Fabrication Temperature-Related Porosity Effects on the Mechanical Properties of Additively Manufactured CFRP Composites

Abstract

:1. Introduction

1.1. Additively Manufactured CFRP Composites

1.2. Current Understanding of Deposition Temperature-Related Porosity Effects in AM Fabricated CFRP Composites

1.3. Research Motivation

2. Materials and Methods

2.1. AM Workpiece Fabrication Procedure

2.2. Measurement Procedure

2.2.1. Mechanical Measurements

2.2.2. Scanning Electron Microscopy

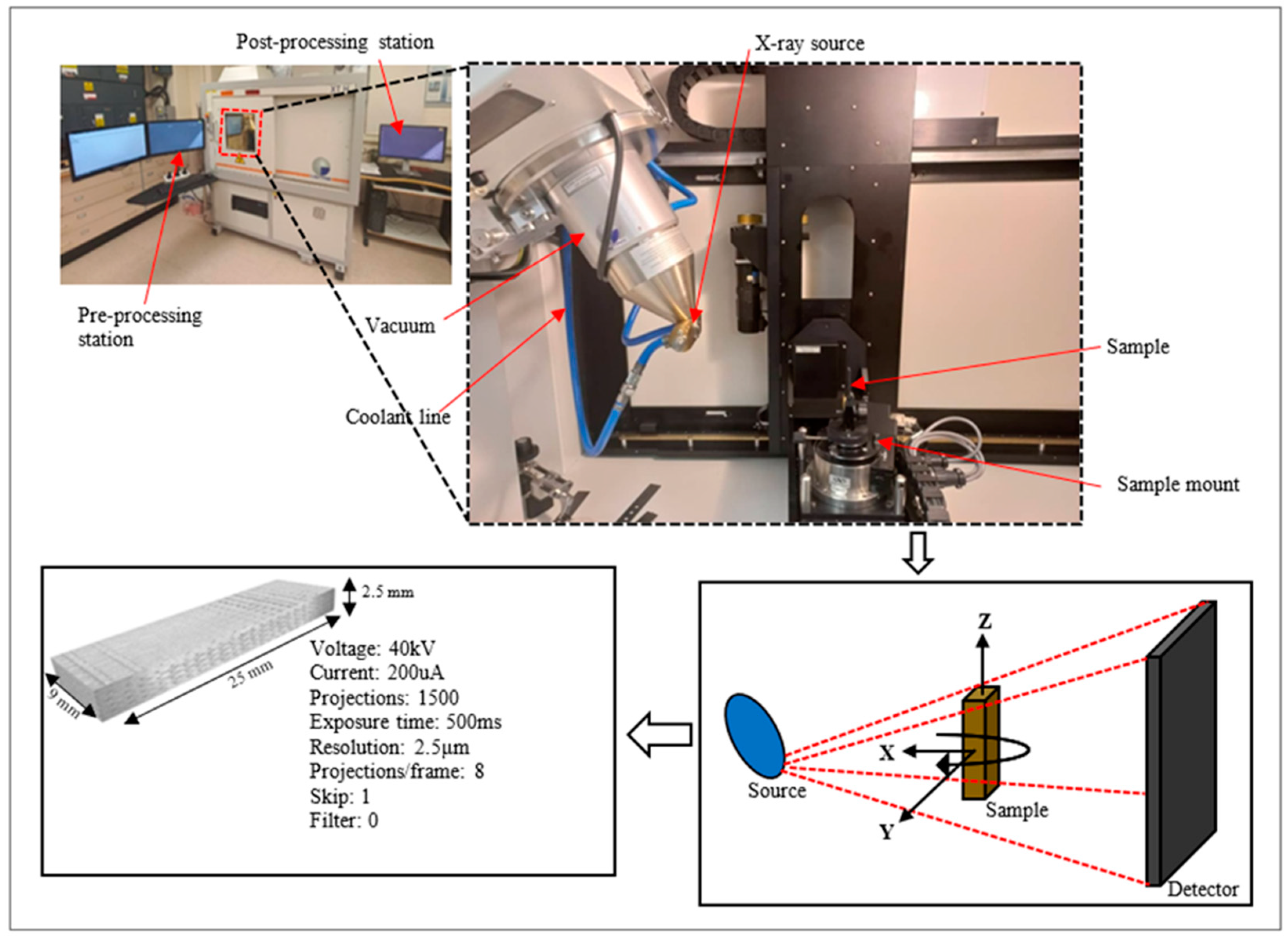

2.2.3. Micro-CT Microscopy

3. Results

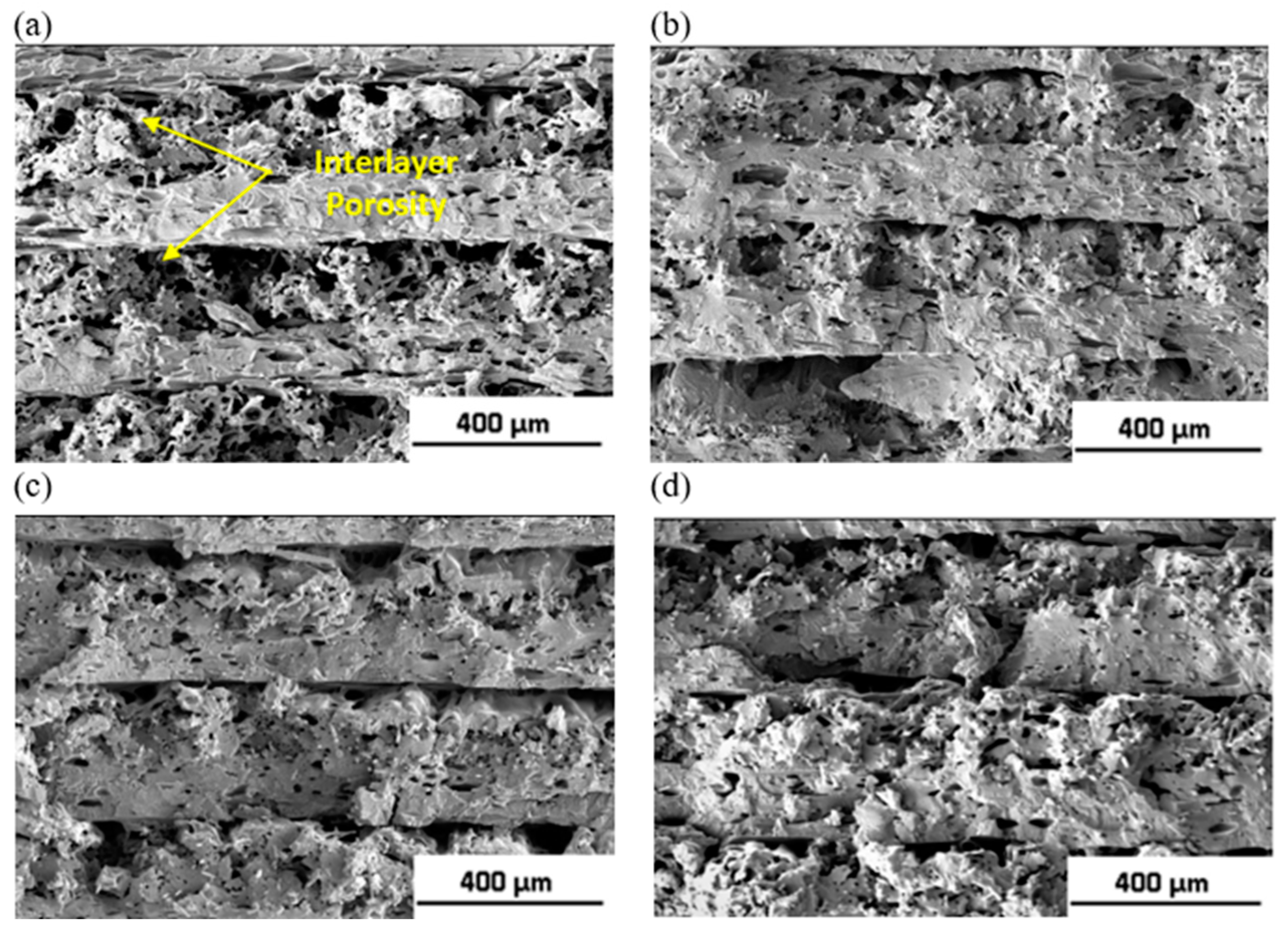

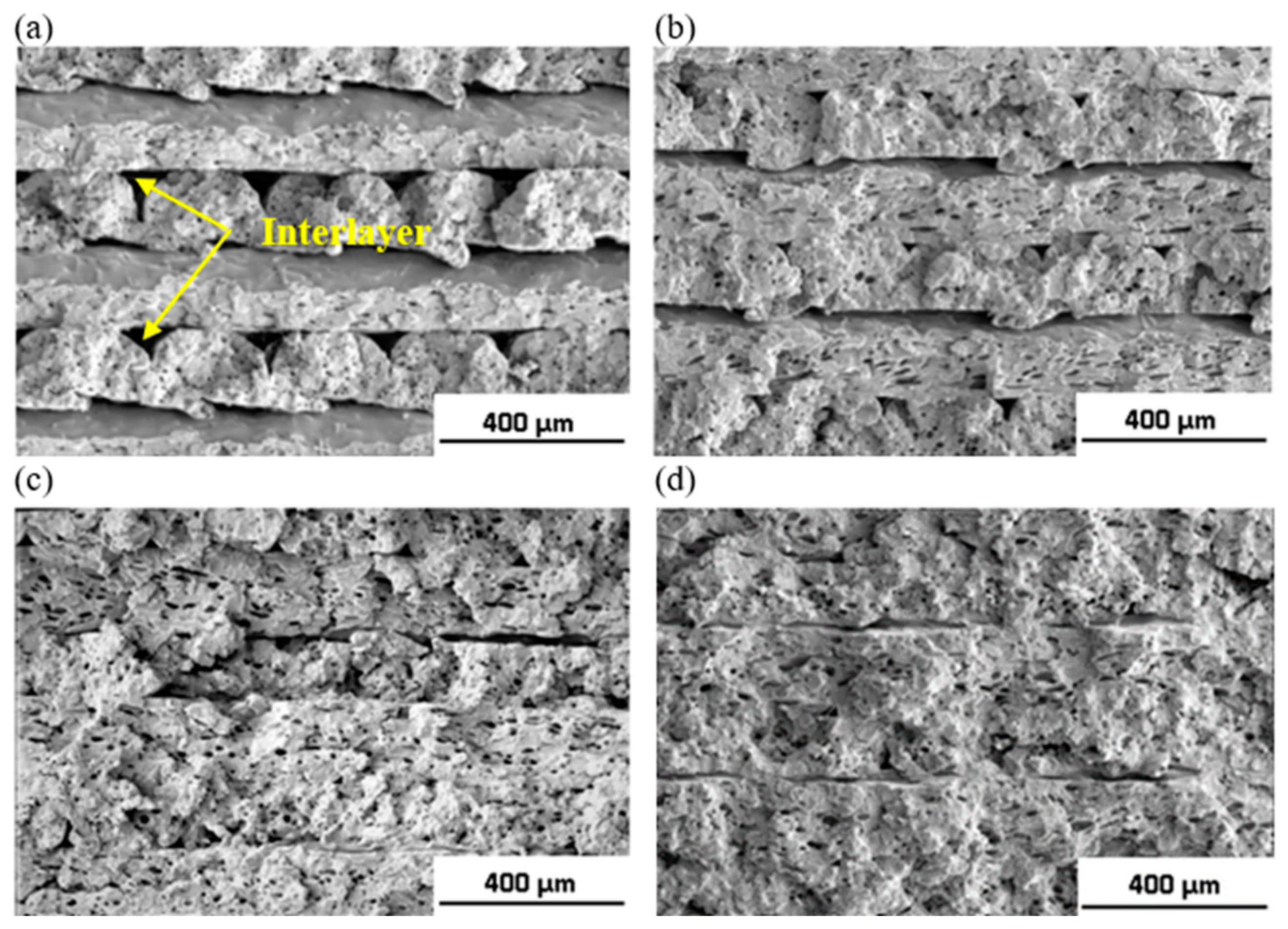

3.1. Scanning Electron Microscopy Results

3.1.1. SEM Result for CF-PA Composite

3.1.2. SEM Result for CF-ABS Composite

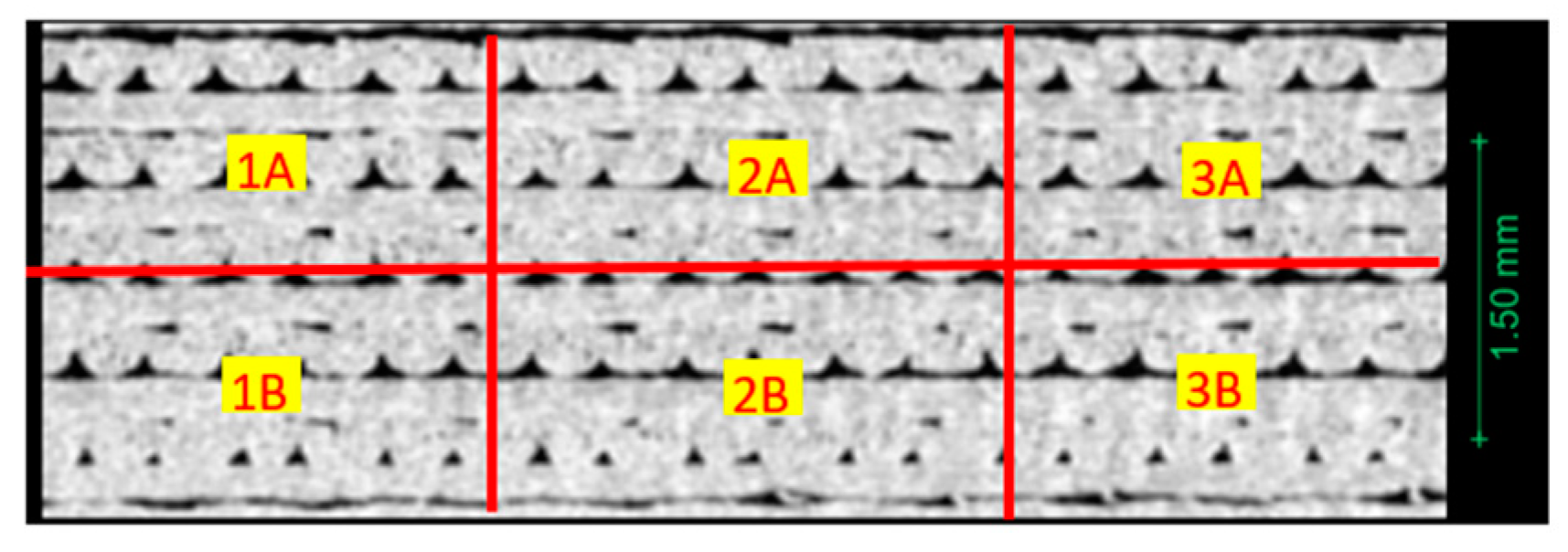

3.2. Micro-CT Scan Result

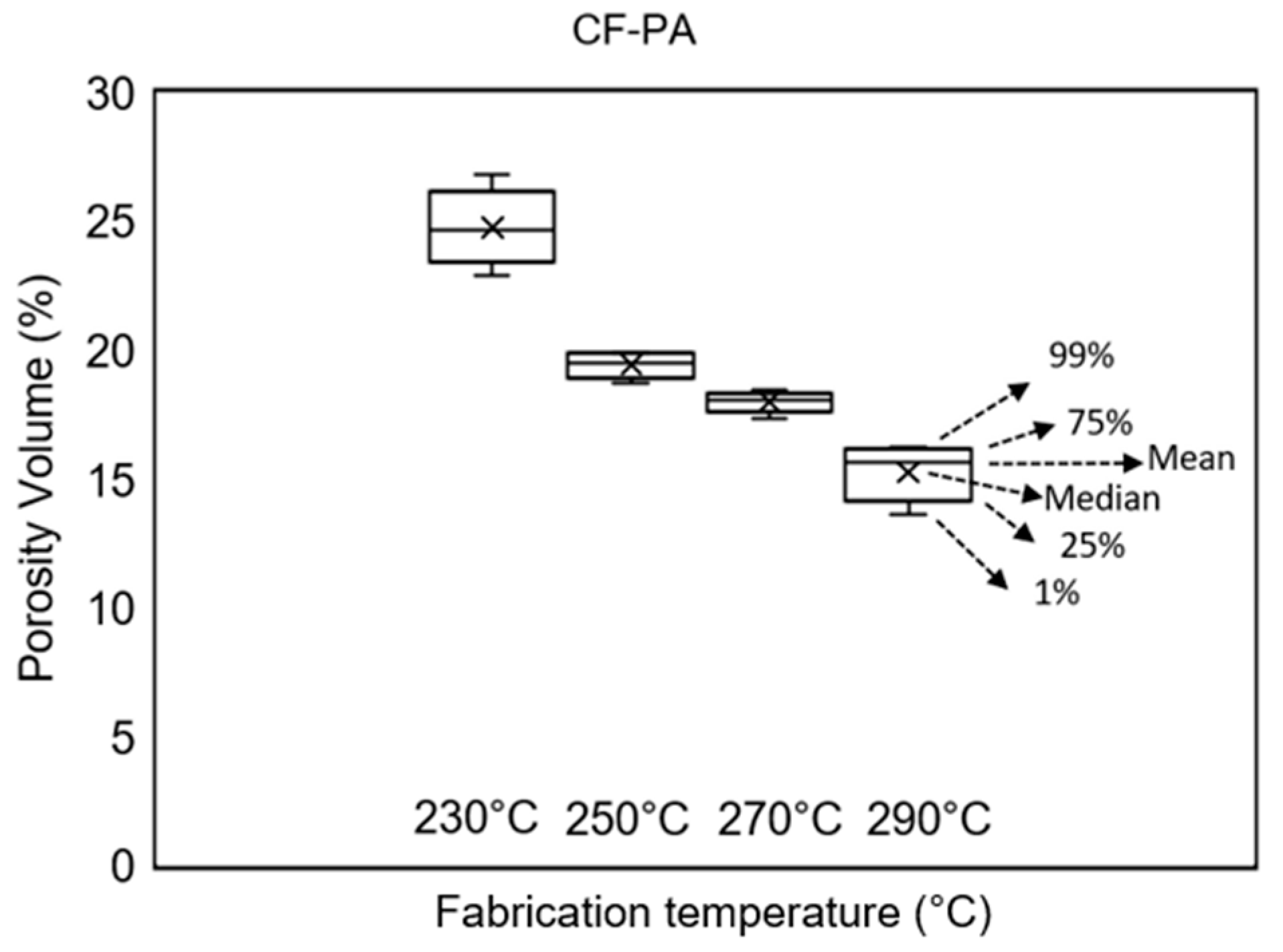

3.2.1. Micro-CT Scan Porosity Results for CF-PA Composite

3.2.2. Micro-CT Scan Porosity Results for CF-ABS Composite

3.3. Fabrication Temperature-Related Porosity Effects on Mechanical Properties

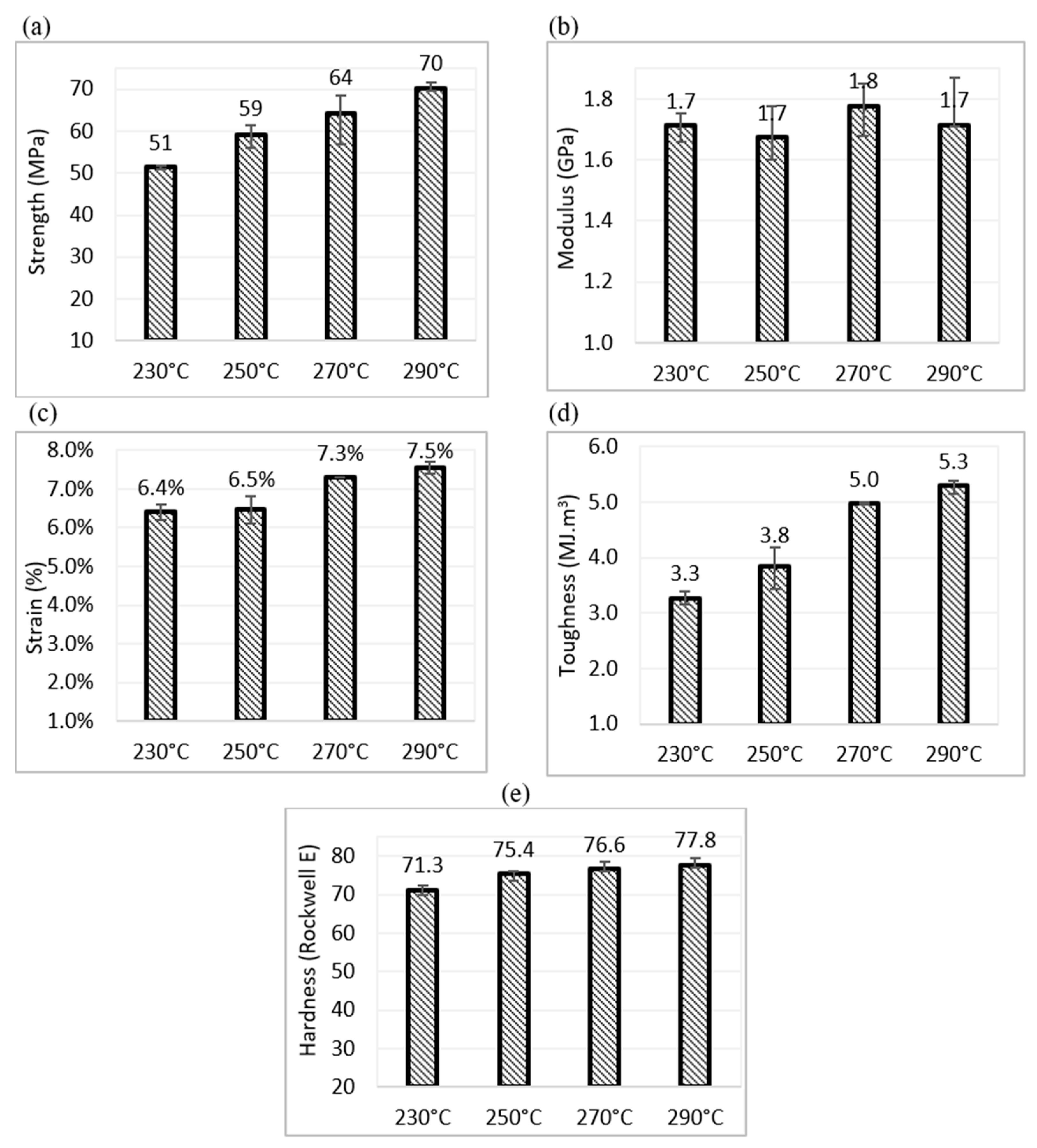

3.3.1. Mechanical Properties of CF-PA Composite

3.3.2. Mechanical Properties of CF-ABS Composite

4. Conclusions

- (1)

- Deposition temperatures have some effects on porosity volumes in AM-fabricated CFRP composites, with semicrystalline CF-PA much more significantly affected than the amorphous CF-ABS composite.

- (2)

- The degree of porosity is largely determined by the characteristics of the matrix material.

- (3)

- A direct relationship exists between CFRP composites’ porosity and mechanical properties.

- (4)

- The overall porosity volumes are determinant of the interlayer and intralayer voids, but the interlayer voids play a greater role in determining the mechanical properties.

- (5)

- Semicrystalline composites exhibit higher porosity volumes than amorphous composites due to rapid recrystallization as the chains rearrange during the cooling of the print beads.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frketic, J.; Dickens, T.; Ramakrishnan, S. Automated Manufacturing and Processing of Fiber-Reinforced Polymer (FRP) Composites: An Additive Review of Contemporary and Modern Techniques for Advanced Materials Manufacturing. Addit. Manuf. 2017, 14, 69–86. [Google Scholar] [CrossRef] [Green Version]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A Review on Stereolithography and Its Applications in Biomedical Engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [Green Version]

- Dimas, L.S.; Buehler, M.J. Modeling and Additive Manufacturing of Bio-Inspired Composites with Tunable Fracture Mechanical Properties. Soft Matter 2014, 10, 4436–4442. [Google Scholar] [CrossRef]

- Mazzoli, A. Selective Laser Sintering in Biomedical Engineering. Med. Biol. Eng. Comput. 2013, 51, 245–256. [Google Scholar] [CrossRef]

- Zhang, W.; Cotton, C.; Sun, J.; Heider, D.; Gu, B.; Sun, B.; Chou, T.W. Interfacial Bonding Strength of Short Carbon Fiber/Acrylonitrile-Butadiene-Styrene Composites Fabricated by Fused Deposition Modeling. Compos. Part B Eng. 2018, 137, 51–59. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber-Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Adeniran, O.; Cong, W.; Bediako, E.; Aladesanmi, V. Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties. J. Compos. Sci. 2021, 5, 325. [Google Scholar] [CrossRef]

- Petrò, S.; Reina, C.; Moroni, G. X-Ray CT-Based Defect Evaluation of Continuous CFRP Additive Manufacturing. J. Nondestr. Eval. 2021, 40, 7. [Google Scholar] [CrossRef]

- Tagscherer, N.; Schromm, T.; Drechsler, K. Foundational Investigation on the Characterization of Porosity and Fiber Orientation Using XCT in Large-Scale Extrusion Additive Manufacturing. Materials 2022, 15, 2290. [Google Scholar] [CrossRef] [PubMed]

- Adeniran, O.; Cong, W.; Aremu, A.; Oluwole, O. Forces in Mechanics Finite Element Model of Fiber Volume Effect on the Mechanical Performance of Additively Manufactured Carbon Fiber Reinforced Plastic Composites. Forces Mech. 2023, 10, 100160. [Google Scholar] [CrossRef]

- Adeniran, O. Mechanical Performance of Carbon Fiber Reinforced Plastic Composites Fabricated by Additive Manufacturing. Ph.D. Thesis, Texas Tech University, Lubbock, TX, USA, 2022. [Google Scholar]

- Ning, F.; Cong, W.; Hu, Z.; Huang, K. Additive Manufacturing of Thermoplastic Matrix Composites Using Fused Deposition Modeling: A Comparison of Two Reinforcements. J. Compos. Mater. 2017, 51, 3733–3742. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive Manufacturing of Carbon Fiber-Reinforced Plastic Composites Using Fused Deposition Modeling: Effects of Process Parameters on Tensile Properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Ajinjeru, C.; Kishore, V.; Lindahl, J.; Sudbury, Z.; Hassen, A.A.; Post, B.; Love, L.; Kunc, V.; Duty, C. The Influence of Dynamic Rheological Properties on Carbon Fiber-Reinforced Polyetherimide for Large-Scale Extrusion-Based Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2018, 99, 411–418. [Google Scholar] [CrossRef]

- Ajinjeru, C.; Kishore, V.; Liu, P.; Lindahl, J.; Hassen, A.A.; Kunc, V.; Post, B.; Love, L.; Duty, C. Determination of Melt Processing Conditions for High-Performance Amorphous Thermoplastics for Large Format Additive Manufacturing. Addit. Manuf. 2018, 21, 125–132. [Google Scholar] [CrossRef]

- Kishore, V.; Ajinjeru, C.; Nycz, A.; Post, B.; Lindahl, J.; Kunc, V.; Duty, C. Infrared Preheating to Improve Interlayer Strength of Big Area Additive Manufacturing (BAAM) Components. Addit. Manuf. 2017, 14, 7–12. [Google Scholar] [CrossRef]

- Cinquin, J.; Chabert, B.; Chauchard, J.; Morel, E.; Trotignon, J.P. Characterization of a Thermoplastic (Polyamide 66) Reinforced with Unidirectional Glass Fibres. Matrix Additives and Fibres Surface Treatment Influence on the Mechanical and Viscoelastic Properties. Composites 1990, 21, 141–147. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D Printing for Continuous Fiber Reinforced Thermoplastic Composites: Mechanism and Performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Adeniran, O.; Cong, W.; Aremu, A. Material Design Factors in the Additive Manufacturing of Short Carbon Fiber Reinforced Plastic Composites: A State-of-the-Art-Review. Adv. Ind. Manuf. Eng. 2022, 5, 100100. [Google Scholar] [CrossRef]

- Vaes, D.; van Puyvelde, P. Semi-Crystalline Feedstock for Filament-Based 3D Printing of Polymers. Prog. Polym. Sci. 2021, 118, 101411. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 1–32. [Google Scholar] [CrossRef] [PubMed]

- Gofman, I.v.; Yudin, V.E.; Orell, O.; Vuorinen, J.; Grigoriev, A.Y.; Svetlichnyi, V.M. Influence of the Degree of Crystallinity on the Mechanical and Tribological Properties of High-Performance Thermoplastics over a Wide Range of Temperatures: From Room Temperature up to 250 °C. J. Macromol. Sci. Part B Phys. 2013, 52, 1848–1860. [Google Scholar] [CrossRef]

- Adeniran, O.; Cong, W.; Bediako, E.; Adu, S.P. Environmental Affected Mechanical Performance of Additively Manufactured Carbon Fiber–Reinforced Plastic Composites. J. Compos. Mater. 2022, 56, 1139–1150. [Google Scholar] [CrossRef]

- Brenken, B.; Dissertation, A. Extrusion Deposition Additive Manufacturing of Fiber Reinforced Semi-Crystalline Polymers. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2017. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Infill Density | % | 100 |

| Printer Enclosed Temperature | °C | 50 ± 5 |

| Bed Temperature | °C | 100 |

| Raster Angle | Deg | 0, 90 |

| Layer Thickness | mm | 0.25 |

| Printing Speed | mm/sec | 30 |

| Nozzle Temperature | °C | 230, 250, 270, 290 |

| Test | ASTM Standard | Equipment | Test Speed | Unit |

|---|---|---|---|---|

| Tensile | D638 (Type I) | MTS Criterion Model 45 | 5.0 | mm/min |

| Rockwell Hardness | D785 | Clark Tester C12A | - | - |

| Scanning Electron Microscopy | - | Thermo Scientific Phenom XL | 100× | Magnification |

| Micro-CT | - | Nikon X-Tex XTH | 2 | Proj/sec |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adeniran, O.; Osa-uwagboe, N.; Cong, W.; Ramoni, M. Fabrication Temperature-Related Porosity Effects on the Mechanical Properties of Additively Manufactured CFRP Composites. J. Compos. Sci. 2023, 7, 12. https://doi.org/10.3390/jcs7010012

Adeniran O, Osa-uwagboe N, Cong W, Ramoni M. Fabrication Temperature-Related Porosity Effects on the Mechanical Properties of Additively Manufactured CFRP Composites. Journal of Composites Science. 2023; 7(1):12. https://doi.org/10.3390/jcs7010012

Chicago/Turabian StyleAdeniran, Olusanmi, Norman Osa-uwagboe, Weilong Cong, and Monsuru Ramoni. 2023. "Fabrication Temperature-Related Porosity Effects on the Mechanical Properties of Additively Manufactured CFRP Composites" Journal of Composites Science 7, no. 1: 12. https://doi.org/10.3390/jcs7010012

APA StyleAdeniran, O., Osa-uwagboe, N., Cong, W., & Ramoni, M. (2023). Fabrication Temperature-Related Porosity Effects on the Mechanical Properties of Additively Manufactured CFRP Composites. Journal of Composites Science, 7(1), 12. https://doi.org/10.3390/jcs7010012