Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker

Abstract

1. Introduction

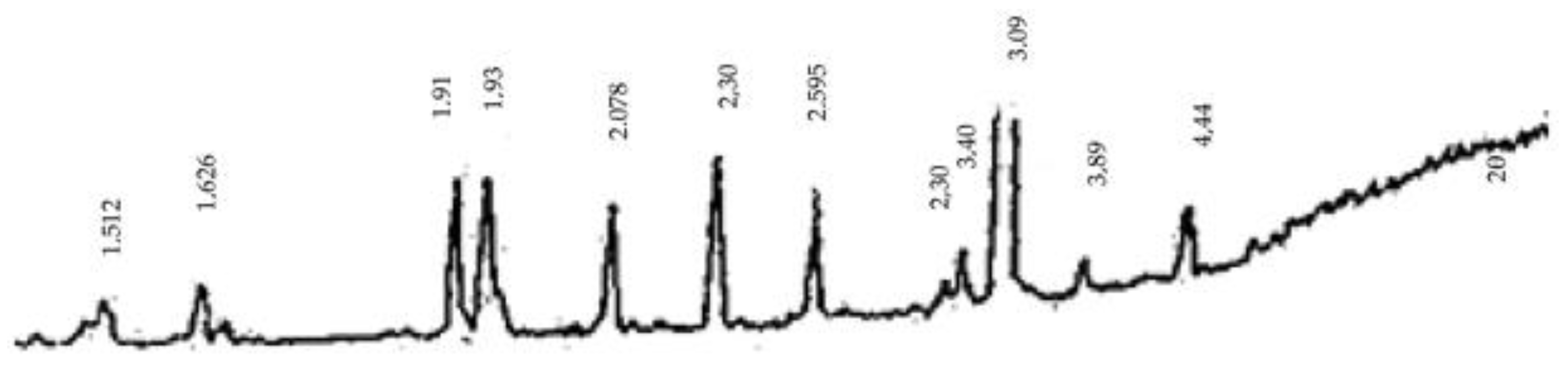

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- − Based on its chemical and elemental composition, the coal ash contained <95% aluminum, calcium, silicon, and iron oxide compounds, the existence of which contributed to the fact that coal ash acted as a secondary raw material for chemical production, in particular, a cheap clay-ferruginous component of the raw material mixture for the production of clinker;

- − Based on the results of the raw mixture optimization modeling, the optimal ratios of coal ash (23.66%) and limestone (76.34%) were established at kn = 0.9;

- − During the simulation of coal ash utilization as a raw material component of a raw mixture with limestone, the technological parameters of firing of the raw mixture at a saturation coefficient of 0.9 and temperature of 1450 °C were determined: in particular, silica module, 1.88; alumina module, 1.92; thermal effect of clinker formation (fec), 336.7 kcal/kg; fuel consumption for firing, kg of conventional fuel (gfuel), 188.7 fuel/t of cl.;

- − As a result of modeling, the optimal mineral structure of clinker was determined, which was presented by the following minerals: C3S, 53.12%; C2S, 17.23%; C3A, 12.34%; C4AF, 11.06%; and MgO, 1.14%;

- − The replacement of traditional raw materials in the form of loess clay and iron ore in the raw material mixture for clinker production with waste in the form of ash from the Balkhash thermal power plant will contribute to a decrease in fuel consumption for firing, kg of conventional fuel (Gfuel), by 13.76%, a decrease in the thermal effect of clinker formation (FEC) by 5.063%, and co-responsibly contribute to a decrease in the firing temperature by 50–70 °C, thereby reducing the cost of the process, ash disposal, and the anthropogenic impact on the environment and the population, while improving sanitary standards and having positive social, economic, and environmental effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable Energy Resources: Current Status, Future Prospects and Their Enabling Technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass in the Generation of Electricity in Portugal: A Review. Renew. Sustain. Energy Rev. 2017, 71, 373–378. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of Renewable Energy Sources in Environmental Protection: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Raza, M.Y.; Wasim, M.; Sarwar, M.S. Development of Renewable Energy Technologies in Rural Areas of Pakistan. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 42, 740–760. [Google Scholar] [CrossRef]

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass Combustion in Fluidized Bed Boilers: Potential Problems and Remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Liu, Q.; Chmely, S.C.; Abdoulmoumine, N. Biomass Treatment Strategies for Thermochemical Conversion. Energy Fuels 2017, 31, 3525–3536. [Google Scholar] [CrossRef]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2012; ISBN 9781136553783. [Google Scholar]

- Cruz, N.C.; Silva, F.C.; Tarelho, L.A.C.; Rodrigues, S.M. Critical Review of Key Variables Affecting Potential Recycling Applications of Ash Produced at Large-Scale Biomass Combustion Plants. Resour. Conserv. Recycl. 2019, 150, 104427. [Google Scholar] [CrossRef]

- Cruz, N.C.; Rodrigues, S.M.; Carvalho, L.; Duarte, A.C.; Pereira, E.; Römkens, P.F.A.M.; Tarelho, L.A.C. Ashes from Fluidized Bed Combustion of Residual Forest Biomass: Recycling to Soil as a Viable Management Option. Environ. Sci. Pollut. Res. 2017, 24, 14770–14781. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Labrincha, J.A.; Rocha, F. Characteristics of Distinct Ash Flows in a Biomass Thermal Power Plant with Bubbling Fluidised Bed Combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- Zhangabay, N.; Suleimenov, U.; Utelbayeva, A.; Buganova, S. Experimental research of the stress-strain state of prestressed cylindrical shells taking into account temperature effects. Case Stud. Constr. Mater. 2022, 18, e01776. [Google Scholar] [CrossRef]

- Silva, F.C.; Cruz, N.C.; Tarelho, L.A.C.; Rodrigues, S.M. Use of Biomass Ash-Based Materials as Soil Fertilisers: Critical Review of the Existing Regulatory Framework. J. Clean. Prod. 2019, 214, 112–124. [Google Scholar] [CrossRef]

- Chin, W.Q.; Lee, Y.H.; Amran, M.; Fediuk, R.; Vatin, N.; Kueh, A.B.H.; Lee, Y.Y. A Sustainable Reuse of Agro-Industrial Wastes into Green Cement Bricks. Materials 2022, 15, 1713. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef]

- European Commission Commission Decision on the European List of Waste (COM 2000/532/EC). Off. J. Eur. Communities 2000, 2000D0532, 1–31.

- Ban, C.C.; Nordin, N.S.A.; Ken, P.W.; Ramli, M.; Hoe, K.W. The High Volume Reuse of Hybrid Biomass Ash as a Primary Binder in Cementless Mortar Block. Am. J. Appl. Sci. 2014, 11, 1369–1378. [Google Scholar] [CrossRef]

- Suleimenov, U.; Abshenov, K.; Utelbayeva, A.; Moldagaliyev, A.; Tursunkululy, T.; Zhangabay, N.; Kolesnikov, A.; Turashova, Z.; Karshyga, G.; Kozlov, P. Analysis of strength and eigenfrequencies of a steel vertical cylindrical tank without liquid, reinforced by a plain composite thread. Case Stud. Constr. Mater. 2023, 18, e02019. [Google Scholar] [CrossRef]

- Knapp, B.A.; Insam, H. Recycling of Biomass Ashes: Current Technologies and Future Research Needs. In Recycling of Biomass Ashes; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–16. [Google Scholar]

- Trivedi, N.S.; Mandavgane, S.A.; Mehetre, S.; Kulkarni, B.D. Characterization and Valorization of Biomass Ashes. Environ. Sci. Pollut. Res. 2016, 23, 20243–20256. [Google Scholar] [CrossRef]

- Schulz, M.; Kourkoulas, D. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006. Off. J. Eur. Union 2014, L150, 195–230. [Google Scholar]

- Utilization of Coal Combustion Products (CCPs) in Europe–European Association Presents New Statistics for 1999. VGB PowerTech 2001, 81, 87–88.

- Adams, T.H. American Coal Ash Association Production and Use News Release. Am. Coal Ash Assoc. 2017, 2017, 1–4. [Google Scholar]

- Ahmaruzzaman, M. A Review on the Utilization of Fly Ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Chen, L.; Ma, B.; Zhang, Y.; Ni, W.; Tsang, D.C.W. Treatment of Municipal Solid Waste Incineration Fly Ash: State-of-the-Art Technologies and Future Perspectives. J. Hazard. Mater. 2021, 411, 125132. [Google Scholar] [CrossRef] [PubMed]

- Chakrawarthi, V.; Dharmar, B.; Avudaiappan, S.; Amran, M.; Flores, E.S.; Alam, M.A.; Fediuk, R.; Vatin, N.I.; Rashid, R.S.M. Destructive and Non-Destructive Testing of the Performance of Copper Slag Fiber-Reinforced Concrete. Materials 2022, 15, 4536. [Google Scholar] [CrossRef] [PubMed]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-Term Durability Properties of Geopolymer Concrete: An in-Depth Review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Tolstoy, A.; Lesovik, V.; Fediuk, R.; Amran, M.; Gunasekaran, M.; Vatin, N.; Vasilev, Y. Production of Greener High-Strength Concrete Using Russian Quartz Sandstone Mine Waste Aggregates. Materials 2020, 13, 5575. [Google Scholar] [CrossRef] [PubMed]

- Fediuk, R.S.; Lesovik, V.S.; Liseitsev, Y.L.; Timokhin, R.A.; Bituyev, A.V.; Zaiakhanov, M.Y.; Mochalov, A.V. Composite Binders for Concretes with Improved Shock Resistance. Mag. Civ. Eng. 2019, 85, 28–38. [Google Scholar] [CrossRef]

- Fediuk, R.; Pak, A.; Kuzmin, D. Fine-Grained Concrete of Composite Binder. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bristol, UK; IOP Publishing, 2017. [Google Scholar]

- Available online: https://info.geology.gov.kz/en/informatsiya/spravochnik-mestorozhdenij-kazakhstana/tverdye-poleznye-iskopaemye/item (accessed on 1 April 2023).

- Semenov, P.A.; Uzunian, A.V.; Davidenko, A.M.; Derevschikov, A.A.; Goncharenko, Y.M.; Kachanov, V.A.; Khodyrev, V.Y.; Meschanin, A.P.; Minaev, N.G.; Mochalov, V.V.; et al. First Study of Radiation Hardness of Lead Tungstate Crystals at Low Temperatures. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2007, 582, 575–580. [Google Scholar] [CrossRef]

- Savenkov, A.; Kolomiets, V. The Use of Ash From Thermal Power Plant Dumps In The Production Of Portland Cement. Bull. Angarsk State Tech. Univ. 2022, 1, 171–174. [Google Scholar] [CrossRef]

- Paul, P.; Maity, S.; Gon, D.; Das, K. Fly Ash–Waste Management and Overview: A Review. researchgate.net 2012, 2012, 84–93. [Google Scholar]

- Luo, Y.; Wu, Y.; Ma, S.; Zheng, S.; Zhang, Y.; Chu, P.K. Utilization of Coal Fly Ash in China: A Mini-Review on Challenges and Future Directions. Environ. Sci. Pollut. Res. 2021, 28, 18727–18740. [Google Scholar] [CrossRef]

- Ferraiolo, G.; Zilli, M.; Converti, A. Fly Ash Disposal and Utilization. J. Chem. Technol. Biotechnol. 1990, 47, 281–305. [Google Scholar] [CrossRef]

- Blissett, R.S.; Rowson, N.A. A Review of the Multi-Component Utilisation of Coal Fly Ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Konovalova, N.; Pankov, P.; Petukhov, V.; Fediuk, R.S.; Amran, M. Structural Formation of Soil Concretes Based on Loam and Fly Ash, Modified with a Stabilizing Polymer Additive. SSRN Electron. J. 2021, 15, 4893. [Google Scholar] [CrossRef]

- Nawaz, M.A.; Ali, B.; Qureshi, L.A.; Usman Aslam, H.M.; Hussain, I.; Masood, B.; Raza, S.S. Effect of Sulfate Activator on Mechanical and Durability Properties of Concrete Incorporating Low Calcium Fly Ash. Case Stud. Constr. Mater. 2020, 13, e00407. [Google Scholar] [CrossRef]

- Volokitina, I.E. Effect of Cryogenic Cooling After Ecap on Mechanical Properties of Aluminum Alloy D16. Met. Sci. Heat Treat. 2019, 61, 234–238. [Google Scholar] [CrossRef]

- Shakurova, N.; Doroganov, E.; Bedina, V.; Trepalina, Y.; Dobrinskaya, O.; Pilenko, A. The Possibility of Using Clays of the Sazdinsky Deposit in the Production of Ceramic Brick. Bull. Belgorod State Technol. Univ. Named After. V. G. Shukhov 2020, 5, 87–95. [Google Scholar] [CrossRef]

- Krasnyi, B.L.; Ikonnikov, K.I.; Lemeshev, D.O.; Sizova, A.S. Fly Ash as Technogenic Raw Material for Producing Refractory and Insulating Ceramic Materials (Review). Glas. Ceram. (Engl. Transl. Steklo I Keram.) 2021, 78, 48–56. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the Ceramics Industry: A Systematic and Critical Review of Policy Options, Developments and Sociotechnical Systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Zhanikulov, N.N. Utilization of Waste from the Enrichment of Non-Ferrous Metal Ores as Secondary Mineral Raw Materials in the Production of Cement Clinker. Ecol. Ind. Russ. 2023, 27, 1–19. [Google Scholar] [CrossRef]

- Ohenoja, K.; Pesonen, J.; Yliniemi, J.; Illikainen, M. Utilization of Fly Ashes from Fluidized Bed Combustion: A Review. Sustain. 2020, 12, 2988. [Google Scholar] [CrossRef]

- Kolesnikova, O.; Syrlybekkyzy, S.; Fediuk, R.; Yerzhanov, A.; Nadirov, R.; Utelbayeva, A.; Agabekova, A.; Latypova, M.; Chepelyan, L.; Volokitina, I.; et al. Thermodynamic Simulation of Environmental and Population Protection by Utilization of Technogenic Tailings of Enrichment. Materials 2022, 15, 6980. [Google Scholar] [CrossRef]

- Efremova, S.V. Scientific and Technical Solutions to the Problem of Utilization of Waste from Plant- and Mineral-Based Industries. Russ. J. Gen. Chem. 2012, 82, 963–968. [Google Scholar] [CrossRef]

- Sizyakova, E.V.; Fokina, S.B.; Ivanov, P.V. Influence of Carbon-Containing Additives on Sintering of Limestone-Nepheline Furnace Charge in Alumina Production. J. Physics Conf. Ser. 2019, 1399, 055042. [Google Scholar] [CrossRef]

- Sapargaliyeva, B.; Suleimenov, U.; Abshenov, K.; Utelbayeva, A.; Kolesnikov, A.; Baibolov, K.; Fediuk, R.; Arinova, D.; Duissenbekov, B.; Seitkhanov, A.; et al. Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone. Materials 2022, 15, 5732. [Google Scholar] [CrossRef]

- Klyuev, S.; Klyuev, A.; Volokitina, I.; Naukenova, A.; Shapalov, S.; Utelbayeva, A.; Kolesnikova, O.; Bazarkhankyzy, A. Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation. Mater. 2022, 15, 2542. [Google Scholar] [CrossRef]

- Utelbayeva, A.; Kolesnikov, A.; Aldiyarov, Z.; Dossybekov, S.; Esimov, E.; Duissenbekov, B.; Fediuk, R.; Vatin, N.I.; Yermakhanov, M.; Mussayeva, S. Experimental Analysis of the Stress State of a Prestressed Cylindrical Shell with Various Structural Parameters. Materials 2022, 15, 4996. [Google Scholar] [CrossRef]

- Augusto, L.; Bakker, M.R.; Meredieu, C. Wood Ash Applications to Temperate Forest Ecosystems—Potential Benefits and Drawbacks. Proc. Plant Soil 2008, 306, 181–198. [Google Scholar] [CrossRef]

- Huotari, N.; Tillman-Sutela, E.; Moilanen, M.; Laiho, R. Recycling of Ash—For the Good of the Environment? For. Ecol. Manage. 2015, 348, 226–240. [Google Scholar] [CrossRef]

- López, R.; Díaz, M.J.; González-Pérez, J.A. Extra CO2 Sequestration Following Reutilization of Biomass Ash. Sci. Total Environ. 2018, 625, 1013–1020. [Google Scholar] [CrossRef] [PubMed]

- Volokitina, I.; Sabitov, L.; Volokitin, A.; Zhuniskaliyev, T.; Kelamanov, B.; Yessengaliev, D.; Yerzhanov, A.; Kolesnikova, O. Study of the Properties of Antifriction Rings under Severe Plastic Deformation. Materials 2022, 15, 2584. [Google Scholar] [CrossRef]

- Volokitina, I.E. Effect of Preliminary Heat Treatment on Deformation of Brass by the Method of ECAP. Met. Sci. Heat Treat. 2021, 63, 163–167. [Google Scholar] [CrossRef]

- Naizabekov, A.; Volokitina, I.; Kolesnikov, A. Changes In Microstructure And Properties Of Austenitic Steel AISi 316 During High-Pressure Torsion. J. Chem. Technol. Metallur. 2022, 57, 809–815. [Google Scholar]

- Sergeeva, I.V.; Botabaev, N.E.; Al’Zhanova, A.Z.; Ashirbaev, K.A. Chemical and phase transitions in oxidized manganese ore in the presence of carbon. Steel Translat. 2017, 47, 605–609. [Google Scholar] [CrossRef]

- Pitman, R.M. Wood Ash Use in Forestry—A Review of the Environmental Impacts. Forestry 2006, 79, 563–588. [Google Scholar] [CrossRef]

- Reijnders, L. Disposal, Uses and Treatments of Combustion Ashes: A Review. Resour. Conserv. Recycl. 2005, 43, 313–336. [Google Scholar] [CrossRef]

- Vasilyeva, N.; Fediuk, R.; Kolesnikov, A. Hardening of Bimetallic Wires from Secondary Materials Used in the Construction of Power Lines. Materials 2022, 15, 3975. [Google Scholar] [CrossRef]

- Volokitina, I.; Siziakova, E.; Fediuk, R.; Kolesnikov, A. Development of a Thermomechanical Treatment Mode for Stainless-Steel Rings. Materials 2022, 15, 4930. [Google Scholar] [CrossRef]

- Ward, C.R.; French, D. Relation between Coal and Fly Ash Mierology, Based on Quantitative X-Ray Diffraction Methods. World Coal Ash (WOCA) 2005, 11, 1–14. [Google Scholar]

- Tamás, F.D. Applications of Differential Thermal Analysis in Cement Chemistry. Cem. Concr. Res. 1971, 1, 455. [Google Scholar] [CrossRef]

- Kamitsou, M.D.; Kanellopoulou, D.G.; Christogerou, A.; Angelopoulos, G.N. A Contribution towards a More Sustainable Cement: Synergy of Mill Scales, Greek Wet Fly Ash, Conventional Raw Materials and Clinkering Temperature. Minerals 2022, 12, 324. [Google Scholar] [CrossRef]

- Sibanda, V.; Ndlovu, S.; Dombo, G.; Shemi, A.; Rampou, M. Towards the Utilization of Fly Ash as a Feedstock for Smelter Grade Alumina Production: A Review of the Developments. J. Sustain. Metall. 2016, 2, 167–184. [Google Scholar] [CrossRef]

- Volokitina, I. Evolution of the Microstructure and Mechanical Properties of Copper under ECAP with Intense Cooling. Met. Sci. Heat Treat. 2020, 62, 253–258. [Google Scholar] [CrossRef]

- Zhanikulov, N.N.; Khudyakova, T.M.; Taimasov, B.T.; Sarsenbayev, B.K.; Dauletiarov, M.S.; Kolesnikov, A.S.; Karshygayev, R.O. Receiving Portland Cement from Technogenic Raw Materials of South Kazakhstan. Euras. Chem.-Technol. J. 2019, 21, 333–340. [Google Scholar] [CrossRef]

- Kolesnikova, O.; Vasilyeva, N.; Kolesnikov, A.; Zolkin, A. Optimization of raw mix using technogenic waste to produce cement clinker. Min. Infor. Anal. Bul. 2022, 10–11, 103–115. [Google Scholar] [CrossRef]

- Khudyakova, T.M.; Kolesnikova, O.G.; Zhanikulov, N.N.; Ashirbaev, H.A.; Kolesnikova, V.A. Low-Basicity Cement, Problems and Advantages of its Utilization. Refrac. Ind. Ceram. 2021, 62, 369–374. [Google Scholar] [CrossRef]

| Chemical Compound | Material, % | |

|---|---|---|

| Limestone | Coal Ash | |

| SiO2 | 1.07 | 54.80 |

| Al2O3 | 0.93 | 17.34 |

| Fe2O3 | 0.69 | 8.37 |

| CaO | 54.32 | 8.79 |

| MgO | 0.75 | 0.89 |

| Loss on ignition | 37.63 | 9.81 |

| Other | 4.1 | - |

| Chemical Composition of the Raw Charge (Mixture) and Clinker | |||||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Loss on Ignition | Other | |

| Raw mixture | 13.78 | 4.81 | 2.51 | 43.55 | 0.78 | 31.05 | 3.52 |

| Clinker | 19.99 | 6.98 | 3.64 | 63.16 | 1.14 | - | 5.1 |

| Modules | Raw mixture | Clinker | |||||

| SC (lime saturation coefficient) | 0.9 | 0.9 | |||||

| n (silica module) | 1.88 | 1.88 | |||||

| p (alumina module) | 1.92 | 1.92 | |||||

| FEC (thermal effect of clinker formation, kcal/kg) | - | 336.7 | |||||

| Gfuel (fuel consumption for firing, kg of conventional fuel/t of cl.) | - | 188.7 | |||||

| Mineralogical composition | |||||||

| Minerals | C3S | C2S | C3A | C4AF | CaSO4 | MgO | |

| Mas.% | 53.12 | 17.23 | 12.34 | 11.06 | 0 | 1.14 | |

| Content of components | |||||||

| Materials | Raw mixture | Clinker | |||||

| kg/kg cl | % | % | |||||

| Limestone | 1.107 | 76.34% | 69.05% | ||||

| Coal ash | 0.343 | 23.66% | 30.95% | ||||

| Total | 1.45 | 100.00% | 100.00% | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muratov, B.; Kolesnikov, A.; Shapalov, S.; Syrlybekkyzy, S.; Volokitina, I.; Zhunisbekova, D.; Takibayeva, G.; Nurbaeva, F.; Aubakirova, T.; Nurshakhanova, L.; et al. Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker. J. Compos. Sci. 2023, 7, 234. https://doi.org/10.3390/jcs7060234

Muratov B, Kolesnikov A, Shapalov S, Syrlybekkyzy S, Volokitina I, Zhunisbekova D, Takibayeva G, Nurbaeva F, Aubakirova T, Nurshakhanova L, et al. Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker. Journal of Composites Science. 2023; 7(6):234. https://doi.org/10.3390/jcs7060234

Chicago/Turabian StyleMuratov, Bekkeldi, Alexandr Kolesnikov, Shermakhan Shapalov, Samal Syrlybekkyzy, Irina Volokitina, Dana Zhunisbekova, Gulchehra Takibayeva, Farida Nurbaeva, Taslima Aubakirova, Lazzat Nurshakhanova, and et al. 2023. "Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker" Journal of Composites Science 7, no. 6: 234. https://doi.org/10.3390/jcs7060234

APA StyleMuratov, B., Kolesnikov, A., Shapalov, S., Syrlybekkyzy, S., Volokitina, I., Zhunisbekova, D., Takibayeva, G., Nurbaeva, F., Aubakirova, T., Nurshakhanova, L., Koishina, A., Seidaliyeva, L., Volokitin, A., Izbassar, A., & Panarin, I. (2023). Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker. Journal of Composites Science, 7(6), 234. https://doi.org/10.3390/jcs7060234