Abstract

Nanocellulose (NC) has emerged as a promising biodegradable material with applications in various industrial fields owing to its high mechanical strength, thermal stability, and eco-friendly properties. Traditional methods for isolating NC from wood-based biomass (WB) involve high energy consumption and extensive chemical usage, leading to environmental and sustainability concerns. This study explored an alternative approach to isolate NC from seaweed-based biomass (SB) (SNC), which contains fewer non-cellulosic components and a higher cellulose content than WB, thereby yielding a more efficient e-isolation process. We employed a combination of modified-acid solution and electron beam (E-beam) technology to isolate NC from SB. The E-beam process enhanced the crystallinity while reducing the particle size, thus facilitating NC isolation with reduced environmental impact and processing time. Moreover, our method significantly reduced the need for harsh chemical reagents and energy-intensive processes, which are typically associated with traditional NC isolation methods. We fabricated biodegradable films with improved mechanical properties using NC as a reinforcing agent in polymer composites, thereby demonstrating the potential of NC-based materials for various applications. Therefore, our proposed approach offers a sustainable and efficient method for NC isolation and serves as a guide for the development of eco-friendly industrial processes. Our findings contribute to ongoing efforts to create sustainable materials and reduce the environmental footprint of the manufacturing industry.

1. Introduction

Recently, biomass has received tremendous growing attraction as a promising alternative material for various industrial fields because the intense global demands for eco-friendly materials are increasing dramatically due to sustainable development [1,2,3,4]. Biomass exhibits outstanding biodegradable properties and contains various industrially valuable components such as lignin, polyphenols, and cellulose. Among these components, cellulose stands out as one of the most promising natural, abundant, and biodegradable materials. This is due to its high mechanical properties and thermal stability, which are derived from the strong hydrogen bonding network both within its glucose chains and between adjacent chains [5,6].

Nanocellulose (NC) is considered a highly attractive material owing to its superior properties, such as transparency, biodegradability, surface area, and strength, compared to cellulose [7,8,9]. Generally, NC is isolated from biomass cellulose by chemical and mechanical methods. First, a homogenizer breaks the hydrogen bond between the crystalline regions using high pressure and speed to isolate NC as a mechanical method. Similarly, a ball mill defibrillates cellulose through physical force between balls and balls with high energy. However, this method has high energy consumption and yields NC with a limited size range, poor thermal stability, low crystallinity, and strength [10,11,12]. Second, chemical methods have often been used for NC mass production, using sulfuric acid (SAc) and 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) to hydrolyze cellulose [13,14,15]. These kinds of chemical reagents selectively oxidize a primary hydroxyl group to the carboxyl group, while the hydroxyl groups of cellulose form a sulfate ester with SAc, resulting in the isolation of NC. However, chemical methods have critical problems, such as high cost, long processing times, and environmental pollution due to the tremendous chemical usage. Thus, several research groups have sought eco-friendly, simple, high-yield, and cost-effective techniques for preparing NC [16].

The majority of NC has been isolated from wood-based biomass (WB). However, an essential strong-base pretreatment process employing high pressure, heating, and high energy is required to isolate NC and remove non-cellulosic components, such as hemicellulose, lignin, and other residual substances [17]. In addition, WB isolation results in low NC. Meanwhile, NC isolated from seaweed-based biomass (SB) has few or no lignin, hemicelluloses, and other residual substances [18]. Therefore, NC isolated from SB exhibits outstanding efficiency and the potential for producing high-value and eco-friendly biodegradable materials with minimal influence on the environment.

Seaweed-based biomass (SB) offers numerous advantages for sustainable development and plays a crucial role in environmental protection and economic growth. As a rapidly renewable resource, seaweed can be harvested on a large scale without deforestation, and it absorbs significant amounts of atmospheric carbon dioxide, thereby reducing greenhouse gas levels. Seaweed farming also supports marine ecosystem protection and eutrophication reduction. Thus, seaweed production is cost-efficient, does not require arable land or freshwater resources, and generates jobs to improve the economy of coastal communities. Additionally, seaweed is easily dried, stored, and transported. These combined benefits highlight the potential of seaweed biomass as a critical resource for future sustainable development [19,20,21,22].

Recently, there has been a considerable demand for environmentally friendly approaches to effectively isolate NC from biomass. Electron beam (E-beam) is receiving a lot of attention as one of the effective approaches. E-beam irradiation produces ions in a material that can initiate a series of chemical reactions and cleave chemical bonds. This ionizing radiation predominantly causes scission (breaking of molecular chains), degradation (breaking down into smaller components), and depolymerization (reducing polymer chains into monomers or shorter polymers) of cellulose. The extent of such degradation increases proportionally with the radiation dose [23,24].

Numerous researchers have meticulously studied the relationship between radiation dose and cellulose degradation [25,26,27]. Their findings consistently showed that higher radiation doses resulted in a more significant degradation of cellulose. This increased degradation is due to the higher energy input, enhanced ionization, and subsequent chemical reactions that break down the cellulose structure. These studies are crucial for understanding the control and optimization of radiation used in cellulose applications, such as the modification of materials for industrial use or the treatment of cellulose-based waste.

In this study, we reported the isolation of NC from SB whereby different particle sizes were obtained depending on the process time and acid concentration. We developed a new method for isolating NC from SB with a considerable decrease in chemical reagent usage and process time by using modified-acid treatment (Mo-Ac) and a highly effective E-beam process. Using the produced NC as the reinforcing agent in polymer composites, we fabricated biodegradable film with enhanced mechanical properties by building network structures between poly (vinyl alcohol) (PVA) and NC. The results of this study can provide a guideline for the effective isolation of NC from SB and its accessibility in next-generation core materials for other industrial and research fields.

2. Materials and Methods

2.1. Materials

Wakame seaweed (Undaria pinnatifida) was harvested during the summer season in Wando Province, Republic of Korea. Microcrystalline cellulose (MC, 20~100 μm) was purchased from Daejung, sulfuric acid (SAc, 95.0%) was purchased from Samchun, hydrogen peroxide (30%) was purchased from Junsei, ethanol (EtOH, 95%) was purchased from Ducksan, and t-butanol (≥99.5%) and poly (vinyl alcohol) (Mw 89,000~98,000) (PVA) were purchased from Sigma Aldrich. All chemicals were used without further purification.

2.2. Methods

2.2.1. Preparation of Nanocellulose (NC) Isolated from Seaweed with Modified-Acid (Mo-Ac) Treatment

The seaweed was pre-washed with distilled water to remove impurities and dried in an oven at 80 °C overnight. Subsequently, the seaweed was ground into small particles (<100 μm), stirred in EtOH, and kept at 80 °C for 1.5 h. The mixtures were then washed several times with EtOH to remove other impurities. After washing, the particles (1 g) were stirred in 100 mL acid solution in 0.5, 1, 3, and 6 M H2SO4, a drop of H2O2 (~100 μL) was added and kept at 45 °C for 6, 12, and 24 h. The slurry was centrifuged for 10 min at 4000 rpm and washed with distilled water until pH 6~7 (supernatant measured by pH meter) several times. The slurry was dispersed in a tert-butanol solution. Finally, the powdery NC was obtained by freeze-drying for 5 days. Samples were named for MNC (NC isolated from microcrystalline cellulose via Mo-Ac treatment) and SNC (NC isolated from seaweed via Mo-Ac treatment).

2.2.2. Preparation of Nanocellulose (NC) Isolated from Seaweed with E-Beam Process

Washed seaweed particles were pretreated with doses of E-beam at 20, 40, and 60 kGy in 2.5 MeV and 1.5 mA followed by Mo-Ac. The slurry was centrifuged for 10 min at 4000 rpm and then washed with distilled water until pH 6~7 (supernatant measured by pH meter) several times. The slurry was dispersed in a tert-butanol solution. Finally, the powdery NC was obtained by freeze-drying.

2.2.3. Fabrication of Nanocellulose-Based PVA Composite Films

The prepared NC was stirred in 5 wt% PVA solution at 1, 2, 5, and 10 parts per hundred resin (phr) at 95 °C overnight, respectively. The well-dispersed polymer composite solutions were then transferred onto clean glass substrates and cast according to the ASTM D-882 standard [28]. The thickness of the films was controlled to approximately 40 µm by using a micro doctor blade.

2.3. Characterization

The surface morphology was observed by scanning electron microscope (SEM), using an S-4800 microscope (Hitachi, Tokyo, Japan). The structural properties were analyzed by Fourier transform infrared spectroscopy (FT-IR) using a Nicolet6700 (Thermo Scientific, Waltham, MA, USA), dynamic light scattering (DLS) using a Malvern Zetasizer Nano-ZS ZEN 3600 (Malvern, UK), and X-ray diffraction (XRD) using an MXD10 (Rigaku, Tokyo, Japan). The thermal properties were obtained by thermal gravimetric analysis (TGA) using a TGA2050 (TA Instruments, New Castle, DE, USA) and differential scanning calorimeter (DSC) using a DSC60A (Shimadzu, Kyoto, Japan). The tensile strength and Young’s modulus were measured by using an AGS-10kNX (Shimadzu, Japan) according to ASTM D-882 [28,29].

3. Results and Discussion

Figure 1 shows the schematic of NC isolated from SB using the Mo-Ac and E-beam methods. The seaweed was washed several times with distilled water to remove surface impurities and then dried overnight in a vacuum oven. The well-dried seaweed was finely ground to enhance the efficiency of subsequent treatments. The ground seaweed was stirred in EtOH and maintained at 80 °C for 1.5 h to remove chlorophyll [30]. The mixtures were washed several times with EtOH to remove any remaining residues. Subsequently, the EtOH-washed seaweed (Et-SW) was treated with a modified acid mixture of H2SO4 and a small amount of H2O2 at 45 °C for various durations. H2SO4 combined with a small amount of H2O2 exhibits stronger oxidizing power than pure H2SO4 and is effective for decomposing amorphous organic material [31,32].

Figure 1.

Schematic of the NC isolation process from seaweed.

Large amounts of strong bases are used to isolate NC from WB before acid treatment, thereby improving its efficiency by removing polyphenols that resist various acids [33,34]. However, a strong base treatment is not required for seaweed because most seaweeds contain small amounts or no polyphenols [35,36]. Additionally, seaweed has superior wettability and a more flexible structure in aqueous solutions than wood, which enhances its responsiveness during acid treatment [37]. Consequently, the isolation of NC from seaweed is an extremely efficient and environmentally friendly process, characterized by short processing times and low chemical and energy usage.

Before Mo-Ac treatment, electron beam (E-beam) irradiation was used to improve the crystallinity of the cellulose and reduce environmental pollution and processing time. This procedure is advantageous because it is fast and simple, requiring no chemical additives to achieve surface modifications of cellulose. As the E-beam dose was increased, the particle size of the cellulose decreased dramatically. The dose, defined as the amount of energy absorbed per mass unit, is measured in kilograys (kGy), with one kGy representing the absorption of one joule of energy per gram of material. For example, when cellulose is exposed to a dose of 1 kGy, each gram of cellulose absorbs one joule of energy from radiation [25]. Therefore, the E-beam process facilitated the isolation of NC with enhanced properties and increased the NC yield without the need for additional chemical reagents.

The treated samples, processed via Mo-Ac and Mo-Ac with E-beam, were centrifuged and washed with distilled water to remove non-reacted cellulose and neutralize the solution. The slurry was then dispersed in a tert-Butanol solution. Finally, the powdery NC was obtained by freeze-drying.

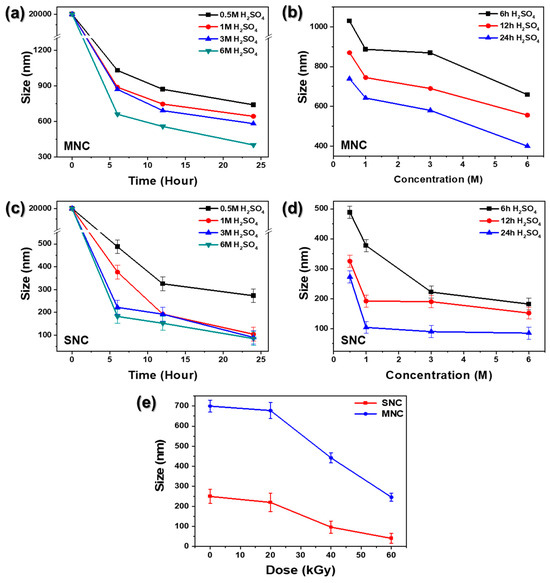

Dynamic light scattering (DLS) analysis is a crucial technique for determining the size distribution of NC. In Figure 2, the particle size of the NC was analyzed according to the time, concentration, and dose of the E-beam. As both the processing time and acid concentration increase, the size of the MNC particles initially decreases, denoting that extended processing durations and elevated acid concentrations promote the breakdown of cellulose into finer particles. However, this reduction in size saturates after 12 h and at a concentration of 3 M, as illustrated in Figure 2a,b. These findings suggest the optimal time and acid concentration for achieving the smallest particle size, thereby preventing over-processing. The SNC results exhibited a clear tendency similar to the MNC results as shown in Figure 2c,d. However, the particle size of SNC decreases more rapidly at a processing time of 12 h and an acid concentration of 3 M compared to that of MNC. These results imply that the smaller size of the SNC under optimal conditions is ascribed to the superior wettability and flexible chemical structure of seaweed, resulting in a higher reaction rate. The optimal conditions were suggested to be 12 h and a concentration of 3 M.

Figure 2.

DLS analysis of the size of NC according to processing time, acid concentration, and dose of E-beam. MNC based on (a) processing time and (b) acid concentration; SNC based on (c) processing time and (d) acid concentration; (e) E-beam- and Mo-Ac-treated SNC and MNC under the optimal condition.

To obtain smaller and finer NC, E-beam irradiation was used for the pretreatment of microcrystalline cellulose (MC) and EtOH-washed seaweed (Et-SW) at doses of 20, 40, and 60 kGy. After E-beam irradiation, Mo-Ac treatment was carried out on each sample under optimal conditions. As the E-beam dose increased, the sizes of the SNC and MNC significantly decreased, and sample collapse was observed at 60 kGy. Thus, NC was successfully isolated from SB with a size of approximately 100 nm using E-beam and Mo-Ac, as shown in Figure 2e.

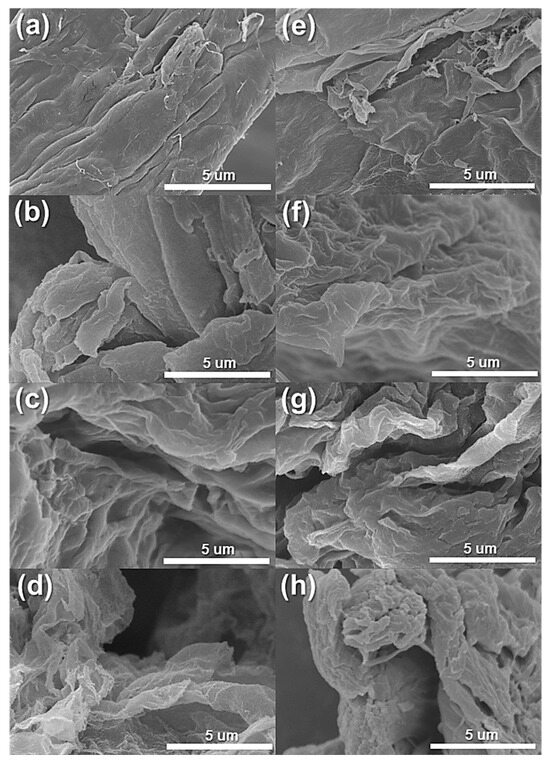

The SEM images in Figure 3 illustrate the progressive structural changes in microcrystalline cellulose (MC) and EtOH-washed seaweed (Et-SW) with increasing E-beam doses. At lower doses of 20 and 40 kGy, MC and Et-SW demonstrated effective size reduction and increased fragmentation, indicating the successful breakdown of the cellulose structure. Thermal degradation became more pronounced at the highest dose of 60 kGy, as shown in Figure 3d,h. These findings indicate that, although E-beam irradiation is highly effective for reducing particle size, an optimal dose should still be identified to prevent over-processing and preserve the structural integrity of the material.

Figure 3.

SEM images of microcrystalline cellulose (MC) and EtOH-washed seaweed (Et-SW) irradiated with different E-beam doses: MC at (a) 0 kGy, (b) 20 kGy, (c) 40 kGy, (d) 60 kGy; Et-SW at (e) 0 kGy, (f) 20 kGy, (g) 40 kGy, (h) 60 kGy.

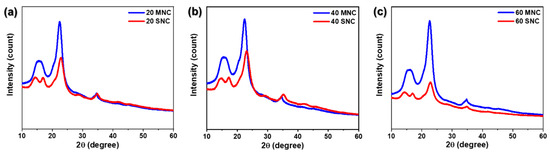

Crystalline structures play an important role in determining the physical and mechanical properties of composite films. XRD analysis, as presented in Figure 4, shows the crystallinity properties of MNC and SNC depending on the E-beam irradiation dose after Mo-Ac treatment under optimal conditions. All SNC samples exhibit an intense peak with a double peak signal between 15° and 20°. In contrast, MNC has a single peak signal between 15° and 20°. These results suggest that MNC has lower crystallinity and the presence of an amorphous region. Additionally, the peak at 23.6° became slightly narrower with increased intensity at an E-beam dose of 40 kGy than that at 20 kGy, implying the effective decomposition of the amorphous structure without collapsing the crystal structure. However, the overall intensity of the peaks decreased significantly at an E-beam dose of 60 kGy, indicating the collapse of the structure due to the high dose of E-beam irradiation. Thus, the optimal E-beam dose for isolating NC without a major collapse in the crystallinity of cellulose was noted to be 40 kGy [38].

Figure 4.

XRD spectra of MNC and SNC with different E-beam doses. (a) 20 kGy, (b) 40 kGy, and (c) 60 kGy.

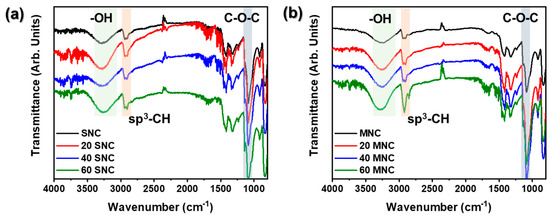

The FT-IR spectra in Figure 5 illustrate the chemical structure changes in SNC and MNC pretreated with different E-beam doses. Noticeably, the intensity of the band corresponding to the -OH groups (green shaded area, 3200~3500 cm−1) slightly increases and broadens with an increasing E-beam dose. Moreover, the shape and intensity of the sp3-CH band (orange shaded area, 2800~3000 cm−1) and C-O-C stretching (gray shaded area, 1050~1150 cm−1) are more clearly deconvoluted and increased. These results confirm that NC prepared by E-beam pretreatment was effectively obtained without significant changes in the chemical structure [39,40].

Figure 5.

FT-IR Spectra of (a) SNC and (b) MNC treated with various E-beam doses.

NC, which is derived from natural sources, exhibits impressive biodegradability and robust mechanical properties. Its nanoscale dimensions make it an ideal candidate as a composite filler. Consequently, a PVA composite was engineered using NC, leveraging its unique characteristics to enhance the properties of polymer composites.

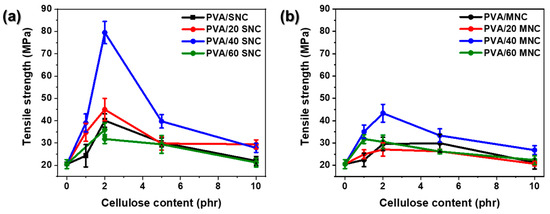

The mechanical properties of the PVA composites were significantly affected by their NC content and structure. Figure 6 shows the tensile strength of PVA composites with different NC contents. All PVA composites achieved the highest tensile strength at 2 phr. In particular, the PVA composite with 2 phr of SNC obtained under 40 kGy E-beam irradiation exhibited a dramatically enhanced tensile strength of 80 MPa. This can be explained by the interaction of strong hydrogen bonds between NC and PVA [41]. However, at higher concentrations (5 and 10 phr), the tensile strength decreases, which can be ascribed to issues such as particle agglomeration. As particle agglomeration increases, the hydrogen bonds between the PVA and the NC decrease, resulting in a decline in the physical properties of the composite. These results suggest that NC provides optimal strength enhancement to the PVA composites at a concentration of 2 phr.

Figure 6.

Tensile strength of the PVA composites with 1, 2, 5, and 10 phr of (a) SNC and (b) MNC.

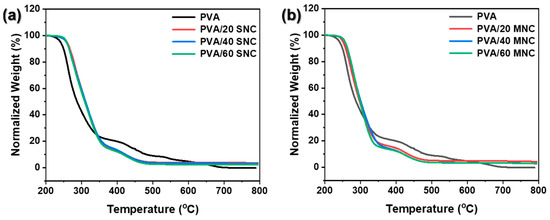

As shown in Figure 7, the thermal stability of the PVA composite with NC upon E-beam irradiation was obtained using TGA. TGA analysis reveals the enhanced thermal stability of the PVA composites with E-beam-treated SNC and MNC. Compared to pure PVA film, all PVA composites achieved superior thermal stability. Both types of NC improved the thermal stability with increasing E-beam doses, whereby the largest enhancement was obtained with the E-beam doses of 40 kGy. This suggests that the E-beam treatment facilitated the dispersion and interactions between the NC and PVA matrix, thereby increasing the thermal stability of the composites.

Figure 7.

TGA analysis of PVA composite with 2 phr (a) SNC and (b) MNC obtained under different E-beam doses.

The TGA analysis demonstrated that the PVA composites with 2 phr SNC and MNC are improved with E-beam treatment, achieving enhanced thermal stability. The results confirmed the optimal dose of 40 kGy for achieving improved thermal properties, and the importance of dose optimization in the E-beam treatment process.

4. Conclusions

In this study, we successfully demonstrated an eco-friendly and efficient method for isolating NC from SB using a combination of Mo-Ac treatment and E-beam irradiation. This innovative approach significantly reduced the need for harsh chemical reagents, which are commonly associated with traditional WB methods, thereby minimizing the environmental impact and processing time.

SNC derived using this method exhibited superior properties to MNC, including enhanced crystallinity and reduced particle size, when treated with the optimal E-beam doses, which was identified to be 40 kGy. At the optimal dose, the desired NC characteristics were achieved without compromising the structural integrity of the material. The resulting NC was utilized as a reinforcing agent in PVA composites, to obtain biodegradable films with improved mechanical properties. The PVA composites exhibited the highest tensile strength with an NC concentration of 2 phr. In particular, the composite obtained using SNC prepared under the E-beam radiation of 40 kGy achieved an impressive tensile strength of 80 MPa, which was attributed to the strong hydrogen bonding interactions between NC and PVA with increased crystallinity of the NC. Thermogravimetric analysis (TGA) further confirmed the enhanced thermal stability of the PVA composites obtained using E-beam-treated SNC and MNC, with the 40 kGy dose providing the largest improvement. This suggests that E-beam treatment promoted the dispersion and interactions between the NC and PVA matrix, realizing thermally stable composites.

Our study presents a sustainable and efficient method for NC isolation from SB, offering a viable alternative to traditional WB methods. This process enhanced the mechanical and thermal properties of NC-based polymer composites and contributed to the development of eco-friendly industrial processes. These findings underscore the potential of NC as a critical material for various industrial applications, promoting the advancement of sustainable materials and reducing the environmental footprint of the manufacturing industry.

Author Contributions

Conceptualization, J.-S.L.; methodology, J.-H.K. and J.-J.J.; formal analysis, J.-H.K. and J.-J.J.; writing—original draft preparation, J.-H.K.; writing—review and editing, J.-S.L.; supervision, J.-S.L.; funding acquisition, J.-S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by research funds from Chosun University (207133006-1, 2021).

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tijjani Usman, I.M.; Ho, Y.-C.; Baloo, L.; Lam, M.-K.; Sujarwo, W. A comprehensive review on the advances of bioproducts from biomass towards meeting net zero carbon emissions (NZCE). Bioresour. Technol. 2022, 366, 128167. [Google Scholar] [CrossRef] [PubMed]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Kwon, E.E.; Nadagouda, M.N.; Aminabhavi, T.M. Biomass utilization and production of biofuels from carbon neutral materials. Environ. Pollut. 2021, 276, 116731. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.; Patil, R. The Road to Sustainable Tire Materials: Current State-of-the-Art and Future Prospectives. Environ. Sci. Technol. 2023, 57, 2209–2216. [Google Scholar] [CrossRef] [PubMed]

- Nahak, B.K.; Preetam, S.; Sharma, D.; Shukla, S.K.; Syväjärvi, M.; Toncu, D.-C.; Tiwari, A. Advancements in net-zero pertinency of lignocellulosic biomass for climate neutral energy production. Renew. Sustain. Energy Rev. 2022, 161, 112393. [Google Scholar] [CrossRef]

- De, S.; James, B.; Ji, J.; Wasti, S.; Zhang, S.; Kore, S.; Tekinalp, H.; Li, Y.; Ureña-Benavides, E.E.; Vaidya, U.; et al. Chapter Three—Biomass-derived composites for various applications. In Advances in Bioenergy; Li, Y., Chang, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; Volume 8, pp. 145–196. [Google Scholar]

- Moon, R.J.; Schueneman, G.T.; Simonsen, J. Overview of Cellulose Nanomaterials, Their Capabilities and Applications. JOM 2016, 68, 2383–2394. [Google Scholar] [CrossRef]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Eichhorn, S.J. Cellulose nanowhiskers: Promising materials for advanced applications. Soft Matter 2011, 7, 303–315. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Liu, Y.; Hai, Y.; Zhang, M.; Chen, P. Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process. Cellulose 2011, 18, 433–442. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D.; Hedenqvist, M.; Ankerfors, M.; Lindström, T. Highly transparent films from carboxymethylated microfibrillated cellulose: The effect of multiple homogenization steps on key properties. J. Appl. Polym. Sci. 2011, 119, 2652–2660. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Habibi, Y.; Rojas, O.J.; Pawlak, J.J. The effect of chemical composition on microfibrillar cellulose films from wood pulps: Mechanical processing and physical properties. Bioresour. Technol. 2010, 101, 5961–5968. [Google Scholar] [CrossRef] [PubMed]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Hashaikeh, R.; Abushammala, H. Acid mediated networked cellulose: Preparation and characterization. Carbohydr. Polym. 2011, 83, 1088–1094. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Isolation and characterization of nanofibers from agricultural residues—Wheat straw and soy hulls. Bioresour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef] [PubMed]

- Suopajärvi, T.; Sirviö, J.A.; Liimatainen, H. Cationic nanocelluloses in dewatering of municipal activated sludge. J. Environ. Chem. Eng. 2017, 5, 86–92. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Chen, W.; Wang, Q.; Liu, Y.; Li, J.; Yu, H. Facile extraction of cellulose nanocrystals from wood using ethanol and peroxide solvothermal pretreatment followed by ultrasonic nanofibrillation. Green Chem. 2016, 18, 1010–1018. [Google Scholar] [CrossRef]

- Baghel, R.S.; Reddy, C.R.K.; Singh, R.P. Seaweed-based cellulose: Applications, and future perspectives. Carbohydr. Polym. 2021, 267, 118241. [Google Scholar] [CrossRef] [PubMed]

- Fasahati, P.; Dickson, R.; Saffron, C.M.; Woo, H.C.; Liu, J.J. Seaweeds as a sustainable source of bioenergy: Techno-economic and life cycle analyses of its biochemical conversion pathways. Renew. Sustain. Energy Rev. 2022, 157, 112011. [Google Scholar] [CrossRef]

- Nakhate, P.; van der Meer, Y. A Systematic Review on Seaweed Functionality: A Sustainable Bio-Based Material. Sustainability 2021, 13, 6174. [Google Scholar] [CrossRef]

- Nilsson, A.E.; Bergman, K.; Gomez Barrio, L.P.; Cabral, E.M.; Tiwari, B.K. Life cycle assessment of a seaweed-based biorefinery concept for production of food, materials, and energy. Algal Res. 2022, 65, 102725. [Google Scholar] [CrossRef]

- Baghel, R.S.; Suthar, P.; Gajaria, T.K.; Bhattacharya, S.; Anil, A.; Reddy, C.R.K. Seaweed biorefinery: A sustainable process for valorising the biomass of brown seaweed. J. Clean. Prod. 2020, 263, 121359. [Google Scholar] [CrossRef]

- Charlesby, A. The degradation of cellulose by ionizing radiation. J. Polym. Sci. 1955, 15, 263–270. [Google Scholar] [CrossRef]

- Driscoll, M.; Stipanovic, A.; Winter, W.; Cheng, K.; Manning, M.; Spiese, J.; Galloway, R.A.; Cleland, M.R. Electron beam irradiation of cellulose. Radiat. Phys. Chem. 2009, 78, 539–542. [Google Scholar] [CrossRef]

- Takács, E.; Wojnárovits, L.; Borsa, J.; Földváry, C.; Hargittai, P.; Zöld, O. Effect of γ-irradiation on cotton-cellulose. Radiat. Phys. Chem. 1999, 55, 663–666. [Google Scholar] [CrossRef]

- Dubey, K.A.; Pujari, P.K.; Ramnani, S.P.; Kadam, R.M.; Sabharwal, S. Microstructural studies of electron beam-irradiated cellulose pulp. Radiat. Phys. Chem. 2004, 69, 395–400. [Google Scholar] [CrossRef]

- Yang, C.; Shen, Z.; Yu, G.; Wang, J. Effect and aftereffect of γ radiation pretreatment on enzymatic hydrolysis of wheat straw. Bioresour. Technol. 2008, 99, 6240–6245. [Google Scholar] [CrossRef]

- Ramaraj, B. Crosslinked poly(vinyl alcohol) and starch composite films. II. Physicomechanical, thermal properties and swelling studies. J. Appl. Polym. Sci. 2007, 103, 909–916. [Google Scholar] [CrossRef]

- Peña, B.; Ferré, L.; Garcia-Valls, R.; Ferrando, F.; Gumí, T. Study of the Mechanical Properties of PSf/Vanillin Films. Influ. Temp. Treatments. Ind. Eng. Chem. Res. 2011, 50, 2073–2079. [Google Scholar] [CrossRef]

- Lan, S.; Wu, L.; Zhang, D.; Hu, C.; Liu, Y. Ethanol outperforms multiple solvents in the extraction of chlorophyll-a from biological soil crusts. Soil Biol. Biochem. 2011, 43, 857–861. [Google Scholar] [CrossRef]

- Gomes, H.T.; Miranda, S.M.; Sampaio, M.J.; Silva, A.M.T.; Faria, J.L. Activated carbons treated with sulphuric acid: Catalysts for catalytic wet peroxide oxidation. Catal. Today 2010, 151, 153–158. [Google Scholar] [CrossRef]

- Mohd Jamil, N.A.; Jaffar, S.S.; Saallah, S.; Misson, M.; Siddiquee, S.; Roslan, J.; Lenggoro, W. Isolation of Cellulose Nanocrystals from Banana Peel Using One-Pot Microwave and Mild Oxidative Hydrolysis System. Nanomaterials 2022, 12, 3537. [Google Scholar] [CrossRef] [PubMed]

- Yano, H.; Hirose, A.; Collins, P.J.; Yazaki, Y. Effects of the removal of matrix substances as a pretreatment in the production of high strength resin impregnated wood based materials. J. Mater. Sci. Lett. 2001, 20, 1125–1126. [Google Scholar] [CrossRef]

- Rojo, E.; Alonso, M.V.; Domínguez, J.C.; Saz-Orozco, B.D.; Oliet, M.; Rodriguez, F. Alkali treatment of viscose cellulosic fibers from eucalyptus wood: Structural, morphological, and thermal analysis. J. Appl. Polym. Sci. 2013, 130, 2198–2204. [Google Scholar] [CrossRef]

- Olsson, J.; Toth, G.B.; Albers, E. Biochemical composition of red, green and brown seaweeds on the Swedish west coast. J. Appl. Phycol. 2020, 32, 3305–3317. [Google Scholar] [CrossRef]

- Yanagisawa, M.; Nakamura, K.; Ariga, O.; Nakasaki, K. Production of high concentrations of bioethanol from seaweeds that contain easily hydrolyzable polysaccharides. Process Biochem. 2011, 46, 2111–2116. [Google Scholar] [CrossRef]

- Kovalenko, I.; Zdyrko, B.; Magasinski, A.; Hertzberg, B.; Milicev, Z.; Burtovyy, R.; Luzinov, I.; Yushin, G. A Major Constituent of Brown Algae for Use in High-Capacity Li-Ion Batteries. Science 2011, 334, 75–79. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Seo, G. FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohydr. Res. 2005, 340, 417–428. [Google Scholar] [CrossRef] [PubMed]

- de Melo, J.C.P.; da Silva Filho, E.C.; Santana, S.A.A.; Airoldi, C. Maleic anhydride incorporated onto cellulose and thermodynamics of cation-exchange process at the solid/liquid interface. Colloids Surf. A Physicochem. Eng. Asp. 2009, 346, 138–145. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Mohan, D.J.; Kang, I.-A.; Doh, G.-H.; Lee, S.; Han, S.O. Nanocellulose reinforced PVA composite films: Effects of acid treatment and filler loading. Fibers Polym. 2009, 10, 77–82. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).