An Investigation of the Fatigue Behavior and Dislocation Substructures of Friction-Stir-Welded SSM 6063 Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

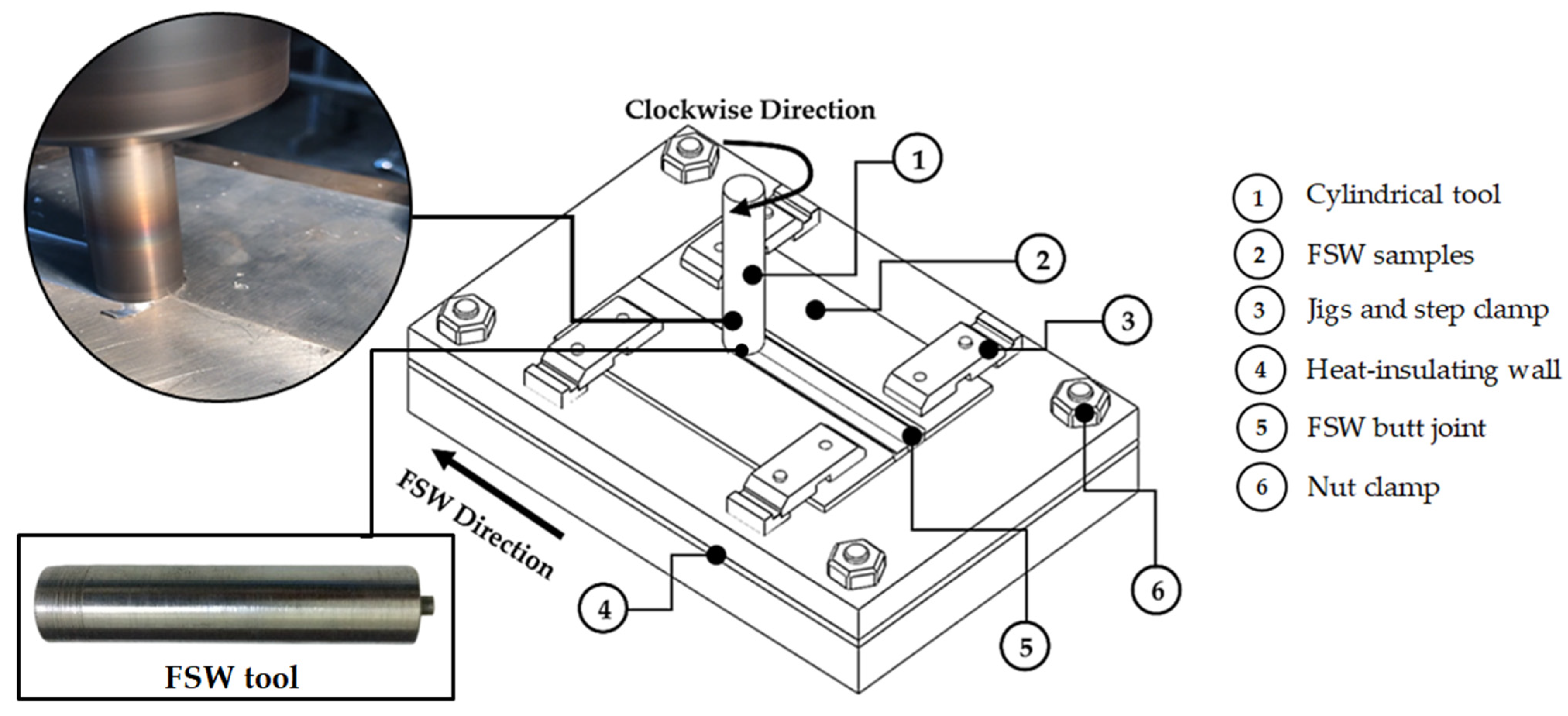

2.2. Friction Stir Welding (FSW) Process

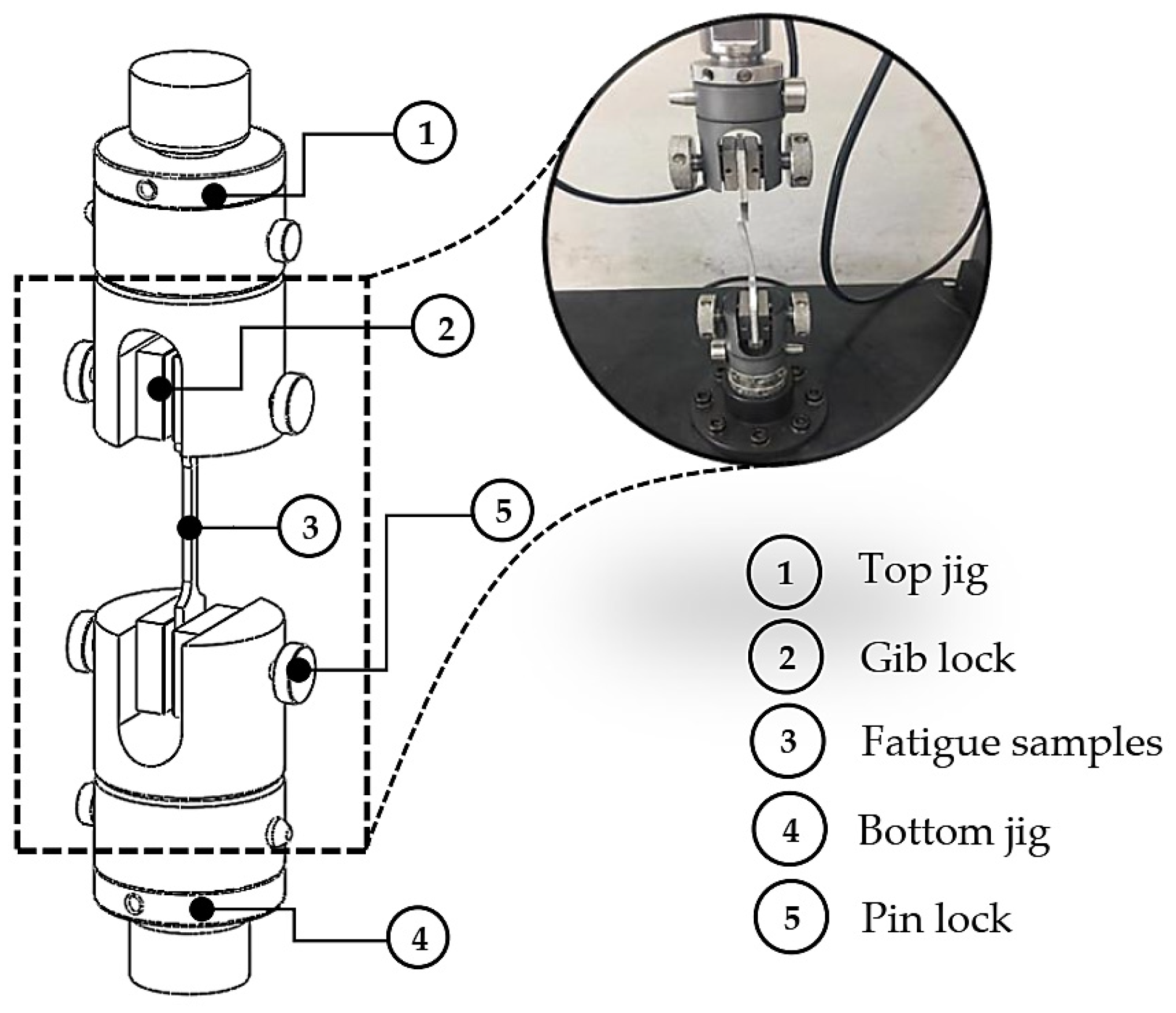

2.3. Fatigue Testing

2.4. Metallurgy Analysis

3. Results and Discussion

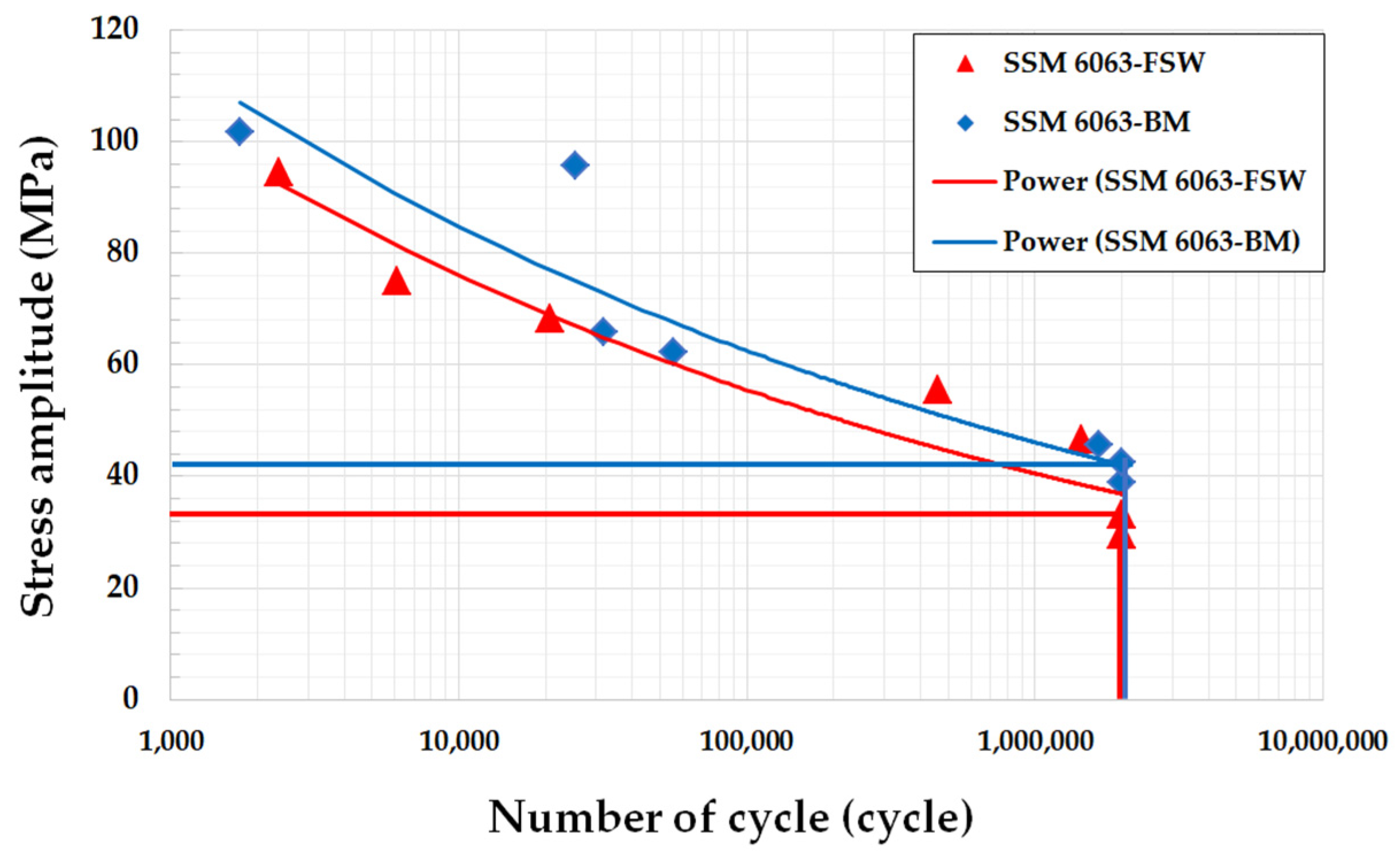

3.1. Fatigue Stress Amplitude Results

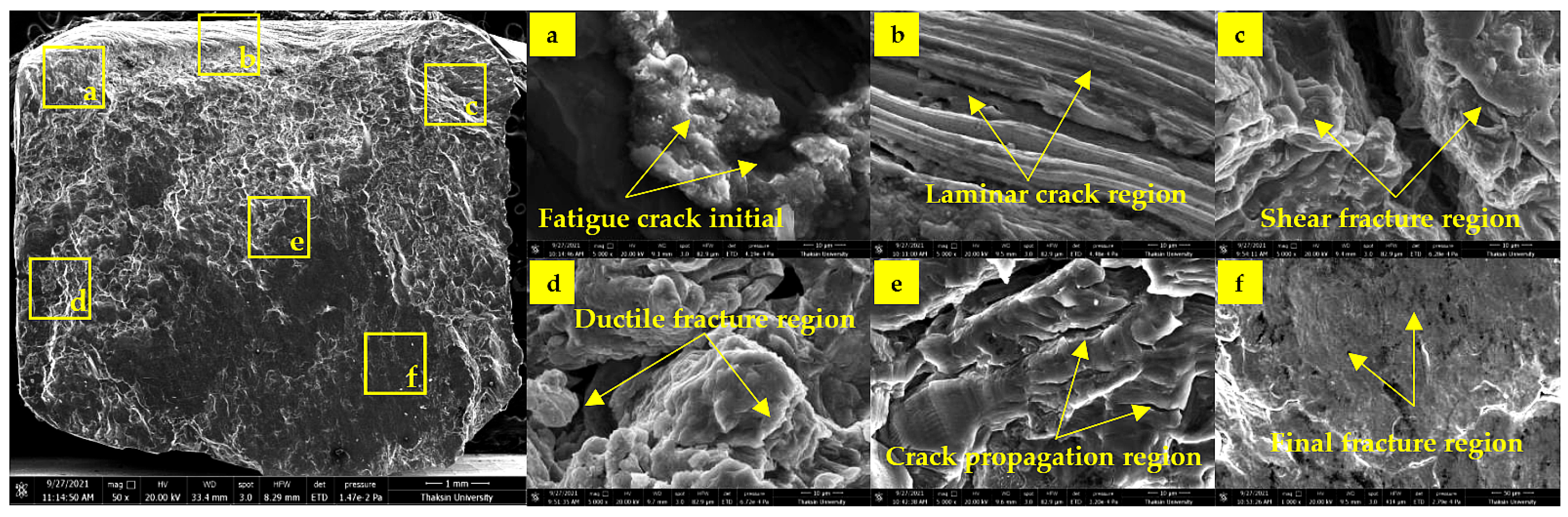

3.2. Characteristics of the Fracture Surface After Fatigue Testing

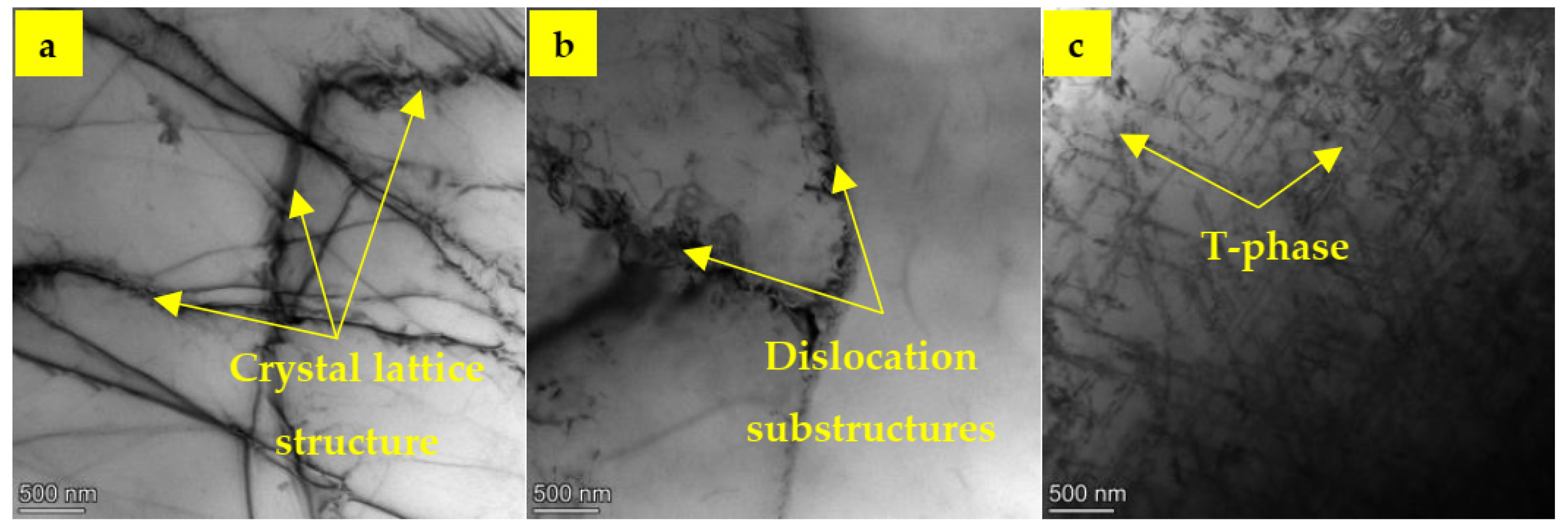

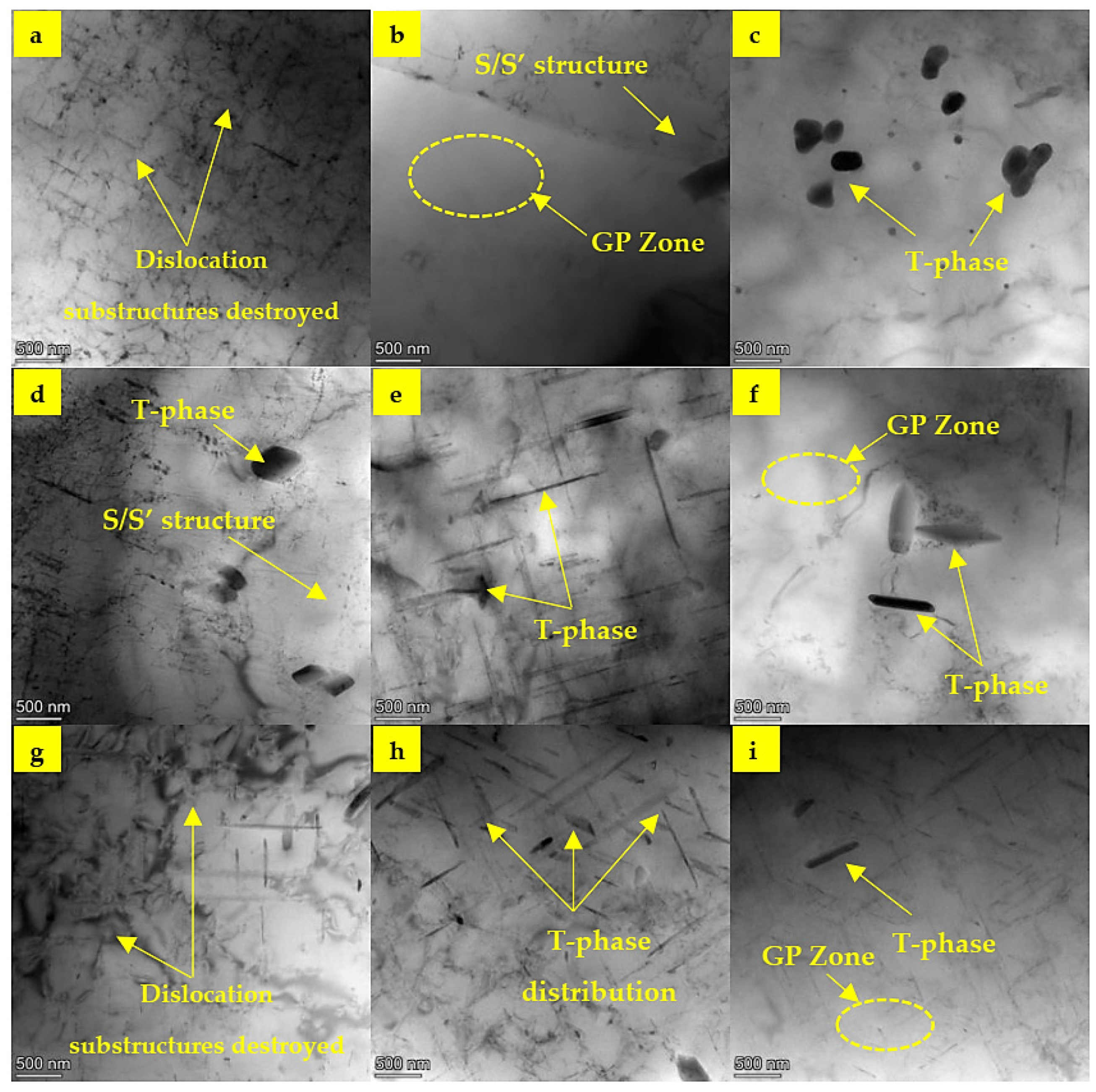

3.3. Transmission Electron Microscope (TEM) Analysis

4. Conclusions

- Fatigue testing for the set number of cycles (limited to 2 × 106) revealed that the BM alloy can resist more than 2 × 106 cycles of cyclic loading at a stress amplitude of 42.46 MPa, while for the FSW alloy the stress amplitude is 33.12 MPa. The calculated endurance limit of the BM was 42.50 MPa. Meanwhile, the FSW SSM 6063 aluminum alloy showed an endurance limit of 32.40 MPa in response to stroke testing at 0.4 mm.

- After fatigue testing, the fracture surface of the FSW samples exhibited plastic deformation behavior. There were two regions of interest: (1) a laminar crack zone, which was arranged in layers near the edge of the fatigue samples; and (2) a shear fracture surface zone, a crack surface caused by accumulated stress in an area near the damaged zone.

- The microstructures revealed during the TEM examination demonstrated that cyclic loading resulted in dislocation substructures, which were subsequently transformed into the SZ, AS-TMAZ, and RS-TMAZ. The dislocation substructures were destroyed and precipitated from an α-primary aluminum matrix phase to an S/S’ structure and from Al5FeSi intermetallic compound recrystallization particles to the T-phase. In particular, in the T-phase transformations, the rod shapes and sizes in the SZ were smaller than in the other two zones (approximately 10–20 nm wide and 20–30 nm long in the SZ; 10–120 nm wide and 20–180 nm long in the AS-TMAZ; and 10–70 nm wide and 20–110 nm long in the RS-TMAZ).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SSM | Semi-solid metal |

| GISS | Gas-induced semi-solid |

| FSW | Friction stir welding |

| ASTM | American Society for Testing of Materials standard |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscope |

| OM | Optical microscopy |

| BM | Base metal |

| SZ | Stir zone |

| AS-TMAZ | Advancing-side thermomechanically affected zone |

| RS-TMAZ | Retracting-side thermomechanically affected zone |

| Tm | Melting point |

| R | Load ratio (Pmin/Pmax) |

| GP zone | Guinier–Preston zone |

| S/S’ | Transformed α-primary aluminum matrix phase |

| T-phase | Transformed Al5FeSi intermetallic compounds |

References

- El-Sayed, M.M.; Shash, A.Y.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Mjali, K.V.; Mkoko, Z.A. Varying rotational speeds and their effect on the mechanical properties of friction stir welded 6082-T651 aluminium alloy plates. Manuf. Lett. 2023, 35, 305–313. [Google Scholar] [CrossRef]

- Sivabalan, S.; Sridhar, R.; Parthiban, A.; Sathiskumar. Experimental investigations of mechanical behavior of friction stir welding on aluminium alloy 6063. Mater. Today Proc. 2021, 37, 1678–1684. [Google Scholar] [CrossRef]

- Wannasin, J.; Janudom, S.; Rattanochaikul, T.; Canyook, R.; Burapa, R.; Chucheep, T.; Thanabumrungkul, S. Research and development of gas induced semi-solid process for industrial applications. Trans. Nonferr. Met. Soc. China 2010, 20, 1010–1015. [Google Scholar] [CrossRef]

- Liu, X.; He, G.; Ding, X.; Mo, D.; Zhang, W.H. Fatigue behavior and dislocation substructures for 6063 aluminum alloy under nonproportional loadings. Int. J. Fatigue 2009, 31, 1190–1195. [Google Scholar] [CrossRef]

- SreeArravind, M.; Kumar, R.; Ravishankar, B.; Kumar, S. Low cycle fatigue behavior of aluminium 6063 alloy under the cyclic frequency of 0.2 Hz. Mater. Today Proc. 2020, 27, 2376–2380. [Google Scholar] [CrossRef]

- Sekhar, A.P.; Nandy, S.; Bakkar, A.; Ray, K.K.; Das, D. Low cycle fatigue response of differently aged AA6063 alloy: Statistical analysis and microstructural evolution. Materialia 2021, 20, 101219. [Google Scholar] [CrossRef]

- Lin, K.; Zhou, L.; Jensen, D.J.; Zhang, X. Dislocation Mechanisms and Local Strength with a View towards Sleeper Screw Failures. Crystals 2023, 13, 656. [Google Scholar] [CrossRef]

- Wang, G.; Che, X.; Zhang, Z.; Zhang, H.; Zhang, S.; Li, Z.; Sun, J. Microstructure and Low-Cycle Fatigue Behavior of Al-9Si-4Cu-0.4Mg-0.3Sc Alloy with Different Casting States. Materials 2020, 13, 638. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Zhou, G.; Liu, R.; Zhang, S. Influence of 0.5% Ag Addition on Low-Cycle Fatigue Behavior of Hot-Extruded Al-5Cu-0.8Mg-0.15Zr-0.2Sc Alloy Subjected to Peak-Aging Treatment. Metals 2023, 13, 1734. [Google Scholar] [CrossRef]

- Kurek, M. Fatigue Prediction of Aluminum Alloys Considering Critical Plane Orientation under Complex Stress States. Materials 2020, 13, 3877. [Google Scholar] [CrossRef] [PubMed]

- Fitzka, M.; Mayer, H. Variable amplitude testing of 2024-T351 aluminum alloy using ultrasonic and servo-hydraulic fatigue testing equipment. Procedia Eng. 2015, 101, 169–176. [Google Scholar] [CrossRef][Green Version]

- Sillapasa, K.; Mutoh, Y.; Miyashita, Y.; Seo, N. Fatigue Strength Estimation Based on Local Mechanical Properties for Aluminum Alloy FSW Joints. Materials 2017, 10, 186. [Google Scholar] [CrossRef]

- Wang, R.; Mi, P. Study on fatigue strength of FSW joints of 5083 aluminum alloy with kissing bond defect. J. Mech. Sci. Technol. 2020, 37, 2761–2766. [Google Scholar] [CrossRef]

- Chehreh, A.B.; Grätzel, M.; Bergmann, J.P.; Walther, F. Fatigue Behavior of Conventional and Stationary Shoulder Friction Stir Welded EN AW-5754 Aluminum Alloy Using Load Increase Method. Metals 2020, 10, 1510. [Google Scholar] [CrossRef]

- Takase, T.; Koyama, A.; Yamashita, Y.; Saki, H. Effect of specimen thickness on fatigue crack growth behavior of friction stir welded 6063-T5 aluminum alloy. Mech. Eng. J. 2016, 3, 16–00156. [Google Scholar] [CrossRef][Green Version]

- Wannasin, J.; Canyook, R.; Wisutmethangoon, S.; Flemings, M.C. Grain refinement behavior of an aluminum alloy by inoculation and dynamic nucleation. Acta Mater. 2013, 61, 3897–3903. [Google Scholar] [CrossRef]

- Meengam, C.; Sillapasa, K. Evaluation of Optimization Parameters of Semi-Solid Metal 6063 Aluminum Alloy from Friction Stir Welding Process Using Factorial Design Analysis. J. Manuf. Mater. Process. 2020, 4, 123. [Google Scholar] [CrossRef]

- Meengam, C.; Dunyakul, Y.; Kuntongkum, S. A Study of the Essential Parameters of Friction-Stir Spot Welding That Affect the D/W Ratio of SSM6061 Aluminum Alloy. Materials 2023, 16, 85. [Google Scholar] [CrossRef]

- ASTM E466-15; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. Designation. ASTM International Standards: West Conshohocken, PA, USA, 2015.

- Liu, K.; Wang, S.; Pan, L.; Chen, X.-G. Thermo-Mechanical Fatigue Behavior and Resultant Microstructure Evolution in Al-Si 319 and 356 Cast Alloys. Materials 2023, 16, 829. [Google Scholar] [CrossRef]

- Lee, B.-H.; Park, S.-W.; Hyun, S.-K.; Cho, I.-S.; Kim, K.-T. Mechanical Properties and Very High Cycle Fatigue Behavior of Peak-Aged AA7021 Alloy. Metals 2018, 8, 1023. [Google Scholar] [CrossRef]

- Teng, Y.; Xie, L.; Zhang, H. Experimental Study on Vibration Fatigue Behavior of Aircraft Aluminum Alloy 7050. Materials 2022, 15, 7555. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Engler-Pinto, C.C.; Tong, J.; Godlewski, L.A.; Zindel, J.W.; Li, L.; Li, M.; Feng, Q. Mechanical response and dislocation substructure of a cast austenitic steel under low cycle fatigue at elevated temperatures. Mater. Sci. Eng. A. 2017, 703, 422–429. [Google Scholar] [CrossRef]

- Moreira, P.; de Oliveira, F.; de Castro, P. Fatigue behaviour of notched specimens of friction stir welded aluminium alloy 6063-T6. J. Mater. Process. Technol. 2008, 207, 283–292. [Google Scholar] [CrossRef]

- Patel, M.; Sangral, S.; Murugesan, J.; Mutoh, Y. Effect of friction stir processing on plain fatigue and fretting fatigue behaviour of the AA6063 alloys. Tribol. Int. 2023, 168, 108642. [Google Scholar] [CrossRef]

- Kumar, S.; Srivastava, A.K.; Singh, R.K.; Dwivedi, S.P. Experimental study on hardness and fatigue behavior in joining of AA5083 and AA6063 by friction stir welding. Mater. Today Proc. 2020, 20, 646–648. [Google Scholar] [CrossRef]

- Zhao, X.; Li, H.; Chen, T.; Cao, B.; Li, X. Mechanical Properties of Aluminum Alloys under Low-Cycle Fatigue Loading. Materials 2019, 12, 2064. [Google Scholar] [CrossRef]

- Tra, T.H.; Okazaki, M.; Suzuki, K. Fatigue crack propagation behavior in friction stir welding of AA6063-T5: Roles of residual stress and microstructure. Int. J. Fatigue 2012, 43, 23–29. [Google Scholar] [CrossRef]

- Das, J.; Banik, S.R.; Reddy, S.R.S.K.; Robi, P.S. Review on process parameters effect on fatigue crack growth rate in friction stir welding. Mater. Today Proc. 2019, 18, 3061–3070. [Google Scholar]

- Bahmanabadi, H.; Shamsarjmand, M. Modeling of fatigue behavior in pre-corroded AZ31 magnesium alloy. Forces Mech. 2024, 14, 100254. [Google Scholar] [CrossRef]

- Łagoda, T.; Głowacka, K.; Kurek, A. Fatigue Life of Aluminum Alloys Based on Shear and Hydrostatic Strain. Materials 2020, 13, 4850. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Xu, L.; Xu, X.; Wang, Q. Fatigue Fracture Characteristics of Ti6Al4V Subjected to Ultrasonic Nanocrystal Surface Modification. Metals 2018, 8, 77. [Google Scholar] [CrossRef]

- Amooie, M.A.; Lijesh, K.P.; Mahmoudi, A.; Azizian-Farsani, E.; Khonsari, M.M. On the Characteristics of Fatigue Fracture with Rapid Frequency Change. Entropy 2023, 25, 840. [Google Scholar] [CrossRef]

- Murashkin, M.; Sabirov, I.; Prosvirnin, D.; Ovid’Ko, I.; Terentiev, V.; Valiev, R.; Dobatkin, S. Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion. Metals 2015, 5, 578–590. [Google Scholar] [CrossRef]

- Mani, S.; Subramanian, R.K. Experimental investigation on the low cycle fatigue performance and fractographic analysis of deep cryogenic treated 6063 aluminium alloy. Structures 2023, 58, 105588. [Google Scholar] [CrossRef]

- González, J.; Bagherifard, S.; Guagliano, M.; Pariente, I.F. Influence of different shot peening treatments on surface state and fatigue behaviour of Al 6063 alloy. Eng. Fract. Mech. 2017, 185, 72–81. [Google Scholar] [CrossRef]

- Ellard, J.J.M.; Mathabathe, M.N.; Siyasiya, C.W.; Bolokang, A.S. Low-Cycle Fatigue Behaviour of Titanium-Aluminium-Based Intermetallic Alloys: A Short Review. Metals 2023, 13, 1491. [Google Scholar] [CrossRef]

- Sillapasa, K.; Surapunt, S.; Miyashita, Y.; Mutoh, Y.; Seo, N. Tensile and fatigue behavior of SZ, HAZ and BM in friction stir welded joint of rolled 6N01 aluminum alloy plate. Int. J. Fatigue 2014, 63, 162–170. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, H.; Li, S.; Zhao, H.; Chen, J.; Qi, L. Microstructure, mechanical properties and fatigue crack growth behavior of friction stir welded joint of 6061-T6 aluminum alloy. Int. J. Fatigue 2020, 135, 105556. [Google Scholar] [CrossRef]

- Sivaraj, P.; Kanagarajan, D.; Balasubramanian, V. Fatigue crack growth behaviour of friction stir welded AA7075-T651 aluminium alloy joints. Trans. Nonferrous Met. Soc. China 2014, 24, 2459–2467. [Google Scholar] [CrossRef]

- Besel, Y.; Besel, M.; Mercado, U.A.; Kakiuchi, T.; Hirata, T.; Uematsu, Y. Influence of local fatigue damage evolution on crack initiation behavior in a friction stir welded Al-Mg-Sc alloy. Int. J. Fatigue 2017, 99, 151–162. [Google Scholar] [CrossRef]

- Mao, X.; Yi, Y.; He, H.; Huang, S.; Guo, W. Second Phase Particles and Mechanical Properties of 2219 Aluminum Alloys Processed by an Improved Ring Manufacturing Process. Mater. Sci. Eng. A 2020, 781, 139226. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, C.; Chen, S.; Wan, M.; Yang, M.; Ji, S.; Zeng, W. Effect of Microstructure on High Cycle Fatigue Behavior of 211Z.X-T6 Aluminum Alloy. Metals 2022, 12, 387. [Google Scholar] [CrossRef]

- Sun, C.; Song, Q. A Method for Predicting the Effects of Specimen Geometry and Loading Condition on Fatigue Strength. Metals 2018, 8, 811. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, W.; Zhang, H.; Yang, W.; Wang, G.; Dong, Y.; Ye, C. Fatigue Performance Rejuvenation of Corroded 7075-T651 Aluminum Alloy through Ultrasonic Nanocrystal Surface Modification. Int. J. Fatigue 2021, 153, 106463. [Google Scholar] [CrossRef]

- Mao, X.; Yi, Y.; Huang, S.; Guo, W.; He, H.; Que, J. Effects of Warm Saddle Forging Deformation on the Reduction of Second-Phase Particles and Control of the Three-Dimensional Mechanical Properties of 2219 Aluminum Alloy Rings. Mater. Sci. Eng. A 2021, 804, 140737. [Google Scholar] [CrossRef]

- Knap, V.; Švecová, I.; Tillová, E.; Kuchariková, L. Influence of Iron Content on SDAS Factor, Al5FeSi Intermetallic Phases and Porosity of the Secondary Aluminum Alloy AlSi7Mg0.6 Used in the Automotive Industry. Transp. Res. Procedia 2021, 55, 814–820. [Google Scholar] [CrossRef]

| Workpiece | Frequency | Stress Ratio | Maximum Cycles | Fatigue Parameters | Recommended Parameters | Reference |

|---|---|---|---|---|---|---|

| Material: Al 2024-T351 Thickness: 4 mm | 20 kHz | R = 0.1 and 0.5 | 107 cycles | The sequence consists of 27 discrete levels between fractions of 0.31 and 1.0 of the nominal amplitude in a succession of 771 realizations. | High-frequency and adapted testing may influence fatigue properties; 2024-T351 aluminum alloy shows comparable lifetimes for constant amplitude tests at load ratios of R = 0.1 and R = 0.5. | [12] |

| Material: 6N01-7N01 Thickness: 6.0 mm | 20 Hz | R = 0.1 | 107 cycles | The stress amplitude ranges from 70 to 140 N/mm2, and two types of test specimens are available: plate and small round bar specimen fatigue testing. | The fatigue strength of FSW 6N01-7N01 at 72 N/mm2 and the relationship between the fatigue strength and hardness of aluminum alloys were investigated. | [13] |

| Material: AA 5083 Thickness: 3 mm | 10 Hz | R = 0.1 | 2 × 106 cycles | Load amplitudes at 2420, 2480, 2530, 2640, 2750, 2860, 3300, 3850, 4400, 4950, 5500, and 5770 N. | Kissing bond defect depth has an obvious effect on the fatigue behavior and maximum fatigue life with 142,743 cycles at a load amplitude of 2480 N and a kissing bond defect depth of 0.45 d/mm. | [14] |

| Material: AW-5754 Thickness: 2 mm | 10 Hz | R = 0.1 | 2 × 105 cycles | The σmax value is 20 MPa, and the σ0/dN value is 10 MPa/104. The surface roughness measurements of the FSW specimen are Rz = 212 µm and Ra = 23 µm. | Load increases the efficiency of fatigue performance and strength of materials. FSW EN AW-5754 is tolerant to fatigue behavior due to its fatigue life and fracture stress, reduced scatter, and deviation. | [15] |

| Material: SSM6063 Thickness: 4 mm | 20 Hz | R = 0.1 | 2 × 106 cycles | Strokes at 0.35, 0.40, 0.45, 0.50, 0.60, 0.70, and 0.80 mm. | This research studies the amplitude fatigue of SSM 6063 aluminum alloy, a new material for semi-solid casting. It focuses on the dislocation substructures that affect the S-N curve, which have not been previously studied. | Present work |

| Element (wt %) | Si | Fe | Cu | Mn | Mg | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| SSM 6063 | 0.60 | 0.35 | 0.10 | 0.10 | 0.45 | 0.10 | 0.10 | 0.10 | Rem. |

| Young’s Modulus | Tensile Strength | 0.2% Proof Stress | Elongation |

|---|---|---|---|

| 68 GPa | 149 ± 3 MPa | 68 ± 4 MPa | 27 ± 4% |

| Parameter | Unit | Value | Affected Process |

|---|---|---|---|

| Rotational speed | rpm | 1320 | Heat inputs, plasticity |

| Travel speed | mm/min | 60 | Welding completeness |

| Plunge rate | mm/min | 9 | Heat initiation |

| Dwell time | s | 12 | Heat accumulation |

| Pin length | mm | 3.2 | Thickness of the samples |

| Pin diameter | mm | 5 | Stirring pattern |

| Shoulder diameter | mm | 20 | Heat transfer area |

| Direction of FSW | --- | clockwise | Material flows |

| Stroke (mm) | SSM 6063 (BM) | SSM 6063 (FSW) | ||

|---|---|---|---|---|

| Stress (MPa) | Number of Cycles | Stress (MPa) | Number of Cycles | |

| 0.35 | 38.92 | 2,000,000 * | 29.47 | 2,000,000 * |

| 0.40 | 42.46 | 2,000,000 * | 33.12 | 2,000,000 * |

| 0.45 | 45.79 | 1,655,334 | 46.72 | 1,440,470 |

| 0.50 | 62.24 | 55,560 | 55.52 | 457,134 |

| 0.60 | 65.81 | 31,835 | 68.31 | 20,780 |

| 0.70 | 95.66 | 25,465 | 75.10 | 6104 |

| 0.80 | 101.72 | 1747 | 94.52 | 2360 |

| Material | Fatigue Life Equation at 2 × 106 Cycles | Endurance Limit (MPa) |

|---|---|---|

| SSM 6063—BM | σ = 287.82x−0.133 | 42.50 |

| SSM 6063—FSW | σ = 268.08x−0.137 | 32.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sillapasa, K.; Nakowong, K.; Khantongkum, S.; Meengam, C. An Investigation of the Fatigue Behavior and Dislocation Substructures of Friction-Stir-Welded SSM 6063 Aluminum Alloy. J. Manuf. Mater. Process. 2025, 9, 128. https://doi.org/10.3390/jmmp9040128

Sillapasa K, Nakowong K, Khantongkum S, Meengam C. An Investigation of the Fatigue Behavior and Dislocation Substructures of Friction-Stir-Welded SSM 6063 Aluminum Alloy. Journal of Manufacturing and Materials Processing. 2025; 9(4):128. https://doi.org/10.3390/jmmp9040128

Chicago/Turabian StyleSillapasa, Kittima, Konkrai Nakowong, Siriporn Khantongkum, and Chaiyoot Meengam. 2025. "An Investigation of the Fatigue Behavior and Dislocation Substructures of Friction-Stir-Welded SSM 6063 Aluminum Alloy" Journal of Manufacturing and Materials Processing 9, no. 4: 128. https://doi.org/10.3390/jmmp9040128

APA StyleSillapasa, K., Nakowong, K., Khantongkum, S., & Meengam, C. (2025). An Investigation of the Fatigue Behavior and Dislocation Substructures of Friction-Stir-Welded SSM 6063 Aluminum Alloy. Journal of Manufacturing and Materials Processing, 9(4), 128. https://doi.org/10.3390/jmmp9040128