Three-Dimensional Printing Limitations of Polymers Reinforced with Continuous Stainless Steel Fibres and Curvature Stiffness

Abstract

:1. Introduction

1.1. Printing of Continuous Fibre-Reinforced Composites

1.2. Geometric Print Designs

1.3. Electrical Resistance

2. Theory and Calculation

2.1. PLA-SSF Filament Fabrication and 3D Printing

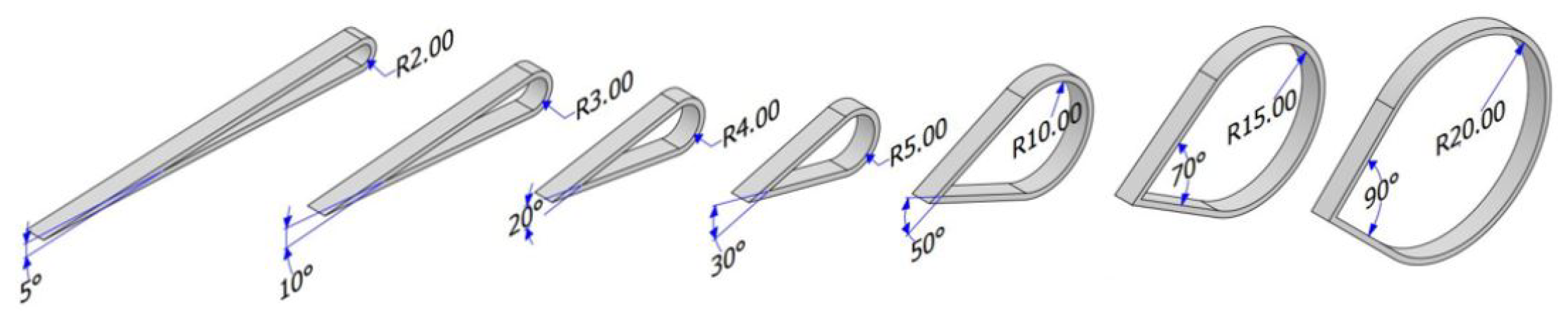

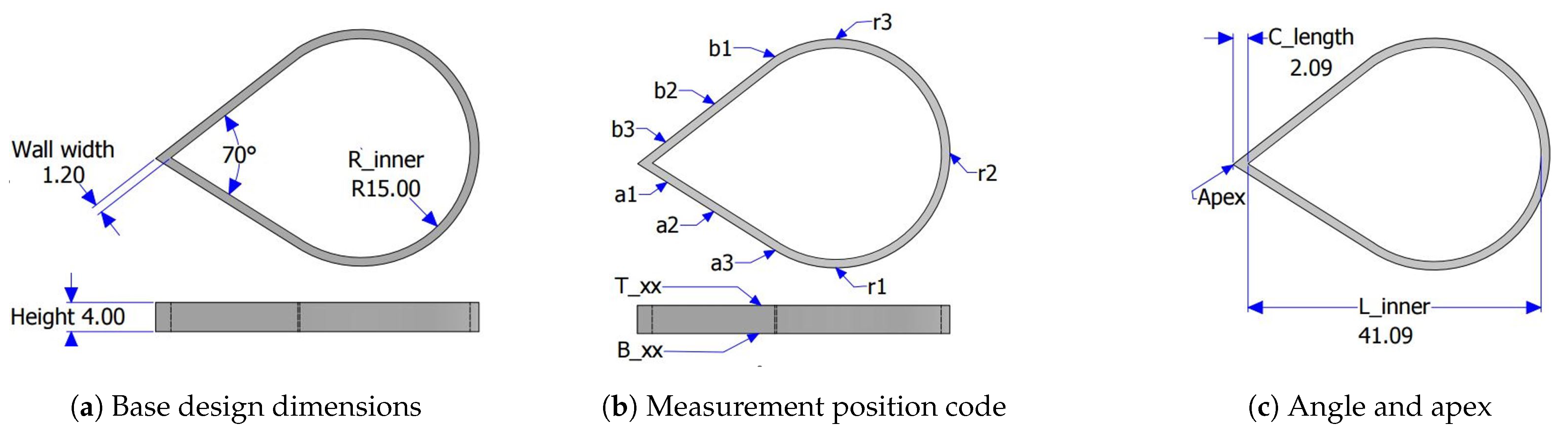

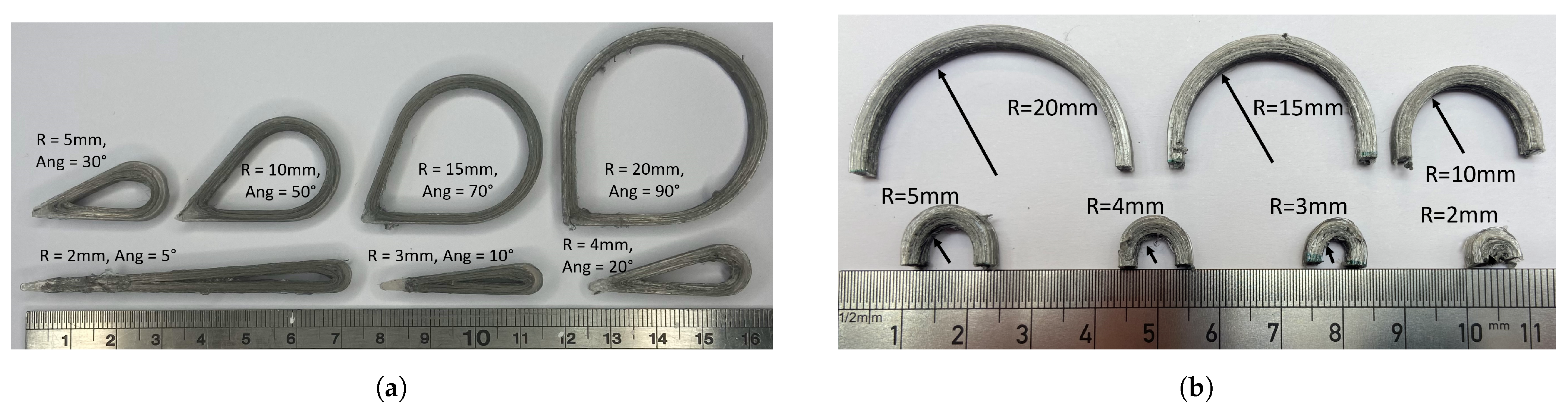

2.2. Three-Dimensional Printing Teardrop and Curvature Stiffness Samples

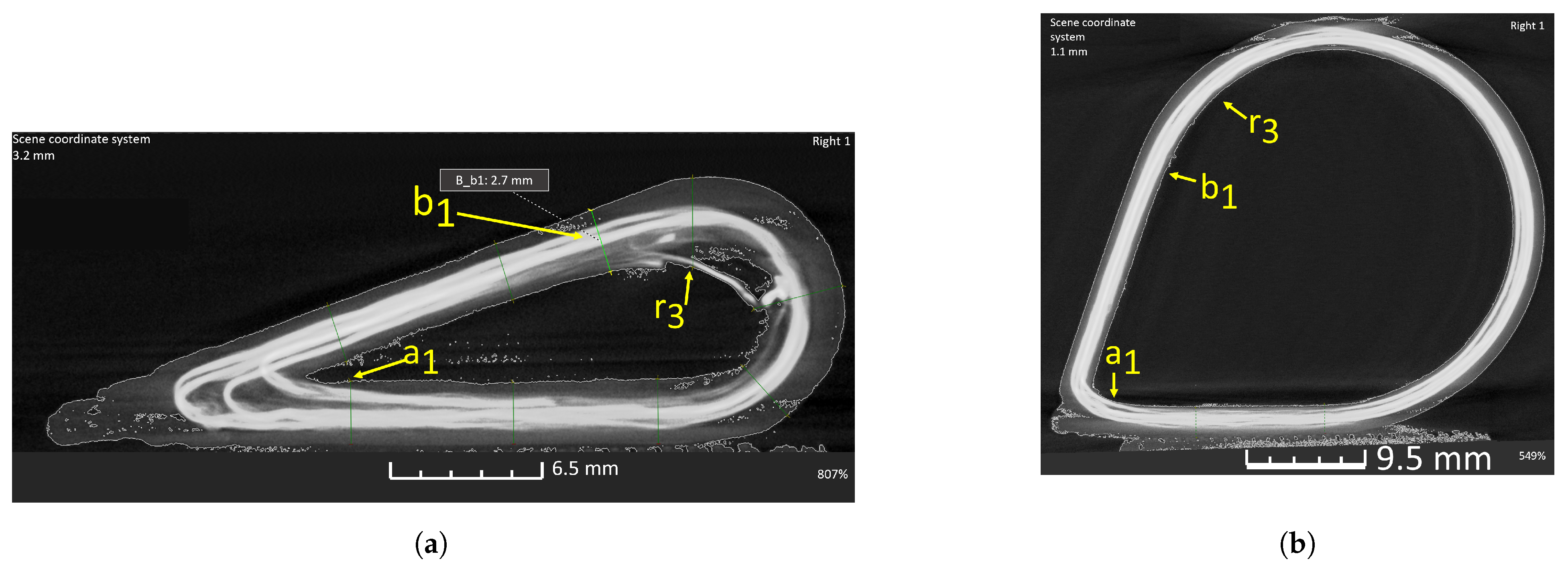

2.3. Characterisation and Geometry Analysis

2.4. Testing Methods: Curvature Bending Testing

2.5. Resistance Response

3. Results

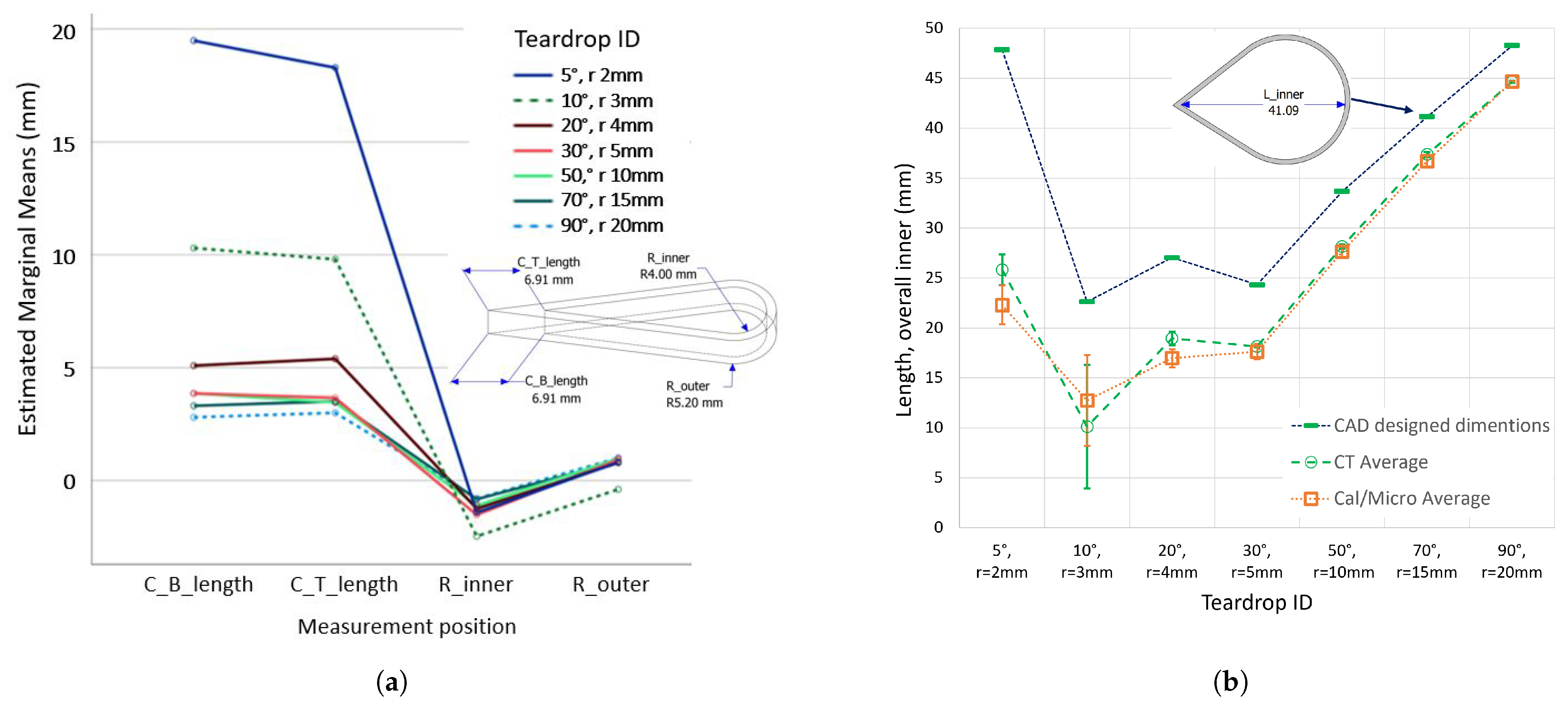

3.1. Three-Dimensional Print Teardrop Geometry Repeatability

3.1.1. Wall Width

3.1.2. Angle and Apex

3.1.3. Semi-Circle Cornering

3.1.4. Height

3.1.5. Deposition Effects

3.2. Curved Bending Test and Resistance Response

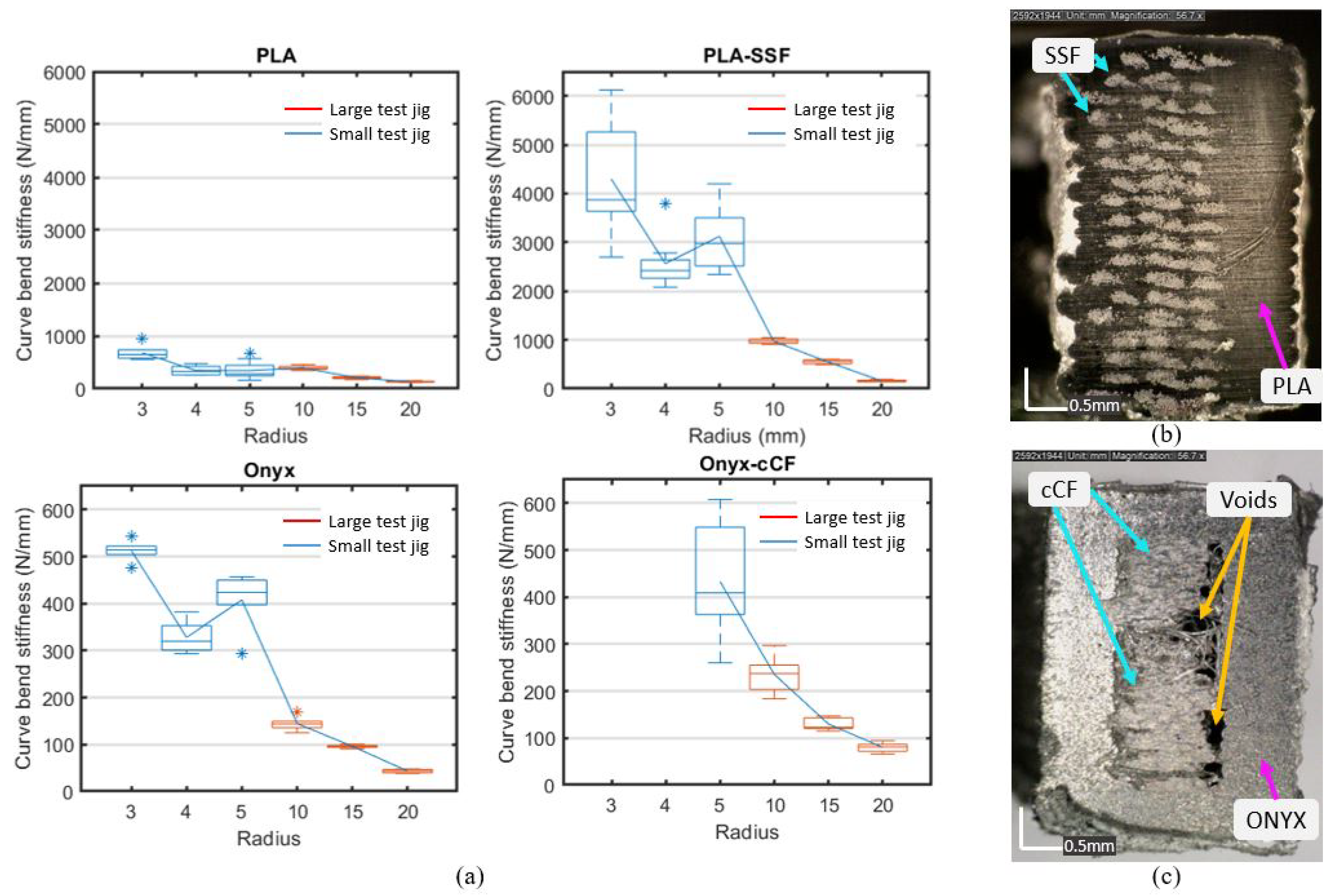

3.2.1. Curved Bending Test

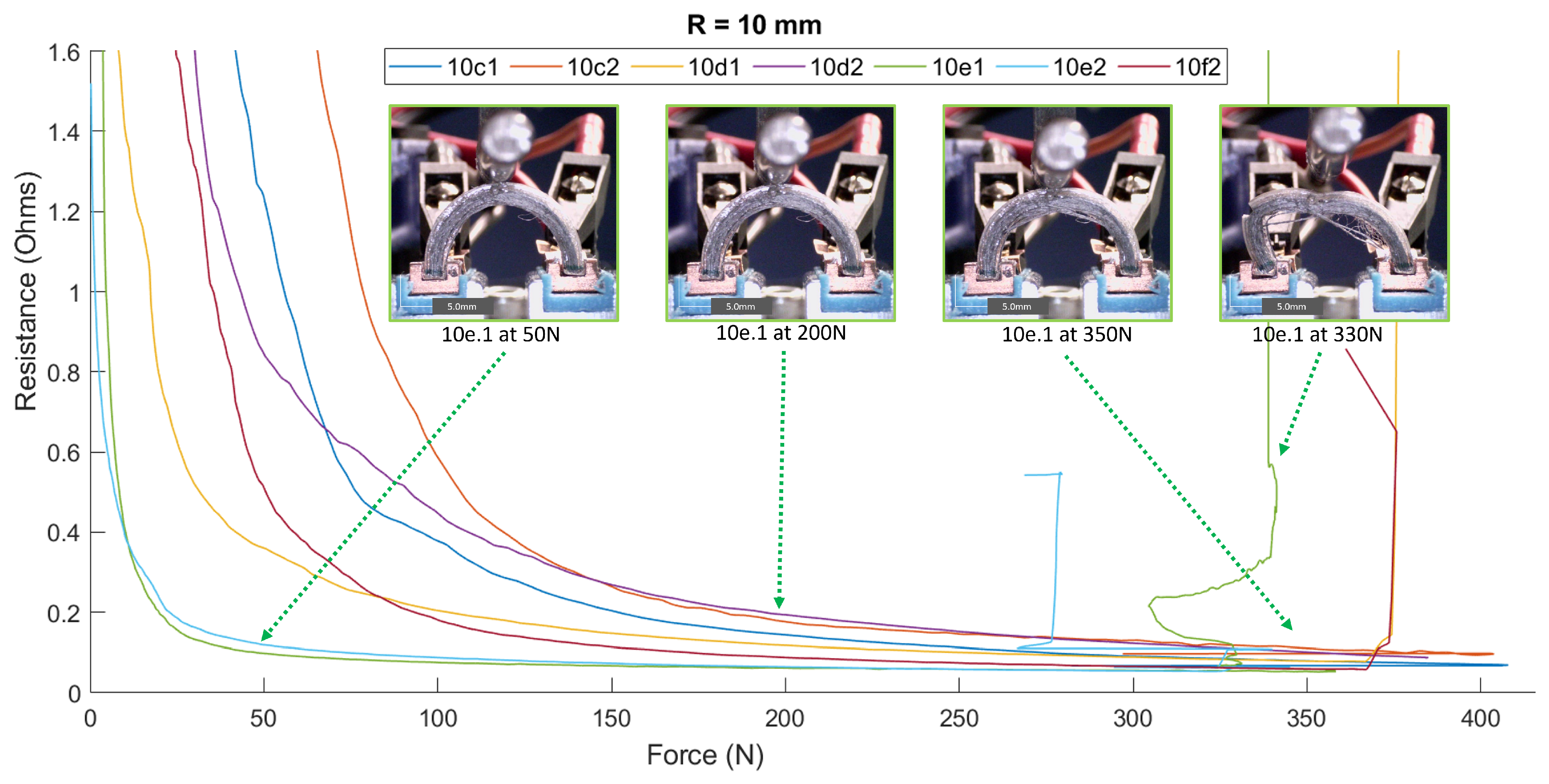

3.2.2. Resistance Responses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| °C | Degrees Centigrade |

| Measurement position | |

| Measurement position | |

| Measurement position | |

| Measurement position | |

| Measurement position | |

| Measurement position | |

| Deformation due to the force | |

| > | Greater than |

| h | Layer Height |

| k | Curvature bending stiffness |

| < | Less than |

| ≤ | Less than or equal to |

| CT | Micro-computed tomography |

| μm | Micrometer |

| mm | Millimetre |

| mm/s | Millimetres Per second |

| N/mm | Newtons per millimetre |

| Ohms | |

| Tensile strength | |

| or | Maximum load or failure |

| Measurement position | |

| Measurement position | |

| Measurement position | |

| rpm | Revolutions per minute |

| 1st Extrusion barrel heater temperature | |

| 2nd Extrusion barrel heater temperature | |

| 3rd Extrusion barrel heater temperature | |

| 4th Extrusion barrel heater temperature | |

| w | Hatch spacing |

| ABS | Acrylonitrile butadiene styrene |

| B | Structures base |

| CAD | Computer-aided design |

| cCF | Continuous carbon fibre |

| CBS | Curvature bending stiffness |

| C_lenght | Corner material length |

| F | Force |

| KS-LCR | Keysights Inductance, Capacitance, and Resistance meter |

| LCR | Inductance, Capacitance, and Resistance meter |

| L_inner | Overall internal length |

| MEX | Material extrusion |

| N | Newton |

| Onyx-cCF | Nylon containing short carbon fibres and continuous carbon fibre |

| PA | Polyamide or nylon |

| PC | Polycarbonate |

| PEEK | Polyetheretherketone |

| PLA | Polylactic acid |

| PLA-cCF | Polylactic acid containing continuous carbon fibre |

| PLA-SSF | Polylactic acid containing continuous stainless steel fibre bundle composite |

| PU | Polyurethane |

| R | Radius |

| R_inner | Inner radius |

| R_outer | Outer radius |

| SEM | Scanning electron 255 microscope |

| SSF | 316 L stainless steel fibre bundle |

| SHM | Structural health monitoring |

| STL | Stereolithography file |

| T | Structure top |

| TEX | Decitex |

| Volume fraction |

References

- Tack, L. Heatable Textiles Flexible and Durable Solutions for Heatable Textiles; Technical Report; NV Bekaert SA: Wetteren, Belgium, 2017. [Google Scholar]

- Tack, L. Bekinox® VN and Bekiflex®for Heatable Textiles; Technical Report; NV Bekaert SA: Wetteren, Belgium, 2019. [Google Scholar]

- Tack, L. Conductive Textiles Durable Textile Solutions for Transferring Power and Signals; Technical Report; NV Bekaert SA: Wetteren, Belgium, 2017. [Google Scholar]

- Saleh, M.A.; Kempers, R.; Melenka, G.W. A comparative study on the electromechanical properties of 3D-Printed rigid and flexible continuous wire polymer composites for structural health monitoring. Sensors Actuators A Phys. 2021, 328, 112764. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.K. 3D printing of polymer composites: Materials, processes, and applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part B Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D printing of fibre-reinforced thermoplastic composites using fused filament fabrication-A review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Beckman, I.P.; Lozano, C.; Freeman, E.; Riveros, G. Fiber selection for reinforced additive manufacturing. Polymers 2021, 13, 2231. [Google Scholar] [CrossRef]

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Hirano, Y.; Matsuzaki, R.; Mizukami, K.; Iizuka, K.; et al. 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Pandelidi, C.; Bateman, S.; Piegert, S.; Hoehner, R.; Kelbassa, I.; Brandt, M. The technology of continuous fibre-reinforced polymers: A review on extrusion additive manufacturing methods. Int. J. Adv. Manuf. Technol. 2021, 113, 3057–3077. [Google Scholar] [CrossRef]

- Krishnan, P. Evaluation and Methods of Interfacial Properties in Fiber-Reinforced Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 343–385. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef] [PubMed]

- Vedrtnam, A.; Ghabezi, P.; Gunwant, D.; Jiang, Y.; Sam-Daliri, O.; Harrison, N.; Goggins, J.; Finnegan, W. Mechanical performance of 3D-printed continuous fibre Onyx composites for drone applications: An experimental and numerical analysis. Compos. Part C Open Access 2023, 12, 100418. [Google Scholar] [CrossRef]

- Sealy, C. Thermoplastic waste recycled into useful composite. Mater. Today 2023, 69, 4–6. [Google Scholar] [CrossRef]

- Clarke, A.J.; Dickson, A.; Dowling, D.P. Fabrication and Performance of Continuous 316 Stainless Steel Fibre-Reinforced 3D-Printed PLA Composites. Polymers 2024, 16, 63. [Google Scholar] [CrossRef] [PubMed]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ibrahim, Y. 3D Printing of Continuous Wire Polymer Composite for Mechanical and Thermal Applications. Ph.D. Thesis, York University, Toronto, ON, Canada, 2019. [Google Scholar]

- Hou, Z.; Tian, X.; Zhang, J.; Li, D. 3D printed continuous fibre reinforced composite corrugated structure. Compos. Struct. 2018, 184, 1005–1010. [Google Scholar] [CrossRef]

- Hamidi, A.; Tadesse, Y. Single step 3D printing of bioinspired structures via metal reinforced thermoplastic and highly stretchable elastomer. Compos. Struct. 2019, 210, 250–261. [Google Scholar] [CrossRef]

- Shang, J.; Tian, X.; Luo, M.; Zhu, W.; Li, D.; Qin, Y.; Shan, Z. Controllable inter-line bonding performance and fracture patterns of continuous fiber reinforced composites by sinusoidal-path 3D printing. Compos. Sci. Technol. 2020, 192, 108096. [Google Scholar] [CrossRef]

- Dong, K.; Liu, L.; Huang, X.; Xiao, X. 3D printing of continuous fiber reinforced diamond cellular structural composites and tensile properties. Compos. Struct. 2020, 250, 112610. [Google Scholar] [CrossRef]

- Yao, X.; Luan, C.; Zhang, D.; Lan, L.; Fu, J. Evaluation of carbon fiber-embedded 3D printed structures for strengthening and structural-health monitoring. Mater. Des. 2017, 114, 424–432. [Google Scholar] [CrossRef]

- Yamamoto, K.; Luces, J.V.S.; Shirasu, K.; Hoshikawa, Y.; Okabe, T.; Hirata, Y. A novel single-stroke path planning algorithm for 3D printers using continuous carbon fiber reinforced thermoplastics. Addit. Manuf. 2022, 55, 102816. [Google Scholar] [CrossRef]

- Saari, M.; Cox, B.; Richer, E.; Krueger, P.S.; Cohen, A.L. Fiber encapsulation additive manufacturing: An enabling technology for 3D printing of electromechanical devices and robotic components. 3D Print. Addit. Manuf. 2015, 2, 32–39. [Google Scholar] [CrossRef]

- Bakas, L.; Rimašauskas, M. Investigation of Electrical Properties of 3D Printed Carbon Fiber Reinforced Composite Structures. Ph.D. Thesis, Kaunas University of Technology, Kaunas, Lithuania, 2023. [Google Scholar]

- Liu, G.; Xiong, Y.; Zhou, L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Compos. Commun. 2021, 27, 100907. [Google Scholar] [CrossRef]

- Callens, M.G.; Gorbatikh, L.; Verpoest, I. Ductile steel fibre composites with brittle and ductile matrices. Compos. Part Appl. Sci. Manuf. 2014, 61, 235–244. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Nakamura, T.; Sugiyama, K.; Ueda, M.; Todoroki, A.; Hirano, Y.; Yamagata, Y. Effects of Set Curvature and Fiber Bundle Size on the Printed Radius of Curvature by a Continuous Carbon Fiber Composite 3D Printer. Addit. Manuf. 2018, 24, 93–102. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension. Compos. Part A Appl. Sci. Manuf. 2018, 113, 114–121. [Google Scholar] [CrossRef]

- Bettini, P.; Alitta, G.; Sala, G.; Di Landro, L. Fused Deposition Technique for Continuous Fiber Reinforced Thermoplastic. J. Mater. Eng. Perform. 2017, 26, 843–848. [Google Scholar] [CrossRef]

- Lu, C.; Qi, M.; Islam, S.; Chen, P.; Gao, S.; Xu, Y.; Yang, X. Mechanical performance of 3D-printing plastic honeycomb sandwich structure. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 47–54. [Google Scholar] [CrossRef]

- Eichenhofer, M.; Wong, J.C.; Ermanni, P. Continuous lattice fabrication of ultra-lightweight composite structures. Addit. Manuf. 2017, 18, 48–57. [Google Scholar] [CrossRef]

- Markforged. Material Datasheet Composites; Technical Report; Markforged: Billerica, MA, USA, 2022. [Google Scholar]

- Yao, Y.; Li, M.; Lackner, M.; Herfried, L. A continuous fiber-reinforced additive manufacturing processing based on PET fiber and PLA. Materials 2020, 13, 3044. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A.M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Li, N. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures. Mater. Des. 2018, 137, 235–244. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. Three-dimensional printing of continuous flax fiber-reinforced thermoplastic composites by five-axis machine. Materials 2020, 13, 1678. [Google Scholar] [CrossRef] [PubMed]

- Carani, L.B.; Humphrey, J.; Rahman, M.M.; Okoli, O.I. Advances in Embedded Sensor Technologies for Impact Monitoring in Composite Structures. J. Compos. Sci. 2024, 8, 201. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Liao, G.; Yao, X.; Fu, J. Mechanical and self-monitoring behaviors of 3D printing smart continuous carbon fiber-thermoplastic lattice truss sandwich structure. Compos. Part Eng. 2019, 176, 107215. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Melenka, G.W.; Kempers, R. Fabrication and tensile testing of 3D printed continuous wire polymer composites. Rapid Prototyp. J. 2018, 24, 1131–1141. [Google Scholar] [CrossRef]

- Galos, J.; Hu, Y.; Ravindran, A.R.; Ladani, R.B.; Mouritz, A.P. Electrical properties of 3D printed continuous carbon fibre composites made using the FDM process. Compos. Part Appl. Sci. Manuf. 2021, 151, 106661. [Google Scholar] [CrossRef]

- Küster, K.; Barburski, M.; Lomov, S.V.; Vanclooster, K. Metal Fibers-Steel. In Inorganic and Composite Fibers: Production, Properties, and Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 219–241. [Google Scholar] [CrossRef]

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, R. Thermo-mechanical processing of metallic materials. In Pergamon Materials Series; Pergamon: Oxford, UK, 2007; Volume 11, pp. 7–30. [Google Scholar] [CrossRef]

- NatureWorks. Ingeo™ Biopolymer 3D850 Technical Data Sheet 3D Printing Monofilament—General Purpose Grade; Technical Report 4; NatureWorks LLC: Minneapolis, MI, USA, 2018. [Google Scholar]

- 3devo. Composer 350 Product Specifications. Technical Report, 3devo, Utrecht, The Netherlands, 2020. Available online: https://cdn2.hubspot.net/hubfs/4595257/Product%20Spec%20Sheets/Composer-350-Specs.pdf (accessed on 26 September 2022).

- Sen, P.K.; Conover, W.J. Practical Nonparametric Statistics, 3rd ed.; Wiley: Hoboken, NJ, USA, 1972; Volume 67, p. 350. [Google Scholar] [CrossRef]

- ASTM D4496-21; Standard Test Method for D-C Resistance or Conductance of Moderately Conductive Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- Cheng, P.; Wang, K.; Le Duigou, A.; Liu, J.; Liu, Z.; Peng, Y.; Ahzi, S. A novel dual-nozzle 3D printing method for continuous fiber reinforced composite cellular structures. Compos. Commun. 2023, 37, 101448. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Cook, J.W.; Skove, M.J.; Stillwell, E.P. Electrical resistance of an elastically bent thin metal wire in a magnetic field. Phys. Rev. B 1979, 20, 5100–5103. [Google Scholar] [CrossRef]

| Filament | Filament Diameter (mm) | Cooling Fans (°C) | Extrude Speed (rpm) | (°C) | (°C) | (°C) | (°C) |

|---|---|---|---|---|---|---|---|

| PLA-SSF | 0.5 (±0.8) | 33.0 | 2.2 | 179 | 186 | 193 | 191 |

| Angle Radii (R), (mm) | 90° 20.0 | 70° 15.0 | 50° 10.0 | 30° 5.0 | 20° 4.0 | 10° 3.0 | 5° 2.0 |

|---|---|---|---|---|---|---|---|

| Speed, (mm/s) | 8 | 8 | 4 | 2 | 1 | 1 | 1 |

| Measurement Code | Description of Position on Geometry | 90° R 20 mm | 70° R 15 mm | 50° R 10 mm | 30° R 5 mm | 20° R 4 mm | 10° R 3 mm | 5° R 2 mm |

|---|---|---|---|---|---|---|---|---|

| R_inner | Inner radius | 20.00 | 15.00 | 10.00 | 5.00 | 4.00 | 3.00 | 2.00 |

| R_outer | Outer radius | 21.20 | 16.20 | 11.20 | 6.20 | 5.20 | 4.20 | 3.20 |

| C_lenght | Corner material length | 1.70 | 2.09 | 2.84 | 4.64 | 6.91 | 13.60 | 27.51 |

| L_inner | Overall internal length | 48.28 | 44.44 | 33.66 | 24.32 | 27.04 | 22.62 | 47.85 |

| Measurement | Angle | 90° | 70° | 50° | 30° | 20° | 10° | 5° |

|---|---|---|---|---|---|---|---|---|

| Code | Radii (R), (mm) | 20.0 | 15.0 | 10.0 | 5.0 | 4.0 | 3.0 | 2.0 |

| Design difference | −0.8 | −0.8 | −1.1 | −1.5 | −1.3 | −2.5 | −1.4 | |

| Design difference | −0.1 | −0.3 | −0.2 | −1.3 | −1.2 | −2.5 | −1.2 | |

| Design difference | +0.1 | 0.0 | +0.1 | −0.1 | −0.3 | −1.9 | −0.3 | |

| Design difference | +1.0 | +0.8 | +1.0 | +0.9 | +0.8 | −0.4 | +0.8 | |

| C_Length | Design difference | +1.0 | +0.8 | +1.0 | +0.9 | +0.8 | −0.4 | +0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clarke, A.J.; Dickson, A.N.; Milosavljević, V.; Dowling, D.P. Three-Dimensional Printing Limitations of Polymers Reinforced with Continuous Stainless Steel Fibres and Curvature Stiffness. J. Compos. Sci. 2024, 8, 410. https://doi.org/10.3390/jcs8100410

Clarke AJ, Dickson AN, Milosavljević V, Dowling DP. Three-Dimensional Printing Limitations of Polymers Reinforced with Continuous Stainless Steel Fibres and Curvature Stiffness. Journal of Composites Science. 2024; 8(10):410. https://doi.org/10.3390/jcs8100410

Chicago/Turabian StyleClarke, Alison J., Andrew N. Dickson, Vladimir Milosavljević, and Denis P. Dowling. 2024. "Three-Dimensional Printing Limitations of Polymers Reinforced with Continuous Stainless Steel Fibres and Curvature Stiffness" Journal of Composites Science 8, no. 10: 410. https://doi.org/10.3390/jcs8100410

APA StyleClarke, A. J., Dickson, A. N., Milosavljević, V., & Dowling, D. P. (2024). Three-Dimensional Printing Limitations of Polymers Reinforced with Continuous Stainless Steel Fibres and Curvature Stiffness. Journal of Composites Science, 8(10), 410. https://doi.org/10.3390/jcs8100410