directly with metal AM technology.

2.2. Survey Procedure and Analysis

Two distinct survey types were developed to gather data on quality strategies in metal AM technology due to variability in participant accessibility and expertise. The two surveys were employed to gather complementary perspectives on quality issues in metal AM technology that could enhance the discussion regarding the exigency of a quality strategy. This approach allows for a better understanding of both current challenges and future directions of AM technology in the industry without imposing direct comparisons between the findings. The first survey targeted Formnext attendees to reflect immediate challenges and concerns faced by professionals involved in developing and deploying metal AM technology across industries, providing a platform to capture practical industrial perspectives about the need for a quality strategy. In contrast, the LinkedIn survey provided a broader audience that includes professionals, researchers in technical roles, and practitioners across different industries working with metal AM technology. This survey provided a range of opinions and reflects trends and future expectations closely tied to the immediate industry challenges.

The first questionnaire exclusively featured multiple-choice questions and was administered during the Formnext event, specifically on the 7th and 8th of November 2023. A mixed-method questionnaire was developed after modifying the first survey as a fundamental research tool to tackle the imperative of a QA&C strategy for metal AM technology. The second survey incorporated open-ended questions, Likert scale assessments, and multiple-choice questions to study participants’ perceptions, experiences, and knowledge regarding quality in metal AM technology and quality strategies for batch production. The questions are generally designed to address aspects encompassing process knowledge, perception of quality in metal AM for batch production, the perceived requirement for quality strategies, challenges, and defect rates for batch production. These survey elements collectively constitute an instrument for data collection, seeking to capture general perceptions, trends, and common challenges from a diverse group of respondents. Rather than quantifying quality metrics in specific industries, the survey aims to understand the necessity of a quality strategy in metal AM technology across industries. It is essential to establish the significance and effect of quality strategies within metal AM technology to determine the necessity for a quality strategy. This entails acquiring a fundamental understanding of the technology.

Each survey comprised three categories used to collect qualitative data. These categories focused on gathering information about the respondents’ knowledge of the commonly used metal processes to understand their expertise. This included identifying 1. the technology the respondents are most familiar with, 2. their position within the AM technology ecosystem as an organisation, and 3. the services they provide to the industry. For the second survey, the first category was based on defining their experience and the metal AM technology they are most familiar with. The second category focused on understanding the perceived challenges and difficulties encountered within the technology regarding implementing quality strategies. The third category evaluated respondents’ perceptions of the role and significance of quality strategies in metal AM to determine the imperative of a QA&C framework for metal AM technology for batch production. These elements collectively form the framework for effective data collection for this study. While these categories allow for subjective interpretation, they were intentionally chosen to capture general perceptions about the need for a quality strategy in metal AM in different industries, which is essential for identifying common challenges in the industrialisation of metal AM. The questionnaires are attached in Appendix A.

The multiple-choice questionnaire comprised 18 questions addressing issues stemming from the absence of quality strategies and well-defined quality management in metal AM technology. Before the event, the questionnaire was developed and tested on 16 random individuals during the first day of the Formnext exhibition. These individuals were chosen to confirm the survey’s design appropriateness, readability, and ease of administration. After this, the survey was modified accordingly. The participants were required to scan a QR code containing a Google form featuring the questions and select at least one answer that aligned with their situation. The questions were answered anonymously and did not require participants’ details. The second survey was refined from the multiple-choice questionnaire and expanded to 20 questions. Its purpose was to examine the experts’ perceptions of quality within the technology. Before distributing this revised survey to participants, it was initially shared with colleagues within the metal AM research group at the University of Twente to evaluate its readability, appropriateness, and ease of administration. A targeted approach was taken to gather participants for the study: a metal additive manufacturing search was conducted on LinkedIn, focusing on individuals in metal AM technology. Initially, 6700 individuals appeared in the search results. Subsequently, the survey was sent to 100 individuals with a message requesting participation. The message sent to the respondent requesting participation and the questions are attached in Appendix B.

The collected data were organised using Google Documents, and the responses were downloaded into spreadsheets for processing. Statistical analysis was applied and conducted using SPSS. Each response was coded into variables and named according to the objective of the corresponding question in the variable view. The responses not part of the survey options were coded as “Other” and presented in Appendix C page for the second survey. Descriptive analysis was employed since the survey was used to understand the need for a QA&C strategy in metal AM technology. According to Taherdoost [15], descriptive data analysis focuses on summarising and describing the characteristics of the observed dataset. Descriptive analysis aims to provide an overview of the data, revealing patterns, trends, and distributions without making inferences beyond the observed data [16]. This study used descriptive analysis to display and describe the perception of individuals in the AM community about the quality issues and their management in the technology, including the presentation of frequencies between participants’ responses. The graphs were summarised using pie charts and bar graphs.

3. Results

The following section presents the results of the analysis of both surveys and their implications. It evaluates the survey responses to identify the need for a quality strategy in metal AM technology. This study analyses both surveys to collectively assess the need for a quality strategy in metal AM technology. This text first evaluates the results of the initial survey sent to Formnext, followed by the second survey.

The importance and role of quality strategy:

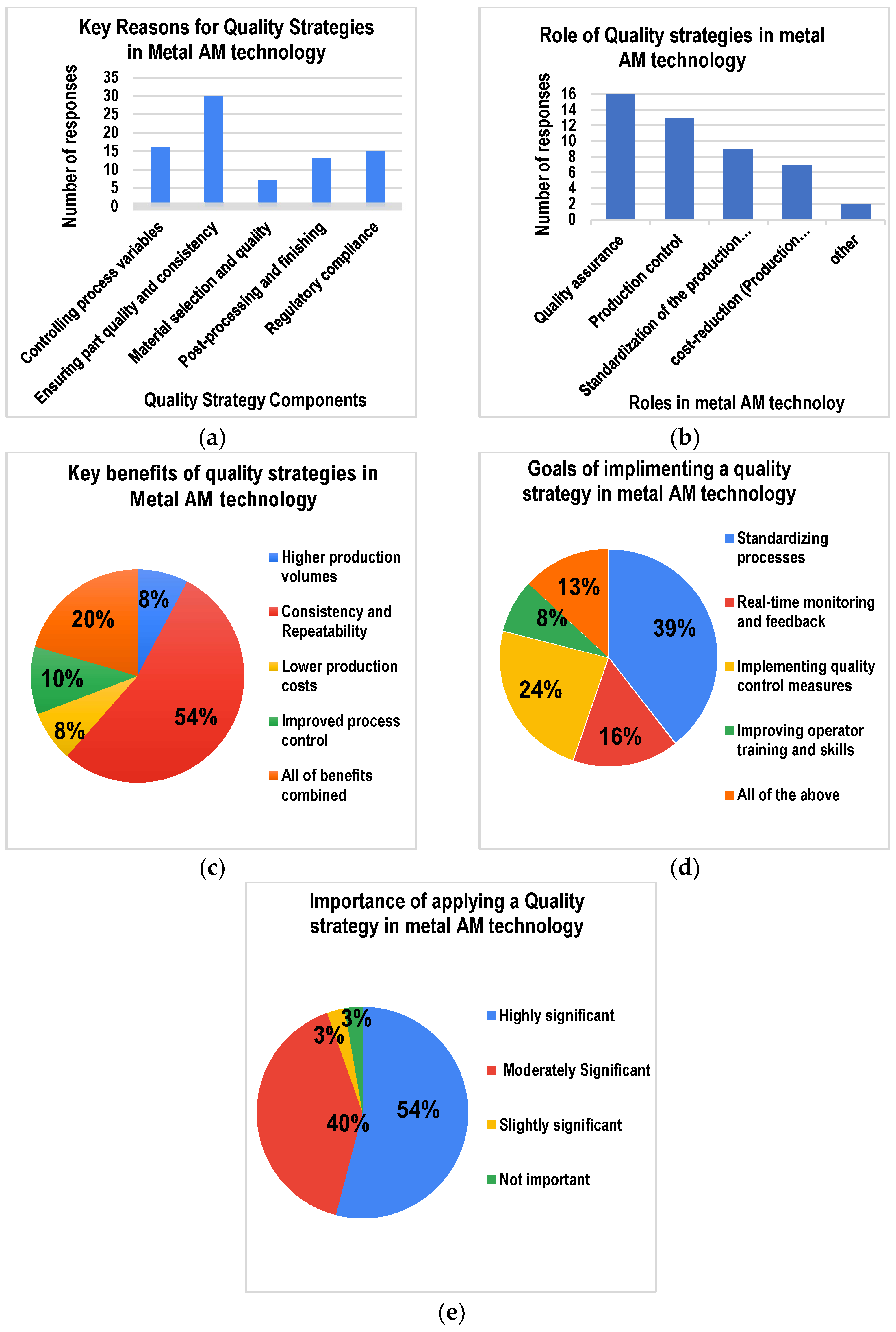

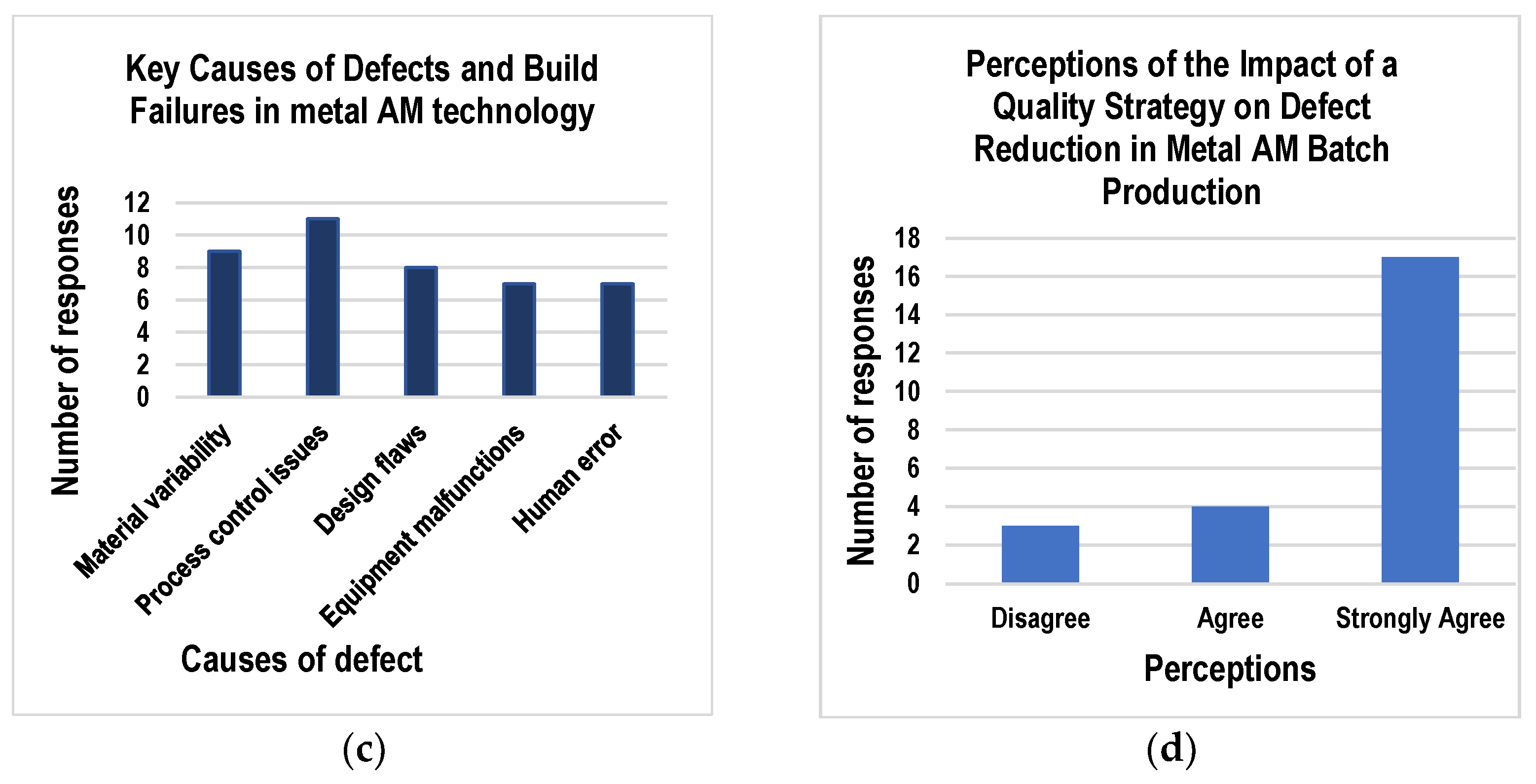

The survey highlights the importance of quality strategies in metal AM technology, as seen by industry experts. The gathered insights emphasise the essential role of effective quality strategies in its success. The respondents were asked to evaluate the importance and need to implement quality strategies in metal AM, reflecting the industry’s recognition of this requirement. The relevant questions are listed in Appendix A.1, specifically numbered 5, 6, 7, 13, and 16. Figure 1 provides a graphical representation of the results obtained after answering these questions. Figure 1a shows the highest response to the question about the importance and the need for a quality strategy, as denoted by Figure 1a. It shows ensuring part quality and consistency as fundamental drivers for adopting quality strategies. Then, controlling process variables is the second most mentioned, stressing the need to address AM’s inherent process variability, followed by material selection and quality, post-processing and finishing, and regulatory compliance, showing a relatively lower prominence.

Figure 1.

The importance and need for quality strategies in metal AM technology, as highlighted by the number of responses for each listed element. (a) Identifies the reasons driving the need for quality strategies in metal AM technology; (b) highlights the role of quality strategies in ensuring consistent production quality; (c) analyses respondents’ understanding of the benefits of quality strategies; (d) examines the necessity of applying quality strategies in metal AM processes; (e) explores respondents’ perceptions of the overall importance of quality strategies in metal AM technology.

When analysing the role of quality strategies described in Figure 1b, quality assurance is the most emphasised, followed by production control and standardisation of the production process. Cost reduction through production improvements and other roles have lower responses. When observing the perceived role of quality strategies in metal AM (Figure 1c), over half of the respondents believe quality strategies will improve consistency and repeatability. This is followed by a smaller number of respondents denoting the perceived role as enabling higher production volumes; reducing production costs; and, lastly, fostering process control. Complimentary to this, 20% of the respondents selected all of the above, suggesting that some respondents perceive the role of quality strategies as multifaceted and having a broader impact. For the purpose of quality strategies in metal AM (Figure 1d) technology, 39% of respondents see the purpose of quality strategies as establishing standardised processes, while 24% of respondents define the purpose as implementing quality control measures and 16% for real-time monitoring and feedback, followed by enhancing operator training and skills at 8% and 13% for all. When observing the significance of applying a quality strategy (Figure 1e), most respondents consider quality strategies very significant, and 40% view them as moderately significant for metal AM technology. Only 6% think quality strategies are somewhat significant or not significant.

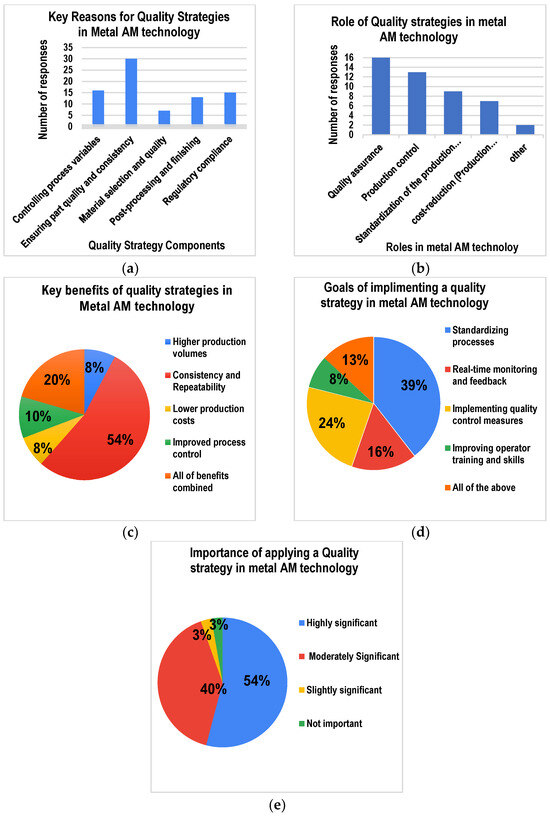

Challenges in Metal AM technology:

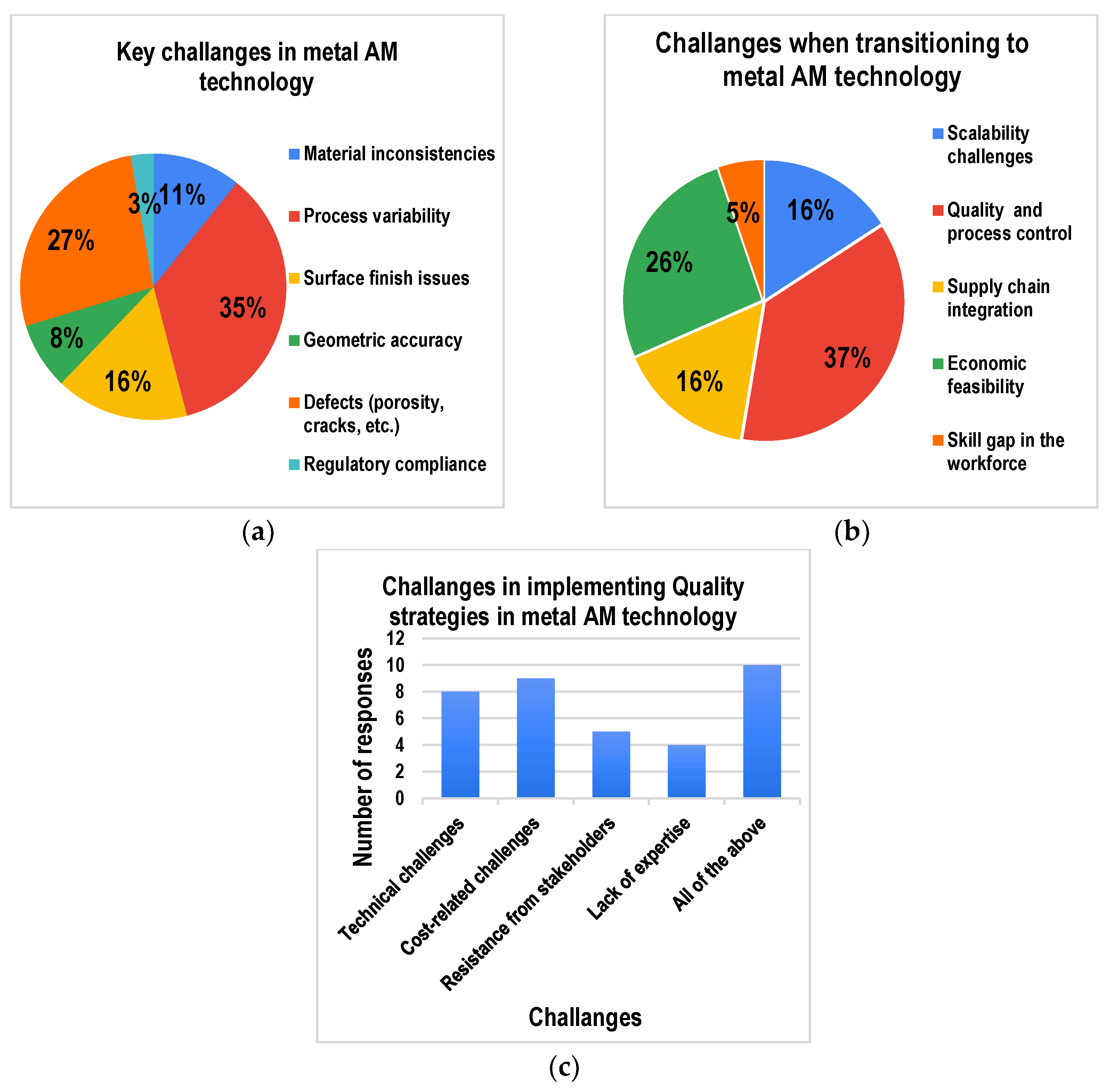

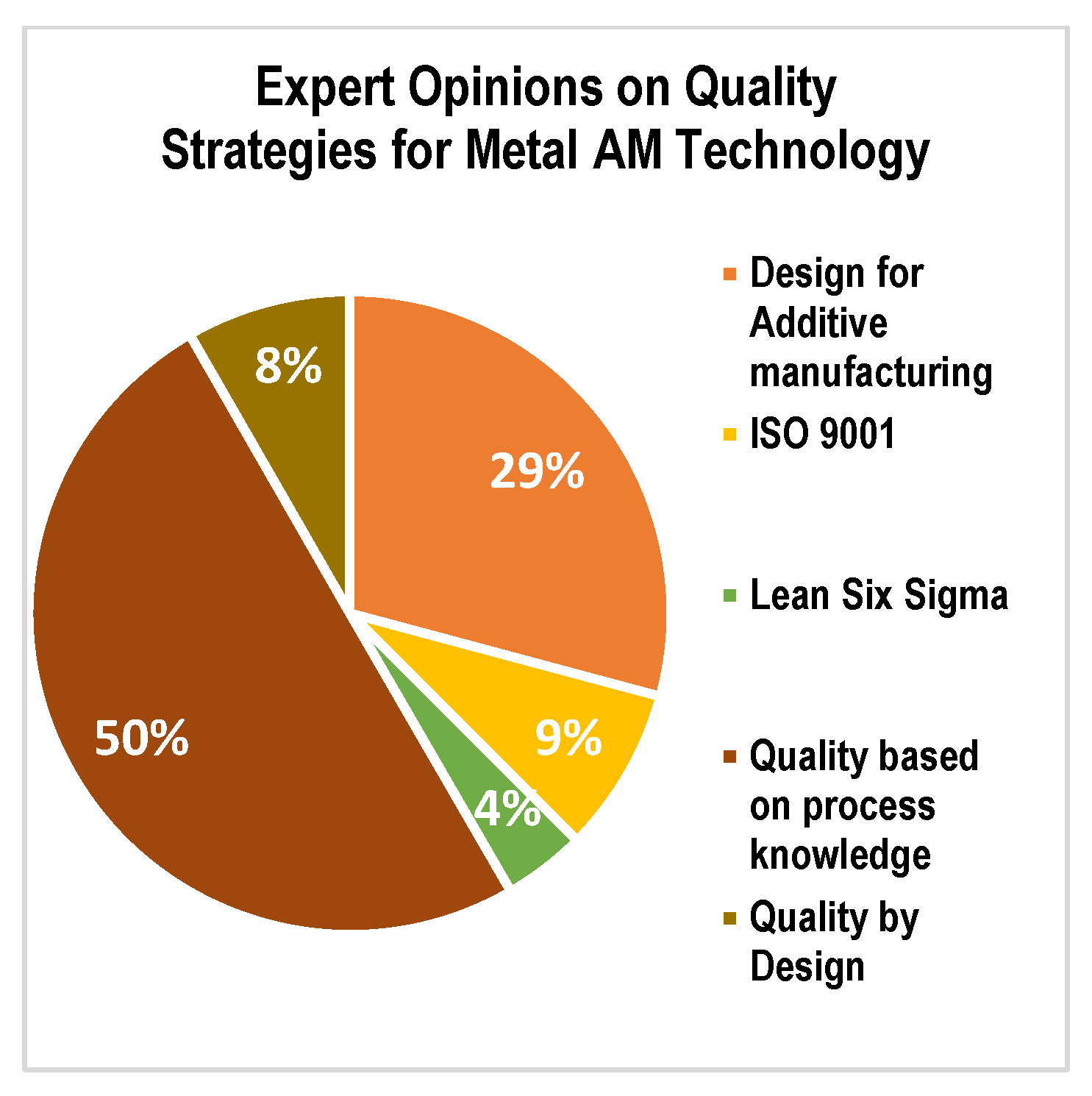

This section aims to outline the challenges experienced in the technology, including when ensuring quality, transitioning to metal AM technology, and implementing quality strategies. These challenges were then classified into three categories: challenges inherent to the technology, transitioning to metal AM technology, and implementing a quality strategy. Questions 8, 10, and 15 address the challenges and are summarised in Figure 2.

Figure 2.

Challenges in metal AM technology can be categorised into three main groups: (a) inherent challenges of the metal AM process; (b) challenges during the transition to metal AM processes; (c) challenges in applying quality strategies, including cost-related issues and a lack of expertise.

Contribution of quality strategies:

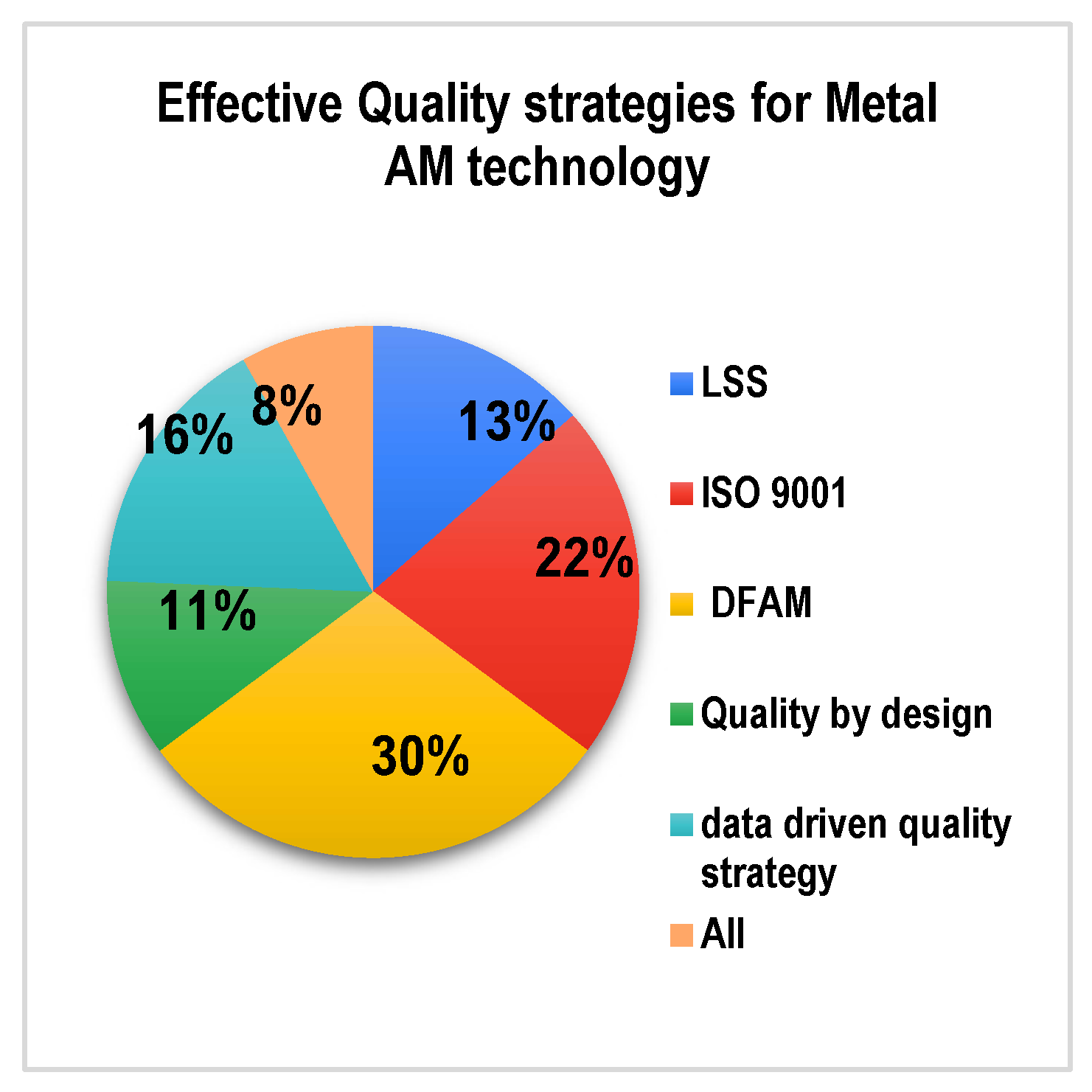

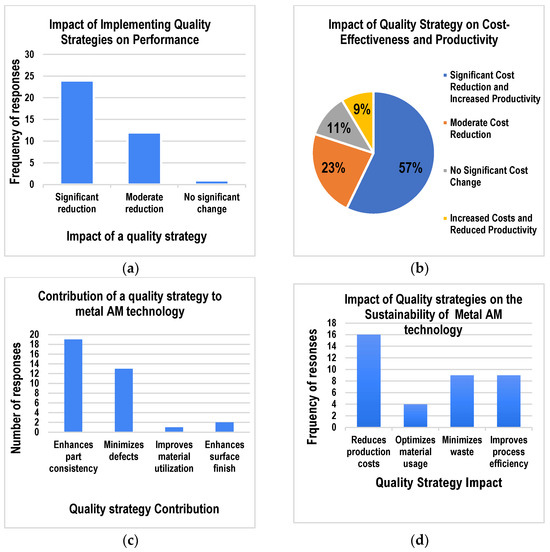

The results show that implementing quality strategies in metal AM technology can reduce defects, ensure higher product reliability, and lower production costs by improving productivity, material utilisation, and waste management. Figure 3 shows a graphical presentation of the perceived contribution of quality strategies in metal technology. Figure 3a,b demonstrate how quality strategies address the challenges of scaling AM technologies for wider industrial adoption through significant defect and error reduction, thus reducing cost and increasing productivity since cost and production efficiency are significant barriers. Figure 3c highlights that quality strategies contribute to enhancing part consistency and minimising defects. This is fundamental for making metal AM suitable for high-precision applications, where consistency and defect minimisation are essential. Furthermore, reducing production cost, optimising material usage, and improving process efficiency, shown in Figure 3d, play critical roles in making metal AM viable for high-volume production, as these factors directly impact production scalability and cost efficiency, in general influencing the sustainability of the technology. These insights collectively demonstrate the potential of quality strategies to enable metal AM to meet the demands of high-volume and high-precision manufacturing while also facilitating scalability.

Figure 3.

Contribution of quality strategies in metal AM by examining respondents’ understanding of (a) general perception of product performance and the significance of quality strategies in manufacturing, (b) benefits of quality strategies on cost-effectiveness and productivity, (c) potential benefits of quality strategies to metal AM technology, (d) influence of quality strategies on the sustainability of the metal AM process.

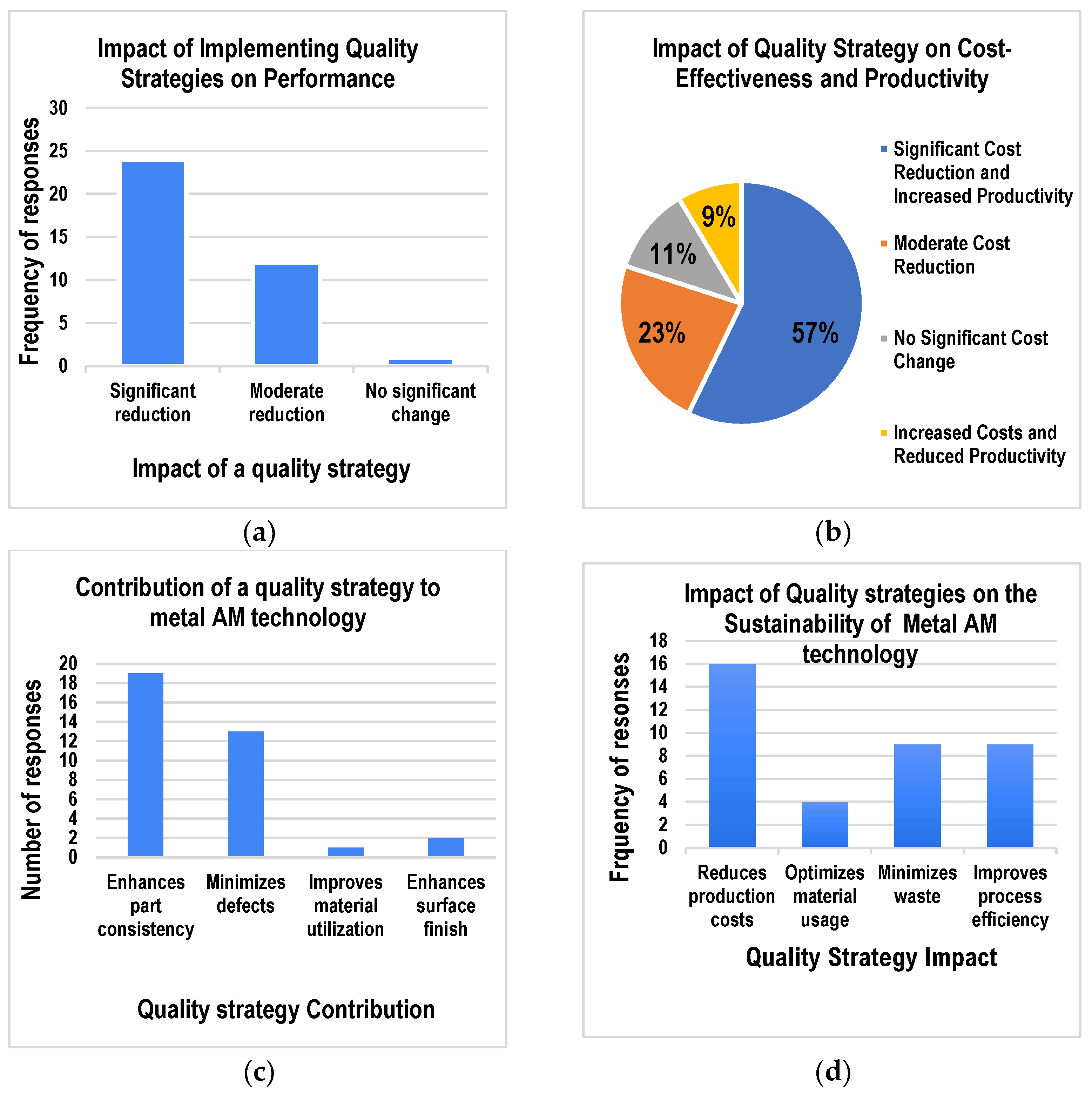

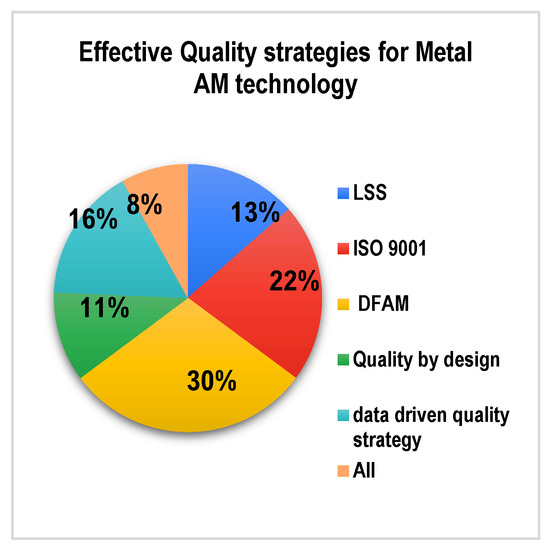

Possible quality strategies for metal AM technology:

The survey also aimed to identify the quality strategies the respondents consider most appropriate for metal AM technology. Figure 4 illustrates the range of potential quality strategies. DfAM helps optimise designs to reduce defects, improve surface quality, and ensure part consistency by accounting for the specific characteristics of AM processes, such as build orientation, material behaviour, and support structure requirements. ISO 9001 [16] provides a structured approach to managing quality, emphasising process control, documentation, and continuous improvement. For metal AM, ISO 9001 ensures that production processes are well-defined and controlled and meet consistency and traceability requirements, which are critical in industries like aerospace and medical devices.

Figure 4.

Effective proactive quality strategies for metal AM technology, as determined by the attendees of Formnext event.

None of the respondents selected the trial and error method as an applicable quality strategy. This implies that the respondents understand the effect of having a well-defined quality system. Data-driven strategies, such as machine learning and real-time process monitoring, use in-process data to detect and correct quality issues as they arise. In metal AM, where defects like porosity or thermally induced stresses can occur unpredictably, leveraging data can help enhance process reliability and product quality through predictive maintenance and real-time adjustments. Lean Six Sigma’s emphasis on process efficiency and defect reduction aligns well with the challenges of metal AM, where controlling process variability is essential to achieving repeatable, high-quality parts. It can also help optimise material usage, reduce waste, and improve throughput in batch production. QbD focuses on building quality into the design and manufacturing process from the outset rather than relying solely on post-process inspections. For metal AM, QbD can help define critical quality attributes (CQAs) and critical process parameters (CPPs) early in development, which is crucial for achieving consistent quality in highly regulated industries. The next section discusses the second survey results to understand the expert’s perception of the need for quality strategies for batch production in metal AM technology.

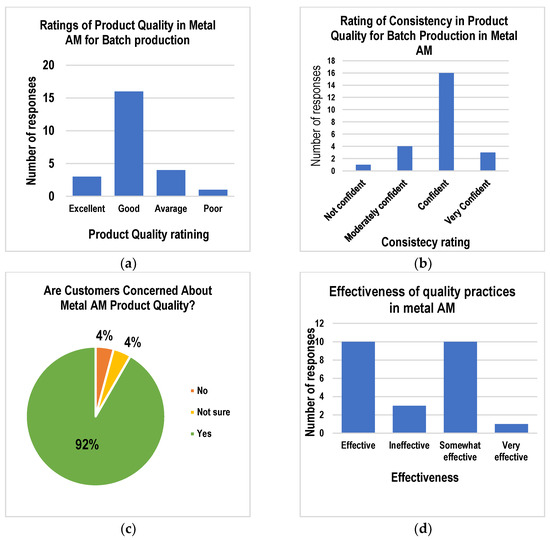

Perceptions of quality in metal AM for batch production:

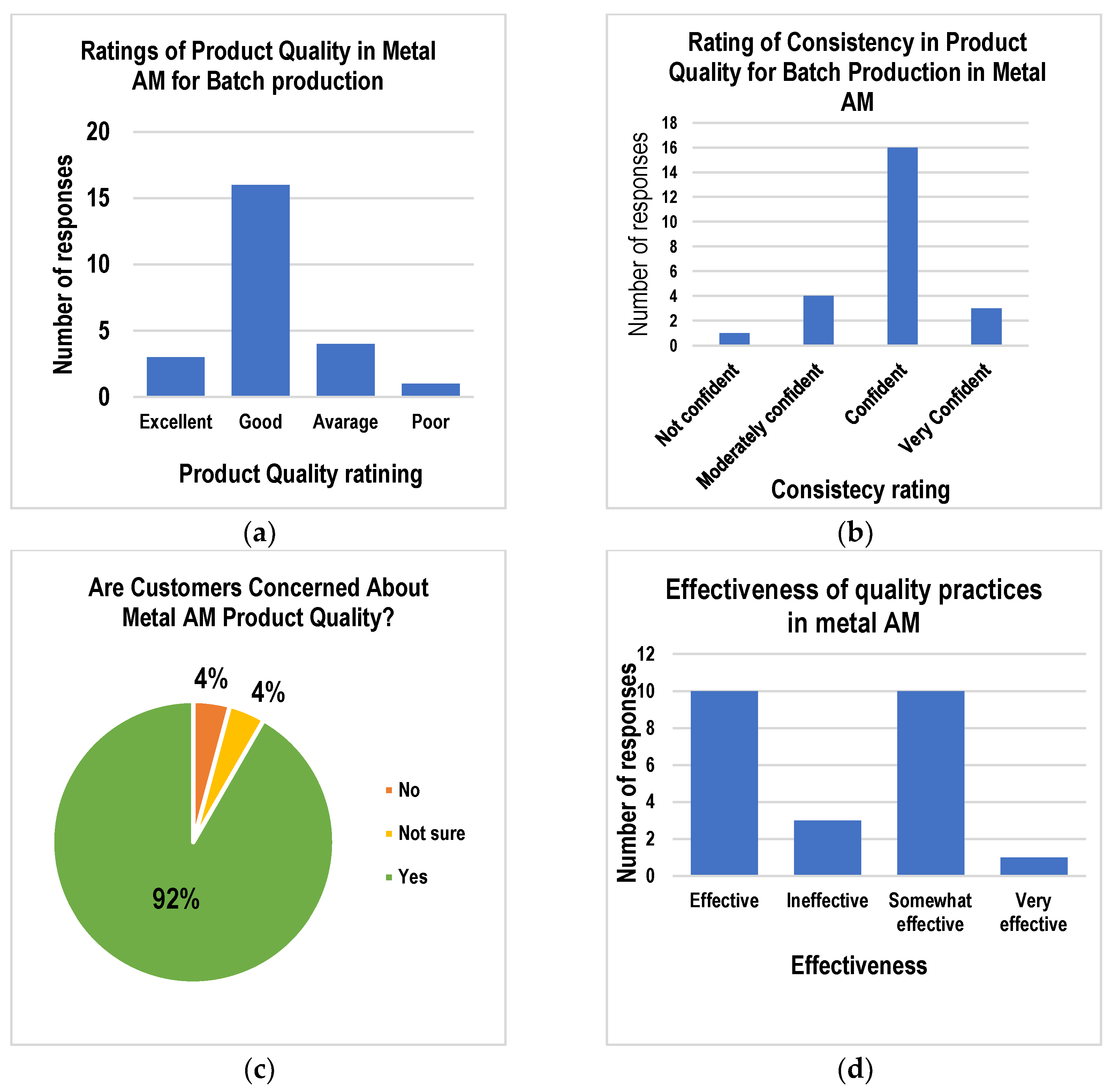

Five questions in the survey described the perceptions of quality in metal AM technology. The questions asked participants to rate the overall product quality and consistency. They were also asked whether customers have specific expectations of the quality of metal AM parts to describe the effectiveness of the current quality practices in metal AM technology and outline how they measure quality. The description of the perceptions of quality is subjective due to the inclusion of various industries with different standards and requirements; therefore, to capture a general response on the description of quality subjective weighting, we used various questions. The responses are summarised in Figure 5. The participants rated the overall product quality in metal AM technology as satisfactory; 66.7% rated product quality as good, 16.7% rated it as average, 12.5% rated it excellent, and only 4.2% rated it poor.

Figure 5.

Perception of quality in metal AM technology, determined by (a) rating product quality in AM technology for batch production, (b) rating the consistency of the product quality, (c) determining whether customers are concerned with product quality from metal AM processes, (d) understanding the effectiveness of current quality practices in metal AM technology.

When asked about the consistency of product quality in batch production, 66.7% of the participants were confident, 16.7% were moderately confident, 12.5% were very confident, and 4.2% were not confident. These results outline the different perspectives on quality in technology and how to achieve it. Additionally, 91.67% of the respondents acknowledged that metal AM technology customers have specific quality expectations of AM parts. This response aligns with the quality characteristic of customer focus, defined by Falk et al. [17], and based on the definition of quality to achieve satisfactory product outcomes for the customer. At least 41.7% of the participants deem the current quality practices in metal AM technology effective. Another 41.7% deem the current practices somewhat effective, 12.5% deem the practices ineffective, and 4.2% deem the current practices very effective.

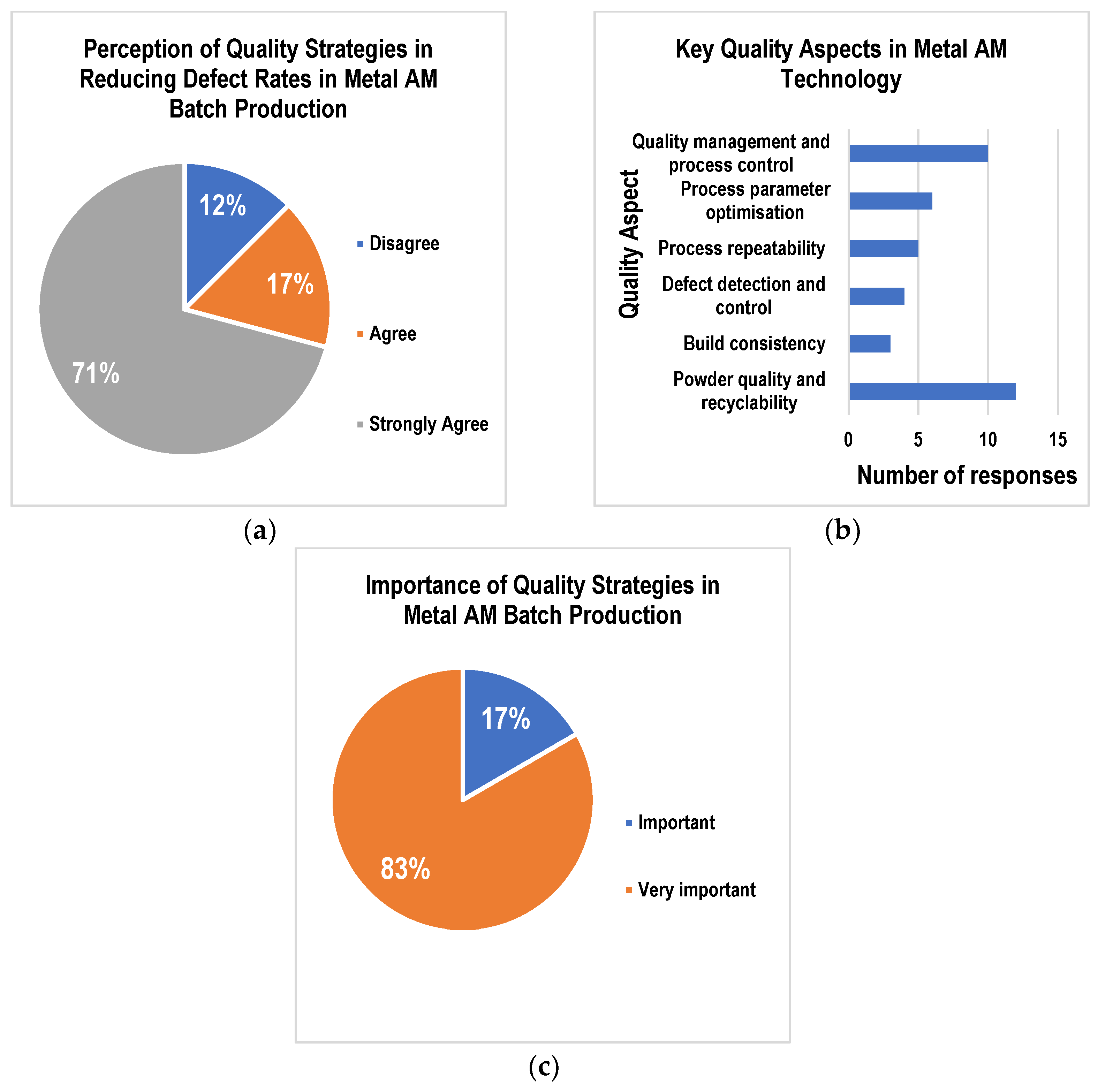

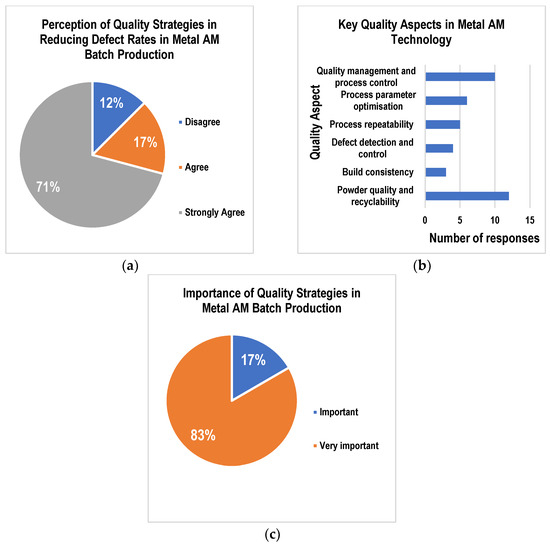

To analyse the aspect of the process that the quality strategy needs to focus on, the participants’ responses were grouped into six themes derived from the responses. Some aspects of the participants listed could not be categorised into the identified themes; they are not included in the graph but in Appendix C Figure A1b. The categorised data are presented in Figure 6, showing that 30% of the participants perceive that a quality strategy is required to address issues in the metal powder quality and its recyclability. Additionally, 15% believe a quality strategy should focus on process parameter optimisation, 25% on quality management and process control, 13% on process reliability, 10% on defect detection and control, and 7% on build consistency. The perceived need also involved understanding the significance of implementing a quality strategy for batch production in metal AM; 16.67% of the participants believed it was important, while 83.33% thought it was imperative.

Figure 6.

The perceived need for quality strategies in AM, including (a) perception of quality strategies on defect reduction; (b) quality aspects in metal AM technology that would benefit from the application of quality strategies, such as process repeatability; (c) Significance of quality strategies, specifically for batch production.

Challenges in metal AM Technology for batch Production:

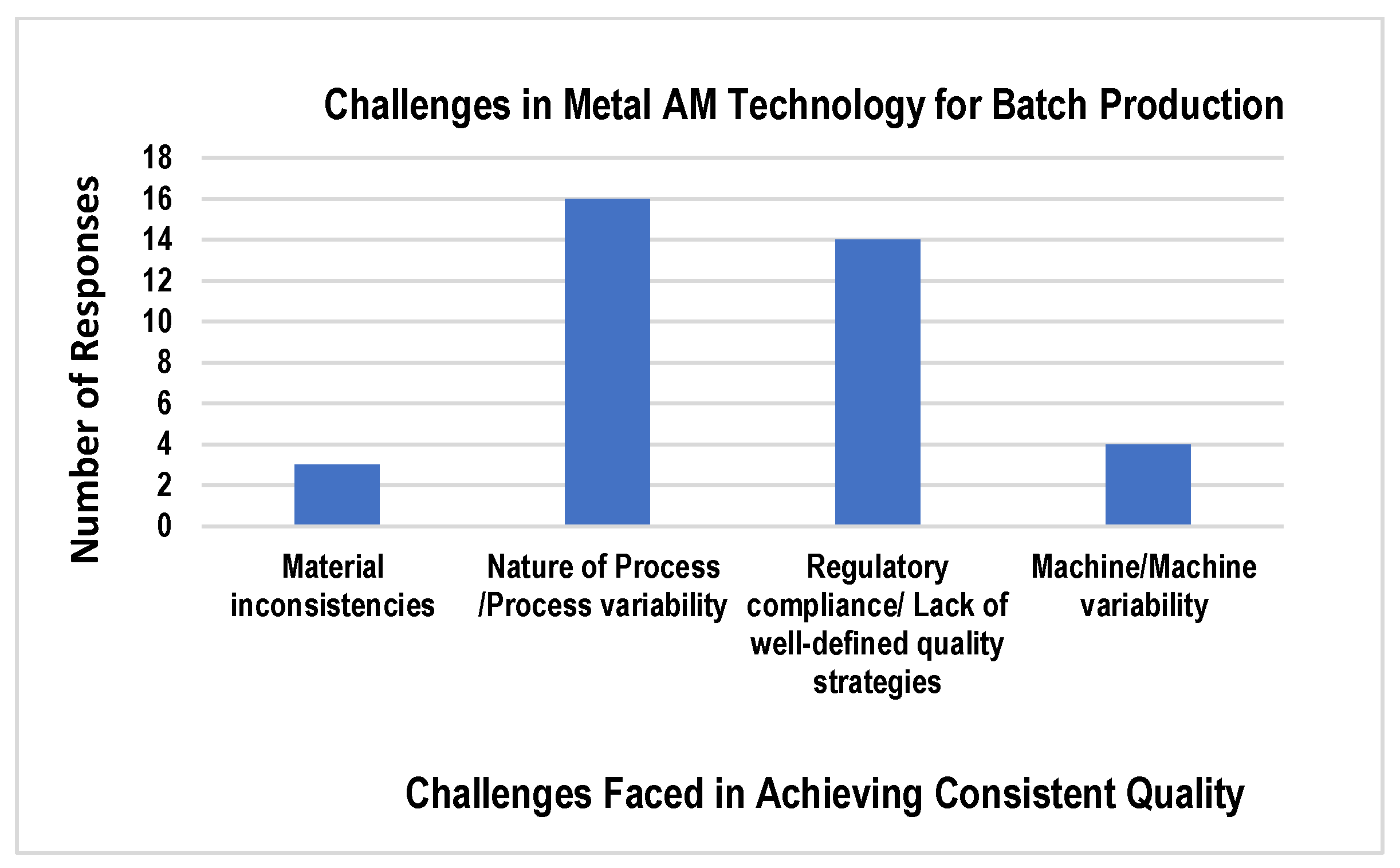

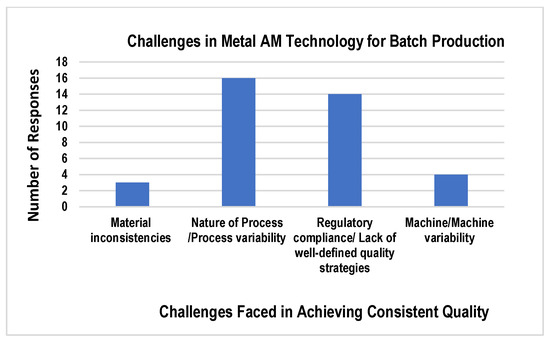

An open-ended question outlined the challenges or obstacles you face in achieving consistent quality in metal AM for batch production. Again, the responses were classified and grouped into themes, and each theme’s frequencies are plotted in Figure 7.

Figure 7.

Fundamental challenges in achieving consistent quality in metal AM technology for batch production.

The most frequently cited challenges include process variability and regulatory compliance. The challenges ranged from process variables to material consistency. Additionally, 43% of the participants perceive the nature of the process and process variability as challenges in metal AM technology, 30% perceive regulatory compliance and a lack of well-defined quality strategies as challenges, and 11% perceive machine and machine variability as challenges. In comparison, 8% perceive inconsistent material as challenges affecting the quality of metal AM technology for batch production.

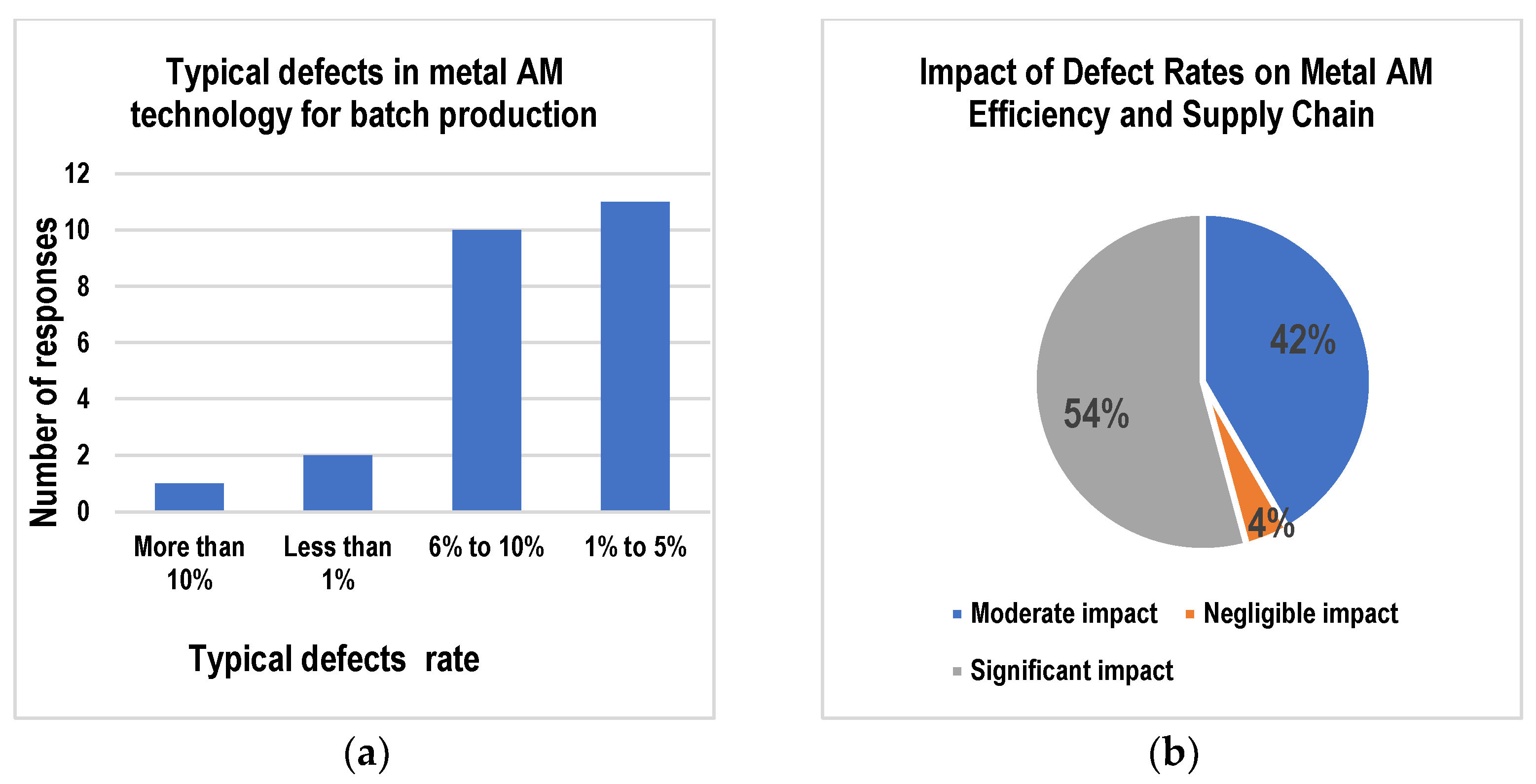

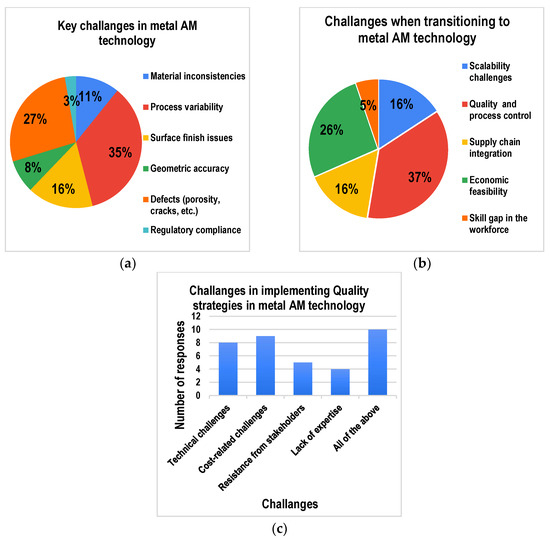

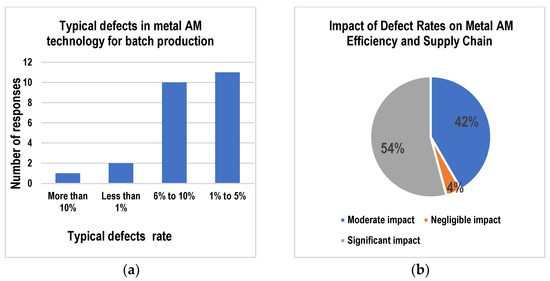

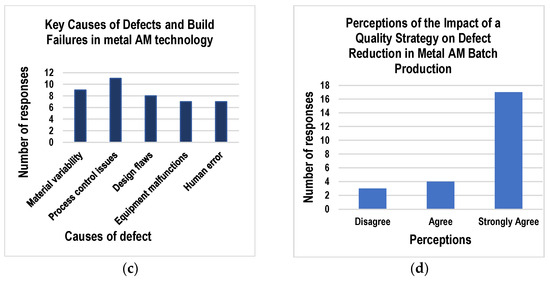

Defect rate in batch production:

The need for a quality strategy was also assessed based on the metal AM technology’s defect/ build failure rate for batch production. The participants were asked four questions that included understanding the typical defect percentage, the impact of the current AM defect rate on the efficacy of the supply chain, the perceived reasons for the occurrence of defects in metal AM technology, and the perceived impact of a quality strategy in reducing defects in the technology. Additionally, 45% of the participants perceived the typical percentage of defects /build failure in metal AM technology to be between 1 and 5%, 41.7% perceived it to be between 6 and 10%, and 8.3% perceived defects in metal AM technology to be less than 1%, while only 4.2% perceived defects /built failure to be more than 10%. The participants’ reactions are plotted in Figure 8.

Figure 8.

Defect rates and their impacts on metal AM technology, illustrated by (a) typical defect rates in batch production, (b) effects of defects on efficiency and the supply chain in metal AM technology, (c) causes of defects in metal AM technology, (d) impact of quality strategies on defect reduction.

Additionally, 54.2% of participants perceive the impact of the current AM defects/ build failure rate on the overall supply chain to be significant, 41.7% perceive it to have a moderate effect, and 4.2% perceive it to have a negligible impact. Furthermore, 26.2% of participants found process control issues in metal AM technology to be the reason for defects in the technology, and the second factor was material variability. Only 21.4% of participants believed design flaws, followed by 19% for equipment malfunction, to be a primary reason for the occurrence of defects. Additionally, 16.7% of participants perceived defects as being due to machine malfunctions, and another 16% also believed that defects are due to human error. The frequency of the primary reasons was quantified by the participant’s responses and presented in a graph below. When asked about the effect of implementing a comprehensive quality strategy on reducing defects, 70.8% strongly agreed, 16.7% of participants agreed, and 12.5% disagreed that implementing a quality strategy would reduce defects in metal MA technology for batch production.

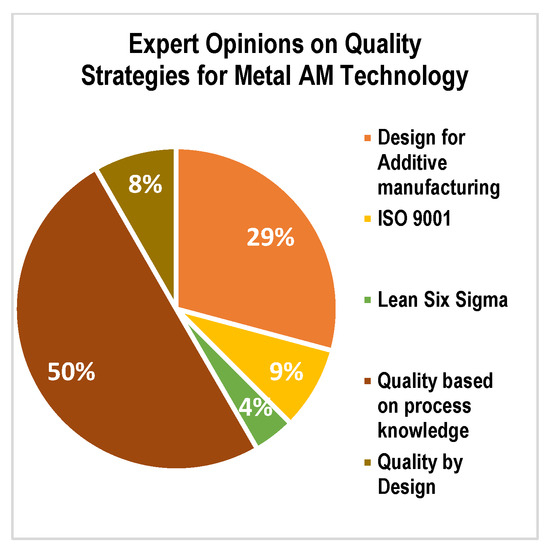

The applicable quality strategies to metal AM technology:

This group was also asked about the quality strategies they consider appropriate for addressing the existing challenges in metal AM technology. The results of the potential quality strategies for metal AM technology are shown in Figure 9. Figure 9 shows that half of the respondents (50%) identified quality based on process knowledge as the most suitable strategy. Additionally, 29% selected Design for Additive Manufacturing (DfAM) as an appropriate quality strategy. In contrast, 8% of respondents chose ISO 9001, and another 8% opted for Quality by Design as a fitting strategy for metal AM technology.

Figure 9.

Potential quality strategies for metal AM technology.

The survey results highlight several critical strategies deemed suitable for enhancing quality in metal AM, each with its specific focus and strengths. ISO 9001 provides a quality management system (QMS) framework and guidelines to ensure consistent quality across manufacturing processes [16], including metal AM. This is significant because all organisation’s operations need to adhere to the ISO standard to do business. While it is a well-regarded industrial standard, its relatively lower selection (8.33) by experts suggests that some respondents may view it as less tailored to AM’s specific needs than other strategies. The respondents chose data-driven quality strategies suitable for metal AM. This approach involves gathering and analysing data to make informed decisions about process control and quality enhancement [18]. In metal AM, where process variability can lead to defects, data-driven strategies are crucial for real-time monitoring, predictive maintenance, and continuous improvement. These strategies allow for the optimisation of parameters and the early detection of potential issues. Falk et al. [17] emphasise the importance of data-driven approaches in AM, highlighting how they can enhance process control and reduce defects by leveraging real-time data. Thirteen per cent of respondents see Lean Six Sigma as an appropriate strategy for metal AM technology. This methodology combines lean manufacturing principles with Six Sigma’s focus on reducing variability and defects [19]. Lean Six Sigma’s application in Metal AM could help streamline processes, eliminate waste, and reduce defects. Its emphasis on process improvement and efficiency makes it a valuable strategy for achieving high-quality outcomes in metal AM. Few studies have evaluated and applied Six Sigma without lean principles to metal AM technology.

4. Discussion

The results reveal variations in respondents’ interpretations of quality categories, reflecting the diverse perspectives of professionals across industries. While this subjectivity poses challenges in drawing precise conclusions, the findings provide valuable insights into the broad perceptions and priorities for quality strategies in metal AM. This indicates the complex nature of quality challenges in metal AM technology that quality strategies should address. It emphasises that quality is not a basic concern but rather a significant factor across various stages of the production process [20]. Furthermore, these results provide a holistic view of the challenges encountered in metal AM technology. However, it is important to note that the dependence on self-reported data and the variation in respondents’ industrial backgrounds may have influenced the evaluation of certain challenges, resulting in possibly under- or over-emphasis on specific issues. The primary focus was on the issues related to ensuring quality by highlighting prominent challenges (1) inherent to metal AM technology, (2) when transitioning to metal AM, and (3) when implementing quality strategies. These challenges are used to draw conclusions regarding the necessity of a quality strategy in metal AM technology. Firstly, the results regarding product quality are discussed, followed by the significance of quality strategies in the technology. Next, this study addresses the prominent challenges identified in both surveys, along with perceptions about potential quality strategies for metal AM technology.

Product quality in metal AM technology:

The survey results indicate that product defects are a common and significant issue in metal AM, marked by 45% of the respondents being between 1–5% and 41.7% who perceived it to be between 6 and 10%. These defect rates are concerning because they can lead to high scrap rates, increased costs, and inefficiencies in production, highlighting the need for adequate quality strategies to minimise these defects. However, it is important to note that these findings are based on perceptions of individuals working with metal AM technology in various industries; their experience in quality monitoring and systems may influence individual perceptions of defects in the technology based on their industry. Despite this limitation, these findings indicate that defects arise from a combination of factors related to technology, materials, machinery, and human factors. Highlighting the complexity of managing quality in metal AM, where defects can originate from various sources. Effective quality strategies must address all these areas—process control, material consistency, machine reliability, and operator training—to reduce defects.

The participants identified process control issues (26.2%) and material variability (21.43%) as the primary reasons for defects in metal AM. These are followed by machine malfunctions (16.7%) and human error (16%). The prominence of process control issues (26.2%) highlights the intricate nature of the metal AM processes, where processing parameters such as laser power, scan speed, and layer thickness play critical roles in ensuring quality, and any deviation could lead to defects. This finding aligns with the existing literature on the effect of processing parameters on resultant quality, emphasising the importance and the need for a quality strategy with control systems to ensure repeatability and precision. Material variability, which accounts for 21.43%, highlights the challenges associated with feedstock consistency. This includes variations in powder quality, particle size distribution, and chemical composition. Such inconsistencies can directly impact mechanical properties, surface finish, and dimensional accuracy. This finding emphasises the importance of quality strategies in ensuring quality and their qualification processes.

Machine malfunctions (16.7%) indicate a reliance on machine reliability for defect-free production. These issues may come from hardware wear and tear, calibration errors, or software glitches. Compared to process control and material variability, machine malfunctions are a smaller but still significant factor, indicating that equipment maintenance is essential but secondary to material and process consistency. Human error (16%) appears relatively low compared to other factors but still plays a notable role. This could include errors in setup, parameter input, or oversight during post-processing. The lower percentage may indicate that advancements in automation and user-friendly interfaces have reduced human dependency on AM processes. Further indicating that quality strategies for metal AM technology should focus on the digital (automated) nature of the technology, including user interfaces with intuitive controls, which may also minimise defects in resultant products. Although these elements are categorised separately, they are often interrelated. In most cases, in AM technology, process control difficulties are intensified by material variability and machine malfunctions. Process control and material variability, being the leading factors, suggest a focus on pre-production and production phases rather than post-production, demonstrating a need for a proactive quality strategy.

Quality strategies are seen as essential for detecting and controlling defects, thereby ensuring the production of parts that meet high standards. Calignano et al. [21] Demonstrated the importance of quality strategies for metal AM by investigating how quality strategies can mitigate defects in metal AM, particularly by optimising process parameters and post-processing techniques. Their results illustrated that quality strategies are necessary for metal AM, not just for ensuring the production of high-quality parts but also for improving economic efficiency, scaling production, and maintaining consistency. The results of analysing these factors (process control issues and material variability machine malfunctions and human error) emphasise an understanding and recognition of process defects within the industry of the critical role of quality strategies in addressing the challenges inherent in metal AM, particularly as the technology matures and is adopted for large-scale production.

Importance of Quality strategies for Metal AM technology:

A substantial portion of respondents (54%) highlight that the primary role of quality strategies is to improve consistency and repeatability in metal AM. This suggests that maintaining control over the process is essential to achieving reliable and uniform part quality, which is vital given the inherent variability in AM processes [22]. Quality assurance (34%) and production control (28%) are selected as crucial roles of quality strategies. This reflects the necessity of implementing measures that ensure parts meet specified standards and that the production process is tightly controlled to avoid defects and inefficiencies. This is directly linked to the definition of quality assurance in manufacturing [23]. The results emphasise the significant role of quality strategies in the successful industrialisation of metal AM technology. The insights from the survey underline the industry’s broad recognition of the necessity for quality strategies, highlighting their significance across various aspects of the metal AM process. The results specifically emphasise the following significant role of quality strategies. Moreover, respondents perceived quality strategies as necessary for reducing production costs (42%) and increasing productivity, indicating that a well-implemented quality strategy can make metal AM more economically viable. This aligns with Herzog et al. [24], who highlight the economic benefits of quality strategies in AM technology. Highlighting that these strategies can lead to cost reductions through improved process efficiencies and reduced material waste. The results of this study show that quality strategies contribute to optimising material usage, minimising waste, and improving overall process efficiency.

Prominent challenges in metal AM technology:

Both survey respondents (43% and 35%) identified the inherent variability in the AM process as a significant challenge. This includes difficulties in controlling and maintaining consistent parameters during manufacturing [25], such as temperature, laser power, and build environment fluctuations. Furthermore, these process variables affect the manufactured part’s properties and overall quality, leading to quality variations in the resultant products. The process variability could also be observed as inconsistencies in parts quality within batch productions, making maintaining uniformity across different builds difficult, and may lead to defects [26]. Defects due to process variability are also observed as presenting significant issues in metal AM, as they compromise the structural integrity and performance of the final parts. These defects are often related to the rapid heating and cooling cycles inherent in the AM process, which can induce stresses and lead to such imperfections [27]. Metal AM often produces parts with rough surfaces that require significant post-processing to meet the desired specifications, adding time and cost to the production process. Geometrical inaccuracies, whether due to design limitations or machine capabilities, are another concern, as they affect the dimensional accuracy of the produced parts, which is critical in high-precision applications.

Machine-related challenges (11%) are also considered inherent to the metal AM technology. They include issues with the machines and their variability, resulting from differences in machine calibration, wear and tear, or even slight differences in machine models. Such variability may lead to inconsistencies in production, making it difficult to achieve uniform quality across different batches and machines [26]. Moreover, both surveys identified material inconsistency (11% and 8%) as a challenge. Material inconsistencies could affect the final product’s quality, especially when tight tolerances and specific material properties are required. Material inconsistencies may arise from variations in powder quality, which may lead to batch-to-batch differences or contamination, leading to unpredictable material properties and part quality [28]. A study by Brocksieper et al. [29] noted that the quality of the powder layers during production directly influences the quality of the resultant products. This is true for batch production, which requires uniform quality of parts. Challenges inherent to metal AM can be summarised as process variability, including temperature variations in processing parameters leading to defects like cracks, porosity, and surface roughness, which compromise the integrity of structural parts and dimensional accuracy. Machine-related variability and inconsistencies in raw materials further aggravate these challenges, making achieving uniform quality across different batches difficult. Solving these issues is critical for improving the reliability and scalability of metal AM in industrial applications.

The economic feasibility (26%) of adopting AM technology is a significant challenge during the transitioning stage, with respondents pointing to the high costs associated with equipment, materials, and operational expenses, which can be prohibitive for some businesses. However, a study by Gonçalves et al. [23] states that the economic feasibility of adopting AM technology depends on the parts manufactured and the nature of the production. It further points out that cost decreases with an increase in annual production volume. This means batch productions are more economically feasible than single-part manufacturing [30]. This understanding ramps up scalability in the technology. Although more studies have proven that batch productions are more economically feasible for metal AM technology, many industries are still reluctant to fully embrace the technology due to quality issues. Scalability challenges reflect the difficulties in expanding AM operations to larger production volumes while maintaining efficiency and part quality. When transitioning to metal AM, the most significant concern is ensuring quality and maintaining control over the process [31]. This highlights the difficulty of scaling up AM processes from prototyping to full-scale production while maintaining consistent quality. Integrating AM into existing supply chains is another challenge, as it requires alignment with traditional manufacturing processes, logistics, and material handling systems. However, understanding the nature of production in metal AM technology is significant for overriding these challenges [32]. This means focusing on AM technology’s unique capabilities and defining operation management strategies, specifically for AM, to leverage its industrial advantage over traditional manufacturing.

The skill gap in the workforce is another challenge. However, a smaller percentage (5%) noted that specialised knowledge and expertise are required to operate and optimise metal AM processes effectively. Another difficulty experienced when transitioning to metal AM technology is regulatory challenges and the absence of well-defined quality control strategies, which are significant obstacles to industrialising the technology. According to Bernard et al. [5], the International Organization for Standardization (ISO) has multiple definitions for the qualification and certification of metal AM technology. This is due to their participation in industries with strict certification requirements, such as aerospace and medical fields. However, there is a lack of consensus on the appropriate methods for certification and qualification in metal AM technology [5]. The respondents identified regulatory compliance as a challenge inherent to the technology, possibly indicating that while compliance is essential, it is less of a technological obstacle and more of a procedural one. This suggests that the AM industry may face difficulties meeting stringent regulatory requirements critical for ensuring safety and reliability across various sectors; the lack of acceptable standardised quality strategies further complicates the ability to produce consistent and reliable parts on a large scale. Holistic quality strategies could be used to bridge this gap.

However, implementing a quality strategy in metal AM faces several technical challenges, such as the complexity of monitoring and controlling AM processes, ensuring repeatability, and dealing with the technology’s inherent variability. According to Moroni et al., the most significant challenges experienced in MAM technology are process variability, process defects, and surface finish issues. These challenges could be defined as process-related [33], and challenges encountered in AM concerning quality monitoring and control can be distinguished as either process-driven or influenced by the capability of the employed AM technology. Process-driven challenges refer to process and machine parameters, while AM technology’s capability issues refer to the measurements and tolerance challenges arising from complex geometries [33]. The challenges experienced when implementing quality strategies include cost-related issues, such as investments in monitoring systems, quality control measures, and post-processing, which lead to cost-related issues. As indicated by the literature focusing on quality [34], stakeholders play a crucial role in the success of quality management and improvements in any industry. Resistance from stakeholders, such as management or customers, can hinder the adoption of quality strategies, possibly due to the perceived costs or disruptions associated with implementing new processes. A lack of expertise in quality strategies and a limited understanding of metal AM technology is also a barrier, as implementing an effective quality strategy in AM requires specialised knowledge in materials science, process engineering, and quality assurance. In a nutshell, challenges in implementing a quality strategy are often intertwined and pose significant obstacles. Table 1 summarises the challenges experienced in the technology.

Table 1.

Categories of challenges in metal AM technology.

The survey results also show that quality and process control are other challenges encountered during the transition to metal AM technology, which has been identified as an ongoing challenge across industries striving to embrace AM technology fully [21].

The difficulties outlined in technology show the need for a quality strategy that should focus on controlling variability. Moreover, this study’s results demonstrate that quality strategies play a complex and significant role in advancing metal AM technology. They further point out that quality strategies must focus on critical areas such as process control, part quality, and cost efficiency; these strategies are critical for enhancing metal AM processes’ performance and reliability. Further, the findings of this study provide a basis for developing a quality strategy that could effectively address these challenges. Additionally, this knowledge is fundamental in guiding future research on the causes of defects and their mitigation in metal AM across industries.

5. Conclusions

This study analysed two surveys involving industry personnel to evaluate the role and necessity of quality strategies in metal AM technology. The findings underline key challenges, including process variability, material inconsistencies, and surface texture issues, highlighting the critical need for robust quality strategies focusing on powder quality, parameter optimisation, and defect detection. While the sample size limits generalisability, the insights of this study provide a foundation for future research to focus on designing quality frameworks that will foster the developments of scalable and reliable metal AM processes, integrating quality management techniques to ensure defect prevention and improve product quality, which will possibly enhance industrial adoption and economic sustainability of the technology.

Author Contributions

Conceptualization, C.S., S.H. and A.J.; methodology, C.S., A.J., software, S.H.; validation, C.S., A.J., S.H. and I.G.; formal analysis, C.S.; A.J., investigation, C.S.; resources, I.G.; data curation, C.S. and A.J.; writing—original draft preparation, C.S. and A.J.; writing—review and editing, C.S., A.J., S.H. and I.G.; visualisation, C.S.; supervision, I.G.; project administration, C.S. and I.G.; funding acquisition, I.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work is based on research supported wholly by the National Research Foundation of South Africa (Grant Numbers: 120210) and the Advanced Manufacturing, Sustainable Product & Energy System (AMSPES) group in the Department of Design, Production, and Management at the University of Twente.

Data Availability Statement

The data provided in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A. The Questionnaires

Appendix A.1. Questionnaire Survey 1 (Formnext)

- Topic: Quality Strategies for Metal Additive Manufacturing and its Industrialization

Thank you for participating in this questionnaire. We are conducting research to understand the significance and impact of implementing a quality strategy in metal additive manufacturing processes. Your responses will contribute to our study on how quality strategies affect product quality, cost-efficiency, and defect reduction in this manufacturing method.

- Section A: General information

This section is important information about our audience’s background and perception of Metal Additive manufacturing.

- 1.

- What type of metal additive manufacturing technology have you worked with or are you familiar with?

- Powder Bed Fusion (e.g., SLM, DMLS)

- Directed Energy Deposition (DED)

- Material Extrusion

If other, please specify

- 2.

- Are you utilising Metal AM for a specific purpose? Please select the relevant application:

- Commercial use

- Research purposes

- both

- 3.

- What is the primary role of your organisation? Please select one:

- System manufacturer (AM Machine provider)

- Software provider

- Both

- System user (producing parts for commercial use)

- 4.

- How does your company measure the quality of parts produced using metal additive manufacturing technology?

- Test coupons with the same design as the printed parts.

- Bulk cuboids built alongside the complex parts in a single build

- The actual printed parts.

- If others, please specify

- Section B: Understanding the importance and the need for quality strategies in metal AM technology

This section aims to define The role of quality strategies in metal AM technology.

- 5.

- What is the importance and the need for quality strategies in metal AM?

- Controlling process variables

- Ensuring part quality and consistency

- Material selection and quality

- Material selection and quality

- Regulatory compliance

- 6.

- What is the role of quality strategies in your company as it relates to metal Additive manufacturing?

- Quality assurance

- Production control

- Standardization of production process

- cost-reduction (Production improvements)

- other,

- 7.

- How do you perceive the role of quality strategies in metal additive manufacturing in general?

- Enabling higher production volumes

- Improving consistency and repeatability

- Reducing production costs

- Fostering process control

- All of the above

- 8.

- What challenges do you encounter in ensuring quality in metal additive manufacturing?

- Material inconsistencies

- Process variability

- Surface finish issues

- Geometric accuracy

- Defects (porosity, cracks, etc.)

- Regulatory compliance

- other

- 9.

- What quality control measures does your organisation currently implement in metal additive manufacturing processes?

- Statistical Process Control (SPC) of finished

- Non-destructive testing (NDT) after printing

- In-process monitoring and inspection

- Other

- 10.

- What challenges do you think companies face when transitioning from prototyping to industrial-scale production in metal additive manufacturing? Please select all that applies to you.

- Scalability challenges

- Quality and process control for series production

- Supply chain integration

- Economic feasibility

- Skill gap in the workforce

- Other

- 11.

- What quality control measures does your organization employ in metal additive manufacturing processes?

- In-process monitoring

- Post-process inspection

- Non-destructive testing (NDT) techniques

- Statistical process control (SPC)

- Other

- 12.

- Do you think the implementation of a quality strategy could bring a noticeable reduction in defects and errors in metal AM for batch production?

- Significant reduction

- Moderate reduction

- No significant change

- Deteriorate

- Not applicable

- 13.

- How can the implementation of a quality strategy help reduce defects and errors in metal additive manufacturing? If Other (please specify)

- Establishing standardised processes

- Through real-time monitoring and feedback

- By implementing quality control measures

- Enhancing operator training and skills

- other

- 14.

- How do you think a quality strategy will affect the cost-efficiency of metal additive manufacturing for batch (series) Production? For any of your responses, please explain in “other”.

- Reduced costs and increased productivity significantly

- Reduced cost moderately

- No significant cost change

- increased cost and productivity

- 15.

- What challenges or obstacles are encountered in implementing a quality strategy in metal additive manufacturing for batch (series) production?

- Technical challenges

- Cost-related challenges

- Resistance from stakeholders

- Lack of expertise

- All of the above

- 16.

- In your opinion, how significant is the implementation of a quality strategy in metal additive manufacturing? Please explain in “other”

- Very significant

- Significant

- Somewhat significant

- Not significant

- 17.

- How does a quality strategy contribute to improving product quality in metal additive manufacturing? if Other (please specify)

- Enhances part consistency

- Minimizes defects

- Improves material utilization

- Enhances surface finish

- Other

- 18.

- How does a quality strategy impact cost-efficiency in metal additive manufacturing? if other, please specify

- Reduces production costs

- Optimizes material usage

- Minimizes waste

- Improves process efficiency

- Other

- 19.

- What quality strategy do you think is appropriate for batch production in Metal AM?

- Lean Six Sigma (statistical process control)

- ISO 9001

- Design for Additive Manufacturing (DFAM)

- Quality by design (Data-driven and parameter optimisation)

- Trial and error method (based on process knowledge)

- Any data-driven quality strategy

- other

Thank you for taking the time to answer our questionnaire. We highly value your response and believe it is critical for advancing technology.

Appendix A.2. Questionnaire Survey 2

- Topic: Determining the exigency of a quality strategy in metal additive manufacturing for batch production

- Introduction

Thank you for taking the time to participate in our survey. Your insights are invaluable for understanding the need for a quality strategy for batch production in metal additive manufacturing (AM) technology. Please share your responses based on your knowledge of Metal AM processes, experiences, perspectives on the quality of parts, and the practices in your organisation related to this technology. Your contribution is valuable, and we appreciate your time and effort in providing us with the information needed for this research.

- Processed Knowledge

- 1.

- How would you rate your understanding of the metal AM processes?

- Very high

- Moderate

- Limited

- Poor

- 2.

- Years of experience in Metal AM technology:

- Less than 1 year

- 1–3 years

- 3–5 years

- More than 5 years

- 3.

- Which metal AM technology have you worked with or are you familiar with?

- Powder Bed Fusion technology

- Directed Energy Deposition (DED)

- Binder Jetting

- Sheet Lamination

- Material extrusion

- Perceptions of quality in metal AM for batch production

- 4.

- How do you rate the overall product quality in metal AM technology for batch production?

- Excellent

- Good

- Average

- Poor

- 5.

- How confident are you in the consistency of product quality in metal AM processes, especially for batch production?

- Very confident

- Confident

- Moderately confident

- Not confident

- 6.

- Do you think customers have specific expectations regarding the quality of products manufactured using metal AM technology?

- Yes

- No

- Not sure

- 7.

- How would you describe the current quality practices in your metal AM processes?

- Very effective

- Effective

- Somewhat effective

- Ineffective

- 8.

- How do you measure quality in bath production in your metal AM process

- Test coupons with the same design as the printed parts.

- Bulk cubes Built alongside complex parts

- Dog bone

- The perceived need for a quality strategy in the metal AM process for batch production

- 9.

- Do you think there is a need for a comprehensive quality strategy in metal AM technology for batch production?

- Strongly agree

- Agree

- Disagree

- Strongly disagree

- 10.

- What aspects of the process do you believe a quality strategy should address in metal AM batch production?

- 11.

- How important do you believe implementing a quality strategy is for metal AM batch production?

- Very important

- Important

- Somewhat important

- Not important

- Challenges in metal AM technology for batch production

- 12.

- What challenges or obstacles do you face in achieving consistent quality in metal AM for batch production?

- Defects /build failure rate in batch production

- 13.

- What is the typical percentage of defect/build failure encountered in your metal AM technology for batch production?

- Less than 1%

- 1% to 5%

- 6% to 10%

- More than 10%

- 14.

- How do you perceive the impact of the current AM defects rate on the efficiency overall supply chain?

- Negligible impact

- Moderate impact

- Significant impact

- No impact

- 15.

- What are the primary reasons for the occurrence of defects and Build failure (scrap) in metal AM technology for batch production?

- Material variability

- Process control issues

- Design flaws

- Equipment malfunctions

- Human error

- 16.

- Do you believe that implementing a comprehensive quality strategy could help reduce the defect rate in metal AM batch production?

- Strongly agree

- Agree

- Disagree

- Strongly disagree

- 17.

- Which quality strategy do you think is appropriate for batch production in Metal AM technology?

- Lean Six Sigma

- Design for Additive Manufacturing (DFAM)

- Quality by design

- Quality based on process knowledge (trial and error)

- Lean manufacturing

- Demographics

- 18.

- Are you using Metal AM for a specific purpose?

- Commercial use

- Research purposes

- Both

- 19.

- What is the primary role of your organisation in terms of metal AM technology?

- System manufacturer (AM Machine provider)

- Software provider

- System user (producing parts for commercial use)

- Raw material supplier

- Service provider (post-processing, metrology, and laser beam maintenance, etc.)

- 20.

- From which country are you responding to this questionnaire?

Do you have specific recommendations or suggestions for improving the quality of metal AM batch production in your organization?

- Conclusion:

Thank you for taking the time to complete this survey. Your response is highly valued, and we believe that it is critical to advancing technology. If you have any additional comments or suggestions, please feel free to share

Appendix B. Letter Requesting Participation

Good day,

I trust this message finds you well. My name is Cindy Sithole, and I am currently researching the need for a quality strategy in metal additive manufacturing (AM) for batch production. Your valuable insights can significantly contribute to defining the purpose of quality strategies and assist in selecting an appropriate strategy for metal AM technology in this study. Your expertise in the field makes you an ideal participant, and I would greatly appreciate it if you could spare a few minutes to complete our survey.

Your responses will be kept confidential and will only be used for research purposes. This survey aims to gather opinions and experiences from professionals like yourself who are involved in metal additive manufacturing processes. By understanding the challenges and requirements in quality management for batch production in the technology, we can collectively work towards enhancing the efficiency and reliability of these manufacturing techniques.

To participate, simply click on the survey link below (accessed on 17 November 2024):

Your input will play a crucial role in understanding the challenges and opportunities in metal additive manufacturing, ultimately contributing to the development of effective quality strategies.

Thank you in advance for your time and contribution. If you have any questions or concerns, please feel free to contact me at c.sithole@utwente.nl.

Best regards,

Cindy Sithole

University of Twente

Appendix C. Survey Results

Appendix C.1. Survey 1 Results (Formnext)

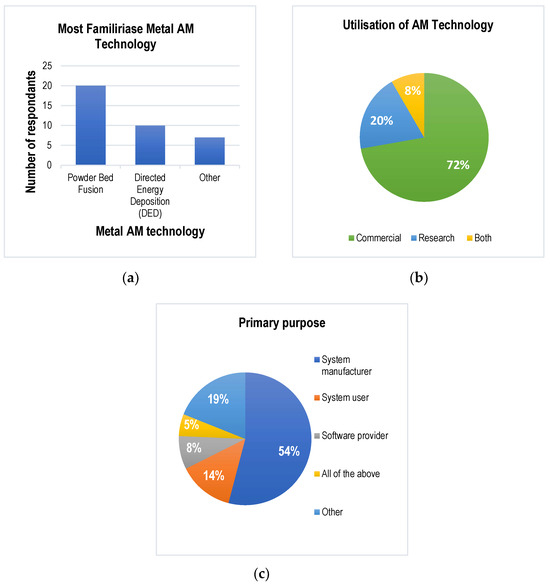

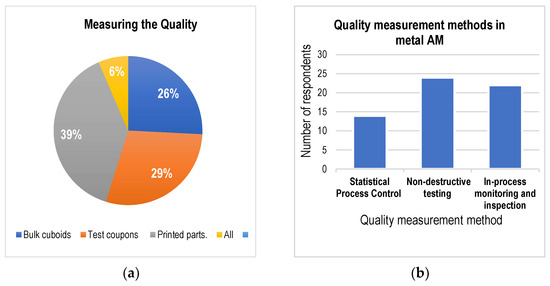

The questionnaire was successfully answered by 34 people who were visitors at the Formnext annual event in the metal section. Among the respondents, 54% are accustomed to Powder Bed Fusion technology (PBF), while 27% are familiar with Direct Energy Deposition (DED), and 19% have a broader knowledge encompassing all metal (Material extrusion, Binder jetting, and material jetting) identified as other technologies. When analysing the application of these technologies, the results indicate that 72% of the respondents employ the technology for commercial purposes, 20% for research, and 8% for both commercial and research purposes. Of the respondents, 54% are system manufacturers, 14% are system users, and 19% are service providers. The service providers encompass powder metal suppliers, laser beam maintenance, and post-processing service providers. Figure A1. Show the graphical representation of the respondents. The questionnaire results are summarised and grouped into themes to best answer the posted research question. The following sections show the results of each question in their themes respectively.

Figure A1.

Metal AM Community (Formnext): (a) Metal AM technologies respondents are familiar with, (b) Applications of metal AM technology, and (c) Respondents’ purposes for using metal AM technology.

Figure A1.

Metal AM Community (Formnext): (a) Metal AM technologies respondents are familiar with, (b) Applications of metal AM technology, and (c) Respondents’ purposes for using metal AM technology.

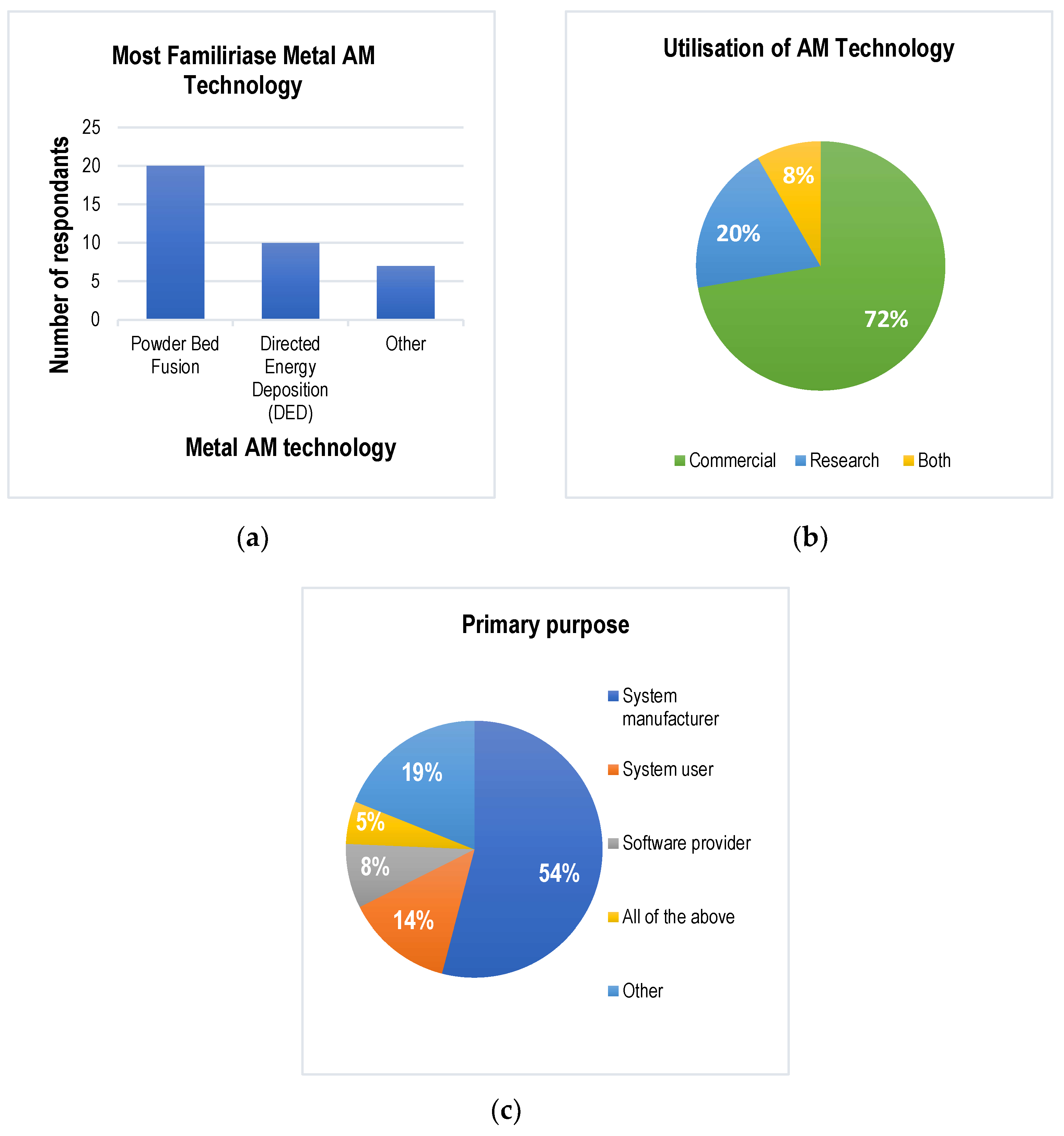

- Quality control measures

Questions 4 and 9 needed to understand how quality is measured in the technology based on the experience of the respondents. 26% of the respondents utilize bulk cubes built alongside complex parts to assess product quality, 29% use test coupons with the same design, and 39% test the actual products after manufacturing. Of the respondents, 40% employed non-destructive testing methods after printing and post-processing to measure the quality of manufactured products, 23% utilized statistical process control on finished products, and 37% employed in-process monitoring and inspections.

Figure A2.

General information on quality measurement in metal AM technology. (a) Measuring quality (b) Quality Measurement methods.

Figure A2.

General information on quality measurement in metal AM technology. (a) Measuring quality (b) Quality Measurement methods.

Appendix C.2. Survey 2 Results (Experts)

- Processed Knowledge

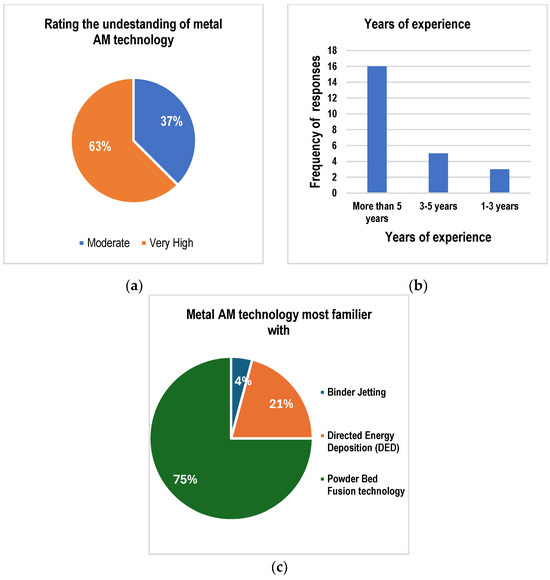

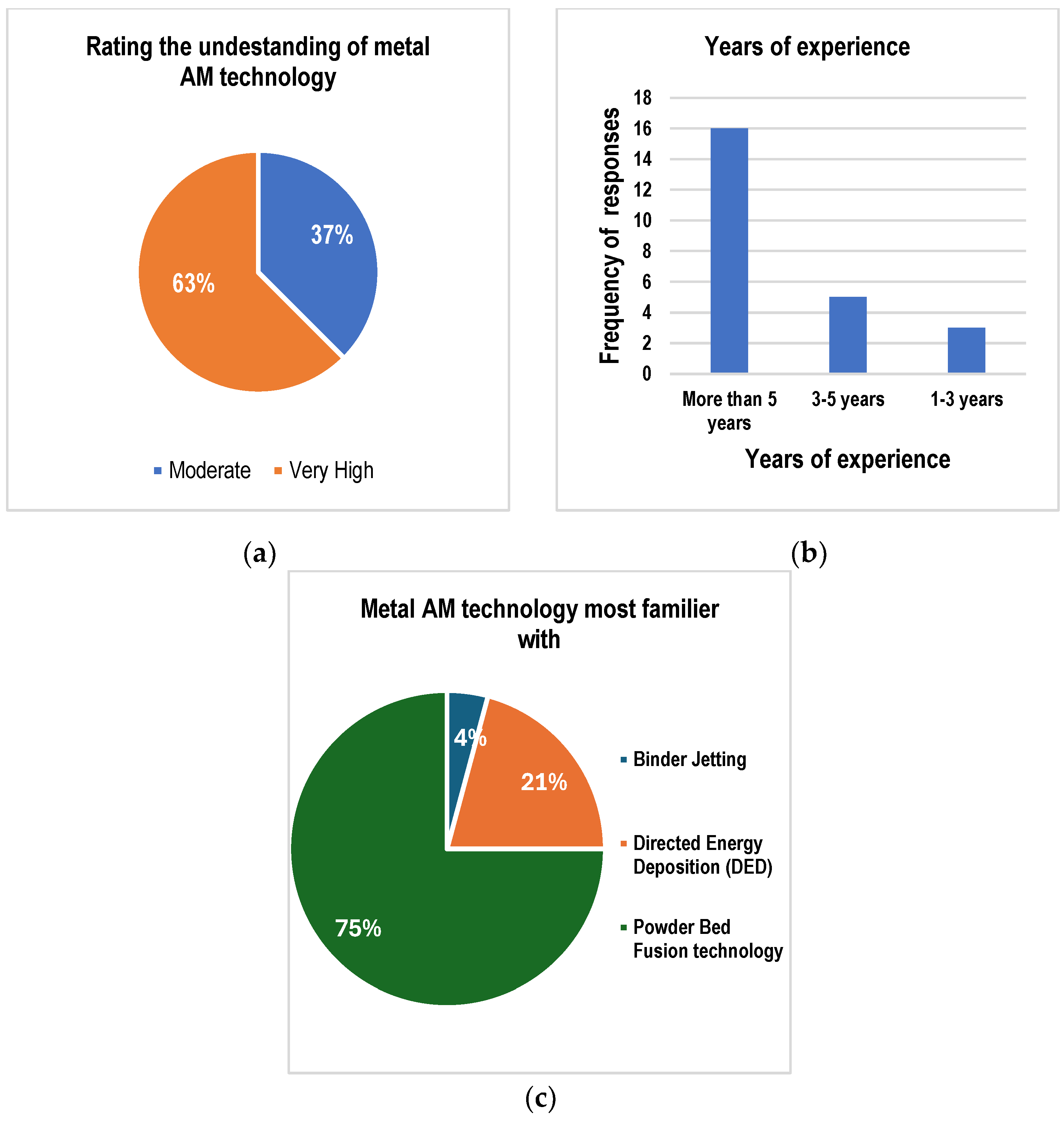

Three questions about their understanding of metal AM technology, their level of experience, and the metal AM technology they are most familiar with were used to determine the respondents’ process knowledge. The respondent’s understanding of the metal AM technology is presented in Figure A3.

Figure A3.

The expert community understanding of metal AM technology. (a) rating the understanding of metal AM technology, (b) Years of experience in metal AM technology and (c) metal AM technology familiar with.

Figure A3.

The expert community understanding of metal AM technology. (a) rating the understanding of metal AM technology, (b) Years of experience in metal AM technology and (c) metal AM technology familiar with.

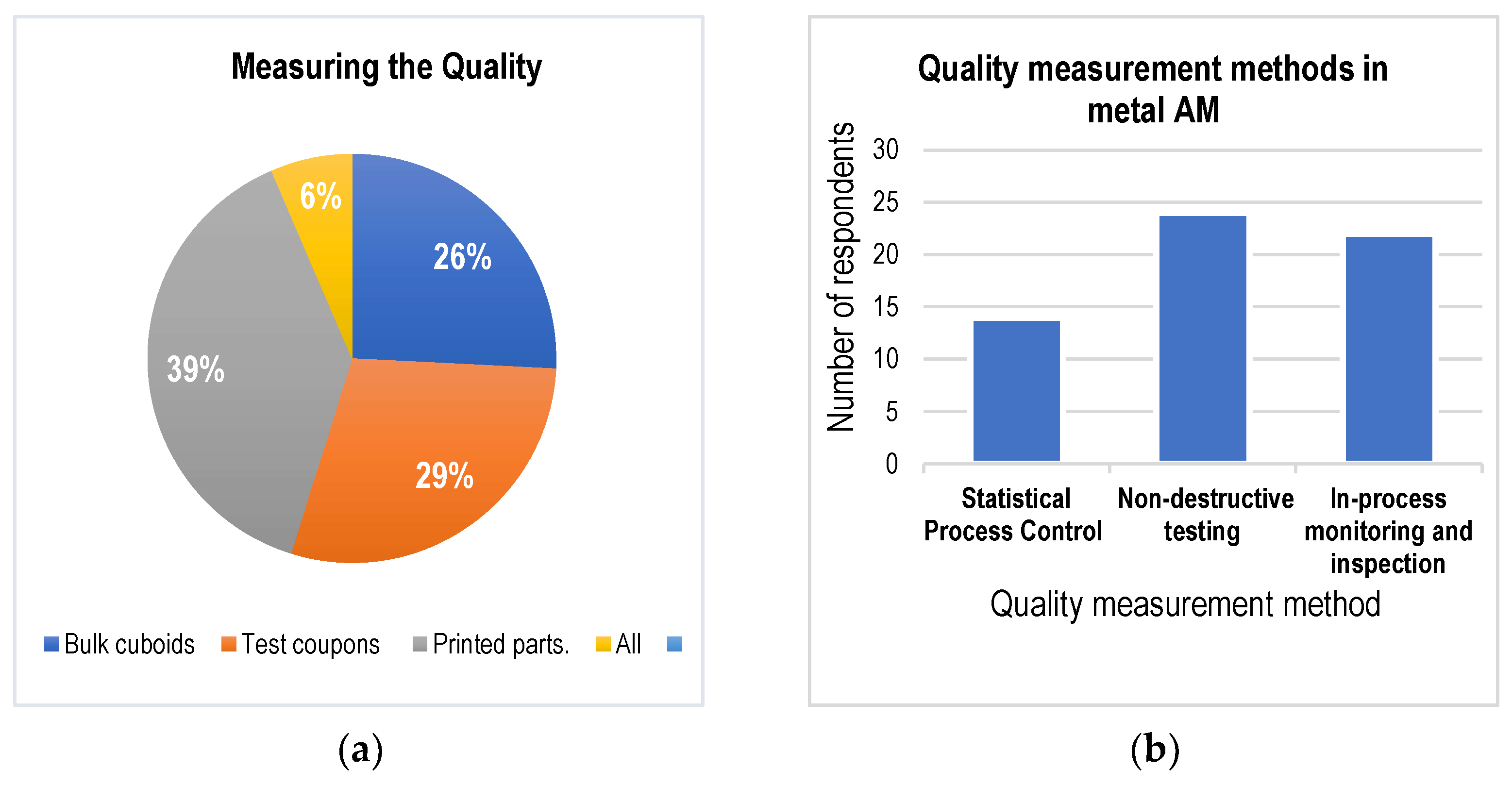

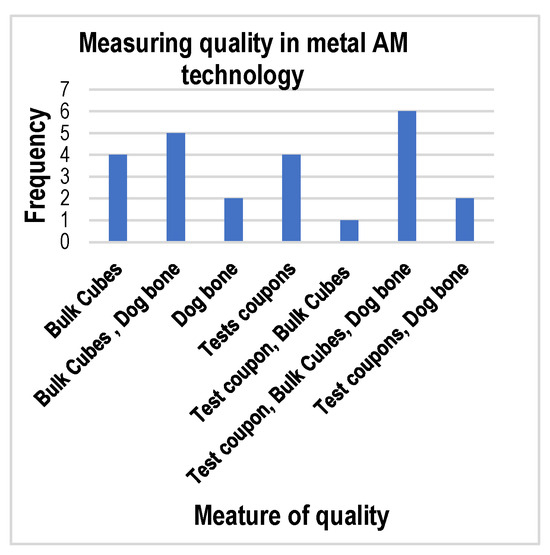

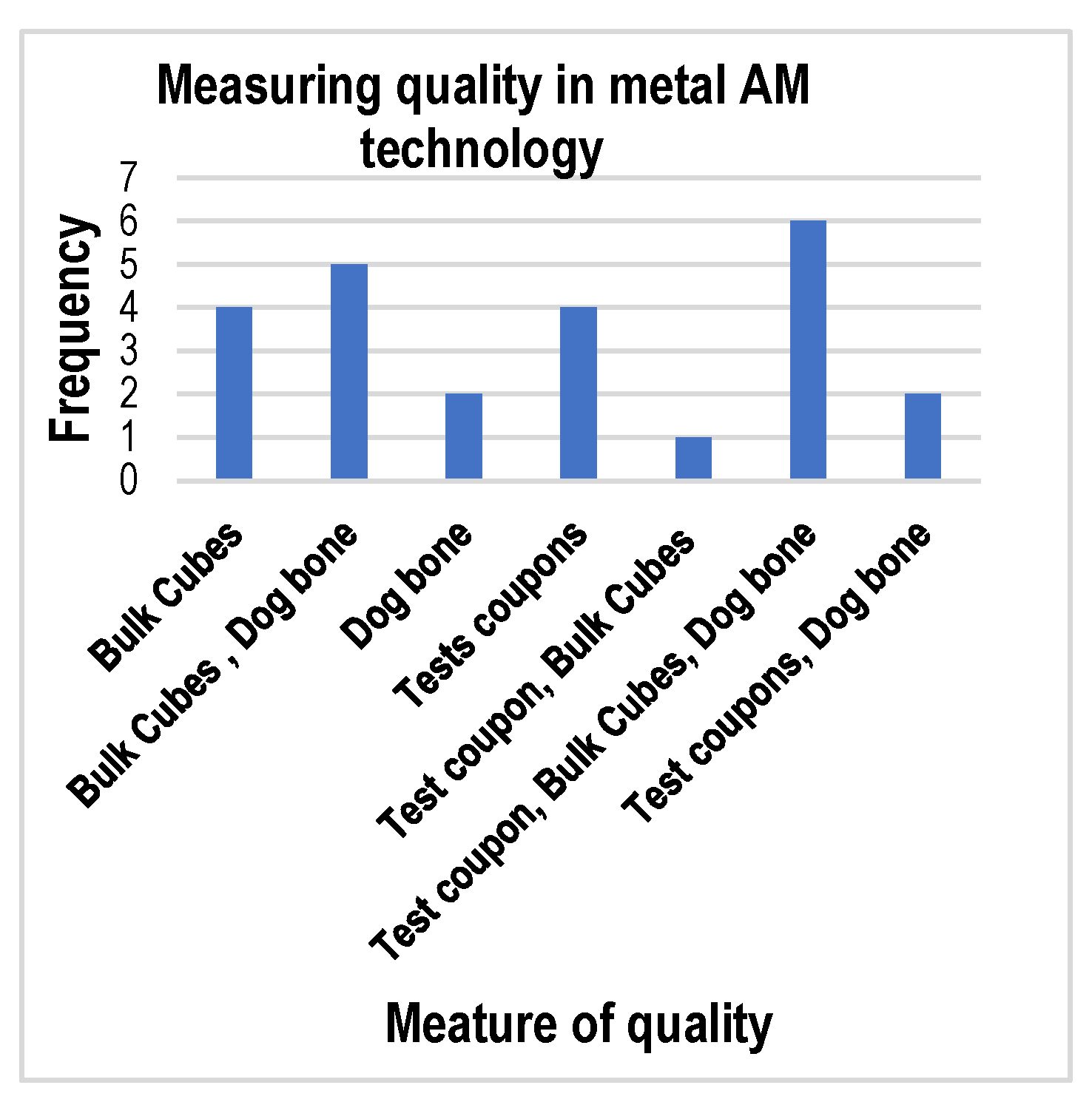

The above figures summarise the process knowledge and assist in defining the respondents as experts in the field. The next figure analyses How quality is measured in the technology, especially for bath production in metal AM processes. The participants were also asked how they measure quality in their metal AM processes. The quality of parts in metal AM is measured using dog bones, bulk cubes built alongside complex parts, or test coupons with the same design as the printed parts, depending on the job and the required quality, as observed in Figure A4.

Figure A4.

Measuring quality in metal AM technology for batch product.

Figure A4.

Measuring quality in metal AM technology for batch product.

Test coupons with the same design and the bulk cubes built alongside complex parts are mainly used to measure the quality and process performance. Figure A5 shows that 16.7% used bulk cubes built alongside complex parts, 20.8% used bulk cubes built alongside complex parts and dog bones,8.3% used just dog bone, another 16.7% used test coupons with the same design as the actual printed parts in the build while 25% of the participants use a combination of them all, i.e., test coupons with the same design as the printed parts., Bulk cubes are built alongside complex parts and dog bones.

- Demographics

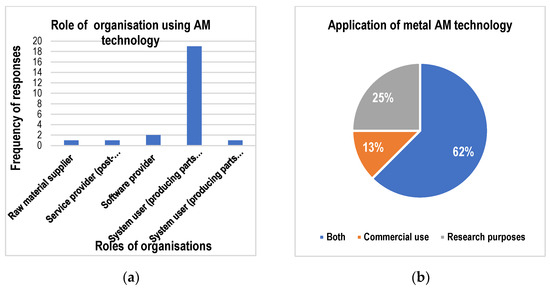

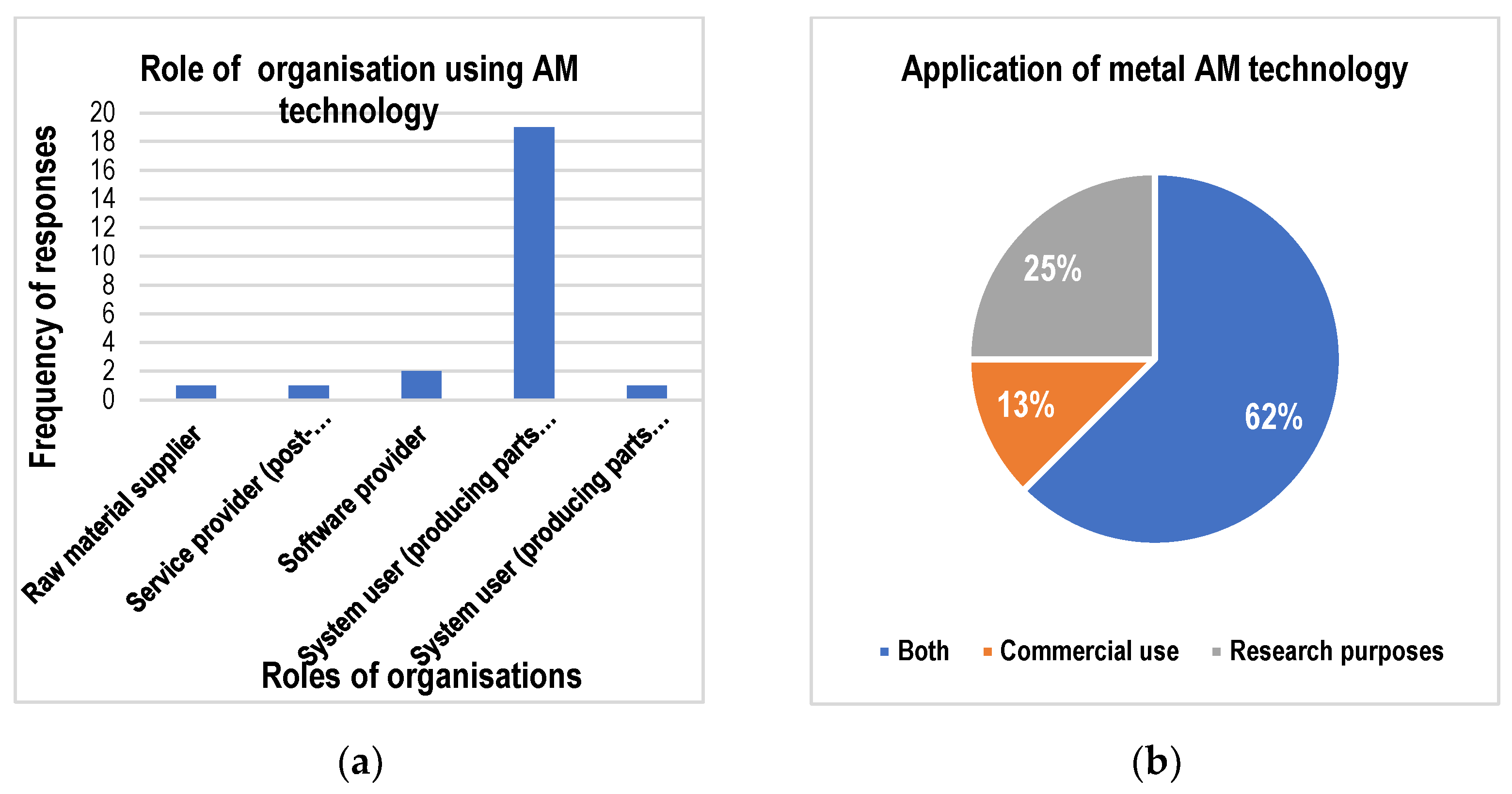

This section focused on understanding the demographics of individuals who answered this survey as experts. Looking at the role of the organisation the respondents are associated with and how they are using metal AM technology presented in Figure A5.

Figure A5.

Demographic of experts in metal AM technology: (a) Primary role of organisation, (b) application of metal AM technology in industry.

Figure A5.

Demographic of experts in metal AM technology: (a) Primary role of organisation, (b) application of metal AM technology in industry.

The last question asks respondents where they are filing the questionnaire from, just to get an overview of the experts. Table A1 shows the geographic locations of the respondents.

Table A1.

Geographic locations of the respondents.

Table A1.

Geographic locations of the respondents.

| Country | Frequency | Percentage (%) |

|---|---|---|

| Belgium | 1 | 4.2 |

| Denmark | 1 | 4.2 |

| Germany | 4 | 16.7 |

| GREECE | 1 | 4.2 |

| India | 1 | 4.2 |

| Netherlands | 4 | 16.7 |

| Poland | 1 | 4.2 |

| Portugal | 2 | 8.3 |

| Russia | 1 | 4.2 |

| Slovenia | 1 | 4.2 |

| South Africa, France, Italy and UAE | 1 | 4.2 |

| Spain | 3 | 12.5 |

| Turkey | 1 | 4.2 |

| UK | 1 | 4.2 |

| United States of America | 1 | 4.2 |

| Total | 24 | 100.0 |

References

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Additive Manufacturing Challenges and Future Developments in the Next Ten Years. In Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2020; pp. 891–902. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, A.M. Additive Manufacturing Technologies, 3rd ed.; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

- Hällgren, S.; Pejryd, L.; Ekengren, J. (Re) Design for Additive Manufacturing. Procedia Cirp 2016, 50, 246–251. [Google Scholar] [CrossRef]

- Bernard, A.; Kruth, J.P.; Cao, J.; Lanza, G.; Bruschi, S.; Merklein, M.; Vaneker, T.; Schmidt, M.; Sutherland, J.W.; Donmez, A.; et al. Vision on Metal additive manufacturing: Developments, challenges and future trends. CIRP J. Manuf. Sci. Technol. 2023, 47, 18–58. [Google Scholar] [CrossRef]

- Lee, J.; Park, H.J.; Chai, S.; Kim, G.R.; Yong, H.; Bae, S.J.; Kwon, D. Review on quality control methods in metal additive manufacturing. Appl. Sci. 2021, 11, 1966. [Google Scholar] [CrossRef]

- Colosimo, B.M.; Huang, Q.; Dasgupta, T.; Tsung, F. Opportunities and challenges of quality engineering for additive manufacturing. J. Qual. Technol. 2018, 50, 233–252. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G. Computers & Industrial Engineering Optimization of zero defect manufacturing strategies: A comparative study on simplified modeling approaches for enhanced efficiency and accuracy. Computer. Ind. Eng. 2024, 187, 109783. [Google Scholar] [CrossRef]

- Qu, M.; Guo, Q.; Escano, L.I.; Nabaa, A.; Hojjatzadeh, S.M.H.; Young, Z.A.; Chen, L. Controlling process instability for defect lean metal additive manufacturing. Nat. Commun. 2022, 13, 1079. [Google Scholar] [CrossRef]

- Yang, H.; Rao, P.; Simpson, T.; Lu, Y.; Witherell, P.; Nassar, A.R.; Reutzel, E.; Kumara, S. Six-Sigma Quality Management of Additive Manufacturing. Proc. IEEE 2021, 109, 347–376. [Google Scholar] [CrossRef]

- Hatami, S. Variation of fatigue strength of parts manufactured by laser powder bed fusion. Powder Metall. 2021, 65, 259–264. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process to cite this version: HAL Id: hal-01825515. J. Mater. Process. Tech. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Prince, M.; Das-Munshi, J. Cross-sectional surveys. In Practical Psychiatric Epidemiology; Oxford University Press: New York, NY, USA, 2020; pp. 127–144. [Google Scholar] [CrossRef]

- Kesmodel, U.S. Cross-sectional studies—What are they good for? Acta. Obstet. Gynecol. Scand. 2018, 97, 388–393. [Google Scholar] [CrossRef] [PubMed]

- Taherdoost, H. Different Types of Data Analysis; Data Analysis Methods and Techniques in Research Projects Authors. Int. J. Acad. Res. Manag. 2020, 9, 1–9. [Google Scholar]

- ISO 9001:2015; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- Falk, K. A Practical Study on How Proactive Quality Approach Can Improve System Development Process to Ensure System-Effectiveness and-Performance. In 29th Annual INCOSE Internal Symposium; ResearchGate: Orlando, FL, USA, 2020; pp. 1–27. [Google Scholar]

- Clancy, R.; Sullivan, D.O.; Bruton, K. Data-driven quality improvement approach to reducing waste in manufacturing. TQM J. 2023, 35, 51–72. [Google Scholar] [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.E.; Pinheiro de Lima, E.; Garbuio, P.A.D.R. Lean, six sigma and lean six sigma: An analysis based on operations strategy. Int. J. Prod. Res. 2014, 52, 804–824. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: Cham, Switzerland, 2015; pp. 1–498. [Google Scholar] [CrossRef]

- Calignano, F.; Galati, M.; Iuliano, L. A metal powder bed fusion process in industry: Qualification considerations. Machines 2019, 7, 72. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Lightweight Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Dahlgaard, J.J.; Kristensen, K.; Kanji, G.K. Fundamentals of Total Quality Management; Taylor & Francis: Beijing, China, 2007. [Google Scholar]

- Herzog, D.; Bartsch, L.; Bossen, B. Productivity optimization of laser powder bed fusion by hot isostatic pressing. Addit. Manuf. 2020, 36, 101494. [Google Scholar] [CrossRef]

- Chua, Z.Y.; Ahn, I.H.; Moon, S.K. Process Monitoring and Inspection Systems in Metal Additive Manufacturing: Status and Applications. Int. J. Eng. Manuf. Green Technol. 2017, 4, 235–245. [Google Scholar] [CrossRef]