Combined Effects of Solar Radiation and High Vacuum on the Properties of Graphene/Polysiloxane Nanocomposites in Simulated Space Environment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Graphene/PDMS Nanocomposites

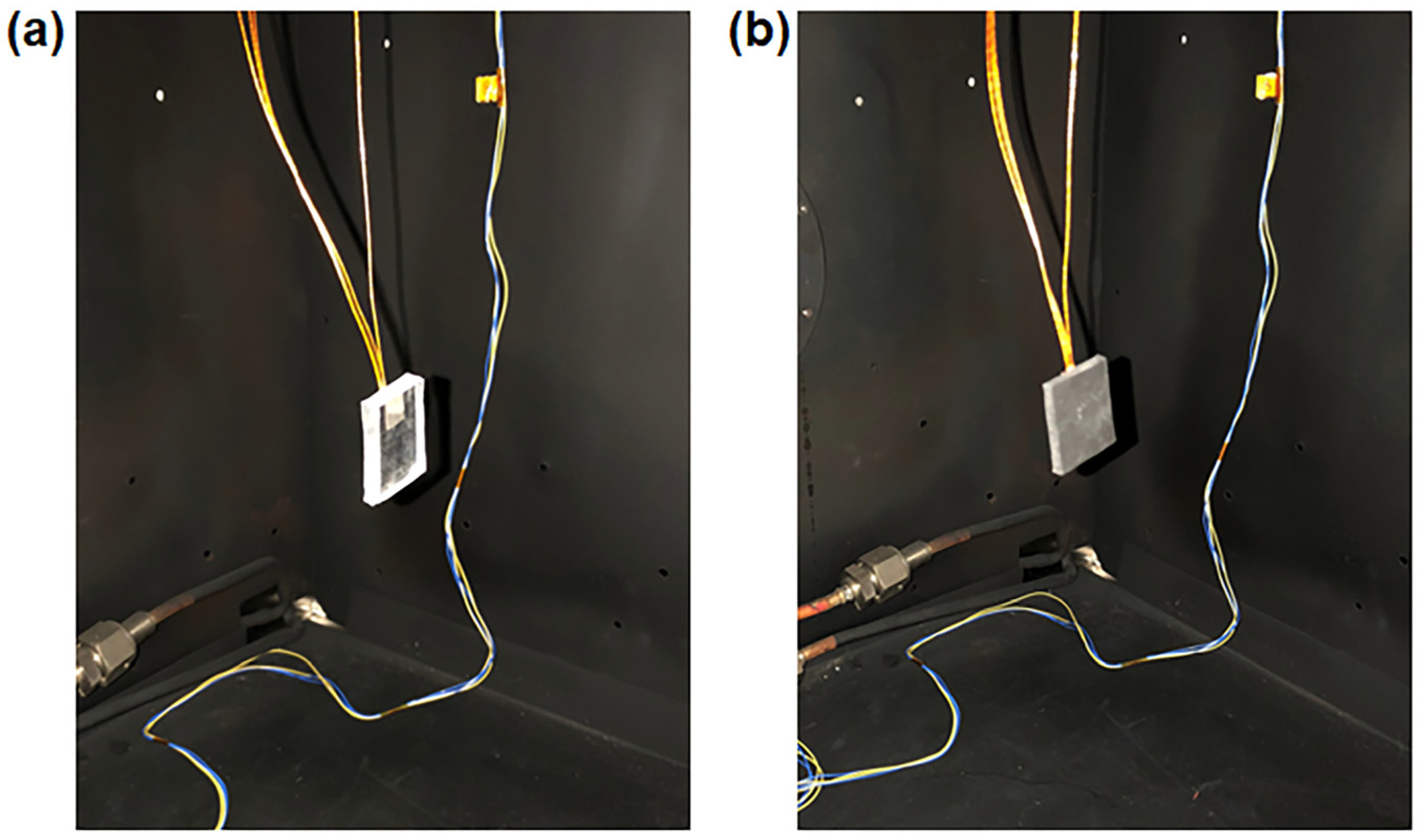

2.3. Tests under Simulated Space Conditions

2.4. Characterisation Methods

3. Results and Discussion

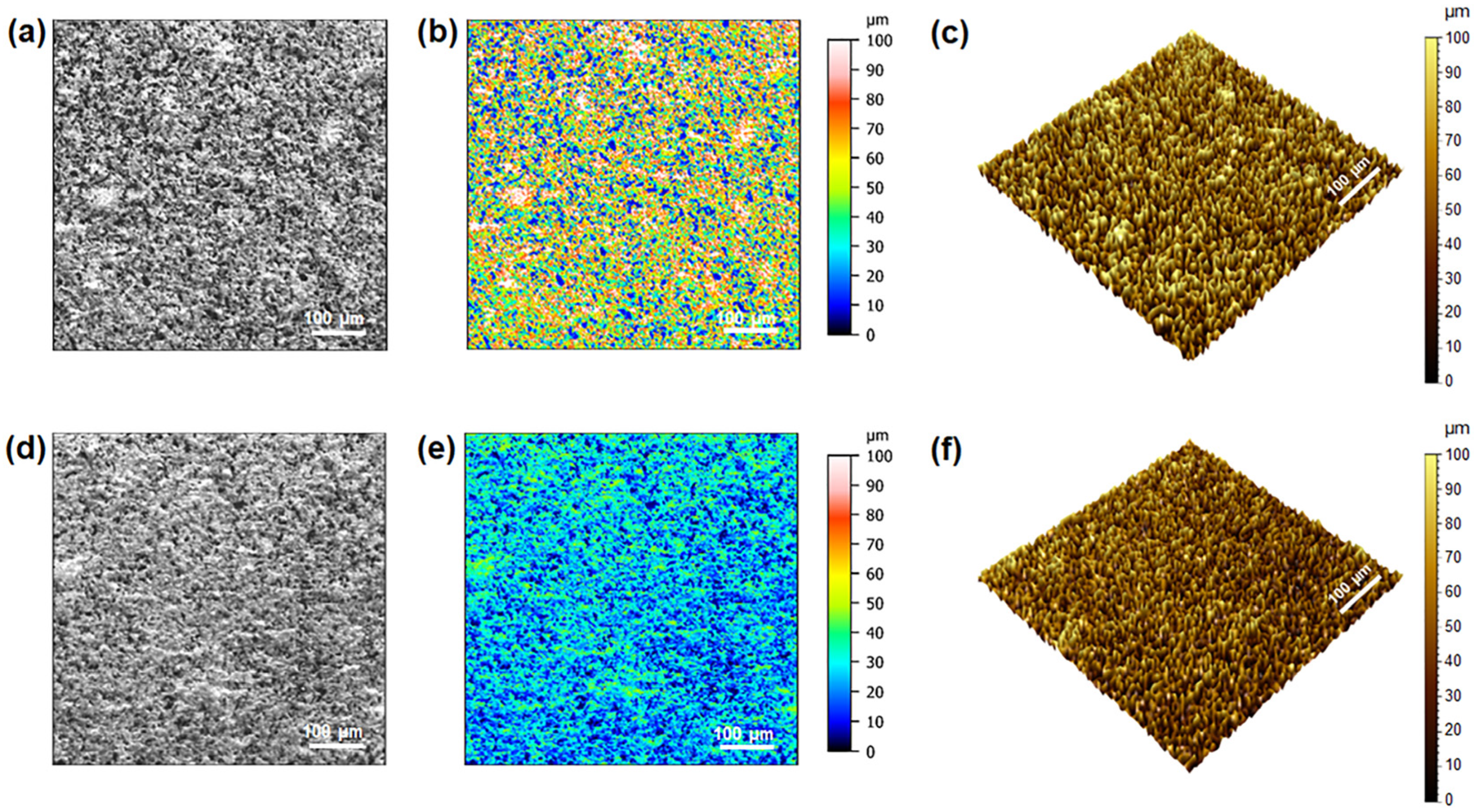

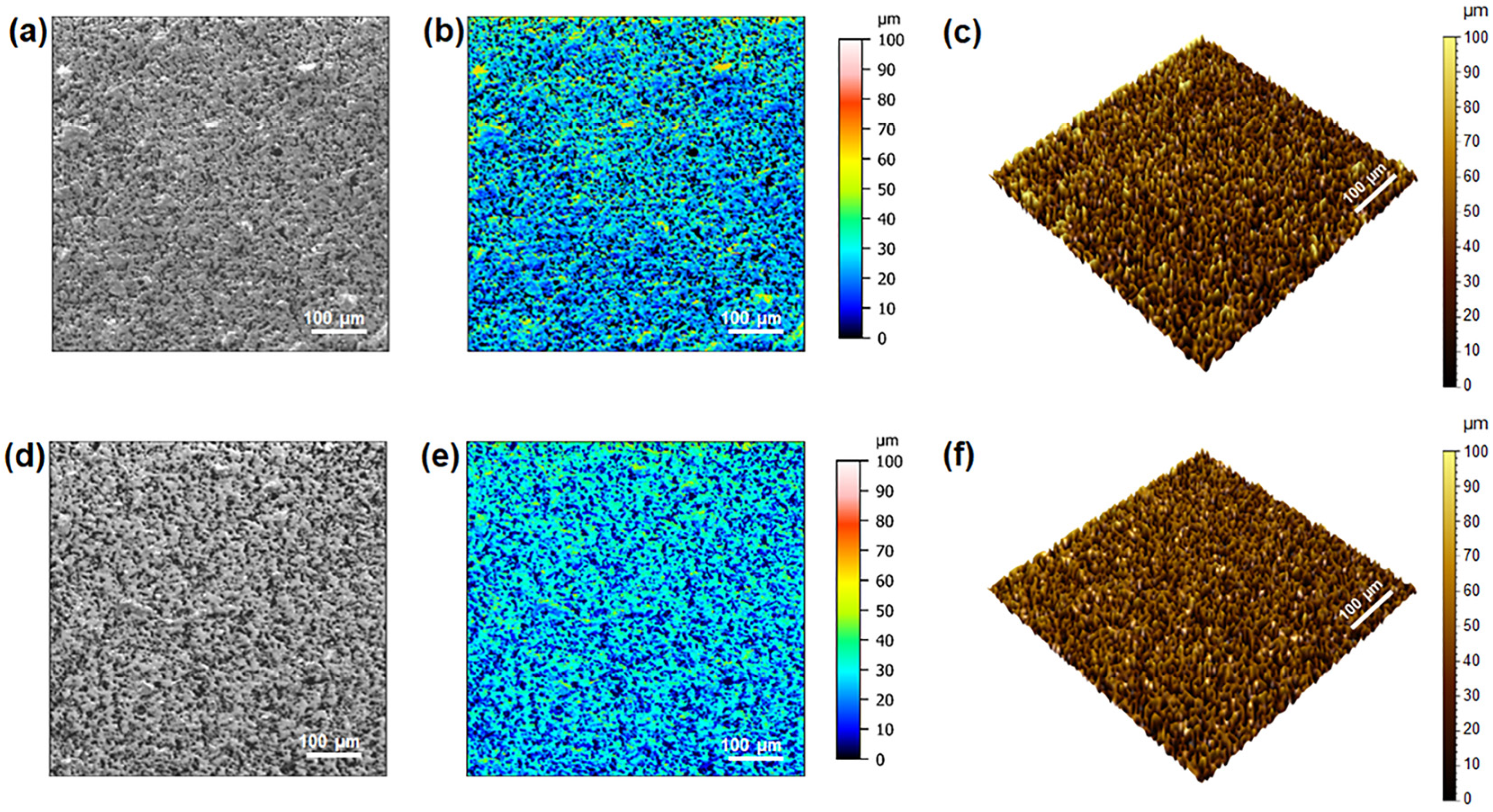

3.1. Morphology and Surface Topography Reconstruction by SEM

3.2. Thermal Analysis of Nanocomposites before and after Exposure

3.3. Outgassing Properties

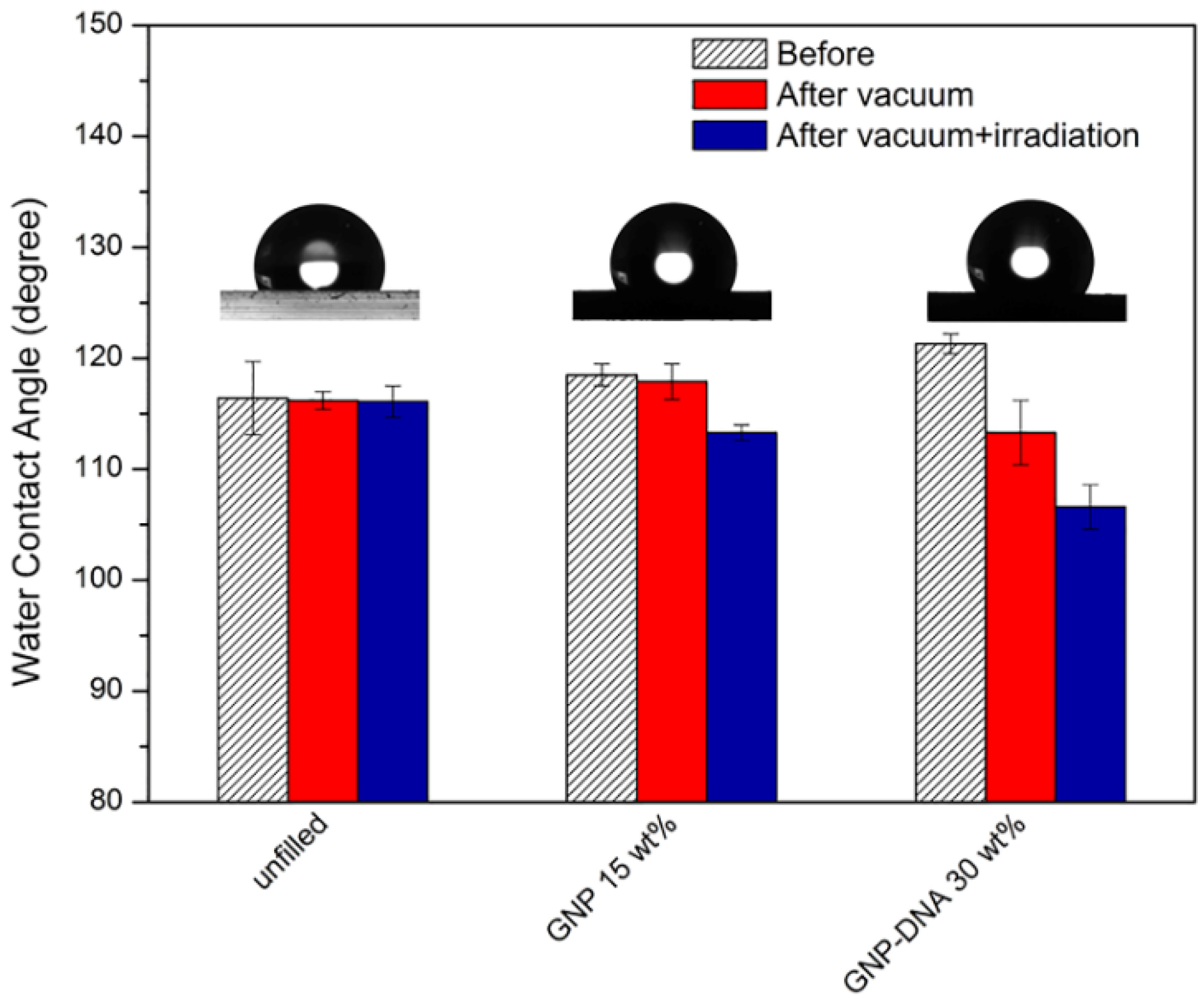

3.4. Effects of the Space Environment on Surface Wettability and SFE

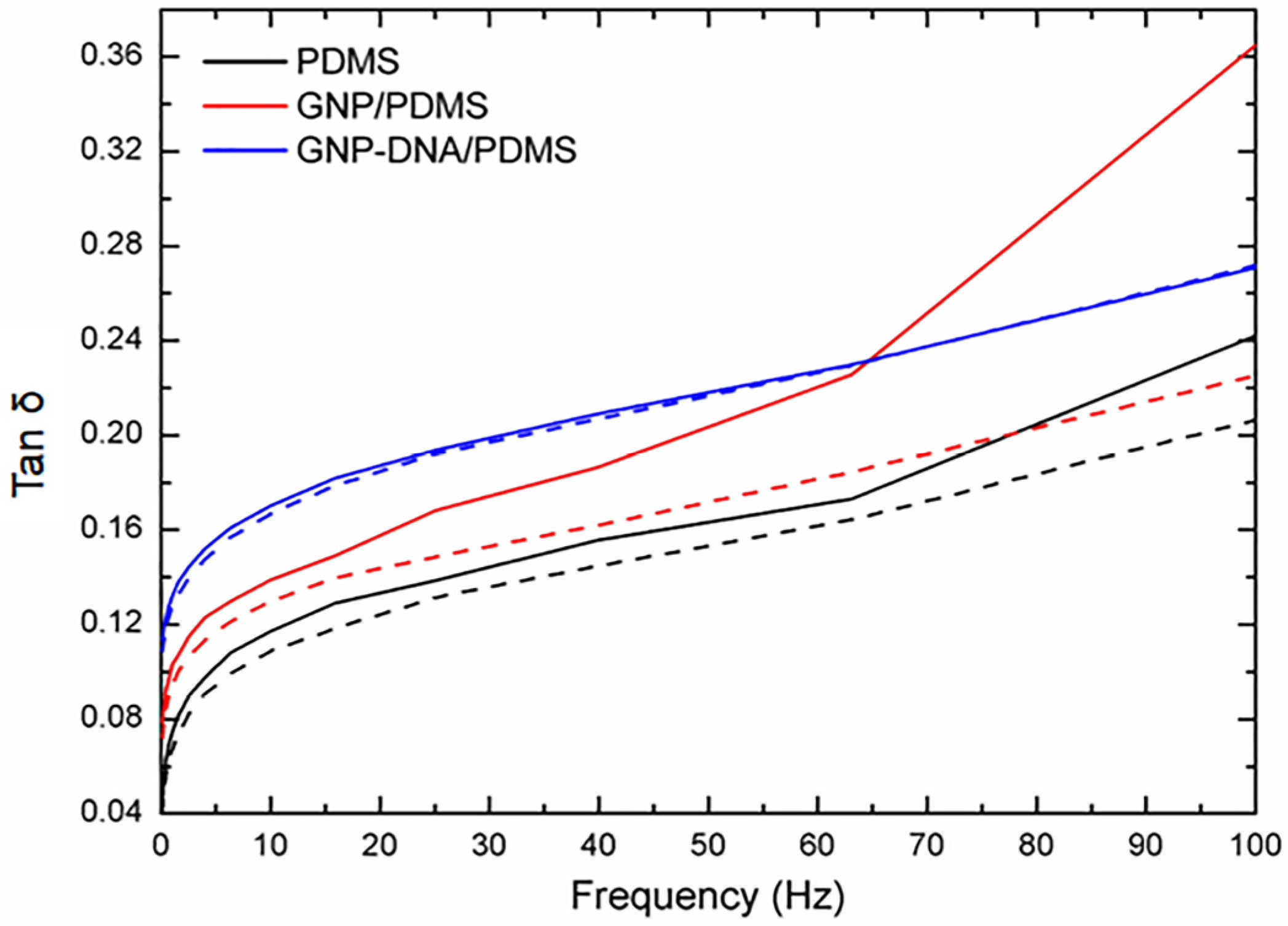

3.5. Exposure Effects on the Mechanical Properties of Nanocomposites Using DMA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kausar, A.; Rafique, I.; Muhammad, B. Aerospace application of polymer nanocomposite with carbon nanotube, graphite, graphene oxide, and nanoclay. Polym. Plast. Technol. Eng. 2017, 56, 1438–1456. [Google Scholar] [CrossRef]

- Peters, M.; Leyens, C. Aerospace and space materials. Mater. Sci. Eng. 2009, 3, 1–11. [Google Scholar]

- Ghidini, T. Materials for space exploration and settlement. Nat. Mater. 2018, 17, 846–850. [Google Scholar] [CrossRef] [PubMed]

- Naser, M.Z.; Chehab, A.I. Materials and design concepts for space-resilient structures. Prog. Aerosp. Sci. 2018, 98, 74–90. [Google Scholar] [CrossRef]

- Zaccardi, F.; Toto, E.; Rastogi, S.; La Saponara, V.; Santonicola, M.G.; Laurenzi, S. Impact of Proton Irradiation on Medium Density Polyethylene/Carbon Nanocomposites for Space Shielding Applications. Nanomaterials 2023, 13, 1288. [Google Scholar] [CrossRef]

- Kessler, M.R. Polymer Matrix Composites: A Perspective for a Special Issue of Polymer Reviews. Polym. Rev. 2012, 52, 229–233. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Khalina, A.; Sapuan, S.; Dayang Laila, A.; Rahmah, M.; Hanafee, Z. A Review: Fibres, Polymer Matrices and Composites. Pertanika J. Sci. Technol. 2017, 25, 4. [Google Scholar]

- Moon, J.-B.; Kim, M.-G.; Kim, C.-G.; Bhowmik, S. Improvement of tensile properties of CFRP composites under LEO space environment by applying MWNTs and thin-ply. Compos. Appl. Sci. Manuf. 2011, 42, 694–701. [Google Scholar] [CrossRef]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in Polyimide-Based Materials for Space Applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef]

- Paesano, A.; Cohee, D.; Palmese, G. Carbon-fiber reinforced thermoplastic materials for rigidizable space systems. J. Thermoplast. Compos. Mater. 2003, 16, 139–170. [Google Scholar] [CrossRef]

- Tribble, A.C. The Space Environment: Implications for Spacecraft Design-Revised and Expanded Edition; Princeton University Press: Princeton, NJ, USA, 2003. [Google Scholar]

- Paillous, A.; Pailler, C. Degradation of multiply polymer-matrix composites induced by space environment. Compos. Part A Appl. Sci. Manuf. 1994, 25, 287–295. [Google Scholar] [CrossRef]

- Grossman, E.; Gouzman, I. Space environment effects on polymers in low earth orbit. Nucl. Instrum. Methods Phys. Res. B 2003, 208, 48–57. [Google Scholar] [CrossRef]

- Harvey, R. Spacecraft neutral self-contamination by molecular outgassing. J. Spacecr. Rockets 1976, 13, 301–305. [Google Scholar] [CrossRef]

- Kaczmarek, H.; Ołdak, D.; Malanowski, P.; Chaberska, H. Effect of short wavelength UV-irradiation on ageing of polypropylene/cellulose compositions. Polym. Degrad. Stab. 2005, 88, 189–198. [Google Scholar] [CrossRef]

- Lee, J.; Maddipatla, M.V.S.N.; Joy, A.; Vogt, B.D. Kinetics of UV Irradiation Induced Chain Scission and Cross-Linking of Coumarin-Containing Polyester Ultrathin Films. Macromolecules 2014, 47, 2891–2898. [Google Scholar] [CrossRef]

- Agarwal, C.; Kalsi, P. UV-irradiation effects on polyester nuclear track detector. Radiat. Phys. Chem. 2010, 79, 844–847. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Zepp, R.; Ruggiero, E.; Acrey, B.; Davis, M.J.B.; Han, C.; Hsieh, H.-S.; Vilsmeier, K.; Wohlleben, W.; Sahle-Demessie, E. Fragmentation of polymer nanocomposites: Modulation by dry and wet weathering, fractionation, and nanomaterial filler. Environ. Sci. Nano 2020, 7, 1742–1758. [Google Scholar] [CrossRef] [PubMed]

- Shehzad, F.; Ahmad, M.I.; Al-Harthi, M.A. Photooxidative degradation of graphene-reinforced high-density polyethylene nanocomposites. J. Appl. Polym. Sci. 2019, 136, 47030. [Google Scholar] [CrossRef]

- Gu, X.; Chen, G.; Zhao, M.; Watson, S.S.; Nguyen, T.; Chin, J.W.; Martin, J.W. Critical role of particle/polymer interface in photostability of nano-filled polymeric coatings. J. Coat. Technol. Res. 2012, 9, 251–267. [Google Scholar] [CrossRef]

- Kumar, A.P.; Depan, D.; Tomer, N.S.; Singh, R.P. Nanoscale particles for polymer degradation and stabilization—Trends and future perspectives. Prog. Polym. Sci. 2009, 34, 479–515. [Google Scholar] [CrossRef]

- Aslam, S.; Yan, F.; Pugel, D.; Franz, D.; Miko, L.; Herrero, F.; Matsumara, M.; Babu, S.; Stahle, C. Development of ultra-high sensitivity wide-band gap UV-EUV detectors at NASA Goddard Space Flight Center. In Proceedings of the Optics and Photonics 2005, San Diego, CA, USA, 18 August 2005. [Google Scholar] [CrossRef]

- Vigué, F.; Tournié, E.; Faurie, J.-P.; Monroy, E.; Calle, F.; Muñoz, E. Visible-blind ultraviolet photodetectors based on ZnMgBeSe Schottky barrier diodes. Appl. Phys. Lett. 2001, 78, 4190–4192. [Google Scholar] [CrossRef]

- Heo, Y.W.; Kang, B.S.; Tien, L.C.; Norton, D.P.; Ren, F.; La Roche, J.R.; Pearton, S.J. UV photoresponse of single ZnO nanowires. Appl. Phys. A 2005, 80, 497–499. [Google Scholar] [CrossRef]

- Das, S.N.; Moon, K.-J.; Kar, J.P.; Choi, J.-H.; Xiong, J.; Lee, T.I.; Myoung, J.-M. ZnO single nanowire-based UV detectors. Appl. Phys. Lett. 2010, 97, 22103. [Google Scholar] [CrossRef]

- Zhai, T.; Li, L.; Wang, X.; Fang, X.; Bando, Y.; Golberg, D. Recent Developments in One-Dimensional Inorganic Nanostructures for Photodetectors. Adv. Funct. Mater. 2010, 20, 4233–4248. [Google Scholar] [CrossRef]

- Peng, L.; Hu, L.; Fang, X. Low-Dimensional Nanostructure Ultraviolet Photodetectors. Adv. Mater. 2013, 25, 5321–5328. [Google Scholar] [CrossRef]

- Bai, S.; Wu, W.; Qin, Y.; Cui, N.; Bayerl, D.J.; Wang, X. High-Performance Integrated ZnO Nanowire UV Sensors on Rigid and Flexible Substrates. Adv. Funct. Mater. 2011, 21, 4464–4469. [Google Scholar] [CrossRef]

- Garipov, G.K.; Khrenov, B.A.; Panasyuk, M.I.; Tulupov, V.I.; Shirokov, A.V.; Yashin, I.V.; Salazar, H. UV radiation from the atmosphere: Results of the MSU “Tatiana” satellite measurements. Astropart. Phys. 2005, 24, 400–408. [Google Scholar] [CrossRef]

- Shi, L.; Nihtianov, S. Comparative Study of Silicon-Based Ultraviolet Photodetectors. IEEE Sens. J. 2012, 12, 2453–2459. [Google Scholar] [CrossRef]

- Feizi, S.; Malekie, S.; Rahighi, R.; Tayyebi, A.; Ziaie, F. Evaluation of dosimetric characteristics of graphene oxide/PVC nanocomposite for gamma radiation applications. Radiochim. Acta 2017, 105, 161–170. [Google Scholar] [CrossRef]

- Feizi, S.; Mehdizadeh, A.; Hosseini, M.A.; Jafari, S.A.; Ashtari, P. Reduced graphene oxide/polymethyl methacrylate (rGO/PMMA) nanocomposite for real time gamma radiation detection. Nucl. Instrum. Methods Phys. Res. A 2019, 940, 72–77. [Google Scholar] [CrossRef]

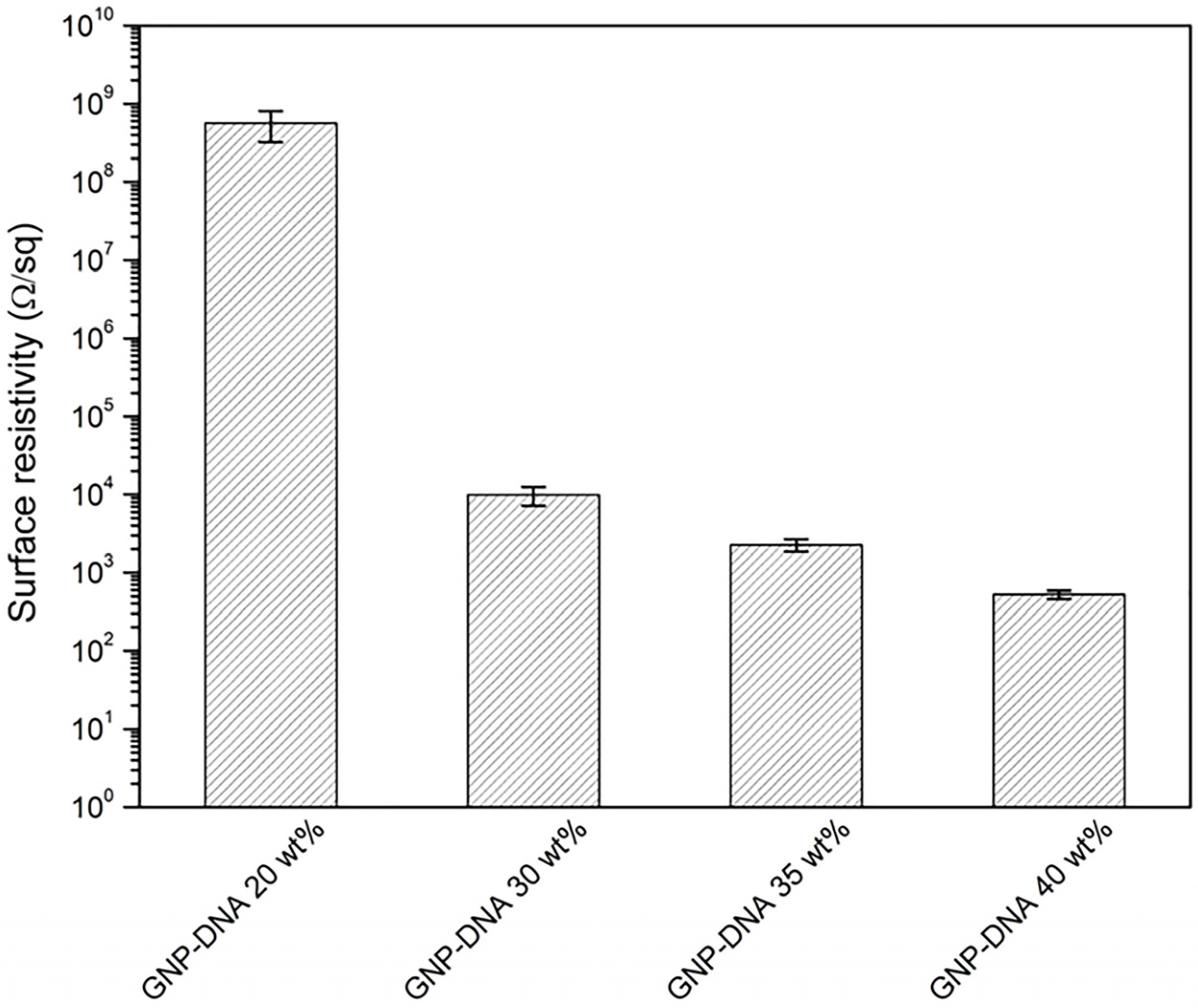

- Toto, E.; Palombi, M.; Laurenzi, S.; Santonicola, M.G. Functional nanocomposites with graphene-DNA hybrid fillers: Synthesis and surface properties under UV irradiation. Ceram. Int. 2019, 45, 9631–9637. [Google Scholar] [CrossRef]

- Clausi, M.; Toto, E.; Botti, S.; Laurenzi, S.; La Saponara, V.; Santonicola, M.G. Direct effects of UV irradiation on graphene-based nanocomposite films revealed by electrical resistance tomography. Compos. Sci. Technol. 2019, 183, 107823. [Google Scholar] [CrossRef]

- Toto, E.; Santonicola, M.G.; Mancini, M.C.; Laurenzi, S. Ultraviolet-sensing surfaces based on hybrid nanocomposites for radiation monitoring systems. In Proceedings of the 4th IEEE International Workshop on Metrology for AeroSpace (MetroAeroSpace), Padua, Italy, 21–23 June 2017; pp. 369–373. [Google Scholar] [CrossRef]

- Toto, E.; Botti, S.; Laurenzi, S.; Santonicola, M.G. UV-induced modification of PEDOT:PSS-based nanocomposite films investigated by Raman microscopy mapping. Appl. Surf. Sci. 2020, 513, 145839. [Google Scholar] [CrossRef]

- Toto, E.; Laurenzi, S.; Santonicola, M.G. Recent trends in graphene/polymer nanocomposites for sensing devices: Synthesis and applications in environmental and human health monitoring. Polymers 2022, 14, 1030. [Google Scholar] [CrossRef]

- Santonicola, M.G.; Coscia, M.G.; Sirilli, M.; Laurenzi, S. Nanomaterial-based biosensors for a real-time detection of biological damage by UV light. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, EMBS, Milan, Italy, 25–29 August 2015; pp. 4391–4394. [Google Scholar] [CrossRef]

- Bradley, M.O. Double-strand breaks in DNA caused by repair of damage due to ultraviolet light. J. Supramol. Struct. Cell. Biochem. 1981, 16, 337–343. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Rosenstein, B.S.; Wang, Y.; Lebwohl, M.; Mitchell, D.M.; Wei, H. Induction of 8-Oxo-7, 8-Dihydro-2’-Deoxyguanosine by Ultraviolet Radiation in Calf Thymus DNA and HeLa Cells. Photochem. Photobiol. 1997, 65, 119–124. [Google Scholar] [CrossRef]

- Borysiak, M.D.; Bielawski, K.S.; Sniadecki, N.J.; Jenkel, C.F.; Vogt, B.D.; Posner, J.D. Simple replica micromolding of biocompatible styrenic elastomers. Lab Chip 2013, 13, 2773–2784. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Cheng, S.; Gao, Q.; Yuan, Y.; Li, A.; Guan, S. PDMS-based conductive elastomeric composite with 3D reduced graphene oxide conductive network for flexible strain sensor. Compos. Appl. Sci. Manuf. 2022, 161, 107113. [Google Scholar] [CrossRef]

- Paris, C.; Sindoni, G. LARES-Lab: A facility for environmental testing of satellite components and micro satellites. In Proceedings of the 2nd International Academy of Astronautics Conference on Dynamics and Control of Space Systems (DyCoSS), Rome, Italy, 24–26 March 2014; pp. 575–582. [Google Scholar]

- Santonicola, M.; Toto, E.; Maria, P.; Paris, C.; Laurenzi, S. Experimental study of solar radiation effects on carbon nanocomposite sensors in simulated space environment. In Proceedings of the 69th International Astronautical Congress, IAC, Bremen, Germany, 1–5 October 2018; pp. 1–8. [Google Scholar]

- Toto, E.; Laurenzi, S.; Santonicola, M.G. Flexible Nanocomposites Based on Polydimethylsiloxane Matrices with DNA-Modified Graphene Filler: Curing Behavior by Differential Scanning Calorimetry. Polymers 2020, 12, 2301. [Google Scholar] [CrossRef]

- Persky, M.J. Review of black surfaces for space-borne infrared systems. Rev. Sci. Instrum. 1999, 70, 2193–2217. [Google Scholar] [CrossRef]

- Mignot, C. Color (and 3D) for scanning electron microscopy. Microsc. Today 2018, 26, 12–17. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Isarov, S.A.; Lee, P.W.; Towslee, J.H.; Hoffman, K.M.; Davis, R.D.; Maia, J.M.; Pokorski, J.K. DNA as a flame retardant additive for low-density polyethylene. Polymer 2016, 97, 504–514. [Google Scholar] [CrossRef]

- Godley, B.F.; Shamsi, F.A.; Liang, F.-Q.; Jarrett, S.G.; Davies, S.; Boulton, M. Blue Light Induces Mitochondrial DNA Damage and Free Radical Production in Epithelial Cells. J. Biol. Chem. 2005, 280, 21061–21066. [Google Scholar] [CrossRef] [PubMed]

- Peak, J.; Peak, M.; Sikorski, R.; Jones, C. Induction of DNA-protein crosslinks in human cells by ultraviolet and visible radiations: Action spectrum. Photochem. Photobiol. 1985, 41, 295–302. [Google Scholar] [CrossRef]

- Fekete, A.; Módos, K.; Hegedüs, M.; Kovács, G.; Rontó, G.; Péter, Á.; Lammer, H.; Panitz, C. DNA damage under simulated extraterrestrial conditions in bacteriophage T7. Adv. Space Res. 2005, 36, 303–310. [Google Scholar] [CrossRef]

- Hegedüs, M.; Kovács, G.; Módos, K.; Rontó, G.; Lammer, H.; Panitz, C.; Fekete, A. Exposure of phage T7 to simulated space environment: The effect of vacuum and UV-C radiation. J. Photochem. Photobiol. B Biol. 2006, 82, 94–104. [Google Scholar] [CrossRef]

- Cierpisz, M.; McPhedran, J.; He, Y.; Edrisy, A. Characterization of graphene-filled fluoropolymer coatings for condensing heat exchangers. J. Compos. Mater. 2021, 55, 4305–4320. [Google Scholar] [CrossRef]

- Savin, A.V.; Mazo, M.A.; Kikot, I.P.; Manevitch, L.I.; Onufriev, A.V. Heat conductivity of the DNA double helix. Phys. Rev. B 2011, 83, 245406. [Google Scholar] [CrossRef]

- Giljean, S.; Bigerelle, M.; Anselme, K.; Haidara, H. New insights on contact angle/roughness dependence on high surface energy materials. Appl. Surf. Sci. 2011, 257, 9631–9638. [Google Scholar] [CrossRef]

- Ashori, A.; Menbari, S.; Bahrami, R. Mechanical and thermo-mechanical properties of short carbon fiber reinforced polypropylene composites using exfoliated graphene nanoplatelets coating. J. Ind. Eng. Chem. 2016, 38, 37–42. [Google Scholar] [CrossRef]

- Tareq, M.S.; Zainuddin, S.; Woodside, E.; Syed, F. Investigation of the flexural and thermomechanical properties of nanoclay/graphene reinforced carbon fiber epoxy composites. J. Mater. Res. 2019, 34, 3678–3687. [Google Scholar] [CrossRef]

- Panwar, V.; Pal, K. Chapter 12—Dynamic Mechanical Analysis of Clay–Polymer Nanocomposites. In Clay-Polymer Nanocomposites; Jlassi, K., Chehimi, M.M., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 413–441. [Google Scholar] [CrossRef]

- Zubair, M.; Jose, J.; Emwas, A.-H.; Al-Harthi, M.A. Effect of modified graphene and microwave irradiation on the mechanical and thermal properties of poly(styrene-co-methyl methacrylate)/graphene nanocomposites. Surf. Interface Anal. 2014, 46, 630–639. [Google Scholar] [CrossRef]

- Bashir, M.A. Use of Dynamic Mechanical Analysis (DMA) for Characterizing Interfacial Interactions in Filled Polymers. Solids 2021, 2, 108–120. [Google Scholar] [CrossRef]

| Sample | Ra (µm) | ||

|---|---|---|---|

| Before Testing | After Testing (HV + Irradiation) | ΔRa/Ra (%) | |

| 30% GNP-DNA/PDMS | 18.8 ± 1.2 | 7.7 ± 0.6 | −59.0 |

| 15% GNP/PDMS | 7.5 ± 0.7 | 6.9 ± 0.4 | −8.0 |

| Sample | TML% | WVR% | ||

|---|---|---|---|---|

| HV | HV + Irradiation | HV | HV + Irradiation | |

| PDMS | 0.08 | 0.14 | 0.04 | 0.04 |

| 15% GNP/PDMS | 0.11 | 0.49 | 0.06 | 0.06 |

| 30% GNP-DNA/PDMS | 0.61 | 1.95 | 0.23 | 0.25 |

| Sample | SFE (mJ/m2) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Before Testing | After Testing (HV) | After Testing (HV + Irradiation) | |||||||

| Total SFE | γd | γp | Total SFE | γd | γp | Total SFE | γd | γp | |

| PDMS | 21.69 | 21.68 | 0.01 | 21.80 | 21.80 | 0 | 20.64 | 20.64 | 0 |

| 15% GNP/PDMS | 19.19 | 19.19 | 0 | 19.84 | 19.77 | 0.07 | 23.31 | 23.20 | 0.11 |

| 30% GNP-DNA/PDMS | 15.32 | 15.32 | 0 | 19.90 | 19.83 | 0.07 | 25.78 | 25.15 | 0.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toto, E.; Laurenzi, S.; Paris, C.; Santonicola, M.G. Combined Effects of Solar Radiation and High Vacuum on the Properties of Graphene/Polysiloxane Nanocomposites in Simulated Space Environment. J. Compos. Sci. 2023, 7, 215. https://doi.org/10.3390/jcs7060215

Toto E, Laurenzi S, Paris C, Santonicola MG. Combined Effects of Solar Radiation and High Vacuum on the Properties of Graphene/Polysiloxane Nanocomposites in Simulated Space Environment. Journal of Composites Science. 2023; 7(6):215. https://doi.org/10.3390/jcs7060215

Chicago/Turabian StyleToto, Elisa, Susanna Laurenzi, Claudio Paris, and Maria Gabriella Santonicola. 2023. "Combined Effects of Solar Radiation and High Vacuum on the Properties of Graphene/Polysiloxane Nanocomposites in Simulated Space Environment" Journal of Composites Science 7, no. 6: 215. https://doi.org/10.3390/jcs7060215

APA StyleToto, E., Laurenzi, S., Paris, C., & Santonicola, M. G. (2023). Combined Effects of Solar Radiation and High Vacuum on the Properties of Graphene/Polysiloxane Nanocomposites in Simulated Space Environment. Journal of Composites Science, 7(6), 215. https://doi.org/10.3390/jcs7060215