1. Introduction

This study focuses on using recycled materials as reinforcements in concrete. The waste products from manufacturing continue to have a detrimental effect on the environment. People are less incentivized to recycle isomorphous polymers compared to metals due to the low financial benefit, if any, and the cheap cost of landfill disposal. The United States alone generated 42.0 million metric tons of plastic waste in 2016, which shows how landfill disposal was more widely used for the recycling of plastics [

1].

Although numerous reinforcement methods for concrete already exist, such as the use of rebar and wire mesh [

2,

3,

4,

5,

6,

7], where the latter is more commonly used in residential driveways, this study explores the possibility of alternative options for the reinforcement of concrete using recycled materials, namely, chopped carbon fibers, plastic waste, rubber aggregates, and glass particles. The compressive strength, modulus, and strain energy absorption of the concrete with each of the abovementioned reinforcements are measured to evaluate the possibility of reducing the cost for residential usage while increasing sustainability.

Wire mesh is one of the most common types of reinforcement used. Adding a wire mesh increases the strength of the concrete, in addition to providing resistance against cracks caused by thermal stresses during temperature variations. However, in this study, alternative reinforcements to wire mesh are investigated. A study performed by Enrique del Castillo investigated the effects of adding plastic waste to lightweight concrete; 100% of the reinforcement was plastic waste with no other reinforcements [

8]. A volume fraction of 7.5% was used as the optimum content for the highest load-carrying capacity. Compression and bending tests were performed at one, seven, and twenty-eight days after curing, with the longer cure times providing increased strength. It is also important to note that increased strength can be directly attributed to the tensile strength of the reinforcements, not to the size of the specimens or the length-to-diameter ratio as concluded in a study by Lam and Tang [

9].

Rubber aggregates have been vastly used in concrete [

10,

11,

12,

13,

14,

15,

16,

17,

18]. Agampodi S.M. et al. studied the effects of rubber particles on the flexural behavior of reinforced concrete beams. In their study, they used rubber that was partially or fully made from crumbled up scrap tires, called Crumbled Rubber Concrete (CRC) [

19]. In their study, they used both varying concrete mixes and varying percentages of rubber reinforcements, ranging from 5.33% to 21.11%. Their results showed that CRCs increased the crack resistance of concrete. J. Wang et al. in their study investigated 10% and 15% rubber-reinforced concrete. Along with the rubber, polypropylene (PP) plastic with a volume fraction of 0.5% was also added [

12]. Compared to Mendis, Wang added PP since only a small percentage of rubber is recycled per year. Testing the mechanical and durability performances, they found that the energy absorption and toughness could be improved by adding rubber aggregates. Their results showed that the strength of the concrete was reduced with higher concentrations of rubber aggregates. This study also found that the specimen with rubber additives showed better post-crack behavior than the control concrete specimen. A consistent result from previous research shows that, while rubber might decrease the compressive strength, it increases the ductility of specimens prior to ultimate failure.

Glass particles are yet another waste product that has been studied as a method of reinforcement in concrete [

20,

21,

22,

23,

24,

25,

26,

27,

28]. Atoyebi and Sadiq in their study collected waste glass particles from Agbara, Nigeria, to use as a replacement for sand as a fine aggregate. In their studies, they manufactured specimens with 0% to 30% sand replacement with different curing times varying from 1 to 90 days [

20]. It was shown that the average failure load was the highest for the 10% replacement volume at 90 days of curing. At the same curing time, increasing the replacement volume to 20% decreased the average failure load. The load-carrying capacity continued to decrease with an increase in the replacement volume from that point onward. It was also observed that increasing the curing time significantly improved the average failure load, with the 90 day curing times showing the highest failure load.

Hosseini et al. studied the shear properties of concrete reinforced with rubber aggregates, glass-fiber-reinforced polymers, and steel fibers [

29]. They looked into the shear properties in addition to the failure modes of a specimen with different reinforcement contents. They observed that the addition of rubber particles decreased the concrete compressive strength, while fiber reinforcement increased the load-carrying capacity of the concrete. However, the rubber aggregates had a performance comparable to that of the fibers with regards to toughness. Tao Wu studied beams reinforced with glass fiber polymer bars [

30]. They found that the specimens had the highest strength values when the fiber volume was 0.6%, but the increase in the fiber volume fraction of the glass bars caused the concrete to become more brittle. By optimizing the fiber volume to 0.6%, the cracking moment increased by 47%, and the load-carrying capacity increased by 22%.

Another commonly wasted material during production is scrap composites or carbon fiber. Carbon fiber is not truly recyclable, and it is being used at higher production rates than ever before due to its increasing affordability. Continuous carbon fiber is commonly used in concrete as a reinforcement for advanced concretes [

31,

32,

33]. However, waste carbon fiber from composite production is an ongoing area of research [

34,

35]. Rodin et al. investigated the effects of adding cured carbon fiber composite material (CCFCM) to concrete [

33]. The study investigated the mechanical properties of the concrete at different reinforcement concentrations at 0%, 3%, 4%, and 5% volume fractions. Their results showed that all test specimens had significantly better mechanical properties when CCFCM was added as a reinforcement. On average, the tensile strength increased by 57–84%, and the flexural strength increased by 36–65%. The specimens were tested at both 7 and 28 days after molding, and the 28-day-old specimens had stronger mechanical properties, consistent with other studies. The highest tensile and flexural strength were observed at a 4% reinforcement density, and they decreased slightly at 5%. Yin et al. investigated the effects of adding a carbon-fiber-reinforced polymer with steel transverse spiral reinforcement [

36]. Their experiments revealed that increasing the concentration of the carbon fiber in the concrete specimens increased the strength during compression tests. In addition to the aforementioned reinforcements, other reinforcements, such as metallic film fibers and palm oil fuel ash [

37], steel fiber aggregates [

38], and recycled tire steel fibers [

39], have shown great potential to serve as concrete reinforcements.

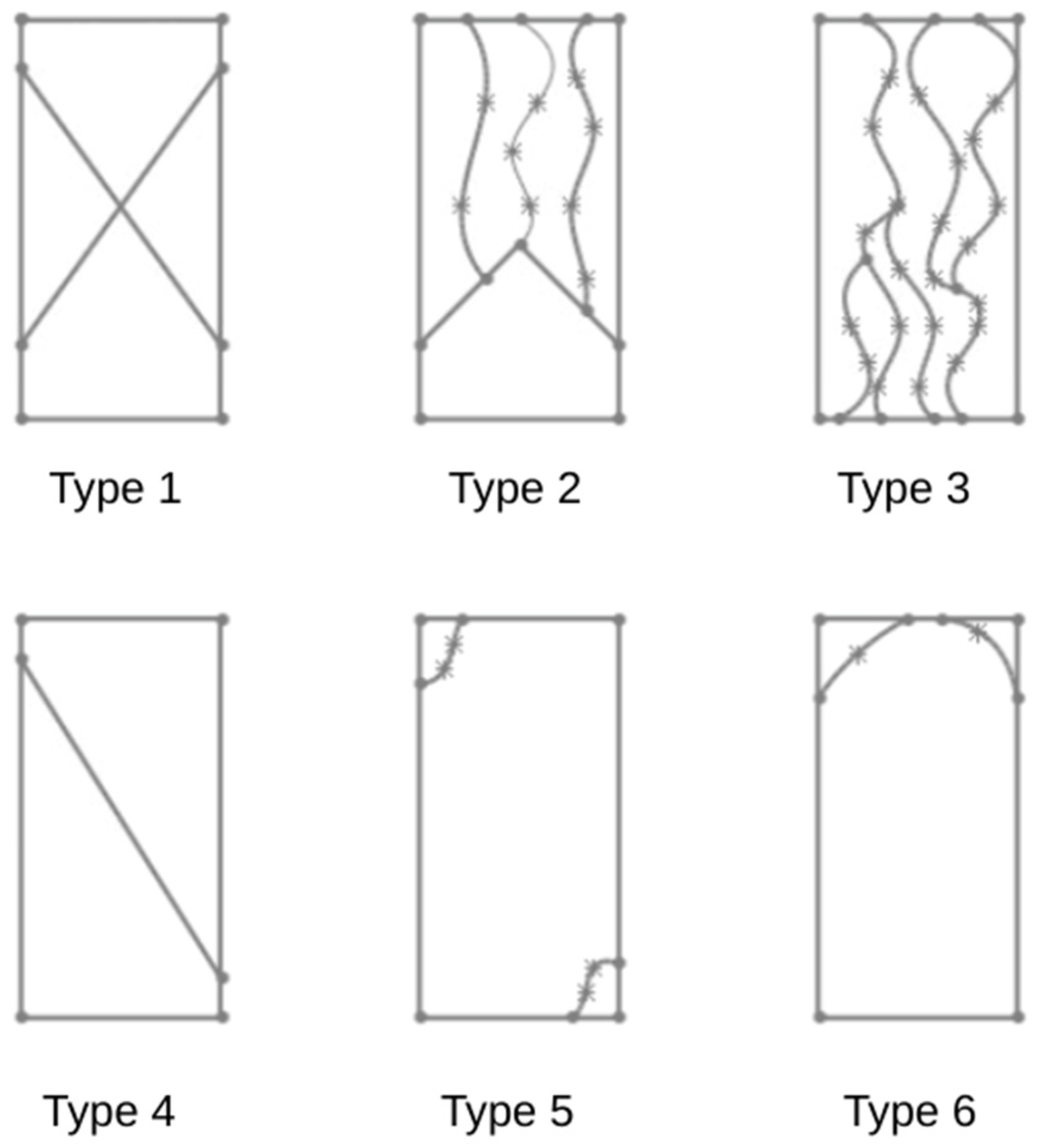

One major challenge in concrete testing is the determination of failure. Upon compression testing, microcracks begin to appear and coalesce to form larger cracks; therefore, concrete specimens may undergo multiple failures until there is no load-carrying capacity. The ultimate mechanical failure in this study was defined at a 30% drop in the max force of the specimen during displacement-controlled compression testing. The ASTM standard C39/C39M lists the common fractures that occur in concrete specimens undergoing compression testing, as shown in

Figure 1 [

40]. ASTM C39 requires extreme degradation for a specimen to be considered failed. For instance, fractures of Types 5 and 6 are not considered a visual failure, while Types 1 to 4 are considered both visual and mechanical failures.

A review of previous works shows that adding advanced reinforcements, such as continuous carbon fibers, wire mesh, and gravel, can significantly enhance the mechanical properties; however, adding waste reinforcements has been shown to have mixed effects on the mechanical properties. For instance, adding rubber pieces tends to decrease the tensile strength, but it increases the crack resistance. When glass is added, concrete specimens manifest more brittle behavior. While several studies have focused on the mechanical properties of one reinforcement type over a range of volume fractions or curing times, there are very few studies covering the mechanical properties of concrete specimens with a wide range of waste reinforcement types. The reinforcements studied in this paper are the direct result of other manufacturing processes without any alterations.

In this study, seven different reinforcements were added to concrete specimens, and four mechanical properties were evaluated for each specimen. The results show that, while the wire mesh had the highest ultimate compressive strength, the chopped-carbon-fiber-reinforced concrete cylinders had the highest toughness by an order of a magnitude. This Introduction is followed by the manufacturing procedure and experimental testing in

Section 2. The experimental results for various mechanical properties are presented and discussed in

Section 3, followed by an overall conclusion of the findings in

Section 4.

2. Manufacturing and Experimental Testing

Compression testing was performed on concrete specimens to evaluate their strength, ductility, and toughness with different reinforcements, as listed below.

Control: A Quikrete specimen without any additional reinforcement.

Wire mesh: A steel wire mesh with square cutouts of 0.635 × 0.635 cm.

Stone: Large stone particles with diameters ranging from 0.575 to 2.847 cm and an average diameter of 1.517 cm.

Plastic Particles: The plastic particles were grade 5 polypropylene, with diameters ranging from 0.187 to 0.836 cm and an average diameter of 0.438 cm.

Rubber: The rubber chunks were made from recycled tires that had the steel removed, and they had diameters ranging from 0.350 to 2.438 cm, with an average diameter of 1.124 cm.

Glass Particles: The glass particles were made from crushed tempered glass, and they had approximate diameters of 0.488 to 1.398 cm, with an average diameter of 0.725 cm.

Carbon Fibers: The carbon fibers were made from 3K and 12K weaves that were separated and cut manually into approximately 7.62 cm strands, and they had diameters ranging from 0.021 to 0.035 cm, with an average diameter of 0.028 cm.

All reinforced specimens were manufactured with the same volume fraction of 10%, as it has been shown to yield the highest compressive strength [

8]. Four specimens for each type of concrete were manufactured for a total of 28 specimens. Cylinder molds with dimensions of 10.16 cm × 20.32 cm ASTM C470/470M [

16] were used to form the concrete following ASTM C31/C31M. Quikrete 5000 was used as the cement mixture [

41]. To ensure that the reinforcement particles were evenly distributed throughout the mold, rodding with a tamping rod was carried out 25 times for each layer. Along with the rodding, a mallet (as specified in Section 5.6 of C31/C31M) was used to help release air pockets and distribute the particles and fibers within. The mallet had a weight of 0.567 ± 0.23 kg and was tapped 15 times against the outside of the mold.

The concrete specimens were produced in different bins with their dedicated reinforcements. One bag of 22.68 kg Quikrete 5000 dry mix was dedicated to each bin, and the corresponding reinforcement was added to the mix, except for the wire mesh, which was added during the filling process of the cylinders. After the mixture of the material and the reinforcements, 2.5 L of water was added to each material bin and mixed until there were no signs of dry concrete powder. ASTM C31/C31M recommends rodding two times; however, for the mesh and carbon fiber reinforcements, more rodding was conducted to ensure that no trapped air was present. The mesh was put into the cylinders every 5.08 cm. The carbon-fiber-reinforced concrete specimens were rodded numerous times since the carbon fiber absorbed a large amount of water, which made it necessary to keep rodding the cylinder until it was finally full.

All specimens were manufactured at room temperature. The tops were smoothed flat and capped to ensure that the concrete remained wet during curing. The concrete specimens were taken out of the molds after 48 h, consistent with ASTM C31/C31M [

18]. To eject each specimen, a Gilson HM-160 Concrete Cylinder stripping tool was used, and no releasing agent was required. The 28 concrete cylinder specimens were cured eight full days prior to testing. All specimens were tested under compression loading on the same day to ensure an equal curing time.

Each specimen was loaded into a Tinius-Olsen compression testing machine, and pads were secured to the top and bottom. Upon the detection of 444.82 N (100lbf), load–displacement was initiated. The specimens were loaded until ultimate failure, defined as a 30% load drop from the maximum force. Such a failure criterion was selected to ensure the ultimate failure and to avoid the termination of testing due to initial cracks (initial load drop) in the concrete. Load–displacement curves were obtained to identify the initiation and progression failure, as well as other mechanical properties. Compression testing was performed under a stress rate of 0.25 MPa/s ± 0.05 MPa/s.

3. Results and Discussion

The first observation upon compression testing was the displayed types of failure as categorized by ASTM C39/C39M and shown in

Figure 1. There are six categories of fractures that can occur in 10.16 × 20.32 concrete cylinders. For some specimens, the type of fracture was not immediately obvious, and the specimen needed to be tapped with a hammer, as directed in ASTM C39, in order to identify the failure type. Types 1 to 4 were extreme types of failure, while Types 5 and 6 were acceptable types of failure based on the 30% load drop-off criterion.

In this study, the pure concrete was observed to primarily exhibit Type 2 failure, with one incident of Type 3 failure. The Type 2 failure of the pure concrete is displayed in

Figure 2, where a distinct cone shape can be seen. The wire mesh specimens had the highest ultimate strength and exhibited Type 5 failure in all instances. The stone specimens, on average, had the third highest ultimate strength and displayed Type 3 failure, in addition to one instance of Type 2 failure and one instance of Type 3 failure. All rubber-reinforced specimens exhibited Type 3 failure and showed resistance to breakage compared to the other cylinders. As seen in

Figure 2D, the portions of the cylinder that fractured were still held together by the pieces of rubber. Glass was the strongest sustainable reinforcement that was tested in terms of the ultimate compressive strength. Over the four tests of glass-reinforced specimens, there were two examples of Type 2 failure and two instances of Type 3 failure. Plastic displayed one instance of Type 2 failure, one instance of Type 3 failure, and two instances of Type 5 failure. Plastic was the second strongest of the reinforcements after glass. For the carbon-fiber-reinforced specimens, all specimens displayed Type 4 failure. Similar to the rubber, the reinforcement remained strongly attached to the matrix, even after ultimate failure was detected. One of the important findings is that, while the wire-mesh-reinforced specimens did show the ultimate compressive strength, the specimen experienced less plastic deformation until failure.

Upon the compression testing of all specimens, the engineering stress was calculated by dividing the applied force by the original cross-sectional area of 81.07 cm

2. Stress–strain graphs (

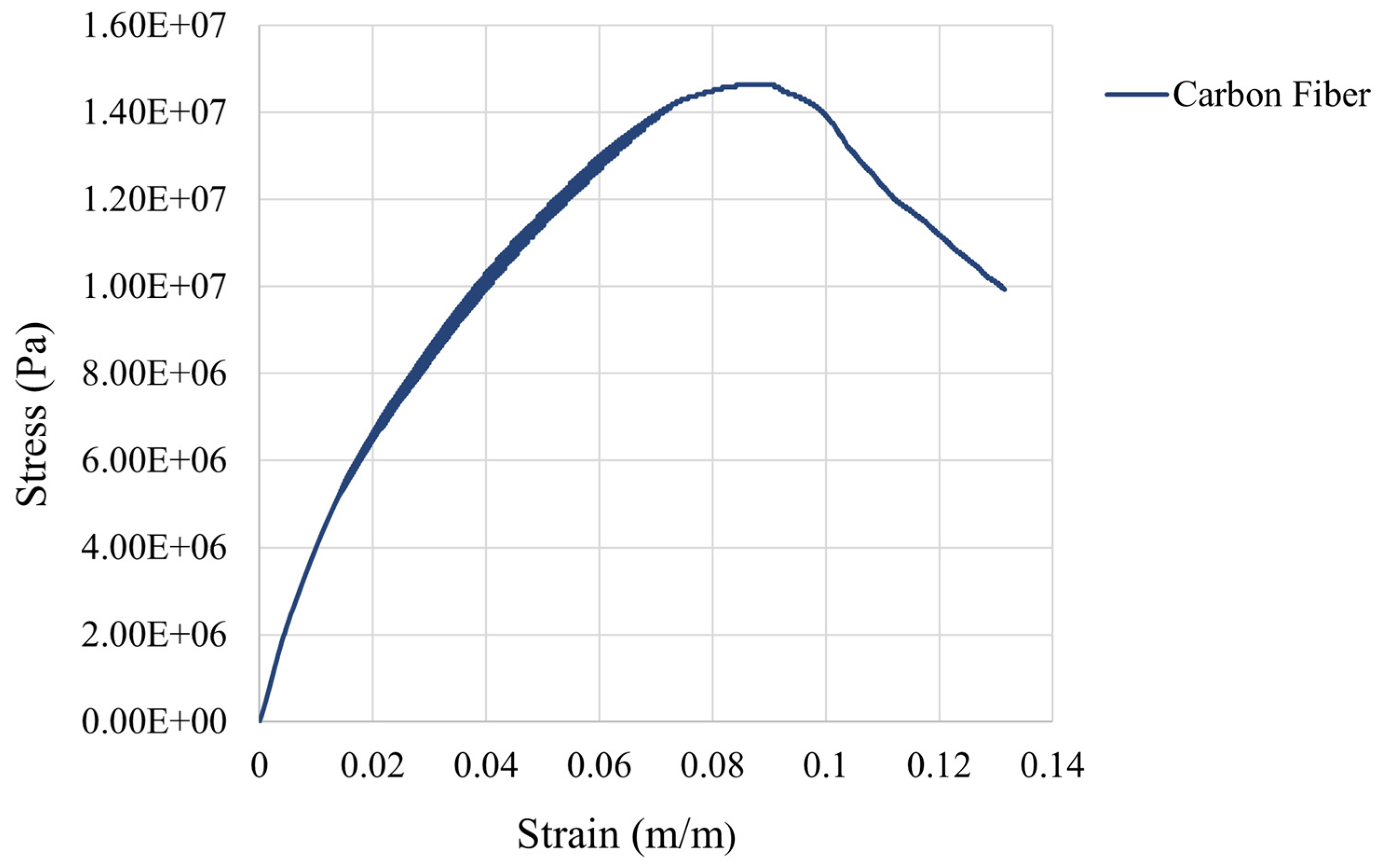

Figure 3 and

Figure 4) were plotted to determine the targeted mechanical properties. The carbon-fiber-reinforced stress–strain curve (

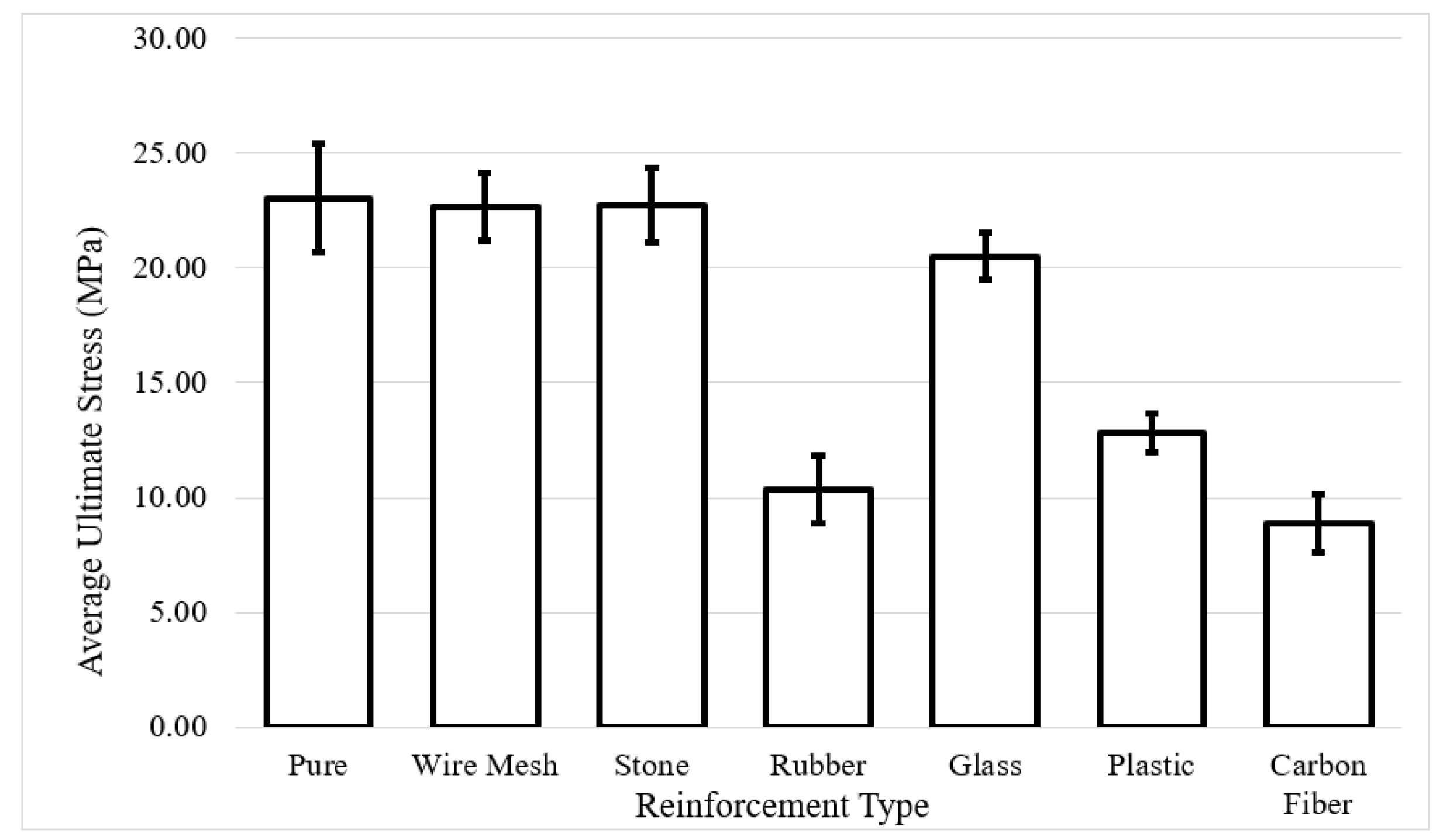

Figure 4) was separately plotted, as the strain-to-failure range was beyond that of the other reinforcements. Based on the analysis of the maximum ultimate compressive stress (UCS) of each specimen, the wire mesh exhibited the highest strength, followed by the stone particle reinforcement, as shown in

Figure 5. The glass particles had comparable results to the stone and wire mesh. The lowest UCs was observed for the rubber- and carbon-fiber-reinforced specimens. It is suspected that the presence of randomly oriented chopped carbon fiber formed stress concentration regions, thus degrading the ultimate strength. The error bars represent the standard deviations of the results based on the four specimen sample sizes for each category. Following the glass particles, the strongest reinforcements were plastic, rubber, and carbon fiber, in that order. The small variation in the results confirms the consistency of the reported values. However, more data are required for in-depth statistical analyses.

Figure 6 reports the average elastic modulus values along with the standard deviations. The highest average elastic modulus was found for the wire-mesh-reinforced specimens, followed by the stone- and the glass-reinforced specimens. Stone had the lowest coefficient of variation among the reinforcement types, while the pure concrete showed the highest variation.

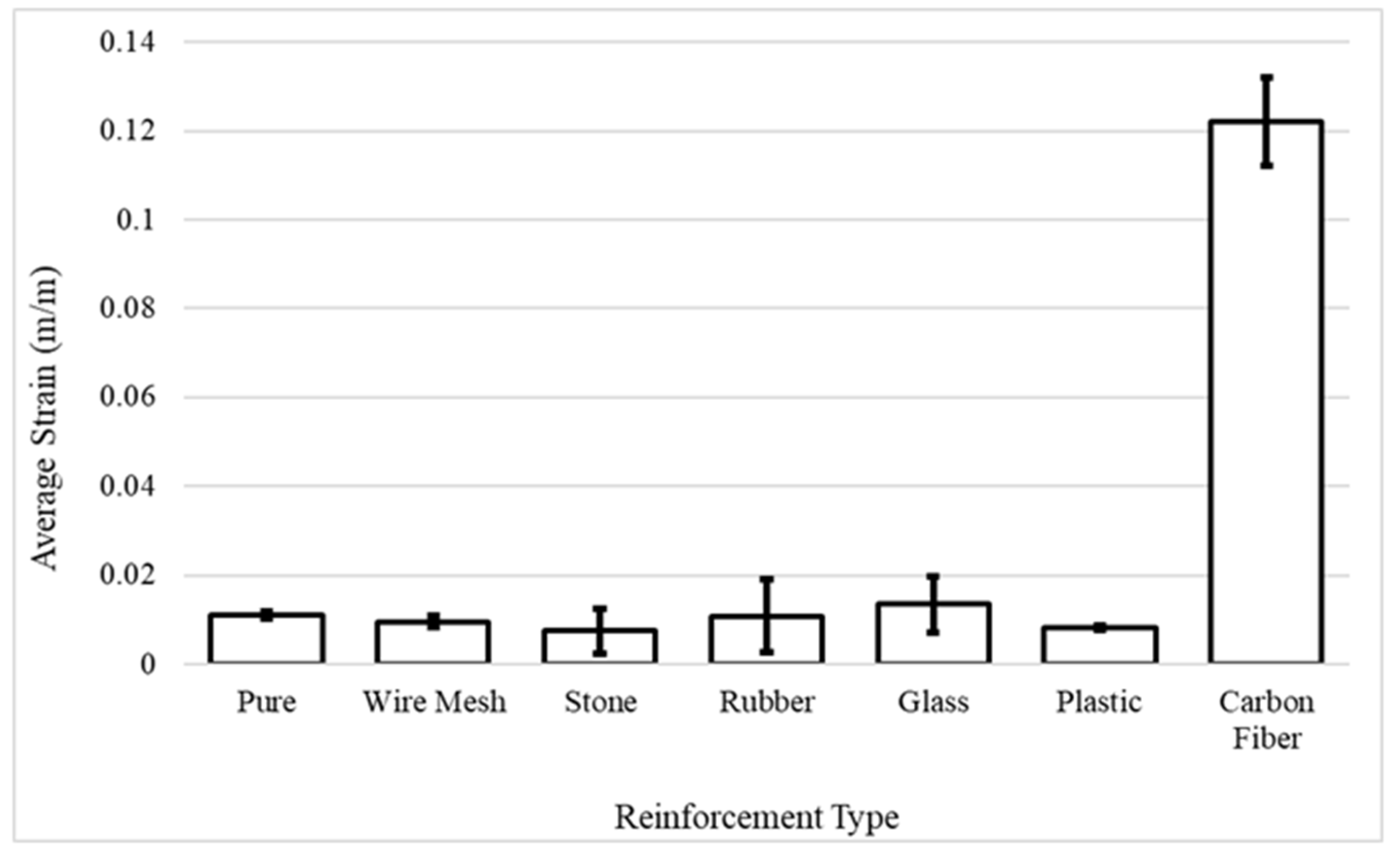

The average strains at failure, which is an indication of material ductility, were determined from the stress–strain curves. The results for all the reinforcement types are shown in

Figure 7. The wire mesh, which had the leading results for the previously discussed properties, had one of the lowest average strains at failure. The carbon-fiber-reinforced concrete showed the highest strains at failure. The carbon-fiber-reinforced concrete was shown to be a good reinforcement, as carbon fiber is a more ductile material that can compensate for the brittle nature of concrete. Throughout the compression testing of the carbon-fiber-reinforced specimens, the specimens barreled out on the sides but did not fracture, which is an indication of ductile performance. Additionally, the carbon fiber specimens had the highest strains at failure, and the coefficient of variation (standard deviation divided by the average) was one of the lowest, second only to glass. The carbon-fiber-reinforced specimens maintained a load-carrying capacity and continued to deform without ultimate failure until a strain of more than 12% was recorded. Such a jump in the ductility of the concrete can have revolutionary advantages in applications ranging from residential driveways to runways. The obtained results are based on the 30% load drop, and a different failure criterion will result in different values of the failure strain; however, the comparative nature of the reinforcement unveils the potential for the use of waste carbon fibers in concrete applications.

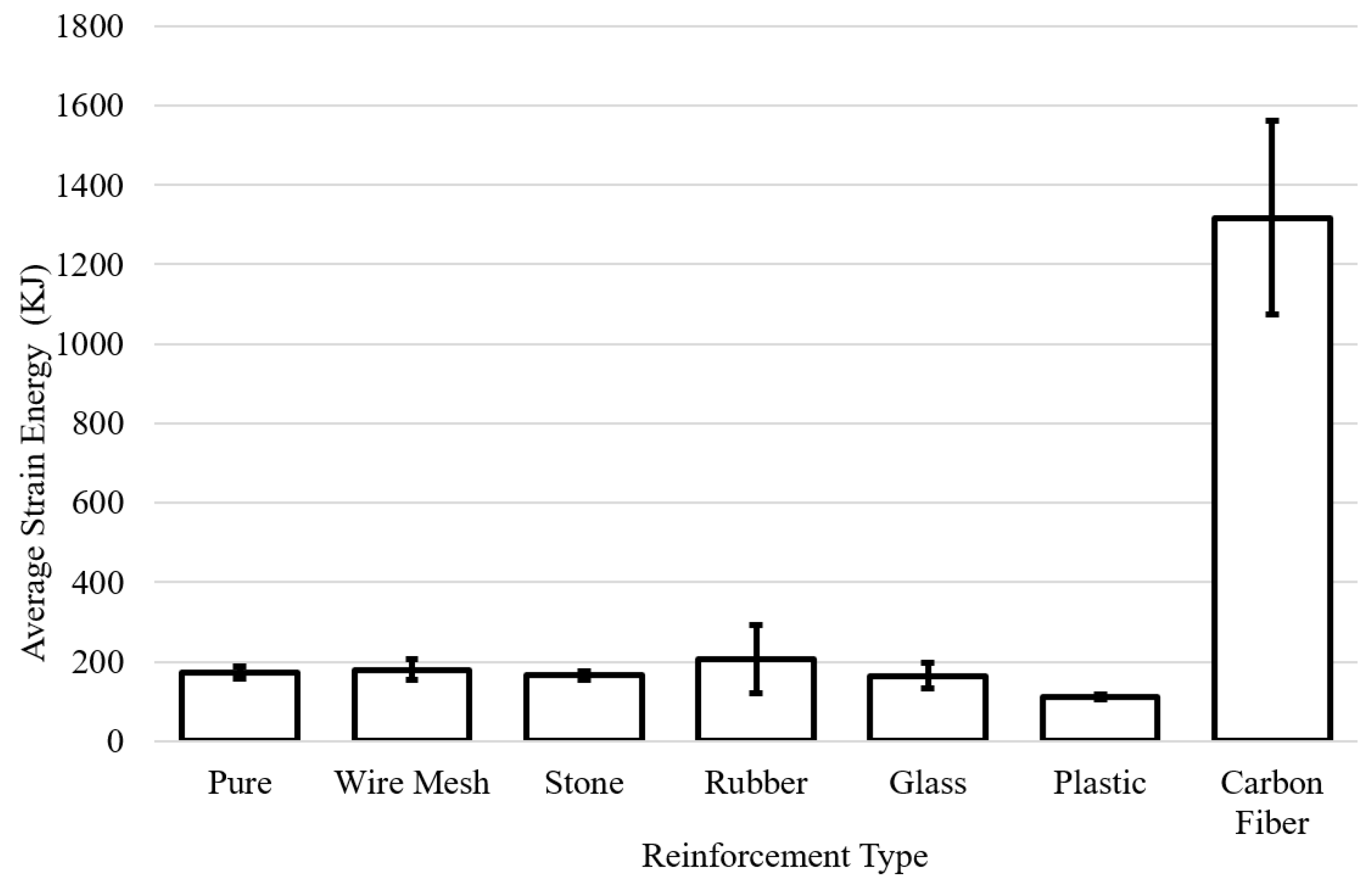

To evaluate the toughness of each specimen, the strain energy was determined by calculating the area under the stress–strain curve, including both elastic and plastic regions, until ultimate failure. A numerical approach based on the trapezoidal fitting of the stress–strain curve was used to capture the area under the curve. The average strain energy values for all the seven types of reinforcements are shown in

Figure 8. The carbon-fiber-reinforced concrete had the highest strain energy, consistent with the strain-to-failure findings. The reinforcement with the next highest strain energy was the rubber. While the stone-reinforced specimens had the second highest ultimate strength and modulus, they showed low ductility, with a strain to failure of less than 1%.

4. Concluding Remarks

In this paper, concrete specimens were manufactured with seven different reinforcements that would have alternatively been wasted in landfill disposal in order to study the feasibility of recycling conventionally unrecycled materials. All the reinforcement materials used are considered waste materials according to their corresponding industry. To evaluate the mechanical properties of the reinforced specimens, compression testing was performed, and four different mechanical properties, namely, the elastic modulus, ultimate compressive strength, strain at failure, and strain energy, were extracted from load–displacement graphs. For each reinforcement category, four specimens were tested to evaluate the consistency of the results. While the stiffness and strength values were not improved by the addition of the recycled waste materials, the strain at failure and strain energy were improved for the rubber- and, more significantly, for the carbon-fiber-reinforced specimens. Enhancing the ductility of concrete to 12% strain at failure can lead to revolutionary applications in transportation and construction. The result shows a promising future for the circular economy by adding waste materials into concrete as a sustainable alternative to the current landfill disposal approach.

For future studies, it would be beneficial to investigate the hybrid effect of sustainable reinforcements. As wire mesh shows the highest compressive strength and carbon fiber shows the highest strain energy, including both reinforcements could offset their weaknesses and complement their strengths. While the ASTM guidelines are based on cylindrical blocks, other geometries, such as concrete slabs for residential driveways or other commonly used applications, should be explored in the testing of reinforced concrete with plastic and fiber waste materials. In this study, the reinforcements were directly used in concrete without any preprocessing; however, the sizing of the reinforcement can have a direct effect on the adhesion between the cement and the reinforcement, hence improving the mechanical performance of the specimen. The distribution and size of particles can serve as other parameters influencing the mechanical properties.