Simulation and Discussion on Strength Mechanism of Trimodal Grain-Structured CNT/Al Composites Using Strain Gradient Theory

Abstract

:1. Introduction

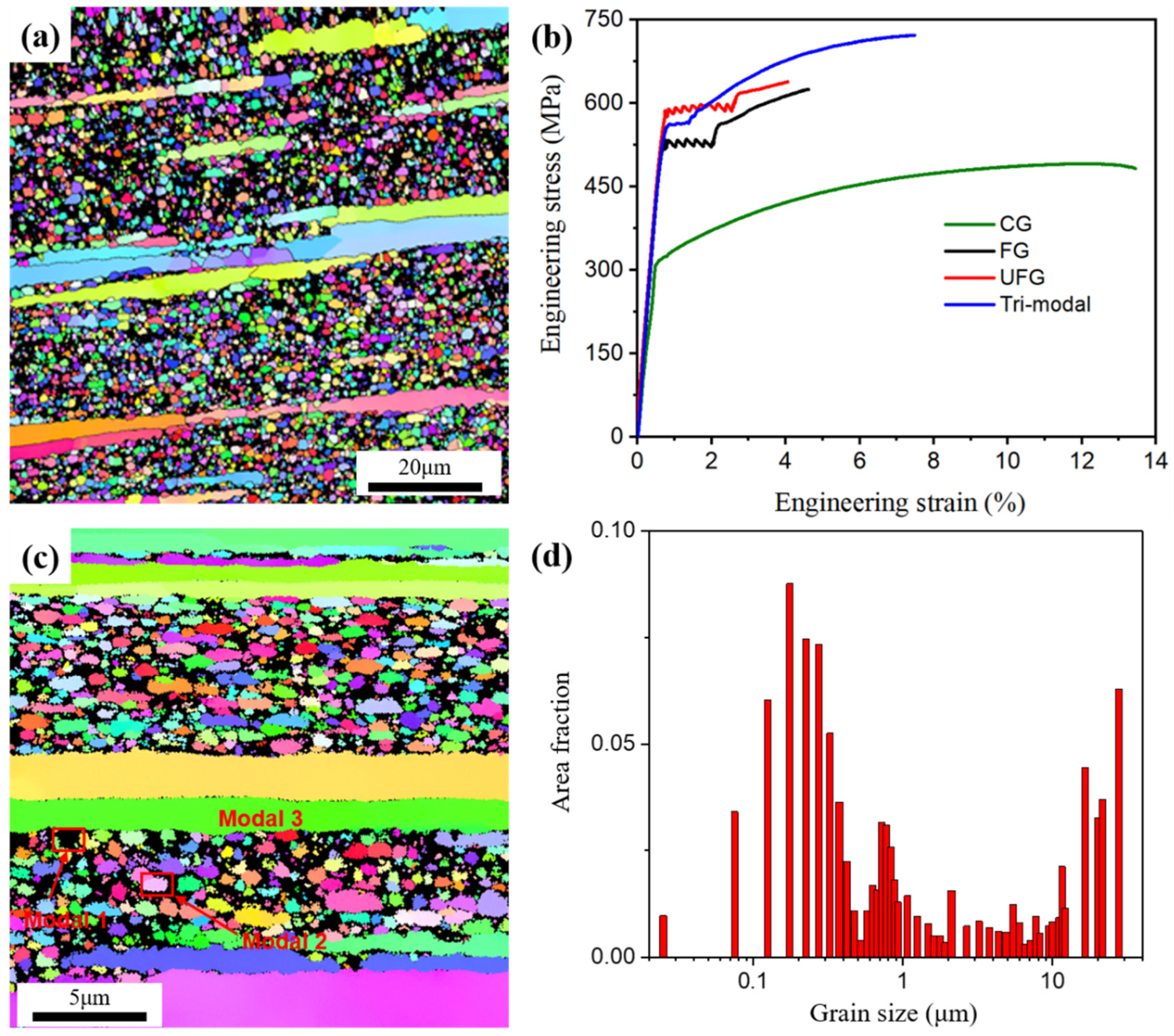

2. Materials, Experimental Procedures, and Observations

3. A Constitutive Model for TGS Composites Considering the Microstructure Deformation Mechanism

3.1. Elastoplasticity

3.2. Flow Stress

3.2.1. Evolution of Yield Stress

3.2.2. Evolution of SSDs

3.2.3. Evolutions of GNDs and Back Stresses

4. Microstructure Simulation

4.1. Microstructure-Based Modeling

4.2. Material Properties

| Parameters | Symbols | UFG | FG | CG | Ref. |

|---|---|---|---|---|---|

| Modulus of elasticity (MPa) | E | 89,000 | 86,000 | 64,600 | |

| Poisson’s ratio | ν | 0.3 | 0.3 | 0.3 | |

| Reference strain rate (S−1) | 1 | 1 | 1 | [23] | |

| Rate sensitively exponent | m | 20 | 20 | 20 | [20] |

| Hall–Petch constant (MPa·m1/2) | 45 | 45 | 45 | [11] | |

| Taylor factor | M | 3.06 | 3.06 | 3.06 | [11,12] |

| Taylor constant | α | 0.26 | 0.3 | 0.34 | |

| Magnitude of Burgers vector (nm) | 0.25 | 0.25 | 0.25 | ||

| Nye factor | 1.9 | 1.9 | 1.9 | [29] | |

| Dynamic recovery constant 1 | 1.5 | 1.5 | 1.5 | [11] | |

| Dynamic recovery constant 2 | 21.25 | 21.25 | 21.25 | [23] | |

| Geometric factor | 0.06 | 0.06 | 0.06 | [11] | |

| Proportionality factor | 0.008 | 0.008 | 0.008 | [11] | |

| Pile-up dislocations constant 1 (m−1) | 46 | 46 | 46 | ||

| Pile-up dislocations constant 2 | 300 | 300 | 300 | ||

| Pile-up factor related to grain size (m−1) | 5.9 | 5.9 | 5.9 | ||

| Correction parameter of pile-up dislocations | 4.82 | 4.82 | 4.82 | ||

| Cut-off radius of the GND domain (m) | R | 3 | 3 | 3 | [11] |

| Initial dislocation density (m−2) | 4 × 1011 | 3 × 1011 | 2 × 1011 | [11] | |

| Grain size (m) | d | 0.2 | 0.77 | 15.23 | |

| Reference grain size (m) | 0.5 | 1 | 30 | ||

| Parameter of material | Symbol | Magnitude | Ref. | ||

| Poisson’s ratio of CNTs | 0.28 | [48,49] | |||

| Poisson’s ratio of Al | 0.33 | [50] | |||

| Volume fraction of CNTs (wt.%) | 1.875 | ||||

| Transverse shear modulus of CNTs | 60 | [49] | |||

| Shear modulus of Al | 25.4 | [44] |

5. Results and Discussion

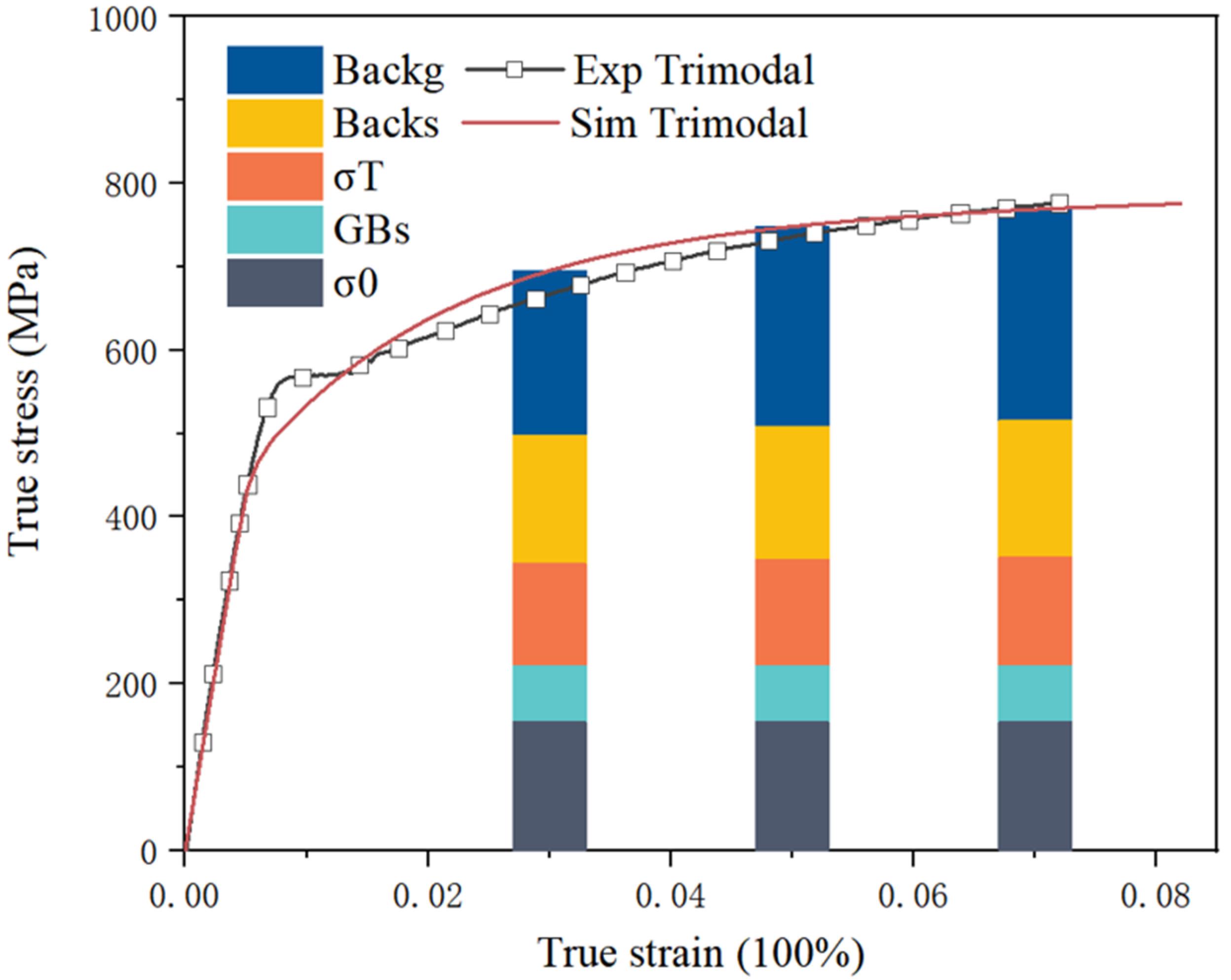

5.1. Mechanical Response

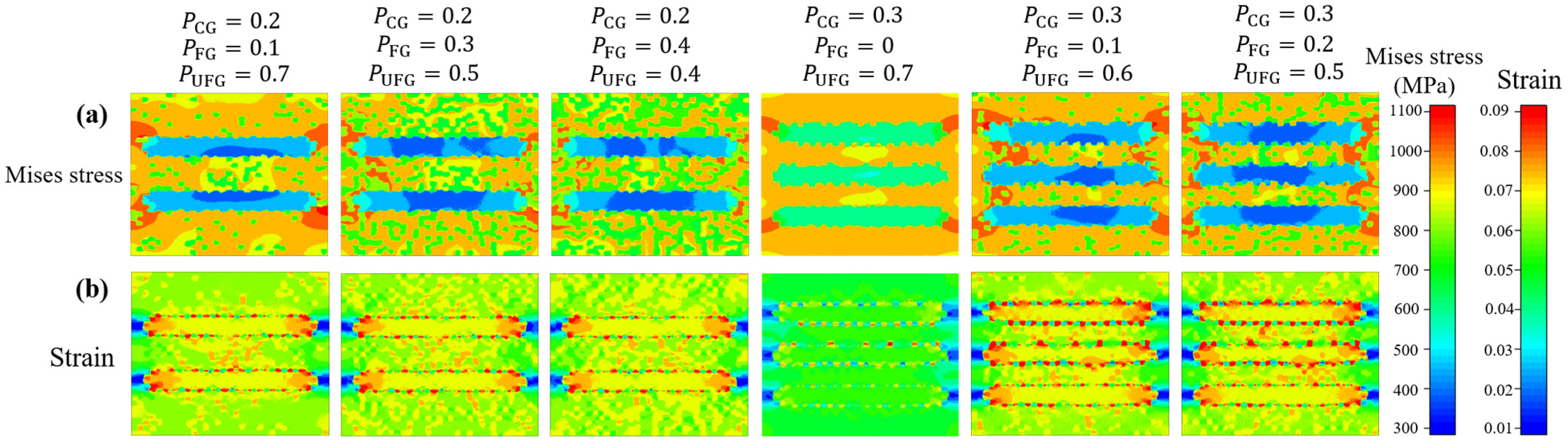

5.2. Discussion of the Strengthening Mechanism

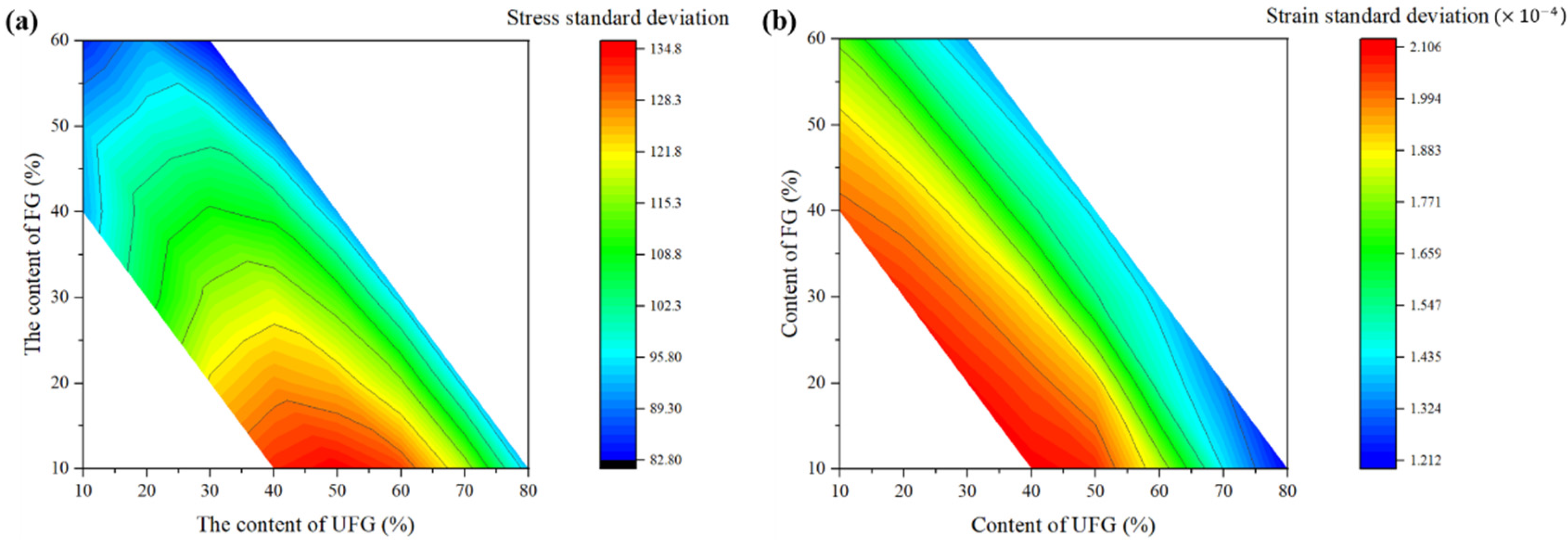

5.2.1. Effect of Domain Volume Fractions on SSDs

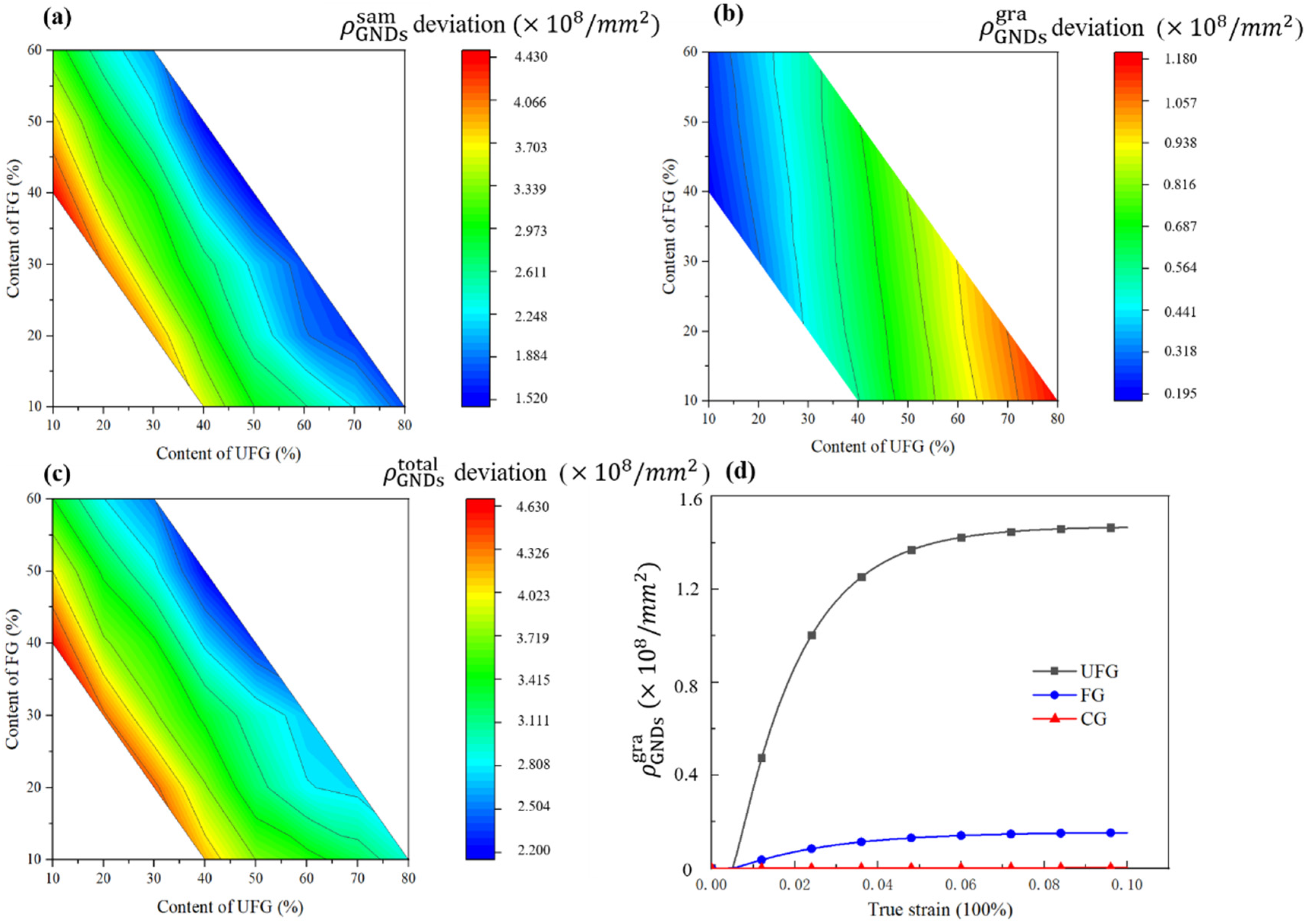

5.2.2. Effect of Domain Volume Fraction on GNDs

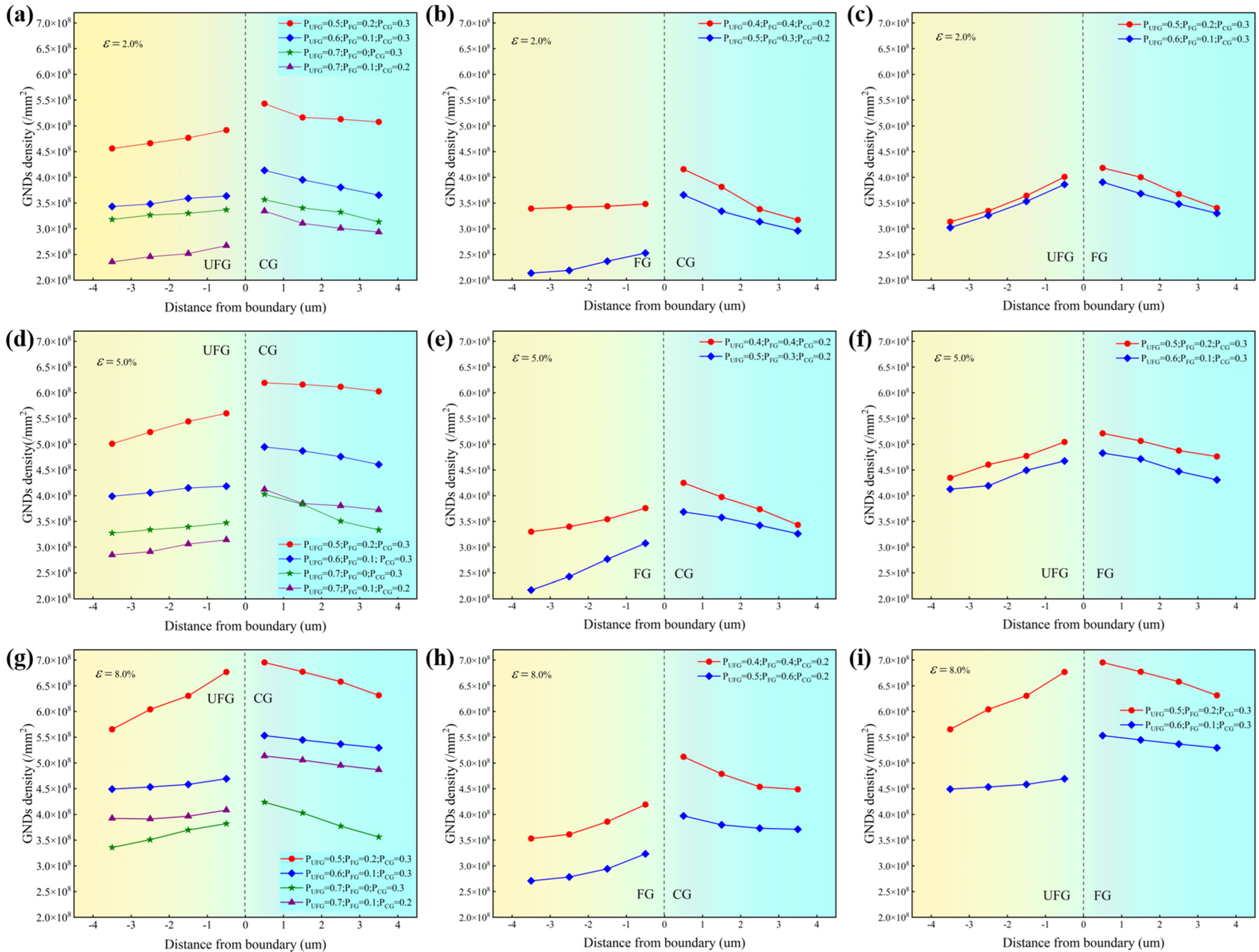

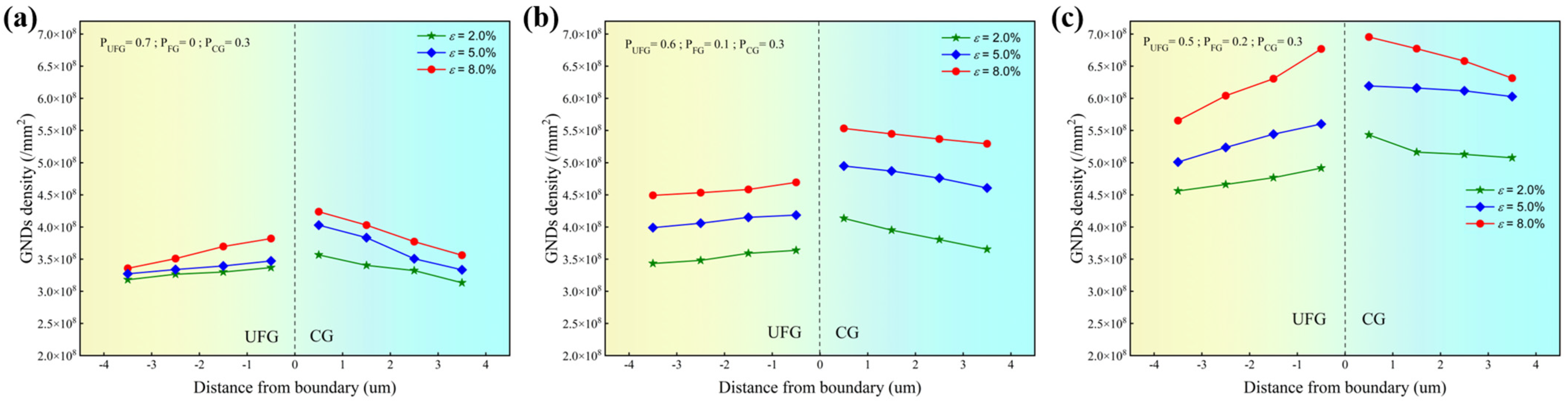

5.2.3. GNDs Evolution at Microstructure Boundary

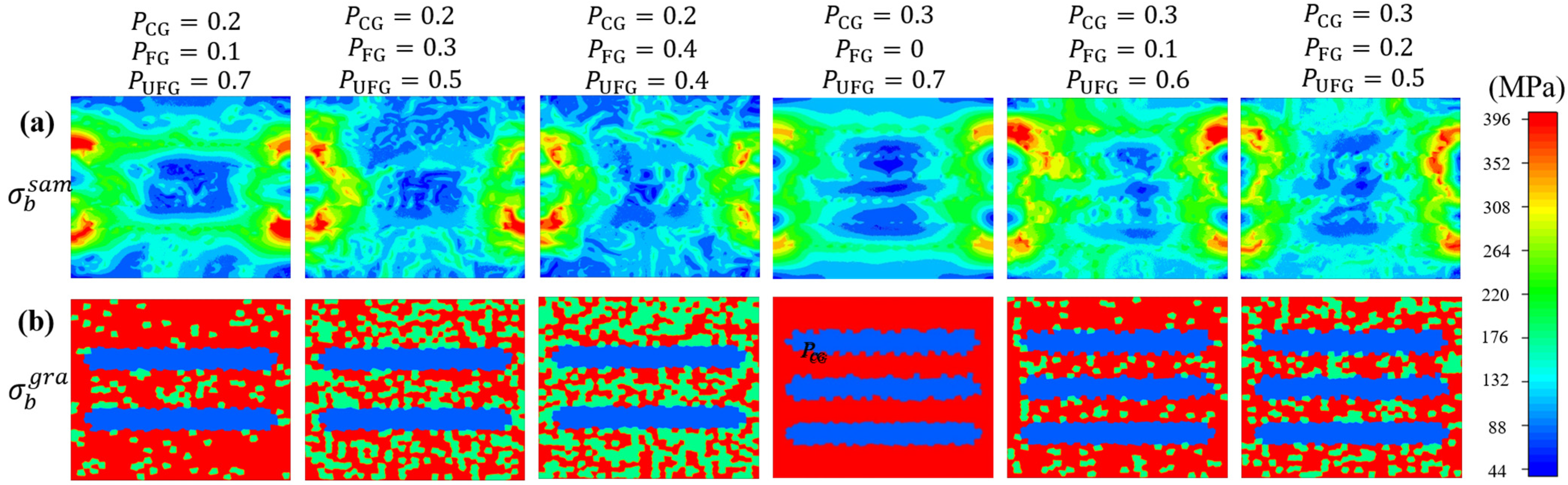

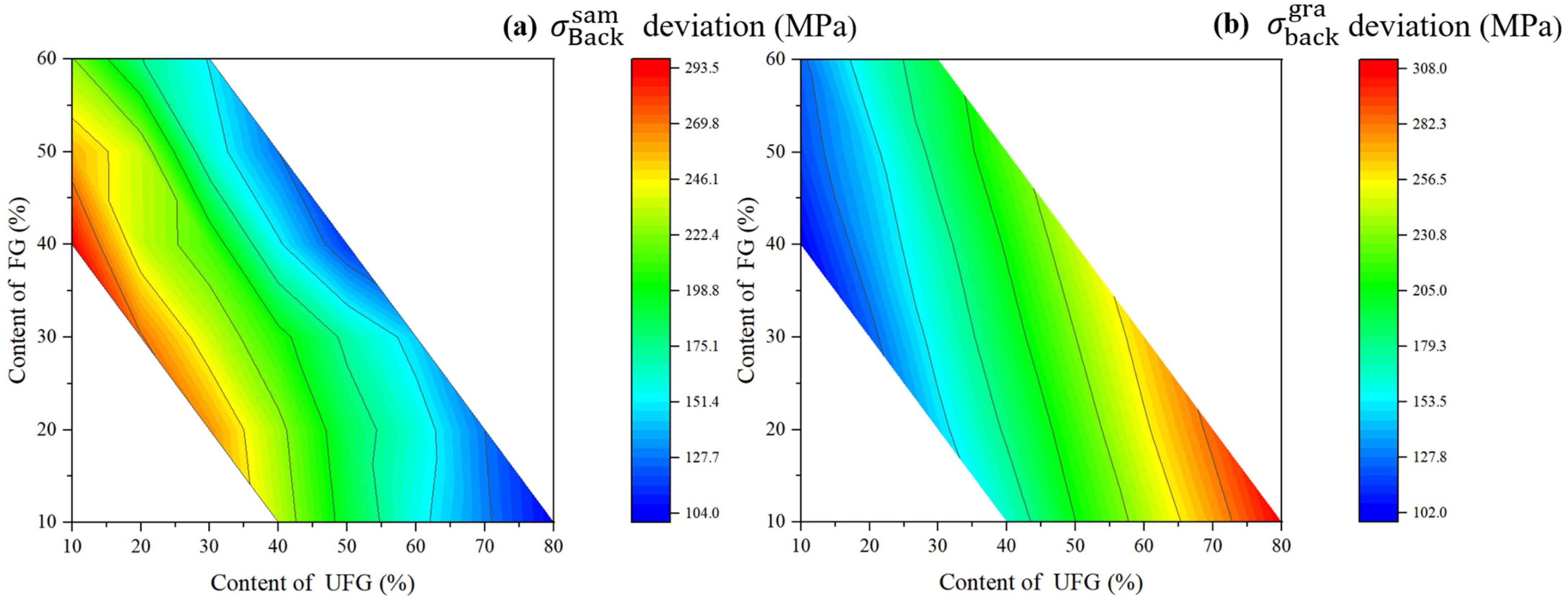

5.2.4. Effect of Domain Volume Fraction on Back Stress

5.3. Strengthening Mechanism of TGS Composites

6. Conclusions

- (1)

- The impact of changes in the three-domain volume fraction on stress–strain distribution was studied. The CG volume fraction was found to have the most significant effect among the three domains. When the CG volume fraction is held constant, the stress–strain distribution becomes more uniform with an increase in FG volume fraction. The incorporation of hard domains (FG and UFG) into soft domains (CG) facilitates significant strain distribution. However, it is noteworthy that the continuous distribution of the soft domain (CG) allows the material to yield under lower stresses.

- (2)

- The variation of boundary GNDs during plastic deformation is analyzed in detail. Our findings indicate that, within a certain range, an increase in FG volume fraction results in a higher accumulation rate of boundary GNDs compared to an increase in CG volume fraction. Furthermore, as the tensile strain increases, the accumulation rate of boundary dislocations attributed to both FG and CG also increases gradually. In order to counteract the strain gradient produced by continuous plastic deformation, back stress–strain hardening develops, enhancing the plasticity of TGS.

- (3)

- This study explains the evolution of back stress with variations in domain volume fraction. The accumulation of GNDs at boundaries contributes to the development of back stress. When the volume fraction of the CG domain remains constant, the FG domain exhibits the most significant impact on back stress. As the FG volume fraction increases, the average back stress initially rises and subsequently falls. Concurrently, back stress serves as an additional stress to overcome, leading to enhanced strain hardening and improved ductility. Furthermore, the FG domain augments the stress-bearing capacity of the UFG domain, thereby contributing to the heightened plasticity and strength of TGS materials.

- (4)

- This study quantified the contributions of Taylor strengthening and back stress to the overall stress–strain response of TGS composites. The analysis shows that back stress, induced by the accumulation of GNDs, significantly contributes to the strain hardening of TGS composites, accounting for 76.3% of the overall effect. This significant contribution is attributed to the enhanced work-hardening capacity of back stress, facilitated by the high interfacial density within the composite.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Yan, D.; Yuan, F.; Jiang, P.; Ma, E.; Wu, X. Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength. Proc. Natl. Acad. Sci. USA 2018, 115, 7224–7229. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Ma, K.; Yang, H.; Li, M.; Lavernia, E.J.; Schoenung, J.M. The Microstructural Design of Trimodal Aluminum Composites. Jom 2014, 66, 898–908. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar]

- Fu, X.; Tan, Z.; Ma, Z.; Li, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Powder assembly & alloying to CNT/Al-Cu-Mg composites with trimodal grain structure and strength-ductility synergy. Compos. Part B-Eng. 2021, 225, 109271. [Google Scholar]

- Liu, Z.Y.; Ma, K.; Fan, G.H.; Zhao, K.; Zhang, J.F.; Xiao, B.L.; Ma, Z. Enhancement of the strength-ductility relationship for carbon nanotube/Al-Cu-Mg nanocomposites by material parameter optimisation. Carbon 2020, 157, 602–613. [Google Scholar] [CrossRef]

- Fu, X.; Tan, Z.; Min, X.; Li, Z.; Yue, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying. Mater. Res. Lett. 2021, 9, 50–57. [Google Scholar]

- Su, J.; Raabe, D.; Li, Z. Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy. Acta Mater. 2019, 163, 40–54. [Google Scholar] [CrossRef]

- Shao, C.W.; Zhang, P.; Zhu, Y.K.; Zhang, Z.J.; Tian, Y.Z.; Zhang, Z.F. Simultaneous improvement of strength and plasticity: Additional work-hardening from gradient microstructure. Acta Mater. 2018, 145, 413–428. [Google Scholar] [CrossRef]

- Lyu, H.; Hamid, M.; Ruimi, A.; Zbib, H.M. Stress/strain gradient plasticity model for size effects in heterogeneous nano-microstructures. International Journal of Plasticity 2017, 97, 46–63. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, X.; Yuan, F.; Kan, Q.; Qu, S.; Kang, G.; Zhang, X. Multiple mechanism based constitutive modeling of gradient nanograined material. Int. J. Plast. 2020, 125, 314–330. [Google Scholar] [CrossRef]

- Hamid, M.; Lyu, H.; Zbib, H. A dislocation-based stress-strain gradient plasticity model for strength and ductility in materials with gradient microstructures. Philos. Mag. 2018, 98, 2896–2916. [Google Scholar] [CrossRef]

- Bi, S.; Liu, Z.Y.; Xiao, B.L.; Xue, P.; Wang, D.; Wang, Q.Z.; Ni, D.R.; Ma, Z.Y. Different fatigue behavior between tension-tension and tension-compression of carbon nanotubes reinforced 7055 Al composite with bimodal structure. Carbon 2021, 184, 364–374. [Google Scholar] [CrossRef]

- Ma, K.; Li, X.N.; Liu, K.; Chen, X.G.; Liu, Z.Y.; Xiao, B.L.; Ma, Z. Improving the high-cycle fatigue strength of heterogeneous carbon nanotube/Al-Cu-Mg composites through grain size design in ductile-zones. Compos. Part B-Eng. 2021, 222, 109094. [Google Scholar] [CrossRef]

- Yang, H.; Topping, T.D.; Wehage, K.; Jiang, L.; Lavernia, E.J.; Schoenung, J.M. Tensile behavior and strengthening mechanisms in a submicron B4C-reinforced Al trimodal composite. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2014, 616, 35–43. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Azizi, R.; Niordson, C.F.; Legarth, B.N. On the homogenization of metal matrix composites using strain gradient plasticity. Acta Mech. Sin. 2014, 30, 175–190. [Google Scholar] [CrossRef]

- Zhu, L.; Shi, S.; Lu, K.; Lu, J. A statistical model for predicting the mechanical properties of nanostructured metals with bimodal grain size distribution. Acta Mater. 2012, 60, 5762–5772. [Google Scholar] [CrossRef]

- Wu, C.; Shi, R.; Luo, G.; Zhang, J.; Shen, Q.; Gan, Z.; Liu, J.; Zhang, L. Influence of particulate B4C with high weight fraction on microstructure and mechanical behavior of an Al-based metal matrix composite. J. Alloys Compd. 2019, 789, 825–833. [Google Scholar] [CrossRef]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Yu, Z.; Zhao, J.; Wei, Y. Hetero-zone boundary affected region: A primary microstructural factor controlling extra work hardening in heterostructure. Acta Mater. 2022, 241, 118395. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, J.; Kang, G.; Zaiser, M. Geometrically necessary dislocations and related kinematic hardening in gradient grained materials: A nonlocal crystal plasticity study. Int. J. Plast. 2023, 163, 103553. [Google Scholar] [CrossRef]

- Li, J.; Weng, G.J.; Chen, S.; Wu, X. On strain hardening mechanism in gradient nanostructures. Int. J. Plast. 2017, 88, 89–107. [Google Scholar] [CrossRef]

- Li, J.; Lu, W.; Chen, S.; Liu, C. Revealing extra strengthening and strain hardening in heterogeneous two-phase nanostructures. Int. J. Plast. 2020, 126, 102626. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Jia, Y.-F.; Li, D.-F.; Yuan, G.-J.; Zhang, X.-C.; Tu, S.-T. A modified kinematic hardening model considering hetero-deformation induced hardening for bimodal structure based on crystal plasticity. Int. J. Mech. Sci. 2021, 191, 106068. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Fu, X.; Yu, Z.; Tan, Z.; Fan, G.; Li, P.; Wang, M.; Xiong, D.-B.; Li, Z. Enhanced strain hardening by bimodal grain structure in carbon nanotube reinforced Al-Mg composites. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 803, 140726. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Pruncu, C.I. Architecture dependent strengthening mechanisms in graphene/Al heterogeneous lamellar composites. Mater. Charact. 2022, 188, 111913. [Google Scholar] [CrossRef]

- Huang, Y.; Qu, S.; Hwang, K.C.; Li, M.; Gao, H. A conventional theory of mechanism-based strain gradient plasticity. Int. J. Plast. 2004, 20, 753–782. [Google Scholar] [CrossRef]

- Hill, R. The Mathematical Theory of Plasticity; Oxford Academic: Oxford, UK, 1950. [Google Scholar]

- Kok, S.; Beaudoin, A.J.; Tortorelli, D.A. On the development of stage IV hardening using a model based on the mechanical threshold. Acta Mater. 2002, 50, 1653–1667. [Google Scholar] [CrossRef]

- Li, J.; Soh, A.K. Modeling of the plastic deformation of nanostructured materials with grain size gradient. Int. J. Plast. 2012, 39, 88–102. [Google Scholar] [CrossRef]

- Zhu, L.; Lu, J. Modelling the plastic deformation of nanostructured metals with bimodal grain size distribution. Int. J. Plast. 2012, 30–31, 166–184. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary Intrinsic Tensile Plasticity in Gradient Nano-Grained Copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [PubMed]

- Sawangrat, C.; Kato, S.; Orlov, D.; Ameyama, K. Harmonic-structured copper: Performance and proof of fabrication concept based on severe plastic deformation of powders. J. Mater. Sci. 2014, 49, 6579–6585. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Zhao, X.; Yue, Z.; Wang, G.; Li, Z.; Soyarslan, C. Role of GNDs in bending strength gain of multilayer deposition generated heterostructured bulk aluminum. Mater. Des. 2022, 219, 110769. [Google Scholar] [CrossRef]

- Salama, E.I.; Abbas, A.; Esawi, A.M.K. Preparation and properties of dual-matrix carbon nanotube-reinforced aluminum composites. Compos. Part A-Appl. Sci. Manuf. 2017, 99, 84–93. [Google Scholar] [CrossRef]

- Yefimov, S.; van der Giessen, E. Size effects in single crystal thin films: Nonlocal crystal plasticity simulations. Eur. J. Mech. A-Solids 2005, 24, 183–193. [Google Scholar] [CrossRef]

- Groma, I.; Csikor, F.F.; Zaiser, M. Spatial correlations and higher-order gradient terms in a continuum description of dislocation dynamics. Acta Mater. 2003, 51, 1271–1281. [Google Scholar] [CrossRef]

- Park, H.K.; Ameyama, K.; Yoo, J.; Hwang, H.; Kim, H.S. Additional hardening in harmonic structured materials by strain partitioning and back stress. Mater. Res. Lett. 2018, 6, 261–267. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J.; Mura, T. Theory of dislocations. J. Appl. Mech. 1983, 50, 476–477. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Fan, G.; Ji, G.; Li, Z.; Guo, Q.; Li, Z.; Zhang, D. Microstructure-based modeling on structure-mechanical property relationships in carbon nanotube/aluminum composites. Int. J. Plast. 2019, 120, 278–295. [Google Scholar] [CrossRef]

- Mahato, J.K.; De, P.S.; Sarkar, A.; Kundu, A.; Chakraborti, P.C. Effect of deformation mode and grain size on Bauschinger behavior of annealed copper. Int. J. Fatigue 2016, 83, 42–52. [Google Scholar] [CrossRef]

- Wang, H.; You, Z.; Lu, L. Kinematic and isotropic strain hardening in copper with highly aligned nanoscale twins. Mater. Res. Lett. 2018, 6, 333–338. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, B.; Li, X.; Zhao, J.; Zaiser, M.; Fan, H.; Zhang, X. Grain boundary effect on nanoindentation: A multiscale discrete dislocation dynamics model. J. Mech. Phys. Solids 2019, 126, 117–135. [Google Scholar] [CrossRef]

- Lu, J.P. Elastic properties of carbon nanotubes and nanoropes. Phys. Rev. Lett. 1997, 79, 1297–1300. [Google Scholar] [CrossRef]

- Xu, Y.R.; Zangvil, A.; Kerber, A. SiC nanoparticle-reinforced Al2O3 matrix composites: Role of intra- and intergranular particles. J. Eur. Ceram. Soc. 1997, 17, 921–928. [Google Scholar] [CrossRef]

- Gaillac, R.; Pullumbi, P.; Coudert, F.-X. ELATE: An open-source online application for analysis and visualization of elastic tensors. J. Phys.-Condens. Matter 2016, 28, 275201. [Google Scholar] [CrossRef]

| Element | Cu | Mg | C | O | Al |

|---|---|---|---|---|---|

| wt.% | 3.38 | 1.6 | 6.73 | 0.7 | Margin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhuang, Q.; Liu, W.; Liu, X.; Badreddine, H.; Saba, F.; Li, Z.; Yue, Z. Simulation and Discussion on Strength Mechanism of Trimodal Grain-Structured CNT/Al Composites Using Strain Gradient Theory. J. Compos. Sci. 2024, 8, 490. https://doi.org/10.3390/jcs8120490

Wang S, Zhuang Q, Liu W, Liu X, Badreddine H, Saba F, Li Z, Yue Z. Simulation and Discussion on Strength Mechanism of Trimodal Grain-Structured CNT/Al Composites Using Strain Gradient Theory. Journal of Composites Science. 2024; 8(12):490. https://doi.org/10.3390/jcs8120490

Chicago/Turabian StyleWang, Sijie, Qianduo Zhuang, Weijie Liu, Xijin Liu, Houssem Badreddine, Farhad Saba, Zhiqiang Li, and Zhenming Yue. 2024. "Simulation and Discussion on Strength Mechanism of Trimodal Grain-Structured CNT/Al Composites Using Strain Gradient Theory" Journal of Composites Science 8, no. 12: 490. https://doi.org/10.3390/jcs8120490

APA StyleWang, S., Zhuang, Q., Liu, W., Liu, X., Badreddine, H., Saba, F., Li, Z., & Yue, Z. (2024). Simulation and Discussion on Strength Mechanism of Trimodal Grain-Structured CNT/Al Composites Using Strain Gradient Theory. Journal of Composites Science, 8(12), 490. https://doi.org/10.3390/jcs8120490