Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications

Abstract

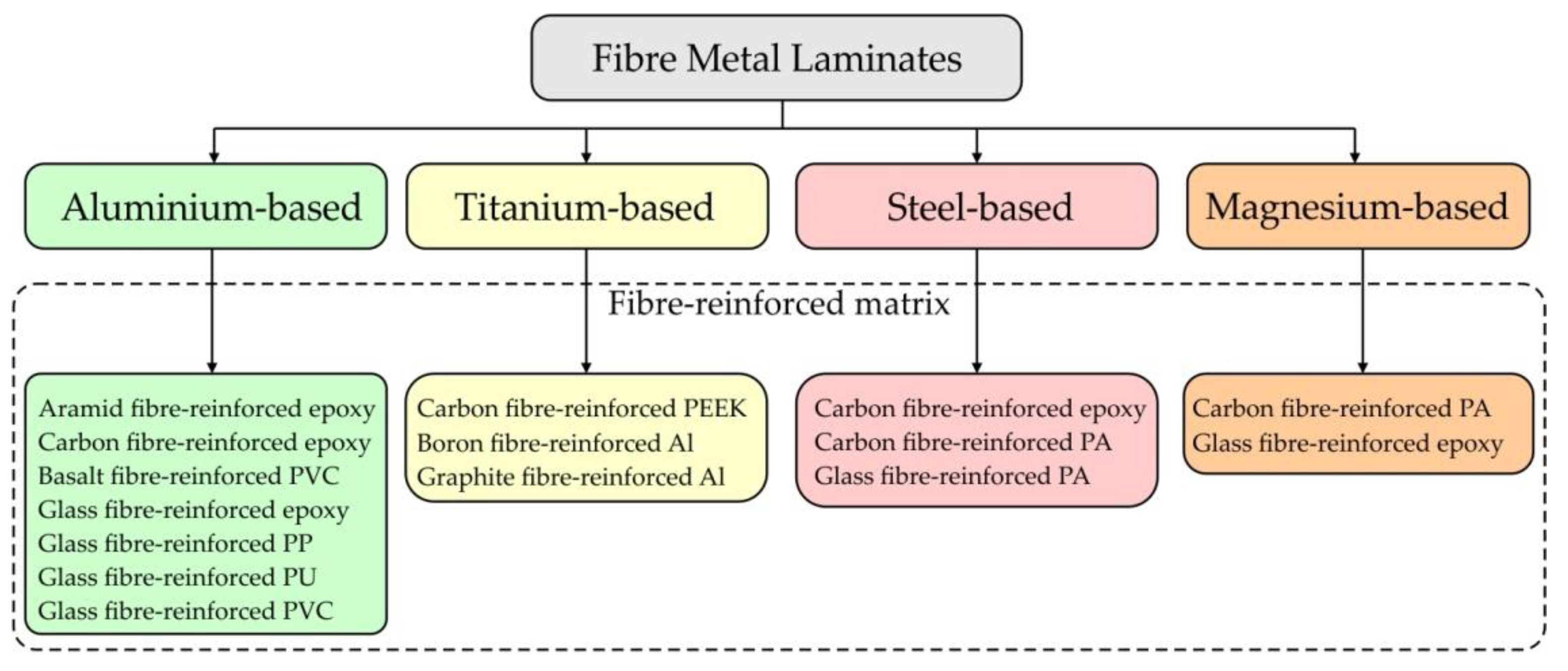

:1. Introduction

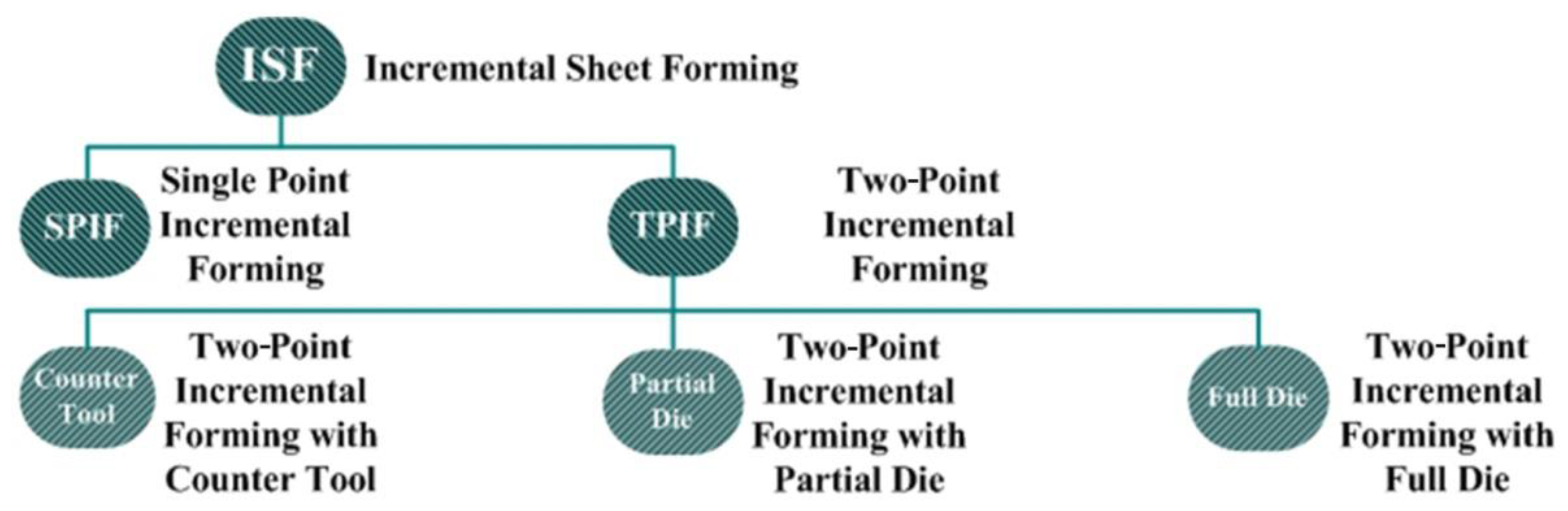

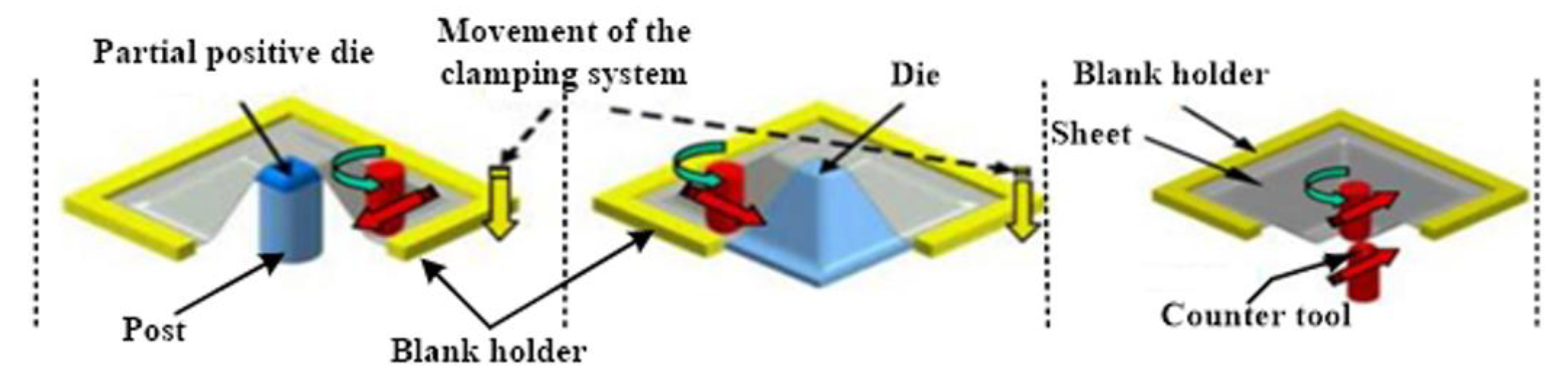

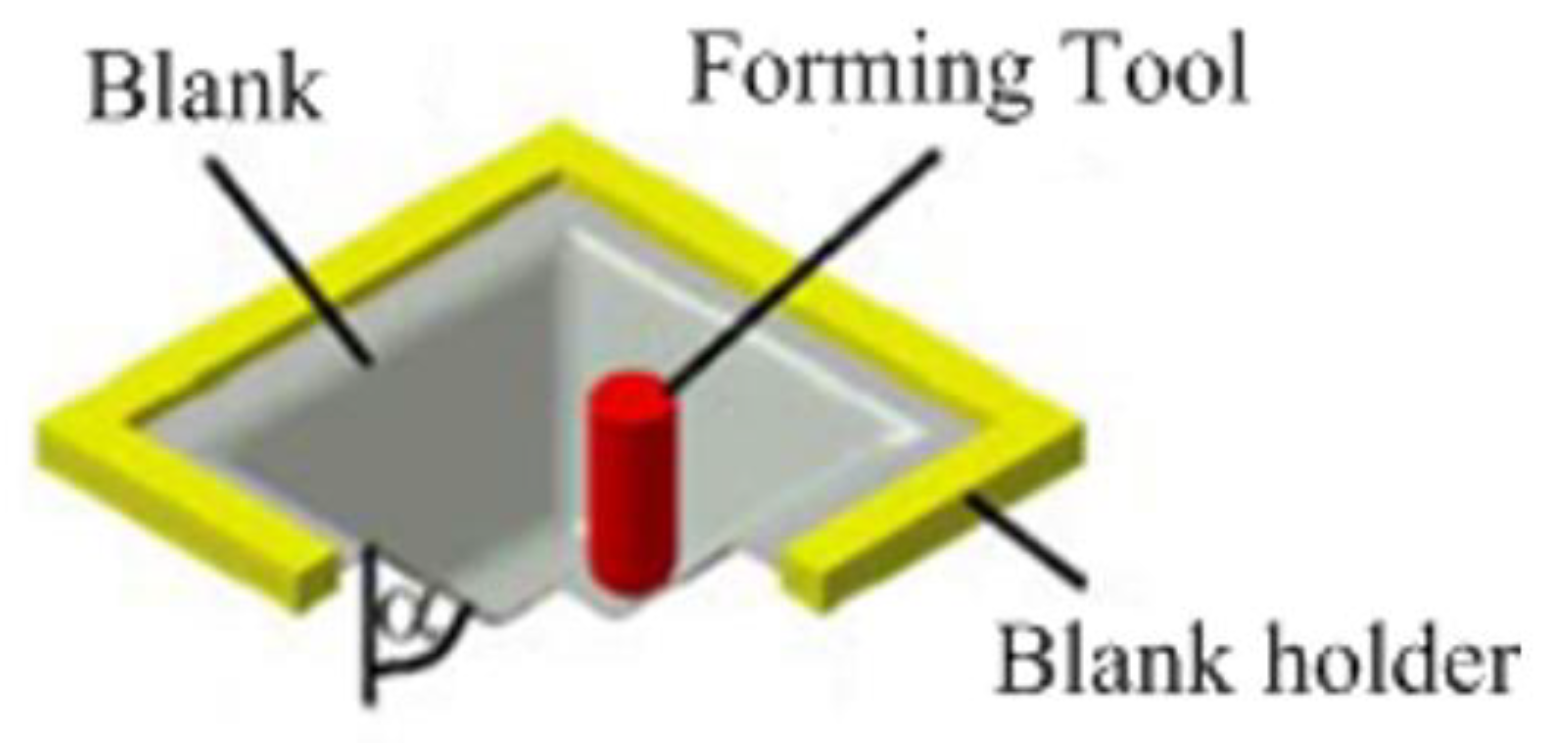

2. Incremental Sheet Forming Methods

- -

- Two-Point Incremental Forming (TPIF);

- -

- Single Point Incremental Forming (SPIF).

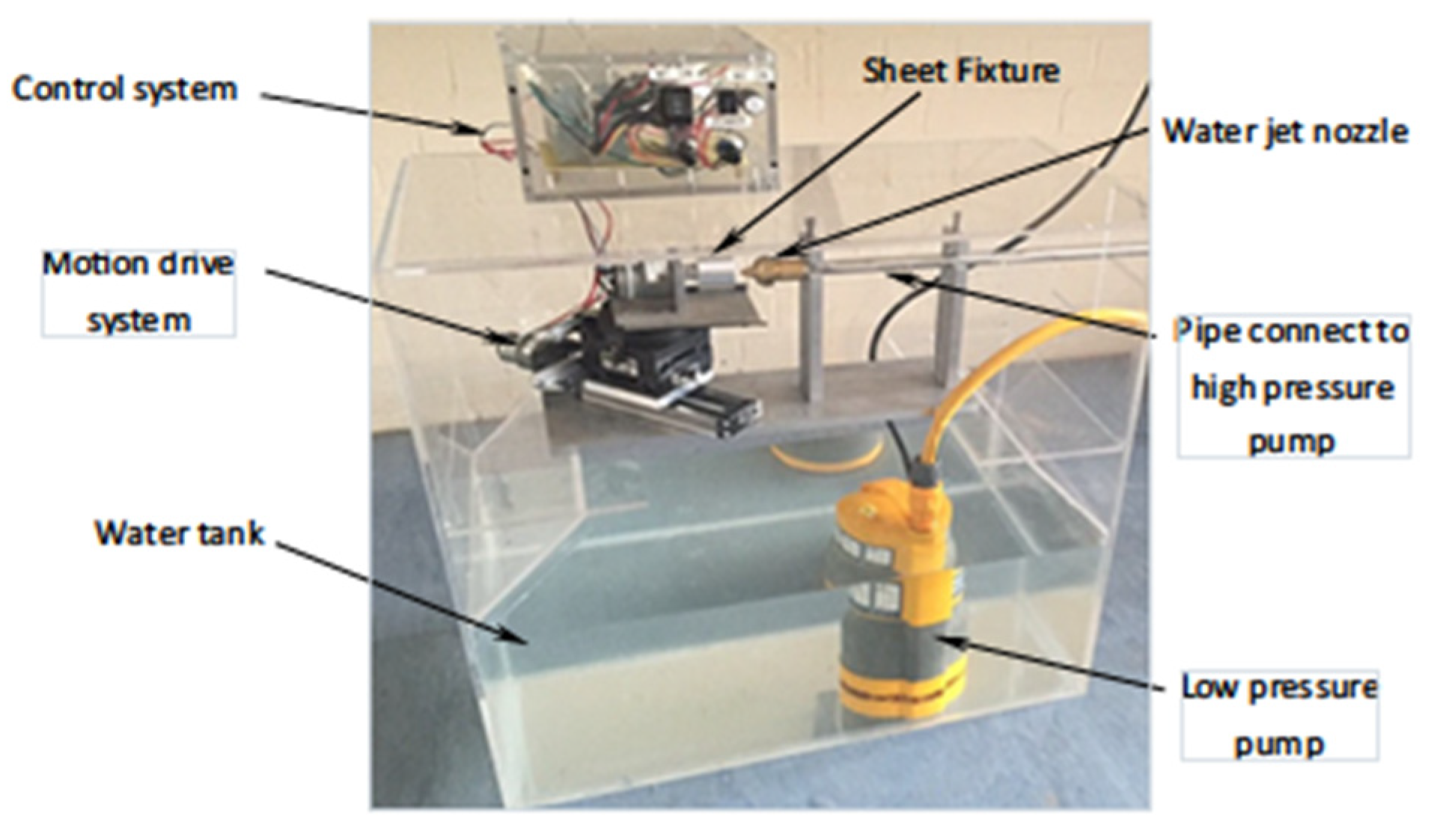

2.1. Water Jet Incremental Forming (WJIF)

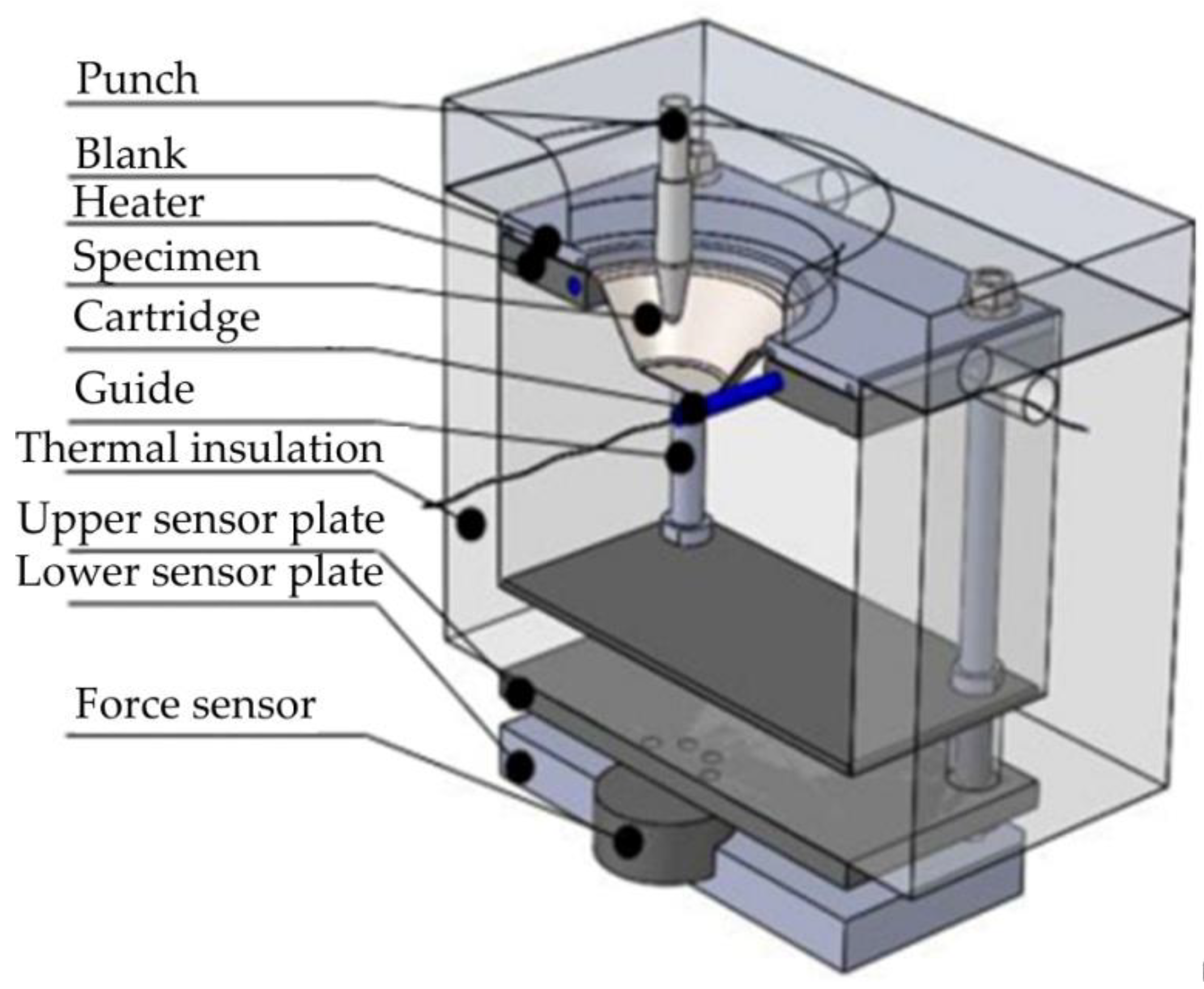

2.2. Hot Incremental Forming

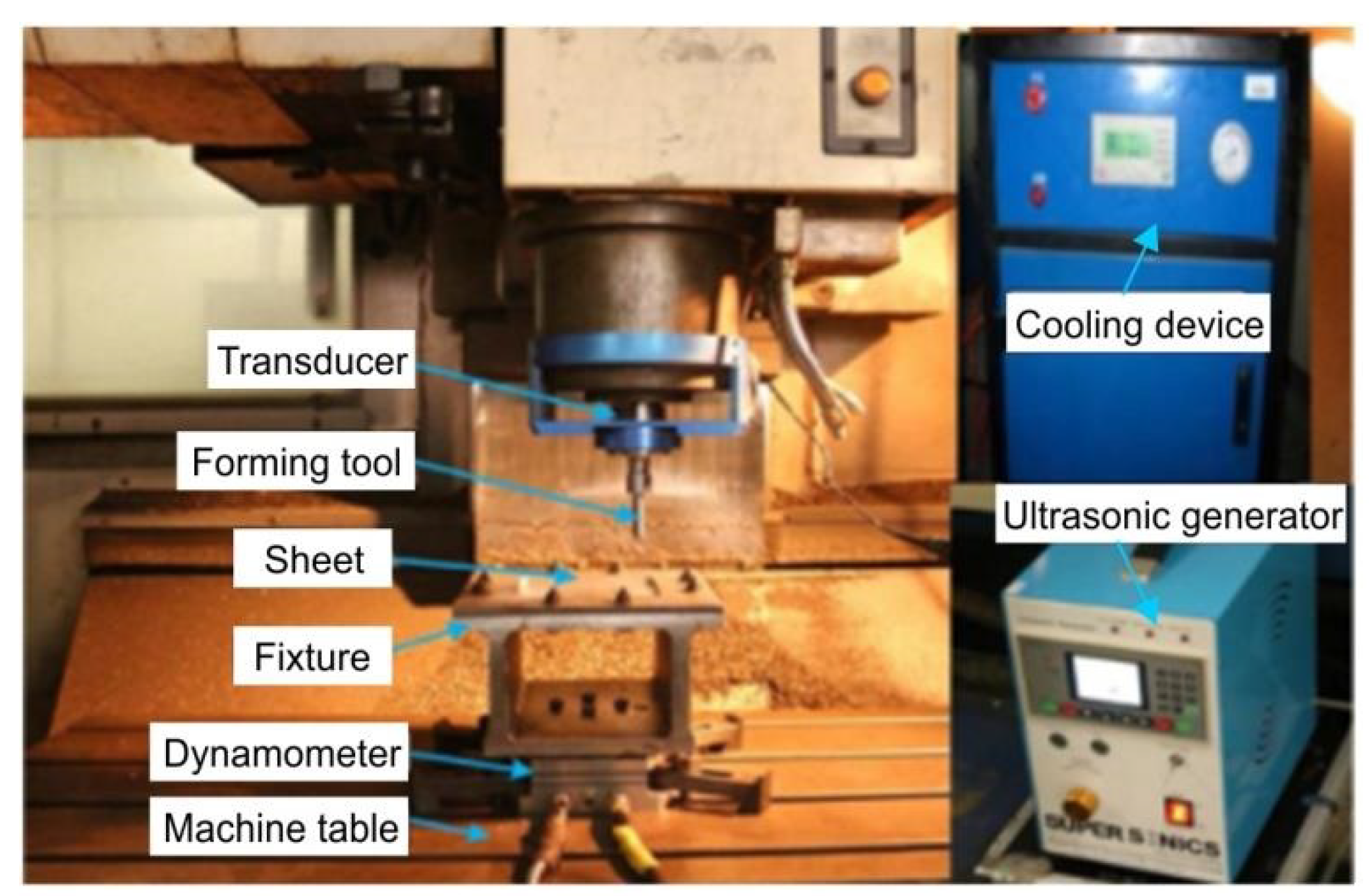

2.3. Ultrasonic Assisted Incremental Sheet Forming

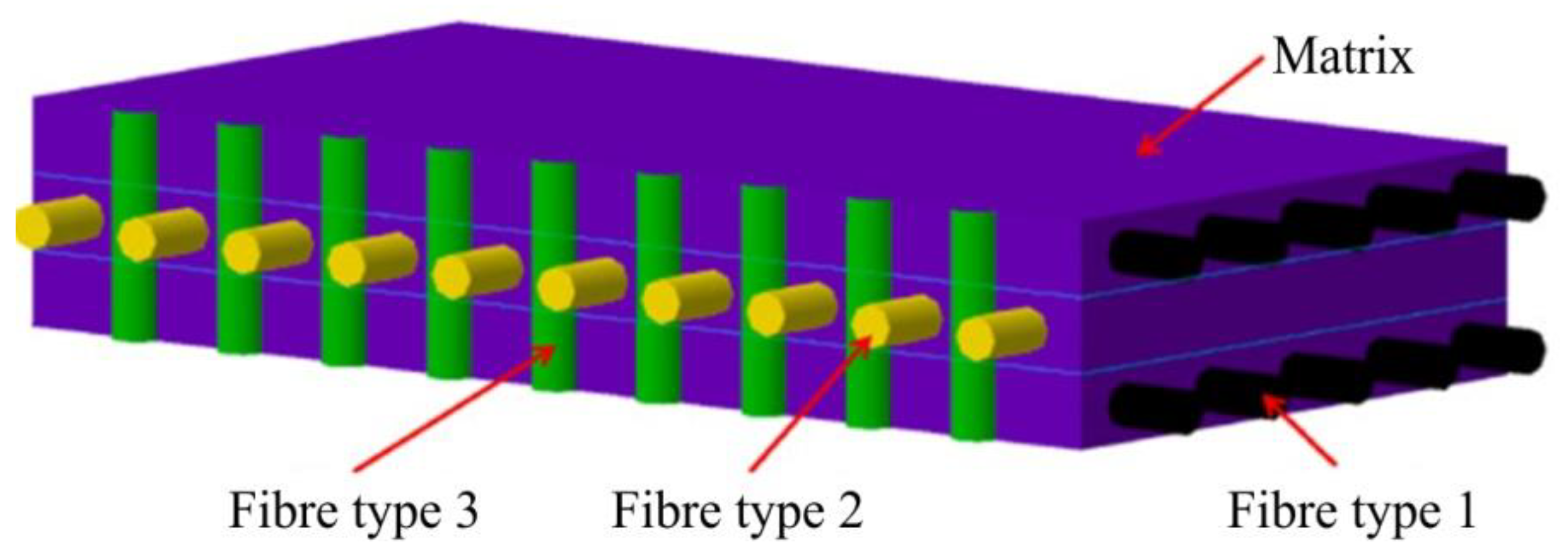

3. Achievements in SPIF of Metal-Based Composites

3.1. Glass-Reinforced Aluminium Laminates

3.2. Carbon-Reinforced Aluminium Laminates

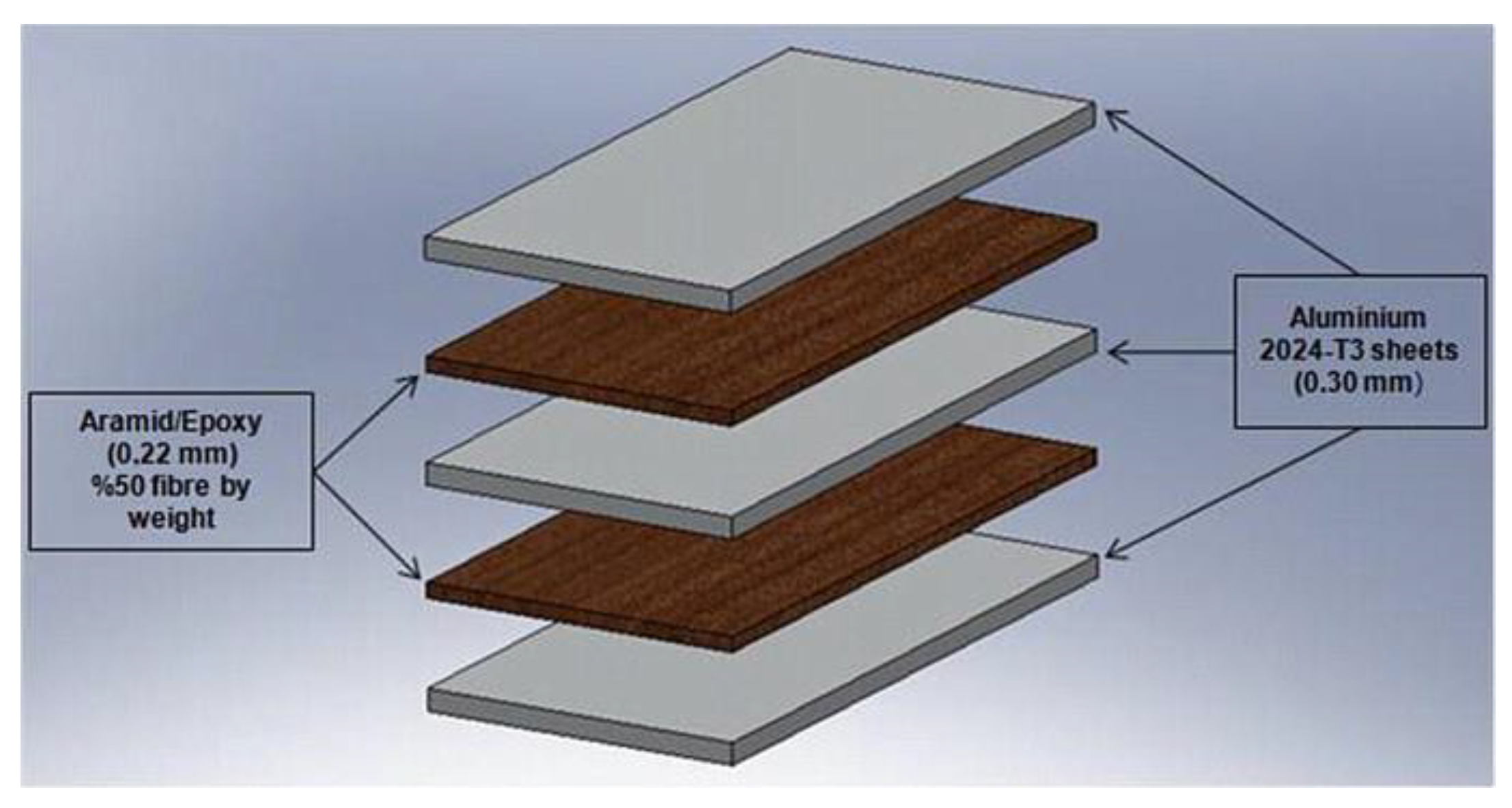

3.3. Aramid-Reinforced Aluminium Laminates

3.4. Aluminium-Based Bimetallic Sheets

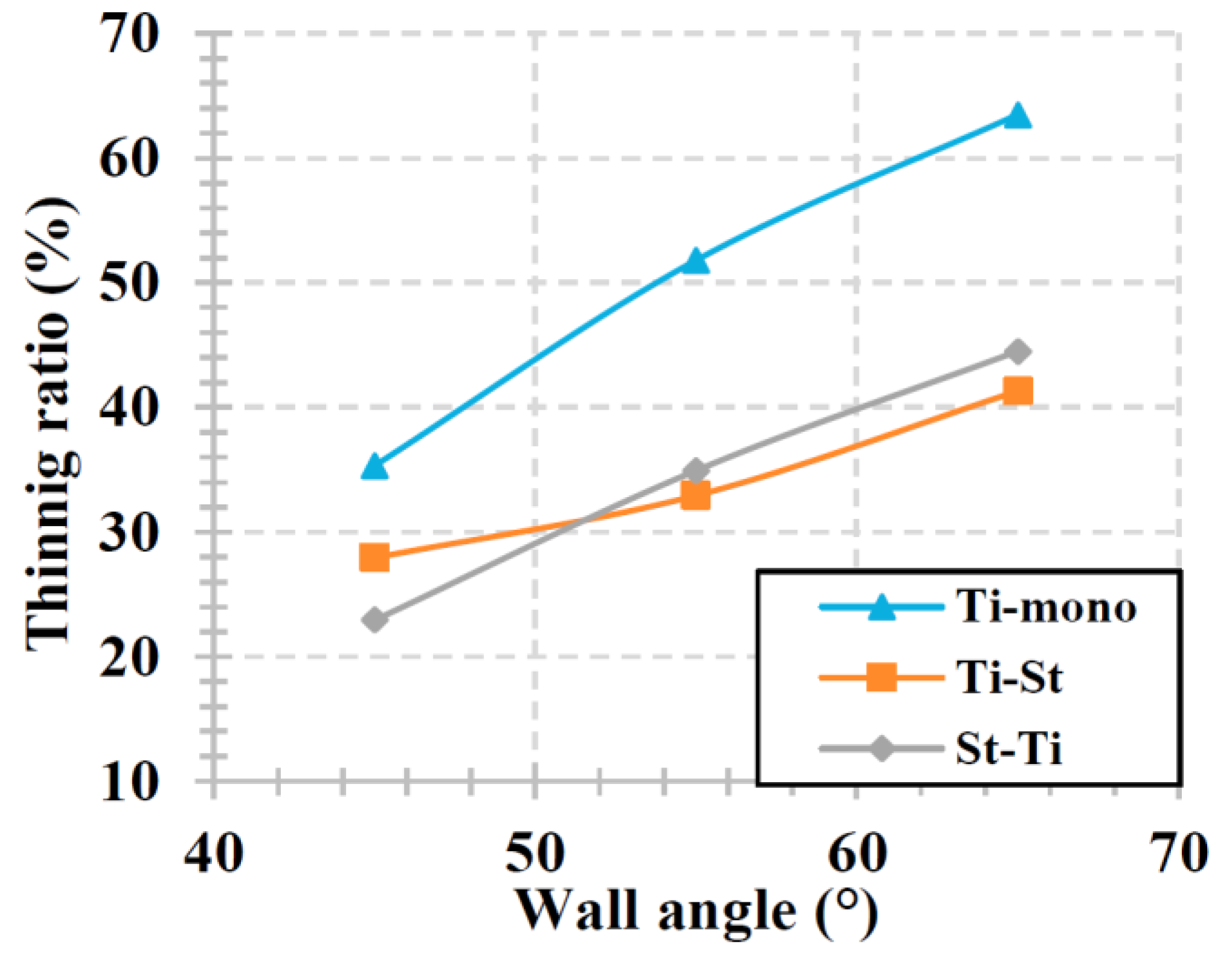

3.5. Titanium-Based Bimetallic Sheets

4. Conclusions

- The main problem to be solved when forming composite materials is the accumulation of resin in the bottom of the drawpiece. The cyclic circumferential movement of the tool causes non-uniform distribution of the resin in the walls of the component;

- Single point incremental forming allows an increase in the strength and improvement in the specific stiffness of FML components;

- The composite core of FMLs prevents local load transfer to the bottom plate—this is the main cause of wrinkling;

- One limitation in the use of ISF is the relatively long processing time. It is suggested that multiple forming tools could be used to work simultaneously on the same components. This effect can be achieved by using multi-tool heads or robots;

- Many authors draw attention to the shortcomings of predictive models for incremental forming processes. It turns out that due to many phenomena and forming parameters simultaneously affecting the formability and accuracy of SPIF-ed components, the predictive models developed for various materials are too general;

- Single point incremental forming of ARALLs is of limited application due to the low strength of the fibre-matrix interface;

- The behaviour of the composite sheet during the ISF process differs from monolayer sheets and depends on the arrangement of the layers. The positioning of layers plays an important role in grain size and twinning density. Friction conditions between the surface of the forming tool and the bimetallic sheet affect the surface quality, the forming force variations, and the formability of the sheet metal;

- Improvement of the formability of bimetallic sheets can be obtained by using the ultrasonic vibration tool, which additionally allows the user to reduce the value of the coefficient of friction by up to several dozen percent depending on the process conditions. During SPIF with and without vibration, the forming force decreases due to the application of ultrasonic vibration to the tool.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kadhum, A.M.; Faris, S.T.; Al-Katawy, A.A. Development and properties of fiber metal laminate used in aircraft wing by using epoxy-novolac. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 032034. [Google Scholar] [CrossRef]

- Mukesh, A.M.; Hynes, N.R.J. Mechanical properties and applications of fibre metal laminates. AIP Conf. Proc. 2019, 2142, 100002. [Google Scholar] [CrossRef]

- Tiwary, A.; Kumar, R.; Chohan, J.S. A review on characteristics of composite and advanced materials used for aerospace applications. Mater. Today Proce. 2022, 51, 865–870. [Google Scholar] [CrossRef]

- Liu, X.; Tian, S.; Tao, F.; Yu, W. A review of artificial neural networks in the constitutive modeling of composite materials. Compos. Part B Eng. 2021, 224, 109152. [Google Scholar] [CrossRef]

- Żaba, K.; Nowosielski, M.; Kita, P.; Kwiatkowski, M.; Tokarski, T.; Puchlerska, S. Effect of heat treatment on the corrosion resistance of aluminized steel strips. Arch. Metall. Mater. 2015, 60, 1825–1831. [Google Scholar] [CrossRef]

- Al-Mosawi, A.I.; Al-Maamori, M.H.; Wetwet, Z.A. Mechanical properties of composite material reinforcing by natural-synthetic fibers. Acad. Res. Int. 2012, 3, 108–112. [Google Scholar]

- Sluzalec, A. On random characteristics of composite materials. Mater. Sci. Technol. 2013, 29, 1272–1274. [Google Scholar] [CrossRef]

- Subesh, T.; Yogaraj, D.; Ramesh, V. Characterization of fiber metal laminates, bonding and manufacturing methods. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1062–1065. [Google Scholar] [CrossRef]

- Chatys, R.; Kuta, K.; Panich, A. Composite body construction optimization and technological design of an electrically powered race car. Zeszy. Naukowe Politech. Rzeszow. Mech. 2018, 90, 421–431. [Google Scholar] [CrossRef]

- Vlot, A.; Vogelesang, L.B.; de Vries, T.J. Towards application of fibre metal laminates in large aircraft. Aircr. Eng. Aerosp. Technol. 2002, 71, 558–570. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Krasowski, B.; Kubit, A.; Wydrzyński, D. Possibilities of application of incremental sheet-forming technique in aircraft industry. Zeszy. Naukowe Politech. Rzeszow. Mech. 2018, 90, 87–100. [Google Scholar] [CrossRef]

- Verma, A.K.; Pradhan, N.K.; Nehra, R.; Prateek. Challenge and advantage of materials in design and fabrication of composite UAV. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012005. [Google Scholar] [CrossRef]

- Bielawski, R. Composite materials in military aviation and selected problems with implementation. Rev. Air Force Acad. 2017, 1, 11–16. [Google Scholar] [CrossRef]

- Borchardt, J.K. Unmanned aerial vehicles spur composites use. Reinf. Plast. 2004, 48, 28–31. [Google Scholar] [CrossRef]

- Asundi, A.; Choi, A.Y.N. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Vlot, A. GLARE–History of the Development of a New Aircraft Material; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Homan, J.J. Fatigue initiation in fibre metal laminates. Int. J. Fatigue 2006, 28, 366–374. [Google Scholar] [CrossRef]

- Alderlieste, R.C. Fatigue and damage tolerance issues of Glare in aircraft structures. Int. J. Fatigue 2006, 28, 1116–1123. [Google Scholar] [CrossRef]

- Dhaliwal, G.S.; Newaz, G.M. Effect of Resin Rich Veil Cloth Layers on the Uniaxial Tensile Behavior of Carbon Fiber Reinforced Fiber Metal Laminates. J. Compos. Sci. 2018, 2, 61. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.G.; Kim, H.C.; Kwon, J.B.; Shin, D.K.; Lee, J.J.; Huh, H. Tensile behavior of aluminum/carbon fiber reinforced polymer hybrid composites at intermediate strain rates. J. Compos. Mater. 2015, 49, 1179–1193. [Google Scholar] [CrossRef]

- Dhaliwal, G.S.; Newaz, G.M. Experimental and numerical investigation of flexural behavior of carbon fiber reinforced aluminum laminates. J. Reinf. Plast. Compos. 2016, 35, 945–956. [Google Scholar] [CrossRef]

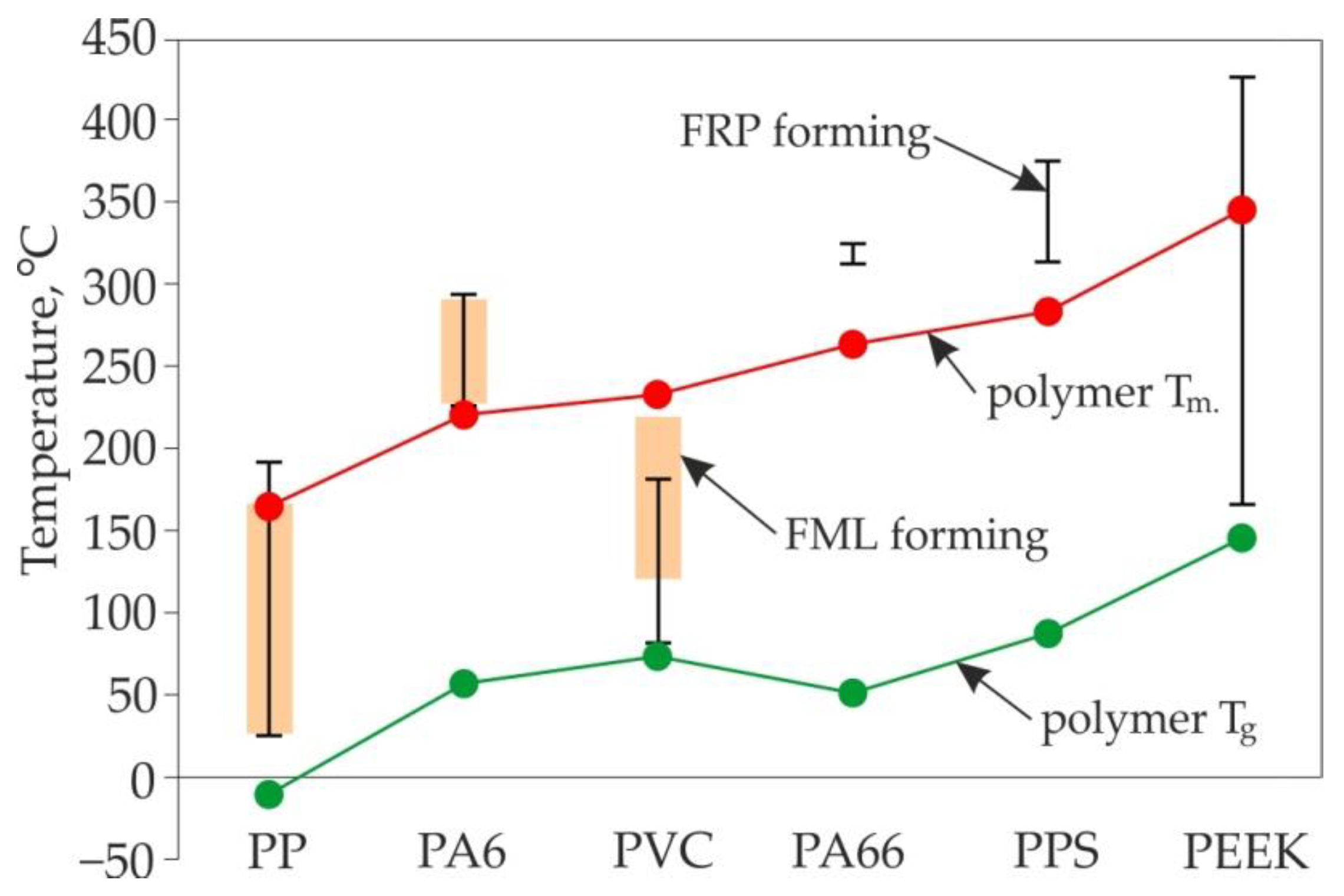

- Cortés, P.; Cantwell, W.J. Structure–Properties Relations in Titanium-Based Thermoplastic Fiber–Metal Laminates. Polym. Compos. 2006, 27, 264–270. [Google Scholar] [CrossRef]

- Thirukumaran, M.; Siva, I.; Winowlin Jappes, J.T.; Manikandan, V. Forming and drilling of fiber metal laminates—A review. J. Reinf. Plast. Compos. 2018, 37, 981–990. [Google Scholar] [CrossRef]

- Bersee, H.E.N. Composite aerospace manufacturing processes. In Encyclopedia of Aerospace Engineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 1–16. [Google Scholar] [CrossRef]

- Miller, J.L.; Progar, D.J.; Johnson, W.S.; Clair, T.L.S. Preliminary Evaluation of Hybrid Titanium Composite Laminates, NASA, Langley Research Center, Hampton Virginia. 1994. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19940024969.pdf. (accessed on 8 January 2020).

- De Cicco, D.; Asaee, Z.; Taheri, F. Low-velocity impact damage response of fiberglass/magnesium fiber-metal laminates under different size and shape impactors. Mech. Adv. Mater. Struct. 2017, 24, 545–555. [Google Scholar] [CrossRef]

- Sinke, J. Forming technology for composite/metal hybrids. In Composites Forming Technologies; Long, A.C., Ed.; Woodhead Publishing: Sawston, Great Britain, 2007; pp. 197–219. [Google Scholar]

- Silva, M.B.; Martins, P.A.F. Incremental sheet forming. Compr. Mater. Process. 2014, 3, 7–26. [Google Scholar] [CrossRef]

- Nimbalkar, D.H.; Nandedkar, V.M. Review of incremental forming of sheet metal components. Int. J. Eng. Res. Appl. 2013, 3, 39–51. [Google Scholar]

- Kulkarni, K.M.; Schey, J.A.; Badger, D.V. Investigation of shot peening as a forming process for aircraft wing skins. J. Appl. Metalwork. 1981, 1, 34–44. [Google Scholar] [CrossRef]

- Friese, A.; Lohmar, J.; Wüstefeld, F. Current applications of advanced peen forming implementation. In Shot Peening; Wagner, P.D.I.L., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Kant, R.; Joshi, S.N.; Dixit, U.S. Research issues in the laser sheet bending process. In Materials Forming and Machining; Woodhead Publishing: Sawston, Great Britain, 2016; pp. 73–97. [Google Scholar]

- Gisario, A.; Barletta, M. Laser forming of glass laminate aluminium reinforced epoxy (GLARE): On the role of mechanical, physical and chemical interactions in the multi-layers material. Op. Lasers Eng. 2018, 110, 364–376. [Google Scholar] [CrossRef]

- Behrens, B.A.; Hübner, S.; Grbic, N.; Micke-Camuz, M.; Wehrhane, T.; Neumann, A. Forming and joining of carbon-fibre-reinforced thermoplastic and sheet metal in one step. Proc. Eng. 2017, 183, 227–232. [Google Scholar] [CrossRef] [Green Version]

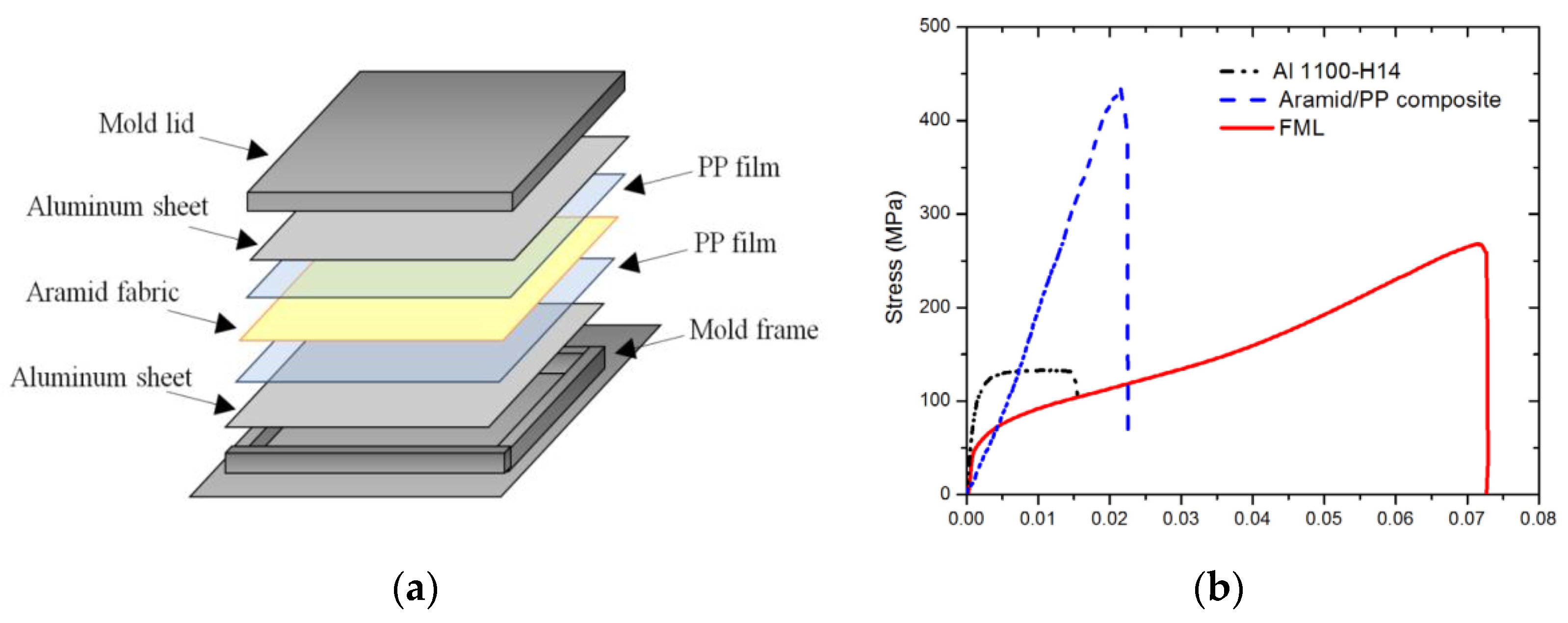

- Mosse, L.; Compston, P.; Cantwell, W.J.; Cardew-Hall, M.; Kalyanasundaram, S. The effect of process temperature on the formability of polypropylene based fibre-metal laminates. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1158–1166. [Google Scholar] [CrossRef]

- Saadatfard, A.; Gerdooei, M.; Aghchai, A.J. Drawing potential of fibre metal laminates in hydromechanical forming: A numerical and experimental study. J. Sand. Struct. Mater. 2018, 22, 1386–1403. [Google Scholar] [CrossRef]

- Psyk, V.; Risch, D.; Kinsey, B.L.; Tekkaya, A.E.; Kleiner, M. Electromagentic forming-a review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Kim, H.K.; Park, E.T.; Song, W.J.; Kang, B.S.; Kim, J. Experimental and numerical investigation of the high-velocity impact resistance of fiber metal laminates and Al 6061-T6 by using electromagnetic launcher. J. Mech. Sci. Technol. 2019, 33, 1219–1229. [Google Scholar] [CrossRef]

- Tzeng, J.T.; Hsieh, K.T. Electromagnetic analysis of composite structures subjected to transient magnetic fields. J. Compos. Mater. 2019, 54, 745–752. [Google Scholar] [CrossRef]

- Li, L.; Lang, L.; Hamza, B.; Alexandrov, S.; Li, S. The influence of different compositions of fiber metal laminates on the fracture in the semi-solidified stamping forming. Int. J. Damage Mech. 2022, 31, 1254–1270. [Google Scholar] [CrossRef]

- Sakhtemanian, M.R.; Honarpisheh, M.; Amini, S. Numerical and experimental study on the layer arrangement in the incremental forming process of explosive-welded low-carbon steel/cp-titanium bimetal sheet. Int. J. Adv. Manuf. Technol. 2018, 95, 3781–3796. [Google Scholar] [CrossRef]

- Leszak, E. Apparatus and process for incremental dieless forming. Patent US3342051A, 19 September 1967. [Google Scholar]

- Fratini, L.; Ambrogio, G.; Di Lorenzo, R.; Filice, L.; Micari, F. Influence of mechanical properties of the sheet material on formability in single point incremental forming. CIRP Ann. 2004, 53, 207–210. [Google Scholar] [CrossRef]

- Ambrogio, G.; Costantino, I.; De Napoli, L.; Filice, L.; Fratini, L.; Muzzupappa, M. Influence of some relevant process parameters on the dimensional accuracy in incremental forming: A numerical and experimental investigation. J. Mater. Process. Technol. 2004, 153, 501–507. [Google Scholar] [CrossRef]

- Bambach, M. A geometrical model of the kinematics of incremental sheet forming for the prediction of membrane strains and sheet thickness. J. Mater. Process. Technol. 2010, 210, 1562–1573. [Google Scholar] [CrossRef]

- Dejardin, S.; Thibaud, S.; Gelin, J.C.; Michel, G. Experimental investigations and numerical analysis for improving knowledge of incremental sheet forming process for sheet metal parts. J. Mater. Process. Technol. 2010, 210, 363–369. [Google Scholar] [CrossRef]

- Filice, L.; Ambrogio, G.; Micari, F. On-line control of single point incremental forming operations through punch force monitoring. CIRP Ann. 2006, 55, 245–248. [Google Scholar] [CrossRef]

- Hirt, G.; Ames, J.; Bambach, M.; Kopp, R. Forming strategies and process modelling for CNC incremental sheet forming. CIRP Ann. 2004, 53, 203–206. [Google Scholar] [CrossRef]

- Ou, L.; An, Z.; Gao, Z.; Zhou, S.; Men, Z. Effects of process parameters on the thickness uniformity in Two-Point Incremental Forming (TPIF) with a positive die for an irregular stepped part. Materials 2020, 13, 2634. [Google Scholar] [CrossRef]

- Silva, M.; Martins, P. Two-point incremental forming with partial die: Theory and experimentation. J. Mater. Eng. Perform. 2013, 22, 1018–1027. [Google Scholar] [CrossRef]

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J.C. Asymmetric single point incremental forming of sheet metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Azaouzi, M.; Lebaal, N. Tool path optimization for single point incremental sheet forming using response surface method. Simul. Modell. Pract. Theory 2012, 24, 49–58. [Google Scholar] [CrossRef]

- Amala Justus Selvam, M.; Velu, R.; Dheerankumar, T. Study of the influence of the process variables on formability and strain distribution in incremental sheet metal working of AA 1050 sheets. In Innovative Design and Development Practices in Aerospace and Automotive Engineering; Springer: Berlin/Heidelberg, Germany, 2017; pp. 493–505. [Google Scholar] [CrossRef]

- Bensaid, K.; Souissi, R.; Boulila, A.; Ayadi, M.; Ben Fredj, N. Numerical investigation of incremental forming process of AISI 304 stainless steel. Ironmak. Steelmak. 2022, 1–10. [Google Scholar] [CrossRef]

- Kim, T.; Yang, D.Y. Improvement of formability for the incremental sheet metal forming process. Int. J. Mech. Sci. 2000, 42, 1271–1286. [Google Scholar] [CrossRef]

- Kumar, Y.; Kumar, S. Incremental sheet forming (ISF). In Advances in Material Forming and Joining; Springer: Berlin/Heidelberg, Germany, 2015; pp. 29–46. [Google Scholar] [CrossRef]

- Jackson, K.; Allwood, J. The mechanics of incremental sheet forming. J. Mater. Process. Technol. 2009, 209, 1158–1174. [Google Scholar] [CrossRef] [Green Version]

- Jeswiet, J.; Geiger, M.; Engel, U.; Kleiner, M.; Schikorra, M.; Duflou, J.; Neugebauer, R.; Bariani, P.; Bruschi, S. Metal forming progress since 2000. CIRP J. Manuf. Sci. Technol. 2008, 1, 2–17. [Google Scholar] [CrossRef]

- Jurisevic, B.; Kuzman, K.; Junkar, M. Water jetting technology: An alternative in incremental sheet metal forming. Int. J. Adv. Manuf. Technol. 2006, 31, 18–23. [Google Scholar] [CrossRef]

- Junkar, M.; Heiniger, K.; Jurisevic, B. The application of water-jet technology for incremental sheet-metal forming. Stroj. Vestn.-J. Mech. Eng. 2004, 50, 613–622. [Google Scholar]

- Cheng, X.M.; Zhou, L.; Wang, L.; Zhou, G. The experiment study of water jet incremental sheet metal forming. Adv. Mater. Res. 2011, 230–232, 1010–1013. [Google Scholar] [CrossRef]

- Sajn, V.; Jurisevic, B.; Kosel, F. Water jet incremental sheet metal forming: Pressure distribution analysis. Int. J. Interact. Design Manuf. 2011, 5, 95–102. [Google Scholar] [CrossRef]

- Li, H.; Yang, X.P. Research on technology of high-pressure water jet incremental sheet metal forming. Appl. Mech. Mater. 2014, 496–500, 148–154. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, W.; Cao, J.; Ehmann, K.F. An experimental and numerical study of dieless water jet incremental microforming. J. Manuf. Sci. Eng. 2019, 141, 041008. [Google Scholar] [CrossRef]

- Jurisevic, B.; Sajn, V.; Kosel, F.; Junkar, M. Introduction of laminated supporting tools in water jet incremental sheet metal forming. Int. J. Adv. Manuf. Technol. 2008, 37, 496–503. [Google Scholar] [CrossRef]

- Lu, B.; Mohamed Bazeer, M.; Cao, J.; Ai, S.; Chen, J.; Ou, H.; Long, H. A study of incremental sheet forming by using water jet. Int. J. Adv. Manuf. Technol. 2017, 91, 2291–2301. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Zhang, T.T.; Lei, L.; Dai, M.Q. The high-pressure liquid jet incremental forming for the aluminum sheet. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 682–690. [Google Scholar] [CrossRef]

- Iseki, H. Flexible and incremental bulging of sheet metal using high-speed water jet. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2001, 44, 486–493. [Google Scholar] [CrossRef] [Green Version]

- Saidi, B.; Giraud Moreau, L.; Cherouat, A.; Nasri, R. Experimental and numerical study on warm single-point incremental sheet forming (WSPIF) of titanium alloy Ti–6Al–4V, using cartridge heaters. J. Br. Soc. Mech. Sci. Eng. 2020, 42, 1–15. [Google Scholar] [CrossRef]

- Ambrogio, G.; Filice, L.; Manco, G. Warm incremental forming of magnesium alloy AZ31. CIRP Ann. 2008, 57, 257–260. [Google Scholar] [CrossRef]

- Liao, J.; Zeng, X.; Xue, X. Surface quality analysis of AZ31B Mg alloy sheet in ultrasonic-assisted warm single-point incremental forming. Int. J. Adv. Manuf. Technol. 2022, 118, 1397–1410. [Google Scholar] [CrossRef]

- Amini, S.; Hosseinpour Gollo, A.; Paktinat, H. An investigation of conventional and ultrasonic-assisted incremental forming of annealed AA1050 sheet. Int. J. Adv. Manuf. Technol. 2017, 90, 1569–1578. [Google Scholar] [CrossRef]

- Sakhtemanian, M.; Honarpisheh, M.; Amini, S. A novel material modeling technique in the single-point incremental forming assisted by the ultrasonic vibration of low carbon steel/commercially pure titanium bimetal sheet. Int. J. Adv. Manuf. Technol. 2019, 102, 473–486. [Google Scholar] [CrossRef]

- Alharbi, N. Experimental study on designing optimal vibration amplitude in ultrasonic assisted incremental forming of AA6061-T6. Eng. Sci. Technol. Int. J. 2022, 30, 101041. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, W.; Wang, Z.; Li, X.; Sun, L.; Li, J.; Zhao, G. Investigation on the material flow and deformation behavior during ultrasonic-assisted incremental forming of straight grooves. J. Mater. Res. Technol. 2020, 9, 433–454. [Google Scholar] [CrossRef]

- Vogelesang, L.B.; Roebroeks, G.H. Metal-resin laminate reinforced with S2-glass fibres. United States Patent US5039571 A, 13 August 1991. [Google Scholar]

- Vogelesang, L.; Vlot, A. Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 2000, 103, 1–5. [Google Scholar] [CrossRef]

- Vlot, A. Glare: History of the Development of a New Aircraft Material; Kluwer Academic Publishers: New York, NY, USA; Boston, MA, USA; Dordrecht, The Netherlands; London, UK; Moscow, Russia, 2004. [Google Scholar]

- Kuiters, S. Feasibility Study on Single Point Incremental Forming. Master’s Thesis, Delft University of Technology, Delft, Holland, 26 October 2016. [Google Scholar]

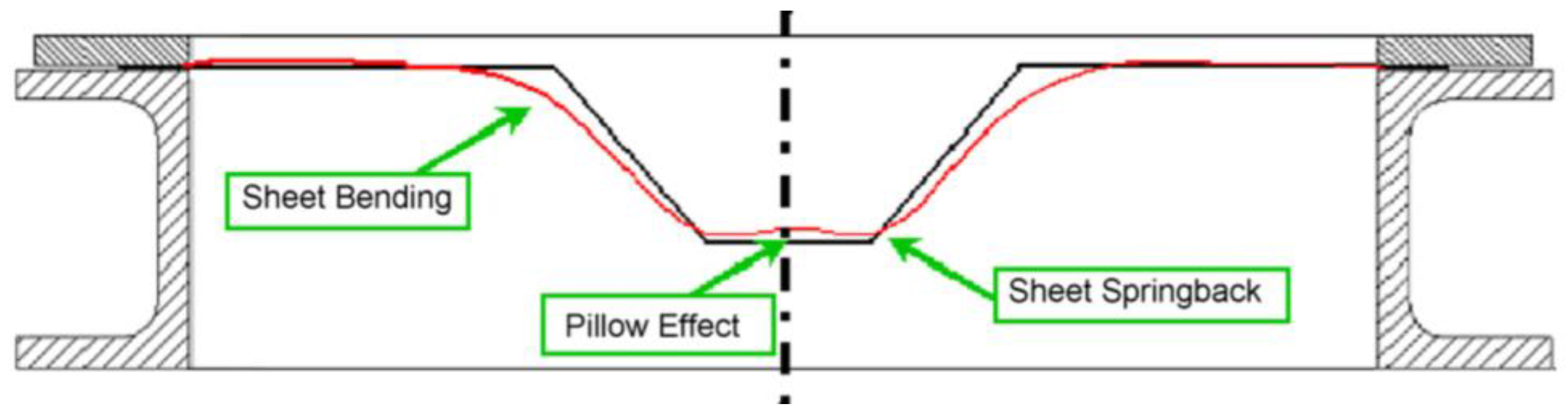

- Micari, F.; Ambrogio, G.; Filice, L. Shape and dimensional accuracy in single point incremental forming: State of the art and future trends. J. Mater. Process. Technol. 2007, 191, 390–395. [Google Scholar] [CrossRef]

- Nowosielski, M.; Żaba, K.; Kita, P.; Kwiatkowski, M. Compensation of springback effect in designing new pressing technologies. In Proceedings of the Metal 2013 Conference, Brno, Czechia, 15–17 May 2013; pp. 1–5. [Google Scholar]

- Kubit, A.; Trzepieciński, T.; Krasowski, B.; Slota, J.; Spišák, E. Strength analysis of a rib-stiffened GLARE-based thin-walled structure. Materials 2020, 13, 2929. [Google Scholar] [CrossRef]

- Fiorotto, M.; Sorgente, M.; Lucchetta, G. Preliminary studies on single point incremental forming for composite materials. Int. J. Mater. Form. 2010, 3, 951–954. [Google Scholar] [CrossRef]

- Vermeeren, C.A.J.R. An historic overview of the development of fibre metal laminates. Appl. Compos. Mater. 2003, 10, 189–205. [Google Scholar] [CrossRef]

- Schut, J.E.; Alderliesten, R.C. Delamination growth rate at low and elevated temperatures in GLARE. In Proceedings of the 25th Congress of International Council of the Aeronautical Sciences, Hamburg, Germany, 3–8 September 2006; Paper ICAS2006-4.1S. pp. 1–7. [Google Scholar]

- Emberey, C.L.; Milton, N.R.; Berends, J.P.T.J.; Van Tooren, M.J.L.; Van der Elst, S.W.G.; Vermeulen, B. Application of knowledge engineering methodologies to support engineering design application development in aerospace. In Proceedings of the 7th AIAA ATIO Conf, 2nd CEIAT Int’l Conf on Innov and Integr in Aero Sciences, 17th LTA Systems Tech Conf, Belfast, Northern Ireland, 8–20 September 2007. [Google Scholar]

- Lv, J.; Yin, J.; Qin, Y.; Dai, Y.; Cheng, Z.; Luo, L.; Liu, X. Post-construction of weaving structure in aramid fiber towards improvements of its transverse properties. Compos. Sci. Technol. 2021, 208, 108780. [Google Scholar] [CrossRef]

- Yuan, W.; Li, Y.; Zhao, J. Mechanical properties of a novel Tri-directional carbonflax-aramid fiber reinforced composite. Compos. Sci. Technol. 2021, 213, 108923. [Google Scholar] [CrossRef]

- Vogelesang, L.B. Development of a New Hybrid Material (ARALL) for Aircraft Structure. Ind. Eng. Chem. Prod. Res. Dev. 1983, 22, 492–496. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Design 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Salve, A.; Kulkarni, R.; Mache, A. A Review: Fiber Metal Laminates (FML’s)-Manufacturing, test methods and numerical modeling. Int. J. Eng. Technol. Sci. 2016, 6, 71–84. [Google Scholar] [CrossRef]

- Tian, J.; Xu, T.; An, L.; Wang, S.; Tan, Y.; Chen, G. Study on behavior and mechanism of low-velocity impact and post-impact flexural properties of carbon-aramid/epoxy resin laminated composites. Compos. Struct. 2022, 300, 116166, in press. [Google Scholar] [CrossRef]

- Hai, Y.; Rongzhen, R.; Chunhu, T.; Hongyun, L. Study on arall failure behaviour under tensile loading. Scripta Mater. 1996, 35, 1379–1384. [Google Scholar] [CrossRef]

- Kwakernaak, A.; Hofstede, J.; Poulis, J.; Benedictus, R. Welding and Joining of Aerospace Materials. In Woodhead Publishing Series in Welding and Other Joining Technologies; Chaturvedi, M.C., Ed.; Woodhead Publishing Limited: Sawston, Great Britain, 2012; pp. 235–287. ISBN 9780128191408. [Google Scholar]

- Park, S.Y.; Choi, W.J. Production Control Effect on Composite Material Quality and Stability for Aerospace Usage. In Advanced Composite Materials: Properties and Applications; Chapter 3; De Gruyter Open Poland: Warsaw, Poland, 2017; pp. 112–194. [Google Scholar] [CrossRef]

- Asghar, W.; Nasir, M.A.; Qayyum, F.; Shah, M.; Azeem, M.; Nauman, S.; Khushnood, S. Investigation of fatigue crack growth rate in CARALL, ARALL and GLARE. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1086–1100. [Google Scholar] [CrossRef]

- Gonzalez-Canche, N.G.; Flores-Johnson, E.A.; Carrillo, J.G. Mechanical characterization of fiber metal laminate based on aramid fiber reinforced polypropylene. Compos. Struct. 2017, 172, 259–266. [Google Scholar] [CrossRef]

- Jung, J.; Sodano, H.A. High strength epoxy nanocomposites reinforced by epoxy functionalized aramid nanofibers. Polymer 2020, 195, 122438. [Google Scholar] [CrossRef]

- Borić, A.; Kalendová, A.; Urbanek, M.; Pepelnjak, T. Characterisation of polyamide (PA)12 nanocomposites with montmorillonite (MMT) filler clay used for the incremental forming of sheets. Polymers 2019, 11, 1248. [Google Scholar] [CrossRef]

- Lin, J.; Bang, S.H.; Malakooti, M.H.; Sodano, H.A. Isolation of aramid nanofibers for high strength and toughness polymer nanocomposites. ACS Appl. Mater. Interf. 2017, 9, 11167–11175. [Google Scholar] [CrossRef] [PubMed]

- Kuang, Q.; Zhang, D.; Yu, J.C.; Chang, Y.-W.; Yue, M.; Hou, Y.; Yang, M. Toward record-high stiffness in polyurethane nanocomposites using aramid nanofibers. J. Phys. Chem. C 2015, 119, 27467–27477. [Google Scholar] [CrossRef]

- Bruschi, S.; Cao, J.; Merklein, M.; Yanagimoto, J. Forming of metal-based composite parts. CIRP Ann. Manuf. Technol. 2021, 70, 567–588. [Google Scholar] [CrossRef]

- Jackson, K.P.; Allwood, J.M.; Landert, M. Incremental forming of sandwich panels. J. Mater. Process. Technol. 2008, 204, 290–303. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, K.; Peng, K. Exploring the deformation potential of composite materials processed by incremental sheet forming: A review. Int. J. Adv. Manuf. Technol. 2022, 118, 2099–2137. [Google Scholar] [CrossRef]

- Silva, M.B.; Skjoedt, M.; Atkins, A.G.; Bay, N.; Martins, P.A.F. Single-point incremental forming and formability—Failure diagrams. J. Strain Anal. Eng. Design 2008, 43, 15–35. [Google Scholar] [CrossRef]

- Neugebauer, R.; Meinel, S.; Glaß, R.; Popp, M. Characterization of contact tensions during incremental forming of metal composites. Int. J. Mater. Form. 2010, 3, 667–670. [Google Scholar] [CrossRef]

- Hassan, M.; Hussain, G.; Wei, H.; Qadeer, A.; AlKahtani, M. Progress on single-point incremental forming of polymers. Int. J. Adv. Manuf. Technol. 2021, 114, 1–26. [Google Scholar] [CrossRef]

- Habib, E.T.; Saeed, A.N.; Vahid, M.; Ali, K.M. Nonlinear deformation analysis and modeling of composite with aluminum layers. J. Mech. Res. Appl. 2010, 2, 39–45. [Google Scholar]

- Ding, Z.; Wang, H.; Luo, J.; Li, N. A review on forming technologies of fibre metal laminates. Int. J. Lightweight Mater. Manuf. 2021, 4, 110–126. [Google Scholar] [CrossRef]

- Honarpisheh, M.; Jobedar, M.M.; Alinaghian, I. Multi-response optimization on single-point incremental forming of hyperbolic shape Al-1050/Cu bimetal using response surface methodology. Int. J. Adv. Manuf. Technol. 2008, 96, 3069–3080. [Google Scholar] [CrossRef]

- Sedighi, M.; Honarpisheh, M. Investigation of cold rolling influence on near surface residual stress distribution in explosive welded multilayer. Strength Mater. 2012, 44, 693–698. [Google Scholar] [CrossRef]

- Gheysarian, A.; Honarpisheh, M. Investigation of fracture depth of al/cu bimetallic sheet in single point incremental forming process. Iran. J. Mater. Form. 2019, 6, 2–15. [Google Scholar] [CrossRef]

- Gheysarian, A.; Honarpisheh, M. Process parameters optimization of the explosive-welded Al/Cu bimetal in the incremental sheet metal forming process. Iran. J. Sci. Technol. Trans. Mech. Eng. 2019, 43, 945–956. [Google Scholar] [CrossRef]

- Honarpisheh, M.; Gheysarian, A. An experimental study on the process parameters of incremental forming of explosively-welded Al/Cu bimetal. J. Comput. Appl. Res. Mech. Eng. 2017, 7, 73–83. [Google Scholar]

- Liu, Z.; Li, G. Single point incremental forming of Cu-Al composite sheets: A comprehensive study on deformation behaviors. Arch. Civil Mech. Eng. 2019, 19, 484–502. [Google Scholar] [CrossRef]

- Żaba, K.; Głodzik, M.; Puchlerka, S.; Pociecha, D.; Nowosielski, M.; Kwiatkowski, M. Analysis of the aluminium formability in the incremental sheet forming process. In Proceedings of the Metal 2015 Conference, Brno, Czechia, 3–5 June 2015; pp. 1–6. [Google Scholar]

- Alinaghian, M.; Alinaghian, I.; Honarpisheh, M. Residual stress measurement of single point incremental formed Al/Cu bimetal using incremental hole-drilling method. Int. J. Lightweight Mater. Manuf. 2019, 2, 131–139. [Google Scholar] [CrossRef]

- Jalali, A.; Hashemi, R.; Rajabi, M.; Tayebi, P. Finite element simulations and experimental verifications for forming limit curve determination of two-layer aluminum/brass sheets considering the incremental forming process. Proc. Inst. Mech. Eng. Part L J. Materi. Design Appl. 2022, 236, 361–373. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Design 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Sakhtemanian, M.R.; Amini, S.; Honarpishe, M. Simulation and investigation of mechanical and geometrical properties of st/cp-titanium bimetal sheet during the single point incremental forming process. Iran. J. Mater. Form. 2018, 5, 1–18. [Google Scholar] [CrossRef]

- Abdelkader, W.B.; Arfa, H.; Bahloul, R. Finite element analysis of single point incremental forming process of metallic composite sheet: Application to titanium-steel bimetal sheet forming. In Proceedings of the Design and Modeling of Mechanical Systems-IV, Hammamet, Tunisia, 18–20 March 2019; Aifaoui, N., Affi, Z., Abbes, M.S., Walha, L., Haddar, M., Romdhane, L., Benamara, A., Chouchane, M., Chaari, F., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 558–566. [Google Scholar]

- Abdelkader, W.B.; Bahloul, R.; Arfa, H. Numerical investigation of the influence of some parameters in spif process on the forming forces and thickness distributions of a bimetallic sheet CP-titanium/low-carbon steel compared to an individual layer. Proced. Manuf. 2020, 47, 1319–1327. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzepieciński, T.; Najm, S.M.; Pepelnjak, T.; Bensaid, K.; Szpunar, M. Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications. J. Compos. Sci. 2022, 6, 295. https://doi.org/10.3390/jcs6100295

Trzepieciński T, Najm SM, Pepelnjak T, Bensaid K, Szpunar M. Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications. Journal of Composites Science. 2022; 6(10):295. https://doi.org/10.3390/jcs6100295

Chicago/Turabian StyleTrzepieciński, Tomasz, Sherwan Mohammed Najm, Tomaž Pepelnjak, Kamel Bensaid, and Marcin Szpunar. 2022. "Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications" Journal of Composites Science 6, no. 10: 295. https://doi.org/10.3390/jcs6100295

APA StyleTrzepieciński, T., Najm, S. M., Pepelnjak, T., Bensaid, K., & Szpunar, M. (2022). Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications. Journal of Composites Science, 6(10), 295. https://doi.org/10.3390/jcs6100295