1. Introduction

The Ju|’hoansi are one of the longest surviving civilisations in the world. Inhabiting the more septentrional regions of Southern Africa, they are part of the o’Kung group of indigenous people called the San, and are recognised as the original inhabitants of the Kalahari Desert [

1]. The San hunting culture can be dated back to at least tens of thousands of years [

2], and one of their major hunting tools is the bow and arrow. The first use of arrows in this region is recorded in cave paintings from between 60,000–64,000 years ago, while the first reference to the use of bone in arrows dates back to approximately 24,000 years ago [

3]. Ju|’hoansi arrows are unique composite constructions and are typically tipped with poison [

4] from

Diamphidia and

Polyclada (Chrysomelidae family) grubs, more commonly known as the arrow-poison beetle [

5]. Poison tipped arrows are game changers in the hunt for larger animals such as Kudu, Gemsbok and wildebeest [

6]. The arrows are fundamentally composites, as they are constructed of several different materials with distinct adhered interfaces. Different parts of the arrow are also individually reinforced composites, and each of the parts of the Ju|’hoansi arrows are described in more detail below.

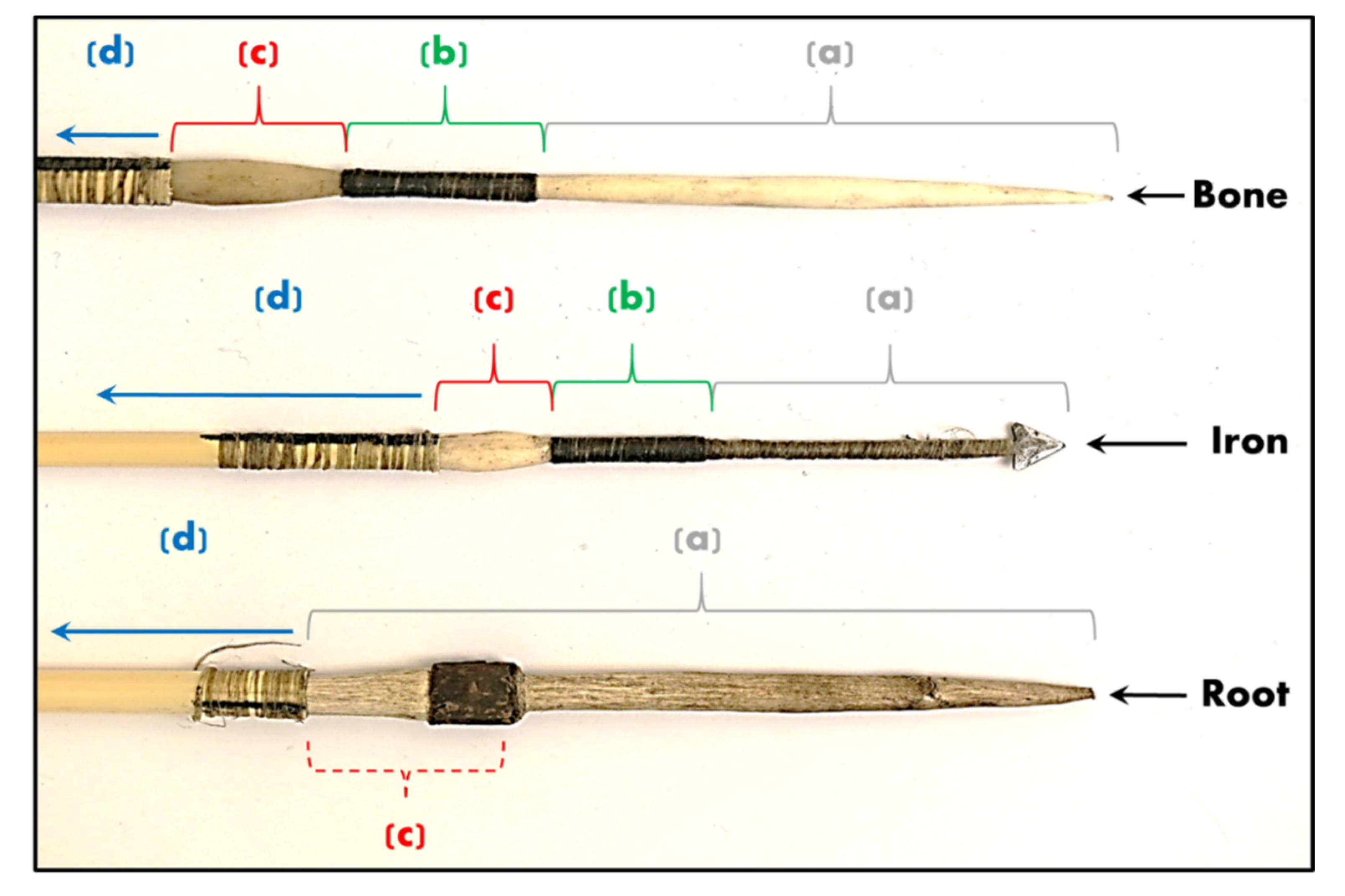

The arrow can be subdivided into four parts, the main shaft, the balance, the link-shaft and the fore shaft (the arrowhead),

Figure 1. The main shaft is a lightweight, stiff grassy stalk from

Phragmites australis, into which a balance is inserted, or the arrowhead itself. The link-shaft (also from

Phragmites australis) is only found in the arrows employing giraffe shin bone or ductile iron as the arrowhead. The end of the main shaft and the whole of the link-shaft are enveloped in tendon taken from the Achilles of either kudu or giraffe and glued onto the surface of the reeds using an adhesive comprised of milky white sap from the

Ozoroa Schinzii bush [

7] mixed with fine black ash from

Aristida adscensionis grass—hereinafter, Ozoroa-glue. The link-shaft is of interest in composites design, as it is understood to be sacrificial, and will break upon impact. This allows for the retrieval of the main shaft and furthermore prevents the animals from brushing off the embedded poisoned tips when fleeing [

8]. The main shaft and the link-shaft are connected by a bony balance in arrows using iron or bone, but is carved into the structure of arrows using hardened root arrowheads.

The arrowhead is typically made from either the hardened root of

Rhus tenuinervis, the shin bones of large animals such as giraffe or from ductile iron [

8,

9]. The most recent of these materials is the ductile iron arrowhead, which was introduced to Southern Africa following the German colonialisation of certain regions [

10] and are salvaged from fencing wire. Iron arrowheads are shaped differently to the root and shin bone arrowheads as they are thin and flat, and have a triangular or fan-shaped tip [

9]. Though metallurgical processes are presumed unknown to the Ju|’hoansi, the metallurgical bloomer process is reported to have been used widely throughout the African continent [

11], possibly dating back as far as the seventh to first centuries B.C. [

12,

13]. Shin bone arrowheads are widely scavenged from the shins of naturally deceased giraffe [

14], and are manufactured through a process of shin bone splitting into small parts, followed by water soaking of the bone, after which the bone is ground down to a sharp tip using both stone and metallic tools. The root arrowheads from

Rhus tenuinervis are sharpened in a similar way to the shin bones, through soaking and grinding, and both are hardened by drying. All three materials are nevertheless bonded into the

Phragmites reeds of the main shaft and/or link-shaft using a glue made from the viscous, water-soluble, amber sap of a

Terminalia Sericea tree, hereinafter Terminalia-glue.

Research on the Ju|’hoansi arrowheads conducted to date provides valuable manufacturing information [

15] on the glues used in their construction, and the chemistry of their poisons [

16,

17,

18,

19]. A, there have been no engineering perspectives on the material and mechanical design of the different types of Ju|’hoansi arrowheads. This article aims to, at least partially, fill this gap in knowledge in anthropological and archaeological composites research.

2. Materials and Methods

2.1. Physical and Optical Characterisation

The densities and geometries were characterised for each of the different types of arrowhead (root, bone and metal). The material cross-sections were furthermore characterised optically using both an optical microscope (Zeiss Axioskop 2 MAT with an AxioCam MRc5 camera) and a scanning electron microscope (JEOL JSM—IT100). The arrowheads were embedded into resin and initially sanded using grit 400, grit 800 and finally grit 1200. Final polishing was conducted in a monocrystalline diamond suspension to ensure a smooth, defect-free surface finish.

2.2. Mechanical Testing of the Arrowheads

Vickers hardness tests were conducted on the cross-sections of each of the arrowheads. Dynamic mechanical thermal analysis (DMTA) was conducted in bending mode for each of the arrowheads between 1–20 Hz at temperatures ranging from 27 °C to 39.5 °C. This is a typical temperature range within which the arrowheads would be used in the Kalahari Desert.

2.3. Mechanical Testing of Arrowhead Connections and Their Components

The link-shaft of the arrow that is designed to break (c.f.

Figure 1) is a composite material of reed that is radially reinforced with, in this case, giraffe tendon. We tested the bare (unreinforced) reed in tension along its axis and in its radial direction. Samples were loaded in an Instron 3369 with a 1 kN load cell at a cross-head rate of 1.5 mm/min. Geometrical measurements of each reed were taken for each reed prior to testing, and two tests were conducted due to material scarcity. The tendons were also tested in tension under the same loading conditions (number of tests = 8). These were prepared by unpeeling them from the reed after which, the glue used to hold them in place on the reed was removed using water (since the glue is soluble in water). The samples were then straightened and dried. Rectangular flat clamps were used to hold the tendons in place, and tape used on the surfaces of the clamps to minimise slippage. Tendons were also tested under tension–tension mode in a DMTA between 1 and 20 Hz at temperatures ranging from 27 °C to 39.5 °C (number of tests = 8).

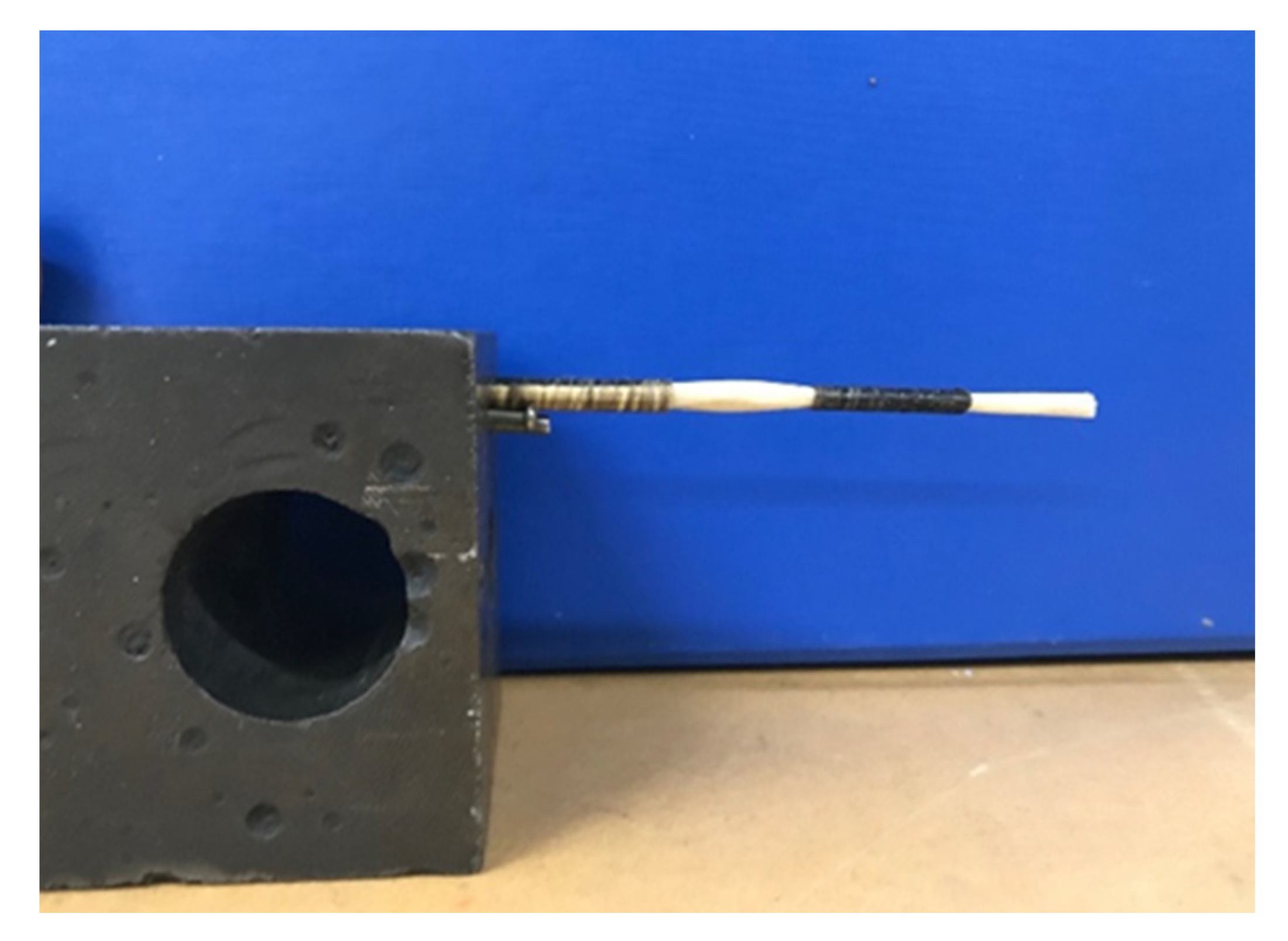

The tendon reinforced reed (adhered by Ozoroa-glue) was then tested radially using the test set-up shown in

Figure 2 (number of tests = 8). Here, we thread two bent wires into the reed and pulled them in opposing directions to test the reinforced radial properties of the composite link joint.

To test the effect of impact on the arrow, in particular the arrow assembly (arrowhead, reed link-shaft, balance and main reed shaft), we tested the assembly in a Charpy Impact Testing Machine (Avery), using impacting energies from a pendulum to mimic those expected at impact. This test additionally allowed us to establish the primary locations of damage in the arrow assembly upon a head on impact with the arrowhead. To ensure a head on impaction with minimal angulated impact force on the arrowhead, we removed the top half of the arrowhead, and shortened the main reed shaft,

Figure 3. Since we had a limited number of samples, these specific tests were only conducted three times using the arrow assembly comprising the bone arrowhead. The purpose of this test was to determine (a) whether the reed link joint would indeed fail prior to the main shaft joint under impact and (b) to assess the mode of failure on impact.

2.4. Finite Element Analyses

Finite element models were developed to ascertain the effects of dynamic impact loads on the magnitude and distribution of stress in each of the arrowheads. This impact force occurs either when the arrowhead hits its target, or if it misses its target, when the arrowhead impacts a different surrounding object such as a tree, the ground or nearby rocks. To simulate this, we used the drop impact simulation feature in SolidWorks. In this simulation, we essentially impact the arrowhead, tip-first, onto a flat surface at a velocity of 60 ms−1. Using our models, we compared the different materials of the arrowheads with respect to their different geometrical designs. We simulated cases where the arrowhead was made up of its original material, and cases where we simulated the one specific material, but within the different arrowhead designs. We did this to ensure that stress distributions could also be easily compared as a function of solely the arrowhead geometry.

3. Results

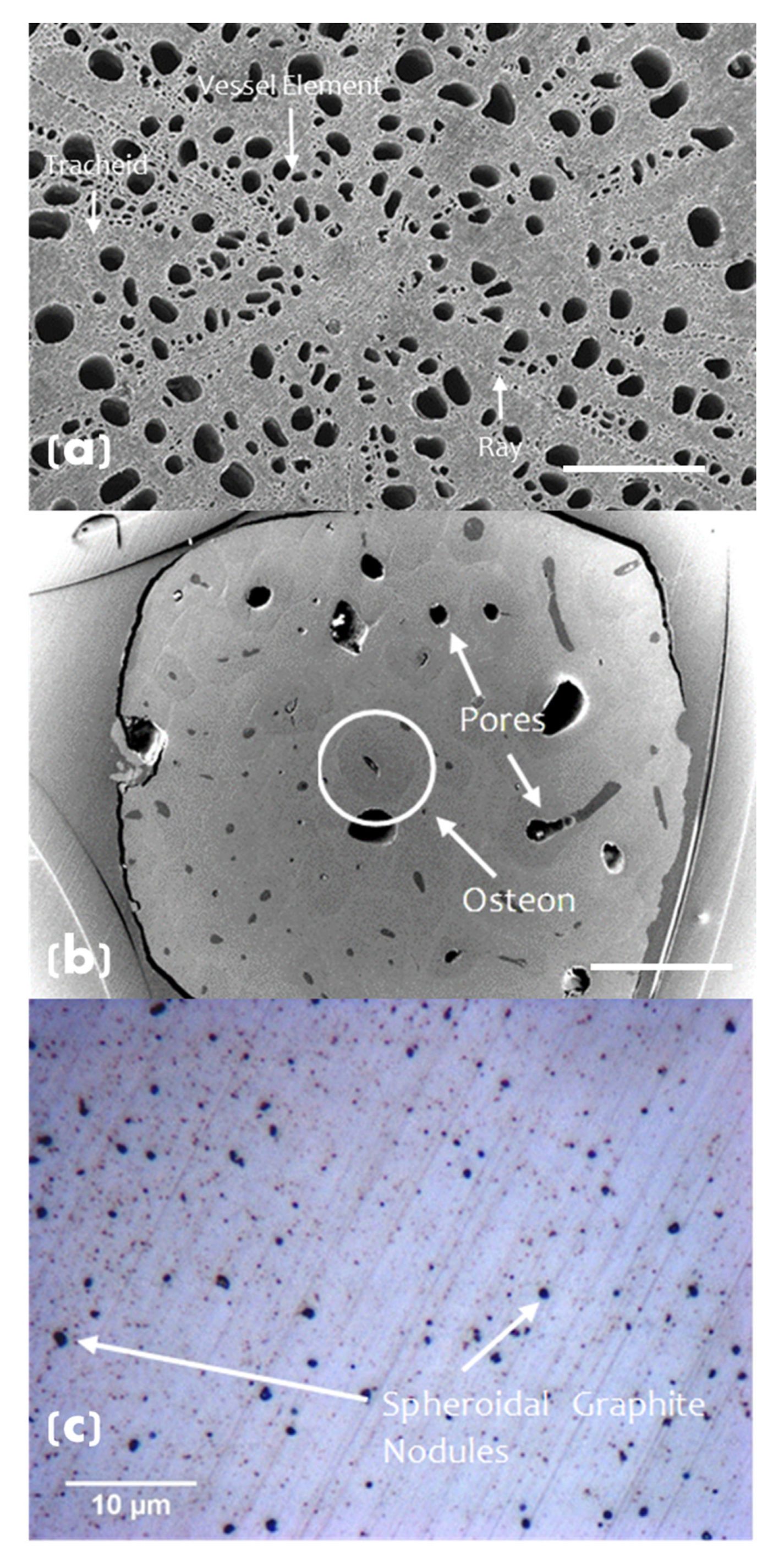

Table 1 provides the measured geometrical, physical and hardness data for the different arrowheads. Density is noted as being inversely proportional to material volume, and this may reflect weight and balance considerations in the design of the arrowheads. Hardness is another consideration in the design of arrowheads, since harder arrowheads will have better prey-penetration potential. Here, we note that on average, hardness is highest in the iron arrowheads, followed by bone, and then by root. The standard deviations are very high in the bone and root samples. This is because these arrowheads have porous microstructures, which decreases the regularity of hardness measurements as the indenter head may fall into a pore, or onto a solid part of the material. This can be seen clearly in

Figure 4a–c, which show micrographs from the cross sections of the root, bone and iron arrowheads, respectively. The root microstructure shown in (a) contains varying compositions of oval shaped openings. These rings that converge towards the centre of the root (Pith) are xylem cells that are purposed as wide vessel members that act as water conducting cells for the root and are therefore hollow in nature. Rays can be seen extending from the pith and these are essentially thin-walled and composed of parenchyma cells [

20], which are often the weak points that result in material splitting. The xylem in this root comprises numerous elongated cells with narrowed ends, fibres and generally thicker walls. These provide structural stiffness and strength, and we note that the roots are prepared in the direction of growth of the xylem, which typically have superior mechanical properties as compared to the properties in the radial direction [

21]. The bone arrowheads exhibit similar unidirectional growth patterns to that of the root, resulting in orthotropic properties [

22]. This is indicated by the pore openings that are visible in the centres of the osteons. Similarly to the root therefore, the cutting direction for the bone is mechanically beneficial as arrowhead impaction will occur in the direction of the growing bone (i.e., the load bearing axis for a standing giraffe).

Very slight decreases in the storage modulus of the root arrowhead were noted to occur as a function of increasing temperature and decreasing loading rate, the range of values varying between 1.04–1.14 GPa. Bone arrowheads contrarily exhibit a slight increase in storage modulus as the temperature was raised from 25–40 °C, though in similitude to the root arrowhead, the bone has viscoelastic response, increasing in storage modulus with respect to loading rate, the range of values varying between 8.2–8.5 GPa. Iron arrowheads showed no discernible variation with respect to either loading rate or temperature, averaging a relatively constant value of 111 GPa through all the tests. Tendon has a storage modulus ranging from 43 MPa at the higher temperatures (40 °C) to 125 MPa at the lowest testing temperatures (27 °C).

The unreinforced reed shaft along its axis has an average Young’s modulus of 9.2 GPa (±4.9 GPa) and a tensile strength of 97.6 MPa (±44.4 MPa). The radial properties of the unreinforced reed shaft are significantly lower than those of the shaft along its axis, with a Young’s modulus of 2.2 MPa (±0.2 MPa), and a strength value of 1 MPa (±0.15 MPa). The tendon used to radially reinforce the reed link-shaft has a strength of 90.4 MPa (±20.8 MPa), which is approximately 90-fold higher than the radial properties of the reed, while its Young’s modulus is ca. 280-fold higher at 0.62 GPa (±0.14 GPa). The reinforced reed will exhibit shared properties of both the reed and the tendon, and when tested radially shows an average breaking strength of 16.6 MPa (±5.7 MPa) and a Young’s modulus of 22 MPa (±10.6 MPa). When compared against the unreinforced reed in its radial axis, there is a ca. 10-fold stiffness increase and a strength increase of ca. 17-fold. Representative stress–strain curves for reinforced and unreinforced reeds tested in their radial directions are provided in

Figure 5. The importance that reinforcing the reed shaft and the reed link-shaft has on the arrow in terms of its use can be understood when we observe the impact test results,

Figure 6, which show that when impacted, the link-shaft joint fails while the rest of the arrow remains undamaged. Members of a Ju|’hoansi family in Namibia had orally communicated this to us as being a purposeful design principle in their bone and metal arrows. The arrow has essentially been designed to break so that the poison tipped arrowhead remains in the hunted animal, whilst the rest of the arrow breaks away allowing it to be collected and re-used.

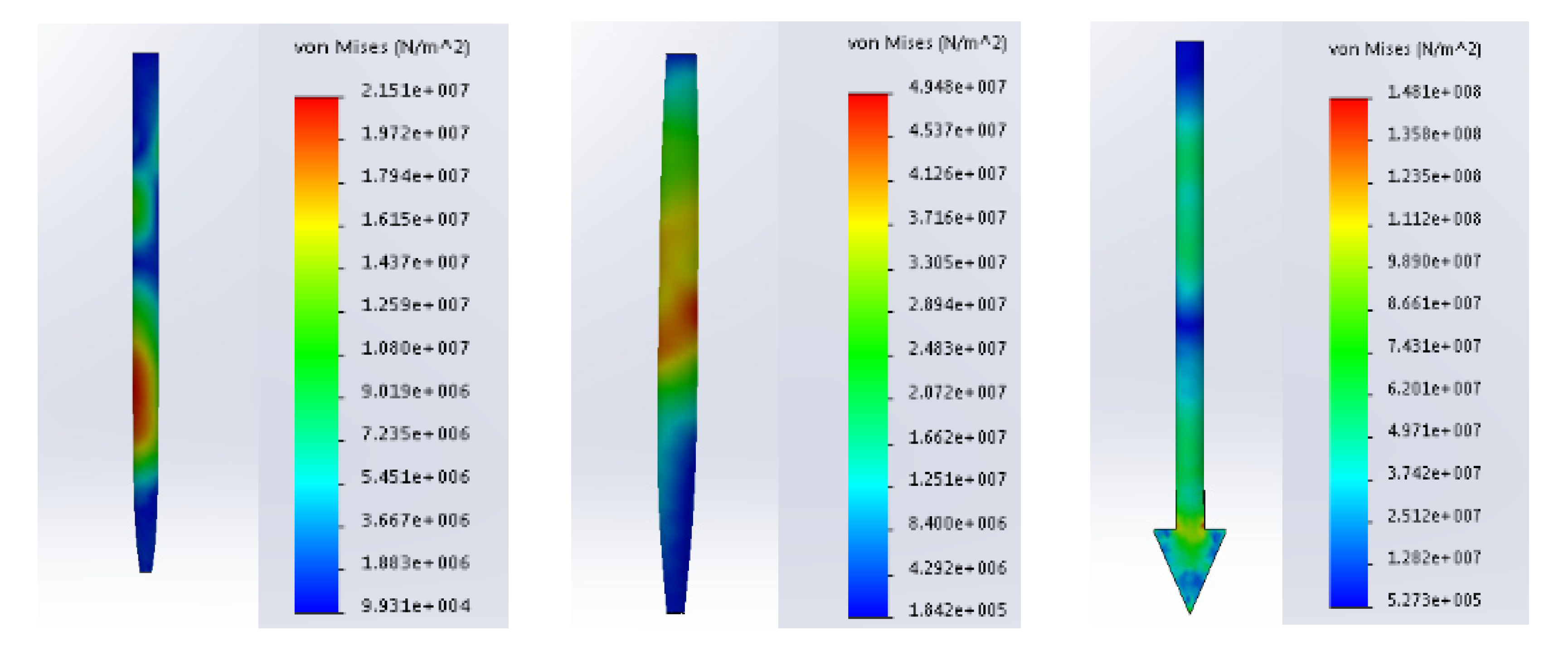

When analysing the effects of impact on specifically the arrowhead, we find that both the material of the arrowhead and its geometrical design affect its utility. The iron arrowhead experiences the highest stresses, followed by the bone and subsequently the root. This is logical since the Young’s modulus of the iron is considerably higher than that of the bone, which in turn is higher than that of the root,

Figure 7. Closer inspection of the stress distributions within each of the arrowheads indicates that the geometrical design for the iron arrowhead tends to hold the high stresses within the tip of the arrowhead (the triangular segment), whereas both the root and bone arrowheads dissipate impact stresses more evenly through their individual structures. This can be understood as being solely a geometrical effect by simulating impact using the three different arrowhead geometries but with a single material, in our case iron, as shown in

Figure 8. In this figure, we note that both the root and the bone arrowhead geometries result in an initial stress spike which decreases in intensity as a function of time. The iron arrowhead geometry contrarily shows a prolonged stress spike, which is significantly higher than those computed for the root and bone arrowhead designs. This indicates that the iron arrowhead geometry is the most effective for penetration into an animal, as not only does it enable the development of a higher stress magnitude at its tip, but it also prolongs these higher stresses for longer periods of time than do the root and bone geometries. We note further that the iron arrowhead geometry can only be used with iron material. When simulating each of the root, bone and iron materials in the iron arrowhead geometry, we find that the root and bone materials experience elastic impact stresses of 1.2 GPa and 1.16 GPa, respectively. These impact stresses are well above the failure stresses of both the root and bone materials, and as such, they cannot effectively be used within the iron arrowhead geometry.

4. Discussion

Based on the research herein, we posit that the Ju|’hoansi people have applied critical thinking in their arrow designs. Notably, the three arrowheads researched herein are made of three dissimilar materials (root, bone and iron) and their utility is coupled to a geometrical construct that is well suited to the specific material used.

The construction of both the reed shaft (main) and the reed link-shaft is essentially that of a reinforced composite. The reed has a high stiffness and strength along its axis, but has a low stiffness in its radial direction. Without reinforcement provided by the strong tendinous matter, high stress concentrations caused by the inserted arrowhead or balance would indubitably lead to radial failure. The reinforcing tendon possesses valuable mechanical properties that prevent the reeds from breaking prematurely. The tendon is comprised of predominantly type 1 collagen, which has a high storage modulus under dynamic loading conditions since it is a viscoelastic material. This material property is important in impact, which is a high strain-rate, dynamic loading condition and tendon is thus a judicious choice of reinforcing material.

The arrowhead link joint is a vital component in the arrow design. The failure of this joint on impact was noted to complement the information we received directly from the Ju|’hoansi as being vital to retrieving valuable material without reducing the effectiveness of the hunt. This not only exhibits consciousness amongst the Ju|’hoansi people in regards to material recycling and reuse, but also indicates that the link-shaft design may have arisen through either empirical testing, or through trial and error during a hunt. If the composite link-shaft was indeed designed in this way, it might be a very early example of empirical science and engineering, predating many of the earliest records of such practices. Nevertheless, since we are unsure of the exact date ranges that the Ju|’hoansi started using the link-shaft, and indeed the methodical approach underlying its development, this conjecture requires further research if it is to gain momentum.

Penetration through the skin of a hunted animal is important for the delivery of poison carried by the arrow tip. A sharper, stiffer, harder arrow tip has a better chance of penetration and though each of the arrow tips have an initial sharpness, the harder materials are able to maintain the tip quality at the point of impact. As such, the Ju|’hoansi’s transition from root to bone to iron indicates a knowledge and understanding of the benefits of hardness in mechanical design. Indeed, the Ju|’hoansi have not only recognised the benefits of using harder materials but have coupled the use of these materials to an arrowhead geometry that is well suited to the material. As mentioned in

Section 3, neither root nor bone materials are suitable for use within the iron arrowhead geometry as the stresses experienced on impact are extremely high with this geometry and will result in material failure. As such these materials are designed with a more bulbous arrowhead geometry, which significantly decreases the chances of the root or bone arrowheads failing. Since the iron is of high density, using iron in either of the bulbous arrowhead geometries chosen for the root and bone materials would result in an extremely top-heavy arrow, which might be of detriment to flight effectiveness. The weight should be sensibly distributed from tip to tail of an arrow if it is to fly without tilt [

23]. It is clear that the Ju|’hoansi have designed the arrow sizes with respect not only to their mechanical properties, but also with respect to their physical properties [

24], with denser materials being designed to be used in lower volume than less dense materials. The primary design parameter appears to be the diameter of the arrowheads, with the root having the largest diameter, followed by the bone, and finally by the iron. This ensures the mass of the arrowhead is kept similar despite the material used and its unique density.

Iron is essentially an isotropic material. It is therefore particularly interesting that when using anisotropic materials such as root and bone, the Ju|’hoansi have chosen to design the arrowhead in a way that ensures impact/penetration will make use of the stiffest and strongest material direction in each of the root and bone materials. In the root arrowheads this is the direction of the growing xylem vesicles, while in the bone arrowheads, this is in the direction of primary bone (lamellar bone) growth (c.f.

Figure 4b,c). By designing these arrowheads with impact/penetration along the strongest axis of the material at a macro-level, the Ju|’hoansi decrease the chances of microcrack propagation and failure during a hunt, and indeed, are able to increase the longevity of the arrowhead.