Recycling Unrecycled Plastic and Composite Wastes as Concrete Reinforcement

Abstract

1. Introduction

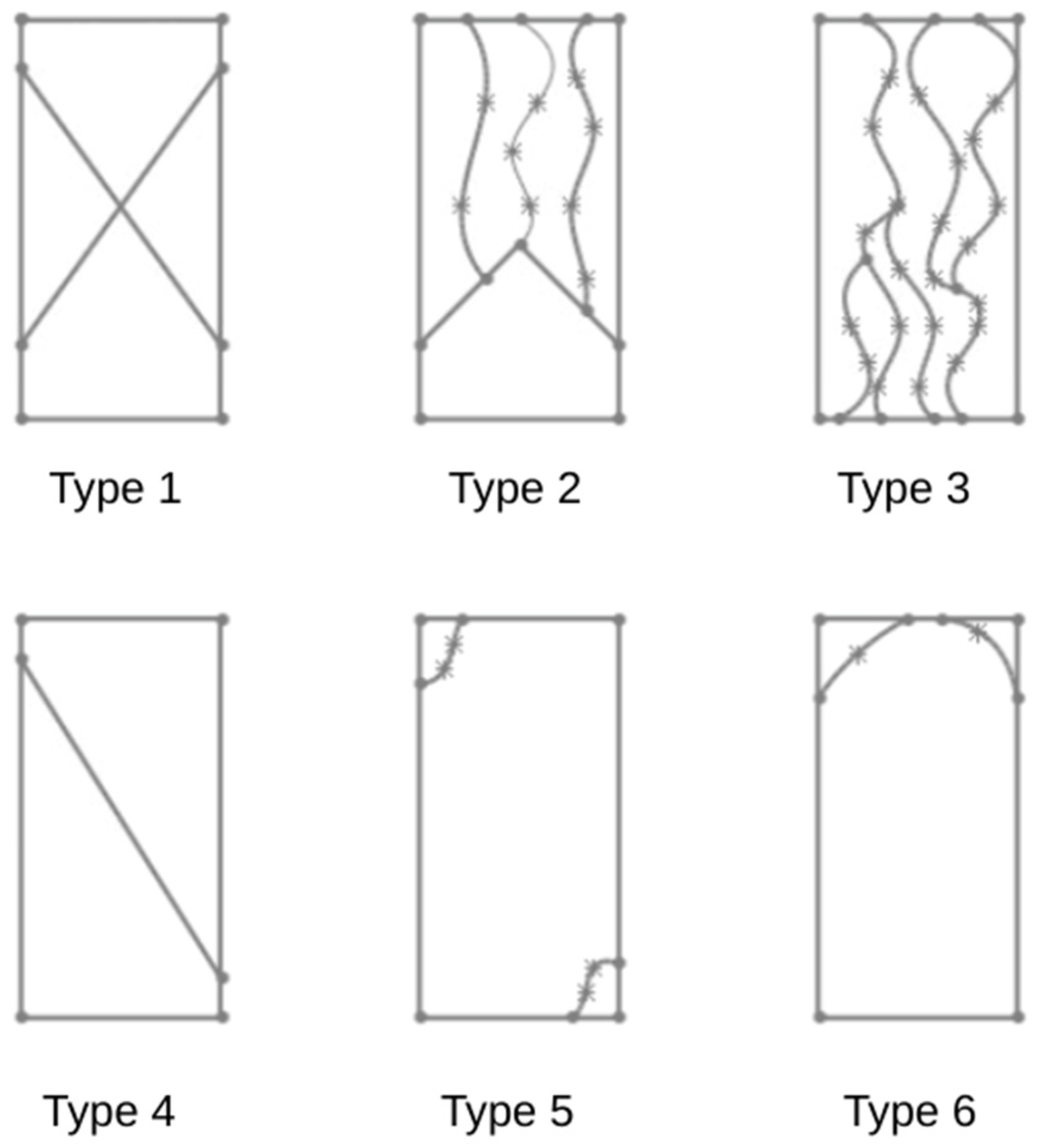

2. Manufacturing and Experimental Testing

- Control: A Quikrete specimen without any additional reinforcement.

- Wire mesh: A steel wire mesh with square cutouts of 0.635 × 0.635 cm.

- Stone: Large stone particles with diameters ranging from 0.575 to 2.847 cm and an average diameter of 1.517 cm.

- Plastic Particles: The plastic particles were grade 5 polypropylene, with diameters ranging from 0.187 to 0.836 cm and an average diameter of 0.438 cm.

- Rubber: The rubber chunks were made from recycled tires that had the steel removed, and they had diameters ranging from 0.350 to 2.438 cm, with an average diameter of 1.124 cm.

- Glass Particles: The glass particles were made from crushed tempered glass, and they had approximate diameters of 0.488 to 1.398 cm, with an average diameter of 0.725 cm.

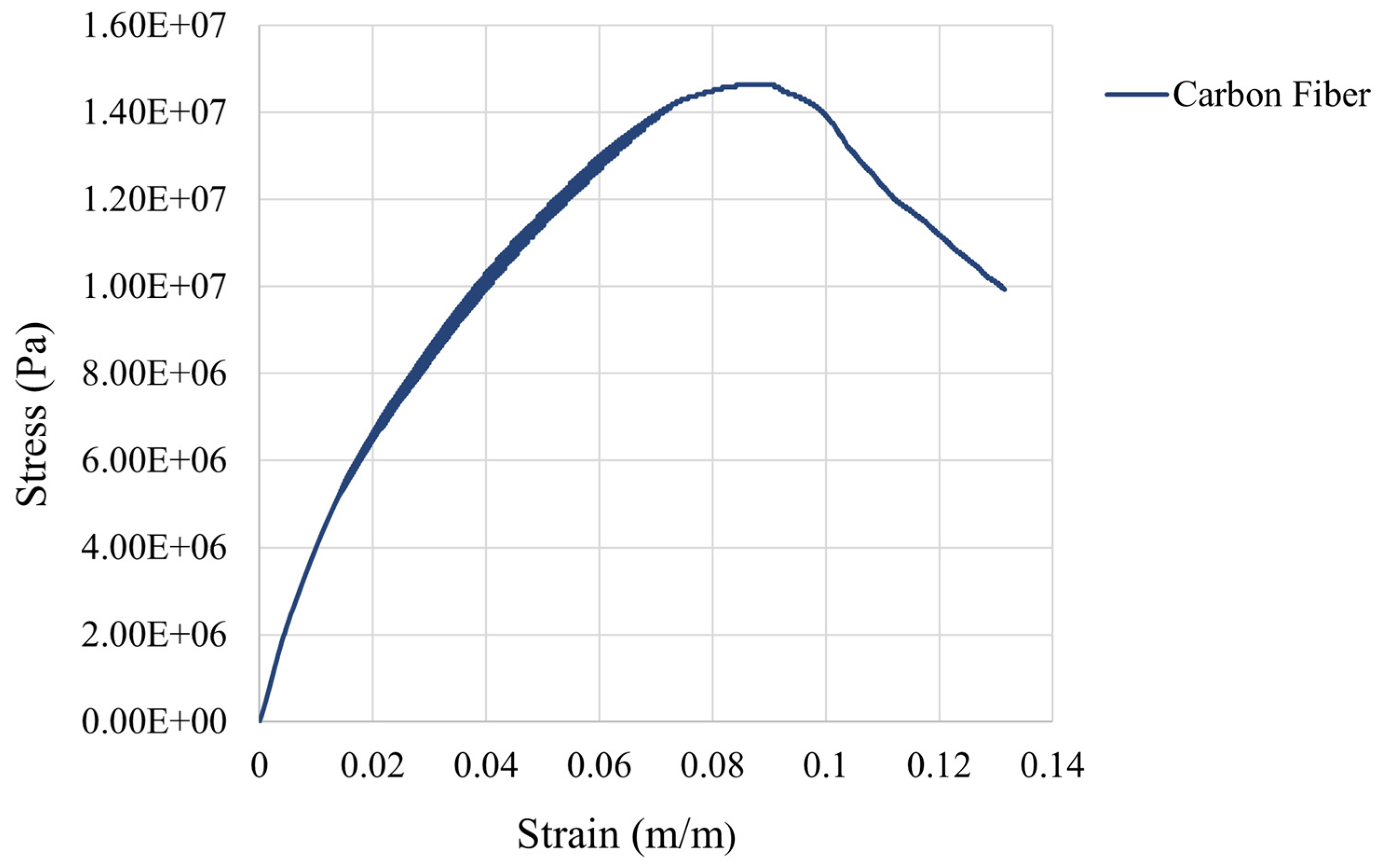

- Carbon Fibers: The carbon fibers were made from 3K and 12K weaves that were separated and cut manually into approximately 7.62 cm strands, and they had diameters ranging from 0.021 to 0.035 cm, with an average diameter of 0.028 cm.

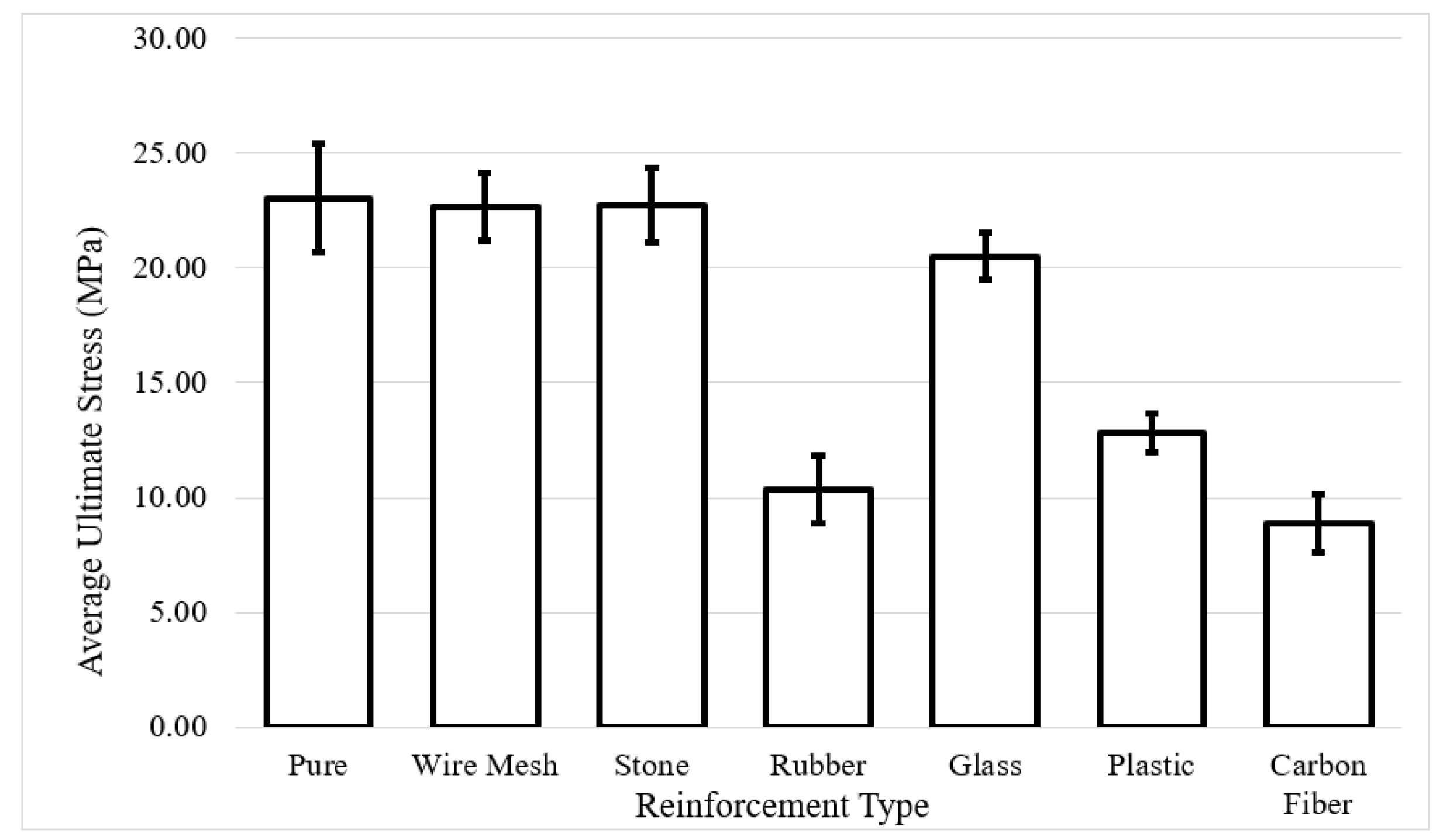

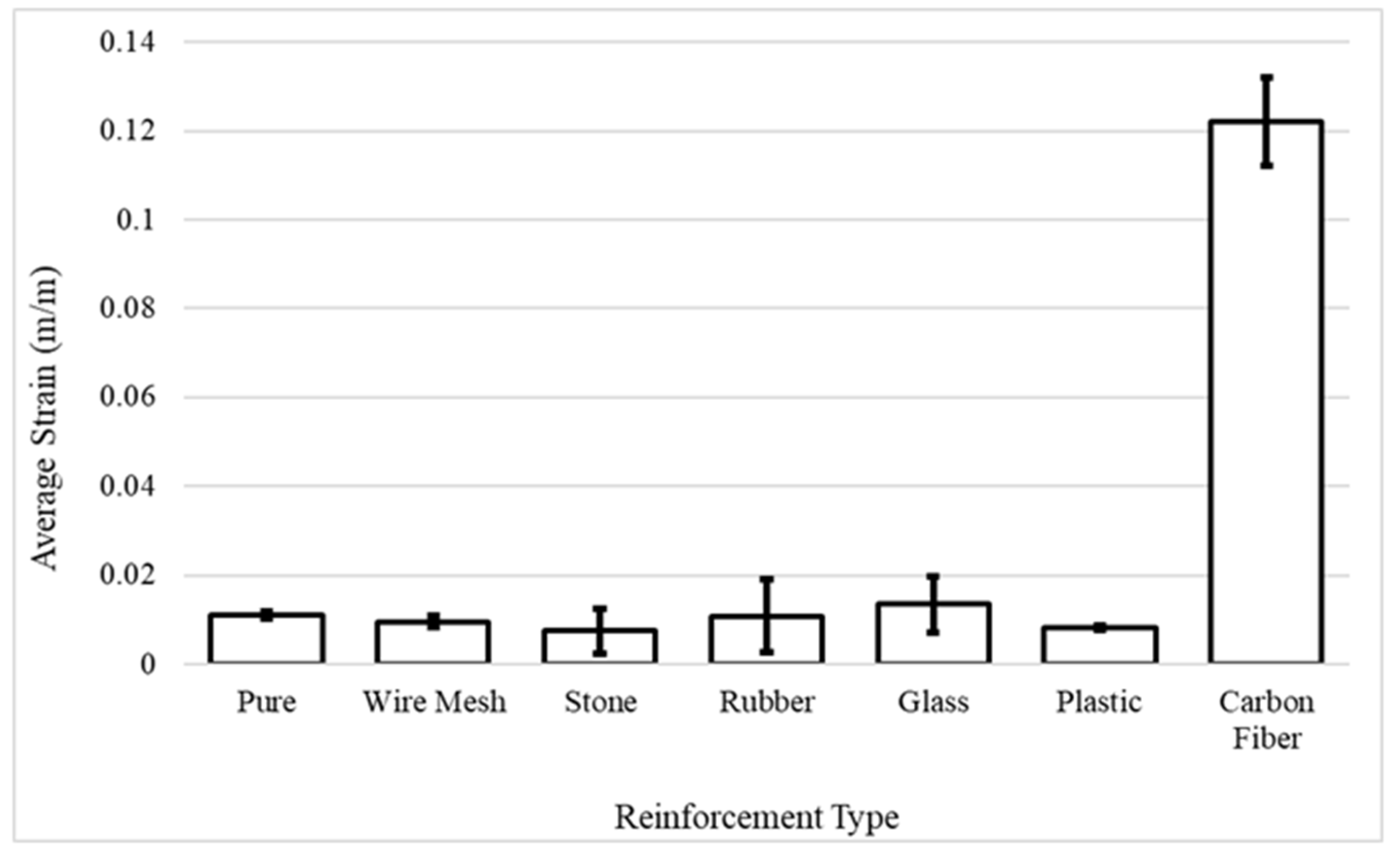

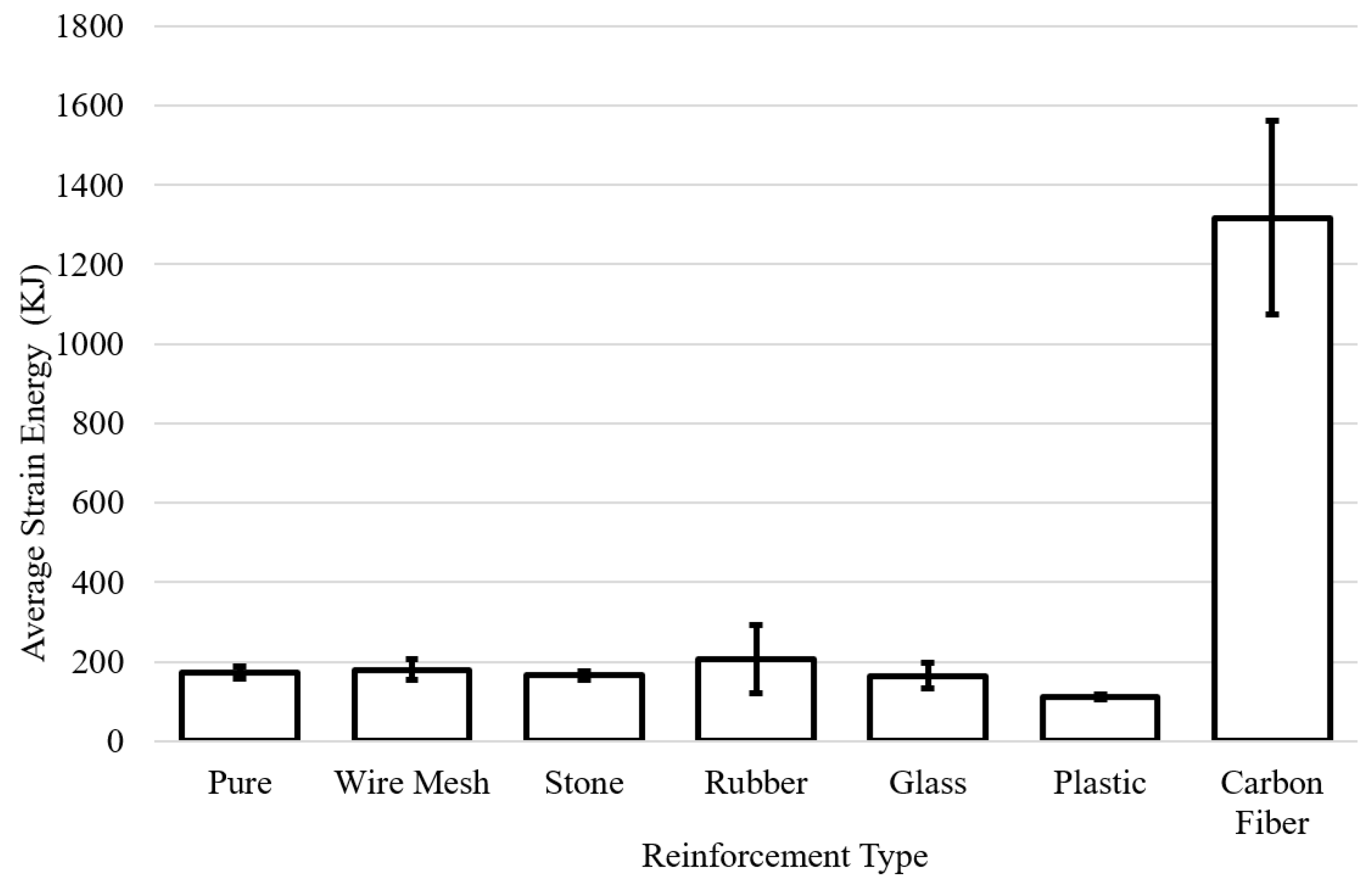

3. Results and Discussion

4. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Law, K.L.; Starr, N.; Siegler, T.R.; Jambeck, J.R.; Mallos, N.J.; Leonard, G.H. The United States’ contribution of plastic waste to land and ocean. Sci. Adv. 2020, 6, eabd0288. [Google Scholar] [CrossRef]

- Bastami, M.; Mousavi, A.E.; Abbasnejadfard, M. Evaluation of Mechanical Characteristics of High-Strength Reinforced Concrete Columns with Hexagonal Chicken Wire Mesh Under Cyclic Loading. Int. J. Concr. Struct. Mater. 2022, 16, 30. [Google Scholar] [CrossRef]

- Damodaran Chitra, M.; Rugmini, B.K. Performance of concrete column using welded wire mesh as lateral ties subjected to lateral loading. Pract. Period. Struct. Des. Constr. 2022, 27, 04021070. [Google Scholar] [CrossRef]

- El-Kholy, A.M.; Dahish, H.A. Improved confinement of reinforced concrete columns. Ain Shams Eng. J. 2016, 7, 717–728. [Google Scholar] [CrossRef]

- El-Kholy, A.M.; Abd El-Mola, S.; Abd El-Aziz, M.A.; Shaheen, A.A. Effectiveness of combined confinement with metal meshes and ties for preloaded and post-heated RC short columns. Arab. J. Sci. Eng. 2018, 43, 1875–1891. [Google Scholar] [CrossRef]

- Emara, M.; Mohamed, H.A.; Rizk, M.S.; Hu, J.W. Behavior of ECC columns confined using steel wire mesh under axial loading. J. Build. Eng. 2021, 43, 102809. [Google Scholar] [CrossRef]

- Gupta, P.K. Confinement of concrete columns with unplasticized poly-vinyl chloride tubes. Int. J. Adv. Struct. Eng. 2013, 5, 19. [Google Scholar] [CrossRef]

- del Rey Castillo, E.; Almesfer, N.; Saggi, O.; Ingham, J.M. Light-weight concrete with artificial aggregate manufactured from plastic waste. Constr. Build. Mater. 2020, 265, 120199. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Strength Models for Fiber-Reinforced Plastic-Confined Concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar] [CrossRef]

- Li, L.J.; Tu, G.R.; Lan, C.; Liu, F. Mechanical characterization of waste-rubber-modified recycled-aggregate concrete. J. Clean. Prod. 2016, 124, 325–338. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Mousavimehr, M. Residual Compressive Stress–Strain Relationship for Hybrid Recycled PET–Crumb Rubber Aggregate Concrete after Exposure to Elevated Temperatures. J. Mater. Civ. Eng. 2019, 31, 04019136. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Mousavimehr, M.; Nematzadeh, M. Predicting post-fire behavior of crumb rubber aggregate concrete. Constr. Build. Mater. 2019, 229, 116834. [Google Scholar] [CrossRef]

- Li, X.; Ling, T.C.; Hung Mo, K. Functions and impacts of plastic/rubber wastes as eco-friendly aggregate in concrete—A review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- Mousavimehr, M.; Nematzadeh, M. Post-heating flexural behavior and durability of hybrid PET–Rubber aggregate concrete. Constr. Build. Mater. 2020, 265, 120359. [Google Scholar] [CrossRef]

- Liang, J.; Zhu, H.; Chen, L.; Han, X.; Guo, Q.; Gao, Y.; Liu, C. Rebar corrosion investigation in rubber aggregate concrete via the chloride electro-accelerated test. Materials 2019, 16, 862. [Google Scholar] [CrossRef] [PubMed]

- Vadivel, T.S.; Thenmozhi, R.; Doddurani, M. Experimental behaviour of waste tyre rubber aggregate concrete under impact loading. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2014, 38, 251–259. [Google Scholar]

- Toma, I.-O.; Taranu, N.; Banu, O.-M.; Budescu, M.; Mihai, P.; Taran, R.-G. the Effect of the Aggregate Replacement By Waste Tyre Rubber Crumbs on the Mechanical Properties of Concrete. Rev. Rom. Mater. J. Mater. 2015, 45, 394–401. [Google Scholar]

- Mendis, A.S.M.; Al-Deen, S.; Ashraf, M. Effect of rubber particles on the flexural behaviour of reinforced crumbed rubber concrete beams. Constr. Build. Mater. 2017, 154, 644–657. [Google Scholar] [CrossRef]

- Atoyebi, O.D.; Sadiq, O.M. Experimental data on flexural strength of reinforced concrete elements with waste glass particles as partial replacement for fine aggregate. Data Br. 2018, 18, 846–859. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Gnappi, G.; Moriconi, G.; Montenero, A. Reuse of ground waste glass as aggregate for mortars. Waste Manag. 2005, 25, 197–201. [Google Scholar] [CrossRef] [PubMed]

- Afshinnia, K.; Rangaraju, P.R. Influence of fineness of ground recycled glass on mitigation of alkali–silica reaction in mortars. Constr. Build. Mater. 2015, 81, 257–267. [Google Scholar] [CrossRef]

- Nodehi, M.; Mohamad Taghvaee, V. Sustainable concrete for circular economy: A review on use of waste glass. Glass Struct. Eng. 2021, 7, 3–22. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Compos. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Nematzadeh, M.; Chastre, C. Prediction of shear behavior of steel fiber-reinforced rubberized concrete beams reinforced with glass fiber-reinforced polymer (GFRP) bars. Compos. Struct. 2021, 256, 113010. [Google Scholar] [CrossRef]

- Wu, T.; Sun, Y.; Liu, X.; Wei, H. Flexural Behavior of Steel Fiber–Reinforced Lightweight Aggregate Concrete Beams Reinforced with Glass Fiber–Reinforced Polymer Bars. J. Compos. Constr. 2019, 23, 04018081. [Google Scholar] [CrossRef]

- Toutanji, H.A.; El-Korchi, T.; Katz, R.N.; Leatherman, G.L. Behaviour of carbon fiber reinforced cement composites in direct tension. Cem. Concr. Res. 1993, 23, 618–626. [Google Scholar] [CrossRef]

- Toutanji, H.A.; El-Korchi, T.; Katz, R.N. Strength and reliability of carbon-fiber-reinforced cement composites. Cem. Concr. Compos. 1994, 16, 15–21. [Google Scholar] [CrossRef]

- Rodin, H.; Rangelov, M.; Nassiri, S.; Englund, K. Enhancing Mechanical Properties of Pervious Concrete Using Carbon Fiber Composite Reinforcement. J. Mater. Civ. Eng. 2018, 30, 04018012. [Google Scholar] [CrossRef]

- Kimm, M.; Sabir, A.; Gries, T.; Suwanpinij, P. Potential of Using Recycled Carbon Fibers as Reinforcing Material for Fiber Concrete. RILEM Bookser. 2020, 30, 949–960. [Google Scholar] [CrossRef]

- Xiong, C.; Lan, T.; Li, Q.; Li, H.; Long, W. Study of Mechanical Properties of an Eco-Friendly Concrete Containing Recycled Carbon Fiber Reinforced Polymer and Recycled Aggregate. Materials 2020, 13, 4592. [Google Scholar] [CrossRef] [PubMed]

- Yin, P.; Huang, L.; Yan, L.; Zhu, D. Compressive behavior of concrete confined by CFRP and transverse spiral reinforcement. Part A: Experimental study. Mater. Struct. Constr. 2016, 49, 1001–1011. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M. Production of sustainable fibre-reinforced concrete incorporating waste chopped metallic film fibres and palm oil fuel ash. Sadhana-Acad. Proc. Eng. Sci. 2018, 43, 156. [Google Scholar] [CrossRef]

- Zong, S.; Liu, Z.; Li, S.; Lu, Y.; Zheng, A. Stress-strain behaviour of steel-fibre-reinforced recycled aggregate concrete under axial tension. J. Clean. Prod. 2021, 278, 123248. [Google Scholar] [CrossRef]

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic compressive behaviour of recycled tyre steel fibre reinforced concrete. Constr. Build. Mater. 2022, 316, 125896. [Google Scholar] [CrossRef]

- ASTM C470; Standard Specification for Molds for Forming Concrete Test Cylinders Vertically 1. ASTM International Standard: West Conshohocken, PA, USA, 2003; Volume 8, pp. 1–5. [CrossRef]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens 1. ASTM International Standard: West Conshohocken, PA, USA, 2003; Volume i, pp. 1–5. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scarpitti, N.; Gavio, N.; Pol, A.; Sanei, S.H.R. Recycling Unrecycled Plastic and Composite Wastes as Concrete Reinforcement. J. Compos. Sci. 2023, 7, 11. https://doi.org/10.3390/jcs7010011

Scarpitti N, Gavio N, Pol A, Sanei SHR. Recycling Unrecycled Plastic and Composite Wastes as Concrete Reinforcement. Journal of Composites Science. 2023; 7(1):11. https://doi.org/10.3390/jcs7010011

Chicago/Turabian StyleScarpitti, Nicholas, Nicholas Gavio, Alexander Pol, and Seyed Hamid Reza Sanei. 2023. "Recycling Unrecycled Plastic and Composite Wastes as Concrete Reinforcement" Journal of Composites Science 7, no. 1: 11. https://doi.org/10.3390/jcs7010011

APA StyleScarpitti, N., Gavio, N., Pol, A., & Sanei, S. H. R. (2023). Recycling Unrecycled Plastic and Composite Wastes as Concrete Reinforcement. Journal of Composites Science, 7(1), 11. https://doi.org/10.3390/jcs7010011