Mechanisms of Component Degradation and Multi-Scale Strategies for Predicting Composite Durability: Present and Future Perspectives

Abstract

:1. Introduction

1.1. Degradation of Composite Materials

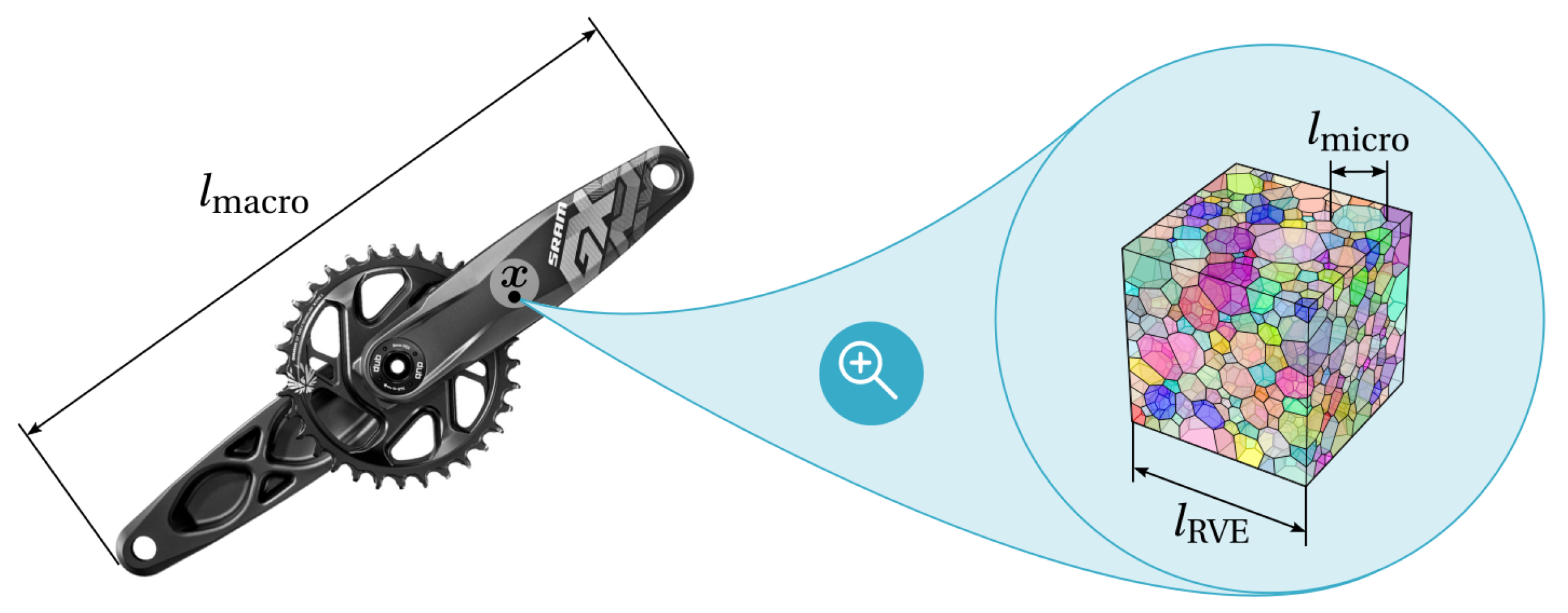

1.2. Multi-Scale Models

1.3. Main Goal and Outline

2. Environmental Effects in Composite Materials

- Polymer matrix composites (PMCs): PMCs constitute a prominent category of composite materials, wherein a polymer matrix binds reinforcing elements to create materials of enhanced strength and versatility. This category can be divided into two sub-categories, namely, particulate composites and fibre-reinforced polymers (FRPs). The latter group is likely one of, if not the most utilised and researched composite materials types in engineering. The fibre reinforcements can be, for example, carbon, glass, or aramid embedded in a polymer matrix such as epoxy, polyester, vinyl ester, or many others.

- Concrete-based composites: Advancements in civil engineering have led to the growing reinforcement of traditional concrete structural elements with high-strength fibres, additives, steel, or FRP bars [48,49,50,51]. The introduction of such reinforcement leads to valuable increases in the strength-to-weight ratio and durability of concrete structures. Nonetheless, they can exhibit time-dependent behaviour under certain environmental and loading conditions [52,53,54,55,56]. Furthermore, in civil construction many structural elements are permanently exposed to degradation agents such as water. This has motivated the scientific community to put notable efforts into optimising both the design of concrete-based composite structures [57,58,59,60] and the production aggregate [61,62,63], to improve durability while utilising more sustainable production routes.

- Biocomposites: From the point of view of sustainability, these composites use natural fibres and a biodegradable polymeric matrix, contributing to the growing emphasis on environmentally conscious material solutions [64]. The long-term behaviour of biodegradable polymers, in particular, is already the focus of extensive research [65,66,67,68,69].

- Hybrids: Hybrid composite materials consist of mixtures of different types of reinforcements and/or matrices, resulting in a synergistic blend of properties appropriate for the application requirements [72].

2.1. Hygrothermal Aging of FRPs

2.1.1. Fibre Degradation Models

- In surface area calculations, all fibres are considered to have the same beginning radius, while the cross-sectional surface area at the ends of the fibres is assumed to be insignificant.

- The length and density of the GFs are both assumed to remain constant throughout the dissolving process.

- The degradation of glass fibres is well-documented, with established mechanisms and defined models guiding the current understanding.

- Carbon fibres are unaffected, and are able to withstand hygrothermal conditions.

- Basalt fibres have been extensively studied in composite contexts; however, the lack of a specific fibre degradation model currently presents a challenge.

- Aramid fibres with well-established degradation mechanisms can form the basis for developing future models.

- While the mechanism of deterioration in natural fibres is recognised, there is no precise model for hygrothermal environments.

2.1.2. Matrix Degradation Models

Solubility

Diffusion

Plasticisation

Swelling

Hydrolysis

2.1.3. Interphase Degradation Models

- Adhesion: Sizing promotes a better adhesion between the fibres and the polymer matrix by creating chemical bonds or interactions at the interface, thereby ensuring strong bonds.

- Protection: Sizing can shield the fibres from environmental factors that would otherwise lead to degradation, such as moisture or chemical exposure.

- Stress/load transfer: Sizing ensures that the load is efficiently distributed throughout the composite, optimizing its mechanical performance [116].

2.2. Thermo-Oxidative Aging of FRPs

2.3. Photo-Oxidative Aging of FRPs

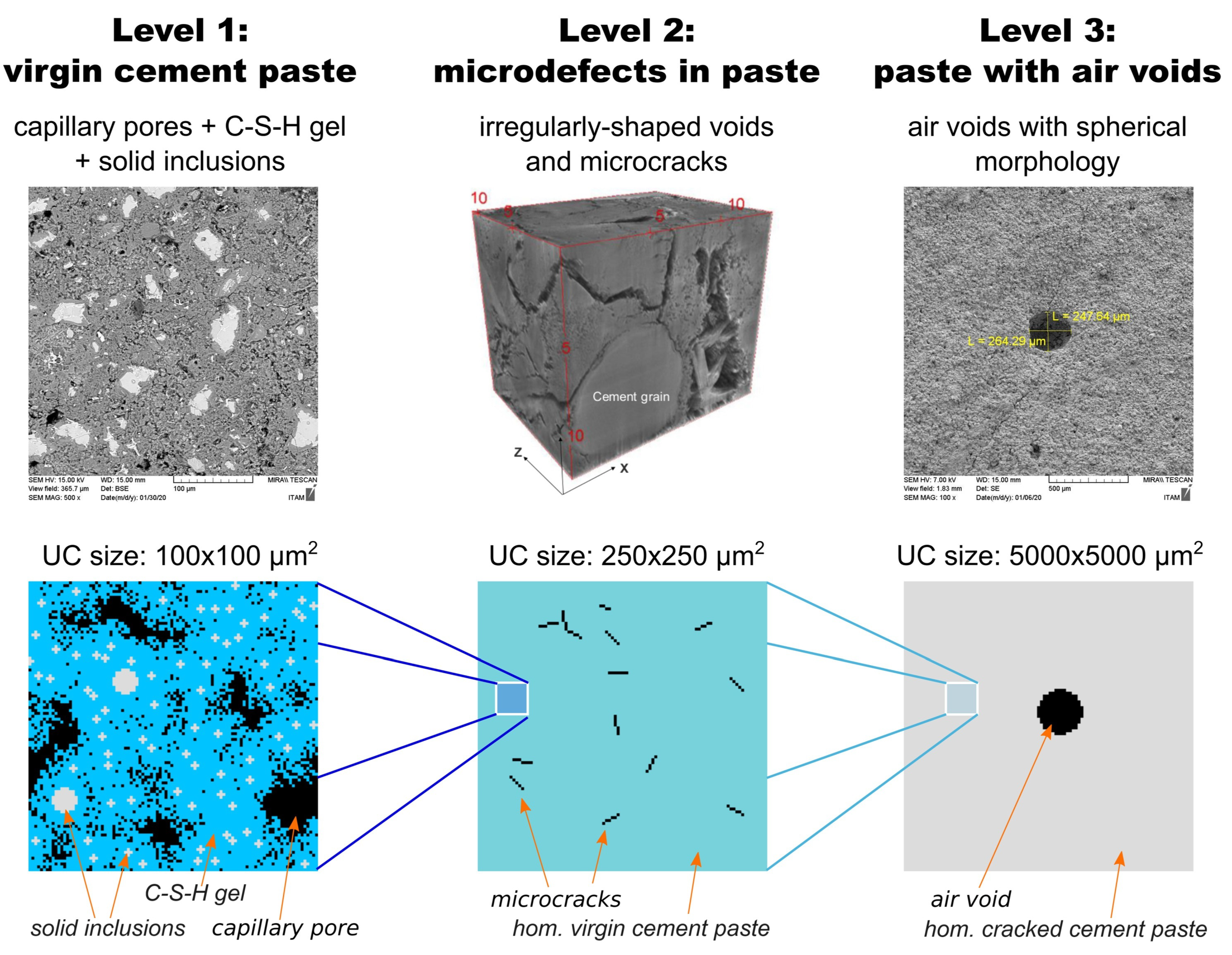

2.4. Aging of Cement-Based Materials

- Virgin state (defect-free): This level is the smallest one, where the mixture of solid inclusions is embedded into an amorphous CSH gel, all surrounded by large capillary pores.

- Microdefects in the paste: physical defects in the form of microcracks and voids appear primarily within the CSH gel.

- Paste with air voids: Bulk cement paste contains air voids (≥100 μm) that can be identified by visual inspection.

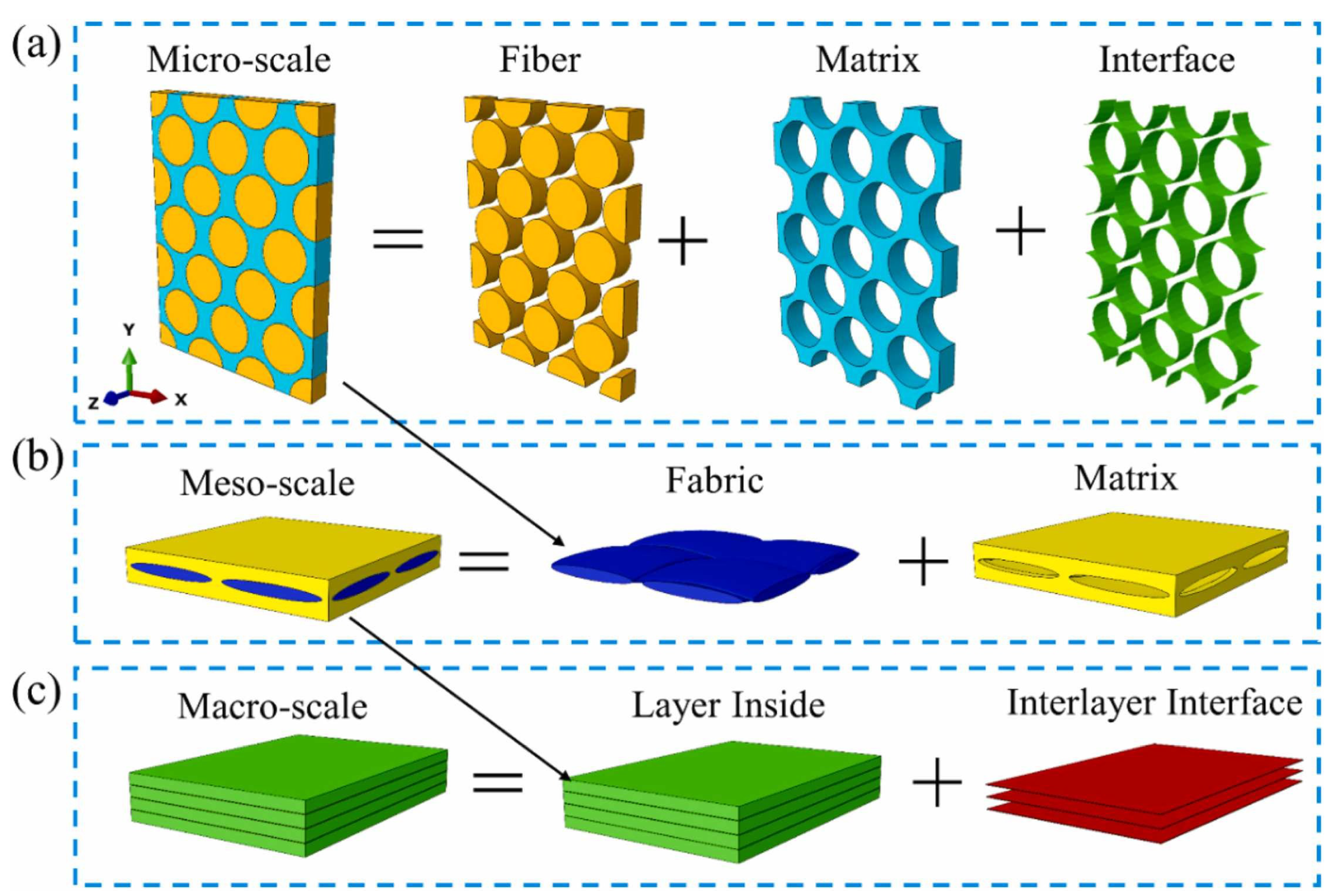

3. Multi-Scale Methods in Structural Mechanics

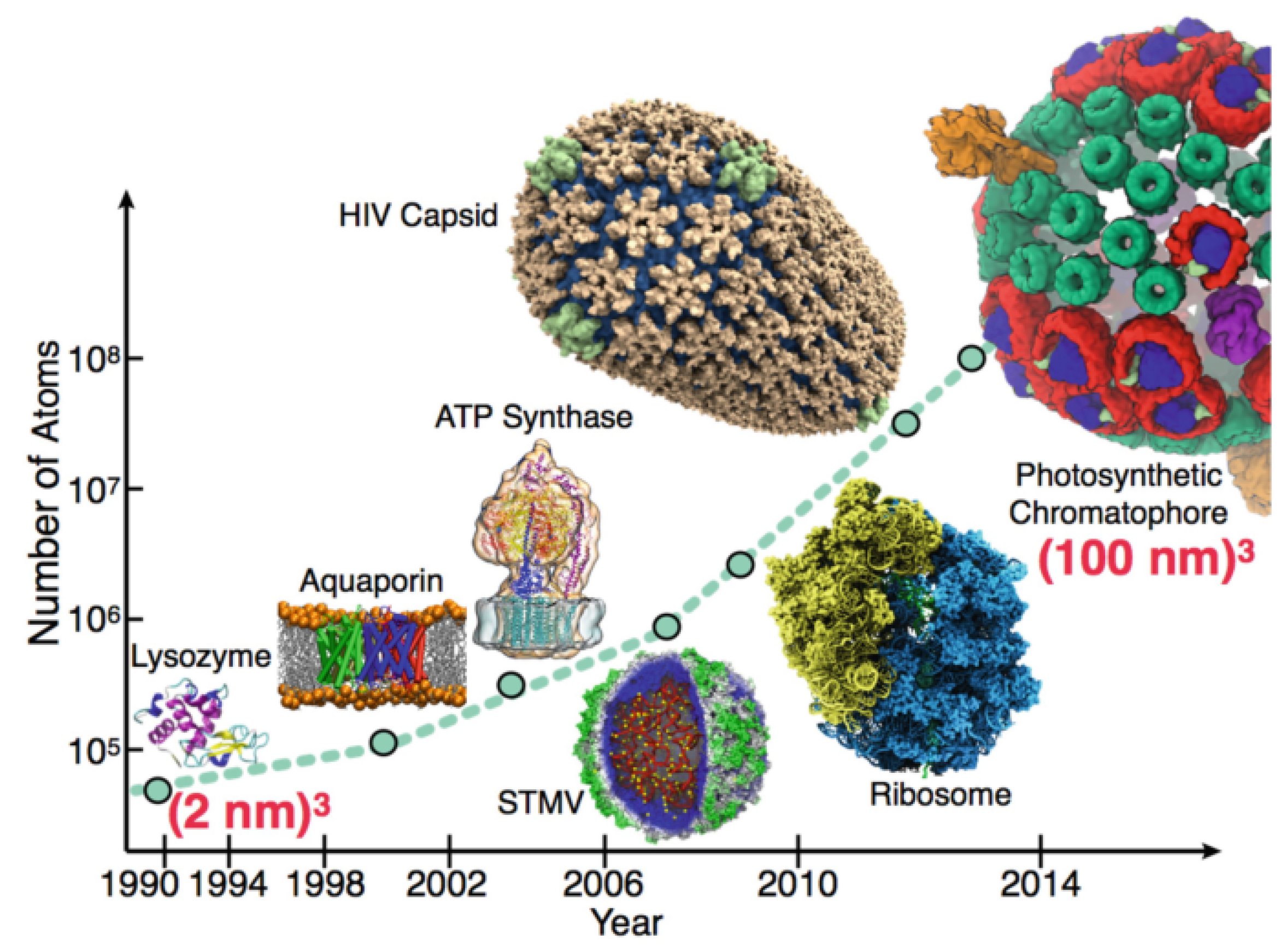

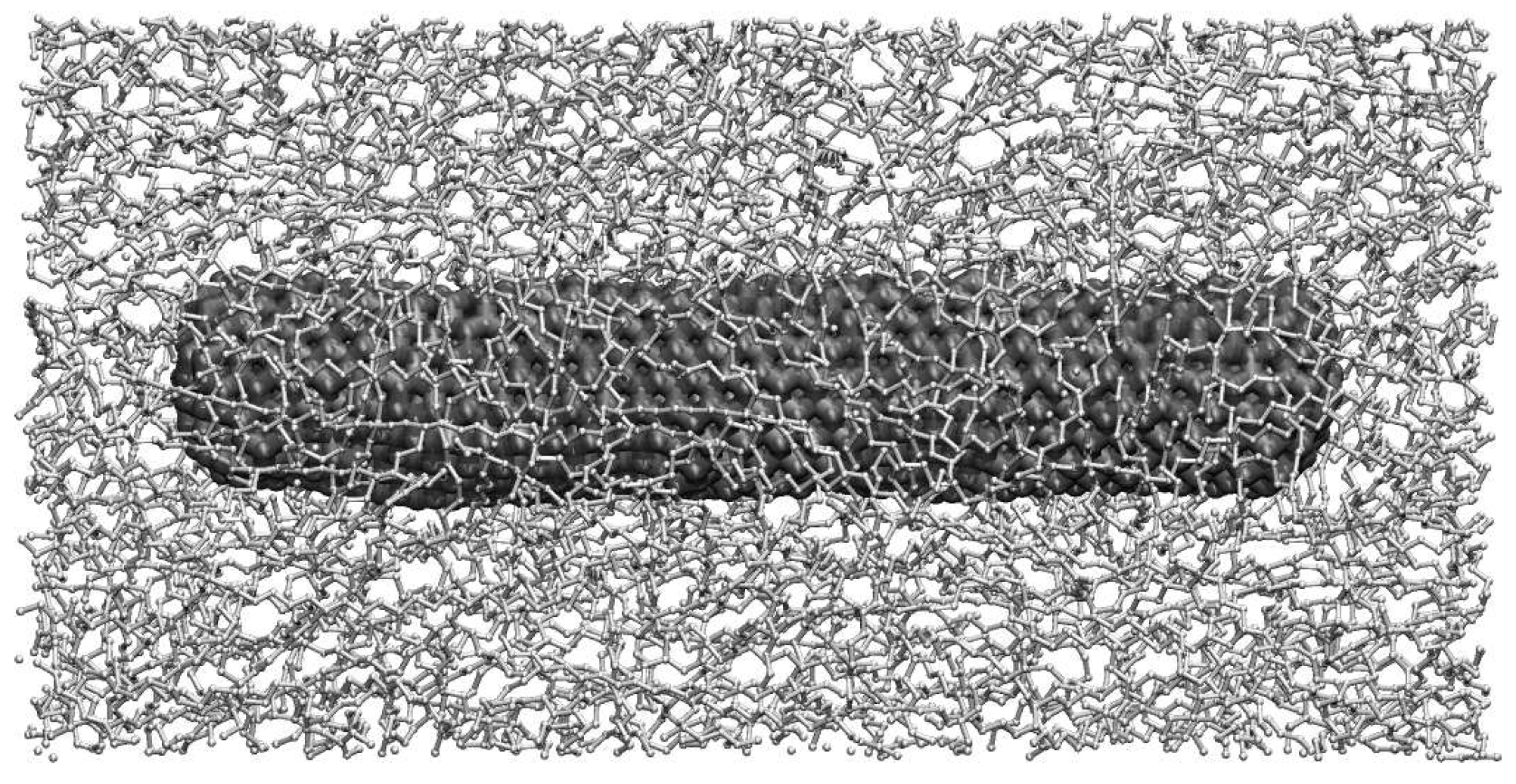

3.1. Discrete Models: Mechanics at Low Length Scales

3.1.1. Density Functional Theory

3.1.2. Molecular Dynamics Simulations

3.1.3. Coarse-Grained Methods

3.1.4. Other Methods

3.2. Continuum Models

3.3. Scale-Bridging Strategies

3.3.1. Concurrent Methods

3.3.2. Hierarchical Methods

3.3.3. Hybrid Methods

3.4. Multi-Scale Modelling and Experimental Testing

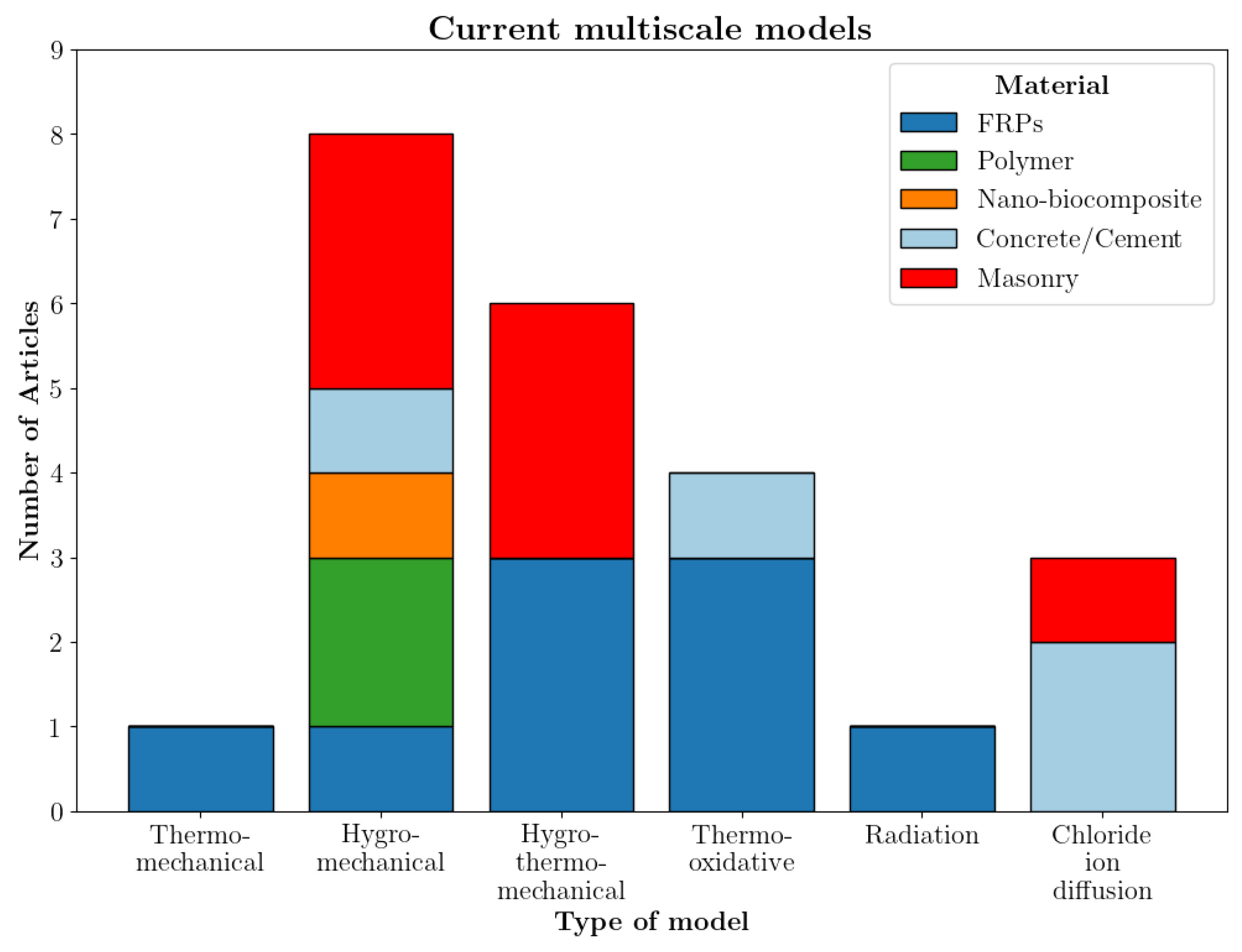

4. Multi-Scale Durability Predictions for Composite Materials

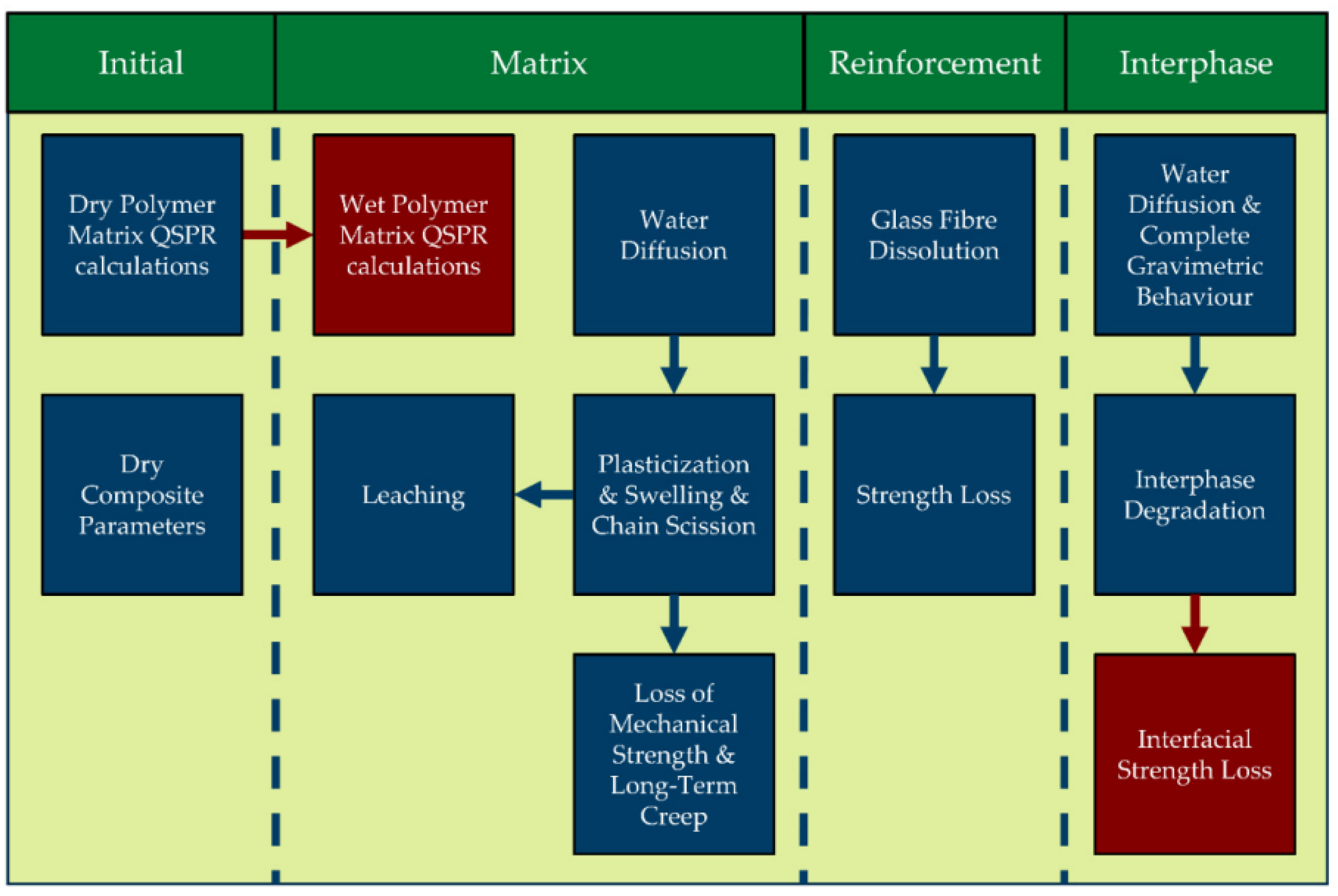

4.1. Modular Paradigm

4.2. Thermomechanical Model

4.3. Hygromechanical Models

4.4. Hygromechanical–Thermomechanical Models

4.5. Thermo-Oxidative Aging Models

4.6. Radioactive Aging Models

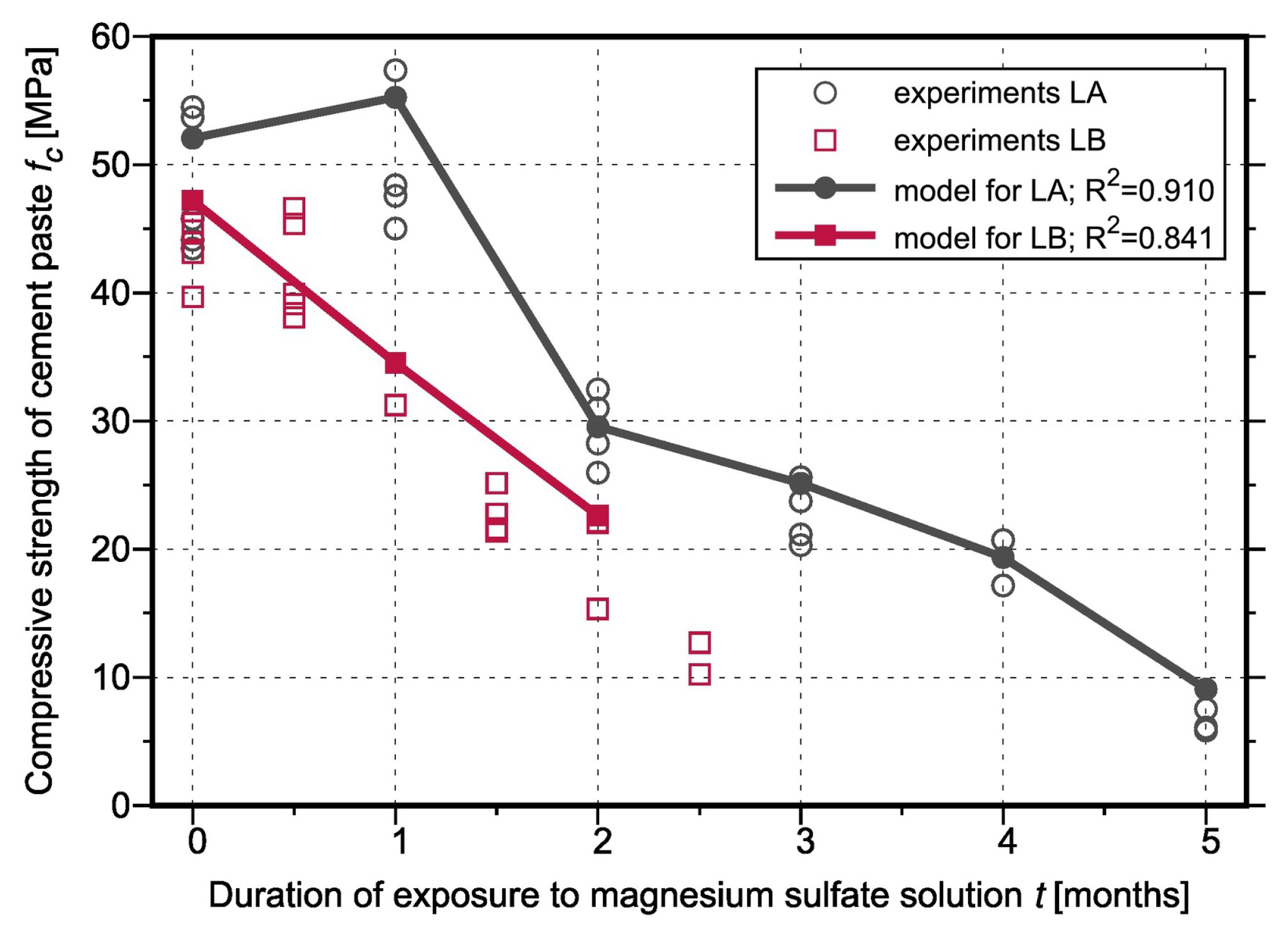

4.7. Aging Models for Cement-Based Materials

4.8. Discussion

5. Future Prospects

- 1.

- Extension to additional environmental effects: Certain environmental effects, such as radiation, are less explored in the existing literature than other factors. Furthermore, some advanced degradation models have been developed recently, such as the aforementioned DCZOK, offering the potential to improve the accuracy of multi-scale models. Conducting in-depth investigations regarding all relevant environmental effects in engineering and materials science, along with the exploration of the most accurate and efficient degradation models for each, could result in an enriched database and a broader landscape of multi-scale strategies for predicting the durability of composites.

- 2.

- Extension to emerging materials: Due to the increasing introduction of new composite materials with innovative design features and configurations across diverse applications, including nano- and biocomposites in medical contexts [295,296] and thermoplastic matrix composites in the marine and automotive sectors [14,15], it is imperative to delve into the environmental degradation mechanisms affecting these novel materials. Understanding and addressing the unique challenges posed by these materials will play a crucial role in facilitating their successful integration into a wider range of practical applications with assurances of long-term safety and reliability.

- 3.

- Integration and the modular paradigm: Existing models have primarily focused on individual environmental factors, such as hygromechanical and radioactive aging. Future research should aim to develop more comprehensive models that can simultaneously integrate multiple environmental stressors in order to attain the aforementioned modular paradigm for durability predictions. Real-world scenarios involve the simultaneous influence of various environmental factors, and understanding their combined effects is crucial. The development of an integrated database and modelling toolbox for the relevant environmental effects and materials, as proposed in the modular paradigm, would also benefit from the accomplishment of the first and second objectives.

- 4.

- Enhancement of predictive capabilities: Advancements in computational techniques, including high-performance computing and the progressive use of data-driven frameworks, are set to increase the predictive power and efficiency of multi-scale methods in the coming years. The continuous development of these multi-scale strategies and their subsequent application to degradation modelling of composite structures is paramount to attaining more accurate durability predictions for a greater range of materials and environmental agents. The inclusion of discrete mechanics models has been particularly useful in multi-scale degradation analysis due to the influence of chemical interactions at lower scales in the macroscopic structural response. That said, improving the current scale bridging schemes between MD simulations and continuum mechanics models could lead to even more accurate results. Moreover, the full potential of several numerical strategies, such as the quasi-continuum method, concurrent multi-scale approaches (which are seeing growing efficiency due to smarter adaptive algorithms), asymptotic homogenisation, and second order CH, along with ROM and surrogate approaches such as PRNNs, has yet to be fully investigated in the context of multi-scale composite degradation modelling.

- 5.

- Synergy between experimental testing and computational modelling: Strengthening the relationship between experimental testing and computational modelling through the calibration and validation of multi-scale strategies with adequate and precise empirical measurements is paramount for a sustainable development of multi-scale methods in composite material degradation analysis. Establishing standardised protocols for model validation will enhance the reliability and comparability of results across different studies, and a more robust understanding of material behaviour can be achieved through rigorous validation efforts. Although numerical predictions cannot fully replace empirical testing, this would allow the overall costs associated with experimental campaigns to be reduced in the long term. Furthermore, the introduction of novel experimental techniques such as advanced imaging, sensing, and characterisation methods can provide richer datasets for model validation and calibration. Integrating data from these techniques into multi-scale models could help to enhance their predictive capabilities.

6. Conclusions

- Several multi-scale models integrating environmental degradation display remarkable effectiveness, demonstrating their efficacy by closely matching experimental data.

- To shape the future of multi-scale modelling in predicting environmental effects on composite materials, it is crucial to address the identified trends and opportunities.

- Enriching our understanding of composite material behavior requires an extension of the research landscape to encompass a broader range of environmental factors and emerging materials.

- The reliability and accuracy of durability predictions can be enhanced by integrating multiple degradation models according to the modular paradigm and by leveraging computational advancements in multi-scale strategies.

- Promoting synergy between experimental testing and numerical modelling is vital to ensure adequate calibration and validation of multi-scale predictions while reducing experimental characterisation tests.

- Although advanced numerical strategies cannot completely replace experimental testing, their integration into material and structural degradation studies can mitigate the major shortcomings of experimental testing, such as intensive consumption of time and resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Starkova, O.; Gagani, A.I.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Krauklis, A.E. Modelling of Environmental Ageing of Polymers and Polymer Composites—Durability Prediction Methods. Polymers 2022, 14, 907. [Google Scholar] [CrossRef]

- Demuts, E.; Shyprykevich, P. Accelerated environmental testing of composites. Composites 1984, 15, 25–31. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M.; Sekine, N. Accelerated testing for long-term durability of GFRP laminates for marine use. Compos. Part B Eng. 2004, 35, 497–502. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M.; Cai, H. Formulation of Long-term Creep and Fatigue Strengths of Polymer Composites Based on Accelerated Testing Methodology. J. Compos. Mater. 2008, 42, 1897–1919. [Google Scholar] [CrossRef]

- Barbosa, A.P.; Fulco, A.P.; Guerra, E.S.; Arakaki, F.K.; Tosatto, M.; Costa, M.C.; Melo, J.D. Accelerated aging effects on carbon fiber/epoxy composites. Compos. Part B Eng. 2017, 110, 298–306. [Google Scholar] [CrossRef]

- Farhey, D.N. Long-Term Performance Monitoring of the Tech 21 All-Composite Bridge. J. Compos. Constr. 2005, 9, 255–262. [Google Scholar] [CrossRef]

- Guan, H.; Karbhari, V.M.; Sikorsky, C.S. Long-term Structural Health Monitoring System for a FRP Composite Highway Bridge Structure. J. Intell. Mater. Syst. Struct. 2007, 18, 809–823. [Google Scholar] [CrossRef]

- Cardini, A.; DeWolf, J. Long-term Structural Health Monitoring of a Multi-girder Steel Composite Bridge Using Strain Data. Struct. Health Monit. 2009, 8, 47–58. [Google Scholar] [CrossRef]

- Waite, S. 19—Certification and airworthiness of polymer composite aircraft. In Polymer Composites in the Aerospace Industry, 2nd ed.; Irving, P., Soutis, C., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2020; pp. 593–645. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Ozola-Davidane, R.; Gagani, A.I.; Starkova, O. Modelling of Environmental Ageing of Polymers and Polymer Composites&Modular and Multiscale Methods. Polymers 2022, 14, 216. [Google Scholar] [CrossRef]

- Plota, A.; Masek, A. Lifetime Prediction Methods for Degradable Polymeric Materials—A Short Review. Materials 2020, 13, 4507. [Google Scholar] [CrossRef] [PubMed]

- Göpferich, A. Mechanisms of Polymer Degradation and Erosion. Biomaterials 1996, 17, 103–114. [Google Scholar] [CrossRef] [PubMed]

- Arhant, M.; Davies, P. Thermoplastic Matrix Composites for Marine Applications; Woodhead Publishing: Cambridge, UK, 2019; pp. 31–53. [Google Scholar] [CrossRef]

- Mallick, P. Thermoplastics and Thermoplastic–Matrix Composites for Lightweight Automotive Structures; Woodhead Publishing: Cambridge, UK, 2010; pp. 174–207. [Google Scholar] [CrossRef]

- Echtermeyer, A.T.; Gagani, A.; Krauklis, A.; Mazan, T. Multiscale Modelling of Environmental Degradation—First Steps. In Durability of Composites in a Marine Environment 2; Davies, P., Rajapakse, Y.D., Eds.; Solid Mechanics and Its Applications, Springer International Publishing: Cham, Switwerland, 2018; pp. 135–149. [Google Scholar] [CrossRef]

- dos Santos, W.F.; Rodrigues Lopes, I.A.; Andrade Pires, F.M.; Proença, S.P. Second-order multi-scale modelling of natural and architected materials in the presence of voids: Formulation and numerical implementation. Comput. Methods Appl. Mech. Eng. 2023, 416, 116374. [Google Scholar] [CrossRef]

- Wang, J.; GangaRao, H.; Liang, R.; Liu, W. Durability and prediction models of fiber-reinforced polymer composites under various environmental conditions: A critical review. J. Reinf. Plast. Compos. 2016, 35, 179–211. [Google Scholar] [CrossRef]

- Guedes, R. Durability of polymer matrix composites: Viscoelastic effect on static and fatigue loading. Compos. Sci. Technol. 2007, 67, 2574–2583. [Google Scholar] [CrossRef]

- Talreja, R. Damage Analysis for Structural Integrity and Durability of Composite Materials. Fatigue Fract. Eng. Mater. Struct. 2006, 29, 481–506. [Google Scholar] [CrossRef]

- Zhao, L.; Hou, D.; Wang, P.; Guo, X.; Zhang, Y.; Liu, J.; Zhang, J. Experimental and molecular dynamics studies on the durability of sustainable cement-based composites: Reinforced by graphene. Constr. Build. Mater. 2020, 257, 119566. [Google Scholar] [CrossRef]

- Horstemeyer, M. Multiscale Modeling: A Review. In Practical Aspects of Computational Chemistry; Springer: Dordrecht, The Netherlands, 2009; pp. 87–135. [Google Scholar] [CrossRef]

- Nguyen, V.P.; Stroeven, M.; Sluys, L. Multiscale failure modeling of concrete: Micromechanical modeling, discontinuous homogenization and parallel computations. Comput. Methods Appl. Mech. Eng. 2012, 201–204, 139–156. [Google Scholar] [CrossRef]

- Sun, B.; Li, Z. A multi-scale damage model for fatigue accumulation due to short cracks nucleation and growth. Eng. Fract. Mech. 2014, 127, 280–295. [Google Scholar] [CrossRef]

- Mangipudi, K.; Onck, P. Multiscale modelling of damage and failure in two-dimensional metallic foams. J. Mech. Phys. Solids 2011, 59, 1437–1461. [Google Scholar] [CrossRef]

- Fernandino, D.O.; Cisilino, A.P.; Toro, S.; Sánchez, P.J. Multi-Scale Analysis of the Early Damage Mechanics of Ferritized Ductile Iron. Int. J. Fract. 2017, 207, 1–26. [Google Scholar] [CrossRef]

- Turteltaub, S.; van Hoorn, N.; Westbroek, W.; Hirsch, C. Multiscale analysis of mixed-mode fracture and effective traction-separation relations for composite materials. J. Mech. Phys. Solids 2018, 117, 88–109. [Google Scholar] [CrossRef]

- Visrolia, A.; Meo, M. Multiscale damage modelling of 3D weave composite by asymptotic homogenisation. Compos. Struct. 2013, 95, 105–113. [Google Scholar] [CrossRef]

- Römelt, P.; Cunningham, P. A multi-scale finite element approach for modelling damage progression in woven composite structures. Compos. Struct. 2012, 94, 977–986. [Google Scholar] [CrossRef]

- Selvaraj, J.; El Said, B. Multiscale modelling of strongly heterogeneous materials using geometry informed clustering. Int. J. Solids Struct. 2023, 280, 112369. [Google Scholar] [CrossRef]

- Ghanbari, J.; Naghdabadi, R. Nonlinear hierarchical multiscale modeling of cortical bone considering its nanoscale microstructure. J. Biomech. 2009, 42, 1560–1565. [Google Scholar] [CrossRef] [PubMed]

- Marques da Silva, J.A.; Vieira de Carvalho, M.; Cardoso Coelho, R.P.; Rodrigues Lopes, I.A.; Andrade Pires, F.M. On the representativeness of polycrystalline models with transformation induced plasticity. Finite Elem. Anal. Des. 2023, 215, 103875. [Google Scholar] [CrossRef]

- He, C.; Ge, J.; Gao, J.; Liu, J.; Chen, H.; Liu, W.K.; Fang, D. From microscale to mesoscale: The non-linear behavior prediction of 3D braided composites based on the SCA2 concurrent multiscale simulation. Compos. Sci. Technol. 2021, 213, 108947. [Google Scholar] [CrossRef]

- Su, X.; Wu, Y.; Jia, M.; Liu, Z.; Jiang, J.; Xu, W. Multiscale creep model for concrete considering from C-S-H gel scale to mesoscale with ITZ and irregular-shaped aggregates. Cem. Concr. Compos. 2023, 143, 105254. [Google Scholar] [CrossRef]

- Han, X.; Xu, C.; Xie, W.; Meng, S. Multiscale computational homogenization of woven composites from microscale to mesoscale using data-driven self-consistent clustering analysis. Compos. Struct. 2019, 220, 760–768. [Google Scholar] [CrossRef]

- Wautier, A.; Veylon, G.; Miot, M.; Pouragha, M.; Nicot, F.; Wan, R.; Darve, F. Multiscale modelling of granular materials in boundary value problems accounting for mesoscale mechanisms. Comput. Geotech. 2021, 134, 104143. [Google Scholar] [CrossRef]

- Miri, A.K.; Heris, H.K.; Mongeau, L.; Javid, F. Nanoscale viscoelasticity of extracellular matrix proteins in soft tissues: A multiscale approach. J. Mech. Behav. Biomed. Mater. 2014, 30, 196–204. [Google Scholar] [CrossRef]

- Shiari, B.; Miller, R.E. Multiscale modeling of crack initiation and propagation at the nanoscale. J. Mech. Phys. Solids 2016, 88, 35–49. [Google Scholar] [CrossRef]

- Lopes, I.A.R.; Pires, F.A.; Reis, F. A Mixed Parallel Strategy for the Solution of Coupled Multi-Scale Problems at Finite Strains. Comput. Mech. 2018, 61, 157–180. [Google Scholar] [CrossRef]

- Reis, F.; Andrade Pires, F. An adaptive sub-incremental strategy for the solution of homogenization-based multi-scale problems. Comput. Methods Appl. Mech. Eng. 2013, 257, 164–182. [Google Scholar] [CrossRef]

- Ghosh, S.; Lee, K.; Raghavan, P. A multi-level computational model for multi-scale damage analysis in composite and porous materials. Int. J. Solids Struct. 2001, 38, 2335–2385. [Google Scholar] [CrossRef]

- Raghavan, P.; Ghosh, S. Concurrent multi-scale analysis of elastic composites by a multi-level computational model. Comput. Methods Appl. Mech. Eng. 2004, 193, 497–538. [Google Scholar] [CrossRef]

- Liu, Z.; Bessa, M.; Liu, W.K. Self-consistent clustering analysis: An efficient multi-scale scheme for inelastic heterogeneous materials. Comput. Methods Appl. Mech. Eng. 2016, 306, 319–341. [Google Scholar] [CrossRef]

- Ferreira, B.P.; Andrade Pires, F.; Bessa, M. Adaptivity for clustering-based reduced-order modeling of localized history-dependent phenomena. Comput. Methods Appl. Mech. Eng. 2022, 393, 114726. [Google Scholar] [CrossRef]

- Rodrigues Lopes, I.A.; Andrade Pires, F.M. Formulation and numerical implementation of a variationally consistent multi-scale model based on second-order computational homogenisation at finite strains for quasi-static problems. Comput. Methods Appl. Mech. Eng. 2022, 392, 114714. [Google Scholar] [CrossRef]

- Lin, K.; Wang, Z. Multiscale Mechanics and Molecular Dynamics Simulations of the Durability of Fiber-Reinforced Polymer Composites. Commun. Mater. 2023, 4, 66. [Google Scholar] [CrossRef]

- Matouš, K.; Geers, M.G.D.; Kouznetsova, V.; Gillman, A. A Review of Predictive Nonlinear Theories for Multiscale Modeling of Heterogeneous Materials. J. Comput. Phys. 2017, 330, 192–220. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Gudonis, E.; Timinskas, E.; Gribniak, V.; Kaklauskas, G.; Arnautov, A.K.; Tamulėnas, V. FRP reinforcement for concrete structures: State-of-the-art review of application and design. Eng. Struct. Technol. 2013, 5, 147–158. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Structural Performance of Stainless Steel Reinforced Concrete Members: A Review. Constr. Build. Mater. 2022, 325, 126673. [Google Scholar] [CrossRef]

- Lu, Y.; Song, X.; Du, R.; Song, D.; Liu, S.; Xu, W.; Wu, X. Study on interfacial performance of ordinary concrete composite structure strengthened by ultra-high performance concrete—A review. Adv. Struct. Eng. 2023, 26, 2797–2813. [Google Scholar] [CrossRef]

- Hamed, E.; Bradford, M.A. Creep in concrete beams strengthened with composite materials. Eur. J. Mech.—A/Solids 2010, 29, 951–965. [Google Scholar] [CrossRef]

- Wen, C.; Lin, Z.; Xu, Z.; Xu, C.; Liu, X.; Yang, G. Time-dependent response of continuous steel-concrete composite beams under sustained loading. J. Constr. Steel Res. 2024, 213, 108339. [Google Scholar] [CrossRef]

- Li, L.; Gao, D.; Li, Z.; Cao, M.; Gao, J.; Zhang, Z. Effect of high temperature on morphologies of fibers and mechanical properties of multi-scale fiber reinforced cement-based composites. Constr. Build. Mater. 2020, 261, 120487. [Google Scholar] [CrossRef]

- Tehami, M.; Ramdane, K.E. Creep behaviour modelling of a composite steel–concrete section. J. Constr. Steel Res. 2009, 65, 1029–1033. [Google Scholar] [CrossRef]

- Tavares, C.; Ribeiro, M.; Ferreira, A.; Guedes, R. Creep behaviour of FRP-reinforced polymer concrete. Compos. Struct. 2002, 57, 47–51. [Google Scholar] [CrossRef]

- Zhou, Y.; Gao, H.; Hu, Z.; Qiu, Y.; Guo, M.; Huang, X.; Hu, B. Ductile, durable, and reliable alternative to FRP bars for reinforcing seawater sea-sand recycled concrete beams: Steel/FRP composite bars. Constr. Build. Mater. 2021, 269, 121264. [Google Scholar] [CrossRef]

- Ali, M.S.; Mirza, M.S.; Lessard, L. Durability assessment of hybrid FRP composite shell and its application to prestressed concrete girders. Constr. Build. Mater. 2017, 150, 114–122. [Google Scholar] [CrossRef]

- Benny, B.; Bazli, M.; Rajabipour, A.; Arashpour, M. Durability of tubular sea water sea sand concrete and fibre-reinforced polymer hybrid structures: Mechanisms and effective parameters: Critical overview and discussion. Constr. Build. Mater. 2023, 366, 130206. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A state-of-the-art review on the durability of geopolymer concrete for sustainable structures and infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Patil, S.; Somasekharaiah, H.; Rao, H.S.; Ghorpade, V.G. Durability and micro-structure studies on fly ash and silica fume based composite fiber reinforced high-performance concrete. Mater. Today Proc. 2022, 49, 1511–1520. [Google Scholar] [CrossRef]

- Sujay, H.; Nair, N.A.; Sudarsana Rao, H.; Sairam, V. Experimental study on durability characteristics of composite fiber reinforced high-performance concrete incorporating nanosilica and ultra fine fly ash. Constr. Build. Mater. 2020, 262, 120738. [Google Scholar] [CrossRef]

- Tejas, S.; Pasla, D. Assessment of mechanical and durability properties of composite cement-based recycled aggregate concrete. Constr. Build. Mater. 2023, 387, 131620. [Google Scholar] [CrossRef]

- Gautam, L.; Jain, A.; Shrivastava, P.; Vyas, S.; Vyas, S.P. Natural Polymers-Based Biocomposites: State of Art, New Challenges, and Opportunities. In Polymeric and Natural Composites; Springer: Dordrecht, The Netherlands, 2021; pp. 1–24. [Google Scholar] [CrossRef]

- Vieira, A.; Marques, A.; Marques, A.T.; Guedes, R.M.; Ribeiro, M.L.; Tita, V. Material Model Proposal for Biodegradable Materials. Procedia Eng. 2011, 10, 1597–1602. [Google Scholar] [CrossRef]

- Vieira, A.; Guedes, R.M.; Ribeiro, M.L.; Tita, V. Constitutive Modeling of Biodegradable Polymers: Hydrolytic Degradation and Time-Dependent Behavior. Int. J. Solids Struct. 2014, 51, 1164–1174. [Google Scholar] [CrossRef]

- Vieira, A.; Guedes, R.M.; Ribeiro, M.L.; Tita, V. Biodegradable Polymers. Volume 1: Advancement in Biodegradation Study and Applications; Chapter Constitutive Modeling and Mechanical Behavior Prediction of Biodegradable Polymers during Degradation; Nova Science Publishers: New York, NY, USA, 2015. [Google Scholar]

- da Silva, S.; Filipe, J. Constitutive Modeling for Biodegradable Polymers for Application in Endovascular Stents. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2008. [Google Scholar]

- Soares, J.S.; Rajagopal, K.R.; Moore, J.E. Deformation-Induced Hydrolysis of a Degradable Polymeric Cylindrical Annulus. Biomech. Model. Mechanobiol. 2010, 9, 177–186. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S.; Avouris, P. Introduction to Carbon Materials Research. In Carbon Nanotubes: Synthesis, Structure, Properties, and Applications; Dresselhaus, M.S., Dresselhaus, G., Avouris, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2001; pp. 1–9. [Google Scholar] [CrossRef]

- Lu, W.; Zu, M.; Byun, J.H.; Kim, B.S.; Chou, T.W. State of the Art of Carbon Nanotube Fibers: Opportunities and Challenges. Adv. Mater. 2012, 24, 1805–1833. [Google Scholar] [CrossRef] [PubMed]

- Chamis, C.; Lark, R. Hybrid Composites—State-of-the-art Review: Analysis, Design, Application and Fabrication. In Proceedings of the 18th Structural Dynamics and Materials Conference, San Diego, CA, USA, 21–23 March 1977. [Google Scholar] [CrossRef]

- Weitsman, Y. Anomalous fluid sorption in polymeric composites and its relation to fluid-induced damage. Compos. Part A Appl. Sci. Manuf. 2006, 37, 617–623. [Google Scholar] [CrossRef]

- Liu, T.; Liu, X.; Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Fakhrul, T.; Islam, M. Degradation Behavior of Natural Fiber Reinforced Polymer Matrix Composites. Procedia Eng. 2013, 56, 795–800. [Google Scholar] [CrossRef]

- Zaki Abdullah, M.; Dan-mallam, Y.; Megat Yusoff, P.S. Effect of Environmental Degradation on Mechanical Properties of Kenaf/Polyethylene Terephthalate Fiber Reinforced Polyoxymethylene Hybrid Composite. Adv. Mater. Sci. Eng. 2013, 2013, 671481. [Google Scholar] [CrossRef]

- Echtermeyer, A.T.; Krauklis, A.E.; Gagani, A.I.; Sæter, E. Zero Stress Aging of Glass and Carbon Fibers in Water and Oil—Strength Reduction Explained by Dissolution Kinetics. Fibers 2019, 7, 107. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Aouissi, H.A.; Bencedira, S.; Burlakovs, J.; Burlakovs, J.; Zekker, I.; Bute, I.; Klavins, M. Influence of Environmental Parameters and Fiber Orientation on Dissolution Kinetics of Glass Fibers in Polymer Composites. J. Compos. Sci. 2022, 6, 210. [Google Scholar] [CrossRef]

- Bashir, S.; Yang, L.; Liggat, J.; Thomason, J. Kinetics of Dissolution of Glass Fibre in Hot Alkaline Solution. J. Mater. Sci. 2018, 53, 1710–1722. [Google Scholar] [CrossRef]

- Khawam, A.; Flanagan, D.R. Solid-State Kinetic Models: Basics and Mathematical Fundamentals. J. Phys. Chem. B 2006, 110, 17315–17328. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Echtermeyer, A.T. Long-Term Dissolution of Glass Fibers in Water Described by Dissolving Cylinder Zero-Order Kinetic Model: Mass Loss and Radius Reduction. Open Chem. 2018, 16, 1189–1199. [Google Scholar] [CrossRef]

- Arrhenius, S. Über die Dissociationswärme und den Einfluss der Temperatur auf den Dissociationsgrad der Elektrolyte. Z. Phys. Chem. 1889, 4U, 96–116. [Google Scholar] [CrossRef]

- Arrhenius, S. Über die Reaktionsgeschwindigkeit bei der Inversion von Rohrzucker durch Säuren. Z. Phys. Chem. 1889, 4U, 226–248. [Google Scholar] [CrossRef]

- Krauklis, A.; Gagani, A.; Veģere, K.; Jerāne, I.; Klavins, M.; Echtermeyer, A. Dissolution Kinetics of R-Glass Fibres: Influence of Water Acidity, Temperature, and Stress Corrosion. Fibers 2019, 7, 22. [Google Scholar] [CrossRef]

- Griffith, A.A.; Taylor, G.I. VI. The Phenomena of Rupture and Flow in Solids. Philos. Trans. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Bush, A.J. Stress Intensity Factors for Single-Edge-Crack Solid and Hollow Round Bars Loaded in Tension. J. Test. Eval. 2006, 110, 216–223. [Google Scholar] [CrossRef]

- Krauklis, A.E. Modular Paradigm for Composites: Modeling Hydrothermal Degradation of Glass Fibers. Fibers 2021, 9, 83. [Google Scholar] [CrossRef]

- Krauklis, A.; Echtermeyer, A. Dissolving Cylinder Zero-Order Kinetic Model for Predicting Hygrothermal Aging of Glass Fiber Bundles and Fiber-Reinforced Composites. In Proceedings of the 4th International Glass Fiber Symposium, Aachen, Germany, 31 October 2018. [Google Scholar]

- Wei, B.; Cao, H.; Song, S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Fan, Y.; Guo, J.; Wang, X.; Xia, Y.; Han, P.; Shangguan, L.; Zhang, M. Comparative Failure Study of Different Bonded Basalt Fiber-Reinforced Polymer (BFRP)-AL Joints in a Humid and Hot Environment. Polymers 2021, 13, 2593. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Zotti, A.; Borriello, A.; Zarrelli, M.; Aniskevich, A. Basalt Fibre Composite with Carbon Nanomodified Epoxy Matrix under Hydrothermal Ageing. Polymers 2021, 13, 532. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Zhang, G. Durability of basalt fibers and composites in corrosive environments. J. Compos. Mater. 2015, 49, 873–887. [Google Scholar] [CrossRef]

- Le Gué, L.; Davies, P.; Arhant, M.; Vincent, B.; Verbouwe, W. Basalt fibre degradation in seawater and consequences for long term composite reinforcement. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108027. [Google Scholar] [CrossRef]

- Horta, A.; Coca, J.; Díez, F.V. Degradation Mechanism and Kinetics of a High Thermally Stable Aromatic Polyamide. Adv. Polym. Technol. 2000, 19, 120–131. [Google Scholar] [CrossRef]

- Horta, A.; Coca, J.; Díez, F.V. Degradation Kinetics of Meta- and Para-aromatic Polyamides. Adv. Polym. Technol. 2003, 22, 15–21. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation Mechanisms of Natural Fiber in the Matrix of Cement Composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Arnold, J.C. 6.10—Environmental Effects on Crack Growth in Composites. In Comprehensive Structural Integrity; Milne, I., Ritchie, R.O., Karihaloo, B., Eds.; Pergamon: Oxford, UK, 2007; pp. 428–470. [Google Scholar] [CrossRef]

- Hansen, C.M. Hansen Solubility Parameters: A User’s Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Clarendon Press: Oxford, UK, 1975. [Google Scholar]

- Carter, H.G.; Kibler, K.G. Langmuir-Type Model for Anomalous Moisture Diffusion in Composite Resins. J. Compos. Mater. 1978, 12, 118–131. [Google Scholar] [CrossRef]

- Berens, A.; Hopfenberg, H. Diffusion and relaxation in glassy polymer powders: 2. Separation of diffusion and relaxation parameters. Polymer 1978, 19, 489–496. [Google Scholar] [CrossRef]

- Jacobs, P.M.; Jones, E.R. Diffusion of moisture into two-phase polymers. J. Mater. Sci. 1989, 24, 2343–2347. [Google Scholar] [CrossRef]

- Bao, L.R.; Yee, A.F.; Lee, C.Y.C. Moisture absorption and hygrothermal aging in a bismaleimide resin. Polymer 2001, 42, 7327–7333. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Akulichev, A.G.; Gagani, A.I.; Echtermeyer, A.T. Time–Temperature–Plasticization Superposition Principle: Predicting Creep of a Plasticized Epoxy. Polymers 2019, 11, 1848. [Google Scholar] [CrossRef]

- Shtarkman, B.; Razinskaya, I. Plasticization mechanism and structure of polymers. Acta Polym. 1983, 34, 514–520. [Google Scholar] [CrossRef]

- Coran, A.Y.; Boustany, K.; Hamed, P. Unidirectional fiber–polymer composites: Swelling and modulus anisotropy. J. Appl. Polym. Sci. 1971, 15, 2471–2485. [Google Scholar] [CrossRef]

- Daniels, B.K. Orthotropic swelling and simplified elasticity laws with special reference to cord-reinforced rubber. J. Appl. Polym. Sci. 1973, 17, 2847–2853. [Google Scholar] [CrossRef]

- Cairns, D.S.; Adams, D.F. Moisture and Thermal Expansion Properties of Unidirectional Composite Materials and the Epoxy Matrix. J. Reinf. Plast. Compos. 1983, 2, 239–255. [Google Scholar] [CrossRef]

- Meng, M.; Rizvi, M.; Le, H.; Grove, S. Multi-scale modelling of moisture diffusion coupled with stress distribution in CFRP laminated composites. Compos. Struct. 2016, 138, 295–304. [Google Scholar] [CrossRef]

- Shirangi, M.H.; Michel, B. Mechanism of Moisture Diffusion, Hygroscopic Swelling, and Adhesion Degradation in Epoxy Molding Compounds. In Moisture Sensitivity of Plastic Packages of IC Devices; Fan, X., Suhir, E., Eds.; Springer: Boston, MA, USA, 2010; pp. 29–69. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Gagani, A.I.; Echtermeyer, A.T. Prediction of Orthotropic Hygroscopic Swelling of Fiber-Reinforced Composites from Isotropic Swelling of Matrix Polymer. J. Compos. Sci. 2019, 3, 10. [Google Scholar] [CrossRef]

- Mazan, T.; Berggren, R.; Jørgensen, J.; Echtermeyer, A. Aging of Polyamide 11. Part 1: Evaluating Degradation by Thermal, Mechanical and Viscometric Analysis. J. Appl. Polym. Sci. 2015, 132, 6249–6260. [Google Scholar] [CrossRef]

- Mazan, T.; Jørgensen, J.; Echtermeyer, A. Aging of Polyamide 11. Part 3: Multiscale Model Predicting the Mechanical Properties after Hydrolytic Degradation. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Vieira, A.; Vieira, J.; Ferra, J.; Pestana, M.; Magalhães, F.D.; Guedes, R.M.; Marques, A.; Marques, A.T. Mechanical Study of PLA-PCL Fibers during in Vitro Degradation. J. Mech. Behav. Biomed. Mater. 2011, 4, 451–460. [Google Scholar] [CrossRef]

- Thomason, J. Glass Fibre Sizing: A Review. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Gagani, A.I.; Echtermeyer, A.T. Long-Term Hydrolytic Degradation of the Sizing-Rich Composite Interphase. Coatings 2019, 9, 263. [Google Scholar] [CrossRef]

- Plonka, R.; Mäder, E.; Gao, S.; Bellmann, C.; Dutschk, V.; Zhandarov, S. Adhesion of epoxy/glass fibre composites influenced by aging effects on sizings. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1207–1216. [Google Scholar] [CrossRef]

- Cuadri, A.; Martín-Alfonso, J. Thermal, thermo-oxidative and thermomechanical degradation of PLA: A comparative study based on rheological, chemical and thermal properties. Polym. Degrad. Stab. 2018, 150, 37–45. [Google Scholar] [CrossRef]

- Bahrololoumi, A.; Mohammadi, H.; Moravati, V.; Dargazany, R. A Physically-Based Model for Thermo-Oxidative and Hydrolytic Aging of Elastomers. Int. J. Mech. Sci. 2021, 194, 106193. [Google Scholar] [CrossRef]

- Gagliardi, M.; Lenarda, P.; Paggi, M. A reaction-diffusion formulation to simulate EVA polymer degradation in environmental and accelerated ageing conditions. Sol. Energy Mater. Sol. Cells 2017, 164, 93–106. [Google Scholar] [CrossRef]

- Mohammadi, H.; Morovati, V.; Korayem, A.E.; Poshtan, E.; Dargazany, R. Constitutive modeling of elastomers during photo- and thermo-oxidative aging. Polym. Degrad. Stab. 2021, 191, 109663. [Google Scholar] [CrossRef]

- Najmeddine, A.; Xu, Z.; Liu, G.; Croft, Z.L.; Liu, G.; Esker, A.R.; Shakiba, M. Physics and chemistry-based constitutive modeling of photo-oxidative aging in semi-crystalline polymers. Int. J. Solids Struct. 2022, 239–240, 111427. [Google Scholar] [CrossRef]

- Florea, M.; Brouwers, H. Chloride binding related to hydration products: Part I: Ordinary Portland Cement. Cem. Concr. Res. 2012, 42, 282–290. [Google Scholar] [CrossRef]

- Bensted, J.; Rbrough, A.; Page, M. 4—Chemical degradation of concrete. In Durability of Concrete and Cement Composites; Page, C., Page, M., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2007; pp. 86–135. [Google Scholar] [CrossRef]

- Sheridan, J.; Sonebi, M.; Taylor, S.; Amziane, S. The effect of long term weathering on hemp and rapeseed concrete. Cem. Concr. Res. 2020, 131, 106014. [Google Scholar] [CrossRef]

- Luccioni, B.; Figueroa, M.; Danesi, R. Thermo-mechanic model for concrete exposed to elevated temperatures. Eng. Struct. 2003, 25, 729–742. [Google Scholar] [CrossRef]

- Gasch, T.; Malm, R.; Ansell, A. A coupled hygro-thermo-mechanical model for concrete subjected to variable environmental conditions. Int. J. Solids Struct. 2016, 91, 143–156. [Google Scholar] [CrossRef]

- Hlobil, M.; Sotiriadis, K.; Hlobilová, A. Scaling of Strength in Hardened Cement Pastes - Unveiling the Role of Microstructural Defects and the Susceptibility of C-S-H Gel to Physical/Chemical Degradation by Multiscale Modeling. Cem. Concr. Res. 2022, 154, 106714. [Google Scholar] [CrossRef]

- Bažant, Z.P. Size effect. Int. J. Solids Struct. 2000, 37, 69–80. [Google Scholar] [CrossRef]

- Horstemeyer, M.F. Integrated Computational Materials Engineering (ICME) for Metals: Using Multiscale Modeling to Invigorate Engineering Design with Science; The Minerals, Metals & Materials Society; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Horstemeyer, M.F. Integrated Computational Materials Engineering (ICME) for Metals: Concepts and Case Studies; John Wiley & Sons, Inc.: New York, NY, USA, 2018. [Google Scholar]

- Hohenberg, P.; Kohn, W. Inhomogeneous Electron Gas. Phys. Rev. 1964, 136, B864–B871. [Google Scholar] [CrossRef]

- Kohn, W.; Sham, L.J. Self-Consistent Equations Including Exchange and Correlation Effects. Phys. Rev. 1965, 140, A1133–A1138. [Google Scholar] [CrossRef]

- Runge, E.; Gross, E.K.U. Density-Functional Theory for Time-Dependent Systems. Phys. Rev. Lett. 1984, 52, 997–1000. [Google Scholar] [CrossRef]

- Becke, A.D. Density-Functional Thermochemistry. I. The Effect of the Exchange-Only Gradient Correction. J. Chem. Phys. 1992, 96, 2155–2160. [Google Scholar] [CrossRef]

- Becke, A.D. Density-Functional Thermochemistry. III. The Role of Exact Exchange. J. Chem. Phys. 1993. [Google Scholar] [CrossRef]

- Arulmozhiraja, S.; Sato, T.; Yabe, A. Benzdiynes Revisited: Ab Initio and Density Functional Theory. J. Comput. Chem. 2001, 22, 923–930. [Google Scholar] [CrossRef]

- Geerlings, P.; Proft, F.D.; Proft, F.D.; Langenaeker, W.; Langenaeker, W. Conceptual Density Functional Theory. Chem. Rev. 2003, 103, 1793–1874. [Google Scholar] [CrossRef] [PubMed]

- Grimme, S.; Ehrlich, S.; Goerigk, L. Effect of the Damping Function in Dispersion Corrected Density Functional Theory. J. Comput. Chem. 2011, 32, 1456–1465. [Google Scholar] [CrossRef]

- Neugebauer, J.; Hickel, T. Density Functional Theory in Materials Science. Wiley Interdiscip. Rev. Comput. Mol. Sci. 2013, 3, 438–448. [Google Scholar] [CrossRef] [PubMed]

- Bassani, G.F.; Liedl, G.L.; Wyder, P. Encyclopedia of Condensed Matter Physics. MRS Bull. 2005, 31, 192–208. [Google Scholar] [CrossRef]

- Tewary, V.K.; Zhang, Y. Modeling, Characterization and Production of Nanomaterials; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar] [CrossRef]

- Omidvar, A.; Anafcheh, M.; Hadipour, N. Computational studies on carbon nanotube–graphene nanoribbon hybrids by density functional theory calculations. Sci. Iran 2013, 20, 1014–1017. [Google Scholar] [CrossRef]

- Barone, V.; Hod, O.; Peralta, J.E. Modeling of Quasi-One-Dimensional Carbon Nanostructures with Density Functional Theory. In Handbook of Computational Chemistry; Leszczynski, J., Ed.; Springer: Dordrecht, The Netherlands, 2016; pp. 1–41. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, B.; Cai, Y.; Dmitriev, S.V.; Li, S. Modelling of Low-dimensional Functional Nanomaterials. Phys. Status Solidi 2022, 16, 2100654. [Google Scholar] [CrossRef]

- Porezag, D.; Frauenheim, T.; Köhler, T.; Seifert, G.; Kaschner, R. Construction of tight-binding-like potentials on the basis of density-functional theory: Application to carbon. Phys. Rev. B 1995, 51, 12947–12957. [Google Scholar] [CrossRef] [PubMed]

- Hepburn, D.J.; Ackland, G.J. Metallic-covalent interatomic potential for carbon in iron. Phys. Rev. B 2008, 78, 165115. [Google Scholar] [CrossRef]

- Wu, Z.; Francis, M.F.; Curtin, W.A. Magnesium Interatomic Potential for Simulating Plasticity and Fracture Phenomena. Model. Simul. Mater. Sci. Eng. 2015, 23, 015004. [Google Scholar] [CrossRef]

- Åqvist, J.; Warshel, A. Simulation of Enzyme Reactions Using Valence Bond Force Fields and Other Hybrid Quantum/Classical Approaches. Chem. Rev. 1993, 93, 2523–2544. [Google Scholar] [CrossRef]

- Bentzien, J.; Muller, R.P.; Florián, J.; Warshel, A. Hybrid Ab Initio Quantum Mechanics/Molecular Mechanics Calculations of Free Energy Surfaces for Enzymatic Reactions: The Nucleophilic Attack in Subtilisin. J. Phys. Chem. B 1998, 102, 2293–2301. [Google Scholar] [CrossRef]

- Burykin, A.; Braun-Sand, S.; Warshel, A. Stochastic QM/MM Models for Proton Transport in Condensed Phase: An Empirical Valence Bond (EVB) Approach. In Proceedings of the Bulletin of the American Physical Society, Los Angeles, CA, USA, 21–25 March 2005. [Google Scholar]

- Marx, D.; Hutter, J. Ab Initio Molecular Dynamics: Theory and Implementation. Mod. Methods Algorithms Quantum Chem. 2000, 1, 301–449. [Google Scholar]

- Iftimie, R.; Minary, P.; Tuckerman, M.E. Ab Initio Molecular Dynamics: Concepts, Recent Developments, and Future Trends. Proc. Natl. Acad. Sci. USA 2005, 102, 6654–6659. [Google Scholar] [CrossRef] [PubMed]

- Hafner, J. Ab-initio Simulations of Materials Using VASP: Density-functional Theory and Beyond. ChemInform 2008, 29, 2044–2078. [Google Scholar] [CrossRef]

- Marx, D.; Hutter, J. Ab Initio Molecular Dynamics: Basic Theory and Advanced Methods; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar] [CrossRef]

- Fermi, E.; Pasta, P.; Ulam, S.; Tsingou, M. Studies on the Nonlinear Problems; Los Alamos National Laboratory (LANL): Los Alamos, NM, USA, 1955. [Google Scholar] [CrossRef]

- Zhang, X.; Nguyen, H.; Paci, J.T.; Sankaranarayanan, S.K.R.S.; Mendoza-Cortés, J.L.; Espinosa, H.D. Multi-Objective Parametrization of Interatomic Potentials for Large Deformation Pathways and Fracture of Two-Dimensional Materials. Npj Comput. Mater. 2021, 7, 113. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.S.; Harrison, J.A. A Reactive Potential for Hydrocarbons with Intermolecular Interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- van Duin, A.C.T.; Dasgupta, S.; Lorant, F.; Lorant, A.F.; Goddard, W.A.; Goddard, W.A. ReaxFF: A Reactive Force Field for Hydrocarbons. J. Phys. Chem. A 2001, 105, 9396–9409. [Google Scholar] [CrossRef]

- Büyüköztürk, O.; Buehler, M.J.; Lau, D.; Tuakta, C. Structural solution using molecular dynamics: Fundamentals and a case study of epoxy-silica interface. Int. J. Solids Struct. 2011, 48, 2131–2140. [Google Scholar] [CrossRef]

- Bell, G.I. Models for the Specific Adhesion of Cells to Cells. Science 1978, 200, 618–627. [Google Scholar] [CrossRef]

- Bell, G.I. Theoretical Models for the Specific Adhesion of Cells to Cells or to Surfaces. In Biological Growth and Spread; Springer: Berlin/Heidelberg, Germany, 1980; pp. 367–376. [Google Scholar] [CrossRef]

- Ackbarow, T.; Chen, X.; Keten, S.; Buehler, M.J. Hierarchies, multiple energy barriers, and robustness govern the fracture mechanics of α-helical and β-sheet protein domains. Proc. Natl. Acad. Sci. USA 2007, 104, 16410–16415. [Google Scholar] [CrossRef]

- Colombini, B.; Bagni, M.A.; Romano, G.; Cecchi, G. Characterization of actomyosin bond properties in intact skeletal muscle by force spectroscopy. Proc. Natl. Acad. Sci. USA 2007, 104, 9284–9289. [Google Scholar] [CrossRef]

- Zhao, H.; Caflisch, A. Molecular Dynamics in Drug Design. Eur. J. Med. Chem. 2015, 91, 4–14. [Google Scholar] [CrossRef]

- Vivo, M.D.; Masetti, M.; Bottegoni, G.; Cavalli, A.; Cavalli, A. Role of Molecular Dynamics and Related Methods in Drug Discovery. J. Med. Chem. 2016, 59, 4035–4061. [Google Scholar] [CrossRef]

- Karplus, M.; Petsko, G.A. Molecular Dynamics Simulations in Biology. Nature 1990, 347, 631–639. [Google Scholar] [CrossRef]

- Karplus, M. Molecular Dynamics Simulations of Biomolecules. Accounts Chem. Res. 2002, 9, 646–652. [Google Scholar] [CrossRef]

- Brodholt, J.P. Molecular dynamics simulations of aqueous NaCl solutions at high pressures and temperatures. Chem. Geol. 1998, 151, 11–19. [Google Scholar] [CrossRef]

- Horbach, J.; Kob, W.; Binder, K. Structural and Dynamical Properties of Sodium Silicate Melts: An Investigation by Molecular Dynamics Computer Simulation. Chem. Geol. 1999, 174, 87–101. [Google Scholar] [CrossRef]

- Ozboyaci, M.; Kokh, D.B.; Corni, S.; Wade, R.C. Modeling and simulation of protein–surface interactions: Achievements and challenges. Q. Rev. Biophys. 2016, 49. [Google Scholar] [CrossRef]

- Müller-Plathe, F. A Simple Nonequilibrium Molecular Dynamics Method for Calculating the Thermal Conductivity. J. Chem. Phys. 1997, 106, 6082–6085. [Google Scholar] [CrossRef]

- Wang, J.; Che, J.; Cagin, T.; Deng, W.Q.; Goddard, W.A. Thermal Conductivity of Diamond and Related Materials from Molecular Dynamics Simulations. J. Chem. Phys. 2000, 113, 6888–6900. [Google Scholar] [CrossRef]

- Greathouse, J.A.; Cygan, R.T.; Fredrich, J.T.; Jerauld, G. Molecular Dynamics Simulation of Diffusion and Electrical Conductivity in Montmorillonite Interlayers. J. Phys. Chem. C 2016, 120, 1640–1649. [Google Scholar] [CrossRef]

- Vu-Bac, N.; Bessa, M.A.; Rabczuk, T.; Liu, W.K. A Multiscale Model for the Quasi-Static Thermo-Plastic Behavior of Highly Cross-Linked Glassy Polymers. Macromolecules 2015, 48, 6713–6723. [Google Scholar] [CrossRef]

- Meng, Z.; Bessa, M.A.; Xia, W.; Liu, W.K.; Keten, S. Predicting the Macroscopic Fracture Energy of Epoxy Resins from Atomistic Molecular Simulations. Macromolecules 2016, 49, 9474–9483. [Google Scholar] [CrossRef]

- Maekawa, K.; Itoh, A. Friction and tool wear in nano-scale machining—A molecular dynamics approach. Wear 1995, 188, 115–122. [Google Scholar] [CrossRef]

- Wolf, D.; Yamakov, V.; Phillpot, S.; Mukherjee, A.; Gleiter, H. Deformation of nanocrystalline materials by molecular-dynamics simulation: Relationship to experiments? Acta Mater. 2005, 53, 1–40. [Google Scholar] [CrossRef]

- Griebel, M.; Hamaekers, J. Molecular dynamics simulations of the elastic moduli of polymer–carbon nanotube composites. Comput. Methods Appl. Mech. Eng. 2004, 193, 1773–1788. [Google Scholar] [CrossRef]

- Griebel, M.; Hamaekers, J.; Wildenhues, R. Molecular dynamics simulations of the influence of chemical cross-links on the elastic moduli of polymer-carbon nanotube composites. In Proceedings 1st Nanoc-Workshop; Sanchez, J., Ed.; LABEIN: Bilbao, Spain, 2005; Also as INS Preprint No. 0503; Available online: http://wissrech.ins.uni-bonn.de/research/pub/hamaekers/GrHaWiINSpreprint0503.pdf (accessed on 20 May 2024).

- Han, Y.; Elliott, J. Molecular dynamics simulations of the elastic properties of polymer/carbon nanotube composites. Comput. Mater. Sci. 2007, 39, 315–323. [Google Scholar] [CrossRef]

- Salnikov, V.; Choi, D.; Karamian-Surville, P. On Efficient and Reliable Stochastic Generation of RVEs for Analysis of Composites within the Framework of Homogenization. Comput. Mech. 2015, 55, 127–144. [Google Scholar] [CrossRef]

- Li, G.; Sharifpour, F.; Bahmani, A.; Montesano, J. A new approach to rapidly generate random periodic representative volume elements for microstructural assessment of high volume fraction composites. Mater. Des. 2018, 150, 124–138. [Google Scholar] [CrossRef]

- Vila-Chã, J.L.; Ferreira, B.P.; Pires, F.A. An adaptive multi-temperature isokinetic method for the RVE generation of particle reinforced heterogeneous materials, Part I: Theoretical formulation and computational framework. Mech. Mater. 2021, 163, 104069. [Google Scholar] [CrossRef]

- Wilson, E.A.; Vant, J.W.; Layton, J.; Boyd, R.; Lee, H.; Turilli, M.; Hernández, B.; Wilkinson, S.R.; Jha, S.; Gupta, C.; et al. Large-Scale Molecular Dynamics Simulations of Cellular Compartments. Methods Mol. Biol. 2021, 2302, 335–356. [Google Scholar] [CrossRef]

- Stoffels, M.T.; Staiger, M.P.; Bishop, C.M. Reduced interfacial adhesion in glass fibre-epoxy composites due to water absorption via molecular dynamics simulations. Compos. Part A Appl. Sci. Manuf. 2019, 118, 99–105. [Google Scholar] [CrossRef]

- Lik-ho Tam, L.H.; Wu, C. Molecular dynamics study on the effect of salt environment on interfacial structure, stress, and adhesion of carbon fiber/epoxy interface. Compos. Interfaces 2019, 26, 431–447. [Google Scholar] [CrossRef]

- Sun, Y.; Jin, Z.; Zhang, X.; Pang, B. Degradation of GFRP bars in alkaline environments: An experimental and molecular dynamics study. J. Build. Eng. 2023, 77, 107449. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, Z. Effects of Seawater Environment on the Degradation of GFRP Composites by Molecular Dynamics Method. Polymers 2022, 14, 2804. [Google Scholar] [CrossRef]

- Wang, X.Q.; Büyüköztürk, O.; Leung, C.K.; Lau, D. Atomistic prediction on the degradation of vinylester-based composite under chloride and elevated temperature. Compos. Sci. Technol. 2022, 226, 109539. [Google Scholar] [CrossRef]

- Rudd, R.E.; Broughton, J.Q. Coarse-grained molecular dynamics and the atomic limit of finite elements. Phys. Rev. B 1998, 58, R5893–R5896. [Google Scholar] [CrossRef]

- Hoogerbrugge, P.J.; Koelman, J.M.V.A. Simulating Microscopic Hydrodynamic Phenomena with Dissipative Particle Dynamics. Europhys. Lett. 1992, 19, 155. [Google Scholar] [CrossRef]

- Español, P. Hydrodynamics from dissipative particle dynamics. Phys. Rev. E 1995, 52, 1734–1742. [Google Scholar] [CrossRef]

- Groot, R.D.; Warren, P.B. Dissipative Particle Dynamics: Bridging the Gap between Atomistic and Mesoscopic Simulation. J. Chem. Phys. 1997, 107, 4423–4435. [Google Scholar] [CrossRef]

- Metropolis, N.; Rosenbluth, A.W.; Rosenbluth, M.N.; Teller, A.H.; Teller, E. Equation of state calculations by fast computing machines. J. Chem. Phys. 1953, 21, 1087–1092. [Google Scholar] [CrossRef]

- Raabe, D. Computational Materials Science: The Simulation of Materials Microstructures and Properties; Wiley VCH: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Schneider, L.; Müller, M. Multi-architecture Monte-Carlo (MC) simulation of soft coarse-grained polymeric materials: SOft coarse grained Monte-Carlo Acceleration (SOMA). Comput. Phys. Commun. 2019, 235, 463–476. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- der Giessen, E.V.; Needleman, A. Discrete dislocation plasticity: A simple planar model. Model. Simul. Mater. Sci. Eng. 1995, 3, 689. [Google Scholar] [CrossRef]

- Yefimov, S.; Groma, I.; van der Giessen, E. A comparison of a statistical-mechanics based plasticity model with discrete dislocation plasticity calculations. J. Mech. Phys. Solids 2004, 52, 279–300. [Google Scholar] [CrossRef]

- Tadmor, E.B.; Phillips, R.; Ortiz, M. Mixed Atomistic and Continuum Models of Deformation in Solids. Langmuir 1996, 12, 4529–4534. [Google Scholar] [CrossRef]

- Tadmor, E.B.; Ortiz, M.; Phillips, R. Quasicontinuum analysis of defects in solids. Philos. Mag. A 1996, 73, 1529–1563. [Google Scholar] [CrossRef]

- Knap, J.; Ortiz, M. An analysis of the quasicontinuum method. J. Mech. Phys. Solids 2001, 49, 1899–1923. [Google Scholar] [CrossRef]

- Kochmann, D.M.; Amelang, J.S. Multiscale Materials Modeling for Nanomechanics; Chapter The Quasicontinuum Method: Theory and Applications; Springer: Cham, Switzerland, 2016; pp. 159–193. [Google Scholar] [CrossRef]

- Bonet, J.; Wood, R.D. Nonlinear Continuum Mechanics for Finite Element Analysis; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Holzapfel, G.A. Nonlinear Solid Mechanics: A Continuum Approach for Engineering; John Wiley and Sons: London, UK, 2000. [Google Scholar]

- de Souza Neto, E.; Peric, D.; Owen, D. Computational Methods for Plasticity: Theory and Applications; Wiley: New York, NY, USA, 2008. [Google Scholar]

- Kachanov, L.M.; Krajčinović, D. Introduction to Continuum Damage Mechanics; Springer: Dordrecht, The Netherlands, 1986. [Google Scholar] [CrossRef]

- Orifici, A.; Herszberg, I.; Thomson, R. Review of methodologies for composite material modelling incorporating failure. Compos. Struct. 2008, 86, 194–210. [Google Scholar] [CrossRef]

- Kanouté, P.; Boso, D.P.; Chaboche, J.L.; Schrefler, B.A. Multiscale Methods for Composites: A Review. Arch. Comput. Methods Eng. 2009, 16, 31–75. [Google Scholar] [CrossRef]

- Soutis, C.; Beaumont, P.W.R. Multi-Scale Modelling of Composite Material Systems: The Art of Predictive Damage Modelling; Woodhead Publishing: Cambridge, UK, 2005. [Google Scholar] [CrossRef]

- Elmasry, A.; Azoti, W.; El-Safty, S.A.; Elmarakbi, A. A comparative review of multiscale models for effective properties of nano- and micro-composites. Prog. Mater. Sci. 2023, 132, 101022. [Google Scholar] [CrossRef]

- Zhao, X.; Ren, H.; Du, W.; Song, D.; Ouyang, Y.; Xu, W.; Liu, Y. Accelerated Ultraviolet Aging Behavior and Numerical Simulation of Ramie/Carbon Fiber Reinforced Polyethylene Terephthalate Glycol Hybrid Composites. Ind. Crop. Prod. 2023, 205, 117531. [Google Scholar] [CrossRef]

- Cusatis, G.; Rezakhani, R.; Alnaggar, M.; Zhou, X.; Pelessone, D. Multiscale computational models for the simulation of concrete materials and structures. In Computational Modelling of Concrete Structures, Proceedings of the EURO-C 2014, St. Anton Am Arlbert, Austria, 24–27 March 2014; Taylor and Francis—Balkema: New York, NY, USA, 2014; pp. 23–38. [Google Scholar] [CrossRef]

- Bangash, M.Y.H. Concrete and Concrete Structures: Numerical Modelling and Applications; Elsevier Applied Science: London, UK, 1989. [Google Scholar]

- Garboczi, E.; Bentz, D. Modelling of the microstructure and transport properties of concrete. Constr. Build. Mater. 1996, 10, 293–300. [Google Scholar] [CrossRef]

- Thilakarathna, P.; Kristombu Baduge, K.; Mendis, P.; Vimonsatit, V.; Lee, H. Mesoscale modelling of concrete—A review of geometry generation, placing algorithms, constitutive relations and applications. Eng. Fract. Mech. 2020, 231, 106974. [Google Scholar] [CrossRef]

- Oñate, E. Sructural Analysis with the Finite Element Method: Vol. 1; Springer: New York, NY, USA, 2009. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method: Vol. 1; McGraw-Hill Book Company: New York, NY, USA, 1994. [Google Scholar]

- Belytschko, T.; Krongauz, Y.; Organ, D.; Fleming, M.; Krysl, P. Meshless methods: An overview and recent developments. Comput. Methods Appl. Mech. Eng. 1996, 139, 3–47. [Google Scholar] [CrossRef]

- Wang, H.; Qin, Q.H. Chapter 1—Overview of meshless methods. In Methods of Fundamental Solutions in Solid Mechanics; Wang, H., Qin, Q.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–51. [Google Scholar] [CrossRef]

- Berger, M.J.; Oliger, J. Adaptive mesh refinement for hyperbolic partial differential equations. J. Comput. Phys. 1984, 53, 484–512. [Google Scholar] [CrossRef]

- Plewa, T.; Linde, T.; Linde, T.; Weirs, V.G.; Weirs, V.G.; Plewa, T. Adaptive Mesh Refinement—Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Liu, F.; Hager, W.W.; Rao, A.V. Adaptive mesh refinement method for optimal control using nonsmoothness detection and mesh size reduction. J. Frankl. Inst. 2015, 352, 4081–4106. [Google Scholar] [CrossRef]

- Geers, M.; Kouznetsova, V.; Brekelmans, W. Multi-scale computational homogenization: Trends and challenges. J. Comput. Appl. Math. 2010, 234, 2175–2182. [Google Scholar] [CrossRef]

- Geers, M.G.D.; Kouznetsova, V.G.; Matouš, K.; Yvonnet, J. Homogenization Methods and Multiscale Modeling: Nonlinear Problems. In Encyclopedia of Computational Mechanics Second Edition; John Wiley & Sons, Ltd.: London, UK, 2017; pp. 1–34. [Google Scholar] [CrossRef]

- Gooneie, A.; Schuschnigg, S.; Holzer, C. A Review of Multiscale Computational Methods in Polymeric Materials. Polymers 2017, 9, 16. [Google Scholar] [CrossRef]

- Abraham, F.F.; Broughton, J.Q.; Bernstein, N.; Kaxiras, E. Spanning the length scales in dynamic simulation. Comput. Phys. 1998, 12, 538–546. [Google Scholar] [CrossRef]

- Tong, Q.; Li, S. A concurrent multiscale study of dynamic fracture. Comput. Methods Appl. Mech. Eng. 2020, 366, 113075. [Google Scholar] [CrossRef]

- Chan, T.; Li, Z.; Yu, Y.; Sun, Z. Concurrent multi-scale modeling of civil infrastructures for analyses on structural deteriorating—Part II: Model updating and verification. Finite Elem. Anal. Des. 2009, 45, 795–805. [Google Scholar] [CrossRef]

- Silani, M.; Ziaei-Rad, S.; Talebi, H.; Rabczuk, T. A semi-concurrent multiscale approach for modeling damage in nanocomposites. Theor. Appl. Fract. Mech. 2014, 74, 30–38. [Google Scholar] [CrossRef]

- Lu, G.; Tadmor, E.B.; Kaxiras, E. From electrons to finite elements: A concurrent multiscale approach for metals. Phys. Rev. B 2006, 73, 024108. [Google Scholar] [CrossRef]

- Hill, R. Elastic properties of reinforced solids: Some theoretical principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Willis, J. Bounds and self-consistent estimates for the overall properties of anisotropic composites. J. Mech. Phys. Solids 1977, 25, 185–202. [Google Scholar] [CrossRef]

- Verhoosel, C.V.; Remmers, J.J.C.; Gutiérrez, M.A.; de Borst, R. Computational homogenization for adhesive and cohesive failure in quasi-brittle solids. Int. J. Numer. Methods Eng. 2010, 83, 1155–1179. [Google Scholar] [CrossRef]

- Nguyen, V.P.; Lloberas-Valls, O.; Stroeven, M.; Sluys, L.J. Computational homogenization for multiscale crack modeling. Implementational and computational aspects. Int. J. Numer. Methods Eng. 2012, 89, 192–226. [Google Scholar] [CrossRef]

- Temizer, I.; Wriggers, P. A multiscale contact homogenization technique for the modeling of third bodies in the contact interface. Comput. Methods Appl. Mech. Eng. 2008, 198, 377–396. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Wriggers, P. Computational homogenization of rubber friction on rough rigid surfaces. Comput. Mater. Sci. 2013, 77, 264–280. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.; Bieler, T.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Vieira de Carvalho, M.; Cardoso Coelho, R.P.; Pires, F.M.A. On the computational treatment of fully coupled crystal plasticity slip and martensitic transformation constitutive models at finite strains. Int. J. Numer. Methods Eng. 2022, 123, 5155–5200. [Google Scholar] [CrossRef]

- Özdemir, I.; Brekelmans, W.A.M.; Geers, M.G.D. Computational homogenization for heat conduction in heterogeneous solids. Int. J. Numer. Methods Eng. 2008, 73, 185–204. [Google Scholar] [CrossRef]

- Ferreira, B.P. Towards Data-Driven Multi-Scale Optimization of Thermoplastic Blends: Microstructural Generation, Constitutive Development and Clustering-Based Reduced-Order Modeling. Ph.D. Thesis, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, 2022. Available online: https://hdl.handle.net/10216/146900 (accessed on 23 December 2023).

- Kouznetsova, V.; Geers, M.; Brekelmans, W. Multi-scale second-order computational homogenization of multi-phase materials: A nested finite element solution strategy. Comput. Methods Appl. Mech. Eng. 2004, 193, 5525–5550. [Google Scholar] [CrossRef]

- Kaczmarczyk, Ł.; Pearce, C.J.; Bićanić, N. Scale transition and enforcement of RVE boundary conditions in second-order computational homogenization. Int. J. Numer. Methods Eng. 2008, 74, 506–522. [Google Scholar] [CrossRef]

- Yi, Y.M.; Park, S.H.; Youn, S.K. Asymptotic homogenization of viscoelastic composites with periodic microstructures. Int. J. Solids Struct. 1998, 35, 2039–2055. [Google Scholar] [CrossRef]

- Andrianov, I.V.; Bolshakov, V.I.; Danishevs’kyy, V.V.; Weichert, D. Higher order asymptotic homogenization and wave propagation in periodic composite materials. Proc. R. Soc. A Math. Phys. Eng. Sci. 2008, 464, 1181–1201. [Google Scholar] [CrossRef]

- Kalamkarov, A.L.; Andrianov, I.V.; Danishevs’kyy, V.V. Asymptotic Homogenization of Composite Materials and Structures. Appl. Mech. Rev. 2009, 62, 030802. [Google Scholar] [CrossRef]

- Arbabi, H.; Bunder, J.; Samaey, G.; Roberts, A.J.; Kevrekidis, I.G. Linking Machine Learning with Multiscale Numerics: Data-Driven Discovery of Homogenized Equations. JOM 2020, 72, 4444–4457. [Google Scholar] [CrossRef]

- Xu, R.; Yang, J.; Yan, W.; Huang, Q.; Giunta, G.; Belouettar, S.; Zahrouni, H.; Zineb, T.B.; Hu, H. Data-driven multiscale finite element method: From concurrence to separation. Comput. Methods Appl. Mech. Eng. 2020, 363, 112893. [Google Scholar] [CrossRef]

- Bessa, M.; Bostanabad, R.; Liu, Z.; Hu, A.; Apley, D.W.; Brinson, C.; Chen, W.; Liu, W. A framework for data-driven analysis of materials under uncertainty: Countering the curse of dimensionality. Comput. Methods Appl. Mech. Eng. 2017, 320, 633–667. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Matouš, K. A nonlinear data-driven reduced order model for computational homogenization with physics/pattern-guided sampling. Comput. Methods Appl. Mech. Eng. 2020, 359, 112657. [Google Scholar] [CrossRef]

- Wulfinghoff, S. Statistically compatible hyper-reduction for computational homogenization. Comput. Methods Appl. Mech. Eng. 2024, 420, 116744. [Google Scholar] [CrossRef]

- Yvonnet, J.; He, Q.C. The reduced model multiscale method (R3M) for the non-linear homogenization of hyperelastic media at finite strains. J. Comput. Phys. 2007, 223, 341–368. [Google Scholar] [CrossRef]

- Hernández, J.; Oliver, J.; Huespe, A.; Caicedo, M.; Cante, J. High-performance model reduction techniques in computational multiscale homogenization. Comput. Methods Appl. Mech. Eng. 2014, 276, 149–189. [Google Scholar] [CrossRef]

- Soldner, D.; Brands, B.; Zabihyan, R.; Steinmann, P.; Mergheim, J. A numerical study of different projection-based model reduction techniques applied to computational homogenisation. Comput. Mech. 2017, 60, 613–625. [Google Scholar] [CrossRef] [PubMed]

- Fritzen, F.; Kunc, O. Two-stage data-driven homogenization for nonlinear solids using a reduced order model. Eur. J. Mech.—A/Solids 2018, 69, 201–220. [Google Scholar] [CrossRef]

- Dvorak, G.J. Transformation Field Analysis of Inelastic Composite Materials. Proc. Math. Phys. Sci. 1992, 437, 311–327. [Google Scholar]

- Michel, J.; Suquet, P. Nonuniform transformation field analysis. Int. J. Solids Struct. 2003, 40, 6937–6955. [Google Scholar] [CrossRef]

- Michel, J.C.; Suquet, P. Non-Uniform Transformation Field Analysis: A Reduced Model for Multiscale Non-Linear Problems in Solid Mechanics. In Multiscale Modeling in Solid Mechanics: Computational Approaches; World Scientific Publishing Company: Singapore, 2009; pp. 159–206. [Google Scholar] [CrossRef]

- van Tuijl, R.A.; Harnish, C.; Matouš, K.; Remmers, J.J.C.; Geers, M.G.D. Wavelet based reduced order models for microstructural analyses. Comput. Mech. 2019, 63, 535–554. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Matouš, K. A nonlinear manifold-based reduced order model for multiscale analysis of heterogeneous hyperelastic materials. J. Comput. Phys. 2016, 313, 635–653. [Google Scholar] [CrossRef]

- Lu, X.; Giovanis, D.G.; Yvonnet, J.; Papadopoulos, V.; Detrez, F.; Bai, J. A data-driven computational homogenization method based on neural networks for the nonlinear anisotropic electrical response of graphene/polymer nanocomposites. Comput. Mech. 2019, 64, 307–321. [Google Scholar] [CrossRef]

- Minh Nguyen-Thanh, V.; Trong Khiem Nguyen, L.; Rabczuk, T.; Zhuang, X. A surrogate model for computational homogenization of elastostatics at finite strain using high-dimensional model representation-based neural network. Int. J. Numer. Methods Eng. 2020, 121, 4811–4842. [Google Scholar] [CrossRef]

- Liu, B.; Lu, W. Surrogate models in machine learning for computational stochastic multi-scale modelling in composite materials design. Int. J. Hydromechatronics 2022, 5, 336–365. [Google Scholar] [CrossRef]

- Rocha, I.; Kerfriden, P.; van der Meer, F. Machine learning of evolving physics-based material models for multiscale solid mechanics. Mech. Mater. 2023, 184, 104707. [Google Scholar] [CrossRef]

- Maia, M.; Rocha, I.; Kerfriden, P.; van der Meer, F. Physically recurrent neural networks for path-dependent heterogeneous materials: Embedding constitutive models in a data-driven surrogate. Comput. Methods Appl. Mech. Eng. 2023, 407, 115934. [Google Scholar] [CrossRef]

- Miehe, C.; Bayreuther, C.G. On multiscale FE analyses of heterogeneous structures: From homogenization to multigrid solvers. Int. J. Numer. Methods Eng. 2007, 71, 1135–1180. [Google Scholar] [CrossRef]

- Plews, J.; Duarte, C. Bridging multiple structural scales with a generalized finite element method. Int. J. Numer. Methods Eng. 2015, 102, 180–201. [Google Scholar] [CrossRef]

- Lin, H.; Lv, L.; Jin, T. Investigation on the Influences of Hygrothermal Aging on the Indentation Size Effects and Micro-Indentation Measurements of PMMA. Part I: Experimental Results. Appl. Sci. 2020, 10, 5454. [Google Scholar] [CrossRef]

- Lin, H.; Lv, L.; Jin, T.; Yin, Q. Investigation on the influences of hygrothermal aging on the indentation size effects and micro-indentation measurements of PMMA. Part II: Analysis and modeling. Polym. Test. 2021, 93, 106938. [Google Scholar] [CrossRef]

- Ghabezi, P.; Harrison, N.M. Indentation characterization of glass/epoxy and carbon/epoxy composite samples aged in artificial salt water at elevated temperature. Polym. Test. 2022, 110, 107588. [Google Scholar] [CrossRef]

- Krauklis, A.E. Predicting Environmental Ageing of Composites: Modular Approach and Multiscale Modelling. Mater. Proc. 2021, 6, 11. [Google Scholar] [CrossRef]

- Lévêque, D.; Schieffer, A.; Mavel, A.; Maire, J.F. Analysis of How Thermal Aging Affects the Long-Term Mechanical Behavior and Strength of Polymer–Matrix Composites. Compos. Sci. Technol. 2005, 65, 395–401. [Google Scholar] [CrossRef]

- Kojic, M.; Milosevic, M.; Kojic, N.; Kim, K.; Ferrari, M.; Ziemys, A. A Multiscale MD–FE Model of Diffusion in Composite Media with Internal Surface Interaction Based on Numerical Homogenization Procedure. Comput. Methods Appl. Mech. Eng. 2014, 269, 123–138. [Google Scholar] [CrossRef] [PubMed]

- Obeid, H.; Clément, A.; Fréour, S.; Jacquemin, F.; Casari, P. On the Identification of the Coefficient of Moisture Expansion of Polyamide-6: Accounting Differential Swelling Strains and Plasticization. Mech. Mater. 2018, 118, 1–10. [Google Scholar] [CrossRef]

- Riaño, L.; Chailan, J.F.; Joliff, Y. Evolution of Effective Mechanical and Interphase Properties during Natural Ageing of Glass-Fibre/Epoxy Composites Using Micromechanical Approach. Compos. Struct. 2021, 258, 113399. [Google Scholar] [CrossRef]

- Ghabezi, P.; Harrison, N. Multi-Scale Modelling and Life Prediction of Aged Composite Materials in Salt Water. J. Reinf. Plast. Compos. 2023, 43, 073168442311601. [Google Scholar] [CrossRef]

- Ullah, Z.; Kaczmarczyk, Ł.; Grammatikos, S.A.; Evernden, M.C.; Pearce, C.J. Multi-Scale Computational Homogenisation to Predict the Long-Term Durability of Composite Structures. Comput. Struct. 2017, 181, 21–31. [Google Scholar] [CrossRef]

- Rocha, I.B.C.M.; van der Meer, F.P.; Raijmaekers, S.; Lahuerta, F.; Nijssen, R.P.L.; Mikkelsen, L.P.; Sluys, L.J. A Combined Experimental/Numerical Investigation on Hygrothermal Aging of Fiber-Reinforced Composites. Eur. J. Mech.—A/Solids 2019, 73, 407–419. [Google Scholar] [CrossRef]

- Guo, F.L.; Huang, P.; Li, Y.Q.; Hu, N.; Fu, S.Y. Multiscale Modeling of Mechanical Behaviors of Carbon Fiber Reinforced Epoxy Composites Subjected to Hygrothermal Aging. Compos. Struct. 2021, 256, 113098. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Ran, Z.; Liu, Y. A new method for generating random fibre distributions for fibre reinforced composites. Compos. Sci. Technol. 2013, 76, 14–20. [Google Scholar] [CrossRef]

- Upadhyaya, P.; Singh, S.; Roy, S. A Mechanism-Based Multi-Scale Model for Predicting Thermo-Oxidative Degradation in High Temperature Polymer Matrix Composites. Compos. Sci. Technol. 2011, 71, 1309–1315. [Google Scholar] [CrossRef]

- Shi, B.; Zhang, M.; Liu, S.; Sun, B.; Gu, B. Multi-Scale Ageing Mechanisms of 3D Four Directional and Five Directional Braided Composites’ Impact Fracture Behaviors under Thermo-Oxidative Environment. Int. J. Mech. Sci. 2019, 155, 50–65. [Google Scholar] [CrossRef]

- Cao, M.; Gao, X.; Tang, B.; Dai, Z.; Li, H.; Yi, J. Multiscale Thermal Oxidative Ageing Mechanisms of Carbon Fiber/Epoxy Plain Woven Composites under Short Beam Shear Loading. Thin-Walled Struct. 2023, 185, 110566. [Google Scholar] [CrossRef]

- Honorio, T.; Bary, B.; Benboudjema, F. Multiscale Estimation of Ageing Viscoelastic Properties of Cement-Based Materials: A Combined Analytical and Numerical Approach to Estimate the Behaviour at Early Age. Cem. Concr. Res. 2016, 85, 137–155. [Google Scholar] [CrossRef]

- Liu, M.; Qiao, P.; Sun, L. Dependence of Chloride Ion Diffusivity on Evolution of Pore-Structures in Freeze-Thawed Shotcrete: Multiscale Characterization and Modeling. Cem. Concr. Compos. 2021, 123, 104222. [Google Scholar] [CrossRef]

- Mou, X.; Wang, Y.; Lu, S.; Bao, J.; Zhang, P.; Zhang, J. Prediction of Effective Chloride Diffusion Coefficient of Recycled Aggregate Concrete Based on Multiscale Analysis. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2023, 40, 2876–2884. [Google Scholar] [CrossRef]

- Sýkora, J.; Krejčí, T.; Kruis, J.; Šejnoha, M. Computational Homogenization of Non-Stationary Transport Processes in Masonry Structures. J. Comput. Appl. Math. 2012, 236, 4745–4755. [Google Scholar] [CrossRef]

- Castellazzi, G.; Colla, C.; de Miranda, S.; Formica, G.; Gabrielli, E.; Molari, L.; Ubertini, F. A Coupled Multiphase Model for Hygrothermal Analysis of Masonry Structures and Prediction of Stress Induced by Salt Crystallization. Constr. Build. Mater. 2013, 41, 717–731. [Google Scholar] [CrossRef]

- Castellazzi, G.; de Miranda, S.; Formica, G.; Molari, L.; Ubertini, F. Coupled Hygro-Mechanical Multiscale Analysis of Masonry Walls. Eng. Struct. 2015, 84, 266–278. [Google Scholar] [CrossRef]

- de Miranda, S.; D’Altri, A.M.; Castellazzi, G. Modeling Environmental Ageing in Masonry Strengthened with Composites. Eng. Struct. 2019, 201, 109773. [Google Scholar] [CrossRef]

- Grementieri, L.; Daghia, F.; Molari, L.; Castellazzi, G.; Derluyn, H.; Cnudde, V.; de Miranda, S. A Multi-Scale Approach for the Analysis of the Mechanical Effects of Salt Crystallisation in Porous Media. Int. J. Solids Struct. 2017, 126–127, 225–239. [Google Scholar] [CrossRef]

- Grementieri, L.; Molari, L.; Derluyn, H.; Desarnaud, J.; Cnudde, V.; Shahidzadeh, N.; de Miranda, S. Numerical Simulation of Salt Transport and Crystallization in Drying Prague Sandstone Using an Experimentally Consistent Multiphase Model. Build. Environ. 2017, 123, 289–298. [Google Scholar] [CrossRef]

- Al Mahmud, M.Z. Exploring the versatile applications of biocomposites in the medical field. Bioprinting 2023, 36, e00319. [Google Scholar] [CrossRef]

- Hasnain, M.S.; Nayak, A.K. 7—Nanocomposites for improved orthopedic and bone tissue engineering applications. In Applications of Nanocomposite Materials in Orthopedics; Inamuddin Asiri, A.M., Mohammad, A., Eds.; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Cambridge, UK, 2019; pp. 145–177. [Google Scholar] [CrossRef]

| Ageing Condition | ILSS (MPa) (Error) | |

|---|---|---|

| AHCl | 79.87 (2.65%) | |

| AHC2 | 75.74 (3.88 %) | |

| AHC3/4 | 70.61 (1.29%) |

| Flexural Modulus (After 28 Days of UV Ageing) (GPa) | ||

|---|---|---|

| EXP | FEM (error) | |

| 4.4 | 3.9 (11%) | |

| 11.4 | 11.1 (2.6%) | |

| 26.7 | 26.4 (1.1%) | |

| 12.4 | 12.9 (4%) | |

| 23.5 | 23.7 (0.9%) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira Rocha, P.R.; Fonseca Gonçalves, G.; dos Reis, G.; Guedes, R.M. Mechanisms of Component Degradation and Multi-Scale Strategies for Predicting Composite Durability: Present and Future Perspectives. J. Compos. Sci. 2024, 8, 204. https://doi.org/10.3390/jcs8060204

Ferreira Rocha PR, Fonseca Gonçalves G, dos Reis G, Guedes RM. Mechanisms of Component Degradation and Multi-Scale Strategies for Predicting Composite Durability: Present and Future Perspectives. Journal of Composites Science. 2024; 8(6):204. https://doi.org/10.3390/jcs8060204

Chicago/Turabian StyleFerreira Rocha, Paulo Ricardo, Guilherme Fonseca Gonçalves, Guillaume dos Reis, and Rui Miranda Guedes. 2024. "Mechanisms of Component Degradation and Multi-Scale Strategies for Predicting Composite Durability: Present and Future Perspectives" Journal of Composites Science 8, no. 6: 204. https://doi.org/10.3390/jcs8060204