Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review

Abstract

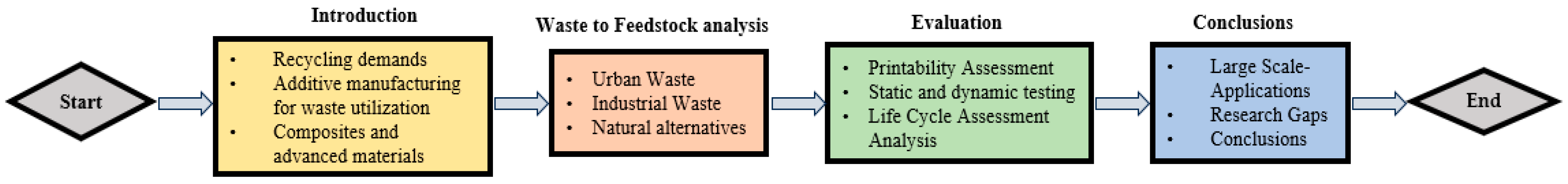

:1. Introduction

2. Recycled Materials and the Introduction of Them in Additive Manufacturing

2.1. Plastics, Polymeric Blends and Polymeric Composites as 3D Printing Raw Material

2.1.1. Urban Polymeric Waste

2.1.2. Industrial Polymeric Waste

2.1.3. Natural Polymers as an Alternative Solution (PLA)

2.1.4. Overview of the Recycling Process of Polymers

2.2. Metal Alloys or Metallic Composites

2.3. Ceramics

3. Evaluation of Recycled Materials Regarding Additive Manufacturing Processes

3.1. Developing Printable Feedstocks, Material Characterization and Optimizing Printing Conditions

3.1.1. Additive Manufacturing of Polymers

3.1.2. Metal Additive Manufacturing

3.1.3. Additive Manufacturing of Ceramics

3.2. Static Analysis, Impact Analysis and Dynamic Mechanical Analysis

3.2.1. Static Mechanical Analysis

3.2.2. Impact Behavior and Dynamic Mechanical Analysis

3.3. Life Cycle Assessment Analysis

4. Large Scale Additive Manufacturing and Possible Future Applications

5. Research Gaps and Solutions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rashid, A.A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Gregory, T. Circular Claims Fall Flat Again—Greenpeace USA. Available online: https://www.greenpeace.org/usa/reports/circular-claims-fall-flat-again/ (accessed on 12 January 2024).

- A UN Treaty to End Plastic Pollution. Available online: https://www.ellenmacarthurfoundation.org/a-un-treaty-to-end-plastic-pollution (accessed on 12 January 2024).

- Circular Economy & SDGs. Available online: https://circulareconomy.europa.eu/platform/sites/default/files/3228_brochure_sdg_-_hch_cmyk_a4_portrait_-_0520-012.pdf (accessed on 10 May 2024).

- Reusable VS Single-Use Packaging: A Review of Environmental Impact—Zero Waste Europe. Available online: https://zerowasteeurope.eu/library/reusable-vs-single-use-packaging-a-review-of-environmental-impact/ (accessed on 12 January 2024).

- Lodha, S.; Song, B.; Park, S.; Choi, H.-J.; Lee, S.W.; Park, H.W.; Choi, S.-K. Sustainable 3D Printing with Recycled Materials: A Review. J. Mech. Sci. Technol. 2023, 37, 5481–5507. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Liter-ature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of Materials and Environmental Perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A Review on Additive Manufacturing of Polymer-Fiber Composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Sanchez-Rexach, E.; Johnston, T.G.; Jehanno, C.; Sardón, H.; Nelson, A. Sustainable Materials and Chemical Processes for Additive Manufacturing. Chem. Mater. 2020, 32, 7105–7119. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Y. 3D-Printed Soft Wearable Electronics: Techniques, Materials, and Applications. In Additive Manufacturing; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–49. [Google Scholar]

- Kladovasilakis, N.; Tsongas, K.; Karalekas, D.; Tzetzis, D. Architected Materials for Additive Manufacturing: A Comprehensive Review. Materials 2022, 15, 5919. [Google Scholar] [CrossRef] [PubMed]

- Wen, C. Metallic Biomaterials Processing and Medical Device Manufacturing; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Bian, L.; Shamsaei, N.; Usher, J. Laser-Based Additive Manufacturing of Metal Parts, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal Powders in Additive Manufacturing: A Review on Reusability and Recyclability of Common Titanium, Nickel and Aluminum Alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Powell, D.; Rennie, A.; Geekie, L.; Burns, N.H. Understanding Powder Degradation in Metal Additive Manufacturing to Allow the Upcycling of Recycled Powders. J. Clean. Prod. 2020, 268, 122077. [Google Scholar] [CrossRef]

- Tadi, S.P.; Maddula, S.S.; Sankar, M.R. Sustainability Aspects of Composite Filament Fabrication for 3D Printing Applications. Renew. Sustain. Energy Rev. 2024, 189, 113961. [Google Scholar] [CrossRef]

- Jang, S.; Park, S.; Bae, C. Development of Ceramic Additive Manufacturing: Process and Materials Technology. Biomed. Eng. Lett. 2020, 10, 493–503. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Guillemot, G.; Gandin, C.; Bellet, M. Three-Dimensional Finite Element Thermomechanical Modeling of Additive Manufacturing by Selective Laser Melting for Ceramic Materials. Addit. Manuf. 2017, 16, 124–137. [Google Scholar] [CrossRef]

- Bae, C.; Halloran, J.W. A Segregation Model Study of Suspension-Based Additive Manufacturing. J. Eur. Ceram. Soc. 2018, 38, 5160–5166. [Google Scholar] [CrossRef]

- Bae, C.; Ramachandran, A.; Halloran, J.W. Quantifying Particle Segregation in Sequential Layers Fabricated by Additive Manufacturing. J. Eur. Ceram. Soc. 2018, 38, 4082–4088. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A Review: Natural Fiber Composites Selection in View of Mechanical, Light Weight, and Economic Properties. Macromol. Mater. Eng. 2014, 300, 10–24. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer Composite. Adv. Mater. Technol. 2018, 4, 1800271. [Google Scholar] [CrossRef]

- Yuan, S.; Li, S.Y.; Zhu, J.; Tang, Y. Additive Manufacturing of Polymeric Composites from Material Processing to Structural Design. Compos. Part B Eng. 2021, 219, 108903. [Google Scholar] [CrossRef]

- Ayre, D. Technology Advancing Polymers and Polymer Composites towards Sustainability: A Review. Curr. Opin. Green Sustain. Chem. 2018, 13, 108–112. [Google Scholar] [CrossRef]

- Sola, A.; Trinchi, A. Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication. Polymers 2023, 15, 4219. [Google Scholar] [CrossRef]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Circular Economy Innovation: A Deep Investigation on 3D Printing of Industrial Waste Polypropylene and Carbon Fibre Composites. Resour. Conserv. Recycl. 2024, 206, 107667. [Google Scholar] [CrossRef]

- Sealy, C. Thermoplastic Waste Recycled into Useful Composite. Mater. Today 2023, 69, 4–6. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.G.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Faraca, G.; Astrup, T.F. Plastic Waste from Recycling Centres: Characterisation and Evaluation of Plastic Recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Di Bartolo, A.; Dintcheva, N.T. Matrix and Filler Recycling of Carbon and Glass Fiber-Reinforced Polymer Composites: A Review. Polymers 2021, 13, 3817. [Google Scholar] [CrossRef] [PubMed]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef] [PubMed]

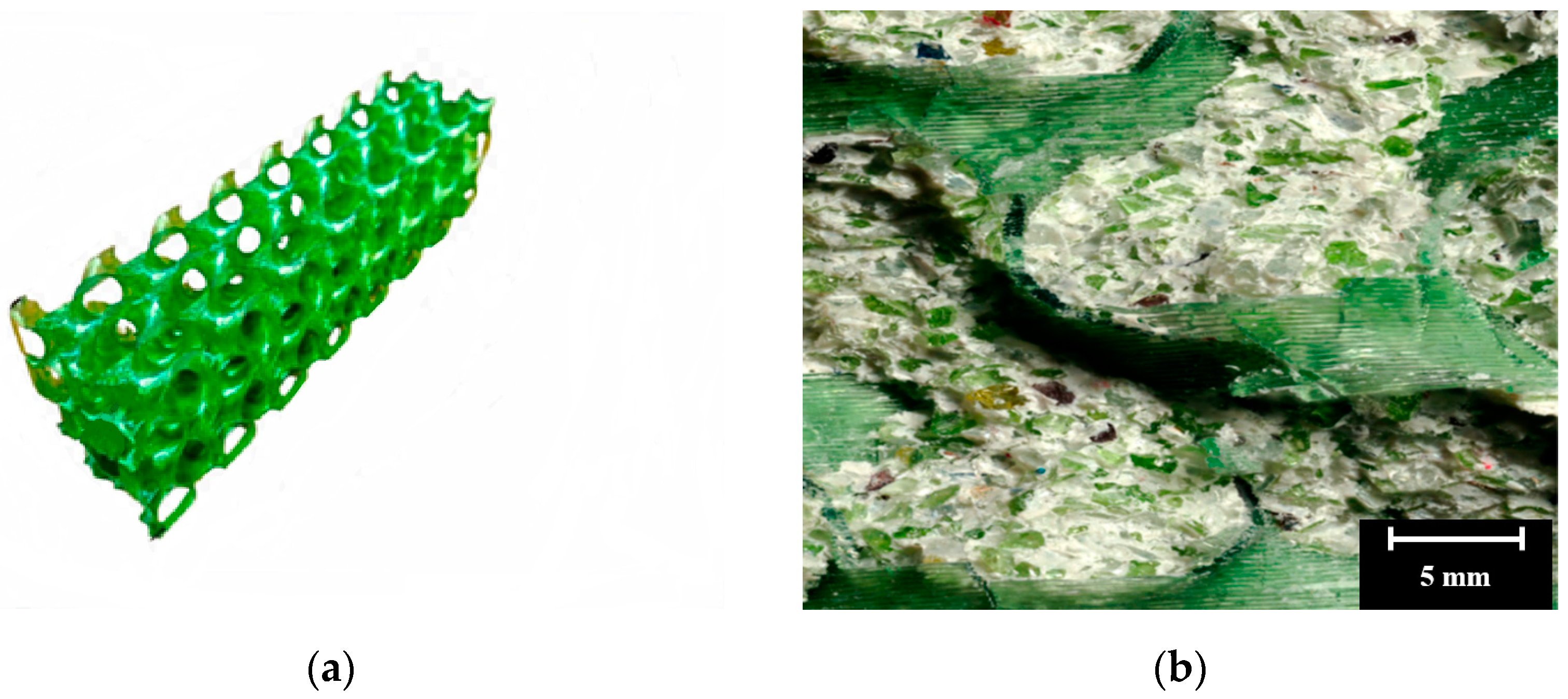

- Rusu, M.; Bâlc, N.; Moldovan, M.; Cuc, S.; Petean, I.; Cosma, C.; Leordean, D. Recycled PET Composites Reinforced with Stainless Steel Lattice Structures Made by AM. Polymers 2023, 15, 4591. [Google Scholar] [CrossRef] [PubMed]

- Strano, M.; Farioli, D.; Di Landro, L.; Mussi, V. Printability of Recycled Feedstock for Extrusion Additive Manufacturing. Adv. Mater. Process. Technol. 2023, 1–26. [Google Scholar] [CrossRef]

- Ror, C.K.; Negi, S.; Mishra, V. Development and Characterization of Sustainable 3D Printing Filaments Using Post-Consumer Recycled PET: Processing and Characterization. J. Polym. Res. 2023, 30, 350. [Google Scholar] [CrossRef]

- Seibert, M.B.; Capote, G.A.M.; Gruber, M.; Volk, W.; Osswald, T.A. Manufacturing of a PET Filament from Recycled Material for Material Extrusion (MEX). Recycling 2022, 7, 69. [Google Scholar] [CrossRef]

- Rashwan, O.; Koroneos, Z.; Townsend, T.G.; Caputo, M.; Bylone, R.J.; Wodrig, B.; Cantor, K. Extrusion and Characterization of Recycled Polyethylene Terephthalate (rPET) Filaments Compounded with Chain Extender and Impact Modifiers for Material-Extrusion Additive Manufacturing. Sci. Rep. 2023, 13, 16041. [Google Scholar] [CrossRef]

- Katalagarianakis, A.; Van De Voorde, B.; Pien, N.; Polyzos, E.; Đuretek, I.; Holzer, C.; Cardon, L.; Bernaerts, K.V.; Van Hemelrijck, D.; Van Vlierberghe, S.; et al. The Effect of Carbon Fiber Content on Physico-Mechanical Properties of Recycled Poly(Ethylene Terephthalate) Composites Additively Manufactured with Fused Filament Fabrication. Addit. Manuf. 2022, 60, 103246. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Grammatikos, S.; Porfyrakis, E.; Maniadi, A.; Mountakis, N. Sustainable Additive Manufacturing: Mechanical Response of Polyethylene Terephthalate Glycol over Multiple Recycling Processes. Materials 2021, 14, 1162. [Google Scholar] [CrossRef] [PubMed]

- Patra, N.R.; Negi, Y.S. Thermal, Structural, and Rheological Modifications in Recycled Polyethylene Terephthalate for a Sustainable Alternative Source for Additive Manufacturing. Polym. Eng. Sci. 2022, 62, 2486–2497. [Google Scholar] [CrossRef]

- Hossain, I.; Chowdhury, M.A.; Zahid, S.; Sakib-Uz-Zaman, C.; Rahaman, M.L.; Kowser, M.A. Development and Analysis of Nanoparticle Infused Plastic Products Manufactured by Machine Learning Guided 3D Printer. Polym. Test. 2022, 106, 107429. [Google Scholar] [CrossRef]

- Borkar, A.; Hendlmeier, A.; Simon, Ž.; Randall, J.D.; Stojcevski, F.; Henderson, L.C. A Comparison of Mechanical Properties of Recycled High-density Polyethylene/Waste Carbon Fiber via Injection Molding and 3D Printing. Polym. Compos. 2022, 43, 2408–2418. [Google Scholar] [CrossRef]

- González, C.; Sanchez, F.A.C.; Boudaoud, H.; Nouvel, C.; Pearce, J.M. Multi-material Distributed Recycling via Material Extrusion: Recycled High Density Polyethylene and Poly (Ethylene Terephthalate) Mixture. Polym. Eng. Sci. 2024, 64, 1555–1570. [Google Scholar] [CrossRef]

- Maldonado-García, B.; Pal, A.K.; Misra, M.; Gregori, S.; Mohanty, A.K. Sustainable 3D Printed Composites from Recycled Ocean Plastics and Pyrolyzed Soy-Hulls: Optimization of Printing Parameters, Performance Studies and Prototypes Development. Compos. Part C Open Access 2021, 6, 100197. [Google Scholar] [CrossRef]

- Ferrari, F.; Corcione, C.E.; Montagna, F.; Maffezzoli, A. 3D Printing of Polymer Waste for Improving People’s Awareness about Marine Litter. Polymers 2020, 12, 1738. [Google Scholar] [CrossRef]

- Kumar, S.; Ramesh, M.P.; Doddamani, M. Recycling Potential of MWCNTs/HDPE Nanocomposite Filament: 3D Printing and Mechanical Characterization. J. Mater. Cycles Waste Manag. 2023, 25, 1168–1178. [Google Scholar] [CrossRef]

- Mijangos, C.; Calafel, I.; Santamaría, A. Poly(Vinyl Chloride), a Historical Polymer Still Evolving. Polymer 2023, 266, 125610. [Google Scholar] [CrossRef]

- Bedi, P.; Singh, R.; Ahuja, I.S.; Hashmi, M.S.J. Rapid Tooling through Micro Additive Manufacturing with Reinforcement of SiC/Al2O3 in LDPE Domestic Waste. Adv. Mater. Process. Technol. 2020, 8, 917–926. [Google Scholar] [CrossRef]

- Singh, N.; Singh, R.; Ahuja, I.S.; Farina, I.; Fraternali, F. Metal Matrix Composite from Recycled Materials by Using Additive Manufacturing Assisted Investment Casting. Compos. Struct. 2019, 207, 129–135. [Google Scholar] [CrossRef]

- Da Silva, D.P.; Pinheiro, J.P.; Abdulghani, S.; Kamma-Lorger, C.S.; Martínez, J.C.; Solano, E.; Mateus, A.; Pascoal-Faria, P.; Mitchell, G.R. Property Mapping of LDPE during 3D Printing: Evaluating Morphological Development with X-ray Scattering. Front. Mech. Eng. 2023, 9, 1232562. [Google Scholar] [CrossRef]

- Renewables—Éirecomposites. Available online: https://www.eirecomposites.com/renewables/ (accessed on 27 May 2024).

- Battegazzore, D.; Cravero, F.; Bernagozzi, G.; Frache, A. Designing a 3D Printable Polypropylene-Based Material from after Use Recycled Disposable Masks. Mater. Today Commun. 2022, 32, 103997. [Google Scholar] [CrossRef]

- Abelenda, A.M.; Aiouache, F. Microfactory Design for Valorization of E-Waste Plastics (Acrylonitrile-Butadiene-Styrene, Polycarbonate, and Polypropylene) on Additive Manufacturing Sector. Recycling 2023, 8, 46. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Arrigo, R.; Battegazzore, D.; Bernagozzi, G.; Cravero, F.; Pedraza, D.N.R.; Frache, A. Recycled PP for 3D Printing: Material and Processing Optimization through Design of Experiment. Appl. Sci. 2022, 12, 10840. [Google Scholar] [CrossRef]

- Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.; Neuber, C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers 2023, 15, 2291. [Google Scholar] [CrossRef] [PubMed]

- Madhan, N.R.; Subramanian, S. Characterization of Tamarind Fruit Shell Power-Reinforced Virgin and Recycled Polypropylene-Based 3D-Printed Composites. Biomass Convers. Biorefin. 2023, 1–14. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.G.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability 2020, 13, 159. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Petsiuk, A.; Dick, R.; Pearce, J.M. Sustainability and Feasibility Assessment of Distributed E-Waste Recycling Using Additive Manufacturing in a Bi-Continental Context. Addit. Manuf. 2022, 50, 102548. [Google Scholar] [CrossRef]

- Gaikwad, V.; Ghose, A.; Cholake, S.T.; Rawal, A.; Iwato, M.; Sahajwalla, V. Transformation of E-Waste Plastics into Sustainable Filaments for 3D Printing. ACS Sustain. Chem. Eng. 2018, 6, 14432–14440. [Google Scholar] [CrossRef]

- Mishra, V.; Ror, C.K.; Negi, S.; Kar, S.; Borah, L.N. Development of Sustainable 3D Printing Filaments Using Recycled/Virgin ABS Blends: Processing and Characterization. Polym. Eng. Sci. 2023, 63, 1890–1899. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar] [CrossRef]

- Laoutid, F.; Lafqir, S.; Toncheva, A.; Dubois, P. Valorization of Recycled Tire Rubber for 3D Printing of ABS- and TPO-Based Composites. Materials 2021, 14, 5889. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Toncheva, A.; Brison, L.; Dubois, P.; Laoutid, F. Recycled Tire Rubber in Additive Manufacturing: Selective Laser Sintering for Polymer-Ground Rubber Composites. Appl. Sci. 2021, 11, 8778. [Google Scholar] [CrossRef]

- Vidakis, N.; Kalderis, D.; Petousis, M.; Maravelakis, E.; Mountakis, N.; Bolanakis, N.; Papadakis, V. Biochar Filler in MEX and VPP Additive Manufacturing: Characterization and Reinforcement Effects in Polylactic Acid and Standard Grade Resin Matrices. Biochar 2023, 5, 39. [Google Scholar] [CrossRef]

- Rimkus, A.; Farh, M.M.; Gribniak, V. Continuously Reinforced Polymeric Composite for Additive Manufacturing—Development and Efficiency Analysis. Polymers 2022, 14, 3471. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Abliz, D.; Li, D.; Ziegmann, G. Recycling and Remanufacturing of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Karimi, N.; Fayazfar, H. Development of Highly Filled Nickel-Polymer Feedstock from Recycled and Biodegradable Resources for Low-Cost Material Extrusion Additive Manufacturing of Metals. J. Manuf. Process. 2023, 107, 506–514. [Google Scholar] [CrossRef]

- Hussain, G.; Mohanty, A.K.; Misra, M. 3D Printing in Upcycling Plastic and Biomass Waste to Sustainable Polymer Blends and Composites: A Review. Mater. Des. 2024, 237, 112558. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, Κ.; Chojnacka, K.; Witek-Krowiak, A. 3D Printing Filament as a Second Life of Waste Plastics—A Review. Environ. Sci. Pollut. Res. 2020, 28, 12321–12333. [Google Scholar] [CrossRef] [PubMed]

- Kladovasilakis, N.; Kontodina, T.; Tsongas, K.; Pechlivani, E.M.; Tzetzis, D.; Tzovaras, D. The Mechanical Performance of Additive Manufactured Silica Lattice Structures. In Springer Tracts in Additive Manufacturing; Springer: Berlin/Heidelberg, Germany, 2023; pp. 263–269. [Google Scholar]

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Influence of Selective Laser Melting Additive Manufacturing Parameters in Inconel 718 Superalloy. Materials 2022, 15, 1362. [Google Scholar] [CrossRef] [PubMed]

- Alamos, F.J.; Schiltz, J.; Attardo, R.; Gatrell, B.A.; Tomonto, C.; Budzinski, J.; McGuffin-Cawley, J.; Pelletiers, T.; Schmid, S.R. Effect of Powder Reuse on Orthopedic Metals Produced through Selective Laser Sintering. Manuf. Lett. 2022, 31, 40–44. [Google Scholar] [CrossRef]

- Sun, H.; Chu, X.; Liu, Z.; Azimi, G.; Zou, Y. Selective Laser Melting of Maraging Steels Using Recycled Powders: A Comprehensive Microstructural and Mechanical Investigation. Metall. Mater. Trans. 2021, 52, 1714–1722. [Google Scholar] [CrossRef]

- Tebaldo, V.; Di Confiengo, G.G.; Duraccio, D.; Faga, M.G. Sustainable Recovery of Titanium Alloy: From Waste to Feedstock for Additive Manufacturing. Sustainability 2023, 16, 330. [Google Scholar] [CrossRef]

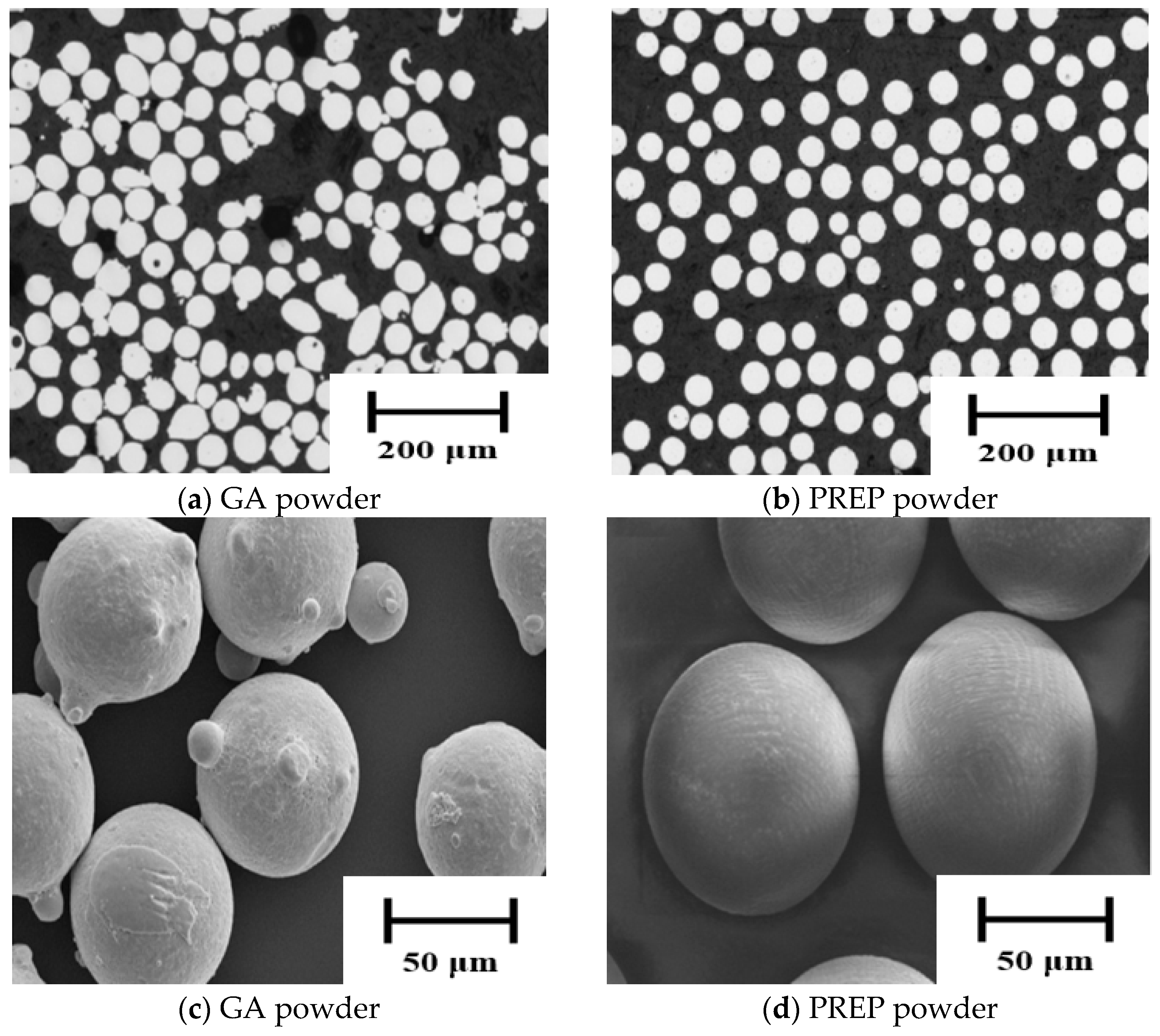

- Chen, Z.; Chen, J.; Linnenbrink, S.; Gasser, A.; Sui, S.; Poprawe, R. A Comparative Study of Inconel 718 Formed by High Deposition Rate Laser Metal Deposition with GA Powder and PREP Powder. Mater. Des. 2016, 107, 386–392. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Xu, S.; Liu, B.; Sui, Q.; Zhao, F.; Gong, L.; Liu, J. Influence of Powder Characteristics on Microstructure and Mechanical Properties of Inconel 718 Superalloy Manufactured by Direct Energy Deposition. Appl. Surf. Sci. 2022, 583, 152545. [Google Scholar] [CrossRef]

- Ruan, G.; Liu, C.; Qu, H.; Guo, C.; Gan, L.; Li, X.; Zhu, Q. A Comparative Study on Laser Powder Bed Fusion of IN718 Powders Produced by Gas Atomization and Plasma Rotating Electrode Process. Mater. Sci. Eng. A 2022, 850, 143589. [Google Scholar] [CrossRef]

- Faleschini, F.; Trento, D.; Masoomi, M.; Pellegrino, C.; Zanini, M.A. Sustainable Mixes for 3D Printing of Earth-Based Constructions. Constr. Build. Mater. 2023, 398, 132496. [Google Scholar] [CrossRef]

- Skibicki, S.; Pułtorak, M.; Kaszyńska, M.; Hoffmann, M.; Ekiert, E.; Sibera, D. The Effect of Using Recycled PET Aggregates on Mechanical and Durability Properties of 3D Printed Mortar. Constr. Build. Mater. 2022, 335, 127443. [Google Scholar] [CrossRef]

- Małek, M.; Kluczyński, J.; Łasica, W.; Jackowski, M.; Szachogłuchowicz, I.; Łuszczek, J.; Torzewski, J.; Grzelak, K. Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding. Materials 2023, 16, 1909. [Google Scholar] [CrossRef]

- Soares, A.; Rodrigues, A.M.; Carmo, R.D.; Rodrigues, A.M.; Gaspar, F.; Júlio, E. Comprehensive Design Methodology for 3D Printing Mortars. Constr. Build. Mater. 2023, 401, 132804. [Google Scholar] [CrossRef]

- Zhao, G.; Fan, Y.; Tang, C.; Wang, Y.; Hao, W. Preparation and Compressive Properties of Cementitious Composites Reinforced by 3D Printed Cellular Structures with a Negative Poisson’s Ratio. Dev. Built Environ. 2024, 17, 100362. [Google Scholar] [CrossRef]

- Molla, A.S.; Sher, W.; Tang, W.; Bahar, M.M.; Bekele, D.N. Composite Building Materials and Construction and Demolition Waste (C&DW): Ecotoxicological Perspectives. In Sustainability and Toxicity of Building Materials; Elsevier eBooks; Woodhead Publishing: Sawston, UK, 2024; pp. 601–625. [Google Scholar]

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.G.; Hmeidat, N.S.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What Makes a Material Printable? A Viscoelastic Model for Extrusion-Based 3D Printing of Polymers. J. Manuf. Process. 2018, 35, 526–537. [Google Scholar] [CrossRef]

- Van De Voorde, B.; Katalagarianakis, A.; Huysman, S.; Toncheva, A.; Raquez, J.; Đuretek, I.; Holzer, C.; Cardon, L.; Bernaerts, K.V.; Van Hemelrijck, D.; et al. Effect of Extrusion and Fused Filament Fabrication Processing Parameters of Recycled Poly(Ethylene Terephthalate) on the Crystallinity and Mechanical Properties. Addit. Manuf. 2022, 50, 102518. [Google Scholar] [CrossRef]

- Alzahrani, M.; Alhumade, H.; Simon, L.C.; Yetilmezsoy, K.; Madhuranthakam, C.M.R.; Elkamel, A. Additive Manufacture of Recycled Poly(Ethylene Terephthalate) Using Pyromellitic Dianhydride Targeted for FDM 3D-Printing Applications. Sustainability 2023, 15, 5004. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V.K. Three-Dimensional-Printed Sustainable Biochar-Recycled PET Composites. ACS Sustain. Chem. Eng. 2018, 6, 13940–13948. [Google Scholar] [CrossRef]

- Kumar, S.; Ramesh, M.R.; Doddamani, M.; Rangappa, S.M.; Siengchin, S. Mechanical Characterization of 3D Printed MWCNTs/HDPE Nanocomposites. Polym. Test. 2022, 114, 107703. [Google Scholar] [CrossRef]

- Roumeli, E.; Terzopoulou, Z.; Pavlidou, E.; Chrissafis, K.; Papadopoulou, E.; Athanasiadou, E.; Triantafyllidis, K.S.; Bikiaris, D.N. Effect of Maleic Anhydride on the Mechanical and Thermal Properties of Hemp/High-Density Polyethylene Green Composites. J. Therm. Anal. Calorim. 2015, 121, 93–105. [Google Scholar] [CrossRef]

- Horta, J.F.; Simões, F.J.P.; Mateus, A. Large Scale Additive Manufacturing of Eco-Composites. Int. J. Mater. Form. 2017, 11, 375–380. [Google Scholar] [CrossRef]

- Oberloier, S.; Whisman, N.G.; Pearce, J.M. Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization. 3d Print. Addit. Manuf. 2023, 10, 1287–1300. [Google Scholar] [CrossRef]

- Stan, F.; Stanciu, N.-V.; Fetecău, C.; Sandu, I.-L. Mechanical Recycling of Low-Density Polyethylene/Carbon Nanotube Composites and Its Effect on Material Properties. J. Manuf. Sci. Eng.-Trans. ASME 2019, 141, 091004. [Google Scholar] [CrossRef]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaria, A.; Tierno, M.; Conde, J.I.; Pascual, B. Searching for Rheological Conditions for FFF 3D Printing with PVC Based Flexible Compounds. Materials 2020, 13, 178. [Google Scholar] [CrossRef]

- Bunjes, A.; Arndt, J.; Geertz, G.; Barton, B. Characterization and Chemometric Modelling of Mechanically Recycled Polypropylene for Automotive Manufacturing. Polymer 2022, 249, 124823. [Google Scholar] [CrossRef]

- Reiter, M.; Miron, V.M.; Lämmermann, S.; Freudenthaler, P.J.; Jerabek, M.; Major, Z. Comparing the Mechanical Properties of Additively Manufactured Post-Consumer Polypropylene to Injection Molded Specimens. Mater. Today Proc. 2022, 70, 55–60. [Google Scholar] [CrossRef]

- Jahromi, F.T.; Nikzad, M.; Prasad, K.; Norén, J.; Isaksson, M.; Arian, A.; Sbarski, I. Additive Manufacturing of Polypropylene Micro and Nano Composites through Fused Filament Fabrication for Automotive Repair Applications. Polym. Adv. Technol. 2022, 34, 1059–1074. [Google Scholar] [CrossRef]

- Smith, P.N.; Obando, A.G.; Griffin, A.; Robertson, M.; Bounds, E.; Qiang, Z. Additive Manufacturing of Carbon Using Commodity Polypropylene. Adv. Mater. 2023, 35, e2208029. [Google Scholar] [CrossRef]

- Saed, M.O.; Lin, X.; Terentjev, E.M. Dynamic Semicrystalline Networks of Polypropylene with Thiol-Anhydride Exchangeable Crosslinks. ACS Appl. Mater. Interfaces 2021, 13, 42044–42051. [Google Scholar] [CrossRef]

- Ghabezi, P.; Flanagan, T.; Harrison, N.M. Short Basalt Fibre Reinforced Recycled Polypropylene Filaments for 3D Printing. Mater. Lett. 2022, 326, 132942. [Google Scholar] [CrossRef]

- Lupone, F.; Tirillò, J.; Sarasini, F.; Badini, C.F.; Sergi, C. 3D Printing of Low-Filled Basalt PA12 and PP Filaments for Automotive Components. J. Compos. Sci. 2023, 7, 367. [Google Scholar] [CrossRef]

- Morales, M.A.; Marañón, A.; Hernández, C.; Porras, A. Development and Characterization of a 3D Printed Cocoa Bean Shell Filled Recycled Polypropylene for Sustainable Composites. Polymers 2021, 13, 3162. [Google Scholar] [CrossRef] [PubMed]

- Yap, L.K.P.; Koay, S.C.; Chan, M.Y.; Ong, T.K.; Huey, H.S.; Ting, C.H.; Meng, P.M. Effects of Corn Husk Fiber as Filler in Recycled Single-use Polypropylene for Fused Filament Fabrication. J. Vinyl Addit. Technol. 2023, 30, 620–634. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K.L. Sustainable Composite Fused Deposition Modelling Filament Using Recycled Pre-Consumer Polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Romani, A.; Levi, M.; Pearce, J.M. Recycled Polycarbonate and Polycarbonate/Acrylonitrile Butadiene Styrene Feedstocks for Circular Economy Product Applications with Fused Granular Fabrication-Based Additive Manufacturing. Sustain. Mater. Technol. 2023, 38, e00730. [Google Scholar] [CrossRef]

- Chawla, K.; Singh, J.; Singh, R. Mechanical Investigations on Secondary Recycled ABS-Based Composite Multi-Layered Tensile and Flexural Specimens Prepared by Fused Filament Fabrication. Prog. Addit. Manuf. 2023, 8, 1195–1208. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-Material Additive Manufacturing of Sustainable Innovative Materials and Structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [PubMed]

- Chawla, K.; Singh, R.; Singh, J.; Mehta, H. Investigations on Mechanical Properties of Secondary Recycled ABS Reinforced with Fe Powder for 3D Printing Applications. Mater. Today Proc. 2022, 50, 2450–2454. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef]

- André, T.; Couvreur, R.; Tamrakar, S.; Mielewski, D.F.; Kızıltaş, A. Closed-loop Recycling of Additive Manufacturing Waste for Value-added Automotive Foam Applications. Polym. Compos. 2023, 1. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Impact of Metal Additive Manufacturing Parameters on the Powder Bed Fusion and Direct Energy Deposition Processes: A Comprehensive Review. Prog. Addit. Manuf. 2021, 6, 349–365. [Google Scholar] [CrossRef]

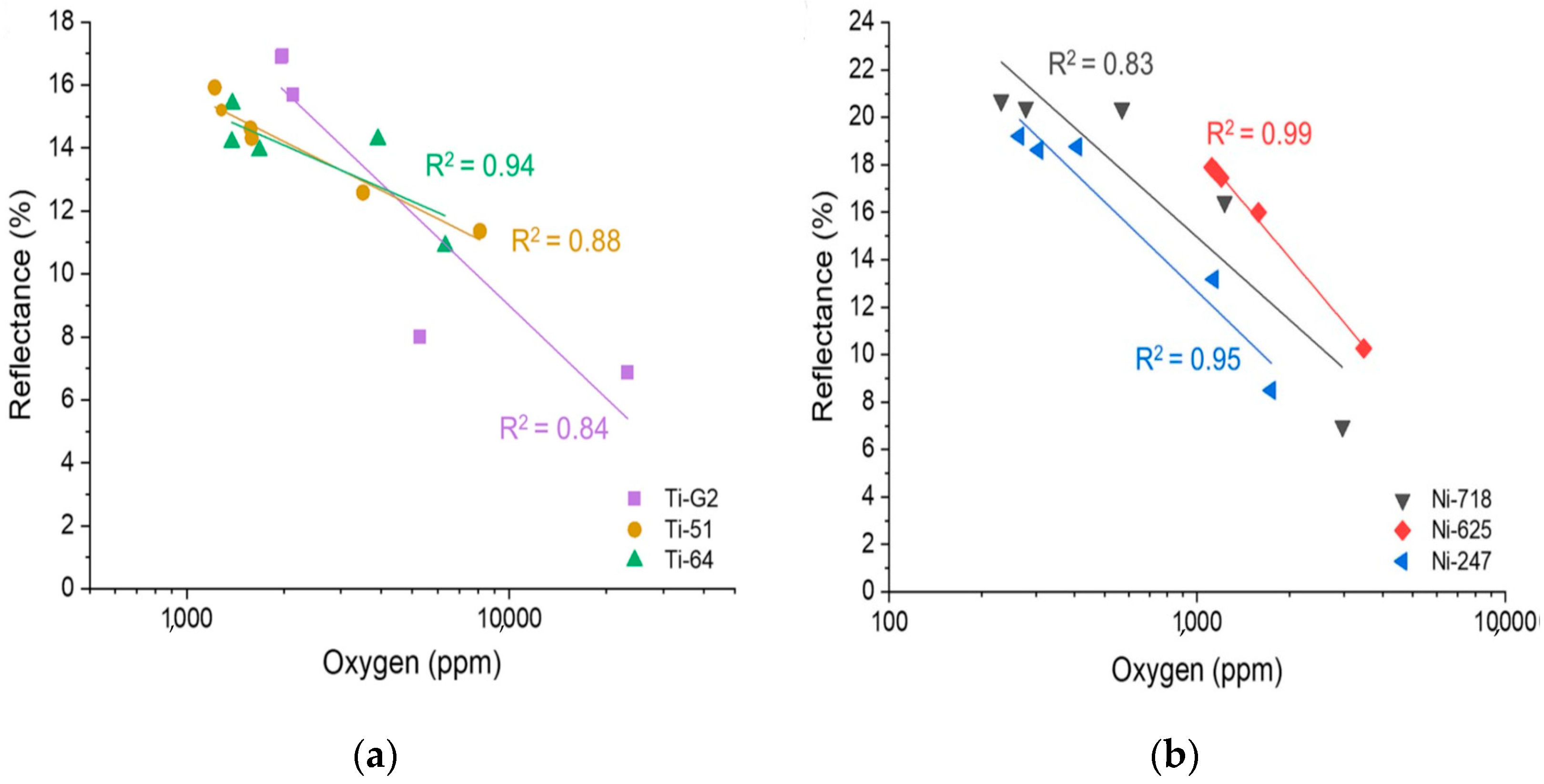

- Gruber, K.; Smolina, I.; Stopyra, W. Assessing Metal Powder Quality for Additive Manufacturing Using Diffuse Light Spectroscopy. Powder Technol. 2024, 434, 119366. [Google Scholar] [CrossRef]

- Bruzzo, F.; Medapati, M.P.R.; Pullini, D.; Ronco, F.; Bertinetti, A.; Tommasi, A.; Riede, M.; López, E.; Brückner, F. Sustainable Laser Metal Deposition of Aluminum Alloys for the Automotive Industry. J. Laser Appl. 2022, 34, 042004. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, J.; Gasser, A.; Sui, S.; Schleifenbaum, J.H. Microstructures, Tensile Properties, and Fracture Mechanisms of Inconel 718 Formed by HDR-LMD with PREP and GA Powders. Int. J. Adv. Manuf. Technol. 2018, 96, 2031–2041. [Google Scholar] [CrossRef]

- Madrid, J.A.; Ortega, G.S.; Carabaño, J.G.; Olsson, N.O.E.; Ríos, J.A.T. 3D Claying: 3D Printing and Recycling Clay. Crystals 2023, 13, 375. [Google Scholar] [CrossRef]

- Jauk, J.; Vašatko, H.; Gosch, L.; Ristoski, K.; Füssl, J.; Stavrić, M. Coextrusion of Clay-Based Composites: Using a Multi-Material Approach to Achieve Gradient Porosity in 3D-Printed Ceramics. Ceramics 2023, 6, 2243–2255. [Google Scholar] [CrossRef]

- Jo, J.H.; Jo, B.-W.; Cho, W.; Kim, J. Development of a 3D Printer for Concrete Structures: Laboratory Testing of Cementitious Materials. Int. J. Concr. Struct. Mater. 2020, 14, 13. [Google Scholar] [CrossRef]

- Pan, T.; Guo, R.; Fu, C.; Pan, T.; Liu, Z.; Yan, Y.F. Extrusion-Based 3D-Concrete-Printing with Different Flow Direction. Constr. Build. Mater. 2023, 408, 133714. [Google Scholar] [CrossRef]

- Fahim, A.-A.; Admassu, N.; Dailey, G.; Khanzadeh-Moradllo, M. Application of Cellulose Nanocrystals in 3D Printed Alkali-Activated Cementitious Composites. J. Build. Eng. 2024, 82, 108380. [Google Scholar] [CrossRef]

- Schneevogt, H.; Stelzner, K.; Yılmaz, B.; Abali, B.E.; Klunker, A.; Völlmecke, C. Sustainability in Additive Manufacturing: Exploring the Mechanical Potential of Recycled PET Filaments. Compos. Adv. Mater. 2021, 30, 263498332110000. [Google Scholar] [CrossRef]

- Singh, N.; Singh, R.; Ahuja, I.S. Recycling of Polymer Waste with SiC/Al2O3 Reinforcement for Rapid Tooling Applications. Mater. Today Commun. 2018, 15, 124–127. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Singh, P. Prospect of 3D Printing for Recycling of Plastic Product to Minimize Environmental Pollution. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 289–299. [Google Scholar]

- Nguyen, H.; Crittenden, K.; Weiss, L.; Bardaweel, H. Recycle of Waste Tire Rubber in a 3D Printed Composite with Enhanced Damping Properties. J. Clean. Prod. 2022, 368, 133085. [Google Scholar] [CrossRef]

- Pechlivani, E.M.; Melidis, L.; Pemas, S.; Katakalos, K.; Tzovaras, D.; Konstantinidis, A. On the Effect of Volumetric Energy Density on the Characteristics of 3D-Printed Metals and Alloys. Metals 2023, 13, 1776. [Google Scholar] [CrossRef]

- Islam, M.J.; Ahmed, T.; Shahjalal, M.; Jihad, A.M.; Based, Z.; Hasan, M.M. Strength, Durability, and Impact Behavior of Recycled Aggregate Concrete with Polypropylene Aggregate. Constr. Build. Mater. 2023, 408, 133646. [Google Scholar] [CrossRef]

- Subbarao, C.V.; Reddy, Y.S.; Inturi, V.; Reddy, M.I. Dynamic Mechanical Analysis of 3D Printed PETG Material. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1057, 012031. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. 3D Printed Thermoplastic Polyurethane Filled with Polyurethane Foams Residues. J. Polym. Environ. 2020, 28, 1560–1570. [Google Scholar] [CrossRef]

- Pricop, B.; Sava, Ș.D.; Lohan, N.M.; Bujoreanu, L.-G. DMA Investigation of the Factors Influencing the Glass Transition in 3D Printed Specimens of Shape Memory Recycled PET. Polymers 2022, 14, 2248. [Google Scholar] [CrossRef] [PubMed]

- Garcia, F.L.; Nunes, A.O.; Martins, M.G.; Belli, M.C.; Saavedra, Y.M.B.; Silva, D.A.L.; Da Silva Moris, V.A. Comparative LCA of Conventional Manufacturing vs. Additive Manufacturing: The Case of Injection Moulding for Recycled Polymers. Int. J. Sustain. Eng. 2021, 14, 1604–1622. [Google Scholar] [CrossRef]

- Horowitz, N.; Frago, J.; Mu, D. Life Cycle Assessment of Bottled Water: A Case Study of Green2O Products. Waste Manag. 2018, 76, 734–743. [Google Scholar] [CrossRef]

- De Bernardez, L.; Campana, G.; Mele, M.; Mur, S. Towards a Comparative Index Assessing Mechanical Performance, Material Consumption and Energy Requirements for Additive Manufactured Parts. In Manufacturing Driving Circular Economy. GCSM 2022; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2023; pp. 302–310. [Google Scholar]

- Chatzipanagiotou, K.-R.; Antypa, D.; Petrakli, F.; Karatza, A.; Pikoń, K.; Bogacka, M.; Poranek, N.; Werle, S.; Amanatides, E.; Mataras, D.; et al. Life Cycle Assessment of Composites Additive Manufacturing Using Recycled Materials. Sustainability 2023, 15, 12843. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; Bowers, L.; Cottrell, G.; Erdem, E.; Knepp, A.K.; Martin, S.B.; Pretty, J.R.; Duling, M.G.; Arnold, E.D.; Wilson, Z.; et al. Towards Sustainable Additive Manufacturing: The Need for Awareness of Particle and Vapor Releases during Polymer Recycling, Making Filament, and Fused Filament Fabrication 3-D Printing. Resour. Conserv. Recycl. 2022, 176, 105911. [Google Scholar] [CrossRef] [PubMed]

- Cáceres, C.; Santander, P.; Da Cruz, F.S.; Troussier, N.; Camargo, M.; Boudaoud, H. Life Cycle Assessment of Filament Production in Distributed Plastic Recycling via Additive Manufacturing. Clean. Waste Syst. 2023, 5, 100100. [Google Scholar] [CrossRef]

- Landi, D.; Spreafico, C.; Russo, D. LCA of Titanium Powder: Empirical Evidence vs Data from Patents, Possible Future Applications. Procedia CIRP 2023, 116, 318–323. [Google Scholar] [CrossRef]

- Jones, K.L.; Li, M.X. Life Cycle Assessment of Ultra-Tall Wind Turbine Towers Comparing Concrete Additive Manufacturing to Conventional Manufacturing. J. Clean. Prod. 2023, 417, 137709. [Google Scholar] [CrossRef]

- Hugo, A.; Scelsi, L.; Hodzic, A.; Jones, F.R.; Dwyer-Joyce, R.S. Development of Recycled Polymer Composites for Structural Applications. Plast. Rubber Compos. 2011, 40, 317–323. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Niemelä, M.; Sepasgozar, S.M.E.; Lai, T.; Su, W.; Reddy, K.R.; Shirowzhan, S.; Sepasgozar, S.M.E.; Marroquín, F.A. Three-Dimensional Printing Using Recycled High-Density Polyethylene: Technological Challenges and Future Directions for Construction. Buildings 2018, 8, 165. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric Composites for Powder-Based Additive Manufacturing: Materials and Applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Romani, A.; Caba, S.; Suriano, R.; Levi, M. Recycling Glass and Carbon Fibers for Reusable Components in the Automotive Sector through Additive Manufacturing. Appl. Sci. 2023, 13, 5848. [Google Scholar] [CrossRef]

- Jahromi, F.T.; Nikzad, M.; Isaksson, M.; Norén, J. Mechanical Properties of 3D-Printed Staking Polypropylene Posts for Repairing Automotive Headlights. Int. J. Adv. Manuf. Technol. 2023, 127, 5553–5567. [Google Scholar] [CrossRef]

- Bañón, C.; Raspall, F. 3D Printing Floating Modular Farms from Plastic Waste. Mater. Today Proc. 2022, 70, 560–566. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, D.; Peng, E.; Ding, J. 3D-Printed Ceramic Structures with in Situ Grown Whiskers for Effective Oil/Water Separation. Chem. Eng. J. 2019, 373, 1223–1232. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. Distributed Manufacturing of Flexible Products: Technical Feasibility and Economic Viability. Technologies 2017, 5, 71. [Google Scholar] [CrossRef]

- Pechlivani, E.M.; Papadimitriou, A.; Pemas, S.; Ntinas, G.; Tzovaras, D. IoT-Based Agro-Toolbox for Soil Analysis and Environmental Monitoring. Micromachines 2023, 14, 1698. [Google Scholar] [CrossRef] [PubMed]

- De Sousa, A.A.; Pinho, A.C.; Piedade, A.P. Mechanical Properties of 3D Printed Mouthguards: Influence of Layer Height and Device Thickness. Mater. Des. 2021, 203, 109624. [Google Scholar] [CrossRef]

- Kornilitsina, E.V.; Lebedeva, E.A.; Astaf’Eva, C.A.; Trukhinov, D.K.; Knyazev, N.S.; Malkin, A.И.; Knyazev, S.; Korotkov, A.; Bǎlǎșoiu, M. Enhanced Electrodynamic Properties Acrylonitrile Butadiene Styrene Composites Containing Short-Chopped Recycled Carbon Fibers and Magnetite. Diam. Relat. Mater. 2023, 135, 109814. [Google Scholar] [CrossRef]

- Crapnell, R.D.; Sigley, E.; Williams, R.J.; Brine, T.; Ferrari, A.G.; Kalinke, C.; Janegitz, B.C.; Bonacin, J.A.; Banks, C.E. Circular Economy Electrochemistry: Recycling Old Mixed Material Additively Manufactured Sensors into New Electroanalytical Sensing Platforms. ACS Sustain. Chem. Eng. 2023, 11, 9183–9193. [Google Scholar] [CrossRef] [PubMed]

- Silva-Neto, H.A.; Duarte-Junior, G.F.; Rocha, D.S.; Bédioui, F.; Varenne, A.; Coltro, W.K.T. Recycling 3D Printed Residues for the Development of Disposable Paper-Based Electrochemical Sensors. ACS Appl. Mater. Interfaces 2023, 15, 14111–14121. [Google Scholar] [CrossRef] [PubMed]

- Tubío, C.R.; Malatini, C.; Barrio, V.L.; Masaguer, C.F.; Amorín, M.; Nabgan, W.; Taboada, P.; Guitián, F.; Gil, Á.; Coelho, A. 3D Printing of a Palladium-Alumina Cermet Monolithic Catalyst: Catalytic Evaluation in Microwave-Assisted Cross-Coupling Reactions. Mater. Today Chem. 2023, 27, 101355. [Google Scholar] [CrossRef]

- Korey, M.; Rencheck, M.; Tekinalp, H.; Wasti, S.; Wang, P.; Bhagia, S.; Walker, R.; Smith, T.; Zhao, X.; Lamm, M.E.; et al. Recycling Polymer Composite Granulate/Regrind Using Big Area Additive Manufacturing. Compos. Part B Eng. 2023, 256, 110652. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Finite Element Analysis of Orthopedic Hip Implant with Functionally Graded Bioinspired Lattice Structures. Biomimetics 2020, 5, 44. [Google Scholar] [CrossRef] [PubMed]

- Kladovasilakis, N.; Bountourelis, T.; Tsongas, K.; Tzetzis, D. Computational Investigation of a Tibial Implant Using Topology Optimization and Finite Element Analysis. Technologies 2023, 11, 58. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Charalampous, P.; Kostavelis, I.; Givissis, P.; Tzovaras, D.; Tzetzis, D. Development of Customized Tibial Implant with Advanced Architected Materials utilizing Selective Laser Melting. Prog. Addit. Manuf. 2023; under peer preview process. [Google Scholar]

| Meaning | Acronym | Meaning | Acronym |

|---|---|---|---|

| Additive Manufacturing | AM | Selective Laser Melting | SLM |

| Injection Molding | IM | Selective Laser Sintering | SLS |

| Power Bed Fusion | PBF | Laser Metal Deposition | LMD |

| Direct Energy Deposition | DED | Liquid Deposition Modeling | LDM |

| Stereolithography | SLA | Gas Atomization | GA |

| Dynamic Mechanical Analysis | DMA | Plasma Rotating Electrode Process | PREP |

| Recycled | r | Melt Flow Index | MFI |

| Polyethylene Terephthalate | PET | Weight Fractions | wt.% |

| Polyethylene Terephthalate Glycol | PETG | Pyromellitic Dianhydride | PMDA |

| High-Density Polyethylene | HDPE | Ethylene–Ethyl–Acrylate | EEA |

| Low-Density Polyethylene | LDPE | Multi-Walled Carbon Nanotubes | MWCNTs |

| Polyvinyl Chloride | PVC | Carbon Fibers, Carbon Black, Carbon Nanotubes | CF, CB, CNTs |

| Polypropylene | PP | Tamarind Fruit Shells | TFS |

| Polystyrene | PS | Corn Husk Fibers | CHF |

| Acrylonitrile Butadiene Styrene | ABS | Cocoa Beans Shells | CBS |

| Ethylene–Vinyl Acetate | EVA | Thermoplastic Polyolefins | TPOs |

| Ground Tire Rubber | GTR | Polyethylene-Grafted Maleic Anhydride | PE-g-MA |

| Polycarbonate | PC | Young’s Modulus | E |

| Polylactic Acid | PLA | Diffuse Light Stereoscopy | DLS |

| Thermoplastic Polyurethane | TPU | Thermogravimetric Analysis | TGA |

| Material Extrusion | MEX | Digital Image Correlation | DIC |

| Fused Filament Fabrication | FFF | Finite Element Analysis | FEA |

| Fused Granular Fabrication | FGF | Ultimate Tensile Strength | UTS |

| Fused Particle Fabrication | FPF | Global Warming Potential | GWP |

| Fused Deposition Modeling | FDM | Cumulative Energy Demand | CED |

| Electron Beam Melting | EBM | Life Cycle Assessment | LCA |

| Recycling Symbol | Plastic (Acronym) | Recyclability | Applications |

|---|---|---|---|

| Polyethylene Terephthalate (PET) | Easy | Packaging, textiles, electronic cables, water bottles [32,33,34,35,36,37,38,39,40] |

| High-Density Polyethylene (HDPE) | Easy | Pipes, chemicals packaging, fuel tanks, bumpers [41,42,43,44,45,46] |

| Polyvinyl Chloride (PVC) | Moderate | Bags, medical equipment, pipes [47] |

| Low-Density Polyethylene (LDPE) | Moderate | Bags, containers, sporting equipment [48,49,50] |

| Polypropylene (PP) | Difficult | Automotive components, turbine blades, medical tools [51,52,53,54,55,56,57,58] |

| Polystyrene (PS) | Difficult | Insulation products, disposable cups [59,60,61,62,63,64,65] |

| Acrylic (ABS), Polycarbonate (PC), Polyamide (PA), Thermoplastic Polyurethane (TPU), etc. | Difficult | Wheel covers, bumpers, headlight lenses, safety equipment [59,60,61,62,63,64,65] |

| Waste Type and Sources | Recycled Polymer | References | |

|---|---|---|---|

| Urban | Plastic Bottles | PET, HDPE LDPE | [34,36,44] |

| Food Packaging | HDPE, LDPE | [43,49] | |

| Plastic Bags | PVC, nylon | [47] | |

| Marine and Ocean | PET, HDPE | [44,46] | |

| Everyday Equipment | PP, ABS, PLA, TPU | [52] | |

| Industrial | Automotive Parts | PP | [54] |

| Ground Tire Rubber | ABS, PP | [62,63] | |

| Electronic Devices | ABS, PC, PS | [53,59,60] |

| Matrix Polymer | Fillers | Weight Fractions | Printing Method | Main Findings | Reference |

|---|---|---|---|---|---|

| rPET | - | - | FPF | Particle shape and influences printability and mechanical response | [32] |

| FDM | Different grades of rPET require different printing conditions | [35] | |||

| Moisture negatively influences printing quality and mechanical properties | [36] | ||||

| Thermal stability decreases after each recycling cycle | [45] | ||||

| FFF | Fan cooling and printing bed temperature affect the crystallinity | [86] | |||

| PMDA | 0.3–0.75 wt.% | FDM | Printable filament, brittle behavior, need for further research | [37,88] | |

| rCFs | 0.4–40.7 wt.% | FFF | Decreased shrinkage | [38] | |

| Biochar | 0.5–5 wt.% | Increased degree of crystallinity led to better dimensional and thermal stability | [88] |

| Matrix Polymer | Fillers | Weight Fractions | Printing Method | Main Findings | Reference |

|---|---|---|---|---|---|

| rHDPE | Waste CFs | 11.2–19.5 wt.% | FDM | Adequate crystallinity with an increase in mechanical response | [42] |

| MWCNTs | 0.5–5 wt.% | FFF | Higher melting temperature and better crystallinity | [46,90] | |

| Sawdust | 45% | FDM | Dimensional deviation of 1–1.5% at 120 °C bed temperature and 188–198 °C nozzle temperature | [92] | |

| rHDPE-rPP blend (70–30) | Biochar | 20 wt.% | FFF | Biochar increased printability | [44] |

| rLDPE | SiC/Al2O3 | 40–50 wt.% | FDM | Improved wear properties | [48,49] |

| MWCNTs | 0.1–5 wt.% | FFF | Increased viscosity leads to better dimensional stability, mechanical recycling didn’t affect the flowability of the composite | [94] |

| Matrix Polymer | Fillers | Weight Fractions | Printing Method | Main Findings | Reference |

|---|---|---|---|---|---|

| rPP | - | - | FFF | Stable morphological behavior and degree of crystallinity compared to virgin PP | [56,58] |

| TFS | 1.5–4.5 wt.% | FDM | Thermal stability at 230 °C adequate degree of crystallinity for 3D printing | [58] | |

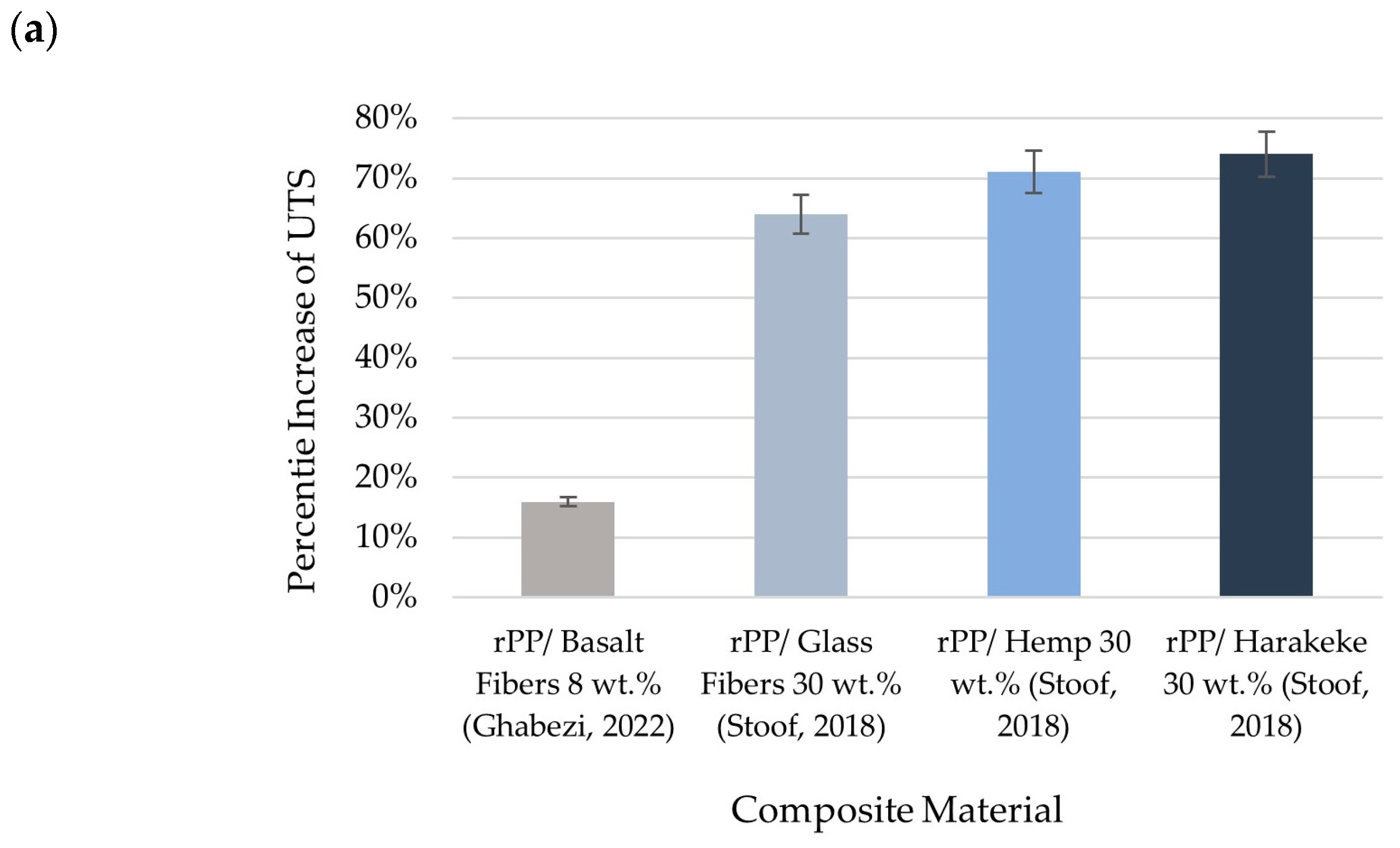

| Bassalt | 2–8 wt.% | High porosity compared to other conventional techniques for the same material, lowering of melting and degradation temperature in comparison to sole rPP | [101,102] | ||

| CBS | 5 wt.% | FFF | Reduced shrinkage and warping effects, decreased crystallinity, degradation were detected at 230 °C but did not affect the printing because of the small residue time | [103] | |

| CHF | 2.5–7.5 wt.% | Elevating CHF concentration led to air gaps and voids. Printable up to 230 °C, reduced warpage, increased stiffness and rigidness | [104] | ||

| Hemp, Harakeke | 10–30 wt.% | Harakeke composite had shrinkage of 0.34%, rPP had 84% | [105] | ||

| CB | 0.5–10 wt.% | Reduced crystallinity on adequate levels for 3D printing, reduced warpage, MFI 13–19 g/10 min | [98] |

| Matrix Polymer | Fillers | Weight Fractions | Printing Method | Main Findings | Reference |

|---|---|---|---|---|---|

| rABS | virgin ABS | 0–50% wt.% | FFF | 80–20 blend of recycled and virgin ABS had the same response as the sole virgin ABS | [61] |

| - | - | Adequate thermal and mechanical behavior till the 5th recycling cycle, significant chemical degradation after the 5th cycle | [64] | ||

| Fe powder | 10 wt.% | FDM | Filaments produced with low speed had higher heat carrying capacity and less porosity. | [107,109] | |

| rPC | rABS | 30 wt.% | FGF | Increased printability on rPC/rABS blend than rPC at speeds of 30–40 mm/s | [106] |

| PU Foam | rTPU | 2.5–7.5 wt.% | SLS | Increased compression strength by 60%, tear resistance by 31%, E modulus by 84% and better sound absorption | [65] |

| TPU | GTR | 10–40 wt.% | SLS | GTR insertion decreased thermal stability, optimal weight fraction of GTR on 30% | [109] |

| Impact Test | Matrix Material | Reinforcement | Weight Fraction | Main Findings | Reference |

|---|---|---|---|---|---|

| Charpy | rPETG | - | - | Brittle behavior of rPETG after the 3rd recycling cycle due to the continuous thermomechanical processing | [39] |

| rPP | Steady impact strength over 6 recycling cycles | [58] | |||

| rABS | [64] | ||||

| PLA | Biochar | 4 wt.% | 140% increase of impact strength on the composite | [66] | |

| Izod | rABS | GTR | 15 wt.% | Adequate impact strength resulting in high elongation at break (ductile behavior) | [63] |

| rPET | PMDA | 5 wt. % | Increase of impact strength from 36 MPa to 43 Mpa | [37] | |

| Drop | Reused Concrete | rPP aggregate | 5 wt.% | Decrease of impact strength by 68% | [126] |

| Test | Matrix Material | Reinforcement | Weight Fraction | Main Findings | Reference |

|---|---|---|---|---|---|

| DMA | rPETG | - | - | Temperature increase leads to decrease of storage modulus, peak damping properties on Tg | [127] |

| rPET | Increase in storage modulus with temperature increase till the peak at Tg | [129] | |||

| Biochar | 5 wt.% | 42% increase in storage modulus on the stated weight fraction, decreased energy absorption (72% damping factor for neat PET and 30% for the sustainable composite) | [89] | ||

| rPP | CB | 10 wt.% | Increased storages modulus (21%) and damping factor (4.45% for neat PP, 11.89% for the sustainable composite) | [98] | |

| rTPU | PU foam | 10 wt.% | Decreased Tg point (from 3 °C to −5 °C). Decreased damping properties (around 45% damping factor for neat TPU, less than 40% on the composite) | [128] | |

| Modal analysis | rABS | GTR | 50 wt.% | 260% increase in damping properties after vibration testing (0.77% for neat ABS, 1.07% for ABS-10 wt.% GTR, 2.78% for ABS-50 wt.% GTR) | [124] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kyriakidis, I.F.; Kladovasilakis, N.; Pechlivani, E.M.; Tsongas, K. Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review. J. Compos. Sci. 2024, 8, 215. https://doi.org/10.3390/jcs8060215

Kyriakidis IF, Kladovasilakis N, Pechlivani EM, Tsongas K. Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review. Journal of Composites Science. 2024; 8(6):215. https://doi.org/10.3390/jcs8060215

Chicago/Turabian StyleKyriakidis, Ioannis Filippos, Nikolaos Kladovasilakis, Eleftheria Maria Pechlivani, and Konstantinos Tsongas. 2024. "Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review" Journal of Composites Science 8, no. 6: 215. https://doi.org/10.3390/jcs8060215

APA StyleKyriakidis, I. F., Kladovasilakis, N., Pechlivani, E. M., & Tsongas, K. (2024). Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review. Journal of Composites Science, 8(6), 215. https://doi.org/10.3390/jcs8060215