Numerical Study of Soil-Thawing Effect of Composite Piles Using GMsFEM

Abstract

:1. Introduction

2. Mathematical Model

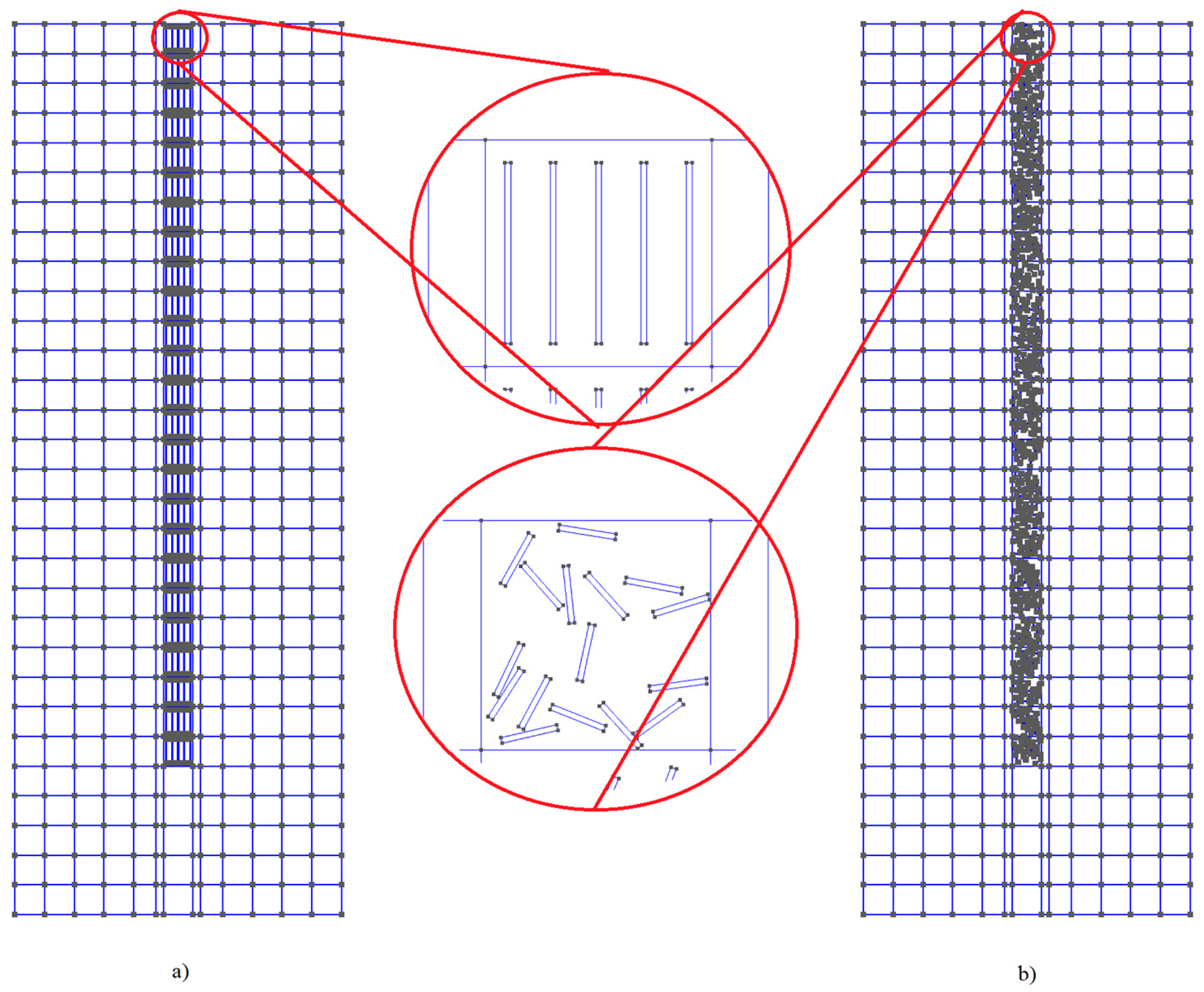

3. Fine-Scale Approximation

4. Generalized Multiscale Finite Element Method (GMsFEM)

- Coarse grid generation

- Offline space construction;

- Construction of snapshot space that will be used to compute an offline space;

- Construction of a small dimensional offline space by performing dimensional reduction in the space of local snapshots;

- Solution of a coarse-grid problem for any force term and boundary condition.

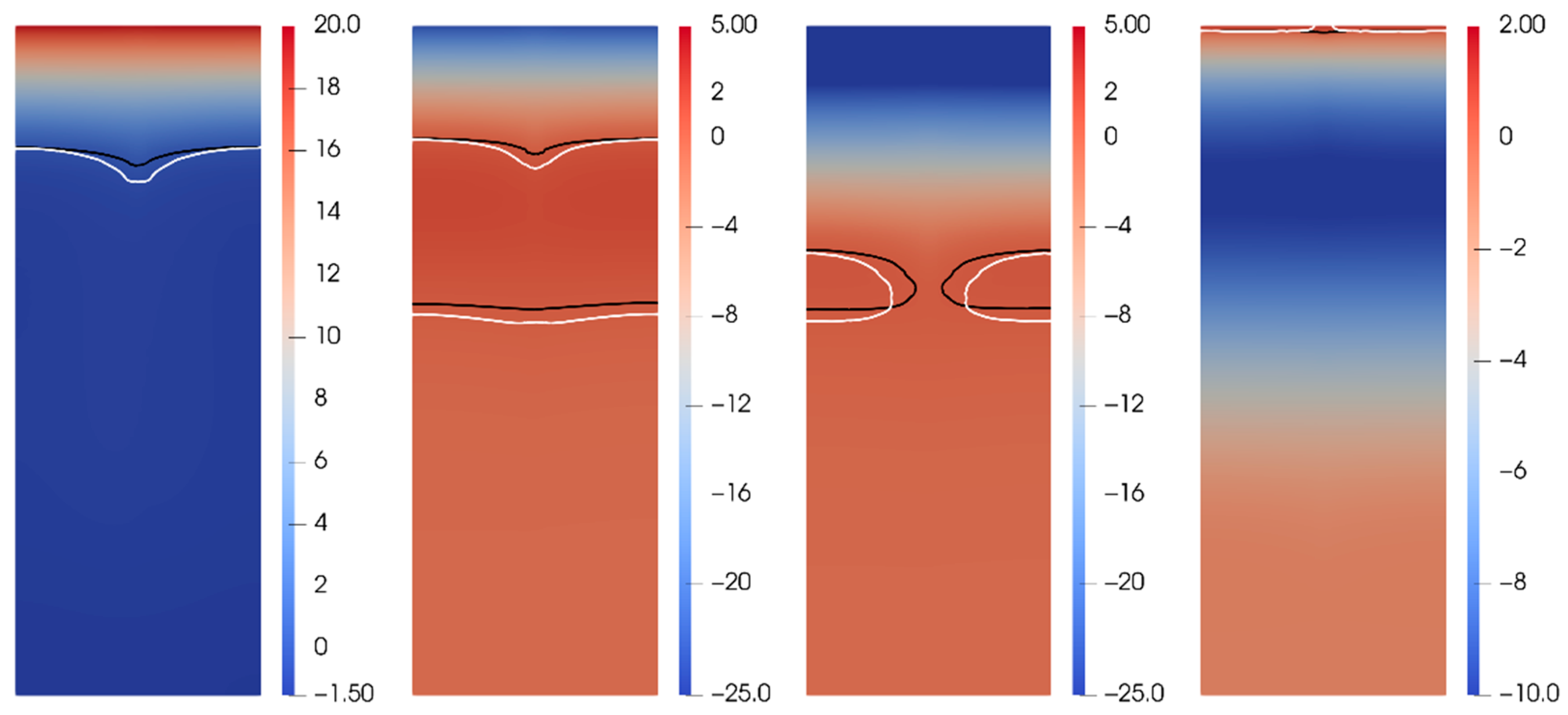

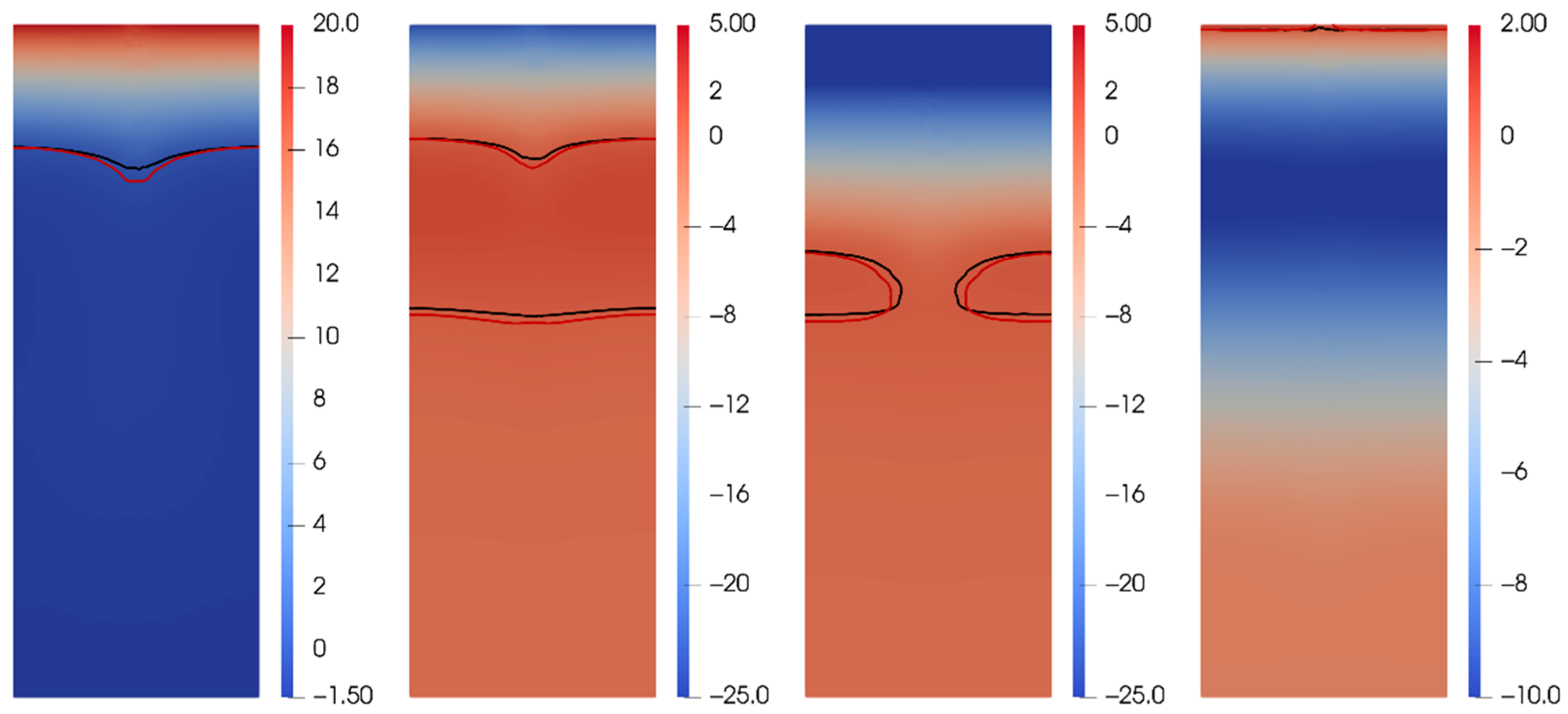

5. Numerical Results

- Cement-sand mortar for filling the sinuses between the soil and the pile with a temperature of ;

- Piles with a cross section of 40 × 40 cm, pile deepening is 10 m from the ground surface.

- Fibers from basalt arranged in a structured manner;

- Fibers made of steel arranged in a structured manner;

- Fibers from basalt located randomly;

- Fibers made of randomly located steel.

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vasiliev, V.I.; Sidnyaev, N.I.; Fedotov, A.A.; Ilyina, Y.u.S.; Vasilieva, M.V.; Stepanov, S.P. Modeling the Distribution of Non-Stationary Temperature Fields in the Permafrost Zone in the Design of Geotechnical Structures; Kurs: Moscow, Russia, 2017. [Google Scholar]

- Nagy, B.; Nehme, S.G.; Szagri, D. Thermal Properties and Modeling of Fiber Reinforced Concretes. Energy Procedia 2015, 78, 2742–2747. [Google Scholar] [CrossRef] [Green Version]

- Zhussupbekov, A.; Shin, E.C.; Shakhmov, Z.; Tleulenova, G. Experimental study of model pile foundations in seasonally freezing soil ground. Int. J. GEOMATE 2018, 15, 85–90. [Google Scholar] [CrossRef]

- Montayeva, A.; Zhussupbekov, A.; Kaliakin, V.N.; Montayev, S. IOP Conference Series: Earth and Environmental Science; Analysis on Technological Features of Pile Foundations Construction in Frozen and Seasonal Thawing Soils, No. 1; IOP Publishing: Bristol, UK, 2021; p. 012006. [Google Scholar]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- Smarzewski, P. Study of Bond Strength of Steel Bars in Basalt Fibre Reinforced High Performance Concrete. Crystals 2020, 10, 436. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part. B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Experimental Study on Bond Behavior in Fiber-Reinforced Concrete with Low Content of Recycled Steel Fiber. J. Mater. Civ. Eng. 2016, 28, 04016068. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical behavior of concretes containing waste steel fibers recovered from scrap tires. Constr. Build. Mater. 2016, 122, 649–658. [Google Scholar] [CrossRef]

- Caggiano, A.; Xargay, H.; Folino, P.; Martinelli, E. Experimental and numerical characterization of the bond behavior of steel fibers recovered from waste tires embedded in cementitious matrices. Cem. Concr. Compos. 2015, 62, 146–155. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- Samarskii, A.A.; Vabishchevich, P.N. Computational Heat Transfer; Wiley: Chichester, UK, 1995. [Google Scholar]

- Bernauer, D.I.M. Motion Planning for the Two-Phase Stefan Problem in Level Set Formulation. Ph.D. Thesis, Chemnitz University of Technology, Chemnitz, Germany, 2010. Available online: https://core.ac.uk/download/pdf/153228887.pdf (accessed on 25 June 2021).

- Vasil’ev, V.; Vasilyeva, M. An Accurate Approximation of the Two-Phase Stefan Problem with Coefficient Smoothing. Mathematics 2020, 8, 1924. [Google Scholar] [CrossRef]

- Vasilyeva, M.; Stepanov, S.; Spiridonov, D.; Vasil’Ev, V. Multiscale Finite Element Method for heat transfer problem during artificial ground freezing. J. Comput. Appl. Math. 2020, 371, 112605. [Google Scholar] [CrossRef]

- Stepanov, S.; Vasilyeva, M.; Vasil’Ev, V.I. Generalized multiscale discontinuous Galerkin method for solving the heat problem with phase change. J. Comput. Appl. Math. 2018, 340, 645–652. [Google Scholar] [CrossRef]

- Efendiev, Y.; Galvis, J.; Hou, T.Y. Generalized multiscale finite element methods (GMsFEM). J. Comput. Phys. 2013, 251, 116–135. [Google Scholar] [CrossRef] [Green Version]

- Efendiev, Y.; Hou, T.Y. Multiscale Finite Element Methods: Theory and Applications; Springer Science & Business Media: Berlin, Germany, 2009; Volume 4. [Google Scholar]

- Efendiev, Y.; Ginting, V.; Hou, T.Y. Multiscale Finite Element Methods for Nonlinear Problems and Their Applications. Commun. Math. Sci. 2004, 2, 553–589. [Google Scholar] [CrossRef] [Green Version]

- Xing, Y.F.; Yang, Y.; Wang, X.M. A multiscale eigenelement method and its application to periodical composite structures. Compos. Struct. 2010, 92, 2265–2275. [Google Scholar] [CrossRef]

- Hou, T.Y.; Wu, X.H. A multiscale finite element method for elliptic problems in composite materials and porous media. J. Comput. Phys. 1997, 134, 169–189. [Google Scholar] [CrossRef] [Green Version]

- Alghamdi, A.; Alharthi, H.; Alamoudi, A.; Alharthi, A.; Kensara, A.; Taylor, S. Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon–Carbon Composite. Materials 2019, 12, 3750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tomkova, B.; Sejnoha, M.; Novak, J.; Zeman, J. Evaluation of effective thermal conductivities of porous textile composites. Int. J. Multiscale Comput. Eng. 2008, 6, 153–167. [Google Scholar] [CrossRef]

- Ai, S.; Fu, H.; He, R.; Pei, Y. Multi-scale modeling of thermal expansion coefficients of C/C composites at high temperature. Mater. Des. 2015, 82, 181–188. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, L.; Li, J.; Jiao, Y. Multi-scale finite element analyses of thermal conductivities of three dimensional woven composites. Appl. Compos. Mater. 2017, 24, 1525–1542. [Google Scholar] [CrossRef]

| Fiber Type | Steel | Basalt |

|---|---|---|

| Density (kg/m3) | 7800 | 2700 |

| Volume content (kg/m3) | 780 | 270 |

| Elastic modulus (GPa) | 200 | 70 |

| Tensile strength (MPa) | >1060 | >1700 |

| Elements | Volumetric Heat Capacity (J/m3/K) | Thermal Conductivity (W/m/K) | Phase Transition Heat (J/m3) | ||

|---|---|---|---|---|---|

| Thawed | Frozen | Thawed | Frozen | ||

| Clay loam | 3.17 | 2.41 | 2.67 | 2.84 | 101,600 |

| Sand | 2.31 | 2.14 | 2.15 | 2.37 | 114,800 |

| Sand | 2.78 | 2.26 | 2.26 | 2.62 | 101,600 |

| Concrete | 2.22 | 1.86 | - | ||

| Basalt fiber | 1.4 | 0.033 | - | ||

| Steel fiber | 368.8 | 53 | - | ||

| M | DOF | ||

|---|---|---|---|

| t = 50 days | |||

| 2 | 744 | 0.86 | 7.48 |

| 4 | 1488 | 0.38 | 6.04 |

| 8 | 2976 | 0.15 | 3.21 |

| t = 200 days | |||

| 2 | 744 | 0.79 | 8.28 |

| 4 | 1488 | 0.39 | 6.63 |

| 8 | 2976 | 0.12 | 3.32 |

| t = 250 days | |||

| 2 | 744 | 0.27 | 5.64 |

| 4 | 1488 | 0.17 | 4.93 |

| 8 | 2976 | 0.05 | 2.84 |

| t = 365 days | |||

| 2 | 744 | 0.58 | 12.55 |

| 4 | 1488 | 0.28 | 10.35 |

| 8 | 2976 | 0.11 | 4.91 |

| M | DOF | ||

|---|---|---|---|

| t = 50 days | |||

| 2 | 744 | 2.86 | 22.43 |

| 4 | 1488 | 0.92 | 9.97 |

| 8 | 2976 | 0.47 | 7.28 |

| t = 200 days | |||

| 2 | 744 | 2.89 | 20.76 |

| 4 | 1488 | 0.86 | 9.41 |

| 8 | 2976 | 0.40 | 6.64 |

| t = 250 days | |||

| 2 | 744 | 2.16 | 21.31 |

| 4 | 1488 | 0.45 | 7.04 |

| 8 | 2976 | 0.21 | 5.34 |

| t = 365 days | |||

| 2 | 744 | 2.95 | 23.65 |

| 4 | 1488 | 0.42 | 13.82 |

| 8 | 2976 | 0.20 | 8.77 |

| M | DOF | ||

|---|---|---|---|

| t = 50 days | |||

| 2 | 744 | 1.56 | 39.13 |

| 4 | 1488 | 0.57 | 12.36 |

| 8 | 2976 | 0.30 | 10.05 |

| t = 200 days | |||

| 2 | 744 | 1.66 | 39.74 |

| 4 | 1488 | 0.59 | 12.71 |

| 8 | 2976 | 0.31 | 10.27 |

| t = 250 days | |||

| 2 | 744 | 1.06 | 37.96 |

| 4 | 1488 | 0.32 | 10.65 |

| 8 | 2976 | 0.17 | 8.79 |

| t = 365 days | |||

| 2 | 744 | 1.07 | 42.13 |

| 4 | 1488 | 0.35 | 16.69 |

| 8 | 2976 | 0.17 | 12.96 |

| M | DOF | ||

|---|---|---|---|

| t = 50 days | |||

| 2 | 744 | 2.40 | 14.64 |

| 4 | 1488 | 0.81 | 9.62 |

| 8 | 2976 | 0.37 | 6.13 |

| t = 200 days | |||

| 2 | 744 | 2.38 | 14.28 |

| 4 | 1488 | 0.80 | 9.49 |

| 8 | 2976 | 0.35 | 5.89 |

| t = 250 days | |||

| 2 | 744 | 1.30 | 11.41 |

| 4 | 1488 | 0.48 | 8.40 |

| 8 | 2976 | 0.18 | 4.78 |

| t = 365 days | |||

| 2 | 744 | 1.09 | 18.42 |

| 4 | 1488 | 0.49 | 13.36 |

| 8 | 2976 | 0.18 | 7.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivtsev, P.V.; Smarzewski, P.; Stepanov, S.P. Numerical Study of Soil-Thawing Effect of Composite Piles Using GMsFEM. J. Compos. Sci. 2021, 5, 167. https://doi.org/10.3390/jcs5070167

Sivtsev PV, Smarzewski P, Stepanov SP. Numerical Study of Soil-Thawing Effect of Composite Piles Using GMsFEM. Journal of Composites Science. 2021; 5(7):167. https://doi.org/10.3390/jcs5070167

Chicago/Turabian StyleSivtsev, Petr V., Piotr Smarzewski, and Sergey P. Stepanov. 2021. "Numerical Study of Soil-Thawing Effect of Composite Piles Using GMsFEM" Journal of Composites Science 5, no. 7: 167. https://doi.org/10.3390/jcs5070167

APA StyleSivtsev, P. V., Smarzewski, P., & Stepanov, S. P. (2021). Numerical Study of Soil-Thawing Effect of Composite Piles Using GMsFEM. Journal of Composites Science, 5(7), 167. https://doi.org/10.3390/jcs5070167