Developing Bio-Nano Composites Using Cellulose-Nanofiber-Reinforced Epoxy

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Raw Materials

2.2. Methods

2.2.1. Fabrication of Epoxy Nanocomposite with Modified CNF

- To remove impurities and agglomerated fibers, 100 g of CNF gel was rinsed through a polyester sieve (40 µm).

- The remaining CNF was dispersed in 250 mL of ethanol and stirred for 3 h with a magnetic stirrer.

- Using a polyester mesh, the alcohol was separated from the nanofibers.

- The treated nanofibers were dispersed and stirred in 250 mL of acetone. Similar to the first step, separation was carried out after 3 h of mixing to ensure that the modification process was complete.

- Steps 1–4 were repeated three times.

- To ensure the complete removal of water, ethanol, and acetone from the CNF, the CNF was centrifuged at a rotation speed of 12,000 rpm for 10 min.

2.2.2. Characterization of Functional Groups of M-CNF

2.2.3. Mechanical, Physical, and Morphological Assessments

3. Results

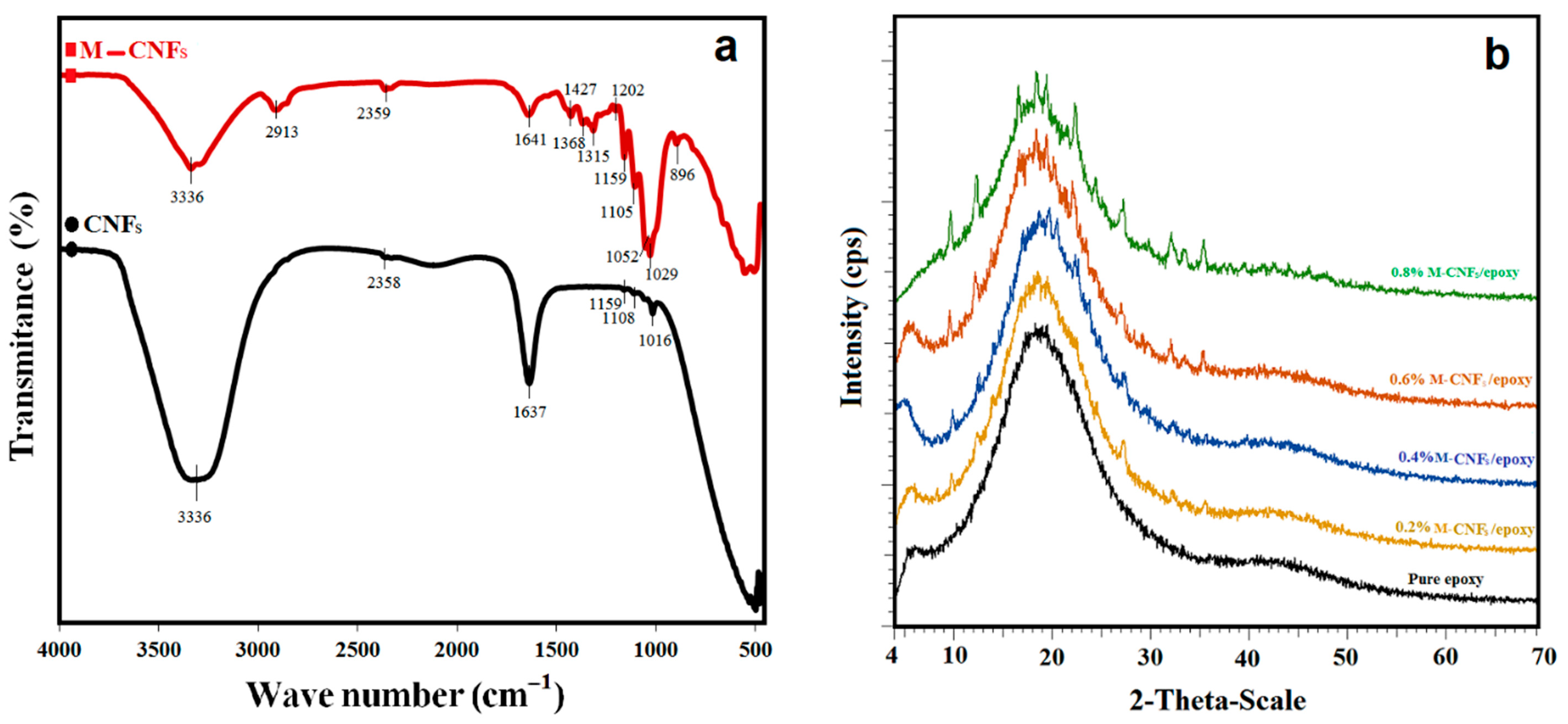

3.1. FTIR Spectroscopy of M-CNF

3.2. XRD Analysis of Reinforced Nanocomposites

3.3. Morphological Properties of Epoxy Nanocomposites with M-CNF

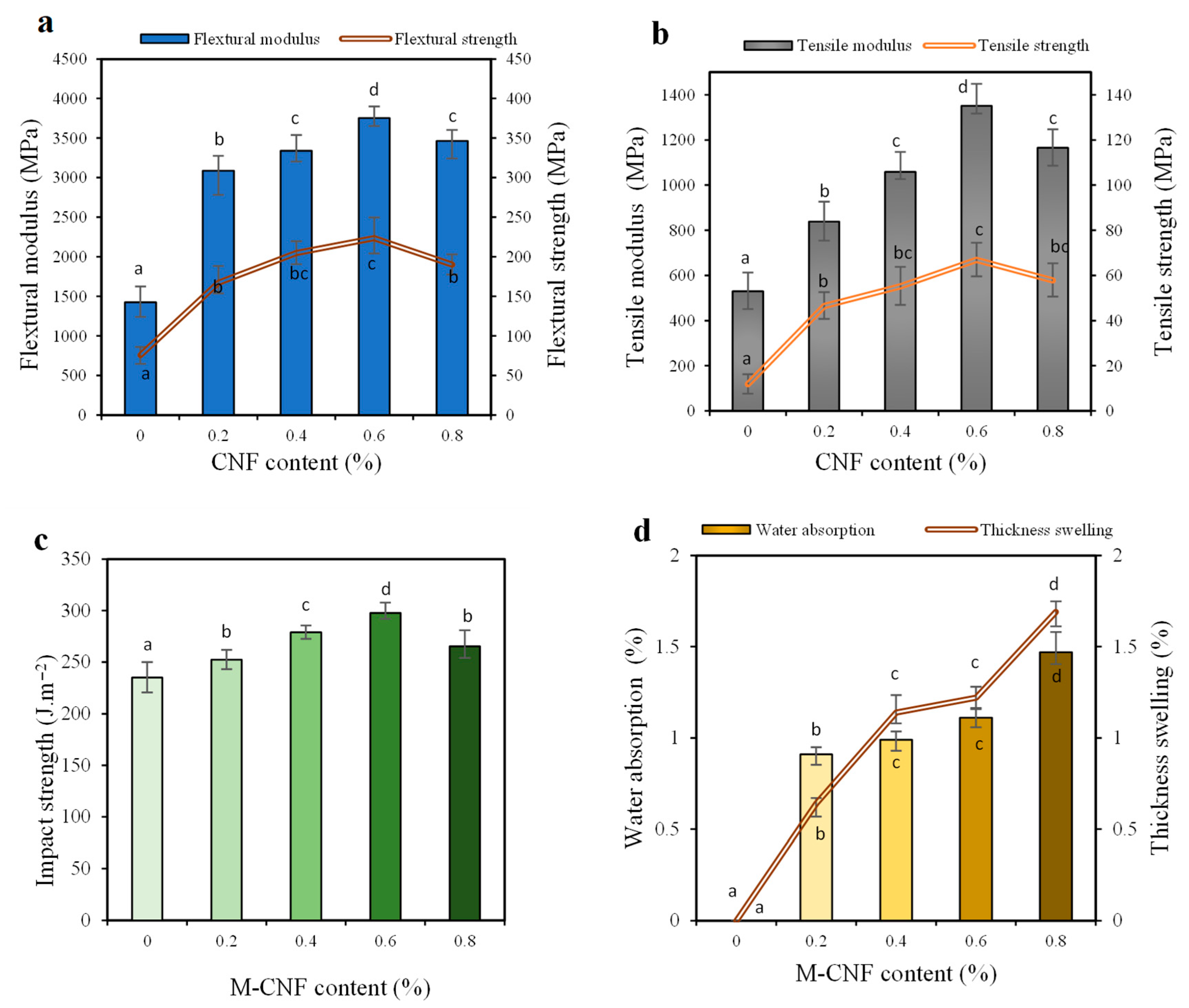

3.4. Performance of Epoxy Nanocomposites with M-CNF

4. Conclusions

- M-CNF showed enhanced compatibility with the epoxy matrix due to the presence of methyl groups on the surface of M-CNF; these methyl groups enhanced interfacial interactions via hydrogen bonding. This, in turn, led to the uniform dispersion of M-CNF in the epoxy matrix.

- Bio-nano composites containing 6% M-CNF showed enhanced mechanical properties as measured by an increase in strength, modulus, tensile, and impact resistance. The enhancement was most notable for tensile strength, which increased from 11.8 to 66.8 MPa.

- At dosages above 0.6% M-CNF, some weakening effects were observed at the interface due to the self-assembly of cellulose nanofiber; therefore, the optimum dosage is suggested as 0.6%. Self-assembled agglomerates served as crack initiation points as evidenced by crack initiation around agglomerated spots.

- Due to the porosity and hydrophilic nature of cellulose nanofiber, the moisture uptake of the specimen was increased by 100% when 0.6% M-CNF was introduced to the epoxy matrix.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shanbedi, M.; Ardebili, H.; Karim, A. Polymer-based triboelectric nanogenerators: Materials, characterization, and applications. Prog. Polym. Sci. 2023, 144, 101723. [Google Scholar] [CrossRef]

- Sun, F.; Jiang, H.; Wang, H.; Zhong, Y.; Xu, Y.; Xing, Y.; Yu, M.; Feng, L.-W.; Tang, Z.; Liu, J. Soft fiber electronics based on semiconducting polymer. Chem. Rev. 2023, 123, 4693–4763. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Xing, S.; Tang, J.; Liu, H.; Lyu, J.; Wang, S.; Yin, C.; Yi, X.; Wu, N. Robust interface-free superhydrophobic polymer-based composites with recoverable and anti-icing properties. Prog. Org. Coat. 2023, 174, 107224. [Google Scholar] [CrossRef]

- Liu, B.; Cao, Q.; Li, J.; Jian, X.; Weng, Z. Facile recycling of anhydride-cured epoxy thermoset under mild conditions with multifunctional hydrazine hydrate. Chin. Chem. Lett. 2023, 34, 108465. [Google Scholar] [CrossRef]

- Verma, C.; Olasunkanmi, L.O.; Akpan, E.D.; Quraishi, M.; Dagdag, O.; El Gouri, M.; Sherif, E.-S.M.; Ebenso, E.E. Epoxy resins as anticorrosive polymeric materials: A review. React. Funct. Polym. 2020, 156, 104741. [Google Scholar] [CrossRef]

- Thajai, N.; Rachtanapun, P.; Thanakkasaranee, S.; Chaiyaso, T.; Phimolsiripol, Y.; Leksawasdi, N.; Sommano, S.R.; Sringarm, K.; Chaiwarit, T.; Ruksiriwanich, W. Antimicrobial thermoplastic starch reactive blend with chlorhexidine gluconate and epoxy resin. Carbohydr. Polym. 2023, 301, 120328. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Ma, L.; Li, B.; Zhang, W.; Zheng, H.; Wu, G.; Huang, Y.; Song, G. One-step generation of silica particles onto graphene oxide sheets for superior mechanical properties of epoxy composite and scale application. Compos. Commun. 2020, 22, 100514. [Google Scholar] [CrossRef]

- Saba, N.; Safwan, A.; Sanyang, M.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.; Sain, M. Thermal and dynamic mechanical properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 102, 822–828. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Yang, J.; Jindal, B.B.; Ariyachandra, E. Influence of nano-TiO2, nano-Fe2O3, nanoclay and nano-CaCO3 on the properties of cement/geopolymer concrete. Clean. Mater. 2022, 4, 100061. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Hossain, N.; Shuvho, M.B.A.; Kowser, M.A.; Islam, M.A.; Ali, M.R.; Ei-Badry, Y.A.; Ei-Bahy, Z.M. Improvement of interfacial adhesion performance of the kevlar fiber mat by depositing SiC/TiO2/Al2O3/graphene nanoparticles. Arab. J. Chem. 2021, 14, 103406. [Google Scholar] [CrossRef]

- Nobile, M.R.; Valentino, O.; Morcom, M.; Simon, G.P.; Landi, G.; Neitzert, H.C. The effect of the nanotube oxidation on the rheological and electrical properties of CNT/HDPE nanocomposites. Polym. Eng. Sci. 2017, 57, 665–673. [Google Scholar] [CrossRef]

- Huang, F.; Zheng, W.; Rad, A.T.; Nieh, M.-P.; Cornelius, C.J. SiO2-TiO2-PBC nanocomposite film morphology, solvent swelling, estimated χ parameter, and liquid transport. Polymer 2017, 123, 247–257. [Google Scholar] [CrossRef]

- He, H.; Li, K.; Wang, J.; Sun, G.; Li, Y.; Wang, J. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composites. Mater. Des. 2011, 32, 4521–4527. [Google Scholar] [CrossRef]

- Yang, Q.; Lin, Y.-H.; Li, M.; Shen, Y.; Nan, C.-W. Characterization of mesoporous silica nanoparticle composites at low filler content. J. Compos. Mater. 2016, 50, 715–722. [Google Scholar] [CrossRef]

- Velmurugan, R.; Mohan, T. Epoxy-clay nanocomposites and hybrids: Synthesis and characterization. J. Reinf. Plast. Compos. 2009, 28, 17–37. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Pandey, J.K.; Lee, H.T.; Takagi, H.; Ahn, S.; Saini, D.; Misra, M. Dispersion of nanocellulose (NC) in polypropylene (PP) and polyethylene (PE) matrix. In Handbook of Polymer Nanocomposites. Processing, Performance and Application: Volume C: Polymer Nanocomposites of Cellulose Nanoparticles; Springer: Berlin/Heidelberg, Germany, 2015; pp. 179–189. [Google Scholar]

- Thakur, V.K. Lignocellulosic Polymer Composites: Processing, Characterization, and Properties; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kargarzadeh, H.; Ahmad, I.; Thomas, S.; Dufresne, A. Handbook of Nanocellulose and Cellulose Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Dorieh, A.; Ayrilmis, N.; Pour, M.F.; Movahed, S.G.; Kiamahalleh, M.V.; Shahavi, M.H.; Hatefnia, H.; Mehdinia, M. Phenol formaldehyde resin modified by cellulose and lignin nanomaterials: Review and recent progress. Int. J. Biol. Macromol. 2022, 222, 1888–1907. [Google Scholar] [CrossRef] [PubMed]

- Dorieh, A.; Khan, A.; Selakjani, P.P.; Pizzi, A.; Hasankhah, A.; Meraj, M.; Pirouzram, O.; Abatari, M.N.; Movahed, S.G. Influence of wood leachate industrial waste as a novel catalyst for the synthesis of UF resins and MDF bonded with them. Int. J. Adhes. Adhes. 2021, 111, 102985. [Google Scholar] [CrossRef]

- Dorieh, A.; Pour, M.F.; Movahed, S.G.; Pizzi, A.; Selakjani, P.P.; Kiamahalleh, M.V.; Hatefnia, H.; Shahavi, M.H.; Aghaei, R. A review of recent progress in melamine-formaldehyde resin based nanocomposites as coating materials. Prog. Org. Coat. 2022, 165, 106768. [Google Scholar] [CrossRef]

- Pour, M.F.; Khanjanzadeh, H.; Dorieh, A.; Kiamahalleh, M.V.; Hoseini, K.D. Utilization of phenol formaldehyde/Fe3O4 nanocomposite as microwave preheating amplifier in laminated veneer lumber (LVL) structure. J. Build. Eng. 2022, 46, 103809. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Curing kinetics and effects of fibre surface treatment and curing parameters on the interfacial and tensile properties of hemp/epoxy composites. J. Adhes. Sci. Technol. 2009, 23, 2085–2107. [Google Scholar] [CrossRef]

- Pour, M.F.; Edalat, H.; Dorieh, A.; Kiamahalleh, M.V.; Shahavi, M.H. Durability-related performance of reinforced bondline by phenol formaldehyde/nano SiO2 composite in Laminated Veneer Lumber (LVL). J. Build. Eng. 2022, 60, 105191. [Google Scholar] [CrossRef]

- Dorieh, A.; Selakjani, P.P.; Shahavi, M.H.; Pizzi, A.; Movahed, S.G.; Pour, M.F.; Aghaei, R. Recent developments in the performance of micro/nanoparticle-modified urea-formaldehyde resins used as wood-based composite binders: A review. Int. J. Adhes. Adhes. 2022, 114, 103106. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Khanlou, H.M.; Hall, W.; Öchsner, A.; Francucci, G. Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos. Part B Eng. 2019, 171, 284–293. [Google Scholar] [CrossRef]

- Peng, S.X.; Shrestha, S.; Yoo, Y.; Youngblood, J.P. Enhanced dispersion and properties of a two-component epoxy nanocomposite using surface modified cellulose nanocrystals. Polymer 2017, 112, 359–368. [Google Scholar] [CrossRef]

- Vazquez, A.; Foresti, M.L.; Moran, J.I.; Cyras, V.P. Extraction and production of cellulose nanofibers. In Handbook of Polymer Nanocomposites. Processing, Performance and Application: Volume C: Polymer Nanocomposites of Cellulose Nanoparticles; Springer: Berlin/Heidelberg, Germany, 2015; pp. 81–118. [Google Scholar]

- Trache, D.; Hussin, M.H.; Chuin, C.T.H.; Sabar, S.; Fazita, M.N.; Taiwo, O.F.; Hassan, T.; Haafiz, M.M. Microcrystalline cellulose: Isolation, characterization and bio-composites application—A review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef] [PubMed]

- Negro, C.; Balea-Martín, A.; Sanchez-Salvador, J.L.; Campano, C.; Fuente, E.; Monte, M.C.; Blanco, A. Nanocellulose and its potential use for sustainable industrial applications. Lat. Am. Appl. Res.-Int. J. 2020, 50, 59–64. [Google Scholar] [CrossRef]

- Camargos, C.H.; Rezende, C.A. Structure–Property relationships of cellulose nanocrystals and nanofibrils: Implications for the design and performance of nanocomposites and all-nanocellulose systems. ACS Appl. Nano Mater. 2021, 4, 10505–10518. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Mueller, U.; Veigel, S. The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Mokhena, T.C.; John, M.J. Cellulose nanomaterials: New generation materials for solving global issues. Cellulose 2020, 27, 1149–1194. [Google Scholar] [CrossRef]

- Moohan, J.; Stewart, S.A.; Espinosa, E.; Rosal, A.; Rodríguez, A.; Larrañeta, E.; Donnelly, R.F.; Domínguez-Robles, J. Cellulose nanofibers and other biopolymers for biomedical applications. A review. Appl. Sci. 2019, 10, 65. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Mehelli, O.; Hussin, M.H.; Bessa, W. Cellulose fibers and nanocrystals: Preparation, characterization and surface modification. In Functionalized Nanomaterials I; CRC Press: Boca Raton, FL, USA, 2020; pp. 171–190. [Google Scholar]

- Foster, E.J.; Moon, R.J.; Agarwal, U.P.; Bortner, M.J.; Bras, J.; Camarero-Espinosa, S.; Chan, K.J.; Clift, M.J.; Cranston, E.D.; Eichhorn, S.J. Current characterization methods for cellulose nanomaterials. Chem. Soc. Rev. 2018, 47, 2609–2679. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Xu, J.; Liu, Z.; Huang, Y.; Jiang, S. Facile, Ecofriendly, and Efficient Preparation of Flexible Gold Nanoparticles@ Bacterial Nanocellulose Surface-Enhanced Raman Scattering Sensors by Magnetron Sputtering for Trace Detection of Hazardous Materials. ACS Sustain. Chem. Eng. 2022, 10, 13059–13069. [Google Scholar] [CrossRef]

- Milotskyi, R.; Serizawa, R.; Yanagisawa, K.; Sharma, G.; Ito, E.R.D.; Fujie, T.; Wada, N.; Takahashi, K. Composite of Cellulose-Nanofiber-Reinforced Cellulose Acetate Butyrate: Improvement of Mechanical Strength by Cross-Linking of Hydroxyl Groups. J. Compos. Sci. 2023, 7, 130. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, J.; Liu, Z.; Huang, Y.; Jiang, S. Rapid and scalable preparation of flexible Ag nanoparticle-decorated nanocellulose SERS sensors by magnetron sputtering for trace detection of toxic materials. Cellulose 2022, 29, 9865–9879. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, J.; Liu, Z.; Huang, Y.; Fu, R.; Jiang, S. Facile and scalable preparation of solution-processed succulent-like silver nanoflowers for 3D flexible nanocellulose-based SERS sensors. Surf. Interfaces 2022, 34, 102391. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a versatile green platform: From biosources to materials and their applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, Y.; Zhu, J.; Le, K.; Servati, P.; Jiang, F. Tough and Ultrastretchable Liquid-Free Ion Conductor Strengthened by Deep Eutectic Solvent Hydrolyzed Cellulose Microfibers. Adv. Funct. Mater. 2022, 32, 2202533. [Google Scholar] [CrossRef]

- El-Moghazy, A.Y.; Amaly, N.; Istamboulie, G.; Nitin, N.; Sun, G. A signal-on electrochemical aptasensor based on silanized cellulose nanofibers for rapid point-of-use detection of ochratoxin A. Microchim. Acta 2020, 187, 535. [Google Scholar] [CrossRef]

- Varghese, R.T.; Cherian, R.M.; Chirayil, C.J.; Antony, T.; Kargarzadeh, H.; Thomas, S. Nanocellulose as an Avenue for Drug Delivery Applications: A Mini-Review. J. Compos. Sci. 2023, 7, 210. [Google Scholar] [CrossRef]

- Kannan, S.; Sahoo, S.K. Influence of flax fiber orientation on mechanical, thermo-mechanical and interfacial adhesion properties of epoxidized methyl ricinoleate modified epoxy composite: A sustainable green composite for cleaner production. Mater. Today Commun. 2022, 33, 104648. [Google Scholar]

- Ojha, A.R.; Biswal, S.K. Thermo physico-mechanical behavior of palm stalk fiber reinforced epoxy composites filled with granite powder. Compos. Commun. 2019, 16, 158–161. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, W.; Song, K.; Yu, Z. Fabrication of mechanical robust keratin composites via mussel-inspired surface modification of cellulose nanocrystals. Mater. Lett. 2022, 321, 132421. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Le Hoang, S.; Vu, C.M.; Pham, L.T.; Choi, H.J. Preparation and physical characteristics of epoxy resin/bacterial cellulose biocomposites. Polym. Bull. 2018, 75, 2607–2625. [Google Scholar] [CrossRef]

- Neves, R.M.; Ornaghi Jr, H.L.; Zattera, A.J.; Amico, S.C. The influence of silane surface modification on microcrystalline cellulose characteristics. Carbohydr. Polym. 2020, 230, 115595. [Google Scholar] [CrossRef] [PubMed]

- Yamato, K.; Yoshida, Y.; Kumamoto, Y.; Isogai, A. Surface modification of TEMPO-oxidized cellulose nanofibers, and properties of their acrylate and epoxy resin composite films. Cellulose 2022, 29, 2839–2853. [Google Scholar] [CrossRef]

- Trinh, B.M.; Mekonnen, T. Hydrophobic esterification of cellulose nanocrystals for epoxy reinforcement. Polymer 2018, 155, 64–74. [Google Scholar] [CrossRef]

- Roszowska-Jarosz, M.; Masiewicz, J.; Kostrzewa, M.; Kucharczyk, W.; Żurowski, W.; Kucińska-Lipka, J.; Przybyłek, P. Mechanical properties of bio-composites based on epoxy resin and nanocellulose fibres. Materials 2021, 14, 3576. [Google Scholar] [CrossRef]

- Sanchez-Salvador, J.L.; Balea-Martín, A.; Negro, C.; Monte, M.C.; Blanco, A. Gel point as measurement of dispersion degree of nano-cellulose suspensions and its application in papermaking. Nanomaterials 2022, 12, 790. [Google Scholar] [CrossRef]

- Sanchez-Salvador, J.L.; Rasteiro, M.G.; Balea-Martín, A.; Sharma, M.; Pedrosa, J.F.; Negro, C.; Monte, M.C.; Blanco, A.; Ferreira, P.J. Influence of dispersion of fibrillated cellulose on the reinforcement of coated papers. Int. J. Biol. Macromol. 2023, 248, 125886. [Google Scholar] [CrossRef] [PubMed]

- Subbotina, E.; Ram, F.; Dvinskikh, S.V.; Berglund, L.A.; Olsén, P. Aqueous synthesis of highly functional, hydrophobic, and chemically recyclable cellulose nanomaterials through oxime ligation. Nat. Commun. 2022, 13, 6924. [Google Scholar] [CrossRef]

- Frka-Petesic, B.; Parton, T.G.; Honorato-Rios, C.; Narkevicius, A.; Ballu, K.; Shen, Q.; Lu, Z.; Ogawa, Y.; Haataja, J.S.; Droguet, B.E. Structural color from cellulose nanocrystals or chitin nanocrystals: Self-assembly, optics, and applications. Chem. Rev. 2023, 123, 12595–12756. [Google Scholar] [CrossRef] [PubMed]

- Song, Q.; Wang, Z.; Xu, D.; Liu, S.; Liu, H.; Zhang, K. Self-assembly of polysaccharide nanocrystals: From aggregation in suspensions to optical materials. Prog. Polym. Sci. 2023, 148, 101768. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Y. Dispersion characterizations and adhesion properties of epoxy composites reinforced by carboxymethyl cellulose surface treated carbon nanotubes. Powder Technol. 2022, 404, 117505. [Google Scholar] [CrossRef]

- Cunha, A.G.; Zhou, Q.; Larsson, P.T.; Berglund, L.A. Topochemical acetylation of cellulose nanopaper structures for biocomposites: Mechanisms for reduced water vapour sorption. Cellulose 2014, 21, 2773–2787. [Google Scholar] [CrossRef]

- Sehaqui, H.; Zimmermann, T.; Tingaut, P. Hydrophobic cellulose nanopaper through a mild esterification procedure. Cellulose 2014, 21, 367–382. [Google Scholar] [CrossRef]

- Goussé, C.; Chanzy, H.; Excoffier, G.; Soubeyrand, L.; Fleury, E. Stable suspensions of partially silylated cellulose whiskers dispersed in organic solvents. Polymer 2002, 43, 2645–2651. [Google Scholar] [CrossRef]

- Zoppe, J.O.; Peresin, M.S.; Habibi, Y.; Venditti, R.A.; Rojas, O.J. Reinforcing poly (ε-caprolactone) nanofibers with cellulose nanocrystals. ACS Appl. Mater. Interfaces 2009, 1, 1996–2004. [Google Scholar] [CrossRef] [PubMed]

- Boujemaoui, A.; Carlsson, L.; Malmström, E.; Lahcini, M.; Berglund, L.; Sehaqui, H.; Carlmark, A. Facile preparation route for nanostructured composites: Surface-initiated ring-opening polymerization of ε-caprolactone from high-surface-area nanopaper. ACS Appl. Mater. Interfaces 2012, 4, 3191–3198. [Google Scholar] [CrossRef]

- Shimizu, M.; Saito, T.; Isogai, A. Water-resistant and high oxygen-barrier nanocellulose films with interfibrillar cross-linkages formed through multivalent metal ions. J. Membr. Sci. 2016, 500, 1–7. [Google Scholar] [CrossRef]

- Wang, B.; Torres-Rendon, J.G.; Yu, J.; Zhang, Y.; Walther, A. Aligned bioinspired cellulose nanocrystal-based nanocomposites with synergetic mechanical properties and improved hygromechanical performance. ACS Appl. Mater. Interfaces 2015, 7, 4595–4607. [Google Scholar] [CrossRef] [PubMed]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 1998.

- Azizi, H.; Eslami-Farsani, R. Study of mechanical properties of basalt fibers/epoxy composites containing silane-modified nanozirconia. J. Ind. Text. 2021, 51, 649–663. [Google Scholar] [CrossRef]

- Thompson, L.; Nikzad, M.; Sbarski, I.; Yu, A. Esterified cellulose nanocrystals for reinforced epoxy nanocomposites. Prog. Nat. Sci. Mater. Int. 2022, 32, 328–333. [Google Scholar] [CrossRef]

- Atykyan, N.; Revin, V.; Shutova, V. Raman and FT-IR Spectroscopy investigation the cellulose structural differences from bacteria Gluconacetobacter sucrofermentans during the different regimes of cultivation on a molasses media. AMB Express 2020, 10, 84. [Google Scholar] [CrossRef] [PubMed]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of cellulosic fibers by FTIR spectroscopy for their further implementation to building materials. Am. J. Anal. Chem. 2018, 9, 303–310. [Google Scholar] [CrossRef]

- Lv, P.; Perre, P.; Perré, G.A. TGA-FTIR analysis of torrefaction of lignocellulosic components (cellulose, xylan, lignin) in isothermal conditions over a wide range of time durations. BioResources 2015, 10, 4239–4251. [Google Scholar] [CrossRef]

- Pandurangan, M.T.; Kanny, K. Study of curing characteristics of cellulose nanofiber-filled epoxy nanocomposites. Catalysts 2020, 10, 831. [Google Scholar] [CrossRef]

- Kurita, H.; Ishigami, R.; Wu, C.; Narita, F. Mechanical properties of mechanically-defibrated cellulose nanofiber reinforced epoxy resin matrix composites. J. Compos. Mater. 2021, 55, 455–464. [Google Scholar] [CrossRef]

- Li, W.; Yao, W.; Wang, J.; Qiu, Z.; Tang, J.; Yang, S.; Zhu, M.; Xu, Z.; Hu, R.; Qin, A. Studying a novel AIE coating and its handling process via fluorescence spectrum. RSC Adv. 2017, 7, 41127–41135. [Google Scholar] [CrossRef]

- Azhary, T.; Wildan, M.W. Mechanical, morphological, and thermal characteristics of epoxy/glass fiber/cellulose nanofiber hybrid composites. Polym. Test. 2022, 110, 107560. [Google Scholar] [CrossRef]

- Nissilä, T.; Hietala, M.; Oksman, K. A method for preparing epoxy-cellulose nanofiber composites with an oriented structure. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105515. [Google Scholar] [CrossRef]

- Yusra, A.I.; Khalil, H.A.; Hossain, M.S.; Davoudpour, Y.; Astimar, A.; Zaidon, A.; Dungani, R.; Omar, A.M. Characterization of plant nanofiber-reinforced epoxy composites. BioResources 2015, 10, 8268–8280. [Google Scholar]

| M-CNF Content (%) | 0 | 0.2 | 0.4 | 0.6 | 0.8 |

|---|---|---|---|---|---|

| Viscosity (cP) | 324 (18) b | 342 (21) b | 349 (23) ab | 379 (24) ab | 387 (21) a |

| Density (kg·m−3) | 1.221 (0.01) a | 1.225 (0.02) a | 1.231 (0.02) a | 1.237 (0.01) a | 1.247 (0.02) a |

| pH | 7.6 (0.98) a | 7.56 (1) a | 7.27 (0.97) a | 6.92 (1.1) a | 6.5 (0.89) a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehdinia, M.; Farajollah Pour, M.; Yousefi, H.; Dorieh, A.; Lamanna, A.J.; Fini, E. Developing Bio-Nano Composites Using Cellulose-Nanofiber-Reinforced Epoxy. J. Compos. Sci. 2024, 8, 250. https://doi.org/10.3390/jcs8070250

Mehdinia M, Farajollah Pour M, Yousefi H, Dorieh A, Lamanna AJ, Fini E. Developing Bio-Nano Composites Using Cellulose-Nanofiber-Reinforced Epoxy. Journal of Composites Science. 2024; 8(7):250. https://doi.org/10.3390/jcs8070250

Chicago/Turabian StyleMehdinia, Meysam, Mohammad Farajollah Pour, Hossein Yousefi, Ali Dorieh, Anthony J. Lamanna, and Elham Fini. 2024. "Developing Bio-Nano Composites Using Cellulose-Nanofiber-Reinforced Epoxy" Journal of Composites Science 8, no. 7: 250. https://doi.org/10.3390/jcs8070250

APA StyleMehdinia, M., Farajollah Pour, M., Yousefi, H., Dorieh, A., Lamanna, A. J., & Fini, E. (2024). Developing Bio-Nano Composites Using Cellulose-Nanofiber-Reinforced Epoxy. Journal of Composites Science, 8(7), 250. https://doi.org/10.3390/jcs8070250