Damage Analysis of Thermoplastic Composites with Embedded Metal Inserts Using In Situ Computed Tomography

Abstract

:1. Introduction

2. Materials and Methods

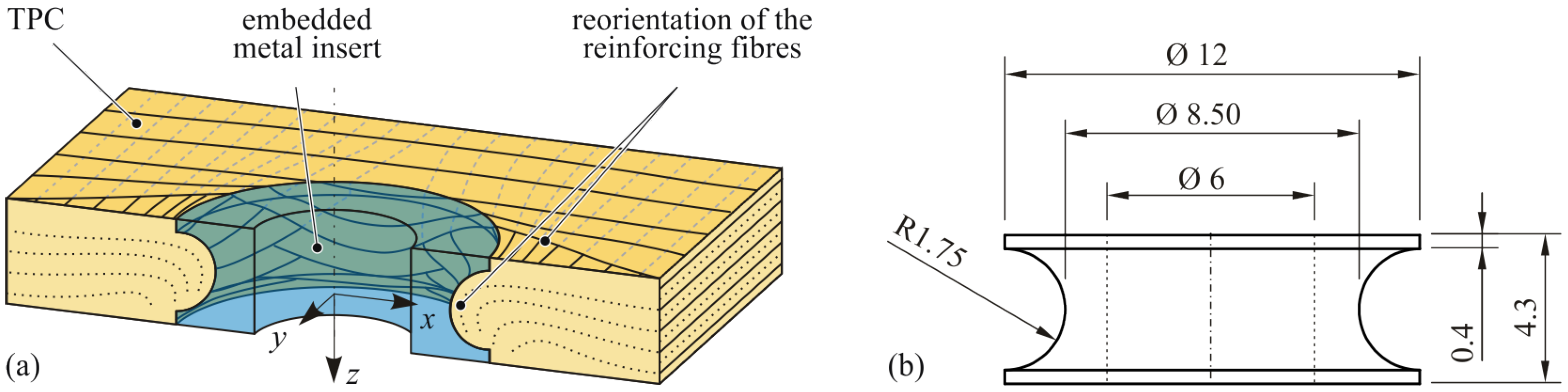

2.1. Material Specification

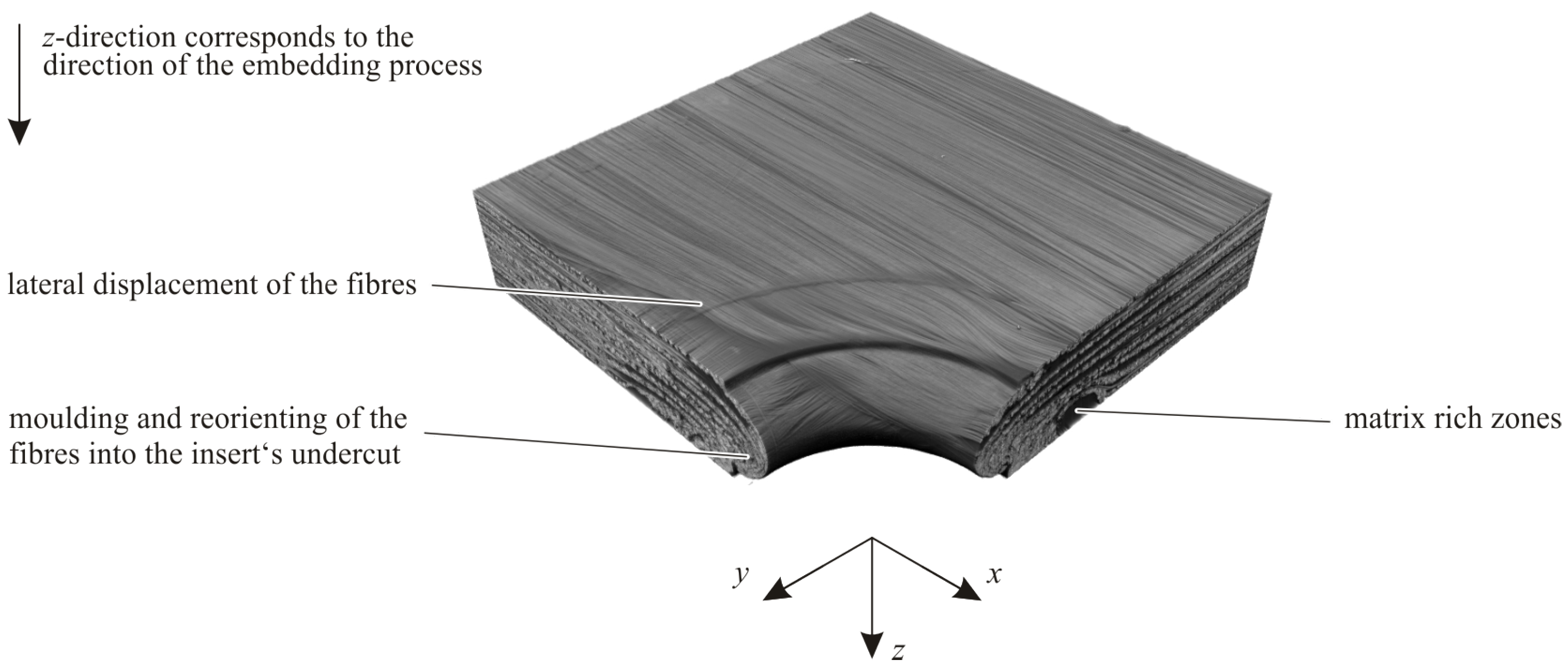

2.2. Specimen Preparation

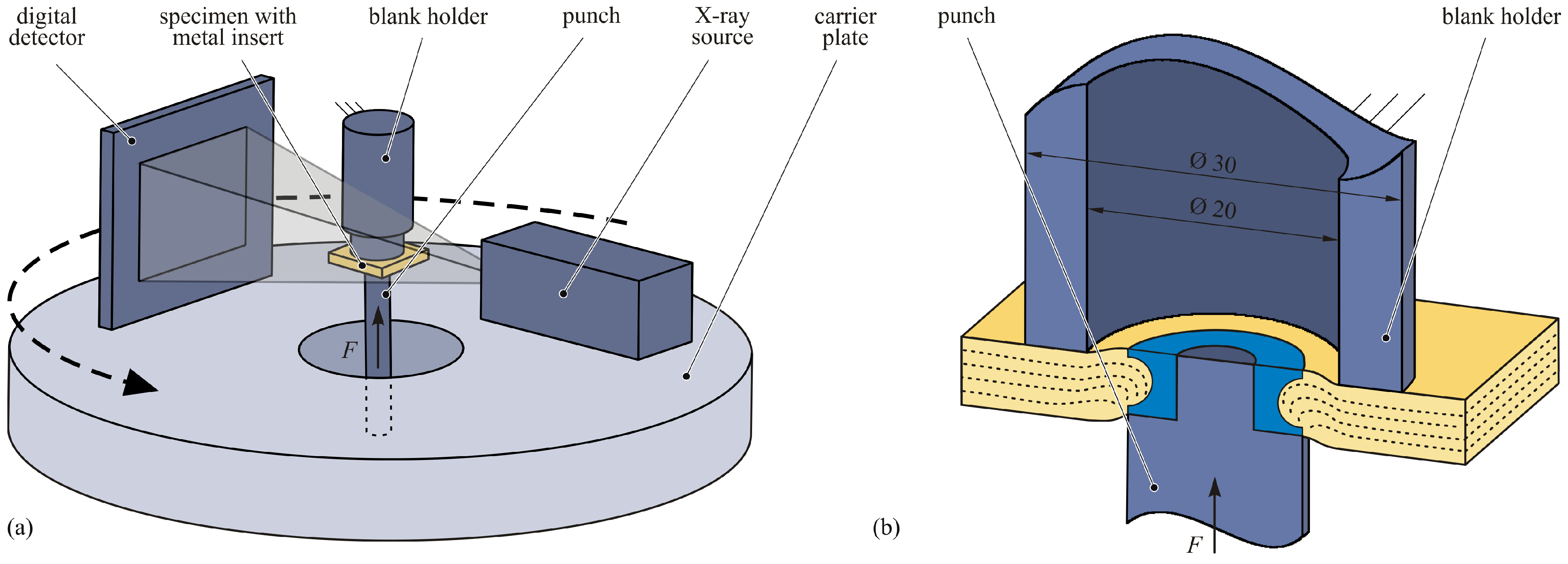

2.3. Test Setup and Procedure

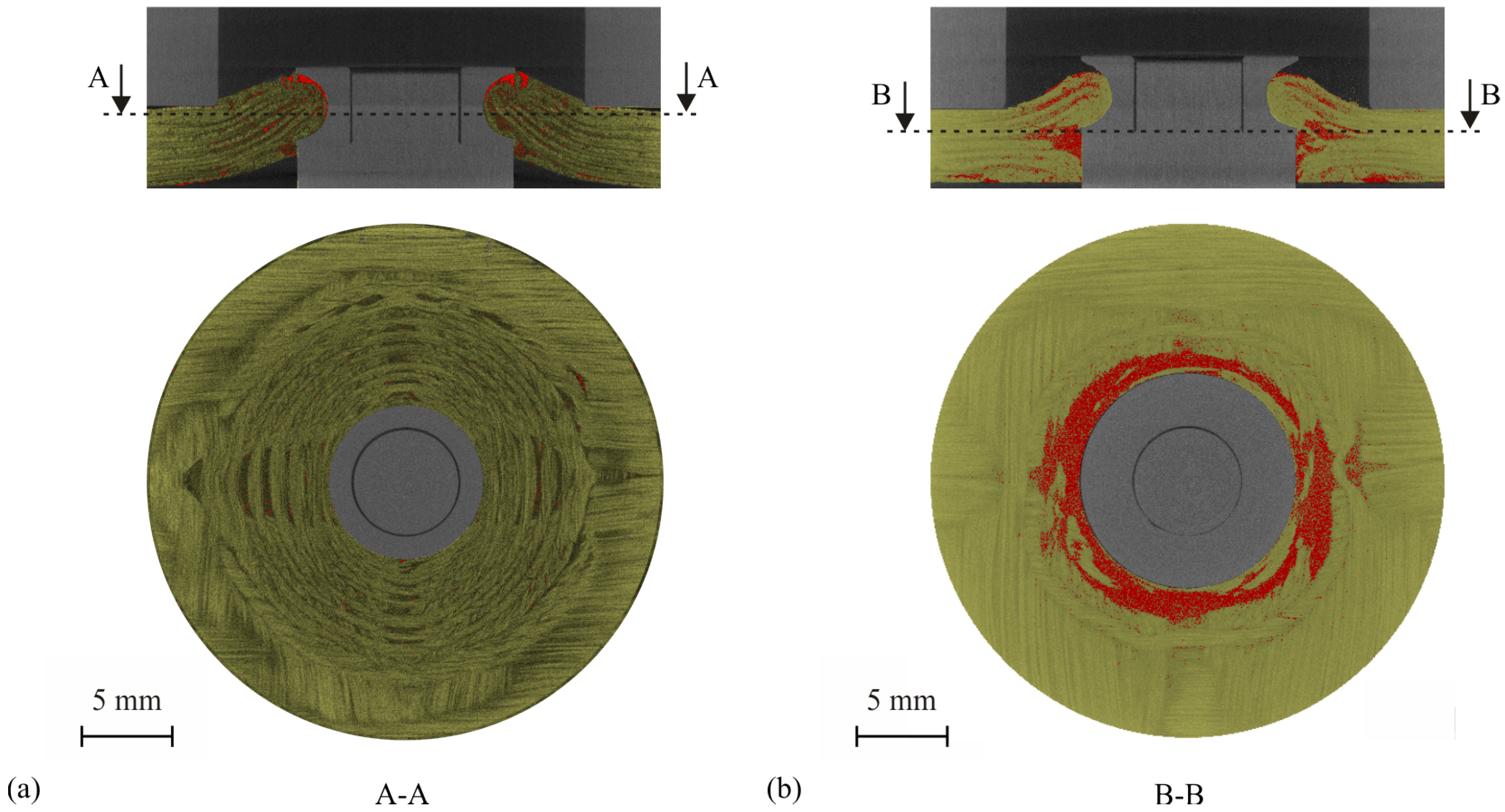

3. Results and Discussion

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| CT | Computed tomography |

| GF | Glass fibre |

| PP | Polypropylene |

| TPCs | Thermoplastic composites |

| UD | Unidirectional |

| V-DIC | Volumetric digital image correlation |

References

- Behrens, B.-A.; Raatz, A.; Hübner, S.; Bonk, C.; Bohne, F.; Bruns, C.; Micke-Camuz, M. Automated Stamp Forming of Continuous Fiber Reinforced Thermoplastics for Complex Shell Geometries. Procedia CIRP 2017, 66, 113–118. [Google Scholar] [CrossRef]

- Herwig, A.; Horst, P.; Schmidt, C.; Pottmeyer, F.; Weidenmann, K.A. Design and mechanical characterisation of a layer wise build AFP insert in comparison to a conventional solution. Prod. Eng. 2018, 12, 121–130. [Google Scholar] [CrossRef]

- Mara, V.; Haghani, R.; Al-Emrani, M. Improving the performance of bolted joints in composite structures using metal inserts. J. Compos. Mater. 2016, 50, 3001–3018. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Cloud, G.L. Strain-Relief Inserts for Composite Fasteners—An Experimental Study. J. Compos. Mater. 1992, 26, 751–768. [Google Scholar] [CrossRef]

- Rispler, A.R.; Steven, G.P.; Tong, L. Photoelastic evaluation of metallic inserts of optimised shape. Compos. Sci. Technol. 2000, 60, 95–106. [Google Scholar] [CrossRef]

- Camanho, P.P.; Matthews, F.L. Bonded metallic inserts for bolted joints in composite laminates. Proc. Instn. Mech. Engrs. Part L 2000, 214, 33–44. [Google Scholar] [CrossRef]

- Camanho, P.P.; Tavares, C.; de Oliveira, R.; Marques, A.; Ferreira, A. Increasing the efficiency of composite single-shear lap joints using bonded inserts. Compos. Part B 2005, 36, 372–383. [Google Scholar] [CrossRef]

- Wilkening, J.; Pottmeyer, F.; Weidenmann, K.A. Research on the interfering effect of metal inserts in carbon fiber reinforced plastics manufactured by the RTM process. In Proceedings of the 17th European Conference on Composite Materials (ECCM17), Munich, Germany, 26–30 June 2016. [Google Scholar]

- Ferret, B.; Anduze, M.; Nardari, C. Metal insters in structural composite materials manufactured by RTM. Compos. Part A 1998, 29, 693–700. [Google Scholar] [CrossRef]

- Gebhardt, J.; Fleischer, J. Experimental investigation and performance enhancement of inserts in composite parts. Procedia CIRP 2014, 23, 7–12. [Google Scholar] [CrossRef]

- Hufenbach, W.; Adam, F.; Kupfer, R. A novel textile-adapted notching technology for bolted joints in textile-reinforced thermoplastic composites. In Proceedings of the 14th European Conference on Composite Materials (ECCM14), Budapest, Hungary, 6–7 June 2010. Paper ID 461. [Google Scholar]

- Hufenbach, W.; Gottwald, R.; Kupfer, R. Bolted Joints with Moulded Holes for Textile Thermoplastic Composites. In Proceedings of the 18th International Conference on Composite Materials, Jeju, Korea, 21–26 August 2011. [Google Scholar]

- Troschitz, J.; Gröger, B.; Würfel, V.; Kupfer, R.; Gude, M. Joining Processes for Fibre-Reinforced Thermoplastics: Phenomena and Characterisation. Materials 2022, 15, 5454. [Google Scholar] [CrossRef] [PubMed]

- Troschitz, J.; Kupfer, R.; Gude, M. Experimental investigation of the load bearing capacity of inserts embedded in thermoplastic composites. In Proceedings of the 4th International Conference Hybrid 2020—Materials & Structures, Online, 28–29 April 2020; pp. 249–254. [Google Scholar]

- Troschitz, J.; Kupfer, R.; Gude, M. Process-integrated embedding of metal inserts in continuous fibre reinforced thermoplastics. Procedia CIRP 2019, 85, 84–89. [Google Scholar] [CrossRef]

- Köhler, D.; Kupfer, R.; Troschitz, J.; Gude, M. In Situ Computed Tomography—Analysis of a Single-Lap Shear Test with Clinch Points. Materials 2021, 14, 1859. [Google Scholar] [CrossRef] [PubMed]

- Füßel, R.; Gude, M.; Mertel, A. In-situ X-ray computed tomography analysis of adhesively bonded riveted lap joints. In Proceedings of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Pottmeyer, F.; Bittner, J.; Pinter, P.; Weidenmann, K.A. In-Situ CT Damage Analysis of Metal Inserts Embedded in Carbon Fiber-Reinforced Plastics. Exp. Mech. 2017, 57, 1411–1422. [Google Scholar] [CrossRef]

- Croom, B.P.; Burden, D.; Jin, H.; Vonk, N.H.; Hoefnagels, J.P.; Smaniotto, B.; Hild, F.; Quintana, E.; Sun, Q.; Nie, X.; et al. Interlaboratory Study of Digital Volume Correlation Error Due to X-Ray Computed Tomography Equipment and Scan Parameters: An Update from the DVC Challenge. Exp. Mech. 2021, 61, 395–410. [Google Scholar] [CrossRef]

- Croom, B.; Wang, W.-M.; Li, J.; Li, X. Unveiling 3D Deformations in Polymer Composites by Coupled Micro X-Ray Computed Tomography and Volumetric Digital Image Correlation. Exp. Mech. 2016, 56, 999–1016. [Google Scholar] [CrossRef]

- Croom, B.P.; Jin, H.; Noell, P.J.; Boyce, B.L.; Li, X. Collaborative ductile rupture mechanisms of high-purity copper identified by in situ X-ray computed tomography. Acta Mater. 2021, 181, 377–384. [Google Scholar] [CrossRef]

| Process Parameter | Unit | Value |

|---|---|---|

| Heating temperature TPC | °C | 210 |

| Mould temperature | °C | 40 |

| Moulding pressure | bar | 8 |

| Pressing area | ||

| Max. feed force of the pin tool | kN | 3 |

| Feed rate of the pin tool | 230 | |

| Max. feed force of the counterpunch | kN | 6 |

| Feed rate of the counterpunch | 160 |

| Parameter | Unit | Value |

|---|---|---|

| X-ray voltage | 80 | |

| Tube current | μA | 250 |

| Exposure time | 2000 | |

| X-ray projections | - | 2880 (8 per 1°) |

| Source-object-distance | 68 | |

| Source-image-distance | 439 | |

| Voxel size | μm | |

| Filter | - | mm copper |

| Parameter | Unit | Value |

|---|---|---|

| X-ray voltage | 150 | |

| Tube current | μA | 250 |

| Exposure time | 500 | |

| X-ray projections | - | 1440 (4 per 1°) |

| Source-object distance | ||

| Source-image distance | ||

| Voxel size | μm | |

| Filter | - | mm copper |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Troschitz, J.; Füßel, R.; Kupfer, R.; Gude, M. Damage Analysis of Thermoplastic Composites with Embedded Metal Inserts Using In Situ Computed Tomography. J. Compos. Sci. 2022, 6, 287. https://doi.org/10.3390/jcs6100287

Troschitz J, Füßel R, Kupfer R, Gude M. Damage Analysis of Thermoplastic Composites with Embedded Metal Inserts Using In Situ Computed Tomography. Journal of Composites Science. 2022; 6(10):287. https://doi.org/10.3390/jcs6100287

Chicago/Turabian StyleTroschitz, Juliane, René Füßel, Robert Kupfer, and Maik Gude. 2022. "Damage Analysis of Thermoplastic Composites with Embedded Metal Inserts Using In Situ Computed Tomography" Journal of Composites Science 6, no. 10: 287. https://doi.org/10.3390/jcs6100287

APA StyleTroschitz, J., Füßel, R., Kupfer, R., & Gude, M. (2022). Damage Analysis of Thermoplastic Composites with Embedded Metal Inserts Using In Situ Computed Tomography. Journal of Composites Science, 6(10), 287. https://doi.org/10.3390/jcs6100287