Experimental Investigation to Optimize the Manufacturing Parameters of Ankle–Foot Orthoses Using Composite and Titanium Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Stockinet made of Perlon (Ottobock Health Care 623T3) 1. The procedures of drawing and melting were used to create Nylon 6, also known as Perlon, Figure 1a.

- Glass fiber (ottobock health care 616G13) as shown in Figure 1b.

- Lamination resin 80:20 polyurethanes (ottobock healthcare 617H19). Most commonly, a diisocyanate and a polyol react to produce polyurethane resin. The foams, elastomers, and fluids for coatings can be either flexible or rigid, depending on the application, Figure 1d.

- Polyvinyl alcohol PVA bag (Ottobock Health Care 99B71). PVA to isolate the composite material around the mold and to put the matrix mixture between two PVAs, Figure 1e.

- Powder is used to harden the composite material (ottobock health care 617P37), Figure 1f.

- One gypsum mold is a parallelogram with the following dimensions: (20 × 12 × 24 cm3), Figure 2a.

- Vacuum device containing a vacuum pump, pipes, and a suction hood. The two major uses for this device are to make a mold free of bubbles by creating a space between the PVA and the mold and to create a cast free of bubbles by creating a space between two PVA bags.

- The university’s Center for Nanotechnology Research made use of three different kinds of ultrasonic equipment: an ultrasonic mixing device, an ultrasonic device of the Hielscher type, and an ultrasonic processor (UP200Ht). Ti nanoparticles and polyurethane resin with varying weight percentages (0, 0.25, 0.5, 0.75, and 1) may be mixed using ultrasonic equipment consisting of an ultrasonic generator, a probe, and settings of 26 kHz and 160 Watt for 60 min [11]. The mixing procedure was carried out following the suggestions for risk minimization provided by the Cheap Tubes Company [34].

- A sensitive scale device with three digits that are used to weigh Ti nanoparticles and calculate the physical properties of the composite material, Figure 2f.

2.2. Response Surface Methodology (RSM)

3. Experimental Approach

3.1. Ankle–Foot Orthoses Laminations with Design Parameters

3.2. Mechanical Tests

3.2.1. The Tensile Test

3.2.2. Bending Test

3.2.3. The Fatigue Test

4. Results and Discussion

4.1. The Physical Properties

4.2. Results of Tensile Tests

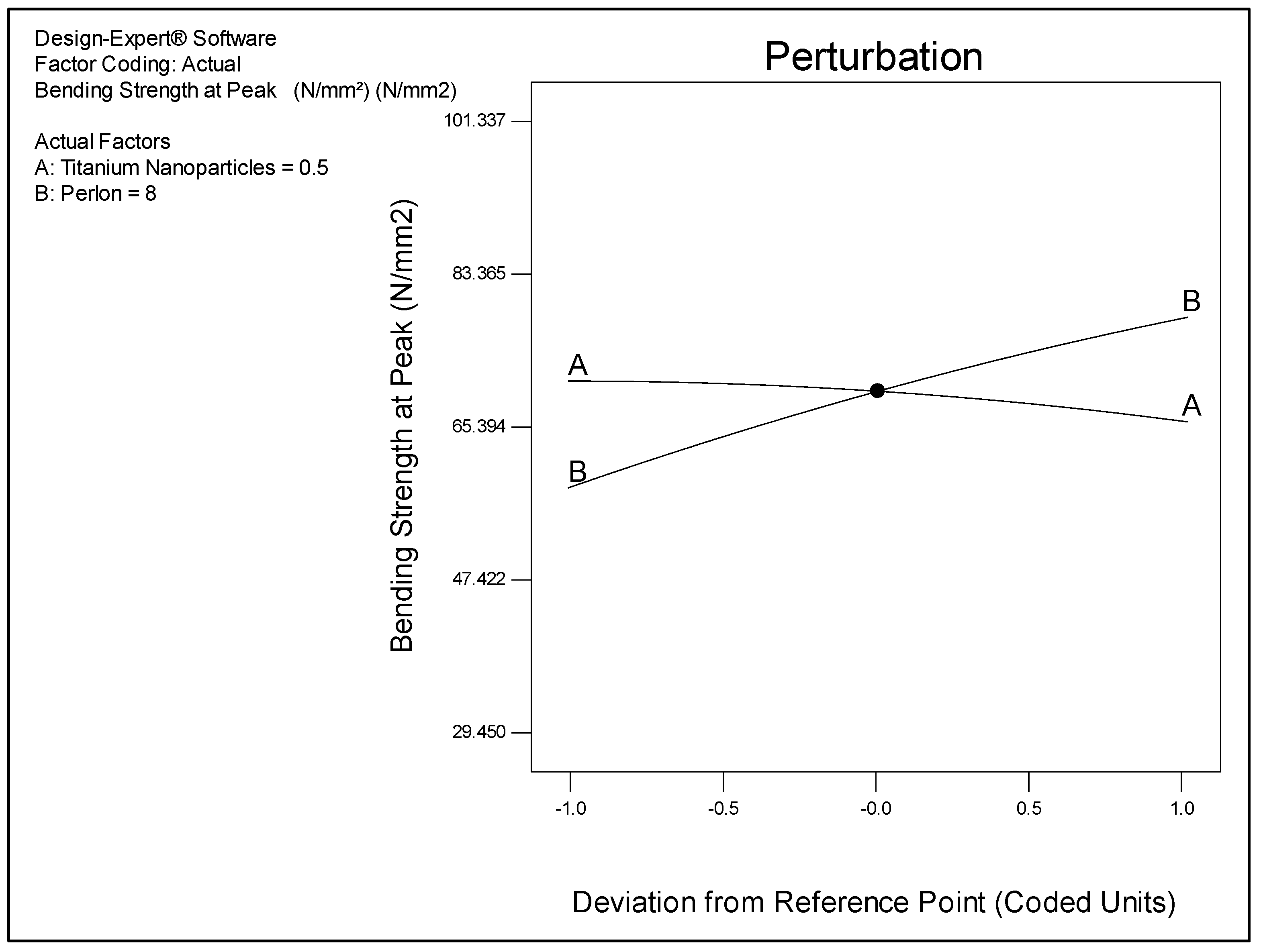

4.3. Results of the Maximum Bending Stress Model

4.4. Determination of the Optimum Input Factors, Bending at the Peak, and Maximum Tensile Stress

4.5. Validation of the Optimum Bending at the Peak and the Maximum Tensile Stress

4.6. Results of the Fatigue Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cuccurullo, S.J. Physical Medicine and Rehabilitation Board Review; Springer Publishing Company: New York, NY, USA, 2019. [Google Scholar]

- Natália, M.; Martins, F. Design of Ankle Foot Orthoses Using Subject Specific Biomechanical Data and Optimization Tools. Master’s Thesis, Instituto Superior Técnico, Lisbon, Portugal, 2014. [Google Scholar]

- Ben Amor, S.; Abdellaoui, S.; Tahan, A.; Louhichi, B.; Tavares, J.M.R.S. Choosing the Best Direction of Printing for Additive Manufacturing Process in Medical Applications Using a New Geometric Complexity Model Based on Part CAD Data. Lect. Notes Comput. Vis. Biomech. 2019, 34, 679–692. [Google Scholar] [CrossRef]

- Ben Amor, S.; Zongo, F.; Eltaief, A.; Maatki, A.; Louhichi, B.; Tahan, A. A new method to select optimal part building orientation for additive manufacturing processes based on geometric complexity and heat shrinkage. Prog. Addit. Manuf. 2023, 8, 211–222. [Google Scholar] [CrossRef]

- Rahman, M.; Zainuddin, S.; Hosur, M.; Malone, J.; Salam, M.; Kumar, A.; Jeelani, S. Improvements in mechanical and thermo-mechanical properties of e-glass/epoxy composites using amino functionalized MWCNTs. Compos. Struct. 2012, 94, 2397–2406. [Google Scholar] [CrossRef]

- Mukherjee, T. Recent progress in process, structure, properties, and performance in additive manufacturing. Sci. Technol. Weld. Join. 2023, 28, 1–5. [Google Scholar] [CrossRef]

- Chiad, J.S. Study the Impact Behavior of the Prosthetic Lower Limb Lamination Materials Due to Low Velocity Impactor. J. Eng. 2023, 20, 82–98. [Google Scholar] [CrossRef]

- Mahjoob, M.; Alameer, A.K.A.; Al-Shammari, M.A. Material Characterization and Fatigue Analysis of Lower Limb Prosthesis Materials. Assoc. Arab. Univ. J. Eng. Sci. 2018, 25, 137–154. [Google Scholar]

- Abbas, S.M.; Takhakh, A.M.; Al-Shammari, M.A.; Al-Waily, M. Manufacturing and analysis of ankle disarticulation prosthetic socket (SYMES). Int. J. Mech. Eng. Technol. 2018, 9, 560–569. [Google Scholar]

- Qi, H.; Teo, K.; Lau, K.; Boyce, M.; Milne, W.; Robertson, J.; Gleason, K. Determination of mechanical properties of carbon nanotubes and vertically aligned carbon nanotube forests using nanoindentation. J. Mech. Phys. Solids 2003, 51, 2213–2237. [Google Scholar] [CrossRef]

- Jber, N.R.; Rashad, A.A.; Shihab, M.S. Effects of carbon nanotubes on the physical properties of a nematic liquid crystal N-(4′-methoxybenzylidene)-4-butylaniline. J. Mol. Struct. 2013, 1043, 28–36. [Google Scholar] [CrossRef]

- Abbas, S.M.; Resan, K.K.; Muhammad, A.K.; Al-Waily, M. Mechanical and fatigue behaviors of prosthetic for partial foot amputation with various composite materials types effect. Int. J. Mech. Eng. Technol. 2018, 9, 383–394. [Google Scholar]

- Yaseen, N.D.; Chiad, J.S.; Ghani, F.M. The Study and Analysis of Stress Distribution Subjected on the Replacement Knee Joint Components Using Photo-Elasticity and Numerical Methods. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 449–464. [Google Scholar] [CrossRef]

- Takhakh, A.M.; Abbas, S.M. Manufacturing and analysis of carbon fiber knee ankle foot orthosis. Int. J. Eng. Technol. 2018, 7, 2236. [Google Scholar] [CrossRef]

- Yousif, L.E.; Resan, K.K.; Fenjan, R.M. Temperature effect on mechanical characteristics of a new design prosthetic foot. Int. J. Mech. Eng. Technol. 2018, 9, 1431–1447. [Google Scholar]

- Oleiwi, J.K.; Hadi, A.N. Experimental and Numerical Investigation of Lower Limb Prosthetic Foot made from Composite Polymer Blends. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 1319–1330. [Google Scholar] [CrossRef]

- Kadhim, F.M.; Takhakh, A.M.; Abdullah, A.M. Mechanical properties of polymer with different reinforcement material composite that used for fabricates prosthetic socket. J. Mech. Eng. Res. Dev. 2019, 42, 118–123. [Google Scholar] [CrossRef]

- Abbas, E.N.; Jweeg, M.J.; Al-Waily, M. Analytical and numerical investigations for dynamic response of composite plates under various dynamic loading with the influence of carbon multi-wall tube nano materials. Int. J. Mech. Mechatron. Eng. 2018, 18, 1–10. [Google Scholar]

- Abdulridha, M.M.; Fahad, N.D.; Al-Waily, M.; Resan, K.K. Rubber creep behavior investigation with multi wall tube carbon nano particle material effect. Int. J. Mech. Eng. Technol. 2018, 9, 729–746. [Google Scholar]

- Taher, A.A.; Takhakh, A.M.; Thaha, S.M. Experimental study and prediction the mechanical properties of nano-joining composite polymers. J. Eng. Appl. Sci. 2018, 13, 7665–7669. [Google Scholar]

- Oleiwi, J.K.; Afif, R.; Anaee, M. Tensile Properties of UHMWPE Nanocomposites. J. Eng. Appl. Sci. 2018, 10649–10656. [Google Scholar]

- Salih, S.I.; Oleiwi, J.K.; Ali, H.M. Investigation the properties of silicone rubber blend reinforced by natural nanoparticles and UHMWpe fiber. Int. J. Mech. Eng. Technol. 2019, 10, 164–178. [Google Scholar]

- Salih, S.I.; Oleiwi, J.K.; Ali, H.M. Modification of silicone rubber by added PMMA and natural nanoparticle used for maxillofacial prosthesis applications. ARPN J. Eng. Appl. Sci. 2019, 14, 781–791. [Google Scholar]

- Mohammed, A.A.; Al-Hassani, E.S.; Oleiwi, J.K. The Nanomechanical Characterization and Tensile Test of Polymer Nanocomposites for Bioimplants. In Technologies and Materials for Renewable Energy, Environment and Sustainability: Tmrees19; AIP Publishing: New York City, NY, USA, 2019; p. 020065. [Google Scholar]

- Al-Waily, M.; Al-Shammari, M.A.; Jweeg, M.J. An Analytical Investigation of Thermal Buckling Behavior of Composite Plates Reinforced by Carbon Nano Particles. Eng. J. 2020, 24, 11–21. [Google Scholar] [CrossRef]

- Rogati, G.; Caravaggi, P.; Leardini, A.; Erani, P.; Fognani, R.; Saccon, G.; Boriani, L.; Baleani, M. A novel apparatus to assess the mechanical properties of Ankle-Foot Orthoses: Stiffness analysis of the Codivilla spring. J. Biomech. 2022, 142, 111239. [Google Scholar] [CrossRef] [PubMed]

- Shahar, F.S.; Sultan, M.T.H.; Safri, S.N.A.; Jawaid, M.; Abu Talib, A.R.; Basri, A.A.; Shah, A.U.M. Physical, thermal and tensile behaviour of 3D printed kenaf/PLA to suggest its usability for ankle–foot orthosis—A preliminary study. Rapid Prototyp. J. 2022, 28, 1573–1588. [Google Scholar] [CrossRef]

- Patel, P.; Gohil, P. Custom orthotics development process based on additive manufacturing. Mater. Today Proc. 2022, 59, A52–A63. [Google Scholar] [CrossRef]

- Gupta, S.; Mittal, D.; Narayan, J.; Jhunjhunwala, S.; Dwivedy, S.K. Design and Manufacturing Process of 3D Printed Ankle-Foot Orthoses for Podiatry. In 3D Printing in Podiatric Medicine; Elsevier: Amsterdam, The Netherlands, 2023; pp. 151–173. [Google Scholar]

- Caravaggi, P.; Zomparelli, A.; Rogati, G.; Baleani, M.; Fognani, R.; Cevolini, F.; Fanciullo, C.; Cinquepalmi, A.; Lullini, G.; Berti, L.; et al. Development of a Novel Passive-Dynamic Custom AFO for Drop-Foot Patients: Design Principles, Manufacturing Technique, Mechanical Properties Characterization and Functional Evaluation. Appl. Sci. 2022, 12, 4721. [Google Scholar] [CrossRef]

- Khandagale, B.D.; Pise, U.V. Numerical and experimental investigation of hinged Ankle-Foot-Orthoses (AFO) using composite laminate material for Cerebral Palsy patient. Mater. Today Proc. 2022, 62, 2070–2080. [Google Scholar] [CrossRef]

- Willis, L.; Kortobi, S.; Williams, G.; Jonaidi, M.; Nasseri, S. Design, Finite Element Analysis and Fabrication of Composite Orthoses for Bunions; A Comprehensive Study. Int. J. Prod. Sound Qual. 2023, 1, 59–77. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, Z.; Xu, B.; Sarakiotis, I.; Du Laing, G.; Yan, C. Measurement and characterization of engineered titanium dioxide nanoparticles in the environment. J. Zhejiang Univ. Sci. A 2014, 15, 593–605. [Google Scholar] [CrossRef]

- Wolfram, J.; Zhu, M.; Yang, Y.; Shen, J.; Gentile, E.; Paolino, D.; Fresta, M.; Nie, G.; Chen, C.; Shen, H.; et al. Safety of Nanoparticles in Medicine. Curr. Drug Targets 2015, 16, 1671–1681. [Google Scholar] [CrossRef]

- Al-Waily, M.; Deli, A.A.; Al-Mawash, A.D.; Ali, Z.A.A.A. Effect of natural sisal fiber reinforcement on the composite plate buckling behavior. Int. J. Mech. Mechatron. Eng. 2017, 17, 30–37. [Google Scholar]

- Kadhim, A.A.; Al-Waily, M.; Ali, Z.A.; Jweeg, M.J.; Resan, K.K. Improvement fatigue life and strength of isotropic hyper composite materials by reinforcement with different powder materials. Int. J. Mech. Mechatron. Eng. 2018, 18, 77–86. [Google Scholar]

- Sadiq, S.E.; Jweeg, M.J.; Bakhy, S.H. The Effects of Honeycomb Parameters on Transient Response of an Aircraft Sandwich Panel Structure. IOP Conf. Ser. Mater. Sci. Eng. 2020, 928, 022126. [Google Scholar] [CrossRef]

- Abbas, H.J.; Jweeg, M.J.; Al-Waily, M.; Ali Diwan, A. Experimental Testing and Theoretical Prediction of Fiber Optical Cable for Fault Detection and Identification. J. Eng. Appl. Sci. 2019, 14, 430–438. [Google Scholar] [CrossRef]

- Abbod, E.A.; Al-Waily, M.; Al-Hadrayi, Z.M.; Resan, K.K.; Abbas, S.M. Numerical and Experimental Analysis to Predict Life of Removable Partial Denture. IOP Conf. Ser. Mater. Sci. Eng. 2020, 870, 012149. [Google Scholar] [CrossRef]

- Sadiq, S.E.; Bakhy, S.H.; Jweeg, M.J. Effects of spot welding parameters on the shear characteristics of aluminum honeycomb core sandwich panels in aircraft structure. Test Eng. Manag. 2020, 83, 7244–7255. [Google Scholar]

- Mansoor, H.I.; Al-Shammari, M.A.; Al-Hamood, A. Experimental analysis of cracked turbine rotor shaft using vibration measurements. J. Mech. Eng. Res. Dev. 2020, 43, 294–304. [Google Scholar]

- ASTM D638-14; Standard Practice for Preparation of Metallographic Specimens. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2016; Volume 82, pp. 1–15.

- ASTM D790-03; American Society for Testing and Materials Information, Handing Series “Standard Test Method for Flexural Properties”. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2000.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019.

- Abdul-Kareem, H.S.; Abdulla, F.A.; Abdulrazzaq, M.A. Effect of Shot Peening and Solidification on Fatigue Properties of Epoxy Base Composite Material. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 032017. [Google Scholar] [CrossRef]

| Factor | Unit | Low Level (−1) | High Level (+1) | −Alpha | +Alpha |

|---|---|---|---|---|---|

| Ti Nanoparticles | % | 0.25 | 0.75 | 0 | 1 |

| The number of Perlon layers | No. of layer | 6 | 10 | 4 | 12 |

| Runs No. | Exp. No | Glass Fiber | Ti Nanoparticles in Code | Perlon (Layers) in Code | Ti Nanoparticles (%) | Perlon (Layers) |

|---|---|---|---|---|---|---|

| 1 | 3 | 1 | −1 | −1 | 0.25 | 6 |

| 2 | 4 | 1 | +1 | −1 | 0.75 | 6 |

| 3 | 8 | 1 | −1 | +1 | 0.25 | 10 |

| 4 | 7 | 1 | +1 | +1 | 0.75 | 10 |

| 5 | 6 | 1 | −2 | 0 | 0 | 8 |

| 6 | 5 | 1 | +2 | 0 | 1 | 8 |

| 7 | 1 | 1 | 0 | −2 | 0.5 | 4 |

| 8 | 9 | 1 | 0 | +2 | 0.5 | 12 |

| 9 | 2 | 1 | 0 | 0 | 0.5 | 8 |

| 10 | 10 | 1 | 0 | 0 | 0.5 | 8 |

| 11 | 11 | 1 | 0 | 0 | 0.5 | 8 |

| 12 | 12 | 1 | 0 | 0 | 0.5 | 8 |

| 13 | 13 | 1 | 0 | 0 | 0.5 | 8 |

| Runs No. | Exp. No | Fiber Glass | Titanium Nanoparticles (%) | Perlon (No. of Layer) | Thick (mm) | Density (g/cm3) | Mass (g) | Volume (cm³) | Weight per Unit Area (g/cm2) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 1 | 0.25 | 6 | 3 | 1.49333 | 7.28 | 4.875 | 0.448 |

| 2 | 4 | 1 | 0.75 | 6 | 2 | 1.64920 | 5.36 | 3.25 | 0.329 |

| 3 | 8 | 1 | 0.25 | 10 | 4 | 1.610769 | 10.47 | 6.5 | 0.644 |

| 4 | 7 | 1 | 0.75 | 10 | 5 | 1.441231 | 11.71 | 8.125 | 0.72 |

| 5 | 6 | 1 | 0 | 8 | 4 | 1.443077 | 9.38 | 6.5 | 0.577 |

| 6 | 5 | 1 | 1 | 8 | 4 | 1.338462 | 8.70 | 6.5 | 0.535 |

| 7 | 1 | 1 | 0.5 | 4 | 3 | 1.167179 | 5.69 | 4.875 | 0.35 |

| 8 | 9 | 1 | 0.5 | 12 | 4 | 1.446154 | 9.40 | 6.5 | 0.578 |

| 9 | 2 | 1 | 0.5 | 8 | 4.5 | 1.434529 | 10.49 | 7.3125 | 0.645 |

| 10 | 10 | 1 | 0.5 | 8 | 4.5 | 1.434529 | 10.49 | 7.3125 | 0.645 |

| 11 | 11 | 1 | 0.5 | 8 | 4.5 | 1.434529 | 10.49 | 7.3125 | 0.645 |

| 12 | 12 | 1 | 0.5 | 8 | 4.5 | 1.434529 | 10.49 | 7.3125 | 0.645 |

| 13 | 13 | 1 | 0.5 | 8 | 4.5 | 1.434529 | 10.49 | 7.3125 | 0.645 |

| Types of Variables | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| A: Titanium nanoparticles | It is in range | 0.25 | 0.75 | 1 | 1 | 3 |

| B: Perlon | It is in range | 6 | 10 | 1 | 1 | 3 |

| Bending strength at the Peak (N/mm2) | Maximized | 13.731 | 94.200 | 1 | 1 | 3 |

| Maximum tensile stress (MPa) | Maximized | 90 | 60 | 1 | 1 | 3 |

| Titanium Nanoparticles Percentage | No. of Perlon Layer | Bending at Break (N/mm2) | Maximum Tensile Stress (MPa) | Desirability | Titanium Nanoparticles Percentage | No. of Perlon Layer |

|---|---|---|---|---|---|---|

| 1 | 0.750 | 10 | 94.151 | 90.632 | 1.0 selected | 1 |

| Titanium Nanoparticles Percentage | No. of Perlon Layer | Exper. Bending at Break (N/mm2) | Predicted Bending at Break (N/mm2) | Exper. Maximum Tensile Stress (MPa) | Predicted Maximum Tensile (MPa) | Error (%) |

|---|---|---|---|---|---|---|

| 0.75 | 10 | 94.200 | 94.151 | --- | --- | 0.05 |

| 0.75 | 10 | --- | --- | 88 | 90.632 | 2.90 |

| Composite Material | Equation for Fatigue Life | Endurance Limits at 106 Cycles (Mpa) | R² |

|---|---|---|---|

| 10 layers of Perlon | 6 = 33.64(Nf) − 0.059 | 15 | |

| 10 Perlon layers, 1 fiber glass, and 0.75% Ti nanoparticles | 6 = 646.64(Nf) − 0.237 | 20 | 0.9765 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalaf, N.J.; Ben Amor, S.; Louhichi, B.; Chiad, J.S.; Seibi, A. Experimental Investigation to Optimize the Manufacturing Parameters of Ankle–Foot Orthoses Using Composite and Titanium Nanoparticles. J. Compos. Sci. 2024, 8, 45. https://doi.org/10.3390/jcs8020045

Khalaf NJ, Ben Amor S, Louhichi B, Chiad JS, Seibi A. Experimental Investigation to Optimize the Manufacturing Parameters of Ankle–Foot Orthoses Using Composite and Titanium Nanoparticles. Journal of Composites Science. 2024; 8(2):45. https://doi.org/10.3390/jcs8020045

Chicago/Turabian StyleKhalaf, Najlaa J., Sabrine Ben Amor, Borhen Louhichi, Jumaa S. Chiad, and Abdennour Seibi. 2024. "Experimental Investigation to Optimize the Manufacturing Parameters of Ankle–Foot Orthoses Using Composite and Titanium Nanoparticles" Journal of Composites Science 8, no. 2: 45. https://doi.org/10.3390/jcs8020045

APA StyleKhalaf, N. J., Ben Amor, S., Louhichi, B., Chiad, J. S., & Seibi, A. (2024). Experimental Investigation to Optimize the Manufacturing Parameters of Ankle–Foot Orthoses Using Composite and Titanium Nanoparticles. Journal of Composites Science, 8(2), 45. https://doi.org/10.3390/jcs8020045