Enhancing Sustainability in Construction: Investigating the Thermal Advantages of Fly Ash-Coated Expanded Polystyrene Lightweight Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

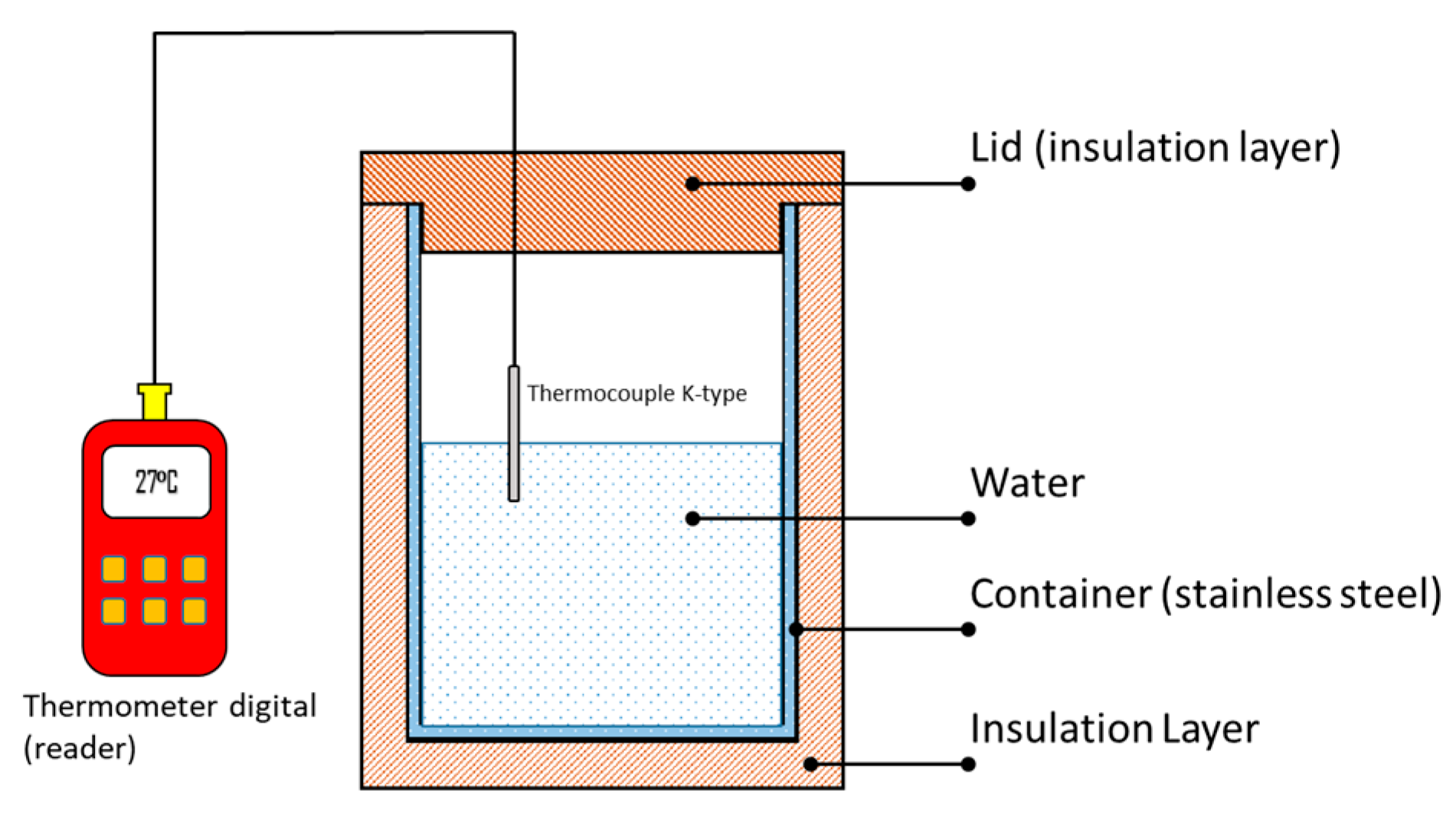

2.2. Test Procedures

- Q = change in heat

- m = mass of object

- c = specific heat capacity

- ΔT = change in temperature

| Heat loss by hot object | = | Heat gained by cold object |

| Qsampel | = | Qwater+container |

| c3·m3· (T2 − T) | = | (c1·m1 + c2·m2) (T − T1) |

| = |

| m1 | : | Mass of calorimeter |

| c1 | : | Specific heat capacity of calorimeter |

| m2 | : | mass of water |

| c2 | : | specific heat capacity of water |

| T1 | : | initial temperature of calorimeter and water |

| m3 | : | mass of solid (specimen) |

| T2 | : | initial temperature of solid (specimen) |

| T | : | Final temperature of mixture |

| c3 | : | Specific heat of solid (specimen) |

3. Results and Discussion

3.1. Density of Concrete

3.2. Early Age Temperature of Concrete

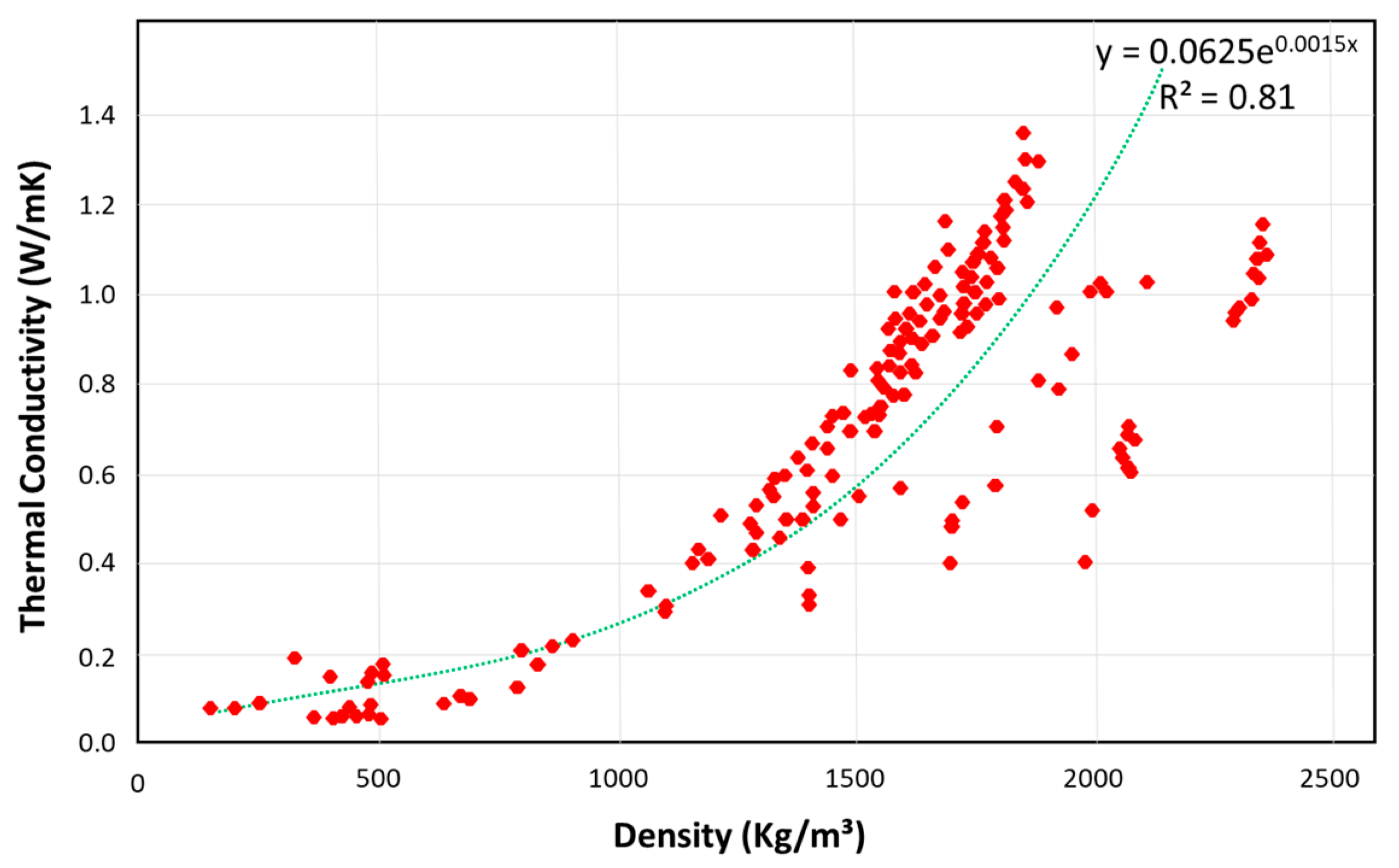

3.3. Thermal Conductivity

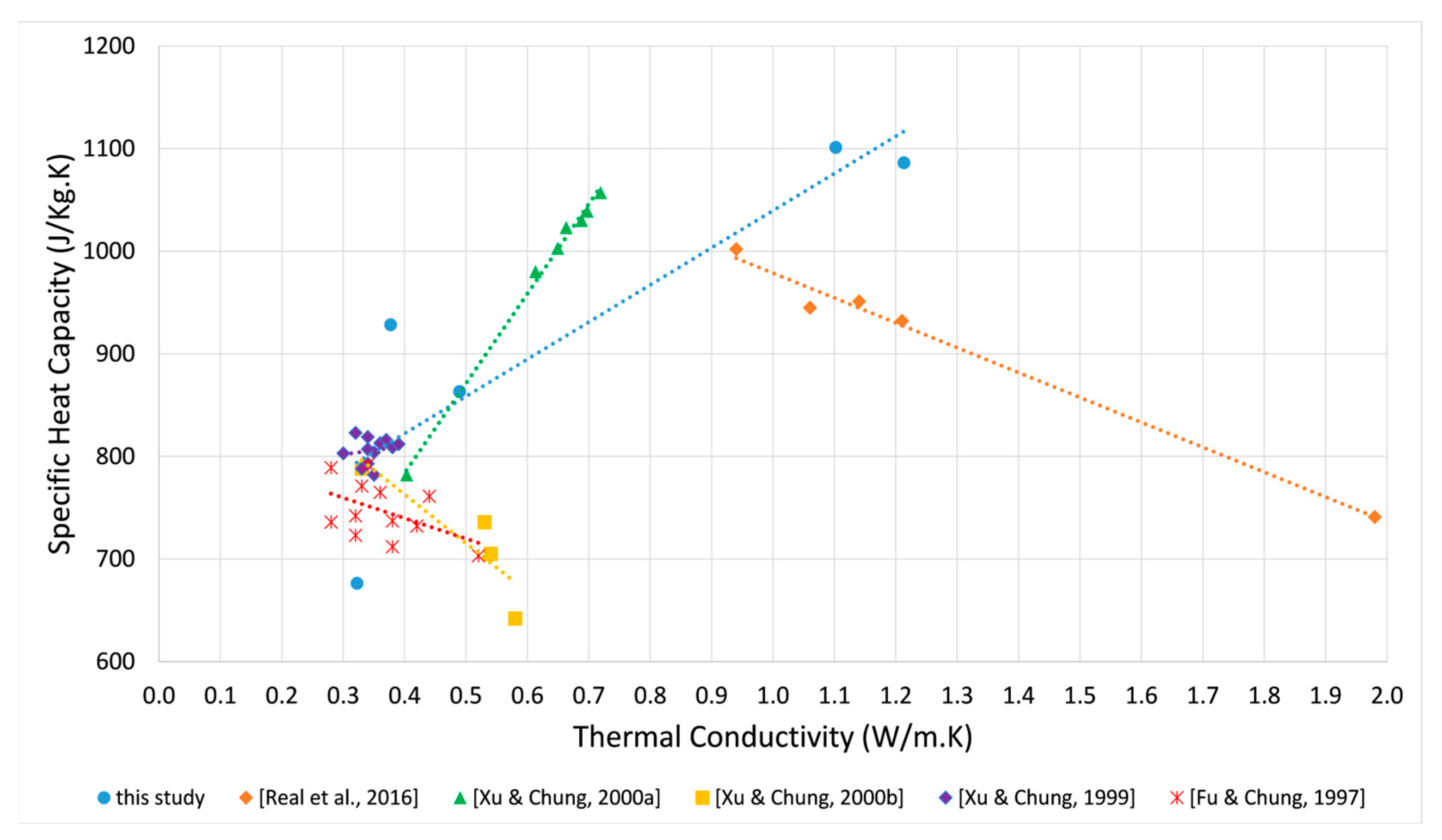

3.4. Specific Heat Capacity

3.5. Heat Flux

- k = thermal conductivity (Watt/m·K)

- Q = the amount of heat transferred through the material (Joules/second) or (Watts)

- Δx = the distance between the two isothermal planes (width or thickness of material)

- A = the area of the surface (m2)

- (T2 − T1) = the difference in temperature

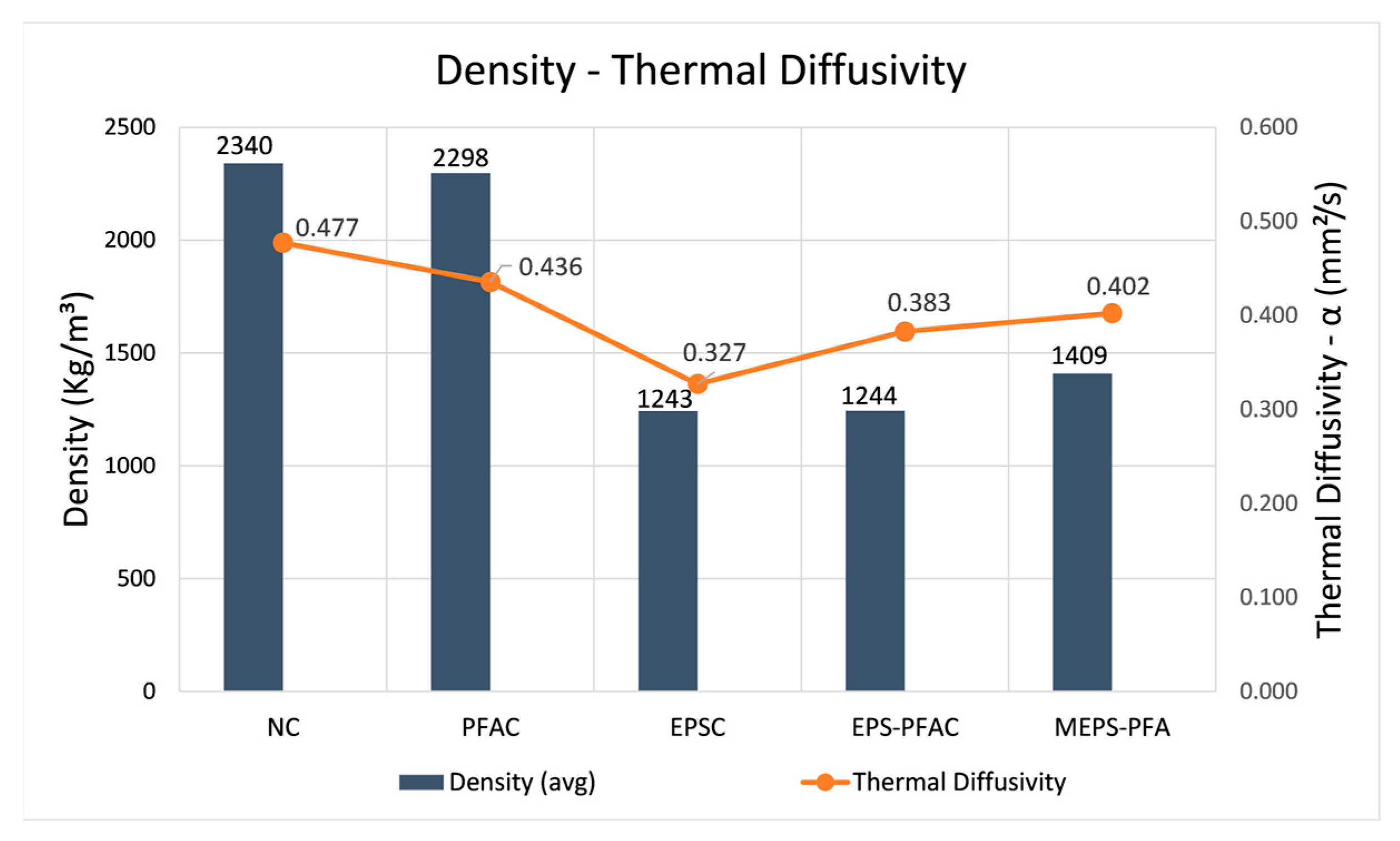

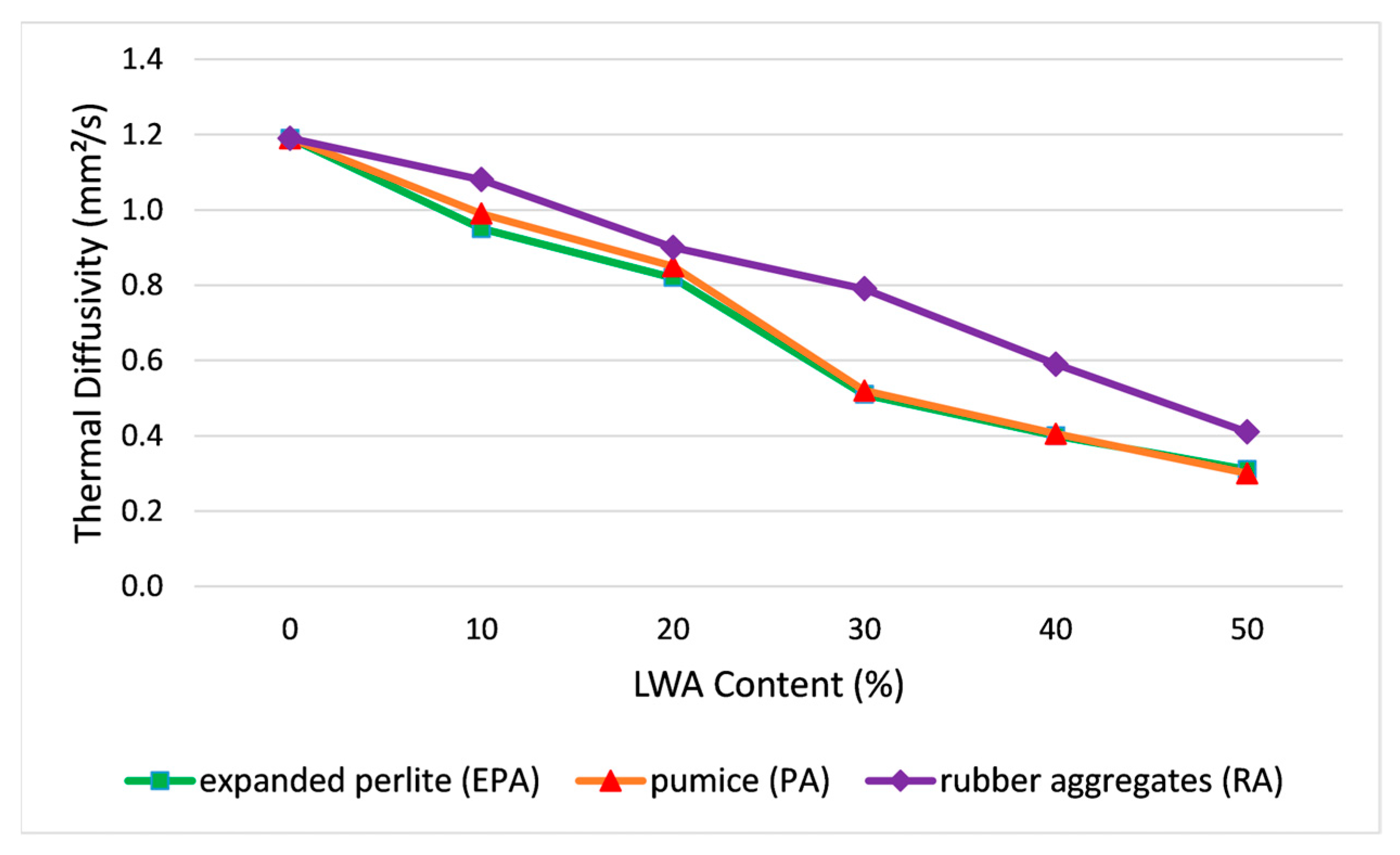

3.6. Thermal Diffusivity

- α = Thermal Diffusivity (m2/s)

- k = thermal conductivity (Watt/m·K)

- ρ = density of material/sample (Kg/m3)

- c = specific heat capacity of material (J/Kg·K)

4. Conclusions

- Coating treatment on expanded polystyrene (EPS) offers no advantage in terms of thermal properties compared to uncoated EPS aggregate concrete. However, MEPS concrete exhibits superior thermal properties compared to ordinary concrete.

- MEPS concrete demonstrates a remarkable 40% reduction in thermal conductivity compared to conventional concrete. This signifies the effectiveness of EPS as an aggregate in reducing heat transfer, a crucial factor in thermal insulation.

- Heat flux analysis reveals a significant 35% decrease in MEPS concrete compared to normal concrete. This indicates a substantially lower rate of energy transmission through the material, enhancing its insulating potential.

- While the specific heat capacity of MEPS concrete is 20% lower than normal concrete, the difference is not as significant as thermal conductivity and heat flux. Nevertheless, a lower specific heat capacity remains advantageous for insulation materials.

- All test objects exhibited relatively low thermal diffusivity values, implying slow heat transfer through the material. This is a desirable characteristic for building insulation materials.

- Employing coated EPS as an aggregate did not yield a significant impact on thermal diffusivity beyond what normal concrete already offers. This is likely due to the inherent low diffusivity of concrete itself.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sargam, Y.; Wang, K.; Alleman, J.E. Effects of Modern Concrete Materials on Thermal Conductivity. J. Mater. Civ. Eng. 2020, 32, 04020058. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Kumar, R.; Srivastava, A.; Lakhani, R. Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review. Sustainability 2021, 14, 331. [Google Scholar] [CrossRef]

- Shafigh, P.; Asadi, I.; Mahyuddin, N.B. Concrete as a thermal mass material for building applications—A review. J. Build. Eng. 2018, 19, 14–25. [Google Scholar] [CrossRef]

- Jovanović, B.; Khorasani, N.E.; Thienpont, T.; Chaudhary, R.K.; Van Coile, R. Probabilistic models for thermal properties of concrete. In Proceedings of the 11th International Conference on Structures in Fire (SiF2020), Online, 30 November–2 December 2020; The University of Queensland: Brisbane, Australia, 2020. [Google Scholar]

- Shiveswarran, R.; Athukorala, N.; Jayasinghe, M.T.R. Embodied Energy and Lifecycle Assessment of EPS based Light-weight Panel Apartments in Tropical Uplands. In 12th International Conference on Structural Engineering and Construction Management; Dissanayake, R., Mendis, P., Weerasekera, K., De Silva, S., Fernando, S., Konthesingha, C., Eds.; Lecture Notes in Civil Engineering; Springer Nature: Singapore, 2023; Volume 266, pp. 783–798. ISBN 978-981-19288-5-7. [Google Scholar]

- Jyoti Basu, D.; Acharjee, D.; Bandyopadhyay, D. Numerical study on fire resistance behavior of EPS sandwich panels. Mater. Today Proc. 2022, 60, 459–465. [Google Scholar] [CrossRef]

- El Kanzaoui, M.; Ennawaoui, C.; Eladaoui, S.; Hajjaji, A.; Guenbour, A.; Boussen, R. Study of the Physical Behavior of a New Composite Material Based on Fly Ash from the Combustion of Coal in an Ultra-Supercritical Thermal Power Plant. J. Compos. Sci. 2021, 5, 151. [Google Scholar] [CrossRef]

- Major, M.; Halbiniak, J. Effect of Adhesion between EPS Granules and Cement Matrix on the Characteristics of Lightweight Concretes. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 032054. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, L.; Li, W.; Yang, H.; Wang, J.; Zhang, W.; Xiong, Z. A new EPS beads strengthening technology and its influences on axial compressive properties of concrete. Sci. Eng. Compos. Mater. 2022, 29, 50–64. [Google Scholar] [CrossRef]

- Wibowo, A.P.; Saidani, M. The effect of fly ash as coating powder on compressive strength of lightweight concrete. Mater. Today Proc. 2023, 85, 29–32. [Google Scholar] [CrossRef]

- ASTM-C518-15; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2015.

- ISO-8301-1991; Thermal Insulation-Determination of Steady-State Thermal Resistance and Related Properties-Heat Flow Meter Aparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- DIN EN 12667; Thermal Performance of Building Materials and Products-Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods-Products of High and Medium Thermal Resistance. DIN-German Institute for Standardization: Berlin, Germany, 2001.

- Islam, M.R.; Tarefder, R.A. Determining thermal properties of asphalt concrete using field data and laboratory testing. Constr. Build. Mater. 2014, 67, 297–306. [Google Scholar] [CrossRef]

- Alhnifat, R.S.; Abdel-Jaber, M.; Nasr Al-Dala’ien, R. Behavior of Lightweight Concrete Incorporating Pozzolana Aggregate and Expanded Polystyrene Beads. Eng. Sci. 2023, 25, 934. [Google Scholar] [CrossRef]

- Bello, I.; Sulaiman, T.A.; Musa, M.M.; Bala, A.A. Assessment of Expanded Polystyrene Beads Waste as Partial Replacement of Coarse Aggregate in Lightweight Concrete. In Proceedings of the 2021 Sustainable Engineering & Industrial Technology Conference, Faculty of Engineering, University of Nigeria, Nsukka, Nigeria, 30 September 2021; Faculty of Engineering, University of Nigeria: Nsukka, Nigeria, 2021. Available online: https://www.researchgate.net/profile/Tasiu-Sulaiman/publication/362219429_Assessment_of_Expanded_Polystyrene_Beads_Waste_as_Partial_Replacement_of_Coarse_Aggregate_in_Lightweight_Concrete/links/62dc85523c7d190316a6c5d4/Assessment-of-Expanded-Polystyrene-Beads-Waste-as-Partial-Replacement-of-Coarse-Aggregate-in-Lightweight-Concrete.pdf (accessed on 26 February 2024).

- Mohammed, I.I.; Nariman, N.A.; Shakor, P.; Ismail, O.; Rizgar, K. Post-Fire Mechanical Properties of Concrete Incorporating Waste EPS (Styrofoam) as Aggregate Replacement. CivilEng 2023, 4, 359–372. [Google Scholar] [CrossRef]

- Mohamad, M.E.; Ting, R.; Razak, A.A.; Kifli, A.Z.; Bakie, A. Compressive Strength of Concrete Containing Expanded Polystyrene Styrofoam (EPS) Concrete and Partial Cement Replacement of Fly Ash and Silica Fume. J. Mech. Eng. 2022, 11, 301–317. [Google Scholar] [CrossRef]

- Sun, Y.; Li, C.; You, J.; Bu, C.; Yu, L.; Yan, Z.; Liu, X.; Zhang, Y.; Chen, X. An Investigation of the Properties of Expanded Polystyrene Concrete with Fibers Based on an Orthogonal Experimental Design. Materials 2022, 15, 1228. [Google Scholar] [CrossRef] [PubMed]

- Saheed, S.; Aziz, F.N.A.A.; Amran, M.; Vatin, N.; Fediuk, R.; Ozbakkaloglu, T.; Murali, G.; Mosaberpanah, M.A. Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs. Sustainability 2020, 12, 9679. [Google Scholar] [CrossRef]

- Wibowo, A.P.; Saidani, M. Mortar with fly ash as a partial cement replacement: Analysing the compressive strength and heat of hydration. E3S Web Conf. 2023, 429, 05033. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Doshi, A.J. Investigating the Influence of Thermal Conductivity and Thermal Storage of Lightweight Concrete Panels on the Energy and Thermal Comfort in Residential Buildings. Buildings 2023, 13, 720. [Google Scholar] [CrossRef]

- Argalis, P.P.; Bumanis, G.; Bajare, D. Gypsum Composites with Modified Waste Expanded Polystyrene. J. Compos. Sci. 2023, 7, 203. [Google Scholar] [CrossRef]

- Demirboğa, R.; Gül, R. The effects of expanded perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete. Cem. Concr. Res. 2003, 33, 723–727. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Abu Hassan, Z.F.B.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Dixit, A.; Pang, S.D.; Kang, S.-H.; Moon, J. Lightweight structural cement composites with expanded polystyrene (EPS) for enhanced thermal insulation. Cem. Concr. Compos. 2019, 102, 185–197. [Google Scholar] [CrossRef]

- ACI122R-02; Guide to Thermal Properties of Concrete and Masonry Systems. American Concrete Institute: Farmington Hills, MI, USA, 2002.

- Wu, Y.; Krishnan, P.; Yu, L.E.; Zhang, M.-H. Using lightweight cement composite and photocatalytic coating to reduce cooling energy consumption of buildings. Constr. Build. Mater. 2017, 145, 555–564. [Google Scholar] [CrossRef]

- Muñoz, P.; González, C.; Recio, R.; Gencel, O. The role of specific heat capacity on building energy performance and thermal discomfort. Case Stud. Constr. Mater. 2022, 17, e01423. [Google Scholar] [CrossRef]

- Xu, Y.; Chung, D.D.L. Increasing the specific heat of cement paste by admixture surface treatments. Cem. Concr. Res. 1999, 29, 1117–1121. [Google Scholar] [CrossRef]

- Xu, Y.; Chung, D.D.L. Effect of sand addition on the specific heat and thermal conductivity of cement. Cem. Concr. Res. 2000, 30, 59–61. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Effects of silica fume, latex, methylcellulose, and carbon fibers on the thermal conductivity and specific heat of cement paste. Cem. Concr. Res. 1997, 27, 1799–1804. [Google Scholar] [CrossRef]

- Real, S.; Gomes, M.G.; Moret Rodrigues, A.; Bogas, J.A. Contribution of structural lightweight aggregate concrete to the reduction of thermal bridging effect in buildings. Constr. Build. Mater. 2016, 121, 460–470. [Google Scholar] [CrossRef]

- Xu, Y.; Chung, D.D.L. Cement of high specific heat and high thermal conductivity, obtained by using silane and silica fume as admixtures. Cem. Concr. Res. 2000, 30, 1175–1178. [Google Scholar] [CrossRef]

- Oktay, H.; Yumrutaş, R.; Akpolat, A. Mechanical and thermophysical properties of lightweight aggregate concretes. Constr. Build. Mater. 2015, 96, 217–225. [Google Scholar] [CrossRef]

| Specimen Code | Cement (+PFA) (kg) | Water (kg) | Sand (kg) | Gravel (kg) | EPS Beads (kg) |

|---|---|---|---|---|---|

| NC | 490 | 225 | 572 | 1063 | - |

| PFAC | 343 (+147) | 225 | 572 | 1063 | - |

| EPSC | 490 | 225 | 572 | - | 7.25 a |

| EPS-PFAC | 343 (+147) | 225 | 572 | - | 7.25 a |

| MEPS-PFA | 490 | 225 | 572 | - | 190 b |

| Specimens | Cube 1 Day | Cylinder 1 Day | Cube 28 Days | Cylinder 28 Days | Average |

|---|---|---|---|---|---|

| NC | 2318.61 | 2320.99 | 2365.97 | 2353.28 | 2339.71 |

| PFAC | 2275.83 | 2275.08 | 2330.10 | 2309.66 | 2297.67 |

| EPSC | 1227.82 | 1215.36 | 1272.97 | 1255.28 | 1242.86 |

| EPS-PFAC | 1232.39 | 1215.31 | 1280.30 | 1249.86 | 1244.47 |

| MEPS | 1378.51 | 1392.32 | 1431.10 | 1433.69 | 1408.90 |

| Specimens | Temperature (°C) | ||

|---|---|---|---|

| Min | Max | At 72 h | |

| NC | 19.84 | 37.49 | 25.58 |

| PFAC | 22.22 | 37.35 | 29.42 |

| EPS-PFAC | 20.40 | 37.13 | 25.34 |

| EPSC1 | 22.05 | 46.62 | 25.32 |

| EPSC2 | 22.63 | 44.83 | 28.60 |

| MEPSC | 21.86 | 47.34 | 25.32 |

| Room temp. 1 | 22.26 | 23.76 | 22.86 |

| Room temp. 2 | 23.22 | 25.06 | 24.34 |

| Room temp. 3 | 24.40 | 26.71 | 25.70 |

| Specimens | Thermal Conductivity (W/m·K) | ||

|---|---|---|---|

| Lower | Upper | Average | |

| NC | 1.157 | 1.268 | 1.213 |

| PFAC | 1.100 | 1.104 | 1.102 |

| EPSC | 0.359 | 0.403 | 0.377 |

| EPS-PFAC | 0.331 | 0.314 | 0.322 |

| MEPS | 0.482 | 0.497 | 0.489 |

| Specimens | Specific Heat Capacity (J/Kg·K) | ||

|---|---|---|---|

| Lower | Upper | Average | |

| NC | 940.47 | 1232.24 | 1086.36 |

| PFAC | 1056.09 | 1146.48 | 1101.29 |

| EPSC | 860.89 | 996.01 | 928.45 |

| EPS-PFAC | 637.85 | 715.07 | 676.46 |

| MEPS | 841.62 | 884.84 | 863.23 |

| Specimens | k (W/m·K) | A (m2) | T2 (°C) | T1 (°C) | Δx (m) | Q (watt = J/s) | q (W/m2) |

|---|---|---|---|---|---|---|---|

| NC | 1.2130 | 0.01 | 35 | 10 | 0.021361 | 14.20 | 1419.62 |

| PFAC | 1.1020 | 0.01 | 35 | 10 | 0.021273 | 12.95 | 1295.10 |

| EPSC | 0.3773 | 0.01 | 35 | 10 | 0.023381 | 4.03 | 403.43 |

| EPS-PFAC | 0.3223 | 0.01 | 35 | 10 | 0.018879 | 4.27 | 426.81 |

| MEPS | 0.4893 | 0.01 | 35 | 10 | 0.024835 | 4.93 | 492.55 |

| Specimens | k (Watt/m·K) | ρ (Kg/m3) | c (J/Kg·K) | α (m2/s) |

|---|---|---|---|---|

| NC | 1.2130 | 2339.71 | 1086.36 | 0.477 × 10−6 |

| PFAC | 1.1020 | 2297.67 | 1101.29 | 0.436 × 10−6 |

| EPSC | 0.3773 | 1242.86 | 928.45 | 0.327 × 10−6 |

| EPS-PFAC | 0.3223 | 1244.47 | 676.46 | 0.383 × 10−6 |

| MEPS | 0.4893 | 1408.90 | 863.23 | 0.402 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wibowo, A.P.; Saidani, M.; Khorami, M. Enhancing Sustainability in Construction: Investigating the Thermal Advantages of Fly Ash-Coated Expanded Polystyrene Lightweight Concrete. J. Compos. Sci. 2024, 8, 157. https://doi.org/10.3390/jcs8040157

Wibowo AP, Saidani M, Khorami M. Enhancing Sustainability in Construction: Investigating the Thermal Advantages of Fly Ash-Coated Expanded Polystyrene Lightweight Concrete. Journal of Composites Science. 2024; 8(4):157. https://doi.org/10.3390/jcs8040157

Chicago/Turabian StyleWibowo, Andi Prasetiyo, Messaoud Saidani, and Morteza Khorami. 2024. "Enhancing Sustainability in Construction: Investigating the Thermal Advantages of Fly Ash-Coated Expanded Polystyrene Lightweight Concrete" Journal of Composites Science 8, no. 4: 157. https://doi.org/10.3390/jcs8040157

APA StyleWibowo, A. P., Saidani, M., & Khorami, M. (2024). Enhancing Sustainability in Construction: Investigating the Thermal Advantages of Fly Ash-Coated Expanded Polystyrene Lightweight Concrete. Journal of Composites Science, 8(4), 157. https://doi.org/10.3390/jcs8040157