Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review

Abstract

:1. Introduction

- Using a vacuum as a driving force for impregnating the fibers does not require the application of high-pressure values, offering the possibility of obtaining dimensions and thicknesses similar to those of thermoset matrix composites.

- The in situ polymerization of the thermoplastic matrix around the fibers allows us to establish and form a strong chemical bond at the interface, which is much more difficult to obtain with traditional spindle processing methods; this allows for an increase in fatigue performance of thermoplastic composites.

- The vacuum infusion process is commonly applied to the production of wind turbine blades and, consequently, does not require the introduction of entirely new processes and technologies.

- The possibility of significantly reducing costs [9].

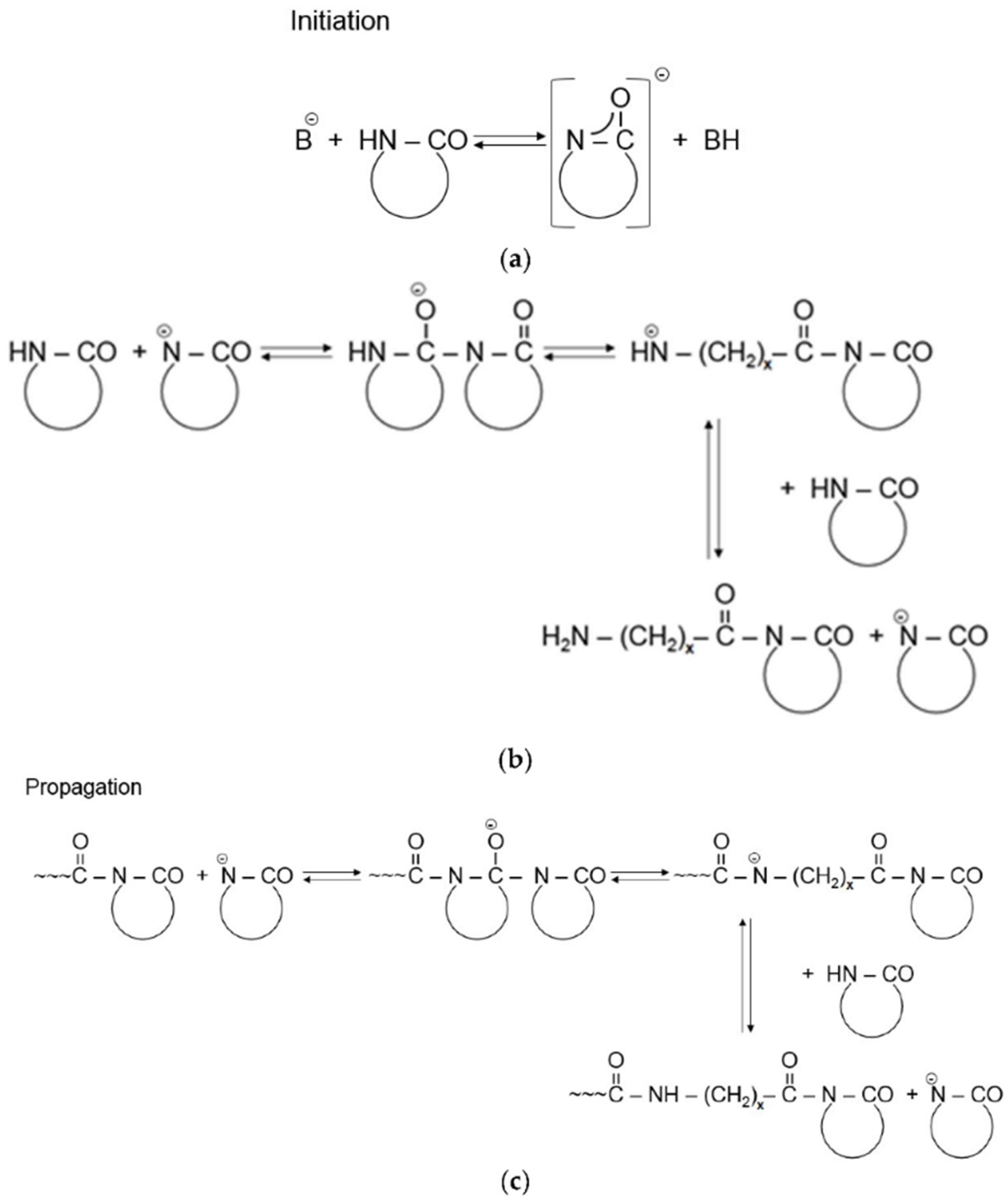

2. Anionic Polymerization of PA-6 from the Epsilon-Caprolactam Monomer

3. In Situ Polymerization

3.1. Casting

3.2. Centrifugal and Rotational Reactive Molding

3.3. Reactive Extrusion

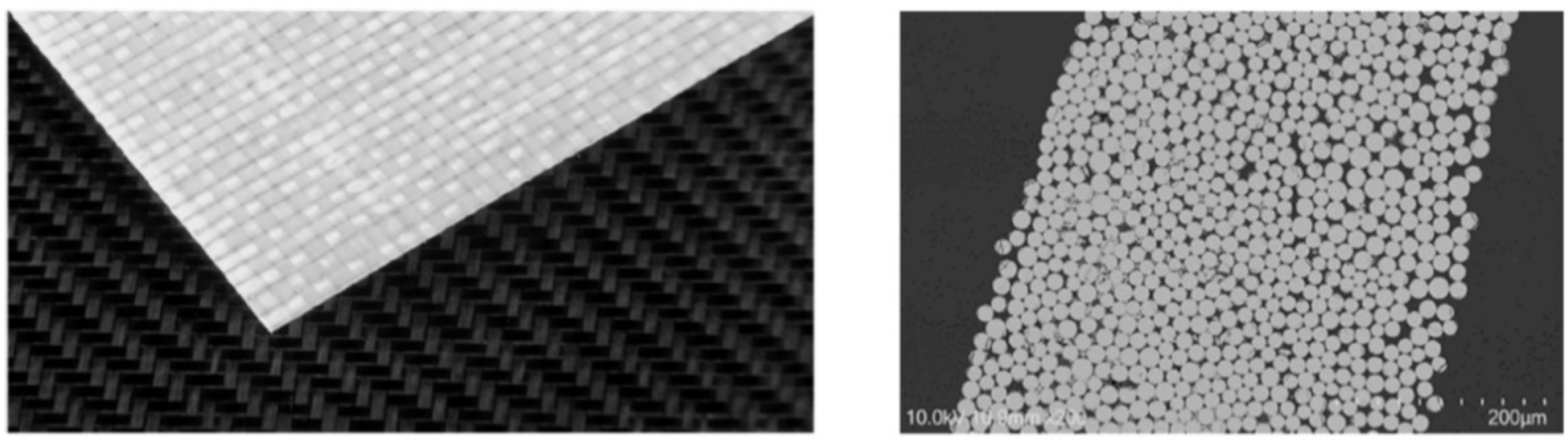

4. In Situ Polymerization for Composites

4.1. Reactive Injection Pultrusion

4.2. Infusion Techniques

4.2.1. Structural Reaction Injection Molding (SRIM)

Injection Molded Thermoplastic Composites

4.2.2. Resin Film Infusion (RFI)

4.2.3. Vacuum Infusion

4.3. Thermoplastic Resin Transfer Molding (T-RTM)

5. Vacuum Infusion Molding

- -

- The rate of polymerization increases with increasing temperature; this true for both thermoplastic and thermoset resins. When processing reactive thermoplastics of a semi-crystalline nature, however, it must be borne in mind that crystallization is adversely affected by temperature [10].

- -

- Some reactive thermoplastic materials, such as PA-6, PA-12, and PBT, have a melt viscosity which is an order of magnitude lower than common thermosetting resins. Consequently, the capillary forces that occur during the impregnation of the fiber preform are significant and constitute a potential source of voids and runner formation [49,56].

- -

- The performance of composites is not only determined by the fibers and the matrix, but also by the fiber–matrix interphase. To improve this bond, glass fibers, for example, are usually coated with silane coupling agents: bifunctional compounds with the ability to bond both with the fibers and with a polymeric matrix of choice. An incompatible coupling agent results in weak interphase or even prevents the polymerization of reactive resins. Coupling agents have been developed for several thermosetting composite resins and for thermoplastic composites produced by melt processing. Specific coupling agents for reactive processing of thermoplastic composites have not been developed yet but have recently become a topic of interest [1,84].

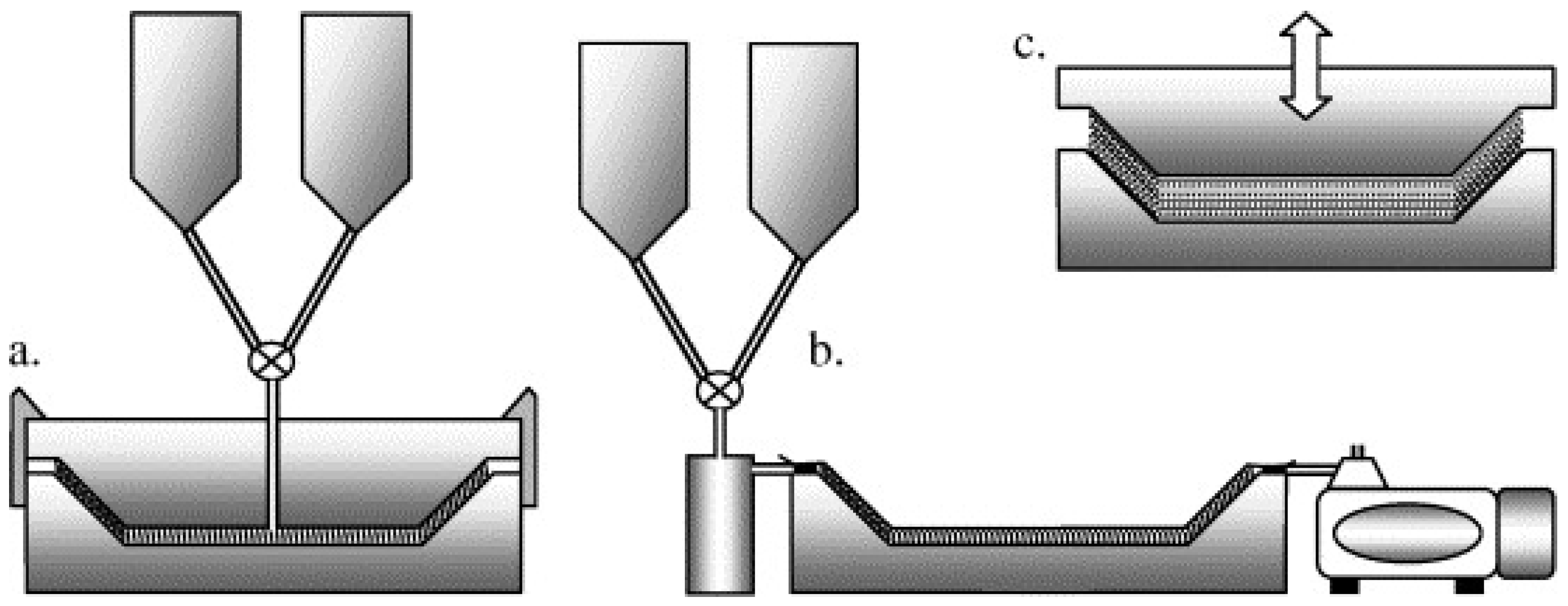

5.1. Examples of Vacuum Infusion Systems

5.2. Analysis of the Operating Conditions of the Process

5.2.1. Effects of the Polymerization Temperature on the Properties of APA-6

5.2.2. Effect of the Polymerization Temperature on the Molar Mass

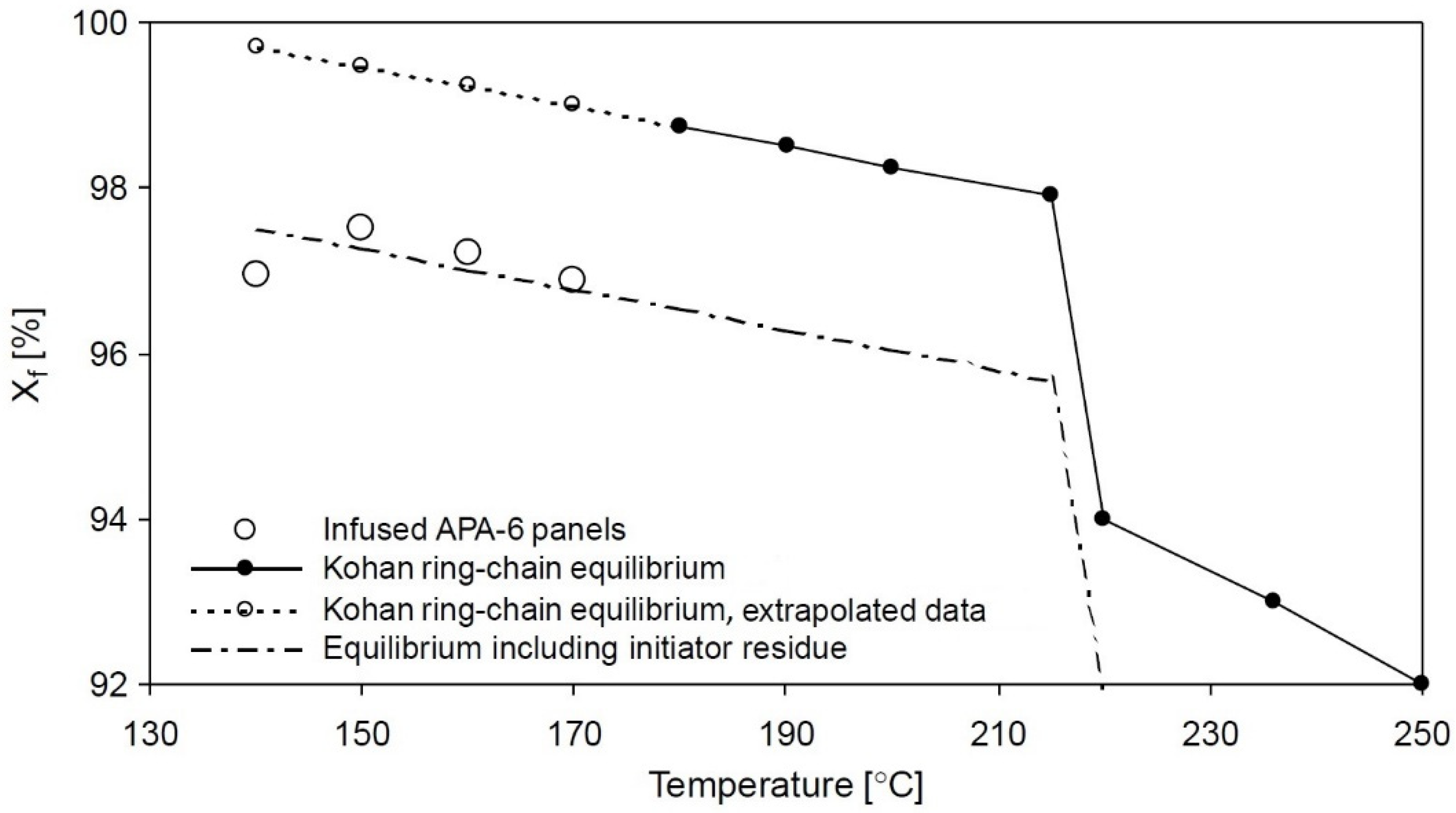

5.2.3. Effect of the Polymerization Temperature on the Degree of Conversion

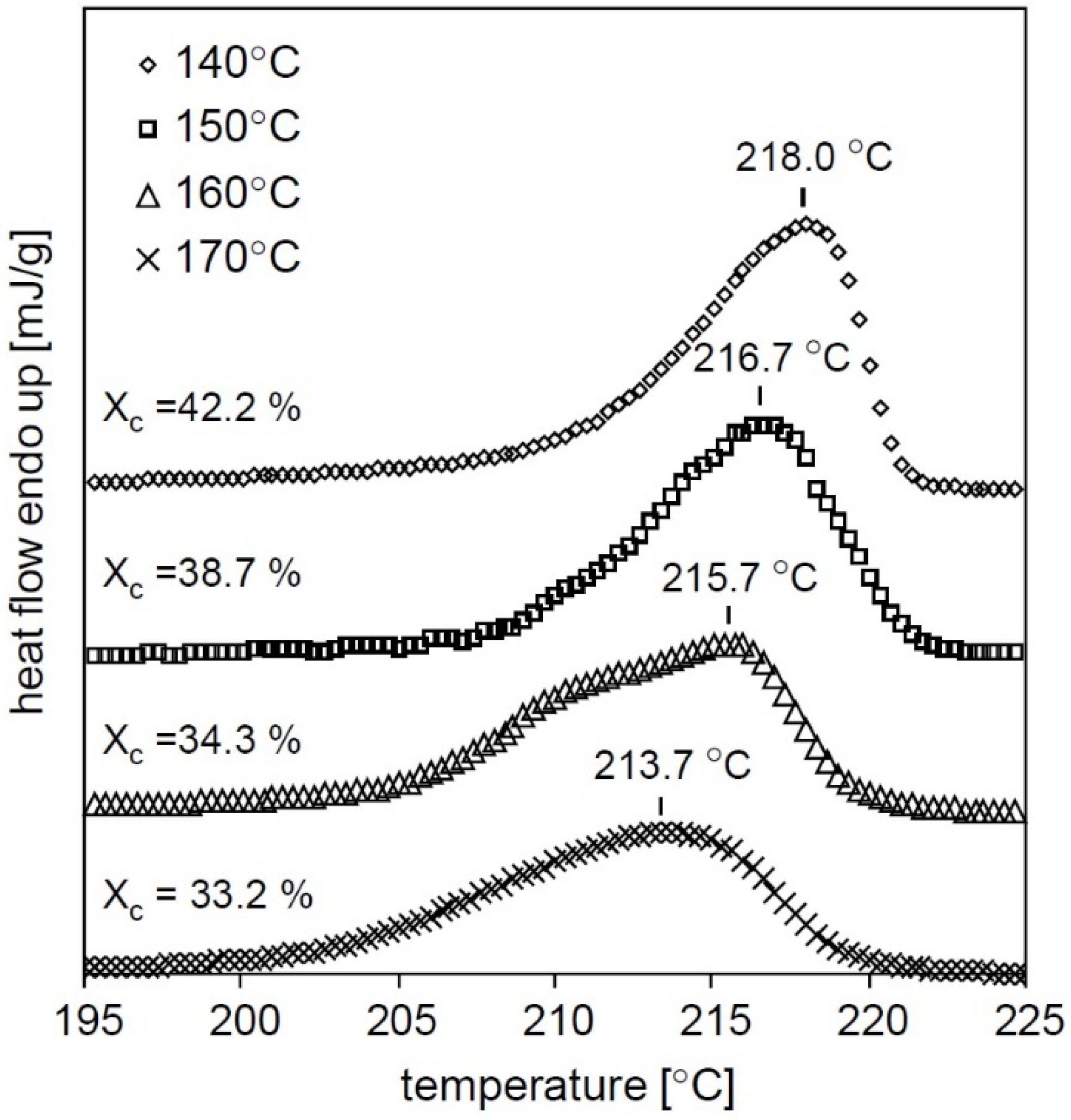

5.2.4. Effect of the Polymerization Temperature on Crystallinity

5.2.5. Effect of the Polymerization Temperature on the Polymer Melting Point

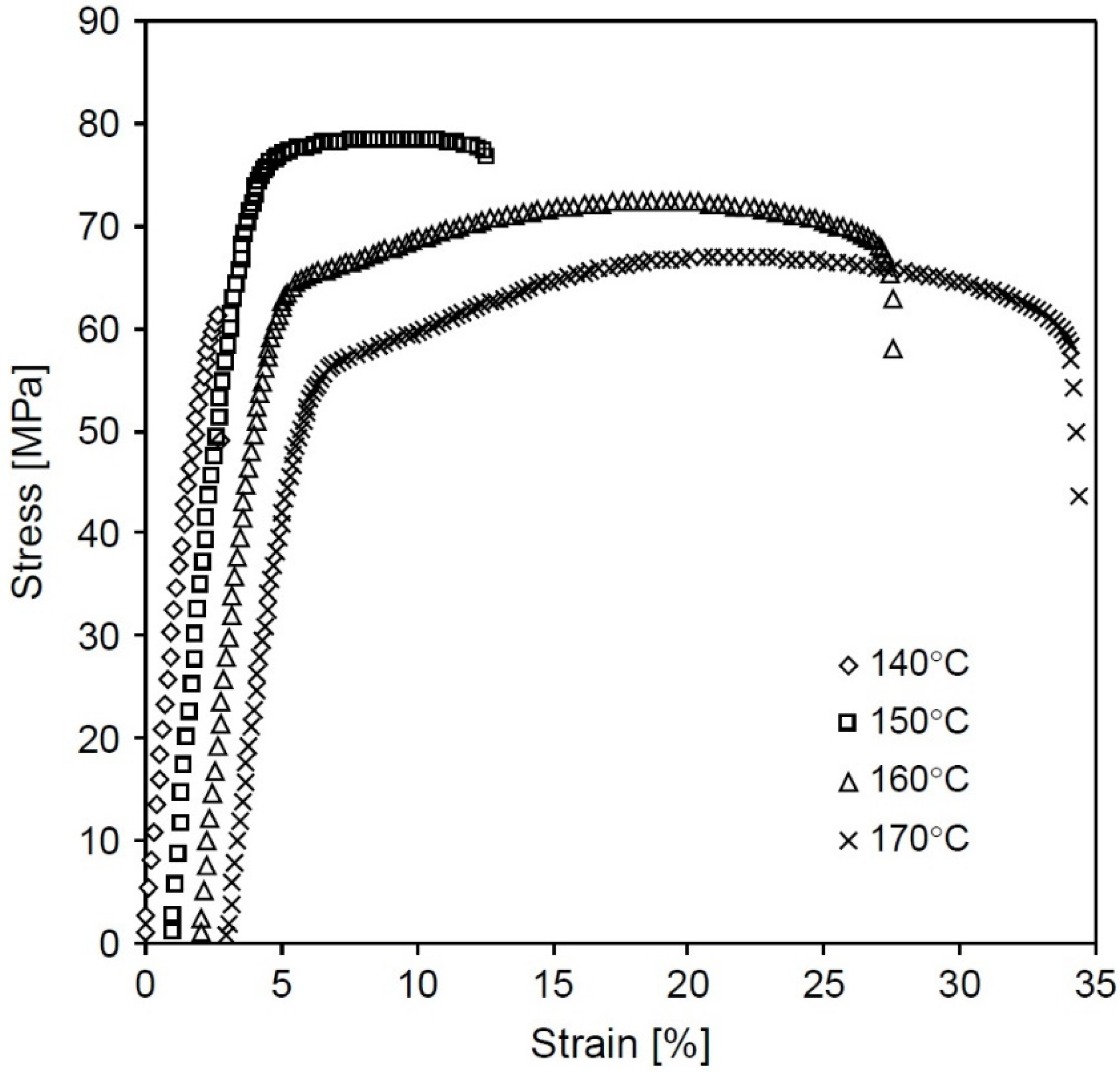

5.2.6. Effect of the Polymerization Temperature on the Tensile Properties

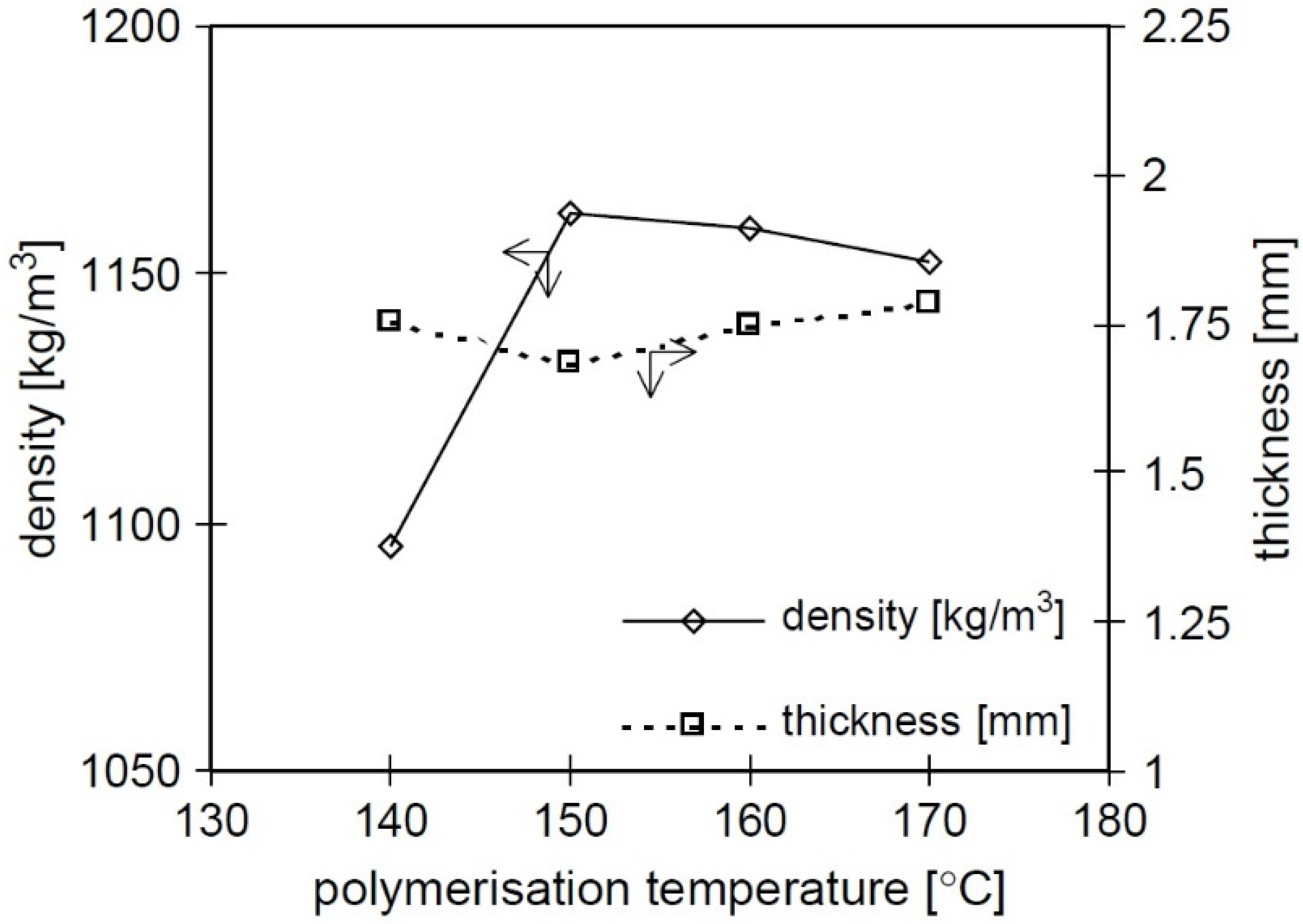

5.2.7. Effect of the Polymerization Temperature on the Polymer Density and Void Content

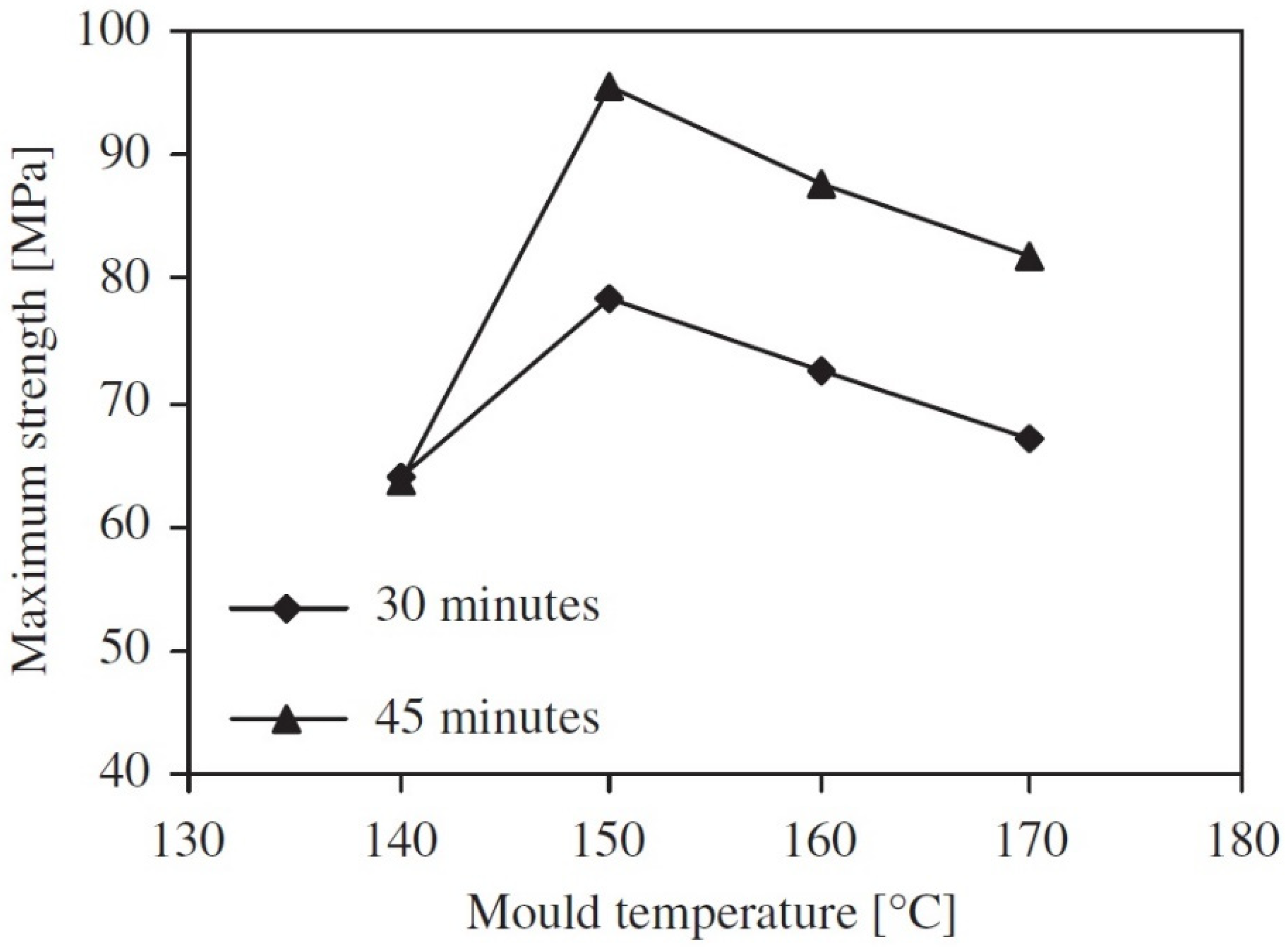

5.2.8. Effect of Demolding Time on Mechanical Properties

5.2.9. Thermal Interaction between Fiber and Matrix

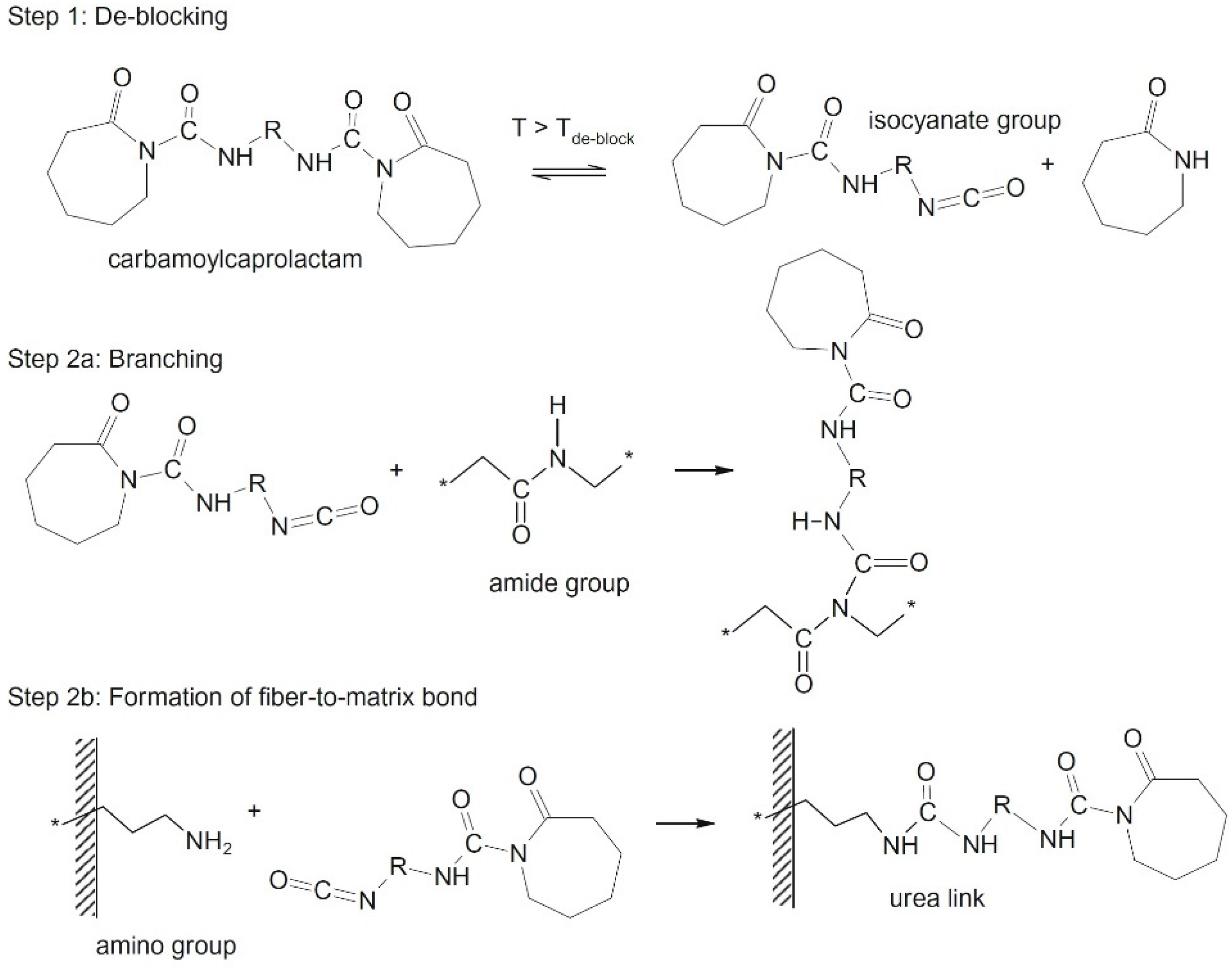

5.2.10. Interaction at the Interface between Fiber and Matrix

5.2.11. Effect of the Polymerization Temperature on the Properties of the Composite

5.3. Examples of Fiber-Reinforced Thermoplastic Composites Currently Available Commercially

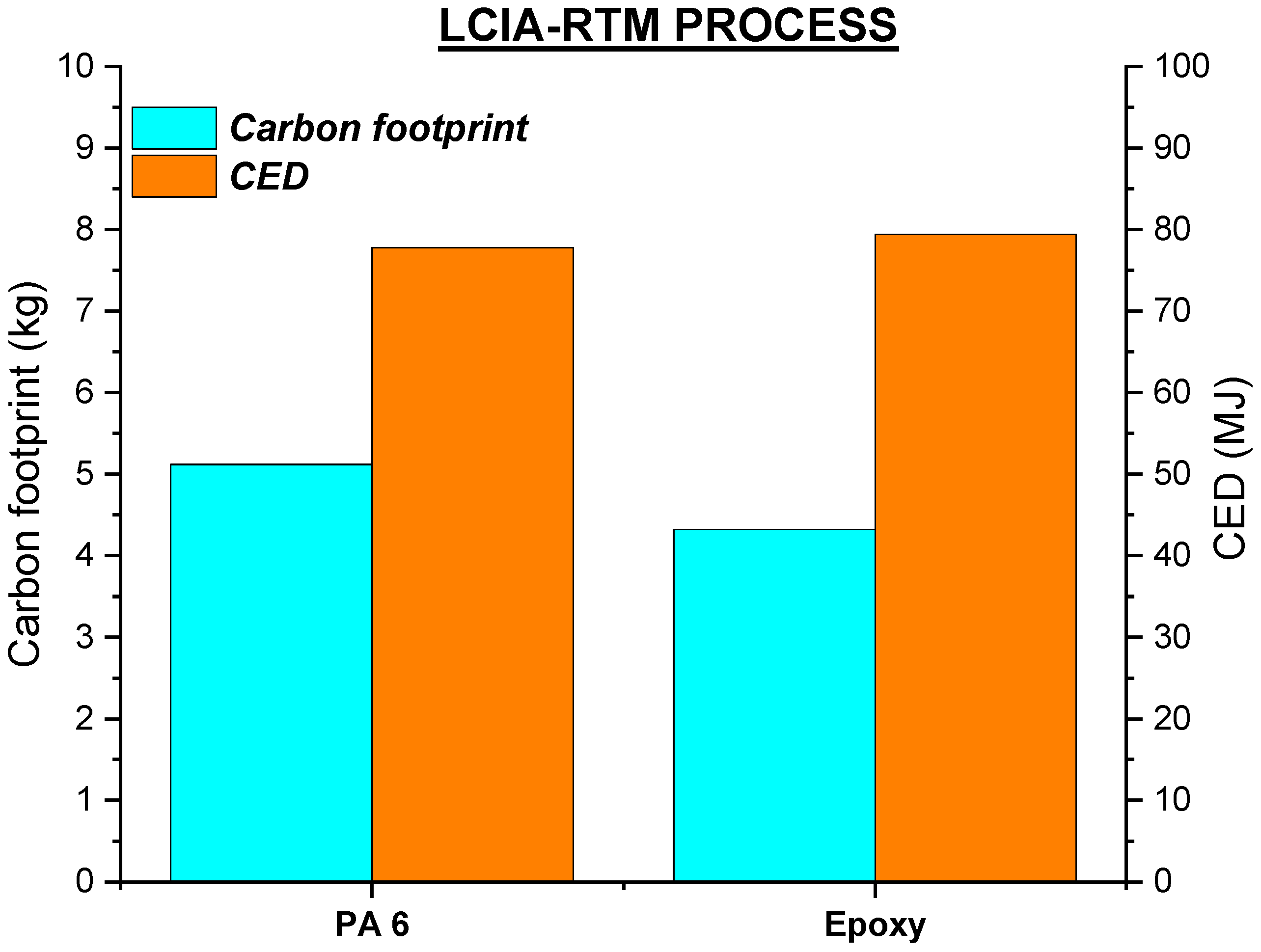

6. Environmental Impact

6.1. Life-Cycle Assessment

6.1.1. Goal and Scope

6.1.2. Inventory

6.1.3. Life Cycle Impact Assessment (LCIA)

- Greenhouse Gas Protocol V1.01/CO2 eq (kg);

- Cumulative Energy Demand V1.09/CED (MJ).

6.2. Limitation

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Laura, D.M.; Keskkula, H.; Barlow, J.W.; Paul, D.R. Effect of glass fiber surface chemistry on the mechanical properties of glass fiber reinforced, rubber-toughened nylon 6. Polymer 2002, 43, 4673–4687. [Google Scholar] [CrossRef]

- Seo, J.; Kim, D.Y.; Kim, D.C.; Park, H.W. Recent Developments and Challenges on Machining of Carbon Fiber Reinforced Polymer Composite Laminates. Int. J. Precis. Eng. Manuf. 2021, 22, 2027–2044. [Google Scholar] [CrossRef]

- Grujicic, M.; Sellappan, V.; Omar, M.A.; Seyr, N.; Obieglo, A.; Erdmann, M.; Holzleitner, J. An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components. J. Mater. Process. Technol. 2008, 197, 363–373. [Google Scholar] [CrossRef]

- Kazan, H.; Farahani, S.; Zheng, T.; Pilla, S. Experimental analysis on the bonding conditions of thermoset-thermoplastic composite parts manufactured by the hybrid single shot method. J. Compos. Mater. 2022, 56, 57–68. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber. J. Clean. Prod. 2022, 333, 130013. [Google Scholar] [CrossRef]

- Sambucci, M.; Valente, M.; Sibai, A.; Marini, D.; Quitadamo, A.; Musacchi, E. Rubber-Cement Composites for Additive Manufacturing: Physical, Mechanical and Thermo-Acoustic Characterization; Springer International Publishing: Cham, Switzerland, 2020; Volume 28. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Bersee, H.E.N.; Jager, W.F.; Picken, S.J. Optimisation of Anionic Polyamide-6 for Vacuum Infusion of Thermoplastic Composites: Choice of Activator and Initiator. Composites Part A: Applied Science and Manufacturing; Elsevier Ltd.: Amsterdam, The Netherlands, 2006; Volume 37, pp. 949–956. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Lindstedt, S.; Vlasveld, D.P.N.; Bersee, H.E.N.; Beukers, A. Reactive processing of anionic polyamide-6 for application in fiber composites: A comparitive study with melt processed polyamides and nanocomposites. Polym. Test. 2006, 25, 873–887. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Joncas, S.; Bersee, H.E.N.; (de Technische Universiteit Delft, Delft, The Netherlands). Personal Communication, 2012.

- Van Rijswijk, K.; Bersee, H.E.N.; Beukers, A.; Picken, S.J.; van Geenen, A.A. Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic composites: Influence of polymerisation temperature on matrix properties. Polym. Test. 2006, 25, 392–404. [Google Scholar] [CrossRef]

- Godara, S.S.; Yadav, A.; Goswami, B.; Rana, R.S. Review on history and characterization of polymer composite materials. Mater. Today Proc. 2021, 44, 2674–2677. [Google Scholar] [CrossRef]

- Krištofiè, M.; Marcinèin, A.; Ujhelyiová, A. The DSC study of PA 6, Polyamides and copolyamides. J. Therm. Anal. Calorim. 2000, 60, 357–369. [Google Scholar] [CrossRef]

- Lin, T.A.; Lin, J.H.; Bao, L. A study of reusability assessment and thermal behaviors for thermoplastic composite materials after melting process: Polypropylene/thermoplastic polyurethane blends. J. Clean. Prod. 2021, 279, 123473. [Google Scholar] [CrossRef]

- Babeau, A.; Comas-Cardona, S.; Binetruy, C.; Orange, G. Modeling of heat transfer and unsaturated flow in woven fiber reinforcements during direct injection-pultrusion process of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2015, 77, 310–318. [Google Scholar] [CrossRef] [Green Version]

- Ibeh, C.C. Nylon (Polyamide) Family. In Thermoplastic Materials: Properties, Manufacturing Methods, and Applications; CRC Press: Boca Raton, FL, USA, 2011; pp. 405–422. [Google Scholar]

- Udipi, K.; Davtkf, R.S.; Kruse, R.L.; Stebbins, L.R. Polyamides from Iactams via anionic ring-opening polymerization: I. Chemistry and some recent findings*. Polymer 1997, 38, 927–938. [Google Scholar] [CrossRef]

- Kubisa, P.; Penczek, S. Cationic Activated Monomer Polymerization of Heterocyclic Monomers. Prog. Polym. Sci. 1999, 24, 1409–1437. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Karger-Kocsis, J. Polymers and related composites via anionic ring-opening polymerization of lactams: Recent developments and future trends. Polymers 2018, 10, 357. [Google Scholar] [CrossRef] [Green Version]

- Mougin, N.; Veith, C.A.; Cohen, R.E.; Gnanou, Y. Anionic Polymerization of Lactams in the Presence of Metal Dialkoxyaluminum Hydrides: Presentation of a New Mechanism. Macromolecules 2004, 25, 2004–2016. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Kovács, J.G. Review of thermoplastic resin transfer molding: Process modeling and simulation. Polymers 2019, 11, 1555. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Liu, S.; Yu, F.; Zhang, J.; Xing, W.; Yu, S. High-yield and high-efficiency conversion of cyclohexanone oxime to ε-caprolactam in a green and facile reaction process over deep eutectic solvents. Chem. Eng. Sci. 2022, 253, 117519. [Google Scholar] [CrossRef]

- Zong, B.; Sun, B.; Cheng, S.; Mu, X.; Yang, K.; Zhao, J.; Zhang, X.; Wu, W. Green Production Technology of the Monomer of Nylon-6: Caprolactam. Engineering 2017, 3, 379–384. [Google Scholar] [CrossRef]

- Rwei, S.P.; Ranganathan, P.; Lee, Y.H. Synthesis and characterization of low melting point PA6 copolyamides from ε-caprolactam with bio-based polyamide salt. J. Mol. Struct. 2019, 1186, 285–292. [Google Scholar] [CrossRef]

- Parton, H.; Verpoest, I. In situ polymerization of thermoplastic composites based on cyclic oligomers. Polym. Compos. 2005, 26, 60–65. [Google Scholar] [CrossRef]

- Nagy, J.; Reith, L.; Fischlschweiger, M.; Steinbichler, G. Modeling the influence of flow phenomena on the polymerization of ε-Caprolactam. Chem. Eng. Sci. 2014, 111, 85–93. [Google Scholar] [CrossRef]

- Teuwen, J.J.E.; van Geenen, A.A.; Bersee, H.E.N. Temperature evolution during processing of thick-walled anionic polyamide 6 composites: Experiment and simulation. Macromol. Mater. Eng. 2013, 298, 722–729. [Google Scholar] [CrossRef]

- Teuwen, J.J.E.; van Geenen, A.A.; Bersee, H.E.N. Novel reaction kinetic model for anionic polyamide-6. Macromol. Mater. Eng. 2013, 298, 163–173. [Google Scholar] [CrossRef]

- Mateva, R.; Ishtinakova, O.; Nikolov, R.N.; Djambova, C.H. Kinetics of Polymerization of e-Caprolactam in the Presence of Inorganic Dispersed Additives. Eur. Polym. J. 2018, 34, 1061–1067. [Google Scholar] [CrossRef]

- Simon, S.L.; Gillham, J.K. Thermosetting cure diagrams: Calculation and application. J. Appl. Polym. Sci. 1994, 53, 709–727. [Google Scholar] [CrossRef]

- Zahorovsky, S.; Drabek, J. Casting of Plastics Containers from Polyamide-6 by Way of Activated Anionic Polymerization of 6-Caprolactam. Plast. Kauc. 1976, 13, 232–234. [Google Scholar]

- Li, C.; Xiang, M.; Zhao, X.; Ye, L. In Situ Synthesis of Monomer Casting Nylon-6/Graphene-Polysiloxane Nanocomposites: Intercalation Structure, Synergistic Reinforcing, and Friction-Reducing Effect. ACS Appl. Mater. Interfaces 2017, 9, 33176–33190. [Google Scholar] [CrossRef]

- Ranade, R.A.; Ding, J.; Wunder, S.L.; Baran, G.R. UHMWPE as interface toughening agent in glass particle filled composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2017–2028. [Google Scholar] [CrossRef]

- Chen, J.; Volinsky, A.A.; He, W. Synthesis and characterization of MC nylon/modified yttrium hydroxide nanocomposites. J. Appl. Polym. Sci. 2016, 133, 43356. [Google Scholar] [CrossRef]

- Xu, S.; Ye, L. Monomer casting nylon-6-b-polyether amine copolymers: Synthesis and properties. Compos. Part B Eng. 2015, 79, 170–181. [Google Scholar] [CrossRef]

- Rusu, G.; Ueda, K.; Rusu, E.; Rusu, M. Polyamides from Lactams by Centrifugal Molding via Anionic Ring-Opening Polymerization. Polymer 2001, 42, 5669–5678. [Google Scholar] [CrossRef]

- Barhoumi, N.; Maazouz, A.; Jaziri, M.; Abdelhedi, R. Polyamide from lactams by reactive rotational molding via anionic ring-opening polymerization: Optimization of processing parameters. Express Polym. Lett. 2013, 7, 76–87. [Google Scholar] [CrossRef]

- Harkin-Jones, E.; Crawford, R.J. Mechanical properties of rotationally molded nyrim. Polym. Eng. Sci. 1996, 36, 615–625. [Google Scholar] [CrossRef]

- Barhoumi, N.; Lamnawar, K.; Maazouz, A. Reactive rotational molding process of PP PA6 bilayer systems experimental investigations. Int. J. Mater. Form. 2008, 1, 671–674. [Google Scholar] [CrossRef]

- Michaeli, W.; Greefenstein, A.; Berghaus, U. Twin-Screw extruders for reactive extrusion. Polym. Eng. Sci. 1995, 35, 1485–1504. [Google Scholar] [CrossRef]

- Wu, L.; Jia, Y.; Sun, S.; Zhang, G.; Zhao, G.; An, L. Numerical simulation of reactive extrusion processes of PA6. J. Appl. Polym. Sci. 2007, 103, 2331–2336. [Google Scholar] [CrossRef]

- Kim, I.; White, J.L. Continuous polymerization of ω-lauryl lactam in an intermeshing corotating twin-screw extruder. J. Appl. Polym. Sci. 2005, 97, 1605–1620. [Google Scholar] [CrossRef]

- Schmidhuber, S.; Fries, E.; Zimmermann, P. It couldn’t be more hybrid. Thermo-plastic-matrix rtm on the roof frame of the roading roadter. Kunstst. Int. 2017, 1, 1–2. [Google Scholar]

- Chen, K.; Jia, M.; Sun, H.; Xue, P. Thermoplastic reaction injection pultrusion for continuous glass fiber-reinforced polyamide-6 composites. Materials 2019, 12, 463. [Google Scholar] [CrossRef] [Green Version]

- Van Rijswijk, K.; Teuwen, J.J.E.; Bersee, H.E.N.; Beukers, A. Textile fiber-reinforced anionic polyamide-6 composites. Part I: The vacuum infusion process. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1–10. [Google Scholar] [CrossRef]

- Novo, P.J.; Silva, J.F.; Nunes, J.P.; Marques, A.T. Pultrusion of fibre reinforced thermoplastic pre-impregnated materials. Compos. Part B Eng. 2016, 89, 328–339. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.F.; Silva, J.F.; Nunes, J.P.; Bernardo, C.A.; Marques, A.T. New Powder Coating Equipment to Produce Continuous Fibre Thermoplastic Matrix Towpregs. Mater. Sci. Fórum 2008, 587, 246–250. [Google Scholar] [CrossRef]

- Angelov, I.; Wiedmer, S.; Evstatiev, M.; Friedrich, K.; Mennig, G. Pultrusion of a flax/polypropylene yarn. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1431–1438. [Google Scholar] [CrossRef]

- Linganiso, L.Z.; Bezerra, R.; Bhat, S.; John, M.; Braeuning, R.; Anandjiwala, R.D. Pultrusion of flax/poly(lactic acid) commingled yarns and nonwoven fabrics. J. Thermoplast. Compos. Mater. 2014, 27, 1553–1572. [Google Scholar] [CrossRef]

- Luisier, A.; Bourban, P.E.; Månson, J.A.E. Reaction injection pultrusion of PA12 composites: Process and modelling. Compos. Part A Appl. Sci. Manuf. 2003, 34, 583–595. [Google Scholar] [CrossRef]

- Epple, S.; Bonten, C. Production of continuous fiber thermoplastic composites by in-situ pultrusion. AIP Conf. Proc. 2014, 454, 454–457. [Google Scholar] [CrossRef] [Green Version]

- Te Nijenhuis, K.; Addink, R.; van der Vegt, A.K. A Study on Composites of Nylon-6 with Hollow Glass Microspheres. Polym. Bull. 1989, 21, 467–474. [Google Scholar] [CrossRef]

- Gabbert, J.D.; Hedrick, R.M.; Tierney, P.A. Reinforced Polymer Compositions; Monsanto Company: St. Louis, MO, USA, 1971. [Google Scholar]

- Williams, G.T. Reinforced and foamed nyrim—An overview. Eng. Plast. 1992, 1, 48–52. [Google Scholar]

- Van Rijswijk, K.; Bersee, H.E.N. Reactive processing of textile fiber-reinforced thermoplastic composites—An overview. Compos. Part A Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Zingraff, L.; Bourban, P.E.; Wakeman, M.D.; Kohler, M.; Manson, J.A.E. Reactive processing and forming of polyamide 12 thermoplastic composites. In Proceedings of the 23rd SAMPE Europe International Conference, Paris, France, 9–11 April 2002. [Google Scholar]

- Michaud, V.; Zingraff, L.; Verrey, J.; Bourban, P.E.; Manson, J.A.E. Resin transfer molding of anionically polymerized polyamide 12. In Proceedings of the 7th International Conference on Flow Processes in Composite Materials (FPCM-7), Newark, DE, USA, 7–9 July 2004. [Google Scholar]

- Zingraff, L.; Bourban, P.E.; Michaud, V.; Manson, J.A.E. Liquid composite moulding of anionically polymerised polyamide 12. In Proceedings of the 14th International Conference on Composite Materials (ICCM-14), San Diego, CA, USA, 14–18 July 2003. [Google Scholar]

- Verrey, J.; Michaud, V.; Manson, J.A.E. Complex Parts with Thermoplastic RTM Techniques. In Proceedings of the 24th International SAMPE Europe Conference, Paris, France, 1–3 April 2003. [Google Scholar]

- Mairtin, P.; McDonnel, P.; Connor, M.T.; Eder, R.; O´Bradaigh, C.M. Process investigation of a liquid PA-12/carbon fibre moulding system. Compos. Part A Appl. Sci. Manuf. 2001, 32, 915–923. [Google Scholar] [CrossRef]

- Zingraff, L.; Michaud, V.; Bourban, P.E.; Manson, J.A. Resin transfer moulding of anionically polymerised polyamide 12. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1675–1686. [Google Scholar] [CrossRef]

- Rosso, P.; Friedrich, K.; Wollny, A.; Mulhaupt, R. A novel polyamide 12 polymerization system and its use for a LCM-process to produce CFRP. J. Thermoplast. Compos. Mater. 2005, 18, 77–90. [Google Scholar] [CrossRef]

- Parton, H.; Baets, J.; Lipnik, P.; Devaux, J.; Verpoest, I. Liquid moulding of textile reinforced thermoplastics. In Proceedings of the 11th European Conference on Composite Materials (ECCM-11), Rhodos, Greece, 31 May–3 June 2004. [Google Scholar]

- Parton, H.; Verpoest, I. Reactive processing of textile reinforced thermoplastics. In Proceedings of the 14th International Conference on Composite Materials (ICCM-14), San Diego, CA, USA, 14–18 July 2003. [Google Scholar]

- Parton, H.; Verpoest, I. Thermoplastic liquid composite molding: Production and characterization of composites based on cyclic oligomers. In Proceedings of the 7th International Conference on Flow Processes in Composite Materials (FPCM-7), Newark, NJ, USA, 7–9 July 2004. [Google Scholar]

- Verrey, J.; Michaud, V.; Manson, J.A.E. Capillary effects in liquid composite moulding with non-crimp fabrics. In Proceedings of the 14th International Conference on Composite Materials (ICCM-14), San Diego, CA, USA, 14–18 July 2003. [Google Scholar]

- Weyrauch, F.; Stadtfeld, H.C.; Mitschang, P. Simulation and control of the LCM-process with future resin systems. In Proceedings of the 7th International Conference on Flow Processes in Composite Materials (FPCM-7), Newark, DE, USA, 7–9 July 2004. [Google Scholar]

- Otaigbe, J.U.; Harland, W.G. Studies in the properties of nylon 6-glass fiber composites. J. Appl. Polym. Sci. 1988, 36, 165–175. [Google Scholar] [CrossRef]

- Potter, K. Resin Transfer Molding; Chapman & Hall: London, UK, 1997. [Google Scholar]

- Zhong, Y.; Liu, P.; Pei, Q.; Sorkin, V.; Louis Commillus, A.; Su, Z.; Guo, T.; Thitsartarn, W.; Lin, T.; He, C.; et al. Elastic properties of injection molded short glass fiber reinforced thermoplastic composites. Compos. Struct. 2020, 254, 112850. [Google Scholar] [CrossRef]

- Zainudin, E.S.; Sapuan, S.M.; Sulaiman, S. Fiber Orientation of Short Fiber Reinforced Injection Molded Thermoplastic Composites: A Review. J. Inject. Molding Technol. 2002, 6, 1–10. [Google Scholar]

- Fu, S.Y.; Lauke, B.; Mader, E.; Hu, X.; Yue, C.Y. Fracture Resistance of Short-Glass-Fiber-Reinforced and Short-Carbon-Fiber-Reinforced Polypropylene under Charpy Impact Load and Its Dependence on Processing. J. Mater. Process. Technol. 1999, 89, 501–507. [Google Scholar] [CrossRef]

- Coll, S.; Murtagh, A.; O’Bradaigh, C. Resin film infusion of cyclic PBT composites consolidation analysis. In Proceedings of the 7th International Conference on Flow Processes in Composite Materials (FPCM-7), Newark, DE, USA, 7–9 July 2004. [Google Scholar]

- Pillay, S.; Vaidya, U.K.; Janowski, G.M. Liquid molding of carbon fabric-reinforced nylon matrix composite laminates. J. Thermoplast. Compos. Mater. 2005, 18, 509–527. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Koppes, K.; Bersee, H.E.N.; Beukers, A. Processing window for vacuum infusion of fiber-rinforced anionic polyamide-6. In Proceedings of the 7th International Conference of Flow Processes in Composite Materials (FPCM-7), Newark, DE, USA, 7–9 July 2004. [Google Scholar]

- Van Rijswijk, K.; Vlasveld, D.P.N.; Bersee, H.E.N.; Picken, S.J. Vacuum injection of anionic polyamide 6. In Proceedings of the 4th International Conference on Composite Structures and Technology (ICCST-4), Durban, South Africa, 21–23 January 2003. [Google Scholar]

- Van Rijswijk, K.; Vlasveld, D.P.N.; van Rhijn, P.; Bersee, H.E.N.; Beukers, A.; Picken, S.J. Process considerations for liquid molding of composites based on anionic polyamide 6. In Proceedings of the 14th International Conference on Composite Materials (ICCM-14), San Diego, CA, USA, 14–18 July 2003. [Google Scholar]

- Van Rijswijk, K.; Joncas, S.; Bersee, H.E.N.; Bergsma, O.K.; Beukers, A. Sustainable vacuum-infused thermoplastic composites for MW-size wind turbine blades—Preliminary design and manufacturing issues. J. Sol. Energy Eng. Trans. ASME 2005, 127, 570–580. [Google Scholar] [CrossRef]

- Kotel’nikov, V.A.; Surin, N.N.; Cherepanov, S.G.; Persits, I.E.; Danilevskaya, L.B.; Konova, I.O.; Gavrilenko, V.V.; Chekulaeva, L.A. Synthesis of cross-linked nylon RIM block copolyamides. Polym. Sci. 1995, 37, 1198–1205. [Google Scholar]

- Toldy, A. Recyclable-by-Design Thermoset Polymers and Composites. Express Polym. Lett. 2012, 15, 1113. [Google Scholar] [CrossRef]

- Kovács, Z.; Pomázi, Á.; Toldy, A. The flame retardancy of polyamide 6—Prepared by in situ polymerisation of ε-caprolactam—For T-RTM applications. Polym. Degrad. Stab. 2022, 195, 109797. [Google Scholar] [CrossRef]

- Pal, K. Új Technológiák Könnyűszerkezetes Autóelemek Gyártására. Mua. Feld. 2014, 6. Available online: https://quattroplast.hu/muanyagipariszemle/2014/06/uj-technologiak-konnyuszerkezetes-autoelemek-gyartasara-02.pdf (accessed on 24 April 2022).

- L. Brügge-Mann GmbH & Co. KG. Bruggemann, AP-NYLON® Additives. Available online: https://www.brueggemann.com/en/ap-nylon-additives (accessed on 31 March 2022).

- Van Rijswijk, K. Thermoplastic Composite Wind Turbine Blades: Vacuum Infusion Technology for Anionic Polyamide-6 Composites; Delft University of Technology: Delft, The Netherlands, 2007. [Google Scholar]

- Otaigbe, J.U. Effect of coupling agent and absorbed moisture on the tensile properties of a thermoplastic RRIM composite. J. Appl. Polym. Sci. 1992, 45, 1213–1221. [Google Scholar] [CrossRef]

- Ben, G.; Hirabayashi, A.; Sakata, K.; Nakamura, K.; Hirayama, N. Evaluation of new GFRTP and CFRTP using epsilon caprolactam as matrix fabricated with VaRTM. Sci. Eng. Compos. Mater. 2015, 22, 633–641. [Google Scholar] [CrossRef]

- Yan, C.; Li, H.; Zhang, X.; Zhu, Y.; Fan, X.; Yu, L. Preparation and properties of continuous glass fiber reinforced anionic polyamide-6 thermoplastic composites. Mater. Des. 2013, 46, 688–695. [Google Scholar] [CrossRef]

- Seemann, W. Plastic Transfer Molding Techniques for the Production of Fiber. U.S. Patent 4902215, 20 February 1989. [Google Scholar]

- Hoa, S.V. Principles of the Manufacturing of Composite Materials, 3rd ed.; DEStech Publications Inc.: Lancaster, PA, USA, 2009. [Google Scholar]

- Wicks, Z.W., Jr. Blocked Isocyanates. Prog. Org. Coat. 1975, 3, 73–99. [Google Scholar] [CrossRef]

- Stavrov, D.; Bersee, H.E.N. Resistance welding of thermoplastic composites-an overview. Compos. Part A Appl. Sci. Manuf. 2005, 36, 39–54. [Google Scholar] [CrossRef]

- Mateva, R.; Delev, O.; Kaschcieva, E. Structure of Poly(ε-caprolactam) Obtained in Anionic Bulk Polymerization. J. Appl. Polym. Sci. 1995, 58, 2333–2343. [Google Scholar] [CrossRef]

- Mateva, R.; Petrov, P.; Rousseva, S.; Dimitrov, R.; Zolova, G. On the structure of poly-caprolactams, obtained with bifunctional N-carbamyl derivatives of lactams. Eur. Polym. J. 2000, 36, 813–821. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; van Geenen, A.A.; Bersee, H.E.N. Textile fiber-reinforced anionic polyamide-6 composites. Part II: Investigation on interfacial bond formation by short beam shear test. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1033–1043. [Google Scholar] [CrossRef]

- Hazell, J. Getting It Right from the Start Developing a Circular Economy for Novel Materials; Green Alliance: London, UK, 2017. [Google Scholar]

- Johns Manville. Available online: https://www.jm.com/en/our-company/ (accessed on 24 April 2022).

- Frischknecht, R.; Jolliet, O. Life Cycle Initiative Global Guidance on Environmental Life Cycle Impact Assessment Indicators; United Nations Environment Programme: Nairobi, Kenya, 2019; Volume 2. [Google Scholar]

- Sonnemann, G.; Vigon, B. Life Cycle Initiative Global Guidance Principles for Life Cycle Assessment Databases: A Basis for Greener Processes and Products; United Nations Environment Programme: Nairobi, Kenya, 2011. [Google Scholar]

- Scheepens, A.; van der Flier, A.; Romeo-Hall, A.; Veugen, R. EuCIA Eco Impact Calculator Background Report. EY CCaSS 2020. [Google Scholar]

- Weidema, P.B.; Vadenbo, C.O.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Wernet, G. Overview and Methodology Data Quality Guideline for the Ecoinvent Database Version 3; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2013. [Google Scholar]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability ILCD. Handbook: Framework and Requirements for LCIA Models and Indicators, 1st ed.; EUR 24586 EN; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar] [CrossRef]

- Plastic Europe. Plastic Europe 2022. Available online: https://plasticseurope.lca-data.com/ (accessed on 31 March 2022).

- Kazemi, M.; Faisal Kabir, S.; Fini, E.H. State of the art in recycling waste thermoplastics and thermosets and their applications in construction. Resour. Conserv. Recycl. 2021, 174, 105776. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Greco, S.; Tosto, C.; Cicala, G. LCA and LCC of a chemical recycling process of waste CF-thermoset composites for the production of novel CF-thermoplastic composites. Open loop and closed loop scenarios. J. Clean. Prod. 2021, 304, 127158. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Blanco, I.; Banatao, D.R.; Pastine, S.J.; Björklund, A.; Cicala, G. Innovative chemical process for recycling thermosets cured with recyclamines® by converting bio-epoxy composites in reusable thermoplastic-an LCA study. Materials 2018, 11, 353. [Google Scholar] [CrossRef] [Green Version]

| Rotational Molding Technique of PA6 | Classical | Reactive |

|---|---|---|

| Temperature | T~240 °C | T = 150 °C |

| Cycle time | t > 40 min | t = 15–20 min |

| Degree of crystallinity (%) | 28 | 49 |

| Intrinsic viscosity (dL/g) | 1.07 | 7 |

| Molecular weight (g/mol) | 30,778 | 182,594 |

| Tensile properties | ||

| Young’s modulus (MPa) | 750 | 1560 |

| Yield stress (MPa) | 62 | 80 |

| Elongation at break (%) | 32 | 64 |

| Polymerization Temperature (8C) | Young’s Modulus (GPa) | Yield Stress (MPa) | Yield Strain (%) | Maximum Stress (MPa) | Maximum Strain (%) | Strain at Break (%) |

|---|---|---|---|---|---|---|

| 140 | 3.7 | 64 | 2.7 | 64 | 2.7 | 2.7 |

| 150 | 3.8 | 76 | 3.5 | 78 | 7.5 | 11.5 |

| 160 | 3.2 | 64 | 3.4 | 73 | 17.0 | 25.2 |

| 170 | 2.7 | 56 | 3.7 | 67 | 19.4 | 31.0 |

| Material | Density (kg/m3) | Conductivity (J/(s m °C)) | Specific Heat (J/(kg °C)) | ΔHpol (J/g) | ΔHcryst (J/g) |

|---|---|---|---|---|---|

| Caprolactam | 950 | 0.14 | 2500 | – | – |

| Anionic polyamide-6 | 1130 | 0.2 | 2250 | 166 | 144 |

| Glass fiber | 2525 | 1 | 840 | – | – |

| Composite | 1760–1912 | 0.57–0.6 | 1670–1545 | 47 | 41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valente, M.; Rossitti, I.; Biblioteca, I.; Sambucci, M. Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review. J. Compos. Sci. 2022, 6, 132. https://doi.org/10.3390/jcs6050132

Valente M, Rossitti I, Biblioteca I, Sambucci M. Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review. Journal of Composites Science. 2022; 6(5):132. https://doi.org/10.3390/jcs6050132

Chicago/Turabian StyleValente, Marco, Ilaria Rossitti, Ilario Biblioteca, and Matteo Sambucci. 2022. "Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review" Journal of Composites Science 6, no. 5: 132. https://doi.org/10.3390/jcs6050132

APA StyleValente, M., Rossitti, I., Biblioteca, I., & Sambucci, M. (2022). Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review. Journal of Composites Science, 6(5), 132. https://doi.org/10.3390/jcs6050132