Investigation of Mechanical Properties of Coffee Husk-HDPE-ABS Polymer Composite Using Injection-Molding Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

Fiber Treatment and Preparation of the Composites

2.3. Characterization of Mechanical Properties Characterization

2.3.1. Tensile Strength

2.3.2. Flexural Strength

2.3.3. Impact Load Test

2.3.4. Absorption of Water

2.3.5. Morphological Studies of Composites by SEM

2.3.6. X-ray Diffraction (XRD) Analysis

3. Results

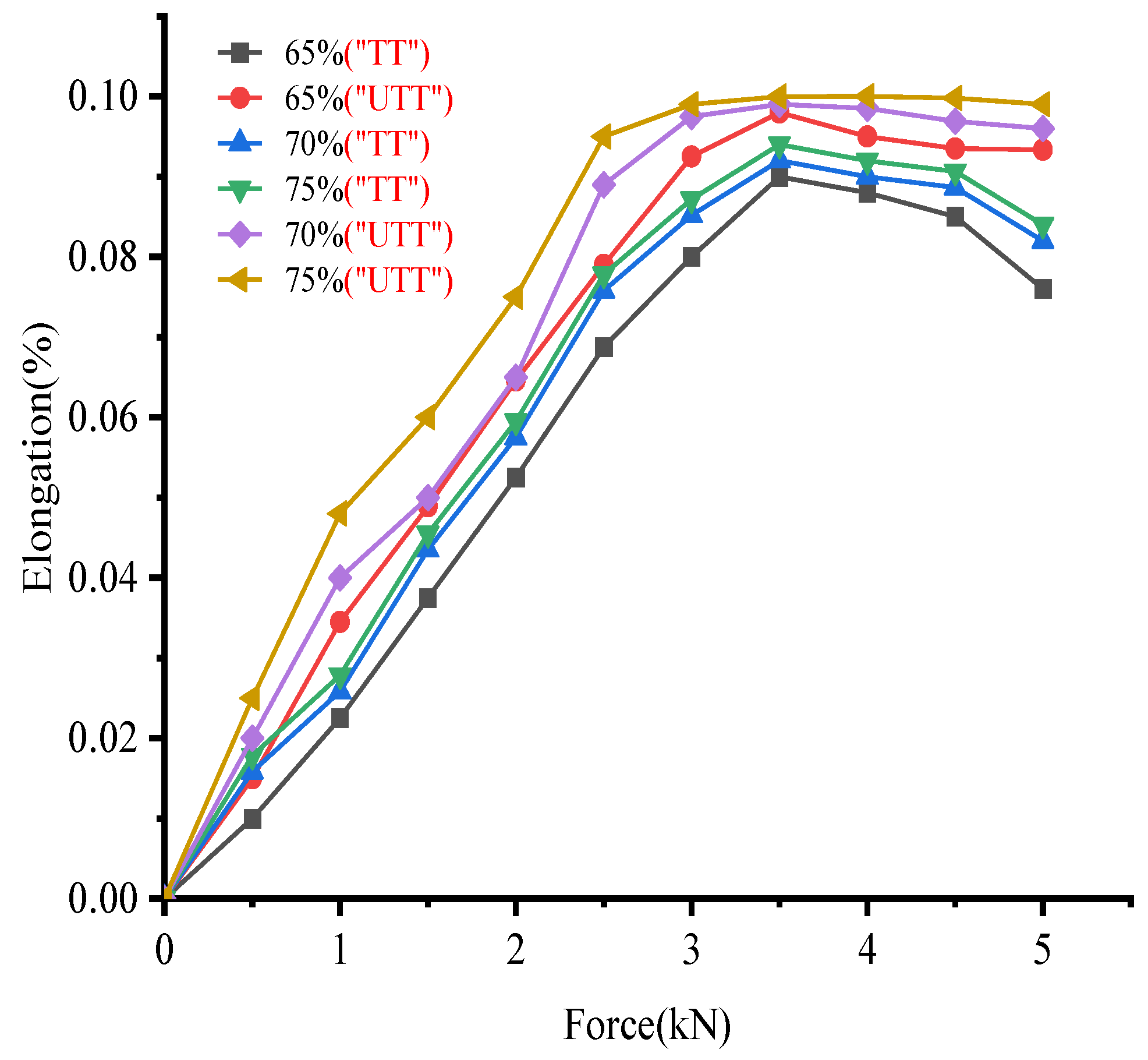

3.1. Tensile Test

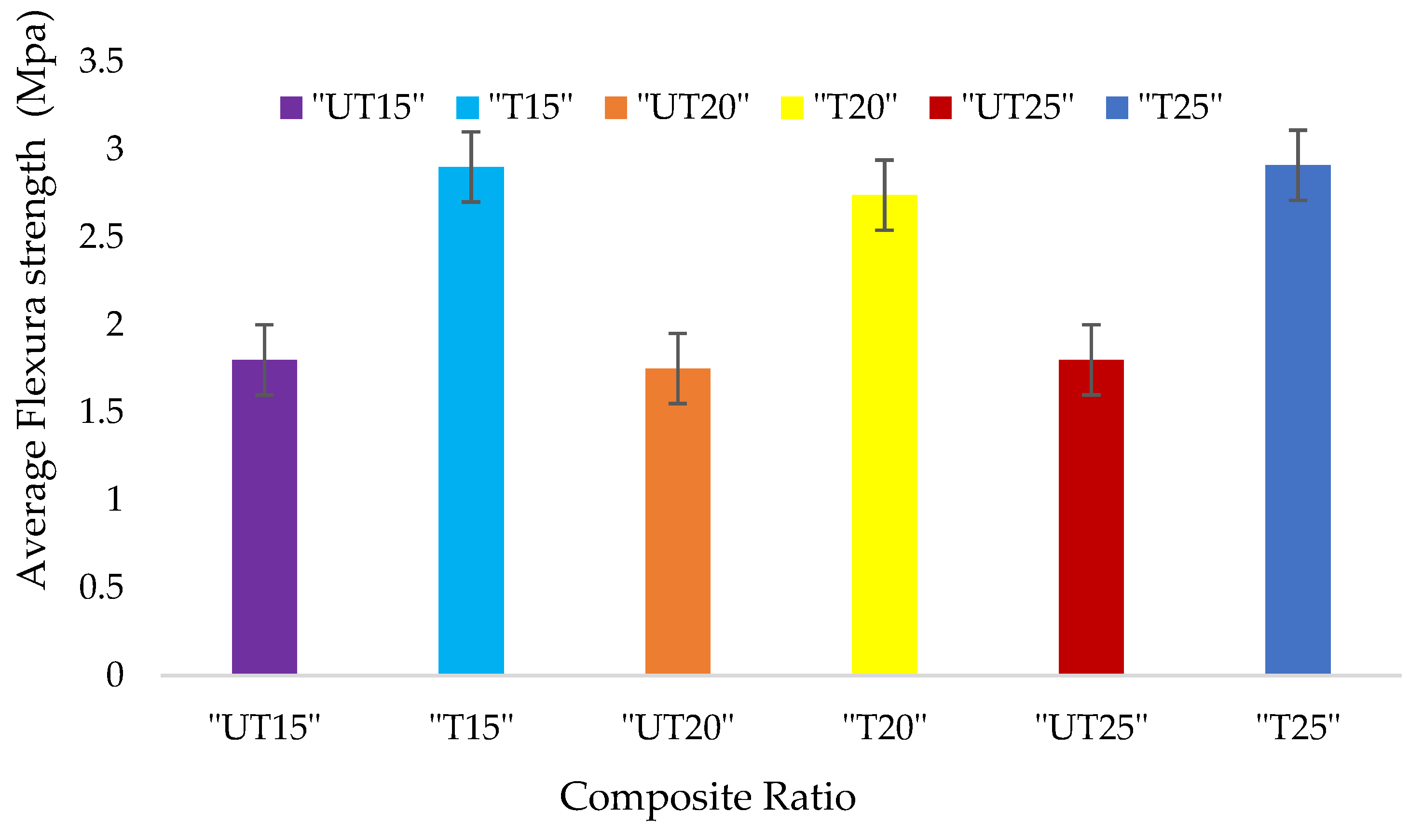

3.2. Flexural Test

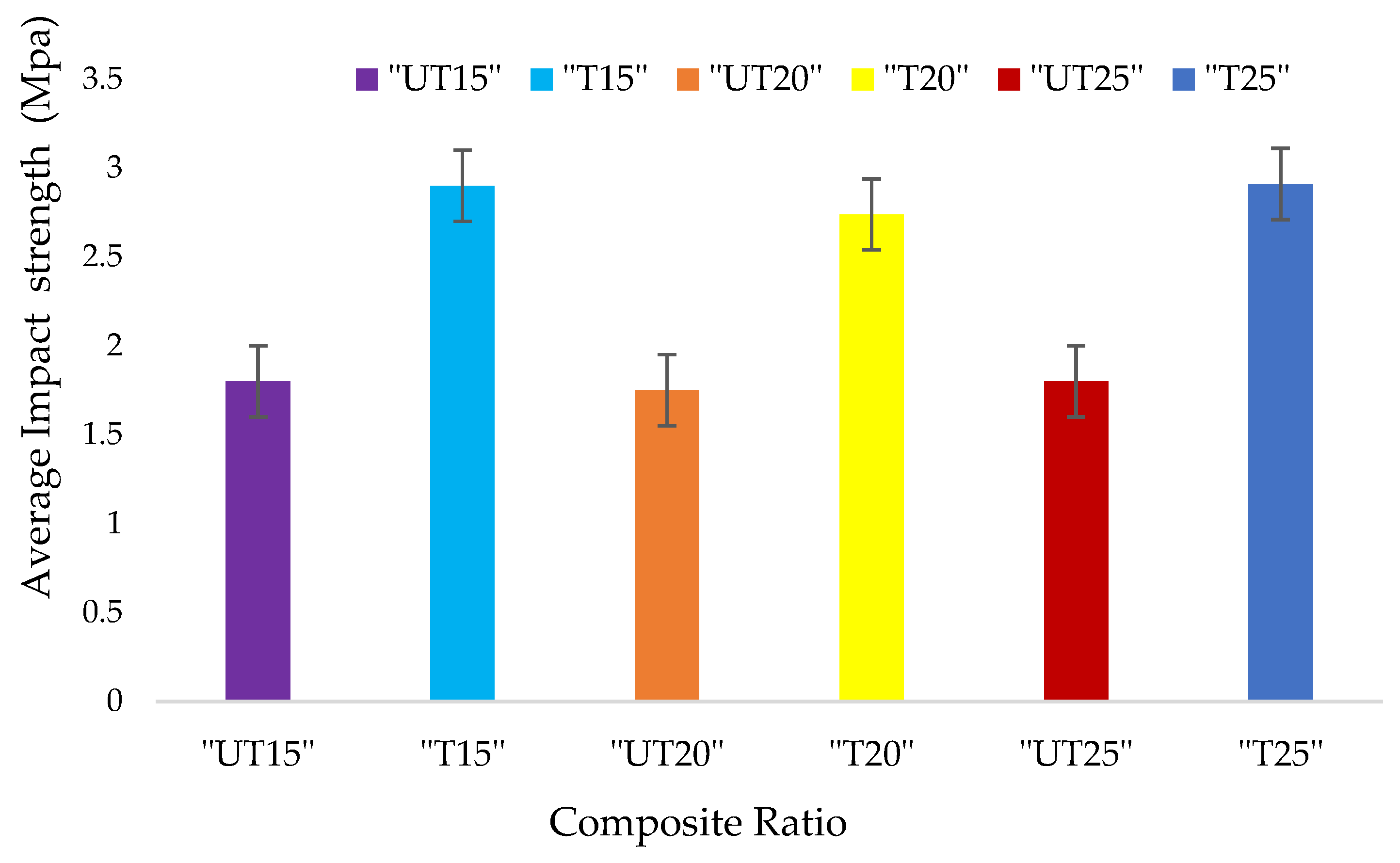

3.3. The Impact Test

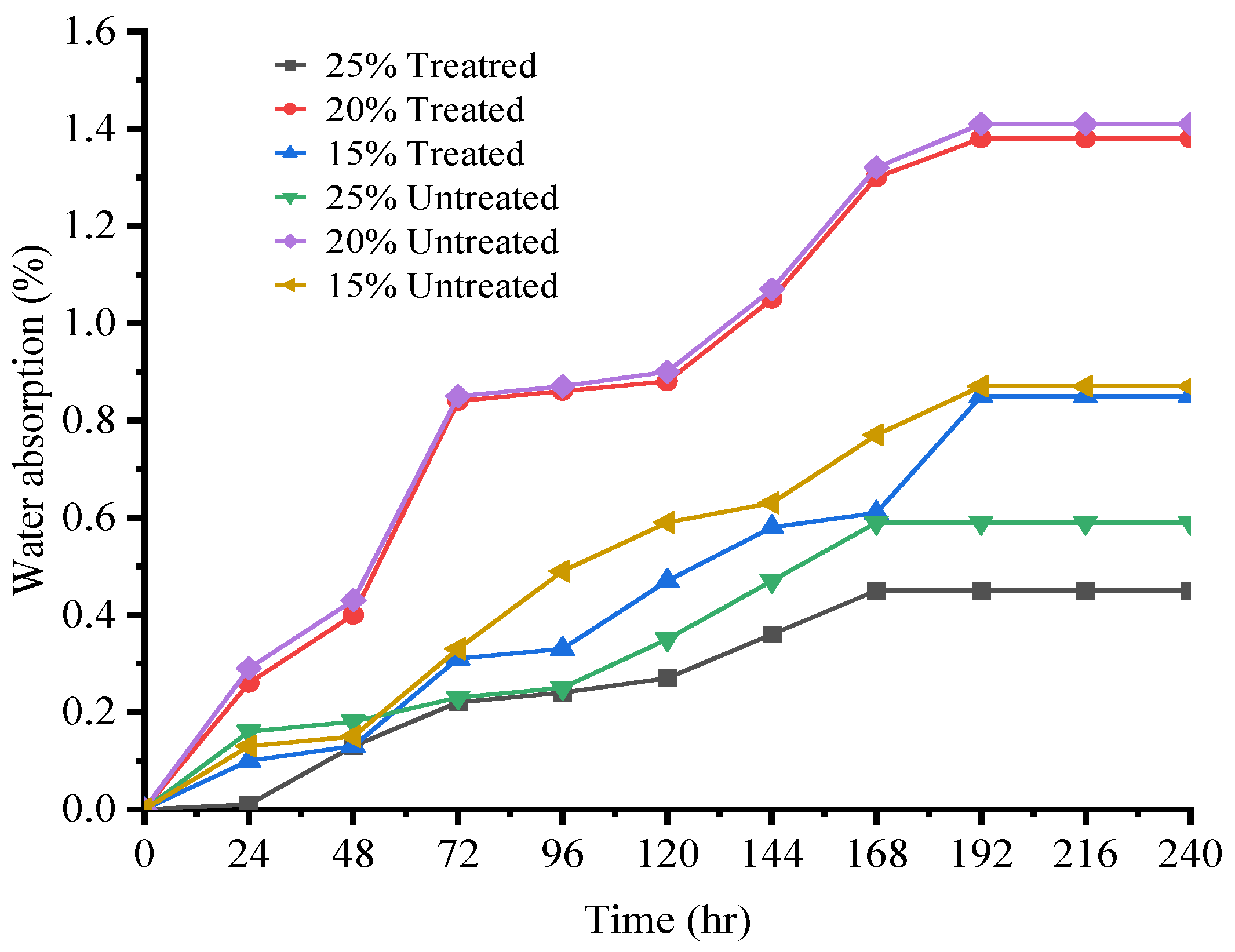

3.4. Moisture Absorption

4. Conclusions

- We prepared and analyzed HDPE functionalized organic reinforcement CH from a coffee industry post-industrial residue.

- The results demonstrate an appropriate reinforcement effect, as evidenced by increased tensile modulus and tensile strength.

- These composites’ improved mechanical properties make them suitable for various applications.

- The organic reinforced composites behaved differently, increasing melting temperature and decreasing crystallization.

- ABS was grafted into HDPE macromolecules to enhance matrix-filler compatibility.

- The SEM image can be used to determine the failure mechanism of composites.

- The effects of CHF loading content and the addition of a coupling agent, acrylonitrile butadiene styrene (ABS), on composite processing and properties were investigated.

- This study’s findings can help determine the best weight ratio for developing CH polymer composites for various applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gonçalves, B.M.; Camillo, M.D.; Oliveira, M.P.; Carreira, L.G.; Moulin, J.C.; Fantuzzi Neto, H.; de Oliveira, B.F.; Pereira, A.C.; Monteiro, S.N. Surface treatments of coffee husk fiber waste for effective incorporation into polymer biocomposites. Polymers 2021, 13, 3428. [Google Scholar] [CrossRef] [PubMed]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Lascano, D.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Montanes, N. Toughened poly (lactic acid)-PLA formulations by binary blends with poly(butylene succinate-co-adipate)-PBSA and their shape memory behaviour. Materials 2019, 12, 622. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- da Luz, F.S.; da Costa Garcia Filho, F.; del-Río, M.T.G.; Cassiano Nascimento, L.F.; Pinheiro, W.A.; Monteiro, S.N. Graphene-incorporated natural fiber polymer composites: A first overview. Polymers 2020, 12, 1601. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr. Polym. 2015, 131, 337–354. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Tahir, N.; Bhatti, H.N.; Iqbal, M.; Noreen, S. Biopolymers composites with peanut hull waste biomass and application for Crystal Violet adsorption. Int. J. Biol. Macromol. 2017, 94, 210–220. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Jorda-Vilaplana, A.; Balart, R.; Torres-Giner, S. A comparative study on the effect of different reactive compatibilizers on injection-molded pieces of bio-based high-density polyethylene/polylactide blends. J. Appl. Polym. Sci. 2019, 136, 47396. [Google Scholar] [CrossRef]

- Kallel, F.; Bettaieb, F.; Khiari, R.; García, A.; Bras, J.; Chaabouni, S.E. Isolation and structural characterization of cellulose nanocrystals extracted from garlic straw residues. Ind. Crops Prod. 2016, 87, 287–296. [Google Scholar] [CrossRef]

- Ortiz-Barajas, D.L.; Arévalo-Prada, J.; Fenollar, A.O.; Rueda-Ordóñez, Y.J.; Torres-Giner, S. Torrefaction of coffee husk flour for the development of injection-Molded green composite pieces of polylactide with high sustainability. Appl. Sci. 2020, 10, 6468. [Google Scholar] [CrossRef]

- Önal, E.; Uzun, B.B.; Pütün, A.E. Bio-oil production via co-pyrolysis of almond shell as biomass and high density polyethylene. Energy Convers. Manag. 2014, 78, 704–710. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Torres, A.; Ferrándiz, M.; Fombuena, V.; Balart, R. Antimicrobial activity of metal cation-exchanged zeolites and their evaluation on injection-molded pieces of bio-based high-density polyethylene. J. Food Saf. 2017, 37, e12348. [Google Scholar] [CrossRef]

- Corrado, A.; Polini, W. Measurement of high flexibility components in composite material by touch probe and force sensing resistors. J. Manuf. Process. 2019, 45, 520–531. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X. Directional dependence of electrical and thermal properties in graphene-nanoplatelet-based composite materials. Results Phys. 2019, 15, 102608. [Google Scholar] [CrossRef]

- Posada, J.C.; Jaramillo, L.Y.; Cadena, E.M.; García, L.A. Bio-based composites from agricultural wastes: Polylactic acid and bamboo Guadua angustifolia. J. Compos. Mater. 2016, 50, 3229–3237. [Google Scholar] [CrossRef]

- Saha, D.; Majumdar, M.K.; Das, A.K.; Sarwaruddin Chowdhury, A.M.; Ashaduzzaman, M. Structural nanocomposite fabrication from self-assembled choline chloride modified kaolinite into poly(Methylmethacrylate). J. Compos. Sci. 2019, 3, 83. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Azmi, M.; Zameri, M.; Saman, M.; Sharif, S. Proposed framework for End-Of-Life vehicle recycling system implementation in Malaysia. In Proceedings of the 11th Global Conference on Sustainable Manufacturing, Berlin, Germany, 23–25 September 2013; Volume 6, pp. 187–193. [Google Scholar]

- Thio, Y.S.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughening of isotactic polypropylene with CaCO3 particles. Polymer 2002, 43, 3661–3674. [Google Scholar] [CrossRef]

- Da Silva, A.L.N.; Rocha, M.C.G.; Moraes, M.A.; Valente, R.C.A.R.; Coutinho, F.M.B. Mechanical and rheological properties of composites based on polyolefin and mineral additives. Polym. Test. 2002, 21, 57–60. [Google Scholar] [CrossRef]

- Mohseni Tabar, M.; Tabarsa, T.; Mashkour, M.; Khazaeian, A. Using silicon dioxide (SiO2) nano-powder as reinforcement for walnut shell flour/HDPE composite materials. J. Indian Acad. Wood Sci. 2015, 12, 15–21. [Google Scholar] [CrossRef]

- Mustafa, S.N. Effect of Kaolin on the Mechanical Properties of Polypropylene/Polyethylene Composite. Diyala J. Eng. Sci. 2012, 05, 162–178. [Google Scholar] [CrossRef]

- Goulart, S.A.S.; Oliveira, T.; Teixeira, A.A.; Miléo, P.C.; Mulinari, D.R. Mechanical behaviour of polypropylene reinforced palm fibers composites. Procedia Eng. 2011, 10, 2034–2039. [Google Scholar] [CrossRef]

- Sobczak, L.; Lang, R.W.; Haider, A. Polypropylene composites with natural fibers and wood—General mechanical property profiles. Compos. Sci. Technol. 2012, 72, 550–557. [Google Scholar] [CrossRef]

- Awal, A.; Cescutti, G.; Ghosh, S.B.; Müssig, J. Interfacial studies of natural fibre/polypropylene composites using single fibre fragmentation test (SFFT). Compos. Part A Appl. Sci. Manuf. 2011, 42, 50–56. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Exploration of Mechanical Properties of Enset—Sisal Hybrid Polymer Composite. Fibers 2022, 10, 14. [Google Scholar] [CrossRef]

- Vázquez Fletes, R.C.; Rodrigue, D. Effect of wood fiber surface treatment on the properties of recycled hdpe/maple fiber composites. J. Compos. Sci. 2021, 5, 177. [Google Scholar] [CrossRef]

- Azam, F.A.A.; Royan, N.R.R.; Yuhana, N.Y.; Radzuan, N.A.M.; Ahmad, S.; Sulong, A.B. Fabrication of porous recycled HDPE biocomposites foam: Effect of rice husk filler contents and surface treatments on the mechanical properties. Polymers 2020, 12, 475. [Google Scholar] [CrossRef]

- Yiga, V.A.; Pagel, S.; Lubwama, M.; Epple, S.; Olupot, P.W.; Bonten, C. Development of fiber-reinforced polypropylene with NaOH pretreated rice and coffee husks as fillers: Mechanical and thermal properties. J. Thermoplast. Compos. Mater. 2020, 33, 1269–1291. [Google Scholar] [CrossRef]

- Nemeth, I. Hotavvezetekek hoszigeteles alatti korrozioja elleni vedelem. Korroz. Figy. 2010, 35, 36–38. [Google Scholar]

- Batu, T.; Lemu, H.G. Investigation of mechanical properties of false banana/glass fiber reinforced hybrid composite materials. Results Mater. 2020, 8, 100152. [Google Scholar] [CrossRef]

- ASTM D790-07; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2002; Volume 14, pp. 1–12.

- ASTM D256-97; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 1998; Volume 8, pp. 14–18.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2010; Volume 98, pp. 25–28.

- Vincenzo, A.; Cataldo, A.; Cavallaro, G. Coffee grounds as filler for pectin: Green composites with competitive performances dependent on the UV irradiation. Carbohydr. Polym. 2017, 170, 198–205. [Google Scholar]

- Rosa, M.; Medeiros, E.; Malmonge, J.; Gregorski, K.; Wood, D.; Mattoso, L.; Glenn, G.; Orts, W.; Imam, S. Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydr. Polym. 2010, 81, 83–92. [Google Scholar] [CrossRef]

- Collazo-Bigliardi, S.; Ortega-Toro, R.; Chiralt Boix, A. Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr. Polym. 2017, 191, 205–215. [Google Scholar] [CrossRef] [PubMed]

- Reis, R.S.; Tienne, L.G.P.; Souza, D.D.H.S.; Marques, M.D.F.V.; Monteiro, S.N. Characterization of coffee parchment and innovative steam explosion treatment to obtain microfibrillated cellulose as potential composite reinforcement. J. Mater. Res. Technol. 2020, 9, 9412–9421. [Google Scholar] [CrossRef]

- Pujol, D.; Liu, C.; Gominho, J.; Olivella, M.; Fiol, N.; Villaescusa, I.; Pereira, H. The chemical composition of exhausted coffee waste. Ind. Crops Prod. 2013, 50, 423–429. [Google Scholar] [CrossRef]

| Sample | CHF (%) | Kaolin (%) | ABS (%) | HDPE (%) |

|---|---|---|---|---|

| HDPE/(CH) | 25 | 3 | 7 | 65 |

| HDPE/(CH) | 20 | 3 | 7 | 70 |

| HDPE/(CH) | 15 | 3 | 7 | 75 |

| HDPE | 100 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amena, B.T.; Altenbach, H.; Tibba, G.S.; Hossain, N. Investigation of Mechanical Properties of Coffee Husk-HDPE-ABS Polymer Composite Using Injection-Molding Method. J. Compos. Sci. 2022, 6, 354. https://doi.org/10.3390/jcs6120354

Amena BT, Altenbach H, Tibba GS, Hossain N. Investigation of Mechanical Properties of Coffee Husk-HDPE-ABS Polymer Composite Using Injection-Molding Method. Journal of Composites Science. 2022; 6(12):354. https://doi.org/10.3390/jcs6120354

Chicago/Turabian StyleAmena, Berhanu Tolessa, Holm Altenbach, Getechew Shunki Tibba, and Nazia Hossain. 2022. "Investigation of Mechanical Properties of Coffee Husk-HDPE-ABS Polymer Composite Using Injection-Molding Method" Journal of Composites Science 6, no. 12: 354. https://doi.org/10.3390/jcs6120354

APA StyleAmena, B. T., Altenbach, H., Tibba, G. S., & Hossain, N. (2022). Investigation of Mechanical Properties of Coffee Husk-HDPE-ABS Polymer Composite Using Injection-Molding Method. Journal of Composites Science, 6(12), 354. https://doi.org/10.3390/jcs6120354