Specific Design of a Self-Compacting Concrete with Raw-Crushed Wind-Turbine Blade

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Conventional Materials

- Siliceous gravel sized 4/12 mm, with a density of 2.66 kg/dm3 and a 24-h water-absorption level of 0.66% wt.

- Siliceous sand sized 0/4 mm, with a density of 2.65 kg/dm3 and a 24-h water-absorption of 0.74% wt.

- Limestone sand sized 0/2 mm, with a density of 2.64 kg/dm3 and a 24-h water-absorption level of 0.52% wt.

- Limestone filler sized < 0.063 mm, with a density of around 2.77 kg/dm3.

2.1.2. Raw-Crushed Wind-Turbine Blade (RCWTB)

2.2. Mix Design

- A cement content of 320 kg/m3.

- Values of the w/c ratio of 0.45 (145 kg/m3 of water) and 0.50 (160 kg/m3 of water), which covered all the usual range of w/c ratios in precast-concrete plants [52].

- Superplasticizing-admixture contents of 2.2% and 2.8% of the cement mass (6.9 kg/m3 and 9.0 kg/m3 of superplasticizing admixtures, respectively). These two values corresponded to the lower and upper limits of the range within the amount of this type of admixture is found when SCC is produced industrially [52].

- Aggregate contents were determined by an optimal adjustment of the overall gradation to Fuller’s curve with an exponent of 0.35. This optimization enabled to fix adequate aggregate proportions to reach self-compactability [50]. Such adjustment is shown in Figure 3. This process yielded contents of 555 kg/m3 of siliceous gravel sized 4/12 mm, 610 kg/m3 of siliceous sand sized 0/4 mm, 625 kg/m3 of limestone sand sized 0/2 mm, and 170 kg/m3 of limestone filler sized < 0.063 mm.

2.3. Experimental Plan

- In the first step of mixing, all aggregates, RCWTB and 30% water were poured into a planetary mixer and mixed for three minutes.

- The second step consisted of adding the cement with 70% water, followed by mixing for another three minutes.

- In the last mixing stage, the superplasticizing admixtures diluted in 0.50 l of water were added. The last three minutes of mixing were then conducted.

3. Results and Discussion

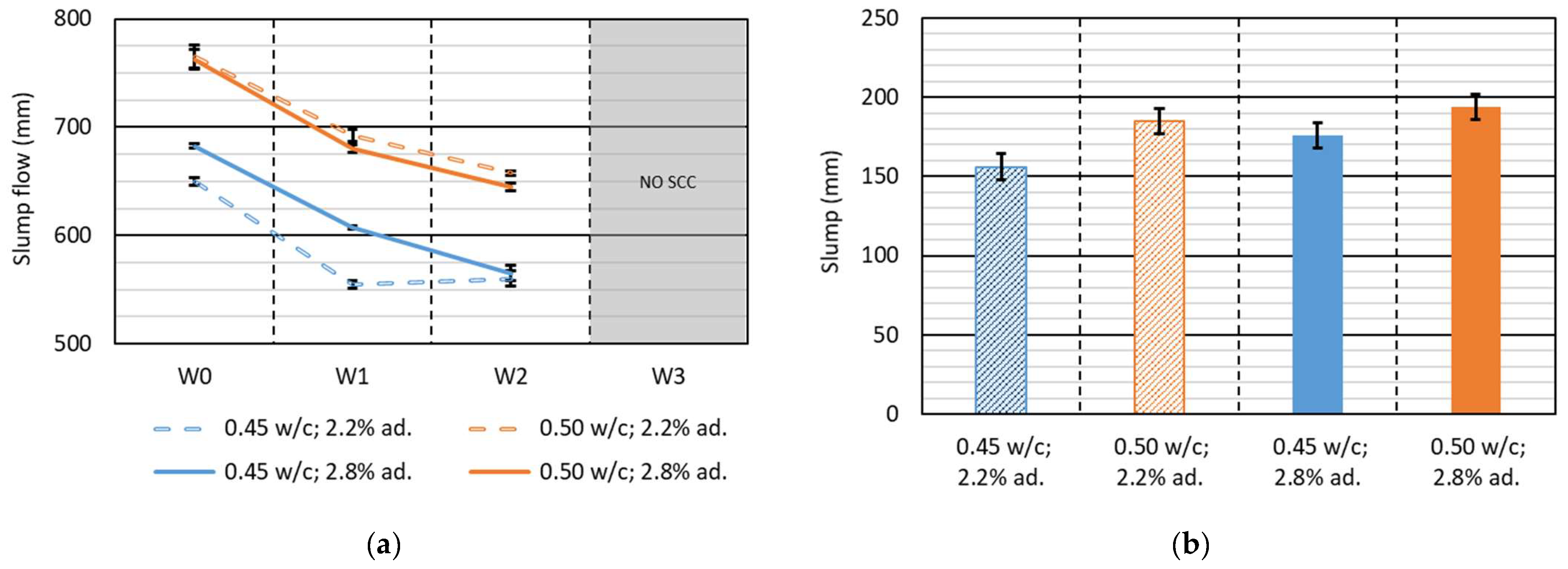

- Group 1. In the first group of mixes, amounts of 0%, 1%, 2% and 3% of RCWTB were added to an SCC with a conventional design. According to all the aspects explained in the mix design section, w/c ratios of 0.45 and 0.50 and contents of superplasticizing admixtures (ad.) of 2.2% and 2.8% of the cement mass were considered for each RCWTB amount. Therefore, four SCC mixes were produced for each RCWTB content (0.45 w/c and 2.2% ad.; 0.45 w/c and 2.8% ad.; 0.50 w/c and 2.2% ad.; and 0.50 w/c and 2.8% ad.), yielding sixteen different mixes.

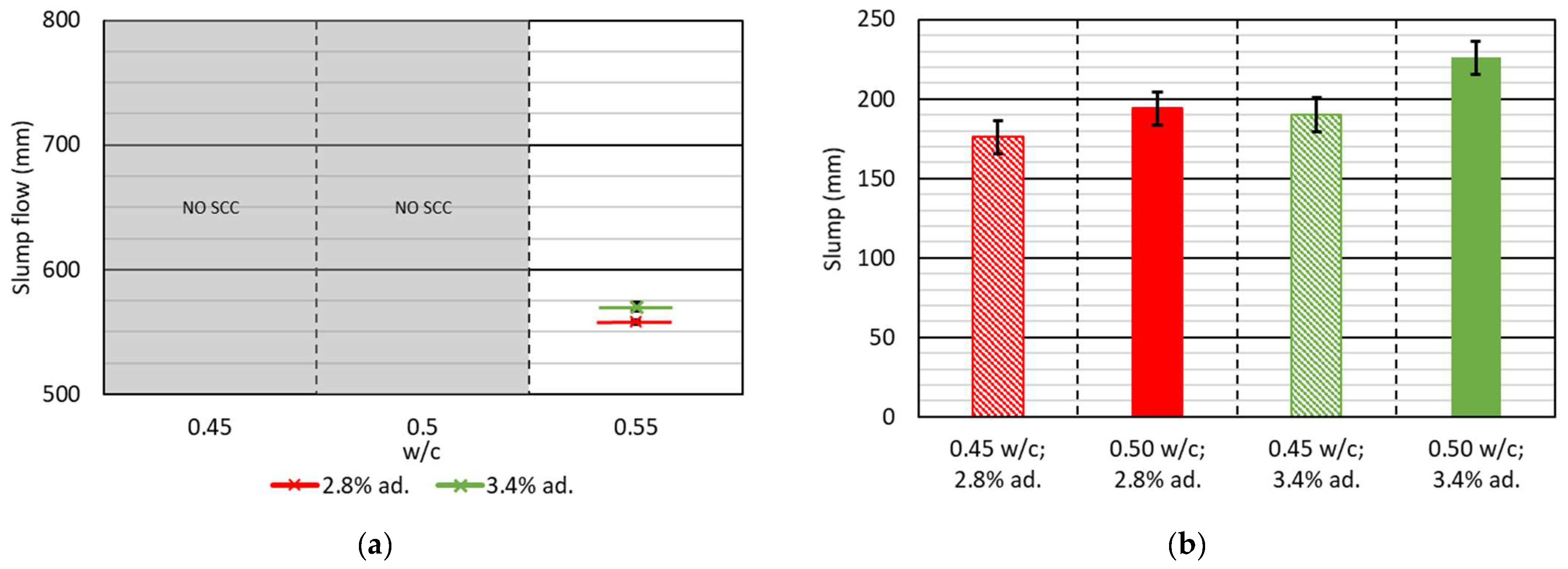

- Group 2. 3% RCWTB with water and admixture contents indicated for Group 1 did not enable to achieve a slump flow higher than 550 mm, minimum required value to consider this concrete as self-compacting according to EN 206 [47]. Therefore, the w/c ratio was increased up to 0.55 and the content of superplasticizer admixtures up to 3.4% of the cement mass. These six mixes conformed the second group.

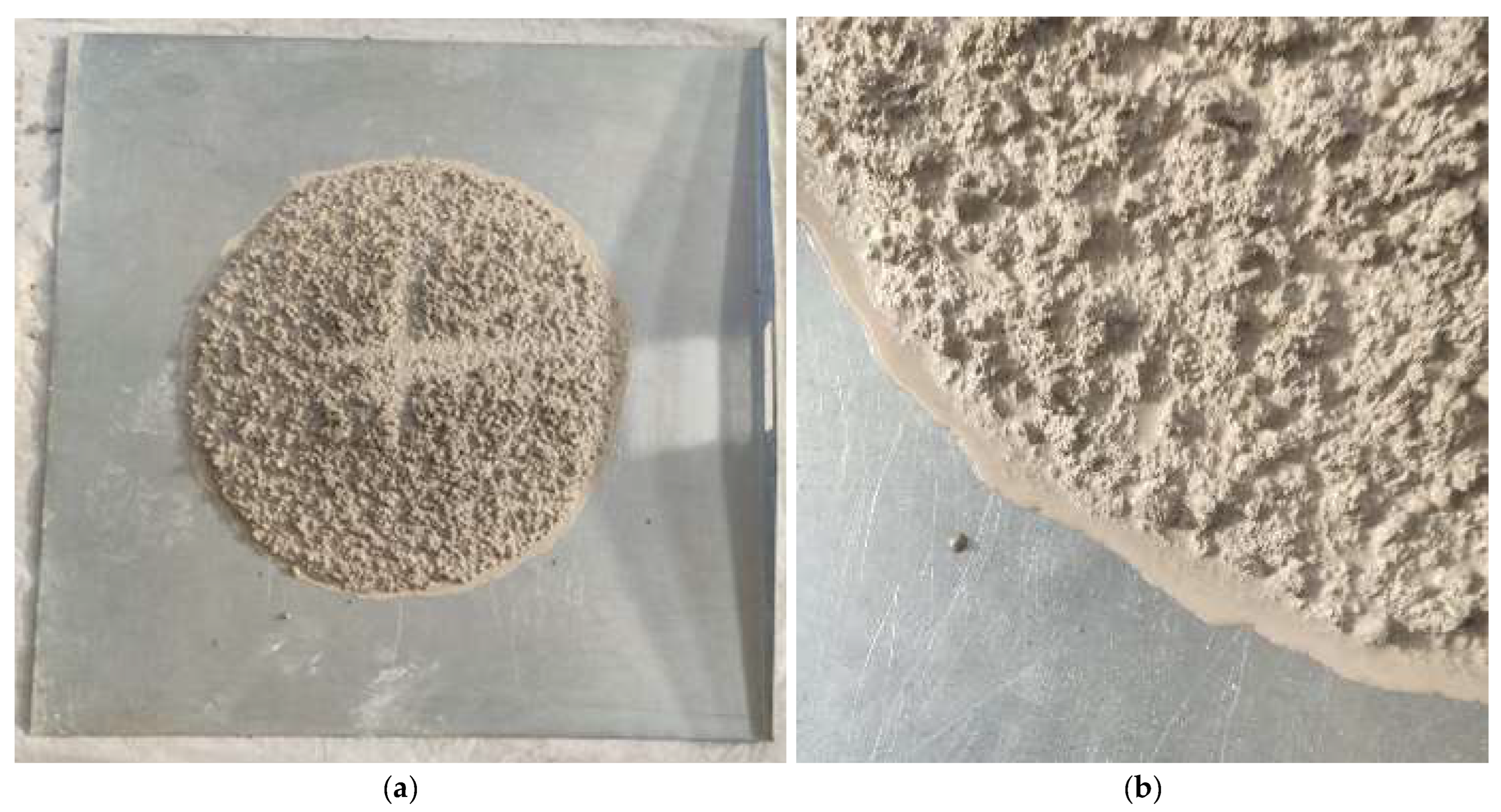

- Group 3. From the experience of increasing the w/c ratio to 0.55, it was found that the water started to segregate from the mix, providing the adjustment unsuitable for achieving stable SCC with 3% RCWTB. Consequently, SCC with 3% RCWTB was designed by fixing the w/c ratio at both 0.45 and 0.50 while increasing the amount of superplasticizing admixtures. Admixture proportions of 3.4, 4.0%, 4.6%, 5.2%, 5.8% and 6.4% of the cement mass were considered. The twelve SCC mixes developed following these criteria comprised the third group.

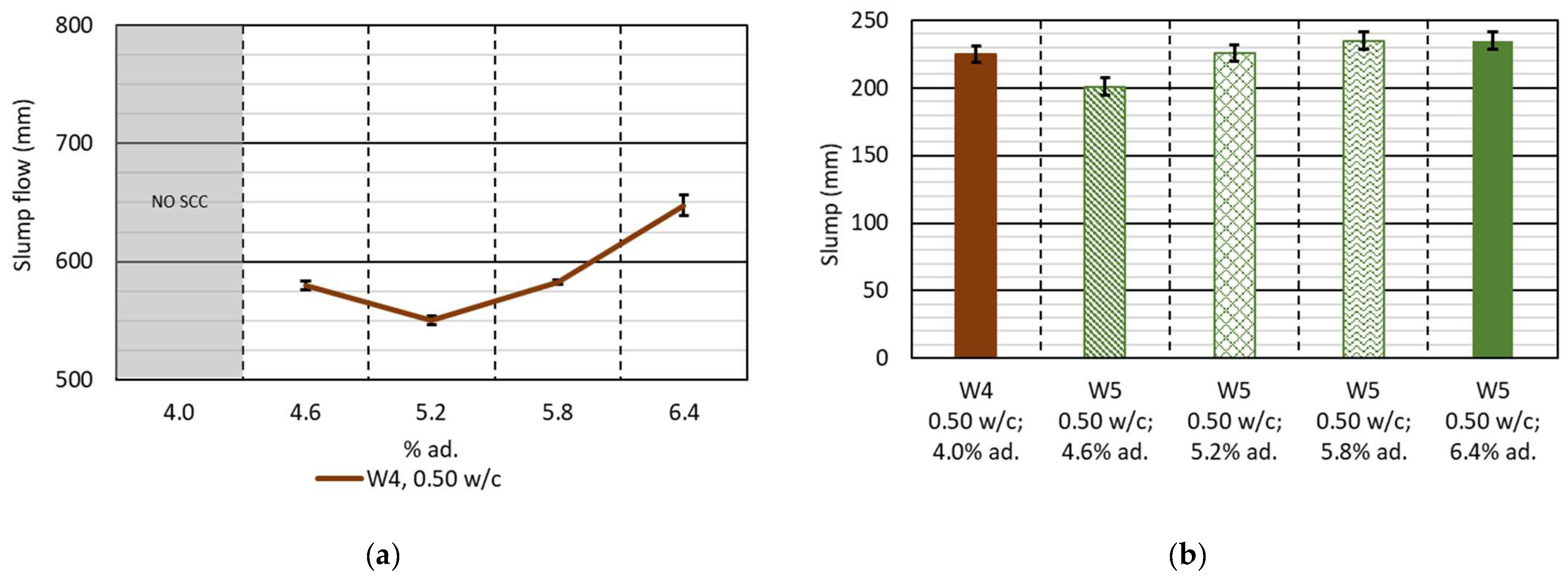

- Group 4. In the last group of mixes, 4% and 5% of RCWTB were added to an SCC with a w/c ratio of 0.50, as it was previously demonstrated to be the most adequate w/c ratio when 3% RCWTB was added to SCC. The minimum content of superplasticizing admixtures for each RCWTB amount was the one that allowed reaching self-compactability with the immediately lower RCWTB content. Admixture proportions up to 6.4% of the cement mass were added in increasing steps of 0.6%, resulting in nine different mixes.

3.1. Group 1: RCWTB Content Between 0% and 3%; w/c Ratio Between 0.45 and 0.50; Admixture Amount Between 2.2% and 2.8% of the Cement Mass

- A clear improvement (16.28% on average) in the slump flow was observed when increasing the w/c ratio from 0.45 to 0.50. This was due to the development of a greater amount of cement paste surrounding the aggregate particles and the RCWTB. Besides, this phenomenon resulted in a decrease in the internal friction between the SCC components, which allowed them to flow more easily [60].

- Regarding the increase in the admixture percentage, there was no clear trend, as opposed to the w/c ratio. The influence of increasing admixture content varied depending on the w/c ratio, with no consistent behavior observed. Thus, the slump flow was improved by 5.11% on average for a w/c ratio of 0.45, while the slump flow decreased by 1.34% on average when a w/c ratio of 0.50 was considered in the SCC. The SCC mixture segregated more quickly, inhibiting the attainment of a high value of slump flow when the maximum admixture percentage and w/c ratio were simultaneously applied, as also found in other experiences with alternative raw materials in SCC [61,62]. The use of superplasticizing admixtures allowed for the reduction of water while maintaining workability [63]. Therefore, low w/c ratios yielded the highest efficiency when increasing the admixtures up to 2.8% wt. of the cement mass for the studied RCWTB contents.

- The described efficiency of increasing the percentage of admixtures was not found when the amount of RCWTB rose. For a w/c ratio of 0.45, increasing the admixture percentage from 2.2% to 2.8% of the cement mass resulted in an increase of the slump flow of 33 mm for 0% RCWTB and only 5 mm for 2% RCWTB. The GFRP fibers within this waste hindered the flow of the other SCC components [64], mainly the coarse aggregate particles, which an increasing admixture proportion could not counterbalance, as in similar research [65].

- The increase in the percentage of RCWTB in general caused a decrease in the slump flow. The most pronounced reduction was found in the mixes with a w/c ratio of 0.45 and 2.8% of admixtures, for which 2% RCWTB reduced the slump flow by 17.21% compared to the W0 mix. This reduction was driven by two primary factors. On the one hand, the GFRP fibers increased the specific surface area of the SCC components to be covered by the cementitious paste [30]. On the other hand, the GFRP fibers hindered the flow of the rest of the SCC components [64]. The decrease in the slump flow that suffered the W3 mixes was so great that self-compactability could not be reached with the water admixture contents considered in this first group when adding that RCWTB amount.

3.2. Group 2: 3% RCWTB; w/c Ratio Between 0.45 and 0.55; Admixture Amount Between 2.8% and 3.4% of the Cement Mass

3.3. Group 3: 3% RCWTB; w/c Ratio Between 0.45 and 0.50; Admixture Amount Between 3.4% and 6.4% of the Cement Mass

- Self-compactability was not achieved for a w/c ratio of 0.45 and admixture contents up to 5.8% of the cement mass, though the slump of concrete improved by 13.68%. Furthermore, SCC with a slump flow of 580 mm was only obtained for a superplasticizing-admixture amount of 6.4% of the cement mass. This increase in superplasticizers reduced cement’s water demand, which allowed to increase the free water of the mix and thus its workability [59].

- Only an admixture content of 3.4% did not lead to self-compactability when considering a w/c ratio of 0.50 (slump of around 225 mm). For the remaining admixture contents, SCC was obtained, although two different trends were found. On the one hand, a reduction of the slump flow of up to 8.37% was noted in the mixes with admixture contents from 4.0% to 5.2%. The increase of free water generated by the admixtures and their inadequate interaction with RCWTB led to a premature segregation of the mixing water [65]. On the other hand, the trend completely changed from a superplasticizing-admixture content of 5.2% of the cement mass, as the slump flow increased by 11.30% for an admixture content of 6.4%. Therefore, higher admixture contents led to better results in terms of flowability when adding 3% RCWTB to SCC. Finally, it should be noted that the mix with 6.4% admixture exhibited a slump flow 1.99% higher than that of the mix with 4.0% admixture. The increase in the superplasticizing-admixture proportion successfully compensated the negative effect of the premature segregation of the mixing water found at lower admixture levels, as established in specific literature related to the effects of the admixtures in concrete [2].

3.4. Group 4: RCWTB Content Between 4% and 5%; 0.50 w/c Ratio; Admixture Amount Between 4.0% and 6.4% of the Cement Mass

- SCC containing 4% RCWTB was developed when the admixture content was at least 4.6% of the cement mass. Additionally, the slump flow results obtained for W4 when increasing the admixture proportion exhibited the same behavior trend as that of SCC from W3 with 0.50 w/c ratio. Thus, the slump flow decreased by 5.17% when increasing the admixtures from 4.6% to 5.2% of the cement mass, and then increased by 17.72% when reaching 6.4% admixture. While superplasticizing admixtures favored a premature segregation of the free water when used up to 5.2% of the cement mass [2], higher amounts of superplasticizers reduced that segregation and interacted better with the RCWTB, allowing higher slump flows to be obtained [65].

- SCC was not achieved for 5% RTCWB, although the slump increased by 5.47% on average with increasing percentages of admixtures. Superplasticizers reduced the water consumed by cement during its hydration, which facilitated the relative displacement and flow of the particles compositing the concrete [72], yet not being enough to reach self-compactability.

- The addition of RCWTB reduced the workability of concrete in all cases, whether or not self-compactability was reached. Thus, 5% RCWTB did not allow SCC to be developed for admixture quantities for which SCC containing 4% RCWTB was successfully produced. Furthermore, the W4 mixes showed lower slump flows than the W3 mixes with exactly the same w/c ratio and admixture content (Figure 9). The GFRP fibers in this residue hindered the displacement and flow of the coarse-aggregate particles [64]. In addition, RCWTB increased the specific surface area of the SCC components to be covered by the cement paste [30].

3.5. Statistical Evaluation Through an ANOVA

- Each w/c ratio led to a different SCC behavior in terms of slump flow and compressive strength, underscoring the importance of carefully controlling this design parameter [74], especially when RCWTB is added.

- The incorporation of RCWTB only affected the slump flow of the SCC in a relevant way when it was added in a proportion equal to or higher than 3%. Over this threshold, conventional SCC design was not valid due to the interposition of the GFRP fibers in the flow of the rest of the SCC components [31]. In terms of compressive strength, however, RCWTB amounts above 2% always led to equivalent performance.

- The superplasticizing-admixture content could be divided into three groups that led to equivalent fresh behavior of the SCC. First, the admixture contents corresponding to a conventional design (2.2% and 2.8%). Second, intermediate contents of 3.4% and 4.0%. Finally, high contents (4.6%, 5.2% and 5.8%). Conventional admixture contents were adequate when adding up to 2% RCWTB, while the proportion of admixtures had to be increased to values generally above 4.0% of the cement mass for RCWTB contents of 3.0% or higher. It is common that the addition of wastes to SCC leads to higher amounts of superplasticizers in the mix design to maintain flowability [63]. The levels of compressive strength were equivalent for admixture amounts between 2.8% and 4.0%.

3.6. MCDM Optmization

4. Conclusions and Future Research Lines

- Increasing the water/cement (w/c) ratio was necessary to achieve self-compactability with higher RCWTB contents. A w/c ratio of 0.45 and 0.50 was adequate for up to 2% RCWTB, while for higher contents, a 0.50 w/c ratio was required. A w/c ratio of 0.55 caused premature segregation of SCC.

- Higher proportions of superplasticizers were needed to achieve self-compactability with larger RCWTB contents. The effectiveness of conventional amounts of admixtures decreased at high RCWTB levels. An admixture content of 2.8% of the cement mass is recommended up to 2% RCWTB, and 4–6% for higher RCWTB amounts.

- Compressive strength decreased with increased RCWTB due to the presence of weak balsa-wood and polymer particles, and increasing w/c ratios and admixture proportions. However, a minimum strength of 25 MPa was always achieved, suitable for structural applications such as slabs, beams, pavements, and precast elements, among others, according standards [47].

- Following a multi-criteria decision-making analysis, the optimal w/c ratio was 0.45 for up to 2% RCWTB, and 0.50 for higher contents. The optimal admixture content was 2.8% of the cement mass up to 2% RCWTB, 4.0% for 3% RCWTB, and 4.6% for 4% RCWTB.

- SCC could not be developed with 5% RCWTB, even with admixture amounts up to 6.4%. The irregular shape and surface roughness of balsa-wood and polymer particles, as well as the GFRP fibers interfered with the flow of the other components, which could not be counterbalanced by adjusting the w/c ratio and admixture content.

- First of all, it would be necessary to evaluate the passing ability of the SCC mixes produced. For this, it is not enough with an adequate flowability [76], but also an adequate segregation resistance that guarantees the cohesion of the mixture when flowing [77], and an adequate packing structure that is capable of properly dragging all the aggregate particles of the SCC [78]. In this way, the proportion of aggregate fines could be accurately adjusted according to fresh requirements [77], while not affecting and even improving the mechanical performance of SCC [79,80,81]. Thus, an SCC containing RCWTB that would be valid for a wide range of applications could be developed from the point of view of the fresh performance.

- Second, an overall analysis of the mechanical, durability, environmental, including toxicity, and economic performance of SCC would be needed. In this way, it is guaranteed that the performance of SCC containing RCWTB is adequate in all performance dimensions [37], not only in terms of fresh behavior and compressive strength, although it is the basic strength property of concrete [51].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hoang, Q.G.; Vu, Q.V. Estimation the Initial Cement Dosage of Concrete from Mechanical Behavior and Chemical Analysis. Civ. Eng. Arch. 2020, 8, 580–585. [Google Scholar] [CrossRef]

- Ferraris, C.F.; Obla, K.H.; Hill, R. The Influence of Mineral Admixtures on the Rheology of Cement Paste and Concrete. Cem. Concr. Res. 2001, 31, 245–255. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Khan, Q.U.Z. Mechanical and Durability Properties of High Performance Concretes Containing Supplementary Cementitious Materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Tensile Strength Behaviour of Recycled Aggregate Concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Nagrockienė, D.; Girskas, G.; Skripkiūnas, G. Properties of Concrete Modified with Mineral Additives. Constr. Build. Mater. 2017, 135, 37–42. [Google Scholar] [CrossRef]

- Özalp, F.; Yilmaz, H.D.; Kara, M.; Kaya, Ö.; Şahin, A. Effects of Recycled Aggregates from Construction and Demolition Wastes on Mechanical and Permeability Properties of Paving Stone, Kerb and Concrete Pipes. Constr. Build. Mater. 2016, 110, 17–23. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled Fibers in Reinforced Concrete: A Systematic Literature Review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Habibi, A.; Ghomashi, J. Development of an Optimum Mix Design Method for Self-Compacting Concrete Based on Experimental Results. Constr. Build. Mater. 2018, 168, 113–123. [Google Scholar] [CrossRef]

- Krząkała, J.; Łaziński, P.; Gerges, M.; Pyrzowski, Ł.; Grządziela, G. Influence of Actual Curing Conditions on Mechanical Properties of Concrete in Bridge Superstructures. Materials 2023, 16, 54. [Google Scholar] [CrossRef]

- Cu, Y.T.H.; Tran, M.V.; Ho, C.H.; Nguyen, P.H. Relationship between Workability and Rheological Parameters of Self-Compacting Concrete Used for Vertical Pump up to Supertall Buildings. J. Build. Eng. 2020, 32, 101786. [Google Scholar] [CrossRef]

- Reddy Suda, V.B. Compressive Strength, Flexural Strength and Modulus of Elasticity Relationships of Ternary Blended Concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1086, p. 012046. [Google Scholar] [CrossRef]

- Novak, J.; Kohoutkova, A. Mechanical Properties of Concrete Composites Subject to Elevated Temperature. Fire Saf. J. 2018, 95, 66–76. [Google Scholar] [CrossRef]

- Schwartzentruber, L.D.; Le Roy, R.; Cordin, J. Rheological Behaviour of Fresh Cement Pastes Formulated from a Self Compacting Concrete (SCC). Cem. Concr. Res. 2006, 36, 1203–1213. [Google Scholar] [CrossRef]

- Santamaría, A.; Orbe, A.; Losañez, M.M.; Skaf, M.; Ortega-Lopez, V.; González, J.J. Self-Compacting Concrete Incorporating Electric Arc-Furnace Steelmaking Slag as Aggregate. Mater. Des. 2017, 115, 179–193. [Google Scholar] [CrossRef]

- Autier, C.; Azema, N.; Taulemesse, J.-M.; Clerc, L. Mesostructure Evolution of Cement Pastes with Addition of Superplasticizers Highlighted by Dispersion Indices. Powder Technol. 2013, 249, 282–289. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Verdú-Vazquez, A.; Patón-Aguilera, M. Diseño de Hormigón Autocompactante Con Aditivos Sintéticos de 4 a Generación. DYNA 2019, 94, 455–459. [Google Scholar] [CrossRef]

- Vanhove, Y.; Djelal, C.; Schwendenmann, G.; Brisset, P. Study of Self Consolidating Concretes Stability during Their Placement. Constr. Build. Mater. 2012, 35, 101–108. [Google Scholar] [CrossRef]

- Long, G.; Gao, Y.; Xie, Y. Designing More Sustainable and Greener Self-Compacting Concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Long, W.-J.; Gu, Y.; Liao, J.; Xing, F. Sustainable Design and Ecological Evaluation of Low Binder Self-Compacting Concrete. J. Clean. Prod. 2017, 167, 317–325. [Google Scholar] [CrossRef]

- Bui, V.K.; Montgomery, D.; Hinczak, I.; Turner, K. Rapid Testing Method for Segregation Resistance of Self-Compacting Concrete. Cem. Concr. Res. 2002, 32, 1489–1496. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Yim Wan, D.L.; Muselin, G. Development of High-Performance Self-Compacting Concrete Using Waste Recycled Concrete Aggregates and Rubber Granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Murthy, N.K.; Rao, N.; Reddy, I.R.; Reddy, M.V.S. Mix Design Procedure for Self-Compacting Concrete. IOSR J. Eng. 2012, 2, 33–41. [Google Scholar] [CrossRef]

- Zong, L.; Zhang, S.P.; Liang, P.X. Experiment Study on the Durability of Dry-Mixing Self-Compacting Concrete. Adv. Mat. Res. 2011, 250–253, 493–496. [Google Scholar]

- Volaš, J.; Broćeta, G.; Krndija, M.L.; Šupić, S.; Pantić, V.; Malešev, M.; Radonjanin, V.; Cumbo, A.; Savić, A.; Lazić, Ž. Effect of the HRWRA Quantity on Durability Properties of Self-Compacting Concrete. In Proceedings of the International Conference on Contemporary Theory and Practice in Construction XVI, Banja Luka, Bosnia and Herzegovina, 13–14 June 2024; Volume 16, pp. 351–362. [Google Scholar]

- Revilla-Cuesta, V.; Fiol, F.; Perumal, P.; Ortega-López, V.; Manso, J.M. Using Recycled Aggregate Concrete at a Precast-Concrete Plant: A Multi-Criteria Company-Oriented Feasibility Study. J. Clean. Prod. 2022, 373, 133873. [Google Scholar] [CrossRef]

- Rasekh, H.; Joshaghani, A.; Jahandari, S.; Aslani, F.; Ghodrat, M. 2—Rheology and Workability of SCC. In Self-Compacting Concrete: Materials, Properties and Applications; Siddique, R., Ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 31–63. ISBN 978-0-12-817369-5. [Google Scholar]

- Paul, V.K.; Khursheed, S.; Jain, S. Benefit Cost Analysis of Self Compacting Concrete over Conventional Reinforced Cement Concrete. Int. J. Res. Eng. Technol. 2017, 6, 64–74. [Google Scholar]

- Zhu, D.; Mobasher, B.; Peled, A. Experimental Study of Dynamic Behavior of Cement-Based Composites. J. Sustain. Cem. Based Mater. 2013, 2, 1–12. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of Steel Fiber Content and Shape on Mechanical Properties of Ultra High Performance Concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Zeyad, A.M. Effect of Fibers Types on Fresh Properties and Flexural Toughness of Self-Compacting Concrete. J. Mater. Res. Technol. 2020, 9, 4147–4158. [Google Scholar] [CrossRef]

- Li, K.F.; Yang, C.Q.; Huang, W.; Zhao, Y.B.; Wang, Y.; Pan, Y.; Xu, F. Effects of Hybrid Fibers on Workability, Mechanical, and Time-Dependent Properties of High Strength Fiber-Reinforced Self-Consolidating Concrete. Constr. Build. Mater. 2021, 277, 122325. [Google Scholar] [CrossRef]

- Ghamari, A.; Kurdi, J.; Shemirani, A.B.; Haeri, H. Experimental Investigating the Properties of Fiber Reinforced Concrete by Combining Different Fibers. Comp. Concr. 2020, 25, 509–516. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Lee, J.-H.; Yoon, Y.-S. Effect of Fiber Content on Mechanical and Fracture Properties of Ultra High Performance Fiber Reinforced Cementitious Composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Hatami Jorbat, M.; Hosseini, M.; Mahdikhani, M. Effect of Polypropylene Fibers on the Mode I, Mode II, and Mixed-Mode Fracture Toughness and Crack Propagation in Fiber-Reinforced Concrete. Theor. Appl. Fract. Mech. 2020, 109, 102723. [Google Scholar] [CrossRef]

- Kwan, W.H.; Cheah, C.B.; Ramli, M.; Chang, K.Y. Alkali-Resistant Glass Fiber Reinforced High Strength Concrete in Simulated Aggressive Environment. Mater. Constr. 2018, 68, 147. [Google Scholar] [CrossRef]

- More, F.M.D.S.; Subramanian, S.S. Impact of Fibres on the Mechanical and Durable Behaviour of Fibre-Reinforced Concrete. Buildings 2022, 12, 1436. [Google Scholar] [CrossRef]

- Manso-Morato, J.; Hurtado-Alonso, N.; Revilla-Cuesta, V.; Skaf, M.; Ortega-López, V. Fiber-Reinforced Concrete and Its Life Cycle Assessment: A Systematic Review. J. Build. Eng. 2024, 94, 110062. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Illikainen, M. Development of Eco-Efficient and Cost-Effective Reinforced Self-Consolidation Concretes with Hybrid Industrial/Recycled Steel Fibers. Constr. Build. Mater. 2018, 166, 214–226. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of Glass Fibre Reinforced Polymer (GFRP) Composite Wastes in Concrete: A Critical Review and Cost Benefit Analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A Review on Recycling and Reuse Methods for Carbon Fiber/Glass Fiber Composites Waste from Wind Turbine Blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural Reuse of Wind Turbine Blades through Segmentation. Comp. Part C Open Access 2021, 5, 100137. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Ortega-López, V.; Manso, J.M. Raw-Crushed Wind-Turbine Blade: Waste Characterization and Suitability for Use in Concrete Production. Resour. Conserv. Recycl. 2023, 198, 107160. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Manso-Morato, J.; Hurtado-Alonso, N.; Skaf, M.; Ortega-López, V. Mechanical and Environmental Advantages of the Revaluation of Raw-Crushed Wind-Turbine Blades as a Concrete Component. J. Build. Eng. 2024, 82, 108383. [Google Scholar] [CrossRef]

- Hernando-Revenga, M.; Revilla-Cuesta, V.; Chica, J.A.; Ortega-López, V.; Manso, J.M. Initial Approach to Self-Compacting Concrete with Raw-Crushed Wind-Turbine Blade: Fresh, CFD and Mechanical Analysis. Appl. Sci. 2024, 14, 9946. [Google Scholar] [CrossRef]

- Baturkin, D.; Hisseine, O.A.; Masmoudi, R.; Tagnit-Hamou, A.; Massicotte, L. Valorization of Recycled FRP Materials from Wind Turbine Blades in Concrete. Resour. Conserv. Recycl. 2021, 174, 105807. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Donnini, J.; Nardinocchi, A. Lightweight Plasters Containing Plastic Waste for Sustainable and Energy-Efficient Building. Constr. Build. Mater. 2015, 94, 337–345. [Google Scholar] [CrossRef]

- EN 197-1; EN-Euronorm. European Committee for Standardization: Brussels, Belgium.

- de Azevedo, A.R.G.; Alexandre, J.; Xavier, G.D.C.; Pedroti, L.G. Recycling Paper Industry Effluent Sludge for Use in Mortars: A Sustainability Perspective. J. Clean. Prod. 2018, 192, 335–346. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Additivity Effects in the Rheology of Fresh Concrete Containing Water-Reducing Admixtures. Constr. Build. Mater. 2011, 25, 2955–2960. [Google Scholar] [CrossRef]

- Nepomuceno, M.C.S.; Pereira-De-Oliveira, L.A.; Lopes, S.M.R.; Franco, R.M.C. Maximum Coarse Aggregate’s Volume Fraction in Self-Compacting Concrete for Different Flow Restrictions. Constr. Build. Mater. 2016, 113, 851–856. [Google Scholar] [CrossRef]

- Elemam, W.E.; Abdelraheem, A.H.; Mahdy, M.G.; Tahwia, A.M. Optimizing Fresh Properties and Compressive Strength of Self-Consolidating Concrete. Constr. Build. Mater. 2020, 249, 118781. [Google Scholar] [CrossRef]

- Fiol, F.; Revilla-Cuesta, V.; Skaf, M.; Thomas, C.; Manso, J.M. Scaled Concrete Beams Containing Maximum Levels of Coarse Recycled Aggregate: Structural Verifications for Precast-Concrete Building Applications. Struct. Concr. 2023, 24, 3476–3497. [Google Scholar] [CrossRef]

- Zhu, W.; Gibbs, J.C. Use of Different Limestone and Chalk Powders in Self-Compacting Concrete. Cem. Concr. Res. 2005, 35, 1457–1462. [Google Scholar] [CrossRef]

- Benjeddou, O.; Soussi, C.; Jedidi, M.; Benali, M. Experimental and Theoretical Study of the Effect of the Particle Size of Limestone Fillers on the Rheology of Self-Compacting Concrete. J. Build. Eng. 2017, 10, 32–41. [Google Scholar] [CrossRef]

- Benaicha, M.; Belcaid, A.; Alaoui, A.H.; Jalbaud, O.; Burtschell, Y. Effects of Limestone Filler and Silica Fume on Rheology and Strength of Self-compacting Concrete. Struct. Concr. 2019, 20, 1702–1709. [Google Scholar] [CrossRef]

- Ortega, J.J.; Ruiz, G.; Poveda, E.; González, D.C.; Tarifa, M.; Zhang, X.X.; Yu, R.C.; Vicente, M.Á.; de la Rosa, Á.; Garijo, L. Size Effect on the Compressive Fatigue of Fibre-Reinforced Concrete. Constr. Build. Mater. 2022, 322, 126238. [Google Scholar] [CrossRef]

- Cantero, B.; Bravo, M.; de Brito, J.; Sáez del Bosque, I.F.; Medina, C. Water Transport and Shrinkage in Concrete Made with Ground Recycled Concrete-Additioned Cement and Mixed Recycled Aggregate. Cem. Concr. Compos. 2021, 118, 103957. [Google Scholar] [CrossRef]

- Cantero, B.; Neves, R.; Sequeira, L.; de Brito, J.; Bravo, M. Optimisation of the Performance of Alkali-Activated Mortars Using CDW Binders from Different Sources. Constr. Build. Mater. 2024, 442, 137677. [Google Scholar] [CrossRef]

- Warda, M.A.; Ahmad, S.S.E.; Mahdi, I.M.; Sallam, H.E.-D.M.; Khalil, H.S. The Applicability of TOPSIS- and Fuzzy TOPSIS-Based Taguchi Optimization Approaches in Obtaining Optimal Fiber-Reinforced Concrete Mix Proportions. Buildings 2022, 12, 796. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effects of Packing Density and Water Film Thickness on the Fluidity Behaviour of Cemented Paste Backfill. Powder Technol. 2020, 359, 27–35. [Google Scholar] [CrossRef]

- Ibrahim, H.A.; Abbas, W.A. Fresh Properties of Self-Consolidating Expired Cement-Fly Ash Cold Bonded Lightweight Aggregate Concrete with Different Mineral Admixtures. Eng. Tech. J. 2023, 41, 734–744. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.S.; Soudki, K.A. Properties of Freshly Mixed Self-Consolidating Concretes Incorporating Rice Husk Ash as a Supplementary Cementing Material. Constr. Build. Mater. 2012, 30, 833–842. [Google Scholar] [CrossRef]

- Li, L.G.; Kwan, A.K.H. Effects of Superplasticizer Type on Packing Density, Water Film Thickness and Flowability of Cementitious Paste. Constr. Build. Mater. 2015, 86, 113–119. [Google Scholar] [CrossRef]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Rahimian Koloor, S.S.; Petrů, M.; Radwan, N. Strength and Flexural Behavior of Steel Fiber and Silica Fume Incorporated Self-Compacting Concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Prakash, R.; Raman, S.N.; Divyah, N.; Subramanian, C.; Vijayaprabha, C.; Praveenkumar, S. Fresh and Mechanical Characteristics of Roselle Fibre Reinforced Self-Compacting Concrete Incorporating Fly Ash and Metakaolin. Constr. Build. Mater. 2021, 290, 123209. [Google Scholar] [CrossRef]

- Mansor, A.M.; Borg, R.P.; Hamed, A.M.; Gadeem, M.M.; Saeed, M.M. The Effects of Water-Cement Ratio and Chemical Admixtures on the Workability of Concrete. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 442, p. 012017. [Google Scholar] [CrossRef]

- Salain, I. Effect of Water/Cement and Aggregate/Cement Ratios on Consistency and Compressive Strength of Concrete Using Volcanic Stone Waste as Aggregates. Civ. Eng. Arch. 2021, 9, 1900–1908. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of Recycled Plastics in Concrete: A Critical Review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Trento, D.; Faleschini, F.; Revilla-Cuesta, V.; Ortega-López, V. Improving the Early-Age Behavior of Concrete Containing Coarse Recycled Aggregate with Raw-Crushed Wind-Turbine Blade. J. Build. Eng. 2024, 92, 109815. [Google Scholar] [CrossRef]

- Kim, Y.-Y.; Lee, K.-M.; Bang, J.-W.; Kwon, S.-J. Effect of W/C Ratio on Durability and Porosity in Cement Mortar with Constant Cement Amount. Adv. Mater. Sci. Eng. 2014, 2014, 273460. [Google Scholar] [CrossRef]

- Wang, L.; Ma, Y.; Li, L. Uncovering the Role of Superplasticizer in Developing Nano-Engineered Ultra-High-Performance Concrete. Front. Mater. 2023, 10, 1177189. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Ng, I.Y.T. Optimum Superplasticiser Dosage and Aggregate Proportions for SCC. Mag. Concr. Res. 2009, 61, 281–292. [Google Scholar] [CrossRef]

- Domone, P.L. A Review of the Hardened Mechanical Properties of Self-Compacting Concrete. Cem. Concr. Compos. 2007, 29, 1–12. [Google Scholar] [CrossRef]

- Nematollahzade, M.; Tajadini, A.; Afshoon, I.; Aslani, F. Influence of Different Curing Conditions and Water to Cement Ratio on Properties of Self-Compacting Concretes. Constr. Build. Mater. 2020, 237, 117570. [Google Scholar] [CrossRef]

- Casagrande, C.A.; Jochem, L.F.; Onghero, L.; Ricardo de Matos, P.; Repette, W.L.; Gleize, P.J.P. Effect of Partial Substitution of Superplasticizer by Silanes in Portland Cement Pastes. J. Build. Eng. 2020, 29, 101226. [Google Scholar] [CrossRef]

- Lai, M.H.; Griffith, A.M.; Hanzic, L.; Wang, Q.; Ho, J.C.M. Interdependence of passing ability, dilatancy and wet packing density of concrete. Constr. Build. Mater. 2021, 270, 121440. [Google Scholar] [CrossRef]

- Lai, M.; Hanzic, L.; Ho, J.C.M. Fillers to improve passing ability of concrete. Struct. Concr. 2019, 20, 185–197. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, B.; Ho, J.C.M.; Ren, F.; Lai, M. Improving passing ability of ultra-heavy-weight concrete by optimising its packing structure. Mag. Concr. Res. 2024, 76, 1266–1278. [Google Scholar] [CrossRef]

- Lai, M.H.; Lin, J.L.; Cui, J.; Ren, F.M.; Kitipornchai, S.; Ho, J.C.M. A novel packing-coupled stress-strain model for confined concrete. Eng. Struct. 2024, 303, 117415. [Google Scholar] [CrossRef]

- Lai, M.H.; Lu, Z.Y.; Luo, Y.T.; Ren, F.M.; Cui, J.; Wu, Z.R.; Ho, J.C.M. Pre- and post-fire behaviour of glass concrete from wet packing density perspective. J. Build. Eng. 2024, 86, 108758. [Google Scholar] [CrossRef]

- Lai, M.H.; Xie, Y.M.; Zhang, B.X.; Ren, F.M.; Kitipornchai, S.; Ho, J.C.M. Iron sand heavy-weight concrete—Pre- and post-fire characteristics from wet packing density perspective. Constr. Build. Mater. 2024, 435, 136728. [Google Scholar] [CrossRef]

| Component | Carbon | Oxygen | Silicon | Calcium | Others |

|---|---|---|---|---|---|

| GFRP fibers | 53.49 | 22.79 | 4.96 | 4.37 | 14.39 |

| Balsa wood | 61.36 | 18.70 | 3.90 | 0.95 | 15.09 |

| Polymers | 60.57 | 13.41 | 9.49 | 0.47 | 16.06 |

| Component | 0.45 w/c; 2.2% ad. | 0.50 w/c; 2.2% ad. | 0.45 w/c; 2.8% ad. | 0.50 w/c; 2.8% ad. |

|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 |

| Water | 145 | 160 | 145 | 160 |

| Admixtures | 6.9 | 6.9 | 9.0 | 9.0 |

| Filler | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 625 | 625 | 625 | 625 |

| Sand 0/4 mm | 610 | 610 | 610 | 610 |

| Gravel 4/12 mm | 555 | 555 | 555 | 555 |

| RCWTB | 0 | 0 | 0 | 0 |

| Component | 0.45 w/c; 2.2% ad. | 0.50 w/c; 2.2% ad. | 0.45 w/c; 2.8% ad. | 0.50 w/c; 2.8% ad. |

|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 |

| Water | 145 | 160 | 145 | 160 |

| Admixtures | 6.9 | 6.9 | 9.0 | 9.0 |

| Filler | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 620 | 620 | 620 | 620 |

| Sand 0/4 mm | 605 | 605 | 605 | 605 |

| Gravel 4/12 mm | 550 | 550 | 550 | 550 |

| RCWTB | 11 | 11 | 11 | 11 |

| Component | 0.45 w/c; 2.2% ad. | 0.50 w/c; 2.2% ad. | 0.45 w/c; 2.8% ad. | 0.50 w/c; 2.8% ad. |

|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 |

| Water | 145 | 160 | 145 | 160 |

| Admixtures | 6.9 | 6.9 | 9.0 | 9.0 |

| Filler | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 615 | 615 | 615 | 615 |

| Sand 0/4 mm | 600 | 600 | 600 | 600 |

| Gravel 4/12 mm | 545 | 545 | 545 | 545 |

| RCWTB | 22 | 22 | 22 | 22 |

| Component | 0.45 w/c; 2.2% ad. | 0.50 w/c; 2.2% ad. | 0.45 w/c; 2.8% ad. | 0.50 w/c; 2.8% ad. |

|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 |

| Water | 145 | 160 | 145 | 160 |

| Admixtures | 6.9 | 6.9 | 9.0 | 9.0 |

| Filler | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 605 | 605 | 605 | 605 |

| Sand 0/4 mm | 595 | 595 | 595 | 595 |

| Gravel 4/12 mm | 540 | 540 | 540 | 540 |

| RCWTB | 33 | 33 | 33 | 33 |

| Component | 0.45 w/c; 2.8% ad. | 0.50 w/c; 2.8% ad. | 0.55 w/c; 2.8% ad. | 0.45 w/c; 3.4% ad. | 0.50 w/c; 3.4% ad. | 0.55 w/c; 3.4% ad. |

|---|---|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 | 320 | 320 |

| Water | 145 | 160 | 175 | 145 | 160 | 175 |

| Admixtures | 9.0 | 9.0 | 9.0 | 10.9 | 10.9 | 10.9 |

| Filler | 170 | 170 | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 605 | 605 | 605 | 605 | 605 | 605 |

| Sand 0/4 mm | 595 | 595 | 595 | 595 | 595 | 595 |

| Gravel 4/12 mm | 540 | 540 | 540 | 540 | 540 | 540 |

| RCWTB | 33 | 33 | 33 | 33 | 33 | 33 |

| Component | 0.45 w/c; 3.4% ad. | 0.45 w/c; 4.0% ad. | 0.45 w/c; 4.6% ad. | 0.45 w/c; 5.2% ad. | 0.45 w/c; 5.8% ad. | 0.45 w/c; 6.4% ad. |

|---|---|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 | 320 | 320 |

| Water | 145 | 145 | 145 | 145 | 145 | 145 |

| Admixtures | 10.9 | 12.8 | 14.7 | 16.6 | 18.6 | 20.5 |

| Filler | 170 | 170 | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 605 | 605 | 605 | 605 | 605 | 605 |

| Sand 0/4 mm | 595 | 595 | 595 | 595 | 595 | 595 |

| Gravel 4/12 mm | 540 | 540 | 540 | 540 | 540 | 540 |

| RCWTB | 33 | 33 | 33 | 33 | 33 | 33 |

| Component | 0.50 w/c; 3.4% ad. | 0.50 w/c; 4.0% ad. | 0.50 w/c; 4.6% ad. | 0.50 w/c; 5.2% ad. | 0.50 w/c; 5.8% ad. | 0.50 w/c; 6.4% ad. |

|---|---|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 | 320 | 320 |

| Water | 160 | 160 | 160 | 160 | 160 | 160 |

| Admixtures | 10.9 | 12.8 | 14.7 | 16.6 | 18.6 | 20.5 |

| Filler | 170 | 170 | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 605 | 605 | 605 | 605 | 605 | 605 |

| Sand 0/4 mm | 595 | 595 | 595 | 595 | 595 | 595 |

| Gravel 4/12 mm | 540 | 540 | 540 | 540 | 540 | 540 |

| RCWTB | 33 | 33 | 33 | 33 | 33 | 33 |

| Component | 0.50 w/c; 4.0% ad. | 0.50 w/c; 4.6% ad. | 0.50 w/c; 5.2% ad. | 0.50 w/c; 5.8% ad. | 0.50 w/c; 6.4% ad. |

|---|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 | 320 |

| Water | 160 | 160 | 160 | 160 | 160 |

| Admixtures | 12.8 | 14.7 | 16.6 | 18.6 | 20.5 |

| Filler | 170 | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 600 | 600 | 600 | 600 | 600 |

| Sand 0/4 mm | 585 | 585 | 585 | 585 | 585 |

| Gravel 4/12 mm | 535 | 535 | 535 | 535 | 535 |

| RCWTB | 44.3 | 44.3 | 44.3 | 44.3 | 44.3 |

| Component | 0.50 w/c; 4.6% ad. | 0.50 w/c; 5.2% ad. | 0.50 w/c; 5.8% ad. | 0.50 w/c; 6.4% ad. |

|---|---|---|---|---|

| Cement | 320 | 320 | 320 | 320 |

| Water | 160 | 160 | 160 | 160 |

| Admixtures | 14.7 | 16.6 | 18.6 | 20.5 |

| Filler | 170 | 170 | 170 | 170 |

| Sand 0/2 mm | 595 | 595 | 595 | 595 |

| Sand 0/4 mm | 580 | 580 | 580 | 580 |

| Gravel 4/12 mm | 525 | 525 | 525 | 525 |

| RCWTB | 55.3 | 55.3 | 55.3 | 55.3 |

| Property | p-Value | Homogeneous Groups | ||||

|---|---|---|---|---|---|---|

| RCWTB | w/c | ad. | RCWTB | w/c | ad. | |

| Slump flow | 0.0000 | 0.0000 | 0.0000 | 0%, 1%, and 2% 3% and 4% | None | 2.2% and 2.8% 3.4% and 4.0% 4.6%, 5.2%, and 5.8% |

| Compressive strength | 0.0000 | 0.0000 | 0.0000 | 2%, 3%, and 4% | None | 2.8%, 3.4%, and 4.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernando-Revenga, M.; Revilla-Cuesta, V.; Hurtado-Alonso, N.; Manso-Morato, J.; Ortega-López, V. Specific Design of a Self-Compacting Concrete with Raw-Crushed Wind-Turbine Blade. J. Compos. Sci. 2024, 8, 540. https://doi.org/10.3390/jcs8120540

Hernando-Revenga M, Revilla-Cuesta V, Hurtado-Alonso N, Manso-Morato J, Ortega-López V. Specific Design of a Self-Compacting Concrete with Raw-Crushed Wind-Turbine Blade. Journal of Composites Science. 2024; 8(12):540. https://doi.org/10.3390/jcs8120540

Chicago/Turabian StyleHernando-Revenga, Manuel, Víctor Revilla-Cuesta, Nerea Hurtado-Alonso, Javier Manso-Morato, and Vanesa Ortega-López. 2024. "Specific Design of a Self-Compacting Concrete with Raw-Crushed Wind-Turbine Blade" Journal of Composites Science 8, no. 12: 540. https://doi.org/10.3390/jcs8120540

APA StyleHernando-Revenga, M., Revilla-Cuesta, V., Hurtado-Alonso, N., Manso-Morato, J., & Ortega-López, V. (2024). Specific Design of a Self-Compacting Concrete with Raw-Crushed Wind-Turbine Blade. Journal of Composites Science, 8(12), 540. https://doi.org/10.3390/jcs8120540